Abstract

Exploring microorganisms with downstream synthetic advantages in lignin valorization is an effective strategy to increase target product diversity and yield. This study ingeniously engineers the non-lignin-degrading bacterium Ralstonia eutropha H16 (also known as Cupriavidus necator H16) to convert lignin, a typically underutilized by-product of biorefinery, into valuable bioplastic polyhydroxybutyrate (PHB). The aromatic metabolism capacities of R. eutropha H16 for different lignin-derived aromatics (LDAs) are systematically characterized and complemented by integrating robust functional modules including O-demethylation, aromatic aldehyde metabolism and the mitigation of by-product inhibition. A pivotal discovery is the regulatory element PcaQ, which is highly responsive to the aromatic hub metabolite protocatechuic acid during lignin degradation. Based on the computer-aided design of PcaQ, we develop a hub metabolite-based autoregulation (HMA) system. This system can control the functional genes expression in response to heterologous LDAs and enhance metabolism efficiency. Multi-module genome integration and directed evolution further fortify the strain’s stability and lignin conversion capacities, leading to PHB production titer of 2.38 g/L using heterologous LDAs as sole carbon source. This work not only marks a leap in bioplastic production from lignin components but also provides a strategy to redesign the non-LDAs-degrading microbes for efficient lignin valorization.

Similar content being viewed by others

Introduction

The valorization of biomass to serve as a source of energy and diverse chemicals and polymers has been extensively investigated and is gradually being industrialized for its advantages in carbon emission reduction and environmental sustainability1,2. The rapid development of biomass biorefining had led to the development of large quantities of lignin as a byproduct, with up to 1.5 kg of lignin produced per liter of cellulosic ethanol3. However, only a very limited fraction of the lignin produced is commercially utilized, and the majority of the lignin stream is used only for heat or electricity generation by combustion, and some even is directly discarded4. The valorization of lignin to high-value products, while crucial for the economic viability and sustainability of lignocellulosic biorefineries, is also challenging due to the heterogeneity of lignin5. Although some microbes, such as wood-rot fungi, can degrade lignin in nature, their lignin mineralization process is slow, greatly hindering their applicability in industrial lignin valorization6. Recently, bacterial metabolic engineering through integration of robust biological elements from different microbial systems to systematically produce high-value products from lignin waste streams has been demonstrated to be a good potential strategy for lignin valorization7.

Meanwhile, developing biodegradable plastics with economic efficiency and sustainability has become a global strategy to address the issues caused by white pollution8,9. There is an urgent need to develop an efficient system to utilize waste biomass resources as cost-effective carbon substrates for sustainable bioplastic synthesis in competitive large-scale commercial applications10,11. The development of technologies for converting lignin to biopolyesters, such as polyhydroxybutyrate (PHB), which is a completely biodegradable bioplastic, has garnered wide interest due to its great significance for both the biomass biorefining and bioplastics industries5,12. The conversion of lignin to biopolyesters requires microorganisms that possess the ability to metabolize aromatic compounds upstream and synthesize biopolyesters downstream13. Some microorganisms in nature, such as Pseudomonas putida KT2440, have been shown to have the capacity to convert lignin-enriched biorefinery waste and LDAs compounds to PHB12. However, the biopolyester accumulation ability of chassis organisms developed to date is insufficient, leading to lower-than-expected polyester production, which is a critical hurdle in the commercialization of biopolyesters14.

Exploring microorganisms with superior capacity in biopolyester accumulation for lignin valorization by further integrating multiple efficient aromatic metabolism pathways is one of the most effective and attractive strategies for cost-effective biopolyester production from lignin waste streams13,15. R. eutropha H16 is a resilient biopolyester production system due to its remarkable metabolic versatility, high-cell-density fermentation capacity and elevated polyester accumulation16. However, R. eutropha H16 lacks an aromatic demethylation system, which is the key and rate-limiting step for lignin-derived methoxy-containing aromatics metabolism5,17. Recent studies have discovered and characterized many critical enzymes for LDAs demethylation, such as VanAB, GcoAB, and LigM, which provide essential biocatalytic elements for upgrading PHB-producing strains for lignin degradation and valorization17,18,19. Nonetheless, integration of the synthesized aromatic demethylation modules into chassis cells for efficient LDAs conversion remains a great challenge. The development of cells with superior compatibility requires not only the introduction of adaptive catalytic elements into the cells but also a series of auxiliary genes that are coordinately expressed.

An intelligent gene regulatory system capable of coordinately regulating the expression of related genes responding to substrates is essential for developing an efficient aromatic demethylation system for lignin conversion20. Some inducible circuits have been developed for gene regulation in R. eutropha H16, while most use additional compounds such as IPTG or arabinose as inducers21,22. External inducers usually exacerbate the metabolic burden and are even toxic to cells, which could lead to an additional increase in production cost23. In recent years, autoregulatory systems, using substrates as inducers to trigger the expression of genes needed for substrate metabolism, have received extensive attention for their advantages in eliminating the cost of external inducers and reducing the unnecessary metabolic burden of cells by more intelligently and precisely regulating the expression of the responding genes20,24. Nevertheless, there is still no report showing any robust autoregulatory system developed for lignin metabolism due to the great challenge of overcoming the complexity and heterogeneity of LDAs. It would be cumbersome and inefficient to develop an exclusive autoregulatory system for each LDAs substrates. Hence, relying on the metabolic characteristics of microbial biological funnels, the regulatory elements that respond to central metabolites can be used as the core to construct the regulatory hub, which can realize the automatic regulation of the metabolism of various LDAs. This is an ideal and sufficient strategy to address the aforementioned challenge for metabolic autoregulation of lignin substrates.

In this work, a self-enhanced autoregulation system is established in R. eutropha H16 to regulate the heterologous expression of genes for efficient conversion of lignin-derived aromatics (LDAs) to PHB. The metabolic capacities of R. eutropha H16 for different types of LDAs are systematically analysed. The potential and main limiting factors for the use of R. eutropha H16 for lignin valorization are identified. To overcome the limitation of R. eutropha H16 in lignin valorization by conversion to PHB, suitable genes with aromatic demethylation functions are screened and expressed in R. eutropha H16 for the efficient metabolism of lignin-derived methoxy-containing aromatics. The native gene-regulating elements responding to the core intermediates of aromatic metabolism in R. eutropha H16 are identified and characterized for their regulatory patterns in the presence of different LDAs. The identified gene-regulating element PcaQ is used to construct a lignin-derived substrate autoregulatory system, and its intelligence in responding to various LDAs is improved via rational design. The autoregulatory system is applied to regulate the multiple genes encoding demethylase and acetaldehyde dehydrogenase to enable R. eutropha H16 to achieve much more efficient conversion of LDAs to biopolyesters. The utilization of a cost-effective and efficient cell factory system shows potential for the conversion and valorization of lignin.

Results

Analysis of the aromatic compounds metabolism ability of R. eutropha H16

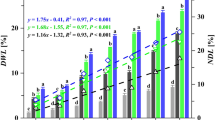

R. eutropha H16 can metabolize various types of substrates, such as fructose, glycerol, oil, and aromatic compounds25. Lignin streams contain a variety of phenolic compounds with different structures26. However, microbes demonstrate different tolerances and metabolic capacities for different aromatic compounds, which are also significantly affected by the substrate concentration and initial microbial inoculum volume during the fermentation process due to the inhibitory effects of most aromatic compounds on the growth of microorganisms. It is critical to systemically characterize the metabolic capacities and patterns of R. eutropha H16 for different LDAs substrates for further design and optimization of the bacterial chassis for efficient conversion of lignin to PHB. Typical lignin-derived model aromatic compounds were used as sole carbon sources to analyse the metabolic capacity of R. eutropha H16 (Fig. 1). With the escalation of lignin depolymerization strategies, aromatic compound monomers such as phenol, benzoic acid, gentisic acid and isovanillic acid were also detected in the depolymerization fractions of lignin27,28,29. Analysing the metabolic capacity of R. eutropha H16 for these components would facilitate a more comprehensive localisation of its participation in lignin valorization. The results showed that R. eutropha H16 could grow and metabolize phenol as the sole carbon source, despite exhibiting a long lag phase (24 h) in the early stage of growth. The growth of R. eutropha H16 reached the plateau stage with complete phenol consumption after 48–54 h of cultivation (Fig. 1a). R. eutropha H16 was able to grow with salicylic acid as the sole carbon source and completely consumed salicylic acid (48 h). There was also a growth lag phase in the metabolic period (Fig. 1b). For benzoic acid, R. eutropha H16 exhibited a much shorter lag phase than that with phenol and salicylic acid, and benzoic acid was converted entirely within 30 h (Fig. 1c). More interestingly, R. eutropha H16 exhibited almost no discernible lag phase when grown on 3-hydroxybenzoate, 4-hydroxybenzoate, gentisic acid, and protocatechuic acid as sole carbon sources, and all the aromatic substrates were completely consumed within 18–24 h of cultivation (Fig. 1d–g). R. eutropha H16 showed a strong ability to metabolize protocatechuic acid. The metabolism of protocatechuic acid by R. eutropha H16 was not affected by the presence of fructose (Supplementary Fig. 1a) or other aromatic compounds, such as gentisic acid (Supplementary Fig. 1b). This indicated that the regulation of PcaQ/PPCA was not inhibited by these substrates.

R. eutropha H16 cultivation in minimal medium supplemented with (a) (PHL), (b) (2-HBA), (c) (BA), (d) (3-HBA), (e) (4-HBA), (f) (GEA), g (PCA), h (VA), i (IVA), j (4-HBD), k (3,4-DHBD) or l (VAN). Cultures were sampled at the indicated time points to evaluate growth by OD600nm determination (using a cell-free blank) and to measure metabolite concentrations in the medium by HPLC-UVVIS. Error bars represent the standard deviation of three biological replicates. The data are the mean ± SD, n = 3. PHL phenol, BA benzoate, 3-HBA 3-hydroxybenzoic acid, 2-HBA salicylic acid, 4-HBA 4-hydroxybenzoic acid, GEA gentisic acid, PCA protocatechuic acid, VA vanillic acid, IVA isovanillic acid, 4-HBD 4-hydroxybenzaldehyde, 3,4-DHBD 3,4-dihydroxybenzaldehyde, VAN vanillin, OD600nm optical density, measured as absorbance at 600 nm. Source data are provided as a Source Data file.

However, growth analysis over a 48-hour period revealed negligible increases in both R. eutropha H16 biomass as well as depletion of supplemented vanillic acid and isovanillic acid as the sole carbon sources (Fig. 1h, i). This result indicated that R. eutropha H16 could not metabolize and convert vanillic acid and isovanillic acid. To mitigate the high toxicity of these aromatic compounds to bacteria with low cell density, R. eutropha H16 was tested with an increased initial inoculum ratio and reduced concentration of aromatic compounds. The results showed that the bacteria could still not grow on vanillic acid (Supplementary Fig. 2a) and isovanillic acid (Supplementary Fig. 2b) as the sole carbon sources. Compared to the structure of protocatechuic acid, vanillic acid and isovanillic acid have an arylmethoxy group in the side chain, which may be the main factor hindering the metabolism of these aromatic compounds by R. eutropha H16. It is worth noting that there are many types and high contents of methoxy-containing aromatics in lignin depolymerization products5,30. To enable efficient O-demethylation of methoxylated aromatics into core intermediates for downstream biosynthesis pathways, integration of exogenous demethylases in R. eutropha H16 is crucial. Additionally, aromatic aldehydes such as vanillin, 4-hydroxybenzaldehyde and 3,4-dihydroxybenzaldehyde are also major products of lignin depolymerization and metabolism31, which show heightened toxicity compared to carboxylic acid compounds32. The results showed that R. eutropha H16 was capable of metabolizing 4-hydroxybenzaldehyde as the sole carbon source to support its slight growth after the 24-hour lag phase and reached a growth plateau after 60 h, while the substrate conversion rate and bacterial biomass accumulation of R. eutropha H16 were much lower than those on 4-hydroxybenzoate (Fig. 1j). For 3,4-dihydroxybenzaldehyde and vanillin, R. eutropha H16 showed no ability to metabolize these compounds based on the bacterial growth and substrate consumption analysis (Fig. 1k, l). Analysing the involvement of R. eutropha H16 in the metabolic pathways of lignin-derived aromatic compounds at the genomic level helps to understand the results of the metabolic data. This also provided a deeper insight into the characterization of lignin-derived aromatic compounds metabolized by R. eutropha H16 (Supplementary Fig. 3). In general, R. eutropha H16 showed a very limited ability to metabolize aromatic aldehydes, and the major aromatic aldehydes strongly inhibited bacterial growth. R. eutropha H16 was still unable to metabolize vanillic acid and vanillin with the addition of fructose as an auxiliary carbon source (Supplementary Fig. 4). Hence, to enable R. eutropha H16 to efficiently convert lignin-derived heterologous aromatic substrates, it is crucial to enhance its metabolic capacity and tolerance of aromatic aldehyde compounds.

Endowing the capacity of aromatic O-demethylation to R. eutropha H16

As mentioned above, R. eutropha H16 showed no ability of aromatic O-demethylation, which was the key and rate-limiting step for the catabolism of heterogeneous LDAs5,19. A robust enzyme system that can be successfully expressed in R. eutropha H16 is critical for conferring aromatic O-demethylation ability to the strain for efficient lignin conversion. In nature, some other microorganisms have evolved the ability to metabolize methoxylated compounds. LigM from Sphingomonas sp. SYK-6 and VanAB from P. putida KT2440, both of which can convert vanillic acid to protocatechuic acid, are two different typical O-demethylases for the metabolism of lignin-derived methoxy-containing aromatics33. However, the compatibility and adaptiveness of the two types of enzymes in R. eutropha H16 for LDAs have not been well characterized.

The ligM gene (Fig.2a) from Sphingomonas sp. SYK-6 was first amplified and transformed into R. eutropha H16 via conjugation to construct the engineered strain H16PM-1. Even though the ligM gene could be successfully expressed, H16PM-1 could still not grow in the medium with vanillic acid as the sole carbon source, without significant decrease of vanillic acid in the medium (Fig. 2b). In addition, regardless of whether the transcription of ligM was enhanced or weakened by replacing the original promoter Plac with promoters with different strengths, such as PphaC, Ptac, Pj5, and Pj5c234, the engineered strains still did not show the ability to grow with vanillic acid as the sole carbon source (Supplementary Fig. 5). As a single-enzyme system, LigM needs tetrahydrofolate as a cofactor rather than the assistance of chaperone proteins to perform its catalytic function. Therefore, an in vivo tetrahydrofolate regeneration system was constructed in H16PM-1 by expressing the ligH and metF genes to supply tetrahydrofolate to LigM for demethylation catalysis. However, the utilization efficiency for vanillic acid was still lower than that for protocatechuic acid (Fig. 2c). This suggests that the demethylation process of the optimized LigM system is still the main rate-limiting step of vanillic acid metabolism.

a Schematic illustration of the conversion of VA to PCA catalyzed by demethylation genes from different sources. b H16PM-1 (R. eutropha H16 harboring PM-1: Plac: ligM) cultivated in minimal medium supplemented with vanillic acid. c Growth and metabolism of H16PM-6 (R. eutropha H16 harboring PM-6: Plac: ligM-ligH-metF) with added cofactor regeneration modules in minimal medium supplemented with vanillic acid. The genes ligH and metF were involved in the regeneration of tetrahydrofolate in Sphingomonas sp. SYK-6. d H16PAB-1 (R. eutropha H16 harboring Plac: vanAB) cultivated in minimal medium supplemented with vanillic acid. e H16PABA (R. eutropha H16 harboring Plac: vanAB-fdhA) with an added formaldehyde detoxification module was cultured in minimal medium with VA as the sole carbon source. f Differences in formate dehydrogenase transcript levels in H16PABA (R. eutropha H16 harboring Plac: vanAB-fdhA) when metabolizing vanillic acid and protocatechuic acid. Change in formate dehydrogenase transcript levels when H16PABA metabolized VA (dark blue) and the transcript level of formate dehydrogenase when PCA was metabolized as a control (light blue). PCA protocatechuic acid, VA vanillic acid, OD600nm optical density, measured as absorbance at 600 nm. Error bars illustrate the standard deviation of three biological replicates. The data are the mean ± SD, n = 3, unpaired two-tailed t test. Source data are provided as a Source Data file.

Meanwhile, vanAB (Fig. 2a) from P. putida KT2440 heterologously expressed in R. eutropha H16 and the vanillic acid metabolism of the engineered strain H16PAB-1 were characterized (Fig. 2d). The results showed that the expression of vanAB could enable the strain to use vanillic acid as the sole carbon resource with a low growth rate and substrate conversion rate. Simply increasing the transcription level of vanAB did not help the H16PAB-1 increase the utilization efficiency for vanillic acid. Moreover, the H16PAB-5 lost the ability to utilize vanillic acid for growth when a stronger promoter, such as Pj5C2, was used (Supplementary Fig. 6).

Unlike LigM, VanAB from P. putida KT2440 is a two-enzyme system containing iron-sulfur structural clusters, and formaldehyde was a byproduct of the catalytic conversion of vanillic acid to protocatechuic acid by VanAB (Fig. 2a and Supplementary Fig. 7a)7,35. R. eutropha H16 was cultured in basal medium with 0.2 g/L formaldehyde as the sole carbon source to analyse its ability to metabolize formaldehyde, which showed that R. eutropha H16 could not metabolize the formaldehyde in the medium even after 72 h cultivation (Supplementary Fig. 7b). The formaldehyde dehydrogenase gene was not annotated in the genome of R. eutropha H16. H16PAD, heterologously expressed the fdhA gene of P. putida KT2440, could completely metabolize formaldehyde after 48 h of cultivation. These results suggested that R. eutropha H16 did not have the capacity to metabolize formaldehyde, even under low concentration of formaldehyde. The optimized formaldehyde detoxification module was further integrated with the VanAB demethylation module to construct the engineered strain H16PABA, which showed highly efficient vanillic acid metabolism. H16PABA completely consumed the vanillic acid in the medium after 22 h of cultivation (Fig. 2e). To further confirm that this significant increase in vanillic acid metabolism was contributed by the formaldehyde detoxification mechanism, the expression of formate-related metabolic genes in H16PABA was analysed with vanillic acid as the sole carbon source. The strain H16PABA showed significant upregulation of key genes related to formate metabolism, such as fdsGBAC36, when grown on vanillic acid compared to that on protocatechuic acid (Fig. 2f). These results effectively demonstrated that the integration of the formaldehyde detoxification module and the VanAB demethylation module successfully endowed R. eutropha H16 with the ability to perform aromatic O-demethylation, exhibiting more efficient performance in the O-demethylation of vanillic acid compared to the LigM-based system in R. eutropha H16.

Identifying and characterizing aromatic response regulatory elements

To construct an autoregulatory system that could regulate robust expression of the genes needed for lignin-derived substrate metabolism, the potential gene regulatory elements that could respond to aromatic substances were first identified and characterized in R. eutropha H16 (Fig. 3). According to the bacterial substrate metabolic analysis and functional gene annotations, there were 6 major gene clusters containing typical gene regulatory elements responsible for the metabolism of benzoate, phenol, salicylic acid, gentisic acid, 4-hydroxybenzoic acid and protocatechuic acid (Fig. 3a). Taking the gene cluster for protocatechuic acid metabolism as an example, the regulatory protein PcaQ is principally responsible for the response to protocatechuic acid and for controlling the expression of related genes such as pcaH137. However, it was still unknown whether PcaQ could respond to other aromatic compounds with structures similar to that of protocatechuic acid and how the regulatory proteins respond to different LDAs. To evaluate the identified endogenous aromatic-related regulatory elements, dynamic range, dose-response, orthogonality and response sensitivity were systematically analysed. In contrast to inducible regulation with nonconsumed ligands such as PBAD or anhydrotetracycline, the regulation of the substrate autoregulatory system fluctuates due to the consumption of the substrate. To better characterize the regulatory systems, we further analysed the sensitivity and persistence in the presence of their corresponding substrate inducers by RT-qPCR (Fig. 3b). Except for PoxR, which took 4 h to start gene expression after induction by phenol, all of the other five regulatory systems were highly sensitive to their substrates and turned on the corresponding gene expression quickly. The regulatory systems responding to their specific aromatic substrate showed differences in duration of regulating persistence. PcaQ, in response to protocatechuic acid, and GenR, responding to gentisic acid and 3-hydroxybenzoic acid, respectively, showed the shortest regulation persistence (6–7 h) compared to the other regulatory systems. The duration of the response of BenM and PobR to the induced substrates lasted approximately 7–9 h. As an inducer of PoxR, phenol had a longer metabolic cycle in the strain, leading to the persistence of regulation for approximately 10 h. The regulatory effect of NagR was the most persistent, with the duration reaching approximately 18 h. The sensitivity and persistence of regulatory elements are closely related to the transport and consumption of inducers. R. eutropha H16 can rapidly metabolize protocatechuic acid and gentisic acid, and thus, the fluctuation of the corresponding regulation systems became more severe with the rapid reduction in the inducer content. Therefore, PcaQ and GenR exhibited the excellent ability for fast switching needed for synthetic circuits. PoxR, however, showed obvious delays in regulation compared to the other systems. The regulatory pattern of NagR is unique in that it can sensitively and quickly respond to inducers to turn on gene expression and maintain it for a long time.

a Schematic diagram showing the location of regulatory elements and associated genes in the genome of R. eutropha H16. The pink color shows the regulatory elements and functional genes related to benzoate metabolism. Regulatory elements and functional genes related to phenol metabolism are displayed in blue. Regulatory elements and functional genes of salicylic acid metabolism are indicated in yellow. Cyan indicates elements and genes that regulate GEA ring-opening metabolism. Green indicates regulatory elements and functional genes for the conversion of 4-HBA to PCA. Purple indicates the elements and functional genes involved in regulating PCA metabolism. b Sensitivity and persistence of different regulatory elements in response to target substrates. The corresponding inducers were added for the six regulatory elements, and samples were taken every one hour to analyse the changes in the transcription level of the reporter gene. c Analysis of the regulatory strength of different regulatory elements. The light color indicates the expression level in the control without added ligand, and the dark color indicates the change in the expression level change after adding ligand for 2 h relative to that without added ligand. The inducers used were arabinose, BA, 2-HBA, 4-HBA, GEA, and PCA, respectively. The data are the mean ± SD, n = 4 biological samples, ***p ≤ 0.001, unpaired two-tailed t test. d Orthogonal analysis of the responses of regulatory elements to different aromatic compounds. The heatmap illustrates the change in reporter gene expression in the presence of ligand relative to that with no ligand added. Measurements were performed 2 h after the addition of 10 mM corresponding ligand. BA benzoate, PHL phenol, 2-HBA salicylic acid, 4-HBA 4-hydroxybenzoic acid, GEA gentisic acid, PCA protocatechuic acid, 3-HBA 3-hydroxybenzoic acid, VA vanillic acid, p-CA p-coumarate, CAF caffeic acid, SA syringic acid, GAA gallic acid, FA ferulic acid. Source data are provided as a Source Data file.

The dynamic range is an important parameter for evaluating inducible gene regulatory systems38. Compared with the basal expression without the addition of inducers, the six regulatory elements all exhibited a wide range of regulation (Fig. 3c and Supplementary Table 1). Meanwhile, PcaQ, BenM, NagR, and PoxR all had stronger expression intensities comparing to the commonly used l-arabinose-inducible AraBAD induction system PBAD (Fig. 3c). The expression intensity of PoxR/PPHL was significantly higher than that of the other five groups of regulatory systems. There was no significant difference in the expression intensity of NagR/P2-HBA and BenM/PBA, but it was significantly higher than that of GenR/PGEA and PcaQ/PPCA. The expression intensities of GenR/PGEA and PcaQ/PPCA were not significantly different, but both were significantly higher than PobR/P4-HBA.

Dose-response curves illustrate the response of regulatory elements to substrate concentrations, showing gene expression levels with respect to ligand concentration, thereby providing information on the effective range of effector concentrations for the inducible system. The reported methods were modified based on the characteristics of the regulatory elements37. Plasmids (Supplementary Table 2 and Supplementary Fig. 8) containing different regulatory elements and fluorescent reporter proteins were constructed and transferred via conjugation to obtain engineered strains (Supplementary Table 3) for testing. Relative normalized fluorescence values were plotted as a function of inducer concentration to obtain a dose response with an induction interval of 600 min for the slow-responding PoxR and 80 min for the other elements (Supplementary Fig. 9).

In inducible gene expression systems, regulatory elements respond to ligands and regulate changes in gene expression levels to enable the completion of metabolic processes. Given that the structural similarity of aromatic compounds can elicit nonspecific responses of regulatory elements, orthogonal experiments were conducted to investigate regulatory element responses to various types of aromatic compounds. In addition to the target ligands, we included LDAs such as ferulic acid and vanillic acid for testing (Fig. 3d). Fluorescence detection revealed that GenR was responsive to salicylic acid, 3-hydroxybenzoic acid, and gentisic acid. PcaQ exhibited responsiveness to not only protocatechuic acid but also 4-hydroxybenzoic acid, vanillic acid, and syringic acid. PobR responded to 4-hydroxybenzoic acid and p-coumarate, possibly for their similar structural features. NagR could respond to the regulatory effects of salicylic acid and gallic acid. Furthermore, Phenol, 4-hydroxybenzoic acid, and vanillic acid could regulate PoxR. The orthogonal compatibility of induced systems is a crucial property when designing multicomponent and scalable circuits and sensing devices37. To include additional LDAs in the substrate metabolism repertoire of R. eutropha H16, PcaQ represented a promising orthogonal switch for circuit design and other synthetic biology applications in lignin valorization.

Construction of a self-induction system responding to aromatic metabolism

Through parametric analysis of the regulatory elements in the early stage, PcaQ was chose to construct an autoregulatory system for its ability to respond to a variety of aromatic compounds. Strains S17PPE and S17PQE (Supplementary Fig. 10a) were constructed by combining egfp with individual promoters PPCA and PcaQ/PPCA, respectively. The results showed that the expression level of egfp was only significantly increased in strain S17PQE with the addition of protocatechuic acid, indicating the activate role of the regulatory protein PcaQ to the promoter PPCA (Supplementary Fig. 10b). The PcaQ of R. eutropha H16 exhibited differences in regulatory properties and operon structure from that reported in S. meliloti39 (Supplementary Fig. 11). We demonstrated that protocatechuic acid was the effector of PcaQ in R. eutropha H16 by constructing the mutant H16∆PHG (Supplementary Fig. 12a) with the assistance of the reporter gene (Supplementary Figs. 12b, c). After converting vanillic acid to protocatechuic acid, the regulatory ability of PcaQ was further enhanced, achieving self-enhancement in the whole regulatory process by promoting the expression of the demethoxyl gene (Fig. 4a). Therefore, PcaQ/PPCA was first used to replace the Plac promoter in the plasmid PABA to construct the plasmid PQABA, and the engineered strain H16PQABA was obtained via conjugation. In the test with vanillic acid as the sole carbon source, to better evaluate the regulatory system, expression systems containing Plac and PBAD were introduced as controls. In the absence of an inducer, H16PBABA could not use vanillic acid to grow during the initial 12 h (Fig. 4b). As leaky expression led to the continuous expression of the demethylase gene, approximately 20% of the vanillic acid was metabolized within 48 h, while the H16PBABA could rapidly metabolize vanillic acid in the early stage and metabolize all the substrates within 24 h when arabinose (2 g/L) was added to the medium as inducer (Fig. 4c). The metabolic rate was similar to that of the constitutive promoter. However, under the regulation of the promoter PcaQ, H16PQABA exhibited a higher substrate conversion rate and biomass accumulation rate, reached a growth plateau at 18 h and completely consumed the substrate vanillic acid (Fig. 4d), which was almost the same conversion rate as that observed for protocatechuic acid metabolism. The research further performed a quantitative expression analysis of key genes expressed by the autoregulatory system throughout the metabolic process (Fig. 4e). The PcaQ/PPCA regulation system could quickly respond to vanillic acid to achieve rapid upregulation of the expression level of the target gene vanAB. With the consumption of aromatic compounds in the system, the expression level of vanAB gradually decreased to the basal level, realizing substrate responding regulation. The above results showed that the autoregulation system not only effectively relieved the rate-limiting step of the demethylation process but also reduced the metabolism burden of the cell. The regulatory element PcaQ/PPCA from R. eutropha H16 was similarly responsive to protocatechuic acid in E. coli S17, E. coli Trans1, and E. coli BL21 (Supplementary Fig. 12d), showing broad applications.

a Schematic diagram of the working principle of the autoregulation system. In an autoregulatory system, expression of the demethylase genes vanAB was regulated by PcaQ/PPCA. Under the condition of leaked expression of promoter PPCA, low level expression of VanAB will convert vanillic acid to protocatechuic acid. The regulatory protein PcaQ, in response to the effector protocatechuic acid, would further activate the expression intensity of promoter PPCA, accelerating the conversion of vanillic acid to protocatechuic acid and completing the metabolism. The expression of vanAB was again restored to the initial level when the substrate was completely consumed. The changes in the expression levels of functional genes were dependent on the substrate rather than other inducers, suggesting that the regulatory system was able to achieve autoregulation of vanillic acid metabolism. b Demethylation metabolism of arabinose-induced system in absence of arabinose. c Demethylation metabolism of arabinose-induced system in presence of arabinose as an inducer. d The demethylation metabolic process was driven by the PcaQ based autoregulatory system. e Changes in the expression level of the vanAB in the metabolic process of different regulatory systems. Samples were taken at predetermined intervals for assessing growth via OD600nm readings with a cell-free blank. VA vanillic acid. In addition, metabolite concentrations in the media were measured using HPLC-UVVIS. Error bars illustrate the standard deviation of three biological replicates. The data are the mean ± SD, n = 3. Source data are provided as a Source Data file.

Aromatic hub metabolite-based autoregulation system

To precisely regulate the expression of heterologous functional genes that metabolize LDAs, the regulatory system needs to respond intelligently to each substrate. However, neither discovering regulatory proteins that directly respond to different types of aromatic compounds or creating protein mutants for each LDAs substrate is unfeasible. To address this challenge, a hub metabolite-based autoregulation (HMA) system was designed to respond to various LDAs based on the characteristics of microbial biological funnel metabolism and the regulatory system PcaQ/PPCA that can respond to the central metabolite protocatechuic acid. The HMA system integrates functional genes required to convert LDAs into the hub metabolite protocatechuic acid, as well as a PcaQ/PPCA mutant with more sensitive regulatory capabilities (Fig. 5). In the designed hub metabolite-based autoregulation system, the low-level leaky expressions of the functional genes guided by PcaQ/PPCA would enable the host to slightly convert the target substrates into protocatechuic acid. The produced protocatechuic acid would have a feedback to the regulatory protein PcaQ to enhance the expression intensity of the functional genes regulated by PcaQ/PPCA, further promoting the conversion of target substrates into the hub metabolite protocatechuic acid, achieving self-enhancing regulation of different types of LDAs simultaneously.

The establishment of the regulatory hub relies on a combination of microbial biofunnel metabolic properties and PcaQ/PPCA of response to the core intermediate protocatechuic acid. In the regulatory hub, the expression of key enzymes of the rate-limiting step, such as aromatic aldehyde dehydrogenase and demethylase, were regulated by PcaQ/PPCA. The autoregulation process relies on the leaky expression of the promoter PPCA to convert different types of monomeric substrates such as vanillin will be partially converted to protocatechuic acid. The modified PcaQ R145K/PPCA was better regulated in response to low concentrations of protocatechuic acid, and the expression levels of key enzymes in the pathway of conversion of upstream substrates to protocatechuic acid, such as aldehyde dehydrogenase and demethylase, were enhanced by feedback. Multiple types of lignin-derived aromatic compounds can achieve metabolic regulation without the need for additional inducers.

For the designed HMA system to operate successfully, it is crucial that the regulatory protein PcaQ exhibits a response sensitivity to protocatechuic acid. To this end, the mutant of regulatory protein PcaQ was rationally designed through protein engineering including hot spots prediction and molecular dynamics calculations. The structure of PcaQ was derived from the Uniprot database (UniProt ID: Q0JYV0) (Fig. 6a). The hot spots around the active pocket and in the substrate channel that affect the binding of the substrate to the protein was predicted by HotSpot Wizard 2.040. The top three scoring hot spots of modifiable key amino acid sites were PcaQ-Met143, Arg145, and Asn146 (Supplementary Figs. 13, 14). By calculating the binding energies of 57 protein mutants (with saturating mutations to three amino acids) and ligand small molecules, the calculations with the lowest binding energies were chosen, and PcaQ M143K, PcaQ R145K, and PcaQ N146R were validated experimentally (Supplementary Fig. 14). The regulatory ability of the 7 obtained mutations (Supplementary Table 3) was analysed with egfp as a reporter gene. The regulatory ability of the mutant PcaQ R145K was more sensitive to inducers and the transcription level of the reporter gene was increased under lower substrate concentrations compared with PcaQ (Fig. 6e). Molecular docking result show that the binding energies of protocatechuic acid with PcaQ and PcaQ R145K reached −5.1 Kcal/mol and −5.9 Kcal/mol respectively. The binding capacity of PcaQ R145K and ligand is better than PcaQ. The active pocket of PcaQ consists of amino acid residues Met, Ser, Asn, Ile, Leu, Pro, and Arg. Most of the binding pockets of PcaQ were hydrophobic amino acid residues (Met, Ile, Leu, and Pro), suggesting that hydrophobic interactions contribute to the binding. The docking results show that PcaQ R145K increase the hydrogen-bonding interaction and hydrophobic interaction of protocatechuic acid with the surrounding amino acids. Protocatechuic acid is able to generate hydrogen-bonding interactions with Ser 115, and form hydrophobic interaction with protocatechuic acid at Leu 113 and Pro 217. These interactions stabilized the binding of protocatechuic acid to PcaQ R145K and demonstrated the high specificity of the interactions. Thus, PcaQ R145K binds better to protocatechuic acid compared to PcaQ (Fig. 6b, c and Supplementary Table 4). These interactions stabilized the binding of protocatechuic acid to PcaQ and demonstrated the high specificity of the interactions. The point mutation altered the interaction force between protocatechuic acid and PcaQ for better binding. This explained why the target gene transcription level could be more effectively increased under lower substrate concentrations. In addition, to further improve the sensitivity of PcaQ, we also made an attempt to double mutant PcaQ R145K and N146R, but both experimental and docking results showed that the effect was not as good as that of single mutant PcaQ R145K (Fig. 6d, e). Therefore, we finally chose PcaQ R145K as the regulatory protein. The strength of the feedback regulation of the hub metabolite-based autoregulatory for different aromatic compounds is closely related to the concentration of intracellular protocatechuic acid. However, the mineralization processes of aromatic compounds in microorganisms are continuous, and the hub-metabolite protocatechuic acid will be metabolized effectively and maintained in a low concentration level. Especially for those aromatics requiring speed-limited “up pathway” for their metabolization, these metabolic process would produce much lower concentration of protocatechuic acid, which would be pose a challenge to the efficient response by the regulatory protein PcaQ. The mutant PcaQ R145K better compensated for this defect and provided stronger feedback regulation under low protocatechuic acid concentrations.

a The structure of the regulatory protein PcaQ (Uniprot ID: Q0JYV0). b The docking diagram of PcaQ with protocatechuic acid. The protocatechuic acid was predicted to form 2 hydrophobic interactions with residues Met143 and Arg145, and 2 hydrogen bonds with residues Ile216 and Asn144 of the PcaQ. It also formed salt bridges with Arg145. c The docking diagram of mutants PcaQ R145K with protocatechuic acid. The protocatechuic acid, which had the most negative consensus docking score, interacted via 6 hydrogen bonds with the PcaQ R145K including residues Ser115, Asn114, Arg162 and Ile216. It also formed 2 hydrophobic interactions with residues Leu113 and Pro217. d Docking diagram of the mutants PcaQ R145K and N146R with protocatechuic acid. The protocatechuic acid was predicted to form 1 hydrophobic interaction with residues Leu113, and 3 hydrogen bonds with residues Ser115, Asn144, Ile216 of the PcaQ R145K and N146R. It also formed salt bridges with Arg162. Hydrogen bonds, hydrophobic interactions, and salt bridges are indicated in yellow, blue, and red, respectively. e PcaQ and the mutants regulate the transcriptional differences of reporter genes under different concentrations of protocatechuic acid (n = 4). Growth and substance metabolism analysis of H16PQABAD and H16PQMABAD with (f) (3,4-DHBD), (g) (4-HBD) or (h) (VAN) as the sole carbon source in the basal medium. The dark color represents H16PQMABAD, and the light color represents H16PQABAD. Samples were taken at predetermined intervals for assessing growth via OD600nm readings with a cell-free blank. In addition, metabolite concentrations in the media were measured using HPLC-UVVIS (n = 3). Error bars illustrate the standard deviation of three biological replicates. The data are the mean ± SD. Abbreviations: 4-HBD 4-hydroxybenzaldehyde, 3,4-DHBD 3,4-dihydroxybenzaldehyde, VA vanillic acid, VAN vanillin. The genome number of vdh (vanillin dehydrogenase of P. putida KT2440) was PP_3357. The genome number of aldBI (aldehyde dehydrogenase of P. putida KT2440) was PP_0545. The genome number of aldBII (aldehyde dehydrogenase of P. putida KT2440) was PP_2680. Source data are provided as a Source Data file.

To further test if the mutant PcaQ R145K could be sufficient enough to respond to various LDAs by integrating with corresponding functional genes for aromatic metabolism, several key lignin depolymerization products were used as substrates to track the growth and gene expression profile of the host cell harboring the PcaQ R145K -based HMA system. 3,4-Dihydroxybenzaldehyde, 4-hydroxybenzaldehyde and vanillin are important products of lignin depolymerization41. There are few studies on the metabolic pathways of aldehyde compounds such as 4-hydroxybenzaldehyde and 3,4-dihydroxybenzaldehyde in microorganisms, which has undoubtedly increased the difficulty in the development of regulatory elements for them. Meanwhile, neither PcaQ nor PcaQ R145K could respond to these aldehydes alone, being the ideal substrates for assessing the HMA system. Three key aldehyde dehydrogenase genes (vdh, aldBI, and aldBII42) involved in vanillin metabolism were selected from P. putida KT2440 and integrated with PcaQ or PcaQ R145K to construct strains H16PQABAD and H16PQMABAD respectively. Both strains obtained the ability to metabolize 3,4-dihydroxybenzaldehyde, 4-hydroxybenzaldehyde, and vanillin as a result of expression of vdh, aldBI, and aldBII. (Fig. 6f–h). However, it was noticed that the strain H16PQMABAD containing the PcaQ R145K-based HMA system could grow faster at the initial stage of 3,4-dihydroxybenzaldehyde and 4-hydroxybenzaldehyde metabolism compared to H16PQABAD (Fig. 6g, h). The HMA system based on PcaQ R145K exhibits heightened sensitivity to low concentrations of protocatechuic acid, compensating for the slow metabolism of 4-hydroxybenzaldehyde and 3,4-dihydroxybenzaldehyde that results in low effector concentrations. This enhances the strength of feedback regulation at the initiation of growth, resulting in a more efficient rate of substrate metabolism. The changes in gene expression levels over time in the metabolic process were analysed, and the results showed that PcaQ R145K-based HMA system could achieve precise substrate autoregulation of the functional genes with a high correlationship with the substrates metabolism profiles (Supplementary Fig. 15). These results demonstrated the feasibility of the HMA system for different LDAs, suggesting its great potential for lignin valorization.

Genomic integration for rubust LDAs conversion to PHB

The stability of microbial function is a key factor affecting biopolyester production. The heterologous expression system in the form of the R. eutropha H16 plasmid is unstable43. After continuous culture, most of the engineered strains lost the plasmid and could not metabolize the vanillin. To avoid the metabolic burden caused by antibiotics and the instability of plasmid-based gene expression, the target genes were integrated to the chromosome of R. eutropha H16. The DNA of the PcaQ-based or PcaQ R145K-based HMA systems were integrated into the chromosomal genome of R. eutropha H16 and thus constructed the engineered strain H16Q1 and H16Q2, respectively. Benefits from the improved responsiveness to protocatechuic acid, H16Q2 containing PcaQ R145K-based HMA systems performed better than H16Q1 in metabolizing vanillic acid. H16Q3, integrated the vanillin dehydrogenase module to the genome of strain H16Q2, could metabolize vanillin and achieved continuous subculture with vanillin as the sole carbon source (Fig. 7a). In the metabolism of vanillic acid, the detoxification efficiency of aldehydes has an impact on the growth and metabolism of microorganisms44. This may be a factor in the faster metabolism of vanillic acid by H16Q3, which contains more aldehyde dehydrogenase, compared to H16Q2. However, comparing with the plasmid system which could effectively convert the vanillin, H16Q3 showed significantly reduced vanillin metabolism efficiency and the accumulation of vanillic acid was detected (Fig. 7b). These results indicated that the demethylation became the limit-rate step for H16Q3 caused by the reducing gene-copy number of vanAB. Increasing the copy number of vanAB in the genome and ensuring that the formaldehyde detoxification module functions preferentially are ways to effectively relieve the rate-limiting step35,45. Therefore, after increasing the copy of vanAB genes regulated by the HMA system and strengthening the preferential expression of the fdhA gene, the strain H16Q4 (Supplementary Table 3) restored the ability to rapidly metabolize vanillic acid and also completely consume vanillin in the culture medium in a shorter period (Fig. 7c).

a Differences in vanillic acid metabolism between the genome integration strains H16Q1, H16Q2 and H16Q3. b Analysis of biomass changes and substrates metabolism during the cultivation of H16Q3 with vanillin as the sole carbon source. Gray represents vanillin, and purple represents vanillic acid. c Analysis of the growth curve and material changes of the H16Q4, which contains two copies of vanAB in its genome, during cultivation with vanillin as the sole carbon source. Gray represents vanillin, and purple represents vanillic acid. d Tolerance of H16Q4 to different concentrations of vanillin. Growth curves of H16Q4 with 7.5 mM (violet), 10 mM (gray), 12.5 mM (green), 15 mM (purple) and 17.5 mM (pink) vanillin as the sole carbon source. e Analysis of tolerance and metabolic capacity of laboratory directed evolution strain (H16Q5) to different concentrations of vanillin. f Differences in PHB accumulation between H16Q1 and H16Q5 in high concentrations of aromatic compounds as substrates. Vanillin was used as the sole carbon source in the PHB accumulation phase, and the fermentation culture was carried out using batch replenishment. The vanillin concentration was 20 mM at the initial and each replenishment, and the replenishment time was 24 h, 48 h and 72 h, respectively. In addition, a supplemental nitrogen source was required once at 48 h of fermentation to enhance the conversion of aromatic compounds (1 g/L). In addition, metabolite concentrations in the media were measured using HPLC-UVVIS. Error bars illustrate the standard deviation of three biological replicates. The data are the mean ± SD, n = 3. VAN vanillin, VA vanillic acid. Source data are provided as a Source Data file.

To achieve a high PHB yield, a high concentration of substrates is required for fermentation. However, H16Q4 showed significant decrease on the growth rate and the substrate consumption rate when the concentration of vanillin in the medium reached to 17.5 mM (Fig. 7d). A laboratory directed evolution strategy was used to domesticate H16Q4 by gradually increasing the concentration of vanillin in the culture medium. In this process, H16Q5, which could robustly grow in high concentrations of vanillin, was successfully isolated using alternating cultures of plate streaking and shake flasks. The results showed that H16Q5 was able to grow rapidly in vanillin at a concentration of 20 mM. After 24 h of culture, H16Q5 almost completely consumed the vanillin in the medium. At an initial concentration of 30 mM vanillin, the rate of vanillic acid consumption by H16Q5 decreased significantly after 36 h of culture, and 5.41 mM of vanillin was remained in the medium after 72 h. In 40 mM vanillin, the growth of H16Q5 showed an obvious lag phase and entered a plateau of growth after 48 h of culture. After 72 h, H16Q5 almost no longer consumed vanillin, and 16.67 mM of vanillin was remained in the medium (Fig. 7e). This result indicated that although H16Q5 was able to tolerate vanillin at a concentration of 40 mM, it could not convert the vanillin completely, which was the reason why H16Q5 did not grow consistently in high concentration of vanillin. We further optimized the culture conditions by increasing dissolved oxygen using baffle flasks and supplementing with replete nitrogen source to enable H16Q5 to completely consume the vanillin (40 mM) in the medium after 72 h of culture (Supplementary Fig. 16). Nonetheless, it is still necessary to consider the negative effects on PHB accumulation caused by excessive increases in dissolved oxygen and nitrogen content of the medium. To further understand how the evolved strain could be tolerant to high concentration (40 mM) vanillin, multiple single colonies of the strains that could still metabolize vanillin rapidly and stably were collected for genome resequencing individually. The sequencing identified totally 27 mutant genes, including those involving transport and energy metabolism (Supplementary Fig. 17). Transporter proteins have gained extensive interesting recently and been demonstrated their important effects on the metabolism of aromatic compounds46,47,48. The roles and mechanisms of each mutant gene for the high concentration vanillin tolerance by R. eurtropha H16 still need to be further investigated.

Additionally, to maximize the benefits of high-density fermentation of R. eutropha H16, bioreactors were utilized for continuous feeding fermentation to create a more efficient process. The inability of H16∆D1LAB to metabolize vanillin resulted in persistent inhibition by high concentrations of vanillin and no increased production of PHB (Fig. 7f and Supplementary Fig. 18a). By optimizing the conditions of dissolved oxygen (DO) and carbon/nitrogen feeding, H16Q5 was able to rapidly metabolize the vanillin, and continually increase the PHB content. H16Q5 converted 76.96 mM out of the total 80 mM of vanillin fed during fermentation with a PHB yield of 3.01 ± 0.26 g/L (Fig. 7f and Supplementary Fig. 18b).

To further test the function of the designed HMA system in the metabolism of mixed aromatic compounds, 6 different types of LDAs were screened to form mixed substrates for metabolism and fermentation experiments. The results showed that the H16ΔD1LAB could rapidly metabolize 4-hydroxybenzoic acid and protocatechuic acid, and slightly metabolize 4-hydroxybenzaldehyde, while had no capacity to metabolize the other three aromatic compounds (Fig. 8a). To the engineering strain H16Q5, all of the six aromatic compounds in the medium were rapidly consumed simultaneously without obvious competitive inhibition to the cells (Fig. 8b). Vanillic acid, vanillin, protocatechuic acid and 4-hydroxybenzoic acid were completely metabolized within 24 h after H16Q5 inoculation, while 4-hydroxybenzaldehyde and 3,4-dihydroxybenzaldehyde were completely metabolized within 36 h. H16Q5 still showed certain metabolic preferences for different types of aromatic compounds. It exhibited a strong ability to metabolize lignin-derived aromatic compounds with higher contents, such as vanillin, while compounds with lower contents, such as 3,4-dihydroxybenzaldehyde, could also be completely metabolized within a certain period. This metabolic preference was consistent with the proportion of lignin depolymerization products, suggesting the potential of H16Q5 in multiple aromatics bioconversion for lignin valorization. Furthermore, H16Q5 exhibited a higher PHB accumulation when cultivated on a mixture of aromatics, yielding 2.18 ± 0.09 g/L, which was 8.4-folds greater than that of the control strain H16ΔD1LAB (Fig. 8c). If vanillin and 3,4-dihydroxybenzaldehyde in lignin depolymerization products cannot be effectively converted, they will have a serious inhibitory effect on cell metabolism49. The continued accumulation of these more toxic aromatic compounds will affect the efficiency of conversion of other aromatic compounds into PHB.

Analysis of the metabolic capacity of H16ΔD1LAB (a) and H16Q5 (b) using mixed aromatics as substrates. Light blue represents 4-hydroxybenzaldehyde, dark blue represents 3,4-dihydroxybenzoic acid, and purple represents vanillic acid. Cyan represents 4-hydroxybenzoic acid, brown represents 3,4-dihydroxybenzaldehyde, and gray represents vanillin. c Differences in PHB accumulation between H16ΔD1LAB and H16Q5 using mixed aromatics as substrate. d Differences in PHB accumulation between H16ΔD1LAB and H16Q5 using lignin LDAs as substrate. Dark column: DCW, light column: PHB. In addition, metabolite concentrations in the media were measured using HPLC-UVVIS. Error bars illustrate the standard deviation of three biological replicates. The data are the mean ± SD, n = 3. 4-HBA 4-hydroxybenzoic acid, PCA protocatechuic acid, VA vanillic acid, 4-HBD 4-hydroxybenzaldehyde, 3,4-DHBD 3,4-dihydroxybenzaldehyde, VAN vanillin. Source data are provided as a Source Data file.

As a proof of concept, we further evaluated the performance of aromatic metabolism and PHB accumulation of the engineering strain H16Q5 with HMA system in the heterogeneous mixture of LDAs extracted from the alkaline pretreated liquor (APL) of Pinus massoniana biomass50,51. The composition analysis showed that vanillin and vanillic acid were the two of the most abundant aromatic compounds in the LDAs, as well as the other aromatics including ferulic acid, 3,4-dihydroxybenzaldehyde and protocatechuic acid (Supplementary Fig. 19 and Supplementary Table 5). The results showed that H16Q5 could effectively utilize the LDAs to accumulate PHB with a yield at 2.38 ± 0.22 g/L after 96 h fed-batch fermentation, which was a record yield of the PHB production from heterologous aromatics as sole carbon (Fig. 8d). Compared with the mixed aromatic hydrocarbons that simulate lignin, the contents of protocatechuic acid and 4-hydroxybenzoic acid in the extracted LDAs are very trace, while the contents of aromatic aldehydes such as vanillin are relatively high. These compounds that could not be metabolized by R. eutropha H16 would inhibit the strain to utilize other available aromatics in the medium to accumulate the PHB. Although H16Q5 was unable to grow with ferulic acid as the sole carbon source, H16Q5 could completely transform a variety of aromatic compounds in the medium, including ferulic acid, when fermented with LDAs (Supplementary Tables 5, 6). This may be due to the presence of vanillin and protocatechuic acid in APL, where the metabolic pathway for H16Q5 metabolizing aromatic compounds was activated, facilitating the conversion of other aromatic monomers such as ferulic acid35. H16Q5 had the ability to quickly convert these aromatics, thereby removing the inhibition and achieving a high biomass and PHB accumulation.

Discussion

Despite having the advantages in LDAs metabolism, lignin-degrading bacteria usually have the limitation with unsatisfying capacity in biopolyester synthesis52,53. Those bacteria with stronger biopolyester accumulation capacity have not been studied for their potential in lignin valorization to produce biopolyesters. For example, the PHB producer R. eutropha H16, displaying many advantageous metabolic traits for PHB biosynthesis, such as high-density fermentation, singular and stable polyester components and exclusive polyester accumulation capacity54,55,56, has never been systematically analysed and developed for lignin bioconversion to produce PHB. To successfully improve the metabolic capabilities and address the limitations of R. eutropha H16 when grown on LDAs, certain factors need to be considered, including appropriate substrate concentrations, sufficient initial cell inoculum and stable culture system, due to the inhibitory effect of aromatic compounds on microorganisms and their disruptive effects on culture system’s pH57. Compared with other inexpensive carbon sources such as glycerol, R. eutropha H16 showed a more prominent rate of conversion and utilization of protocatechuic acid as substrate and could accumulate higher biomass rapidly58,59. Protocatechuic acid is an important intermediate monomer in the process of lignin biodegradation. It can be produced through the metabolic funnel of the microbes from various aromatic compounds depolymerized from lignin. The R. eutropha H16 engineered strain with enhanced upstream metabolic capabilities shows immeasurable potential in lignin valorization. This strategy provides a one stop solution for the introduction of more non-lignin-degrading microorganisms with downstream metabolic advantages for lignin valorization. The goal of biorefinery integration was the efficient conversion of the full biomass components, of which the efficient conversion of lignin has been the rate-limiting step in biorefinery integration. In contrast to carbohydrates, lignin conversion entails a variety of challenges such as the toxicity of high concentrations of aromatic compounds to cells and the heterogeneity of aromatic compounds. This study provided a strategy to overcome these challenges for biological lignin valorization. The efficiency of the HMA system was demonstrated by the record 2.38 g/L PHA yield with lignin-derived aromatics as sole carbon source which is higher than that reported (Supplementary Data 1). The strategy developed in this study can also be applied to convert lignin to other valuable products. The continuous increase in lignin conversion efficiency will effectively contribute to the realization of the ultimate objective of complete biomass biorefinery integration.

It has been shown that demethylation is one of the major barriers to restrict many microorganisms from participating in lignin valorization60. Horizontal transfer of demethylation function requires consideration of multiple factors to achieve. Cai et al. showed that overexpression of ligM in R. opacus PD630 could significantly enhance its demethylation ability7. While the enzyme LigM, as well as DesA, need tetrahydrofolate as a cofactor to conduct demethylation catalysis, which most likely depend on the special system obtained by the evolution of Sphingomonas sp. SYK-661. When we heterologously expressed LigM as well as the tetrahydrofolate regeneration system for R. eutropha H16, even though it endowed the strain with demethylation ability, the efficiency was much lower than that by VanAB, which is another type of demethylase with two-enzyme system containing iron-sulfur cluster62. It suggests that the adaptability of the demethylation catalytic system to the chassis is important to make the genetic components to be functional effectively. R. eutropha H16 harbors many enzymes with iron-sulfur clusters, and has impeccable NAD(P)H regeneration system63, thereby the VanAB-based demethylation system could be adaptable well to the host to achieve highly efficient demethylation of the vanillic acid. As an important cofactor involved in LigM and DesA catalysis, the content of tetrahydrofolate and the regeneration system will have an impact on demethylation efficiency. Fully understanding the supply mechanism of this cofactor in Sphingomonas sp. SYK-6 will effectively improve the application of this type of demethylation genes64. To achieve efficient degradation of the lignin-derived methoxy-containing aromatics, timely removing of the demethylation byproduct formaldehyde is required. The introduction of formaldehyde dehydrogenase relieves the accumulation of toxic formaldehyde and regenerates the cofactor NADPH needed for the demethylase. The lack of demethylation ability of R. eutropha H16 can be effectively filled by complementing suitable demethylation genes and removing the inhibitory effect caused by catalytic by-products. Incorporating the metabolism of methoxy-containing aromatics such as vanillic acid into the substrate metabolism map of R. eutropha H16 improves the conversion efficiency of lignin components to PHB.

The broadening of the substrate range of the catalytic element better addresses the challenge of the complex heterogeneity of lignin19,65. However, the regulatory elements currently mined for major LDAs show certain regulatory specificity66. Definitely, it is unfeasible to design regulation system one by one for each lignin-derived substrate. To overcome the barrier, a more efficient system needs to be developed to intelligently respond to various LDAs. The importance of regulatory elements in metabolic engineering has received more attention, and mining switches with different properties is crucial for complex metabolic regulation67,68. The six regulatory elements from R. eutropha H16 displayed three different types of traits: fast opening and fast closing, slow opening and fast closing, and fast opening and slow closing. These different types of regulatory properties are necessary for the development of complex pathways in metabolic engineering69. The regulatory differences among different regulatory elements also provide more possibilities for gradient expression or rhythmic regulation70. Different from the purpose of a comprehensive screening of regulatory elements in the genome37, the present study developed regulatory elements to enhance the metabolism of aromatic compounds by R. eutropha H16 with the explicit purpose of constructing regulatory hubs that were effective in regulating the metabolism of complex substrates. By modifying PcaQ, the mutant PcaQ R145k enhanced the response ability to low concentrations of effectors. Compared with the regulatory elements developed for monomers such as vanillin20, the regulatory hub constructed in this study can effectively realize the metabolic regulation of complex substrates and was more in line with the needs of lignin depolymerization product metabolism. The concept and process of constructing the regulatory hub were equally insightful. This study also demonstrated that the PcaQ of R. eutropha H16 was able to use the metabolic core intermediate protocatechuic acid as an effector with different regulatory properties comparing with the previously reported PcaQ of S. meliloti39.

Compared with the regulation of lac operator by IPTG or PBAD by arabinose, the HMA system constructed based on PcaQ R145K/PPCA in this study can achieve the regulation of substrate metabolism without the addition of inducers, highlighting the autoregulatory property. This avoids the cellular toxicity and additional cost of inducers such as IPTG. Even though there were some regulatory similarities to the system in response to vanillin constructed by Wu et al. 20, the HMA system constructed in this study shows the advantage in simultaneously responding to different aromatics, which is essential for efficient lignin valorization. The engineered strain with HMA system could efficiently convert the mixed aromatics or the LDAs to produce PHB, suggesting the advantage of the designed HMA system in autoregulation of multiple genes responding to lignin depolymerized aromatics. In addition, the HMA system could also be further used to reduce the metabolic burden to promote the utilization of biomass hydrolyzate by reducing the expression of related genes after removing the inhibition of aromatic compounds71. Besides the single strain harboring multiple enzymes to convert different aromatics to PHB, which is the strategy applied in this study, engineered R. eutropha consortium, where each strain is responsible for specific substrates conversion, could be designed in future to further promote the lignin conversion efficiency and the precision of targeting gene regulation. In addition, other hub metabolites (i.e., catechol) during the degradation of the heterologous lignin depolymerized aromatics could be used to design the similar autoregulatory system with same concept approved by this study.

Methods

Plasmids construction

The plasmids constructed in this study are shown in Supplementary Table 2 and were all assembled by the Gibson method. DNA was extracted from the sample strains by using the Bacterial DNA Kit (Yeasen Biotechnology, China). DNA templates were amplified by PCR using Phanta Max Master Mix high-fidelity polymerase (Vazyme, China). PCR products were gel-purified using the FastPure Gel DNA Extraction Mini Kit (Vazyme, China) and subsequently subjected to Gibson assembly (TransGen Biotech, China). The assembled plasmid was transformed into Escherichia coli S17-1λpir, successfully constructed plasmids were confirmed by sequencing the screened single clones, and the target plasmid was transferred into R. eutropha H16 via conjugative transfer. All plasmids constructed and related information for this study were listed in Supplementary Table 2. Supplementary Data 2 lists the primers used in this study for plasmid construction. The primers were synthesized by Tianyi Huiyuan Biotechnology Co., Ltd.

Construction of mutant strains of R. eutropha H16

All the engineered strains were derivatives of R. eutropha H16. The donor strain for conjugative transformation was E. coli S17-1λpir. Both expression strains and gene editing strains were constructed via conjugative transfer25. The pBBR1-MCS-2 was used as the backbone of the expression plasmid. Knockout and knock-in of engineered strains were constructed using the suicide plasmid pK18mobsacB25. Strains with kanamycin resistance were screened on agar plates containing 200 μg/mL kanamycin. The gene editing strains need to be further cultured in NaCl free LB medium containing 15% sucrose. PCR was finally utilized to screen out the engineered strains that successfully accomplished gene knock-in or knock-out. The strains used in this work are listed in Supplementary Table 3.

Culture of the bacterial strain

All chemicals in this study were purchased from Aladdin and Sigma. Luria–Bertani (LB) medium was used for E. coli S17-1λpir culture at 37 °C. For solid medium preparation, 20 g/L agar was added. R. eutropha H16 derivatives were cultured at 30 °C in RM medium72. The components of RM per 1 liter included 1.4 g (NH4)2SO4, 1.0 g MgSO4·7H2O, 0.015 g CaCl2·2H2O, 35.2 mL sterile 1 M pH 7.0 phosphate buffer (113 g/L K2HPO4 and 47 g/L KH2PO4), 1.0 mL sterile trace element solution (0.5 g/L MgSO4·7H2O, 0.4 g/L ZnSO4·7 H2O, 0.02 g/L MnSO4·H2O, 0.015 g/L H3BO3, 0.01 g/L NiCl2·6H2O, 0.25 g/L EDTA, 0.05 g/L CoCl2·6H2O and 0.005 g/L CuCl2·2H2O), 1.0 mL sterile stock A solution (2.0 g/L NaMoO2·2H2O and 5.0 g/L FeNa·EDTA). Antibiotics were added to the growth medium, if necessary, at the following concentrations: 30 µg/mL kanamycin for E. coli S17-1λpir and 200 µg/mL kanamycin for R. eutropha H1673.

Growth curves and fluorescence measurement

The growth rate of R. eutropha H16 and the modified engineered strains were estimated by measuring the cell density at 600 nm (OD600nm) using an ultraviolet (UV) spectrophotometer. To avoid plasmid loss, freshly transformed bacterial cells was used for each fluorescence measurement. The sample preparation was based on the method of Erik et al.37, with several modifications based on the circumstances of this experiment. In particular, the cells were cultured for 6–12 h after the addition of inducer and then precipitated by centrifugation at 12,000×g for 5 min at 30 °C. The cell was resuspend in an equal volume of phosphate-buffered saline, and then 100 μL of resuspended cells was transferred to 96-well microtiter plate (dark bottom, black; Corning, Costar). The EGFP fluorescence was quantified using the FlexStation3 microplate reader. The fluorescence excitation and emission wavelengths were set to 488 nm and 509 nm, respectively. The gain factor was manually set to 100%. All the fluorescence data presented in this study was normalized with the cell optical density at 600 nm.

Analysis of metabolites by HPLC

All the samples after fermentation were collected by centrifugation and filtered through a 0.2 μm filter to prepare samples for high performance liquid chromatography (HPLC) analysis. HPLC analysis using an Agilent 1260 Infinity Series with a diode array detector (DAD) was conducted to determine the concentration of LDAs in the fermentation broth. The analysis was performed on an Agilent 5TC-C18 (2), 4.6 × 250 mm column. The column was maintained at a constant temperature of 30 °C. The mobile phase comprised formic acid water (80%) and acetonitrile (20%) at a flow rate of 1 mL/min. The detection wavelength for the compounds was set at 272 nm, with a total run time of 27 min. To ensure calibration stability, a standard was analysed after every 20 samples72. Standard curves were used to quantify the concentration of aromatic compounds in samples.

Extraction of total RNA and analysis of gene transcript levels

Bacterial cells (OD600nm 0.6 ± 0.1) were collected by centrifugation at 4 °C and 12,000×g for 2 min. Total RNA was extracted from bacterial samples using the RNAex Pro RNA Extraction Reagent and SteadyPure RNA extraction kit (Accurate Biotechnology, China). Total RNA samples (1000 ng) were reverse transcribed using the Evo M-MLV reverse transcription kit to obtain cDNA (Accurate Biotechnology, China). The real-time quantitative PCR (RT-qPCR) was carried out in an ABI QS3 fluorescence quantitative PCR instrument (ABI, USA). The reaction was carried out according to the protocol of the SYBR Green Pro Taq HS Premixed qPCR kit (Accurate Biotechnology, China). The hold stage was as follows: 50 °C for 2 min and 95 °C for 10 min. The RT-qPCR stage was as follows: 40 cycles of 95 °C for 5 s and 60 °C for 30 s. The melting curve stage was as follows: 95 °C for 15 s, 60 °C for 60 s, and 95 °C for 1 s. The relative expression level was calculated using the 2–ΔΔCt method. The gyrB gene was used as an internal standard74.

Hot spots identification and molecular docking

In silico mutagenesis and screening simulation represent a valid alternative to laboratory methods to drive the in vivo testing toward more focused objectives75. HotSpot Wizard 2.0 can automate identification of hot spots and design of smart libraries for engineering proteins76. In this study, we used HotSpot Wizard (https://loschmidt.chemi.muni.cz/hotspotwizard/) to predict the hot spots about PcaQ. The top three hot spots were chosen for saturation mutagenesis using PyMOL. A quick preliminary screening was conducted by AutoDock 4.0, and the algorithm was chosen to be Genetic Algorithm (GA) with a pickup number of 56, setting the maximum number of energy evaluations to 2500000, and outputting the results to be analysed for free energy. Eventually, the lowest binding energy in each mutation site were chosen for experimental validation (PcaQ M143K, PcaQ R145K, and PcaQ N146R).

In this study, we used semi-flexible docking to form stable complexes. Protocatechuic acid, (PCA, PubChem CID: 72) was molecularly docked to the protein PcaQ (Uniprot ID: Q0JYV0) by AutoDock Vina 1.1.2. Protein pre-processing was accomplished using PyMol 2.4 to remove the water molecules and redundant ligands and meanwhile add the hydrogen atoms. The mutants such as PcaQ R145K and PcaQ R145K and N146R were accomplished by PyMol 2.4. AutoDock Tools 1.5.6 was used to generate PDBQT files for docking simulations. The dimensions of the protein docking box were 40 Å × 40 Å × 40 Å with a grid spacing of 0.664 Å. The coordinates of the docking box were: x: y: z: -2.571: 2.388: 4.731. Other parameters were kept at their default values. The docking results were set to output the 10 best docking positions. The docking conformation with the lowest binding energy and highest clustering frequency was the most potential binding mode between the ligand and the protein. The docking results were visualized using PyMol 2.4.

Adaptive laboratory evolution

The genome integration strains were first inoculated in RM medium containing 15 mM vanillic acid as the sole carbon source and then subjected to successive subculture. After completion of the initial growth lag period, the concentration of vanillic acid in the medium was increased with a 2.5 mM gradient until the engineered strain could grow rapidly in the medium containing 40 mM vanillic acid, during which the cells were continually passaged. Simultaneously, HPLC was utilized to monitor the concentration of vanillic acid and screen out the evolutionarily engineered strains that could rapidly utilize this substrate.

Fermentation in bioreactor

Laboratory-scale fermenter growth studies were performed in 5 L fermenters (ZY-6005 miniQ, China) with a working volume of 2.5 L. Growth temperature and pH were automatically maintained at 30 °C and 7.0, respectively. The stirring speed was initially set at 200 rpm and gradually increased to 600 rpm to keep the dissolved oxygen (DO) concentration above 30% air saturation during growth. The metabolic rate and tolerance to aromatic compounds were enhanced by increasing the initial inoculum OD. Aromatic concentrations were monitored offline using HPLC and maintained at 20–30 mM. APL and LDAs were prepared with reference to Allison’s method47. Briefly, pine wood was added at 10% (w/v) solids content to a reactor containing 2% NaOH solution, and the reaction system was maintained at 135 °C for 60 min. At the end of the reaction, the pH of the liquid slurry was adjusted to 7.0 with 5 M H2SO4. The neutralised solution was then centrifuged at 12,000×g for 40 min and filtered through filter paper to obtain APL. The APL was concentrated and extracted with ethyl acetate several times, the extract was filtered and washed with ice water, and dried in a vacuum drying oven for more than 48 h to obtain LADs as solids. In addition, the extraction protocol was optimized by adding steps such as mechanical crushing of pine wood and increasing the duration of the final extraction. The total amount of aromatic compounds added in the mixed aromatic fermentation test is 100 mM, and the amount added in the fermentation test of LDAs refers to the total concentration of mixed aromatic compounds.

Analysis of dry cell weight (DCW) and PHB content

To obtain the bacterial cells, the fermentation broth was collected in a preweighed centrifuge tube and centrifuged at 12,000×g for 10 min. The supernatant was then discarded, and the cells were washed twice with distilled water. Subsequently, the cells were freeze-dried and weighed to determine the dry cell weight (DCW).

The PHB content was analysed using the method of Braunegg et al.77. For this purpose, 20–30 mg of ground lyophilized cells were added to a tube. Then, 2 mL of chloroform and 2 mL of methanolysis solution (85% v/v methanol and 15% v/v H2SO4) were added. The tubes were heated at 100 °C for 180 min, and subsequently, the PHB content was determined by gas chromatography (GC-6580, Agilent Technologies, USA). In the present study, a 15–25 mg sample of PHB (3-HB standard, Sigma-Aldrich, USA) served as the designated standard for experimentation.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

Sequencing read files from this study are available in the NCBI repository under Sequence Read Archive (SRA) BioProject accession PRJNA1162438. Source data are provided with this paper and Figshare [https://figshare.com/s/b058ba339a4254083dc1]. Source data are provided with this paper.

References

Questell-Santiago, Y. M., Galkin, M. V., Barta, K. & Luterbacher, J. S. Stabilization strategies in biomass depolymerization using chemical functionalization. Nat. Rev. Chem. 4, 311–330 (2020).

Abu-Omar, M. M. et al. Guidelines for performing lignin-first biorefining. Energy Environ. Sci. 14, 262–292 (2021).

Bruijnincx, P. C., Rinaldi, R. & Weckhuysen, B. M. Unlocking the potential of a sleeping giant: lignins as sustainable raw materials for renewable fuels, chemicals and materials. Green. Chem. 17, 4860–4861 (2015).

Weiland, F., Kohlstedt, M. & Wittmann, C. Guiding stars to the field of dreams: Metabolically engineered pathways and microbial platforms for a sustainable lignin-based industry. Metab. Eng. 71, 13–41 (2022).

Li, F. et al. Microbial lignin valorization through depolymerization to aromatics conversion. Trends Biotechnol. 40, 1469–1487 (2022).

Kamimura, N., Sakamoto, S., Mitsuda, N., Masai, E. & Kajita, S. Advances in microbial lignin degradation and its applications. Curr. Opin. Biotechnol. 56, 179–186 (2019).

Cai, C., Xu, Z., Zhou, H., Chen, S. & Jin, M. Valorization of lignin components into gallate by integrated biological hydroxylation, O-demethylation, and aryl side-chain oxidation. Sci. Adv. 7, eabg4585 (2021).

Vethaak, A. D. & Legler, J. Microplastics and human health. Science 371, 672–674 (2021).