Abstract

Compared to H2-assisted activation mode, the direct dissociation of CO2 into carbonyl (*CO) with a simplified reaction route is advantageous for CO2-related synthetic processes and catalyst upgrading, while the stable C = O double bond makes it very challenging. Herein, we construct a subnano MoO3 layer on the surface of Mo2N, which provides a dynamically changing surface of MoO3↔MoOx (x < 3) for catalyzing CO2 hydrogenation. Rich oxygen vacancies on the subnano MoOx surface with a high electron donating capacity served as a scissor to directly shear the C = O double bond of CO2 to form CO at a high rate. The O atoms leached in CO2 dissociation are removed timely by H2 to regenerate active oxygen vacancies. Owing to the greatly enhanced dissociative activation of CO2, this MoOx/Mo2N catalyst without any supported active metals shows excellent performance for catalyzing CO2 hydrogenation to CO. The construction of highly disordered defective surface on heterostructures paves a new pathway for molecule activation.

Similar content being viewed by others

Introduction

The global warming caused by the increasing CO2 emission has attracted extensive attention around the world. In addition to being a greenhouse gas, CO2 can be considered as an available inert carbon source to synthesize a range of value-added chemicals and hydrocarbon fuels1,2,3,4,5. For CO2-related fine synthesis processes, carbonyl (*CO) is a pivotal platform species for the generation of the final products by coupling the further CO hydrogenation or carbonylation6,7,8,9,10. The formation of *CO is closely linked to the activation of CO2, which is always a great challenge due to its chemical inertness and the thermodynamic stability. In general, CO2 activation pathways can be classified into two pathways, i.e., H2-assisted CO2 activation and the direct dissociation of CO211,12. The major difference between the two is whether CO2 reacts with the dissociated H species to form reaction intermediates, which then produce *CO or directly dissociates to *CO. Based on previous reports, both for metal complexes as homogeneous catalysts and supported metal catalysts in heterogeneous catalysis, the activation of CO2 dominantly follows the H2-assisted mode13,14,15, in which the formation of active intermediates not only complicates the entire reaction route but also places redundant structural requirements on catalysts. The activation of CO2 molecules by the high-rate cleavage of stable C = O double bond is a potential strategy and a crucial scientific issue to overcome the above obstacles, although it seems to be very difficult to achieve.

It has been established that due to the unique catalytic properties of oxygen vacancy, defect engineering based on reducible oxides has been widely used in CO2-related catalytic reactions16,17,18,19. On the one hand, the formation of oxygen vacancy can modulate the geometric and electronic structure of adjacent active metals20,21, thus promoting the activation of CO2 and the further formation of active intermediates at the active metal-oxygen vacancy interfaces. On the other hand, as one of typical coordination-unsaturated sites, oxygen vacancy itself can adsorb CO2 molecules to participate in the catalytic reactions16,22. However, for conventional reducible oxides, companied by the formation of oxygen vacancies, the exposed metal sites with unsaturated coordination donate poor electrons to the anti-bonding orbitals of CO2, which largely limits the cleavage of the C = O bonds23. If rich surface oxygen vacancies with strong electron donating capacity can be constructed, the above issues will be solved, while it has been rarely reported. According to recent reports, molybdenum nitride and molybdenum carbide-related catalysts exhibited an excellent catalytic efficiency in C1 chemistry24,25,26,27,28. However, the high activity of MoC, Mo2C and Mo2N-based catalysts is always attributed to the MoC, Mo2C and Mo2N bulk structure11,25,26,27,28, and the catalytic properties of MoO3 passivation layer are ignored, especially for Mo2N with well-defined MoO3 surface structure25,29. In our previous works, we pioneered the finding that the MoO3 passivation layer with low formation energy of oxygen vacancies on the bulk Mo2N was the intrinsic active surface of a Pt/Mo2N catalyst to catalyze the water gas shift reaction29. Subsequently, the synergistic interface between Pt clusters and oxygen vacancies on the defective MoOx (x < 3) passivation layer was confirmed to largely enhance the H2-assisted CO2 activation30. However, due to the superficial understanding of the intrinsic catalytic properties and the redox behavior of the defective MoOx structure, the constructed active sites on a relatively ordered MoOx surface in previous works was still unable to achieve the dissociative activation of CO2. Nevertheless, compared to conventional reducible oxides, the special MoO3/Mo2N heterostructure with lower oxygen vacancy formation energy shows a huge potential to develop a new-type defective surface with strong electron donating capacity to directly cleave the solid C = O double bond over CO2.

Herein, we clearly revealed the ultra-active redox property of subnano MoO3 surface on bulk Mo2N and constructed a dynamically changing surface to achieve the directly dissociative activation of CO2. Under reductive atmospheres, companied with the reduction of Mo-O species, a deep-reduced subnano MoOx (1<x < 3) surface on Mo2N with high-density oxygen vacancies was created. This highly disordered subnano surface with abundant coordination-unsaturated Mo sites provided a favorable geometric and electronic microenvironment, which directly cleavage the stable C = O double bond in CO2 (CO2→CO + Osurface) via the electron transfer mediated by exposed Mo sites. The oxygen vacancies occupied by oxygen atoms leached from the CO2 dissociation were easily regenerated by H2 (H2+Osurface→H2O). This in situ cyclic consuming and generating process of oxygen vacancies accelerated the transfer of oxygen atoms from CO2 to catalyst surface and then to final product, effectively catalyzing the CO2 hydrogenation to CO, known as the reverse water gas shift (RWGS) reaction. Under harsh reaction conditions (600 °C, GHSV = 200,000 mL/gcat/h), in the absence of any supported active metals, this MoOx/Mo2N catalyst exhibited a promoted CO2 conversion (~48%), complete CO selectivity and durable cyclic stability (900 h), which even surpassed most of supported metal catalysts and demonstrated a great potential for industrial applications.

Results

Redox and catalytic properties of the MoOx/Mo2N catalyst

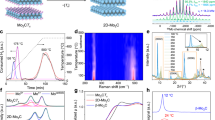

The MoO3/Mo2N heterostructure was prepared by passivating the obtained Mo2N synthesized from MoO3 precursor29. As shown in Fig. 1a, only the diffraction peaks of γ-Mo2N were detected in the X-ray diffraction (XRD) pattern of the fresh and used samples, which indicated the bulk structure of this catalyst was γ-Mo2N. In contrast to the XRD results, the Raman spectra only showed the signal of MoO3 at 115, 128, 151, 197, 217, 242, 287, 339, 381, 667, 823 and 996 cm−1, indicating that the surface MoO3 was formed during the passivation process of γ-Mo2N in 1% O2/Ar or exposure to air (Fig. 1b)31,32,33. And due to the weak Raman signal of γ-Mo2N, only MoO3 signal could be detected. Then, in situ Raman measurements were conducted to explore the intrinsic structure and the redox property of the surface MoO3 in various atmospheres. As illustrated in Fig. 1c, after switching synthetic air to Ar flow at room temperature, the Raman signal of MoO3 disappeared, and the peaks at 195, 222, 348, 485, 560, 722 cm−1 of MoOx (x < 3) were detected, which indicated that the MoO3 transformed into defective MoOx31,32. This conversion indicated that oxygen vacancies were formed even under inert gas atmospheres at room temperature. When H2 was introduced, the MoOx signal could be detected at low temperatures. However, when the temperature was increased to 500 °C, the MoOx signal was absent. The MoOx Raman signal reappeared when the test temperature was returned to room temperature, indicating that the MoOx passivation layer was still the intrinsic catalytic surface under the high-temperature reducing atmosphere. The absence of MoOx Raman signal at 500 °C might be caused by the thermal emission that masked the weak vibrational information or the presence of laser that enhanced the reduction of surface oxygen atoms34. After that, the MoO3 signal was reproduced when the sample was exposed to synthetic air again. And based on the Raman spectra shown in Supplementary Fig. 1a, during above in situ Raman tests, no obvious MoO2 and Mo2N species could be detected. These in situ Raman results showed that the surface MoO3 structure on bulk Mo2N was highly reactive, which underwent dynamic structural transformations under different atmospheres. Subsequently, we measured temperature-programmed reduction by H2 (H2-TPR) to further explore the redox properties of the catalyst. As shown in Fig. 1d, the reduction peaks in H2-TPR were attributed to the reduction of the Mo-O species on Mo2N. It was noticed that even at 950 °C, the H2 consumption was still found, demonstrating that part of the oxygen atoms was strongly coordinated with Mo atoms and were very hard to be removed by H2. Besides, the observed signals of NH3 and N2 in the H2-TPR could be contributed to the desorption of adsorbed NH3 during the nitridation process and the denitriding of Mo2N, respectively. The reduction of Mo-O species in this catalyst was also confirmed by the CO-TPR tests (Supplementary Fig. 1b). Interestingly, compared to MoO3/Mo2N, the reference MoO3 sample was hardly reduced, which required a much higher reduction temperature (Supplementary Fig. 1c‒e). Based on our previous investigations, this improved reducibility of the surface MoO3 in MoO3/Mo2N heterostructure was attributed to the stress between the MoO3 passivation surface and the bulk Mo2N29.

a XRD pattern of fresh and used samples. b Raman spectra of fresh and used samples. c The in situ Raman spectra of MoOx/Mo2N with consecutive switch of air, Ar and H2. d H2-TPR pattern of MoO3/Mo2N. e Four-step surface reaction experiment on H2-pretreated MoOx/Mo2N with consecutive switch of Ar, CO2, Ar and H2 at 600 °C. f In situ Raman of MoOx/Mo2N with consecutive switch of H2, Ar and CO2 at 500 °C. g The schematic diagram of proposed reaction pathway and corresponding structural evolution.

In addition, we also quantified the amount of reduced oxygen atoms during the H2 reduction process through H2-TPR experiments. Through the quantification of the H2 consumption peaks from Supplementary Fig. 2a, we obtained that ~1905 µmol/g of oxygen atoms were reduced during the H2 reduction from room temperature to 600 °C. After that, we utilized the H2 reduction from room temperature to 950 °C to reduce all oxygen atoms in the catalyst (Supplementary Fig. 2b) and quantify the overall oxygen content of the entire catalyst. By quantifying the H2 consumption in the H2-TPR result (Supplementary Fig. 2c and d), the content of oxygen atoms in the sample was ~2844 µmol/g. Based on above results, after the H2 reduction at 600 °C, ~67.0% of oxygen atoms could be reduced, and ~33.0% of O atoms in the MoO3 passivation layer was inert. Due to only MoO3 signals were detected in the Raman spectra of the as-prepared sample, we could assume that almost all Mo-O species on the surface of the as-prepared catalyst existed in the form of MoO3. Therefore, we could obtain that the average value of x in MoOx after the H2 pretreatment was about 1.0. And during the H2 pretreatment from RT to 600 °C, the range of x over the MoOx active structure could be evaluated as 1<x < 3. With the increase of the H2-pretreatment temperature to 600 °C, the value of x could reduce to 1.0.

The reduction of O atoms in the MoO3 passivation layer is accompanied by the formation of oxygen vacancies. In general, oxygen vacancies can exhibit an enhanced catalytic activity to adsorb and activate oxygen-containing reactant molecules16,32. CO2 is a typical oxygen-containing molecule, while the stable C = O bond makes the catalytic conversion of CO2 very challenging. Herein, the four-step surface reaction experiment with consecutive switch of Ar→CO2→Ar→H2 was carried out to explore the absorption and activation of CO2 on the highly reduced MoOx surface. Before the surface reaction measurement, the MoO3/Mo2N heterostructure was pretreated by 5% H2/Ar at 600 °C for 1 h, and thus the defective MoOx surface with rich oxygen vacancies was in situ constructed. As shown in Fig. 1e, for the H2-pretreated sample, after the introduction of CO2, CO signal appeared obviously, suggesting the direct conversion of CO2 to gaseous CO. The gradually weakening CO2 signal demonstrated that the sites to convert CO2 into CO gradually decreased. Then, with the introduction of H2, the observed H2O signal indicated that CO2 underwent the direct C = O cleavage on the highly reduced MoOx surface and H2 reacted with the oxygen atoms leached from the CO2 dissociation to form H2O. This four-step surface reaction experiment was conducted cyclically three times and gave repeatable results, strongly confirming that CO2 was directly dissociated on the highly reduced MoOx surface to produce gaseous CO. The accumulated oxygen atoms in the MoOx surface were cleaned by H2 to regenerate the consumed active sites. The in situ Raman of MoOx/Mo2N with a successive switch of H2, Ar and CO2 suggested the dynamical evolution of the oxidation state under H2 and CO2 atmospheres (Fig. 1f). Under H2 flow at 500 °C, no Raman signal of Mo-O species was found at such a test temperature. However, the Raman signal of MoOx formed with the following introduction of CO2 flow under the same test temperature, which indicated CO2 re-oxidized the reduced catalyst surface. This catalyst could reproduce such a structure evolution in three continuous rounds of Raman tests. By combing the results of the surface reaction experiment and in situ Raman, we speculated that the defective MoOx surface with rich oxygen vacancies was an intrinsic active structure to directly dissociate CO2 to generate CO. Further, the CO-TPD result indicated that there was no obvious desorbed CO signal from room temperature to 600 °C, suggesting a very weak CO adsorption on the MoOx/Mo2N surface (Supplementary Fig. 1f). The rapid desorption of CO prevented the further hydrogenation of the formed CO to CH4, accelerating the equilibrium shift based on the Le Chatelier’s principle. As a result, the unique MoOx structure on Mo2N possessed a favorable microenvironment to catalyze the RWGS reaction. The discussion of the proposed catalytic pathway was concluded in Fig. 1g. First, during H2 pretreatment, the MoO3 passivation layer on the bulk Mo2N was reduced to generate abundant vacancies, and then CO2 was dissociated on the defective MoOx surface to form gaseous CO. Subsequently, H2 timely removed the leached O atoms from the CO2 dissociation to promote the regeneration of active vacancy sites. Accompanied by the redox cycle of the MoOx surface, the RWGS reaction proceeded rapidly through the redox mechanism.

The effect of CO2 on the bulk Mo2N structure was also clarified in this work. Under CO2 flow, for H2-pretreated MoOx/Mo2N, with the increase of test temperature, CO signal was detected companied by the CO2 consumption (Supplementary Fig. 3a). We also found that in the absence of H2, CO2 conversion decreased gradually with the extension of the test time at 600 °C, 700 °C and 800 °C, respectively (Supplementary Fig. 3a‒c). For MoO3/Mo2N without H2 pretreatment, CO2 could also be converted into CO, but at a slower rate (Supplementary Fig 3d). Combined with the in situ XRD pattern of MoO3/Mo2N under 2% CO2/Ar, it could be speculated that CO2 could oxidize the bulk Mo2N to MoO2, and thus forming CO (Supplementary Fig. 3e). However, with the conversion of bulk Mo2N to MoO2, the active MoOx surface could not be regenerated, which explained why the initial intensity of the H2O signal in Fig. 1e continued to decrease with the increase of the number of the treatment cycles. In brief, during the CO2 hydrogenation, H2 was necessary to timely remove oxygen atoms generated from the CO2 dissociation, thus preventing the over-oxidation of internal Mo2N to MoO2. In addition, compared to product CO, the formed H2O during the reaction was also able to oxidize the bulk Mo2N structure (Supplementary Fig. 3f and g).

In order to compare the catalytic property of this highly reduced MoOx with that of conventional reducible metal oxides, we carried out the CO2 dissociation experiments over the H2-reduced CeO2 sample. As a typical reducible metal oxide, CeO2 has been widely used in various important catalytic reactions35,36,37,38,39. The H2-TPR result of CeO2 showed that before 600 °C, CeO2 underwent obvious reduction (Supplementary Fig. 4a). And the amount of reduced O atoms from room temperature to 600 °C over CeO2 was quantitatively calculated to be ~748 µmol/g. Then, we used CO2 flow to treat the CeO2 after the H2 pretreatment at 600 °C. Interestingly, based on CO2 treatment experiments and in situ diffuse reflectance infrared Fourier transform spectroscopy tests (DRIFTS), we found that for H2-pretreated CeO2, CO2 did not dissociate to generate CO, but formed stable carbonates (Supplementary Fig. 4b‒d). Due to the deep black color of MoO3/Mo2N, we could not find any adsorption signals of carbon/oxygen-containing intermediates from the DRIFTS (Supplementary Fig. 4e). Nevertheless, the temperature-programed desorption of CO2 (CO2-TPD) suggested that compared to H2-pretreated CeO2, it was difficult for CO2 to form carbonate intermediate on the MoOx/Mo2N surface (Supplementary Fig. 4f). Therefore, we inferred that the significant difference in the catalytic activity of oxygen vacancies on MoOx/Mo2N and CeO2 leaded to two distinct catalytic mechanisms toward the RWGS reaction. According to whether CO2 can be dissociated directly into CO, the mechanisms of the RWGS reaction can be divided into redox pathway and associative pathway12,40. Because the direct cleavage of stable C = O double bond in CO2 happened on highly reduced MoOx surface, the catalytic process catalyzed by MoOx/Mo2N followed the redox mechanism. On the contrary, for the H2-reduced CeO2, the strong adsorption rather than the direct dissociation of CO2 on CeO2 was confirmed, suggesting the reaction catalyzed by CeO2 could only follow the associative mechanism.

Catalytic performance of the MoOx/Mo2N catalyst in the RWGS reaction

For the RWGS reaction with harsh reaction conditions, supported catalysts with active metals were susceptible to suffering from deactivation due to the sintering of active metals, although they might exhibit a high initial activity. Owing to the unique redox properties and the absence of supported active metal, the MoOx/Mo2N catalyst is expected to achieve both high activity and solid stability for the high-temperature RWGS reaction. As shown in Fig. 2a, under a high gaseous hourly space velocity (GHSV) of 200,000 mL/gcat/h, the MoOx/Mo2N catalyst exhibited very high activity and complete CO selectivity. At 600 °C, the CO2 conversion was close to the thermodynamic equilibrium limitation. And in six rounds of cyclic stability tests, the catalytic activity was reproduced well, suggesting the durability of this catalyst under the start-up cool-down conditions. In addition, CO selectivity of this catalyst was 100%, no CH4 was detected throughout the activity evaluation, therefore, this catalyst effectively catalyzed the RWGS reaction rather than methanation (Supplementary Fig. 5a). Compared to H2-pretreated CeO2, MoOx/Mo2N with the unique redox properties demonstrated a much higher activity. Besides, the apparent activation energy (Ea) of MoOx/Mo2N was only 45.0 kJ/mol (Fig. 2b), which was lower than that of CeO2 (102.1 kJ/mol) and Pt-CeO2 (55.6 kJ/mol). The low Ea value suggested the RWGS reaction could easily take place on MoOx/Mo2N with the redox mechanism. Importantly, even compared to most reference-supported metal catalysts with CeO2 and Al2O3 as supports, MoOx/Mo2N showed largely improved catalytic performance (Fig. 2c). And compared to other Mo-based catalysts including MoO3, Mo2C and MoS2, MoOx/Mo2N exhibited better catalytic performance (Supplementary Fig. 5c and d). We would like to emphasize that in this work, in order to more accurately compare the activity between the MoOx/Mo2N catalyst and other reference catalysts, all the reference catalysts in Fig. 2 and Supplementary Fig. 5 were prepared in-house and their activity tests were measured by using the same reactor under the same test conditions. Among all reference catalysts, Pt/CeO2 had a higher CO2 conversion than MoOx/Mo2N, while it had a poorer CO selectivity (Supplementary Fig. 5b). It was worth noting that with the weakening of external diffusion limitation, the CO formation yield of MoOx/Mo2N could reach 159.6×10−5 mol/gcat/s at a very high GHSV of 3,800,000 mL/gcat/h (Supplementary Fig. 5e), exceeding almost all reported catalysts in previous literatures (Supplementary Table 1).

a CO2 conversion over MoOx/Mo2N in the RWGS reaction for six start-up cool-down cycles (Test conditions: 0.1 MPa, 300 °C‒600 °C, GHSV = 200,000 mL/gcat/h). b Apparent activation energy (Ea) of MoOx/Mo2N, Pt/CeO2 and CeO2 catalysts. c Comparison of CO2 conversion over MoOx/Mo2N with other reference catalysts. The reference catalysts were synthesized by ourselves in our lab, and the corresponding catalytic tests were carried out on same reactor. d Three rounds of stability tests over MoOx/Mo2N under harsh reaction conditions with 600 °C and a high GHSV of 200,000 mL/g/h (the time interval between two rounds of testing was 55 days).

In order to assess the durability of the MoOx/Mo2N catalyst in the high-temperature RWGS reaction, three rounds of stability tests were measured at 600 °C. The duration of each test was 300 h, and the time interval between two rounds of testing was 55 days. As shown in Fig. 2d, this catalyst maintained stable CO2 conversion and CO selectivity over 900 h with a CO2 conversion more than 45% and a complete CO selectivity. Importantly, even after 55 days of exposure to air, the active sites of the used sample were not deactivated by air corrosion, suggesting a superior recyclability. Meanwhile, compared to other reported catalysts, this MoOx/Mo2N catalyst without any supported active metals could effectively avoid the deactivation caused by the sintering of active metals, suggesting a great potential in practical application (Supplementary Fig. 5f). In addition to the atmospheric reaction condition, this catalyst maintained its activity well in a 20-hour stability test at enhanced reaction pressures of 2.0 Mpa (400 °C) and 1.0 Mpa (600 °C) (Supplementary Fig. 5g and h).

In order to investigate the relationship between the catalytic activity and the H2/CO2 ratio, we further supplemented the activity tests of the catalyst under other H2/CO2 ratios (2:1 and 1:1). As shown in Supplementary Fig. 6a–d, under the gas flow with the H2/CO2 ratio of 1:1 and 2:1, the CO2 conversion of the catalyst was much lower than the equilibrium line, which suggested that the catalytic activity was poor at a low H2 proportion. The XRD results of the used catalysts showed distinct diffraction peaks of MoO2 but no Mo2N (Supplementary Fig. 6e), indicating that during the reaction, bulk Mo2N was oxidized by CO2. Compared to the XRD result of the used catalyst under a H2/CO2 ratio of 3:1 (Fig. 1a), above XRD results confirmed that the catalytic performance and the redox behavior of MoOx was largely determined by the H2/CO2 ratio. A high H2 proportion could guaranteed the reversible redox of MoOx during the reaction, but the low H2 proportion could not protect the bulk Mo2N from the over-oxidation by CO2, which led to the irreversible redox of the MoOx structure and the decrease of the catalytic performance.

Surface and bulk structure of the MoOx/Mo2N catalyst

As shown in the high-resolution transmission electron microscopy (HRTEM) images (Supplementary Fig. 7a‒c), the fresh catalyst showed a sheet-like morphology consisting of Mo2N particles, and no information of MoO3 passivation surface could be detected. After the high-temperature RWGS reaction, this catalyst could remain the sheet-like morphology with that of the fresh sample (Supplementary Fig. 7d). And as illustrated from the high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) images of the fresh and used catalysts (Fig. 3a‒c and Supplementary Fig. 7e and g), the information of MoO3 component was still absent. However, after the RWGS reaction, a disordered surface layer with a thickness of less than 1 nm was clearly observed, which could be regarded as the pivotal surface structure to form oxygen vacancy-rich subnano MoOx layer to activate CO2 during CO2 hydrogenation. Meanwhile, the surface Mo-O species could be verified by the elemental mapping, with O signal was highly dispersed on Mo2N surface (Fig. 3d and Supplementary Fig. 7f and h). Besides, although O element signal was weak, STEM-EDS line scanning of the fresh and used samples indicated a decrease in the atomic fraction of O from the surface to the bulk, which also demonstrated the presence of surface Mo-O species (Fig. 3e, f and Supplementary Fig. 8a‒f). Scanning Electron Microscope (SEM) images also suggested that the fresh catalyst showed a stacked sheet-like structure, and the nanosheets were made up of numerous nanoparticles (Supplementary Fig. 8g). After the RWGS reaction, the morphology of the catalyst maintained stable (Supplementary Fig. 8h). The X-ray photoelectron spectroscopy (XPS) over the fresh and used catalysts in Mo 3d, O 1 s, and N 1 s regions clearly illustrated the reduction of surface MoO3 and the denitrification of Mo2N. As shown in Supplementary Fig. 9a and Supplementary Table 2, the Mo 3d XPS spectra contained mixed components with contributions from Mo6+, Mo5+, Mo4+ and Mo-N25. The appearance of Mo6+ confirmed the presence of the surface MoO3. Furthermore, the Mo6+ signal over the used sample was much weaker than that of the fresh sample, indicating the reduction of MoO3 during the RWGS reaction. By combining the in situ Raman spectra in Fig. 1c, it could be confirmed that when the used sample was exposed to air, a part of reduced Mo atoms could be re-oxidized to MoO3. The reduction of MoO3 was also confirmed by the O 1 s XPS spectra with much-decreased lattice oxygen after the reaction (Supplementary Fig. 9b). And the significant increase of surface oxygen species for the used catalyst demonstrated the created oxygen vacancies during the surface MoO3 reduction favored the adsorption of oxygen-contained molecules in air, such as H2O and CO2 (Supplementary Fig. 9b and f).

a‒c HAADF-STEM of spent MoOx/Mo2N after the RWGS reaction. d STEM and element mapping of Mo, N and O of spent MoOx/Mo2N after the RWGS reaction. e HAADF-STEM image of the used sample and f, STEM-EDS elemental line scanning of O element over the highlighted area in e. g Ex situ and quasi in situ Mo 3d XPS for fresh MoOx/Mo2N and MoOx/Mo2N after H2 pretreatment and high-temperature RWGS reaction at 600 °C. h In situ Raman spectra of MoOx/Mo2N under the RWGS reaction atmosphere at various temperatures. i In situ XRD pattern of MoOx/Mo2N under 5% H2/Ar. j The scheme of surface evolution over MoO3/Mo2N under different atmospheres and temperatures.

Then, in order to identify the oxidation states of surface Mo species in the H2 pretreatment and the RWGS reaction, the quasi in situ XPS was measured. As shown in Fig. 3g, high-temperature H2 pretreatment led to the reduction of MoO3, and although the RWGS reaction gas contained 23% CO2, the oxidation states of Mo remained relative durable in the actual reaction process. Combined with the results of four-step surface reaction experiment and in situ Raman (Fig. 1c, d), the stable oxidation states of Mo were owing to the timely removal of the generated oxygen atoms from the CO2 dissociation by H2. Compared to the used sample with abundant adsorbed oxygen species (Supplementary Fig. 9b), the limited surface oxygen species of samples after the in situ H2 pretreatment and the RWGS reaction was related to the quick CO2 dissociation, CO desorption and H2O formation (Supplementary Fig. 9d and f). Meanwhile, the catalysts that underwent the H2 pretreatment and the reaction process possessed a weaker N 1 s signal compared to the fresh sample25, suggesting the denitrification of Mo2N and the formation of nitrogen vacancies (Supplementary Fig. 9c and e). We speculated that in the reaction process, nitrogen vacancies were likely to be occupied by oxygen atoms from CO2, and then converted to oxygen vacancies by the further H2 reduction. After that, the surface and subsurface structure information over the catalyst after the long-term RWGS reaction (70 h) was also investigated. As shown in Supplementary Fig. 10a, the catalyst suffered from partial carbonization during the RWGS reaction, with the observation of the Mo-C signal. While, the largely increased Mo nitride signal after the Ar ion etching indicated the subsurface of the catalyst had more Mo-N species24,25, suggesting that the bulk Mo-N structure was relative stable under the CO2 hydrogenation process (Supplementary Fig. 10b). Besides, the Mo6+ content on the catalyst surface was higher than that in the catalyst subsurface, again confirming the presence of the MoO3 passivation layer on bulk Mo2N (Supplementary Fig. 10c).

The in situ Raman was carried out to further explore the intrinsic surface structure during the actual reaction process. Under the reaction atmosphere, the MoOx (x < 3) signal appeared at room temperature and maintained until 500 °C (Fig. 3h). Based on the quasi in situ XPS spectra of Mo 3d and O 1 s, as well as the Raman spectra after the sample was cooled down to room temperature, the absence of MoOx signal in the Raman spectra at 500 °C did not imply the complete removal of surface Mo-O species, but indicated the masked vibrational information caused by the high test temperatures. Importantly, although the MoOx surface structure possessed extremely active redox properties, the bulk Mo2N exhibited a solid stability under reductive atmosphere. As illustrated in Fig. 3i and Supplementary Fig. 9g, under 5% H2/Ar and the RWGS reaction flow at 600 °C for 8 and 6 h, respectively, only diffraction peaks of Mo2N could be detected, suggesting a high stability of the bulk-phase Mo2N. The surface structural evolution over MoO3/Mo2N under different atmospheres and temperatures was illustrated in Fig. 3j. In summary, for the MoO3/Mo2N heterostructure, the subnano MoO3 passivation layer inhibited the overoxidation of the internal Mo2N in air, guaranteeing the excellent recyclability of this catalyst. In addition, under the reductive reaction atmosphere, the bulk Mo2N not only endowed with subnano MoO3 surface active redox properties but also prevented the collapse of the active surface.

CO2 activation mechanism and RWGS reaction pathway

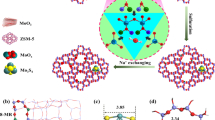

By utilizing a series of in situ characterization techniques, the presence of rich and efficient oxygen vacancies on the highly reduced subnano MoOx surface during the reaction process had been confirmed. The density functional theory (DFT) calculations were further performed to explore the crucial role of surface oxygen vacancies in CO2 activation. Based on characterization results, a model of the MoO3/Mo2N heterostructure was constructed (Supplementary Fig. 11a, b). In addition, the models of MoOx/Mo2N with different oxygen defect concentrations were shown in Supplementary Fig. 11c. We thoroughly examined both physical and chemical adsorption configurations of CO2 on these models. For the 2Ov and 4Ov models, CO2 molecules adsorb at isolated oxygen vacancies, primarily through weaker physical adsorption, with adsorption energies less than −0.1 eV. Chemical adsorption at these sites was energetically unfavorable, showing positive adsorption energies. Conversely, for the 6Ov, 8Ov, and 14Ov models, CO2 chemically adsorbs at sites with adjacent vacancies, resulting in significantly more negative adsorption energies, indicating stronger bonding (Fig. 4a and Supplementary Fig. 12). In this process, oxygen and carbon atoms from CO2 bonded with coordination-unsaturated Mo sites. An increase in oxygen vacancy density on the catalyst surface could effectively enhance the adsorption energy of CO2. According to H2-TPR, CO-TPR and in situ Raman results, we obtained MoOx/Mo2N catalysts with varying oxygen vacancy concentrations by regulating H2-pretreated temperatures. By analysing the O 1 s XPS spectra of the related samples, we found that the oxygen vacancy concentration was positively correlated with the pretreatment temperatures under 5% H2/Ar (Supplementary Fig. 13a, b). And by combining these findings with activity evaluations, we speculated that the increased oxygen vacancy concentration led to improved catalytic activity (Fig. 4b).

In addition, the CO2 activation also relies on the electron transfer between the chemically adsorbed CO2 molecule and the catalyst surface2,15,41. The injection of electrons into the anti-bonding orbitals of the CO2 molecule directly determines the activation of C = O bonds. Projected electronic density of states (Supplementary Fig. 14) demonstrated that CO2 had effective interactions with the defective MoOx catalytic surface. Moreover, as shown in Supplementary Fig. 15a of the differential charge density, due to the high electron-donating capacity of the oxygen-rich surface, CO2 molecule acquired electrons from the surrounding coordination-unsaturated Mo atoms, suggesting the effective CO2 activation on catalyst surface. And the integration of Δρ further confirmed the strong electronic interaction between the adsorbed CO2 and the MoOx surface with rich oxygen vacancies (Supplementary Fig. 15b). Based on DFT simulations, the differences in CO2 activation mechanisms on MoOx/Mo2N and the traditional reducible oxide of CeO2 were also investigated. For MoOx/Mo2N, we chose MoOx (8Ov)/Mo2N as the initial catalyst model. As illustrated in Supplementary Fig. 16, on the H2-reduced CeO2 surface, the chemisorbed CO2 molecule on oxygen vacancies tended to react with another lattice oxygen atom to form carbonates rather than directly dissociating into CO. This was consistent with the observation of carbonate signals and the absence of gaseous CO in the in situ DRIFTS (Supplementary Fig. 4c, d). However, compared to CeO2, the adsorption configuration of CO2 on MoOx/Mo2N surface was quite different, in which two oxygen atoms and one carbon atom from CO2 could be activated simultaneously by forming chemical bonds with two adjacent coordination-unsaturated Mo atoms on the catalyst surface. Therefore, CO2 could be effectively activated through the electron transfer mediated by more than one exposed Mo site. This efficient activation of CO2 facilitated the direct breaking of the stable C = O double bond to form *CO and *O with a much lower energy barrier of 1.50 eV (Supplementary Fig. 16a), which could be easily overcome at reaction temperature. Conversely, the formation of *CO3 on the MoOx surface was more difficult, with a relatively higher energy barrier of 1.77 eV. These results indicated that, compared to the reduced CeO2 surface, the subnano MoOx passivation surface with high-density oxygen vacancies possessed much improved ability to directly dissociate CO2 (Supplementary Fig. 16b, c).

To understand the underlying reaction pathway of CO2 hydrogenation to CO on the MoOx surface, we conducted the further DFT calculation (Fig. 4c). CO2 was first captured by an oxygen vacancy, which was a prerequisite for CO2 hydrogenation. The subsequent dissociation of CO2 to *CO and *O was the critical step for the catalyst to catalyze CO2 hydrogenation to CO, which had an energy barrier of 1.5 eV. Then the formed *CO left the catalyst surface to generate gaseous CO. Subsequently, the *O left on the catalyst surface reacted with a dissociated H atom to form *OH, which followed by the reaction with another dissociated H atom to produce H2O. We calculated the energy barriers for the transition states of dissociative H2 adsorption (H2 + 2* → 2*H) and H2O formation (*H + *OH → H2O + 2*), which were 0.97 eV and 1.23 eV at 0 K, respectively. These barriers were comparatively lower than the CO2 dissociation barrier (*CO2 → *CO + *O), which is 1.5 eV, suggesting that CO2 dissociation was indeed the rate-limiting step in this reaction over MoOx/Mo2N catalysts. With H2O desorption, the consumed reactive oxygen vacancy was regenerated, and the catalyst structure returned to its initial state. Our calculations also showed that raising reaction temperature from 0 K to 600 K could effectively accelerate the desorption of the formed intermediates, especially for *CO, preventing the poisoning of active oxygen vacancies.

Discussion

The catalytic conversion of CO2 is largely determined by the CO2 activation. In this work, by utilizing the active redox property of MoO3 passivation layer on Mo2N, we constructed high-performance MoOx surface with rich and efficient oxygen vacancies, which achieved the direct cleavage of C = O double bonds over CO2. The high-density oxygen vacancies with abundant coordination-unsaturated Mo sites provided a favorable spatial and electronic environment, largely promoting the CO2 activation via the electron transfer mediated by exposed Mo sites. The reversible switch of different Mo oxidation states on MoOx surface allowed the cyclic consumed and regenerated oxygen vacancies to serve as independent active sites to complete the whole CO2 hydrogenation process. In addition, by using comprehensive in situ characterizations, the intrinsic active structure of Mo2N-based catalytic materials was deeply uncovered. The MoO3 passivation surface on Mo2N exhibited unusual catalytic properties, although it has been ignored in almost all other reports. These findings in this work showed that as a heterostructure with unique surface redox properties, MoOx/Mo2N possessed huge application potential in various heterogeneous reactions. This work also provided a well reference to develop effective defect engineering in designing high-performance catalysts without relying on supported active metals.

Methods

Synthesis of MoO3

The MoO3 precursor was prepared by hydrothermal method. Firstly, 1.0 g of triblock copolymer (P123) was dispersed in deionized water (40 mL) by stirring for 1 h. Then, 0.9 g of Na2MoO4·9H2O was dissolved in deionized water (5 mL) and transferred into the obtained P123 solution. After stirring for 30 min, 3 mL of HCl (37 wt.%) was added. Subsequently, the obtained stock solution was transferred into a Teflon bottle and then tightly sealed in a stainless-steel autoclave. The hydrothermal reaction was carried out at 100 °C for 12 h in the oven. After that, the produced solid was washed by deionized water and ethanol followed by drying at 70 °C for 10 h. Finally, the above solid was calcined in a tube furnace at 400 °C for 4 h.

Synthesis of MoO3/Mo2N

400 mg of MoO3 was loaded in a quartz tube and placed in a horizontal tube furnace. Then, the MoO3 was heated under pure NH3 with a gas flow of 40 mL/min at 650 °C (5 °C/min) for 4 h. And then, after complete cooling to room temperature, the 1% O2/Ar (30 mL/min) was switched to passivate the obtained black powder for 2 h.

In this work, the as-prepared MoO3/Mo2N catalyst with MoO3 passivation layer was denoted as MoO3/Mo2N. And due to the MoO3 passivation layer on Mo2N could be easily reduced under H2 and RWGS reaction flow, the catalyst underwent Ar, H2, or RWGS reaction flow treatment was denoted as MoOx/Mo2N catalyst (1<x < 3).

Catalyst characterization

X-ray diffraction (XRD)

The XRD pattern was measured on PANalytical X’pert3 powder diffractometer (40 kV, 40 mA) using Cu Ka radiation. Appropriate mass of powder sample was placed in a quartz-glass holder for the ex situ XRD measurement. For in situ XRD, appropriate mass of powder sample was sealed in the in situ chamber. And in situ XRD tests of the following two programs were carried out.

(1) The oxidation of the bulk Mo2N over MoO3/Mo2N under CO2 flow. The sample was purged by 2% CO2/Ar at room temperature to remove the residual air and then heated to 600 °C with a heating rate of 10 °C/min. The XRD pattern was measured at room temperature (25 °C), 100 °C, 300 °C and 600 °C after stabilizing at the set temperature for 30 min. Then, XRD test was carried out every 1.5 h at 600 °C.

(2) The stable bulk Mo2N over MoO3/Mo2N under H2 flow. The sample was purged by 5% H2/Ar at room temperature to remove the air in sample chamber and then heated to 600 °C (10 °C/min). The XRD pattern was obtained every 1.5 h at 600 °C under 5% H2/Ar. For RWGS reaction conditions, the sample was purged by 30% H2, 10% CO2/N2 at room temperature and then heated to 600 °C (10 °C/min).

Raman

All ex situ and in situ Raman spectra were collected by a LabRAM HR800 spectrometer (HORIBA JY) with excited laser at 473 nm. Approximately 10 mg of catalyst was used in the in situ Raman testing. The Raman reaction cell (Xiamen TOPS) equipped with a quartz window and a heating module that allowed samples to be heated controllably. A manual six-way valve was used to rapidly switch the gases without dead volume. In addition, recycled ethanol was used to cool down the cell during the high-temperature testing. For MoO3 sample, 5% H2/Ar was injected at room temperature, and then the sample was heated from room temperature to 500 °C. The corresponding Raman spectra were measured at 100 °C, 300 °C and 500 °C, respectively. For MoOx/Mo2N, the in situ Raman spectra were obtained by using the following programs.

(1) The Raman spectra were collected under air. Then, pure Ar was injected at room temperature to remove the air, and Raman spectra were measured. After that, the gas was switched into 5% H2/Ar, and the sample was heated to 500 °C from room temperature with a ramping rate of 10 °C/min. Raman spectra were collected under Ar flow after the H2 treatment at room temperature, 100 °C, 200 °C, 300 °C, 400 °C, 500 °C and cooling down to room temperature, respectively. Then, after cooling to room temperature, Raman spectrum was measured after the exposure of air.

(2) The MoOx/Mo2N sample was treated by 23% CO2/69% H2/Ar from room temperature to 550 °C (10 °C/min). Raman spectra were collected in Ar flow after the treatment under the RWGS reaction flow at room temperature, 100 °C, 200 °C, 300 °C, 400 °C, 500 °C, 550 °C, respectively. Then after cooling down to room temperature, the Raman spectra was measured again.

(3) The MoOx/Mo2N sample was heated from room temperature to 500 °C under 5% H2/Ar. At 500 °C, after H2 treatment for 15 min, pure Ar was injected for another 15 min, and Raman spectra were collected under Ar flow. Then, the gas was switched from Ar to 2% CO2/Ar for 15 min, and Raman spectra were measured. Above test program was cycled for three times.

X-ray photoelectron spectroscopy (XPS)

All XPS experiments were measured on a Thermo Scientific ESCALAB Xi+ XPS instrument. The C 1 s line located at 284.8 eV was used to calibrate each spectrum for accurate binding energies. For the ex situ XPS measurement of the used catalysts after different pretreatment temperatures, the sample was pretreated at 400 °C, 500 °C and 600 °C under 5% H2/Ar for 1 h, respectively, and then followed one-hour RWGS reaction at 400 °C. The reaction at 400 °C was chosen to avoid that at higher temperature, the RWGS reaction atmosphere would further reduce Mo-O species on the catalyst surface, which could mask the effect of the pretreatment temperature on oxygen vacancy concentration. For the XPS etching experience, the ion energy of Ar ion was set to 2000 eV. For the quasi in situ XPS measurements, the samples after the treatments at predetermined temperature and gas flow were transferred from the pretreatment chamber to the test room under the vacuum without exposure to air. The quasi in situ XPS measurements were carried out by the following three programs.

(1) The spectrums of C 1 s, O 1 s, N 1 s, Mo 3d were measured after the sample was treated by 5% H2/Ar at 600 °C for 1 h.

(2) The spectrums of C 1 s, O 1 s, N 1 s, Mo 3d were obtained after the sample was treated by 23% CO2/69% H2/N2 at 600 °C for 5 h.

Transmission electron microscopy (TEM)

The TEM was conducted on a JEOL JEM-1011 instrument operating at 100 kV. The powder sample was dispersed in ethanol under ultrasound. And then, the sample was dropped at the carbon-coated Cu grid before test. The high resolution transmission electron microscopy (HRTEM) was measured at JEM-2100. The High-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) images were acquired at Spectra 300 (Thermofisher). The STEM-EDS elemental line scanning and STEM-EDS elemental area mapping element mapping were obtained from the same equipment under the STEM mode.

Temperature program reduction by hydrogen (H2-TPR)

For MoO3 sample, H2-TPR was carried out on Builder PCSA-1000 instrument with a thermal conductivity detector (TCD) to test the H2 consumption. The sample was first pretreated by pure air at 300 °C for 30 min with a ramping rate of 10 °C /min. After cooling at room temperature, the flow was switched to 5% H2/Ar, and the H2 consumption was measured under 5% H2/Ar with a ramping rate of 10 °C/min from room temperature to 950 °C. For MoO3/Mo2N sample, the H2-TPR was obtained on a mass spectrometer. In order to prevent the bulk Mo2N from oxidation by air, the sample was pretreated by pure Ar at 300 °C for 30 min. And after cooling to room temperature, the H2-TPR was acquired from room temperature to 950 °C (10 °C/min). For the quantification of reduced oxygen atoms during the H2 pretreatment process, 50 mg of MoO3/Mo2N was pretreated at 600 °C (10 °C/min) under pure Ar flow for 20 min to exclude the disruption of the desorption signals of NH3 and N2, and after cooling to room temperature, H2-TPR was acquired from room temperature to 600 °C (10 °C/min) and maintained at 600 °C for 1500 s. For the quantification of all oxygen atoms in MoO3/Mo2N, 150 mg of MoO3/Mo2N was pretreated at 950 °C (10 °C/min) under pure Ar flow for 20 min to exclude the disruption of the desorption signals of NH3 and N2, and after cooling to room temperature, H2-TPR was acquired from room temperature to 950 °C (10 °C/min) and maintained at 950 °C for 1500 s. And during this process, in order to exclude the influence of denitriding and the formation of NH3 at high temperature on the TCD signal, the products generated from the H2-TPR was further detected by mass spectrometer.

Temperature program reduction by CO (CO-TPR)

The mass spectrometer was used to analyze the outlet gases for the CO-TPR. After pretreatment of MoOx/Mo2N by pure Ar at 300 °C for 30 min, the CO-TPR was measured under 2% CO/Ar from room temperature to 950 °C.

Temperature program desorption by CO (CO-TPD)

The mass spectrometer was used to analyze the outlet gases for the CO-TPD. Firstly, 50 mg of MoO3/Mo2N was pretreated under 5% H2/Ar at 600 °C for 1 h. After cooling to room temperature, the sample was treated by 2% CO/Ar (30 mL/min) for 30 min followed by purging with Ar flow (30 mL/min) for 30 min to remove all physically adsorbed CO molecules on catalyst surface. And then, the CO-TPD measurement was carried out from room temperature to 600 °C with a ramping rate of 10 °C/min. The desorption of CO was detected online by a mass spectrum.

CO2 treatment experiment

The CO2 treatment experiment was performed on a lab-made reactor and the outlet gases were further analyzed by mass spectrum and an infrared gas analyzer (Gasboard-3100, Wuhan Sifang Corp.). The equipped infrared gas analyzer was used to obtain the CO2 conversion rates. For MoO3/Mo2N and CeO2, before CO2 treatment, the samples were pretreated by 5% H2/Ar at 600 °C for 1 h. After cooling to room temperature, the samples were purged by pure Ar to clear the residual H2. Then, 2% CO2/Ar was switched to reactor and then the samples were heated from room temperature to 800 °C. The test temperatures were maintained at 600 °C, 700 °C and 800 °C for 1 h, respectively. The CO2 treatment experiment of non-pretreated MoO3/Mo2N was also operated by using the same test program. For 10 h of CO2 treatment over H2-pretreated MoOx/Mo2N, the 2% CO2/Ar was switched to 5% H2/Ar at 600 °C and 700 °C, respectively, and the outlet components were analyzed by a mass spectrum and an infrared gas analyzer.

Four-step surface reaction experiment

A mass spectrometer was used to analyze the gaseous products online during the surface reaction. 100 mg of sample was pretreated at 600 °C for 1 h under 5% H2/Ar (30 mL/min) with a ramping rate of 10 °C/min. After that, the sample was purged by Ar, followed by the consecutive switch of 2% CO2/Ar, Ar, 5% H2/Ar and Ar for three times. All the spectrometer signal was measured at the temperature of 600 °C.

In situ diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) spectra

The in situ DRIFTS spectra of the CeO2 sample were collected by using a Bruker Vertex 70 FTIR spectrometer. An acquisition time of 30 s at a resolution of 4 cm−1 was used for the spectrum collection. The DRIFTS cell (Harrick) was equipped with CaF2 windows and a heating cartridge that allowed samples to be heated. A quick switching system was used to rapidly change the gases without a dead volume through a six-way valve. Prior to the in situ DRIFTS measurement, ~20 mg sample was pretreated at 600 °C for 60 min under 5% H2/Ar mixed gas. And then, the background spectra were collected under Ar flow at 600 °C. After the collection of the background spectrum, the mixed gas of 2% CO2/Ar was introduced into the chamber. Continuous recording of the IR profiles was maintained for 3 min. All DRIFTS results were analyzed by using OPUS software.

Activity evaluation and kinetics measurement

A fixed-bed reactor was used for all RWGS reaction tests. For activity tests, 15 mg catalyst (20–40 mesh) was loaded in quartz tube and pretreated at appropriate temperature under 5% H2/Ar for 1 h. After the sample was cooled to room temperature, 23% CO2/69% H2/Ar at 50 mL/min was switched to the reactor. The catalytic activity was measured at 300 °C, 400 °C, 500 °C and 600 °C, respectively. At each test temperature, the products were analyzed after 1 h of steady-state reaction by an on-line gas chromatograph (GC-2014C, Shimadzu) equipped with a TCD detector. For stability test, for the first round test, the sample was pretreated under 5% H2/Ar at 600 °C for 1 h. After one round of stability test, the reaction tube containing the sample was removed from the heating furnace. Subsequently, after the sample has been exposed to air for 55 days, the reaction tube with sample was placed in the reactor again, and other stability tests were performed without any pretreatment. CO2 conversion and CO selectivity were calculated using the following equations:

where \({n}_{{\text{CO}}_{2}}^{\text{in}}\) is the CO2 concentration at inlet and \({n}_{{\text{CO}}_{2}}^{\text{out}}\), \({n}_{\text{CO}}^{\text{out}}\), \({n}_{{\text{CH}}_{4}}^{\text{out}}\) are the concentrations of CO, CO2, CH4 in the outlet.

In the tests of apparent activation energy (Ea) over measured catalysts, the CO2 conversion was controlled within 15% by regulating the mass of catalysts, test temperature and flow rates. The CO yields at 600 °C under different weight hourly space velocities were measured by using 3 mg of catalyst, and the corresponding detailed parameters were given in Supplementary Table 1. The reaction rates of measured catalysts were calculated by using the following equation:

where \(r\) is the RWGS reaction rate by means of CO2 (molCO2/gcat/s). F is the total flow rate of CO2 in reaction stream (mol/s). \({{Conv}.}_{\text{CO}2}\) is the concentration of converted CO2 (%). \(W\) is the mass of the catalyst (g). During the RWGS reaction from 300 °C to 600 °C, the carbon balance exceeded 97.5%.

Data availability

The main data supporting the findings of this study are available within the article and its Supplementary Information. Source data of Figs. 1, 2, 3f‒i and 4b are provided with this paper. Extra data are available from the corresponding author upon request. Source data are provided with this paper.

References

Hu, J. et al. Sulfur vacancy-rich MoS2 as a catalyst for the hydrogenation of CO2 to methanol. Nat. Catal. 4, 242–250 (2021).

Hao, Q. et al. Nickel dual-atom sites for electrochemical carbon dioxide reduction. Nat. Synth. 1, 719–728 (2022).

Parastaev, A. et al. Boosting CO2 hydrogenation via size-dependent metal–support interactions in cobalt/ceria-based catalysts. Nat. Catal. 3, 526–533 (2020).

Wang, C. et al. Product Selectivity Controlled by Nanoporous Environments in Zeolite Crystals Enveloping Rhodium Nanoparticle Catalysts for CO2 Hydrogenation. J. Am. Chem. Soc. 141, 8482–8488 (2019).

Zhong, J. et al. State of the art and perspectives in heterogeneous catalysis of CO2 hydrogenation to methanol. Chem. Soc. Rev. 49, 1385–1413 (2020).

Cui, M. et al. Liquid fuel synthesis via CO2 hydrogenation by coupling homogeneous and heterogeneous catalysis. Chem 7, 726–737 (2021).

Ramirez, A. et al. Selectivity descriptors for the direct hydrogenation of CO2 to hydrocarbons during zeolite-mediated bifunctional catalysis. Nat. Commun. 12, 5914 (2021).

Sang, R. et al. A practical concept for catalytic carbonylations using carbon dioxide. Nat. Commun. 13, 4432 (2022).

Sibi, M. G. et al. Synthesis of Monocarboxylic Acids via Direct CO2 Conversion over Ni–Zn Intermetallic Catalysts. ACS Catal 11, 8382–8398 (2021).

Xia, Y. S. et al. Tandem utilization of CO2 photoreduction products for the carbonylation of aryl iodides. Nat. Commun. 13, 2964 (2022).

Porosoff, M. D., Yang, X., Boscoboinik, J. A. & Chen, J. G. Molybdenum carbide as alternative catalysts to precious metals for highly selective reduction of CO2 to CO. Angew. Chem. Int. Ed. 53, 6705–6709 (2014).

Su, X., Yang, X., Zhao, B. & Huang, Y. Designing of highly selective and high-temperature endurable RWGS heterogeneous catalysts: recent advances and the future directions. J. Energy Chem. 26, 854–867 (2017).

Hu, Y. et al. Tracking Mechanistic Pathway of Photocatalytic CO2 Reaction at Ni Sites Using Operando, Time-Resolved Spectroscopy. J. Am. Chem. Soc. 142, 5618–5626 (2020).

Ou, H. et al. Atomically Dispersed Au-Assisted C–C Coupling on Red Phosphorus for CO2 Photoreduction to C2H6. J. Am. Chem. Soc. 144, 22075–22082 (2022).

Pan, Y. et al. Electron induction of atomically dispersed Fe sites by adjacent Te atoms promotes CO2 activation in electroreduction. Chem Catal 3, 100610 (2023).

Bobadilla, L. F., Santos, J. L., Ivanova, S., Odriozola, J. A. & Urakawa, A. Unravelling the Role of Oxygen Vacancies in the Mechanism of the Reverse Water–Gas Shift Reaction by Operando DRIFTS and Ultraviolet–Visible Spectroscopy. ACS Catal 8, 7455–7467 (2018).

Geng, Z. et al. Oxygen Vacancies in ZnO Nanosheets Enhance CO2 Electrochemical Reduction to CO. Angew. Chem. Int. Ed. 57, 6054–6059 (2018).

Li, L. et al. Atom-Economical Synthesis of Dimethyl Carbonate from CO2: Engineering Reactive Frustrated Lewis Pairs on Ceria with Vacancy Clusters. Angew. Chem. Int. Ed. 61, e202214490 (2022).

Yang, S.-C. et al. Synergy between Ceria Oxygen Vacancies and Cu Nanoparticles Facilitates the Catalytic Conversion of CO2 to CO under Mild Conditions. ACS Catal 8, 12056–12066 (2018).

Nelson, N. C., Chen, L., Meira, D., Kovarik, L. & Szanyi, J. In Situ Dispersion of Palladium on TiO2 During Reverse Water-Gas Shift Reaction: Formation of Atomically Dispersed Palladium. Angew. Chem. Int. Ed. 59, 17657–17663 (2020).

Xiong, X. et al. Photocatalytic CO2 Reduction to CO over Ni Single Atoms Supported on Defect-Rich Zirconia. Adv. Energy Mater. 10, 2002928 (2020).

Zhang, W. et al. Defect-engineering of mesoporous TiO2 microspheres with phase junctions for efficient visible-light driven fuel production. Nano Energy 66, 104113 (2019).

Zhu, D. et al. Study of Direct Synthesis of DMC from CO2 and Methanol on CeO2: Theoretical Calculation and Experiment. Ind. Eng. Chem. Res. 61, 10804–10817 (2022).

Lin, L. et al. Reversing sintering effect of Ni particles on gamma-Mo2N via strong metal support interaction. Nat. Commun. 12, 6978 (2021).

Yao, S. et al. Exploring Metal–Support Interactions To Immobilize Subnanometer Co Clusters on γ–Mo2N: A Highly Selective and Stable Catalyst for CO2 Activation. ACS Catal 9, 9087–9097 (2019).

Khoshooei, M. A. et al. An active, stable cubic molybdenum carbide catalyst for the high-temperature reverse water-gas shift reaction. Science 384, 540–546 (2024).

Zhang, X. et al. A stable low-temperature H2-production catalyst by crowding Pt on α-MoC. Nature 589, 396–401 (2021).

Yao, S. et al. Atomic-layered Au clusters on α-MoC as catalysts for the low-temperature water-gas shift reaction. Science 357, 389–393 (2017).

Zhang, Z. et al. Intrinsically Active Surface in a Pt/gamma-Mo2N Catalyst for the Water-Gas Shift Reaction: Molybdenum Nitride or Molybdenum Oxide? J. Am. Chem. Soc. 142, 13362–13371 (2020).

Liu, H. et al. Ptn-Ov synergistic sites on MoOx/gamma-Mo2N heterostructure for low-temperature reverse water-gas shift reaction. Nat. Commun. 13, 5800 (2022).

Camacho-López, M. A. et al. Micro-Raman study of the m-MoO2 to α-MoO3 transformation induced by cw-laser irradiation. Opt. Mater. 33, 480–484 (2011).

Xin, H. et al. Overturning CO2 Hydrogenation Selectivity with High Activity via Reaction-Induced Strong Metal-Support Interactions. J. Am. Chem. Soc. 144, 4874–4882 (2022).

Zhao, C. et al. Hydrogenated Molybdenum Oxide Overlayers Formed on Mo Nitride Nanosheets in Ambient-Pressure CO2/H2 Gases. ACS Appl. Mater. Interfaces 14, 26194–26203 (2022).

Gueutue, E. S. F. et al. Nanosecond time-resolved Raman spectroscopy for solving some Raman problems such as luminescence or thermal emission. J Raman Spectrosc 49, 822–829 (2018).

Chen, A. et al. Structure of the catalytically active copper–ceria interfacial perimeter. Nat. Catal. 2, 334–341 (2019).

Fu, X. et al. Direct Identification of Active Surface Species for the Water-Gas Shift Reaction on a Gold-Ceria Catalyst. J. Am. Chem. Soc. 141, 4613–4623 (2019).

Huang, W. & Gao, Y. Morphology-dependent surface chemistry and catalysis of CeO2 nanocrystals. Catal. Sci. Technol. 4, 3772–3784 (2014).

Rodriguez, J. A., Grinter, D. C., Liu, Z., Palomino, R. M. & Senanayake, S. D. Ceria-based model catalysts: fundamental studies on the importance of the metal-ceria interface in CO oxidation, the water-gas shift, CO2 hydrogenation, and methane and alcohol reforming. Chem. Soc. Rev. 46, 1824–1841 (2017).

Yu, W. et al. Construction of Active Site in a Sintered Copper-Ceria Nanorod Catalyst. J. Am. Chem. Soc. 141, 17548–17557 (2019).

Chen, X. et al. Identification of relevant active sites and a mechanism study for reverse water gas shift reaction over Pt/CeO2 catalysts. J. Energy. Chem. 25, 1051–1057 (2016).

Li, H., Zhao, J., Luo, L., Du, J. & Zeng, J. Symmetry-Breaking Sites for Activating Linear Carbon Dioxide Molecules. Acc. Chem. Res. 54, 1454–1464 (2021).

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (2021YFA1501103, C.-J.J.), National Science Fund for Distinguished Young Scholars of China (22225110, C.-J.J.), the National Science Foundation of China (22075166, C.-J.J. and 22271177, W.-W.W.), National Nature Science Foundation of China (22402087, J.-C.L.), the Science Foundation of Shandong Province of China (ZR2023ZD21, C.-J.J.) and the Tianjin Science and Technology Plan Project (22JCQNJC01490, J.-C.L.). We thank the Center of Structural Characterizations and Property Measurements at Shandong University for the help on sample characterizations.

Author information

Authors and Affiliations

Contributions

C.J.J., W.W.W. and J.C.L. supervised this work; H.X.L., C.J.J., and W.W.W. designed the experiments, analyzed the results, and complete the manuscript; J.C.L. performed the DFT calculations; H.X.L. and W.W.W. carried out the ex situ and in situ characterizations; H.X.L. and X.P.F. performed the catalysts preparation and activity evaluation and analyzed the obtained results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Luis F. Bobadilla and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, HX., Wang, WW., Fu, XP. et al. Direct cleavage of C=O double bond in CO2 by the subnano MoOx surface on Mo2N. Nat Commun 15, 9126 (2024). https://doi.org/10.1038/s41467-024-53484-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-53484-y

This article is cited by

-

Encompassing Synthetic Methods to Modification Strategies: Cu-MOF-Derived Electrocatalysts for Enhancing CO2 Reduction

Topics in Current Chemistry (2025)