Abstract

Alternating-current electroluminescent fibres are promising candidates as light sources for smart textiles and soft machines. However, physical damage from daily use causes device deterioration or failure, making self-healable electroluminescent fibres attractive. In addition, soft robots could benefit from light-emitting combined with magnetically actuated functions. Here, we present a self-healing and actuatable Scalable Hydrogel-clad Ionotronic Nickel-core Electroluminescent (SHINE) fibre which achieves a record luminance of 1068 cd × m−2 at 5.7 V × μm−1. The SHINE fibre can self-heal across all constituent layers after being severed, recovering 98.6% of pristine luminance and maintaining for over 10 months. SHINE fibre is also magnetically actuatable due to the ferromagnetic nickel electrode core, enabling a soft robotic fibre with omnidirectional actuation and electro-luminescence. Our approach to this multifunctional fibre broadens the design of fibre electronics and fibre robots, with applications in interactive displays and damage-resilient navigation.

Similar content being viewed by others

Introduction

Alternating-current electroluminescent (EL) fibres have broad applications in smart textiles and soft machines1,2,3,4. The fibre form factor enables intrinsic flexibility and freedom of movement, enabling bending, twisting, and adaptation to narrow spaces5. However, physical damage in EL fibres can lead to deterioration or failure. Dynamic bonding within self-healing polymers to facilitate autonomous repair could be incorporated6,7, but creating an all-layer (e.g., electrodes and dielectrics) self-healable fibres remain challenging. Thus, only planar EL devices on flat substrates demonstrated self-healing capabilities8,9,10,11. Self-healing across all layers in fibre-shaped electronic devices remains elusive, especially in EL fibres12,13,14,15,16.

To achieve all-layer self-healable EL fibres, major challenges remain in developing a self-healing transparent fibre electrode, and ensuring its compatibility with the EL layer and the counter electrode. Self-healing fibre electrodes are generally composed of conductive mediums embedded in self-healing polymer fibres16,17. The necessity for good transparency imposes stringent requirements on electrode materials. Ensuring layer compatibility poses additional challenges, which composes of two aspects. First, interface wettability is needed when fabricating a self-healing EL fibre, but greater challenges occur in a fibre comprising discrepant materials which interface curvedly. For example, hydrogels (hydrophilic) and elastomers/fluoropolymers (hydrophobic) have been widely developed as self-healing polymer matrixes18,19, but poor interface wetting exists when coating a hydrogel layer on an elastomer fibre20.

Second, self-healing compatibility is needed for all fibre layers, but different self-healing polymers require different external conditions to facilitate self-healing. For instance, heating generally promotes self-healing in elastomers/fluoropolymers but causes functional deterioration in hydrogels due to water loss. Consequently, the requirements for a self-healing transparent fibre electrode and compatibility among all fibre layers should be satisfied to achieve a self-healing EL fibre.

EL devices are useful for optical signaling and feedback in emerging soft robots. This was demonstrated in light-emitting soft robots that integrated EL devices and pneumatic actuators8,21,22; they have shown potential to adapt to variable environments but are too bulky to access narrow spaces. Peristaltic dielectric elastomer actuators and ferromagnetic continuum robots in one-dimensional (1D) configuration can navigate narrow tubular spaces23,24 but lack self-healing capabilities and require device integration for light emission. The integration processes in these soft robots and actuators can lead to additional assembly challenge and energy consumption. Thus, an integration-free, self-healing, and intrinsically actuatable EL fibre is desirable.

Here, we present a self-healing actuatable Scalable Hydrogel-clad Ionotronic Nickel-core Electroluminescent (SHINE) fibre via ion-induced gelation of a hygroscopic hydrogel on a fluoropolymer-based bilayer coaxial fibre with nickel (Ni) core layer. The self-healing transparent hydrogel electrode was uniformly coated on the self-healing fluoropolymer-based fibre, and we observed no interface failure during fabrication and application, which we attributed to the ion pre-coating process. Furthermore, the hygroscopic hydrogel addressed the self-healing incompatibility between the hydrogel and the fluoropolymer, enabling SHINE fibre to recover 98.6% of pristine luminance after being completely severed.

After self-healing, the luminance remained stable for over 10 months under ambient conditions and the healed fibre was stable under bending to a bending radius of ~5 mm. Additionally, SHINE fibre can be actuated by external magnetic fields due to the ferromagnetic conducting Ni microparticles in the core layer.

We achieved a record luminance of 1068 cd × m−2 at an alternating-current electric field (\(\vec{{\rm E}}\)) of 5.7 V × μm−1 after device optimization and manufactured a SHINE fibre of 5.5 meters in length via a reel-to-reel process. We further demonstrated potential applications as light-emitting soft robotic fibres and interactive displays. SHINE fibre also exhibits capacitive proximity sensing and can be wirelessly powered. We anticipate this fibre can act as a platform to develop intrinsically multifunctional soft electronics and robots.

Results And Discussion

Design of SHINE fibres

We designed the self-healing actuatable SHINE fibre in a compact coaxial 1D configuration containing a Ni electrode core, an EL dielectric interlayer, and a transparent hydrogel electrode cladding (Fig. 1a). Both the Ni electrode core and EL dielectric interlayer were obtained from composites of fluoropolymer PVDF-HFP (poly(vinylidene fluoride-co-hexafluoropropylene)). The electrode core was composed of Ni microparticles and PVDF-HFP (abbreviated as Ni/PVDF-HFP); the EL interlayer was composed of zinc sulphide phosphor microparticles and PVDF-HFP (abbreviated as ZnS/PVDF-HFP). Here, Ni microparticles work as ferromagnetic conducting fillers which not only help establish conductive paths in the core but also make the core magnetically actuatable, and PVDF-HFP as a high-κ dielectric binder for the ZnS microparticles enhances the luminance at low electric fields8,25. Meanwhile, a small amount of fluorosurfactant, Zonyl FS-300, was also added in these two composites to introduce dipole-dipole interactions between the fluorosurfactant and the fluoropolymer, thus improving the self-healing of composites19. Moreover, Zonyl FS-300 works as a plasticizer and improves the self-healing ability by improving the mobility of PVDF-HFP chains, as evidenced by the master curves of storage moduli and loss moduli and the viscosity functions (Supplementary Figs. 1 and 2).

a Schematic and composition of SHINE fibre. Inset at the top right is a cross-sectional optical microscope image of a SHINE fibre. Scale bar, 200 μm. b A SHINE fibre of 5.5-meter length lit up under indoor light (Vac = 400 V, fac = 100 Hz, TEL = 167 μm, and \(\vec{{\rm E}}\) = 2.4 V × μm−1). Scale bar, 2 cm. c Healed SHINE fibres with green and orange colors under bending. Scale bar, 1 mm. d Magnetic responsiveness of an interactive display consisting of SHINE fibres with different colors. The display changes between “sad” and “smiley” expressions under an external magnetic field (B) provided by a permanent magnet underneath. The working distance of the magnet is 5 mm. Scale bar, 3 cm.

Unlike the core and interlayer where fluoropolymer composites were adopted, we used a hygroscopic hydrogel, dried to reach the equilibrium water content under ambient conditions, as the outer electrode for its high transparency and stability. A dried hydrogel electrode can also reduce its self-adhesion, facilitating the nondestructive separation of the electrode (Supplementary Fig. 3). The electrode is an ionic conductor based on a sodium alginate - calcium chloride (abbreviated as SA-C) network and the conducting ions of lithium chloride (LiCl)26,27. The self-healing ability is achieved by introducing a polyvinyl alcohol - sodium tetraborate decahydrate ((abbreviated as PVA-B) network and glycerol (Gly), where PVA-B provides dynamic borate ester bonds and Gly works as a plasticizer28,29. This PVA-B/SA-C/LiCl/Gly hydrogel presents higher ionic conductivity than other self-healing transparent conductive ionogels in which ionic liquids are commonly used30.

After fabricating the three fibre layers, SHINE fiber was achieved, exhibiting simultaneous omnidirectional actuation and electro-luminescence upon the application of alternating-current voltage (Vac) to Ni and hydrogel electrodes (Supplementary Fig. 4). The materials design and engineering enable a lit SHINE fibre with a length of 5.5 meters (Fig. 1b). More importantly, SHINE fibre exhibits self-healing ability across all three layers both optically and mechanically. This is evidenced by rejoining two fibre segments of different colors, after which the fibres self-heal, restore electro-luminescence, and can endure bending (Fig. 1c). Besides, the fibre is actuatable due to its ferromagnetic Ni electrode core, allowing applications as light-emitting soft robotic fibres and interactive displays (Fig. 1d).

Scalable fabrication

Our SHINE fibre can be fabricated to meters in length via two consecutive steps: first, coaxially wet-spinning Ni electrode and EL dielectric via liquid-solid phase separation31,32; second, coating hydrogel electrode via ion-induced gelation (Fig. 2a)33.

a Schematic of the scalable fabrication process combining liquid-solid phase separation in coaxial wet-spinning and ion-induced gelation in hydrogel coating. b SEM images and corresponding energy-dispersive X-ray spectroscopy (EDX) mapping of fluorine (F) and chloride (Cl) elements of bilayer coaxial fibres coated by hydrogel with and without pre-coating of ion source solution. Scale bar, 1 mm. c Water content and ionic conductivity of PVA-B/SA-C/LiCl/Gly hydrogel measured for over 10 months. d Transmittance in the visible spectrum measured for PVA-B/SA-C/LiCl/Gly hydrogel (~370 μm thickness). Inset is an optical microscope image of a SHINE fibre surface, showing the good transparency of the hydrogel. Scale bar, 1 mm. e The fibre can be fabricated to a few meters and lit up (Vac = 400 V, fac = 50 Hz, TEL = 167 μm, and \(\vec{{\rm E}}\) = 2.4 V×μm−1). Scale bar, 10 cm. f The luminance performance of SHINE fibre at different \(\vec{{\rm E}}\) and fac. TEL = 141 μm. g Comparison of the luminance versus \(\vec{{\rm E}}\) of our SHINE fibre with previously reported EL fibres. h Ratio between luminance at a point in time (L) and pristine luminance (L0) of SHINE fibre for over 10 months. Samples for long-term characterizations were stored under ambient conditions with a temperature of (20.8 ± 0.5) °C and relative humidity of (74.3 ± 2.7) %. Error bars are standard deviations of results from three samples.

In the first step, a customized coaxial nozzle was used for wet-spinning (Supplementary Fig. 5), and deionized water was used as the coagulating bath. Ni/PVDF-HFP and ZnS/PVDF-HFP dispersions in acetone with similar shear-thinning behaviours (Supplementary Fig. 6) were separately fed to the inner and outer parts of the coaxial nozzle, followed by extrusion through the nozzle into water. Once the extrudate entered water, acetone diffused from the polymer dispersions to water, yielding a solidified compact Ni/PVDF-HFP @ ZnS/PVDF-HFP bilayer coaxial fibre. This fast liquid-solid phase separation occurred because acetone is miscible with water, while acetone is a good solvent of PVDF-HFP but water is a non-solvent.

The wet-spinning process and the quality of bilayer coaxial fibre are affected by filler loadings, acetone amount, and flow rates (Supplementary Note 1). Higher filler loading and less acetone result in higher viscosity and hence induce extrusion jams, whilst lower filler loading and more acetone cause shape deformation and size deviation of the fibre. The flow rate difference between the core and sheath also changes the fibre morphology. For example, while keeping the Ni/PVDF-HFP flow rate unchanged, increasing the ZnS/PVDF-HFP flow rate augments EL interlayer thickness (TEL) and reduces Ni core diameter. However, ZnS/PVDF-HFP flow rates which are too low or too high lead to fibre non-uniformity or interface voids, respectively. Therefore, to obtain uniform void-free fibres, we used optimized dispersion concentrations and flow rates for both the Ni core Ni/PVDF-HFP (60/40 wt/wt, 10 μL × min−1) and the EL interlayer ZnS/PVDF-HFP (67/33 wt/wt, 10 μL × min−1), which were adopted in the following sections unless otherwise specified. These optimizations contributed to a continuous PVDF-HFP matrix bridging the two layers with Ni and ZnS microparticles dispersed inside separately (Supplementary Fig. 7).

In the second step, the hydrogel electrode cladding was introduced on the dry Ni/PVDF-HFP @ ZnS/PVDF-HFP bilayer coaxial fibre by immersing the fibre in an ion source, a hydrogel precursor, and the ion source again successively. This hydrogel formation happened spontaneously and instantly on the fibre because of ion-induced gelation. For example, as calcium ions (Ca2+) cross-linked sodium alginate (SA) chains, we obtained a SA-C/LiCl conductive hydrogel cladding (Supplementary Fig. 8) by immersing the fibre in CaCl2 (ion source), SA/LiCl (hydrogel precursor), and CaCl2 (ion source) solutions in sequence. Similarly, the self-healing hydrogel PVA-B/SA-C/LiCl/Gly was achieved when borax/CaCl2 was adopted as the ion source and PVA/SA/LiCl/Gly as the hydrogel precursor. The borate ions can reversibly cross-link the PVA chains to form a self-healing hydrogel.

Notably, during the fabrication, we first immersed the fibre in the ion source for ion pre-coating before gelation. This mitigates the poor interface wetting between the aqueous hydrogel precursor solution and the PVDF-HFP composite fibre with a hydrophobic and curved surface. The pre-coated ions can enhance the affinity between the precursor and the fibre, as is evidenced by the notably decreased water contact angle (Supplementary Fig. 9), further facilitating the formation of a thin, partially cross-linked hydrogel layer at the interface. This finally enabled the formation of a uniform hydrogel cladding on the fibre. In contrast, a fibre without pre-coating failed to have a uniform hydrogel cladding (Fig. 2b). Further, the existence of LiCl and Gly largely contributes to the good hygroscopicity and water retention of the hydrogel electrode, keeping its water content (~40 wt%) and ionic conductivity (~10 mS × cm−1) stable under ambient conditions for over 10 months without encapsulation (Fig. 2c). Additionally, the hydrogel electrode also presents high transparency in the visible spectrum (Fig. 2d and Supplementary Fig. 10), which is important for optoelectronic applications.

Thus, we fabricated a tri-layer coaxial SHINE fibre through coaxial wet-spinning and ion-induced gelation. This procedure enables SHINE fibre to be produced reel-to-reel to a length of several meters (Fig. 2e, Supplementary Movie 1). The fibre demonstrated luminance with < 14% fluctuation along the longitudinal direction in 2 m length (Supplementary Fig. 11) and uniform electro-luminescence in the enlarged view (Supplementary Fig. 12). SHINE fibre had well-defined interfaces without layer detachment across all three layers (Supplementary Figs. 13 and 14). The fibres can be designed to emit light with different colors by using differently doped ZnS phosphor microparticles (Supplementary Fig. 15). SHINE fibre also worked stably under bending, twisting and knotting states with good flexibility (Supplementary Fig. 16). Furthermore, SHINE fibre can be stretched with a moderate strain of 25% (Supplementary Fig. 17) and knitted into a strap (Supplementary Fig. 18), demonstrating its post-processing ability for potential applications including optoelectronic textiles and soft robots.

Luminance performance

By tuning ZnS and Ni loadings in the high-k PVDF-HFP matrix, we obtained the highest luminance at low \(\vec{{\rm E}}\) in EL fibre field. We first prepared and investigated SHINE fibres with increasing ZnS loading from 33 to 67 wt%. Higher ZnS loading resulted in higher luminance at the same \(\vec{{\rm E}}\) which further increased with increasing \(\vec{{\rm E}}\) (Supplementary Fig. 19). In contrast, Ni loading in the electrode core had a different impact on the luminance. When Ni loading increased from 50 to 70 wt%, the fibre with 60 wt% Ni performed best. A higher Ni loading was expected to increase the conductive paths in the Ni electrode, but more Ni microparticles led to more voids generated in the resulting fibres. The voids were unfavorable for both electrical and mechanical properties of Ni electrode (Supplementary Figs. 20–22) and detrimental to the high-k dielectric property of EL interlayer by introducing air gaps at the layer interface, which could lower the \(\vec{{\rm E}}\) across the EL interlayer. Therefore, our EL fibres with the highest luminance were made from bilayer coaxial fibres with 67 wt% ZnS and 60 wt% Ni, which achieved a high luminance of 1068 ± 8.5 cd × m−2 at \(\vec{{\rm E}}\) of 5.7 V × μm−1 (Fig. 2f). Compared to other EL fibres, this luminance performance is 10 times of the previously reported luminance at similar \(\vec{{\rm E}}\) (100 cd × m−2 at 5.5 V × μm−1) and 3.5 times of the previous record luminance (307 cd × m−2 at 9.1 V × μm−1) (Fig. 2g)1,2,34,35,36,37. A reason for the improved performance is the choice of the high-k PVDF-HFP as the embedding medium for ZnS microparticles38, which increases the ratio of the \(\vec{{\rm E}}\) across the ZnS microparticles compared to the mean \(\vec{{\rm E}}\) (applied voltage divided by the TEL, Supplementary Note 2)8. Furthermore, SHINE fibre can be readily driven to emit light by a modern commercial EL driver with a supply voltage of 3 V (Supplementary Fig. 23, Supplementary Movie 2). Notably, although a hydrogel electrode was used, its hygroscopicity and water retention ability allow our SHINE fibre to remain stable for over 10 months with little decrease in luminance (Fig. 2h)27,39,40.

In addition to high luminance and long lifetime, SHINE fibre has made advancements over previously reported EL fibres in self-healing and actuation capabilities (Supplementary Table 1)1,2,12,20,34,35,36,37,41,42,43.

Self-healing

SHINE fibre is self-healing across all constituent layers, which has not been achieved yet, to the best of our knowledge. The healing procedure consists of three stages (Fig. 3a). The severed SHINE fibre is rejoined at room temperature (RT) to first let the hydrogel electrode self-heal via dynamic borate ester bonds28, followed by heating the fibre at 50 °C to improve the self-healing of the Ni electrode and EL interlayer via dipole-dipole interactions19. After the fibre cools back to RT, the hydrogel electrode recovers its ionic conductivity by absorbing moisture from air. As presented in Fig. 3b, a lit pristine SHINE fibre was severed in the middle, and after self-healing the fibre was lit up again and withstood a bending radius of ~5 mm (curvature κ ≈ 200 m−1), indicating the recovery of both luminance and mechanical property. SEM images corroborate the self-healing observation for all three layers of SHINE fibre by showing that the cut interface lines diminished for Ni electrode and EL interlayer, and the healed interface of hydrogel electrode remained intact after heating (Fig. 3c).

a Schematic of self-healing process. The hydrogel electrode self-heals under ambient conditions while the EL interlayer and Ni electrode self-heals at 50 °C. Water loss occurs in the hydrogel during heating, leading to a decrease in hydrogel conductivity; however, both water content and conductivity recover when the hydrogel regains water by absorbing moisture from air at RT (rehydration). b Photos showing a lit pristine fibre, the cut fibre, and the healed fibre which light up entirely again and is bent to a bending radius of ~5 mm. Scale bars, 1 cm. c SEM images showing self-healing of the cut interface on hydrogel electrode, EL interlayer, and Ni electrode, respectively. The black dashed boxes indicate the cut and healed area of the hydrogel electrode, which started to heal under ambient conditions during preparation for SEM and remained intact after heating. All fibres were heated at 50 °C for 24 h. Scale bar, 20 μm. d and e The decrease in water content (d) and ionic conductivity (e) of different hydrogels after heating at 50 °C for 24 h, followed by rehydration for 24 h. f The luminance at increasing fac for SHINE fibre before and after heating on the hotplate with 50 °C for 9 days followed by rehydration. g Representative tensile stress-strain curves of SHINE fibre before and after self-healing at different temperatures and the average self-healing efficiencies. Healing time for RT samples is 24 h while it is 48 h for 50 °C samples (heating for 24 h followed by rehydration for 24 h). The tensile rate is 20 mm·min−1. h Luminance of pristine SHINE fibre compared to luminance after the fibre was cut and healed. Vac = 400 V, fac = 300 Hz, TEL = 138 μm, and \(\vec{{\rm E}}\) = 2.9 V × μm−1. i Ratio between luminance at a point in time (L) and pristine luminance (L0) of healed SHINE fibre for over 10 months at different fac under ambient conditions. The Ni and ZnS loadings in samples for Fig. 3 were 60 wt% and 50 wt%, respectively. Error bars are standard deviations of results from three samples.

We further demonstrated the materials design and self-healing strategy in detail. As we would expect, applying heat for self-healing of Ni electrode and EL interlayer is detrimental to hydrogel electrode, as its ionic conductivity will decrease due to water loss at elevated temperatures. We resolve this contradiction by designing the PVA-B/SA-C/LiCl/Gly hydrogel that self-heals and recovers its conductivity by absorbing moisture from the surroundings. This self-healing is achieved based on dynamic borate ester bonds (PVA/Borax)28 with the assistance of hygroscopic salt (LiCl)27, plasticizer (glycerol)29, and polyelectrolyte (SA-CaCl2)26,44,45.

To investigate the effects of the hydrogel components, we studied the water content, ionic conductivity and their recovery after heating of four hydrogel formulations: PVA-B (PVA/Borax), PVA-B/LiCl (PVA/Borax with addition of LiCl), PVA-B/SA-C/LiCl (PVA/Borax with addition of SA-CaCl2 and LiCl) and PVA-B/SA-C/LiCl/Gly (PVA /Borax with addition of SA-CaCl2, LiCl and glycerol). All hydrogels studied here were placed under ambient conditions to reach their equilibrium water content before use.

We first measured the water content and ionic conductivity. PVA-B had the lowest water content, and its ionic conductivity was 1660 times lower than PVA-B/LiCl. Further addition of SA-C improved the ionic conductivity by 190%, from 4.7 mS × cm−1 for PVA-B/LiCl to 13.5 mS × cm−1 for PVA-B/SA-C/LiCl. Although further addition of glycerol slightly decreased the conductivity to 9.5 mS × cm−1 due to its non-conducting nature, the glycerol had a plasticizing effect29, which improved self-healing of the hydrogel electrode (Supplementary Figs. 24 and 25).

Next we observed the recovery of water content and ionic conductivity. After heating at 50 °C for 24 h, the hydrogel PVA-B/SA-C/LiCl/Gly lost water content and ionic conductivity but recovered to 97% and 98% of their original values, respectively, under ambient conditions. In comparison, the recovery of PVA-B/LiCl and PVA-B/SA-C/LiCl were lower, and PVA-B had low ionic conductivity and water content throughout (Fig. 3d, e, Supplementary Fig. 26). This was due to LiCl, glycerol, and SA-CaCl2 absorbing moisture from the surroundings27,39,40,44,45, which recovered water content and ionic conductivity of the hydrogel electrode. We further found that increasing the surrounding humidity can facilitate the recovery of PVA-B/SA-C/LiCl/Gly hydrogel electrode (Supplementary Fig. 27). Also, SHINE fibre luminance dropped with the decrease of humidity but recovered as the humidity reverted (Supplementary Fig. 28). Heating the SHINE fibre at a constant humidity had little effect on the luminance while heating the fibre on the hotplate, which was used to improve fibre self-healing, led to luminance degradation (Supplementary Fig. 29). However, the luminance can be recovered after the fibre reabsorbs moisture from air, and this recovery is still achievable after heating for 9 days (Fig. 3f).

We then investigated the self-healing performance of each layer and the whole fibre after being cut completely. The recovery of electrical property occurs at the instance of fibre contact. For example, Ni electrode can recover in seconds after the cut fibre are gently pressed to rejoin, indicating the instant restoration of conductive paths across the cut interface, which enables electro-luminescence recovery of cut SHINE fibre upon contact (Supplementary Fig. 30, Supplementary Movie 3).

The recovery of mechanical property is a much slower process but is indispensable for reliable device operation. The mechanical self-healing efficiency can be quantified through tensile stress-strain curves46,47,48, and we use the ratios between the area integration under the curves (i.e., the fracture toughness) of healed and pristine materials as the mechanical self-healing efficiencies46. Increasing the concentration of fluorosurfactant Zonyl enhanced the mechanical self-healing efficiency of Ni electrode but led to resistance increase (Supplementary Fig. 31), thus 10 wt% Zonyl was adopted to achieve an optimal balance. Extending the healing time improved the mechanical self-healing efficiencies of all layers (Supplementary Fig. 32, Supplementary Movie 4). Increasing the healing temperature to 50 °C also had a positive effect in the mechanical self-healing efficiencies of all layers (Supplementary Fig. 33). Interestingly, the dynamic borate ester bonds were less affected despite water loss and contraction stress in hydrogel at 50 °C. With all layers self-healable mechanically, SHINE fibre can self-heal and recover its 78.5% of pristine toughness when self-healing at 50 °C followed by reabsorbing moisture under ambient conditions, and this self-healing efficiency is almost 14 times to that at RT (Fig. 3g).

SHINE fibre recovered 98.6% of its pristine luminance after self-healing (Fig. 3h). We also showed the self-healing of SHINE fibres with different colors and with different TEL (Fig. 1c, Supplementary Figs. 34 and 35). Furthermore, the effective self-healing and the hygroscopic hydrogel electrode enabled SHINE fibre to maintain the luminance at different driving frequencies (fac) for over 10 months after self-healing (Fig. 3i)27,39,40.

The strategy developed here enables the integration of heat-requiring and heat-sensitive materials within a self-healing system, which can contribute to the design of more types of self-healing devices.

Magnetic actuation

As ferromagnetic metal fillers, Ni provides the Ni electrode with electrical conductivity and allows the compact coaxial SHINE fibre to be magnetically actuatable. The omnidirectional actuation and electro-luminescence throughout the entire fibre offer a versatile method for delivering light in narrow spaces.

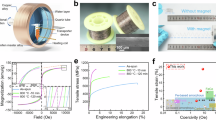

Although a higher Ni loading increases the magnetization of Ni electrode (Supplementary Fig. 36), an optimal loading of 60 wt% was chosen based on the electrical, mechanical, and luminance properties (as discussed earlier). As an actuatable 1D compact light-emitting device, bending is inevitable during actuation. SHINE fibre exhibited great flexibility and robustness in a bending test with little luminance degradation at the bending radius of 1.1 mm (κ = 909 m−1) (Supplementary Fig. 37). There was also no observable interface detachment and no luminance degradation for at least 2000 bending cycles at a bending radius of 8 mm (κ = 125 m−1). (Fig. 4a).

a SHINE fibre maintained its luminance after bending for 2000 cycles at a bending radius of 8 mm (κ = 125 m−1). The insets reveal that the fibre maintained its compact coaxial structure before and after bending; no interface failure was observed (white dashed areas). L and L0 refer to the luminance at a bending cycle and the initial luminance without bending, respectively. Scale bar, 60 μm. b A SHINE fibre with a length of ~65 cm actuated by an external magnetic field (B) to perform curling, with potential applications as light-emitting ferromagnetic soft robotic fibres. The direction of B is labeled at the bottom left in blue color. The working distance of the magnet was 5 mm. Scale bar, 10 cm. c Illustration of a millimeter-scale 3D pipe of two inner diameters (d1 = 5.2 mm; d2 = 4.2 mm) and three bend shapes (L shape, κ = 107.0 m−1; U shape, κ = 63.7 m−1; V shape, κ = 228.1 m−1). A SHINE fibre (~35 cm long) navigated this 3D pipe successfully. d Self-healing of SHINE fibre during navigation in a U-bend pipe (inner diameter = 5.2 mm, κ = 63.7 m−1). The fibre restored its pristine electro-luminescence and actuation capabilities via self-healing after being severed. The dashed white boxes highlight the cut location. All arrows indicate the directions of motion. Scale bars in (c and d) 10 mm.

Next, we presented that SHINE fibre can realize on-demand locomotion under a magnetic field (Supplementary Movie 5). For example, in a duration of 30 s, a 65-cm-long straight SHINE fibre performed curling with simultaneous light emission, where the motion was controlled by the movement of a magnet (Fig. 4b, Supplementary Fig. 38). We also prototyped an interactive face-changing display by using SHINE fibres of different colors. Through controlling the fibre bending directions with an external magnetic field, the display can switch between “sad” and “smiley” faces, indicating the potential of building interactive displays with actuatable SHINE fibres (Fig. 1d).

Our SHINE fibre can be further applied to navigating narrow spaces inaccessible to human hands. To demonstrate the navigation ability of SHINE fibre, we prepared a millimeter-scale pipe bent in three dimensions (3D pipe) of two inner diameters (d1 = 5.2 mm; d2 = 4.2 mm) and three bend shapes (L shape, κ = 107.0 m−1; U shape, κ = 63.7 m−1; V shape, κ = 228.1 m−1) (Fig. 4c, Supplementary Fig. 39). The pipe was filled with silicone oil to mimic the oily working environment of pipelines. A SHINE fibre was then introduced and navigated in the pipe using a magnet. It is observed that the fibre not only smoothly transited between the d1 and d2 zones, but also overcame the three sharp bends due to its flexibility (Supplementary Movie 6).

Notably, SHINE fibre can recover its actuation ability and electro-luminescence via self-healing even after being severed (Fig. 4d, Supplementary Movie 7). We demonstrated this in a U-bend pipe (d = 5.2 mm; κ = 63.7 m−1). A SHINE fibre was first lit and navigated into the pipe, then thoroughly cut into two parts. After rejoining and healing (heating at 50 °C for 3 h followed by rehydration in air for 1.5 h), the fibre restored its light emission and managed to navigate through the U-bend.

The magnetic responsiveness is intrinsic to SHINE fibre, hence the actuation and light emission mechanisms do not require device integration, unlike other reported light-emitting soft robots8,21,22,23,24. This reduces device complexity and avoids additional assembly difficulties and energy consumption. Furthermore, the compact coaxial configuration and ion-induced gelation fabrication method endows SHINE fibre with flexibility and robustness, making it suitable for damage-resilient soft robots. To expand the scope of applications and avoid potential electrical hazard during long-term contact (though the current is quite small), we can also add a transparent encapsulation layer (Supplementary Figs. 40 and 41).

Besides magnetic actuation, SHINE fibre also exhibited capacitive proximity sensing49,50, and we demonstrated the interactive optical signaling of SHINE fibre triggered by human approach (Supplementary Note 3, Supplementary Movie 8). Separately, through two inductively coupled coils operating at 13.56 MHz8,51, SHINE fibre can be wirelessly powered, rendering fully untethered light-emitting soft robots (Supplementary Note 4).

In summary, we developed a SHINE fibre that is intrinsically self-healing and actuatable. The fibre was manufactured by coaxial wet-spinning and ion-induced gelation processes. A 5.5-meter-long SHINE fibre and a record luminance of 1068 ± 8.5 cd × m−2 were achieved, respectively. SHINE fibre exhibits robustness, self-healing across all constituent layers after being severed and further maintaining the restored luminance for over 10 months. This fibre is capable of magnetic actuation, proximity detection, and being wirelessly powered, making it suitable for optical soft robots and human-robot interactions. We anticipate that our strategy can be applied to achieving other multilayer self-healing devices in low-dimensional configurations and inspire more types of intrinsically multifunctional devices in soft robots, smart displays, wearable electronics, etc.

Methods

Materials

Poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP FC 2230, 3 M, 100%), electroluminescent (EL) zinc sulphide (ZnS, 91 − 99%) phosphor microparticles (Lonco), nickel microparticles (Ni, Vale Type 255, > 99%), and lithium chloride (LiCl, TCI, > 98.0%(T)) were used as received. Sodium alginate (SA, W201502), poly(vinyl alcohol) (PVA 99 + % hydrolyzed, Mw 89000–98000), calcium chloride (CaCl2, ≥ 96%), sodium tetraborate decahydrate (borax, ≥ 99.5%), 1,3-diaminopropane (DAP, ≥ 99%) and silicone oil (viscosity 10 cSt (25 °C)) were obtained from Sigma-Aldrich and used as received. Zonyl FS-300 (abcr, ≥ 20 − < 30%) was dried in an oven at 70 °C before use.

Hydrogel stock solutions were prepared by dissolving 50 g of SA in 800 g of deionized water or 60 g of PVA in 400 g of deionized water at 90 °C. Crosslinking solutions were obtained by dissolving 20 g of CaCl2 in 100 g of deionized water, or 1.5 g of borax and 10 g of CaCl2 in 100 g of deionized water.

Fabrication of SHINE fibres

A typical procedure to fabricate our coaxial SHINE fibre is as follows: two bottles each containing 2 g of PVDF-HFP dissolved in 1.8 mL of acetone were prepared. For Ni electrode core, 3 g of Ni (60 wt%) was added to the first bottle to obtain Ni/PVDF-HFP dispersion, and for EL interlayer, 4 g of ZnS particles (67 wt%) was added to the second bottle to obtain ZnS/PVDF-HFP dispersion; both bottles were mixed using a speedmixer (FlackTek). The contents of the bottles were transferred into separate plastic syringes (Terumo) and syringe pumps (Harvard Apparatus) were used to extrude the ZnS/PVDF-HFP and Ni/PVDF-HFP dispersions through a coaxial nozzle (inner diameter of 0.8 mm and outer diameter of 1.5 mm, Changzhou Lingxian Textile Machinery Co., Ltd) into a tank of deionized water. The flow rates of the syringe pumps for Ni/PVDF-HFP (core) and ZnS/PVDF-HFP (sheath) dispersions were set at 10 μL × min−1. The extruded bilayer coaxial fibre was collected and allowed to dry under ambient conditions. For the SA based hydrogel electrode, 6.36 g of LiCl was dissolved in 20 g of deionized water and added to 85 g of the SA stock solution to obtain a hydrogel precursor solution with 1.5 M LiCl (SA/LiCl). The bilayer coaxial fibre was sequentially immersed into the CaCl2 solution, the SA/LiCl hydrogel precursor solution and the CaCl2 solution again to form the hydrogel cladding via ion-induced gelation. After the hydrogel dried under ambient conditions to reach the equilibrium, SHINE fibre was obtained. Copper wires and tapes were then used to connect electrodes to the power source. If a higher resistance to tension is needed for as-prepared bilayer coaxial fibres, DAP (a cross-linking agent for PVDF-HFP) can be added into the above Ni/PVDF-HFP and ZnS/PVDF-HFP dispersions.

Fabrication of SHINE fibre with self-healing ability was similar, with the addition of 182 µL of Zonyl (10 wt%) to the Ni/PVDF-HFP dispersion and 91 µL of Zonyl (5 wt%) to the ZnS/PVDF-HFP dispersion. The hydrogel precursor solution with 1.0 M LiCl was a mixture of LiCl (2.71 g in 4.8 g of water), glycerol (9.91 g), PVA and SA stock solutions (46 g and 20.4 g, respectively), i.e., PVA/SA/LiCl/Gly; the borax/CaCl2 solution was used as the ion source during ion-induced gelation.

Materials characterization

Optical micrographs were taken using an optical microscope (Keyence VHX6000) and scanning electron microscope (SEM) images were taken using a SEM (Zeiss Supra 40). Resistance values of Ni electrode fibres were measured using a sourcemeter (Keithley 2450). Electrochemical impedance spectroscopy (EIS) on hydrogel electrodes were obtained using an LCR meter (Zurich Instruments MFIA). Hydrogel samples were dip-coated onto glass slides (2.5 cm wide) with copper tape (spaced 2 cm apart) as electrodes followed by drying under ambient conditions for 3 days, and thickness was measured using a micrometer screw gauge. Humidity tests were conducted on separate hydrogel samples in a benchtop humidity chamber (Espec SH-262). Conductance was calculated as the reciprocal of resistance, and conductivity from the formula σ = l/RA–where l was the distance between the electrodes, R was the bulk resistance obtained from the EIS graph, and A was the cross-sectional area of hydrogel sample obtained by multiplying thickness and width of the sample.

Tensile tests on films and fibres were conducted using a universal testing machine (Instron 68SC-1) with a 10 N load cell. To make film samples, Ni electrode and EL interlayer polymer dispersions were separately cast in a petri-dishes to form films. Hydrogel films were obtained by dip-coating on glass slides (repeated twice to increase thickness) and left to dry for 3 days before test. Film samples were cut into rectangular shape and thickness was measured using a micrometer screw gauge.

Rheology tests for all PVDF-HFP based dispersions were carried out using a rotational rheometer (Anton Paar MCR302) with parallel plate (25 mm), and sample thickness was set at 1 mm. Thermogravimetric analysis (TGA) on the hydrogels was conducted at a heating rate of 10 °C × min−1 (TA Instruments TGA Q500). Transmittance of hydrogels were tested using a UV-Vis spectrometer with integrating sphere (Shimadzu UV 2600i) using hydrogel samples coated on glass slides.

Device characterization

The power source (Trek 610E) of SHINE fibres amplifies sine wave signals generated by an analog output module (NI 9263) using a custom LabVIEW script, in which reported voltages are peak voltages. Luminance values of SHINE fibres were measured by a luminance meter (Konica Minolta CS200). Capacitance values of SHINE fibres were measured using the LCR meter. To quantify the relationship of the measured capacitance with the distance, a SHINE fibre was fixed on a stage with one end connected to an LCR meter, and at the other end a finger approached at varying distance. The fibre capacitance was recorded with reference to the distances read off a vertically fixed ruler. Magnetic actuation of SHINE fibres and ferromagnetic soft robots was done manually using a permanent magnet. The permanent magnet (MISUMI, NE142) is round with a diameter of 23.5 mm and a thickness of 25 mm. The 3D pipe was assembled from three glass tubes of L shape, U shape, and V shape.

Data availability

All data generated or analysed during this study are included in the Article and its Supplementary Information, and are available from the corresponding author upon request.

References

Shi, X. et al. Large-area display textiles integrated with functional systems. Nature 591, 240–245 (2021).

Cho, S., Chang, T., Yu, T., Gong, S. L. & Lee, C. H. Machine embroidery of light-emitting textiles with multicolor electroluminescent threads. Sci. Adv. 10, eadk4295 (2024).

Xiong, J., Chen, J. & Lee, P. S. Functional fibers and fabrics for soft robotics, wearables, and human–robot interface. Adv. Mater. 33, 2002640 (2021).

Yang, W. et al. Single body-coupled fiber enables chipless textile electronics. Science 384, 74–81 (2024).

Li, P. et al. Wearable and interactive multicolored photochromic fiber display. Light Sci. Appl. 13, 48 (2024).

Tan, Y. J., Susanto, G. J., Anwar Ali, H. P. & Tee, B. C. Progress and roadmap for intelligent self‐healing materials in autonomous robotics. Adv. Mater. 33, 2002800 (2021).

Cooper, C. B. et al. Autonomous alignment and healing in multilayer soft electronics using immiscible dynamic polymers. Science 380, 935–941 (2023).

Tan, Y. J. et al. A transparent, self-healing and high-κ dielectric for low-field-emission stretchable optoelectronics. Nat. Mater. 19, 182–188 (2020).

Son, D. et al. An integrated self-healable electronic skin system fabricated via dynamic reconstruction of a nanostructured conducting network. Nat. Nanotech. 13, 1057–1065 (2018).

Kim, Y. M., Kwon, J. H., Kim, S., Choi, U. H. & Moon, H. C. Ion-cluster-mediated ultrafast self-healable ionoconductors for reconfigurable electronics. Nat. Commun. 13, 3769 (2022).

Liang, G. et al. Self-healable electroluminescent devices. Light Sci. Appl. 7, 102 (2018).

Cho, S. H. et al. Shape‐deformable self‐healing electroluminescence displays. Adv. Optical Mater. 7, 1801283 (2019).

Huang, Y. et al. Magnetic-assisted, self-healable, yarn-based supercapacitor. ACS Nano 9, 6242–6251 (2015).

Rao, J. et al. All-fiber-based quasi-solid-state lithium-ion battery towards wearable electronic devices with outstanding flexibility and self-healing ability. Nano Energy 51, 425–433 (2018).

Wu, X., Meng, L., Wang, Q., Zhang, W. & Wang, Y. A self-healable asymmetric fibered-supercapacitor integrated in self-supported inorganic nanosheets array and conducting polymer electrodes. Chem. Eng. J. 352, 423–430 (2018).

Sun, H. et al. Self‐healable electrically conducting wires for wearable microelectronics. Angew. Chem. Int. Ed. 53, 9526–9531 (2014).

Wang, S. et al. A dynamically stable self-healable wire based on mechanical-electrical coupling. Natl Sci. Rev. 11, nwae006 (2024).

Li, S., Zhou, X., Dong, Y. & Li, J. Flexible self‐repairing materials for wearable sensing applications: elastomers and hydrogels. Macromol. Rapid Commun. 41, 2000444 (2020).

Guo, H. et al. Artificially innervated self-healing foams as synthetic piezo-impedance sensor skins. Nat. Commun. 11, 5747 (2020).

Yang, C. et al. Ionotronic luminescent fibers, fabrics, and other configurations. Adv. Mater. 32, 2005545 (2020).

Larson, C. et al. Highly stretchable electroluminescent skin for optical signaling and tactile sensing. Science 351, 1071–1074 (2016).

Zhang, P. et al. Integrated 3D printing of flexible electroluminescent devices and soft robots. Nat. Commun. 13, 4775 (2022).

Tang, C. et al. A pipeline inspection robot for navigating tubular environments in the sub-centimeter scale. Sci. Robot. 7, eabm8597 (2022).

Kim, Y., Parada, G. A., Liu, S. & Zhao, X. Ferromagnetic soft continuum robots. Sci. Robot. 4, eaax7329 (2019).

Zhou, Y. et al. Bright stretchable electroluminescent devices based on silver nanowire electrodes and high-k thermoplastic elastomers. ACS Appl. Mater. Interfaces 10, 44760–44767 (2018).

Yang, J., Bai, R., Chen, B. & Suo, Z. Hydrogel adhesion: a supramolecular synergy of chemistry, topology, and mechanics. Adv. Funct. Mater. 30, 1901693 (2020).

Lu, Q. et al. A printable and conductive yield-stress fluid as an ultrastretchable transparent conductor. Research 2021, 9874939 (2021).

Cho, S., Hwang, S. Y., Oh, D. X. & Park, J. Recent progress in self-healing polymers and hydrogels based on reversible dynamic B–O bonds: boronic/boronate esters, borax, and benzoxaborole. J. Mater. Chem. A 9, 14630–14655 (2021).

Ye, Z. et al. Glycerol‐modified poly (vinyl alcohol)/poly (ethylene glycol) self‐healing hydrogel for artificial cartilage. Polym. Int. 72, 27–38 (2023).

Cao, Y. et al. Self-healing electronic skins for aquatic environments. Nat. Electron. 2, 75–82 (2019).

Zheng, L. et al. Conductance-stable liquid metal sheath-core microfibers for stretchy smart fabrics and self-powered sensing. Sci. Adv. 7, eabg4041 (2021).

Zhang, S. et al. Biomimetic spinning of soft functional fibres via spontaneous phase separation. Nat. Electron. 6, 338–348 (2023).

Fu, X. et al. Cation-induced assembly of conductive MXene fibers for wearable heater, wireless communication, and stem cell differentiation. ACS Biomater. Sci. Eng. 9, 2129–2139 (2023).

Liang, G. et al. Coaxial‐structured weavable and wearable electroluminescent fibers. Adv. Electron. Mater. 3, 1700401 (2017).

Hu, D., Xu, X., Miao, J., Gidron, O. & Meng, H. A stretchable alternating current electroluminescent fiber. Materials 11, 184 (2018).

Sun, T. et al. Transient fiber-shaped flexible electronics comprising dissolvable polymer composites toward multicolor lighting. J. Mater. Chem. C. 7, 1472–1476 (2019).

Liu, D. et al. Customizable and stretchable fibre-shaped electroluminescent devices via mulitcore-shell direct ink writing. J. Mater. Chem. C. 8, 15092–15098 (2020).

Lee, H. et al. Low-voltage stretchable electroluminescent loudspeakers with synchronous sound and light generation. ACS Appl. Mater. Interfaces 15, 16299–16307 (2023).

Han, L. et al. Mussel-inspired adhesive and conductive hydrogel with long-lasting moisture and extreme temperature tolerance. Adv. Funct. Mater. 28, 1704195 (2018).

Xia, H. et al. Hygroscopic solutes enable non‐van der Waals electrolytes for fire‐tolerant dual‐air batteries. Angew. Chem.Int. Ed., 63, e202318369 (2024).

Li, G. et al. Autonomous electroluminescent textile for visual interaction and environmental warning. Nano Lett. 23, 8436–8444 (2023).

Zhang, Z. et al. Textile display for electronic and brain‐interfaced communications. Adv. Mater. 30, 1800323 (2018).

Zhang, Z. et al. A one-dimensional soft and color-programmable light-emitting device. J. Mater. Chem. C. 6, 1328–1333 (2018).

Xia, H. et al. Hygroscopic chemistry enables fire‐tolerant supercapacitors with a self‐healable “solute‐in‐air” electrolyte. Adv. Mater. 34, 2109857 (2022).

Wang, X. Q. et al. Macromolecule conformational shaping for extreme mechanical programming of polymorphic hydrogel fibers. Nat. Commun. 13, 3369 (2022).

White, S. R. et al. Autonomic healing of polymer composites. Nature 409, 794–797 (2001).

Cordier, P., Tournilhac, F., Soulié-Ziakovic, C. & Leibler, L. Self-healing and thermoreversible rubber from supramolecular assembly. Nature 451, 977–980 (2008).

Li, C.-H. et al. A highly stretchable autonomous self-healing elastomer. Nat. Chem. 8, 618–624 (2016).

Guan, F. et al. Silver nanowire–bacterial cellulose composite fiber-based sensor for highly sensitive detection of pressure and proximity. ACS Nano 14, 15428–15439 (2020).

Moheimani, R., Aliahmad, N., Aliheidari, N., Agarwal, M. & Dalir, H. Thermoplastic polyurethane flexible capacitive proximity sensor reinforced by CNTs for applications in the creative industries. Sci. Rep. 11, 1104 (2021).

Lin, R. et al. Digitally-embroidered liquid metal electronic textiles for wearable wireless systems. Nat. Commun. 13, 2190 (2022).

Acknowledgements

This work is supported by Agency for Science and Technology Singapore (A*STAR) RIE2025 Manufacturing, Trade and Connectivity (MTC) grant M22K2c0081, A*STAR grant A-0005401-02-00, the NUS iHealthtech PI grant and the National University of Singapore (NUS) Startup Grant (2017-01 to B.C.K.T.). G.X.W. was supported by the NUS Research Scholarship. H.C.G. is supported by the Eric and Wendy Schmidt AI In Science Postdoctoral Fellowship. We thank Dr. S.W. Tan for help with rheology tests.

Author information

Authors and Affiliations

Contributions

B.C.K.T., X.M.F., G.X.W., and H.C.G. conceived and designed the experiments; B.C.K.T. supervised the project. X.M.F., G.X.W., and H.C.G. carried out experiments and collected the data. X.M.F., G.X.W., H.C.G., and Z.J.Y. worked on materials fabrication and characterization. X.M.F., G.X.W., and Y.J.T. contributed to the enhancement of luminance and self-healing. G.X.W., H.C.G., X.M.F., and Z.J.Y. contributed to magnetic actuation and proximity detection. H.J.K., J.S.H., and X.M.F. contributed to wireless power design. H.C.G., H.J.K., X.M.F., and G.X.W. worked on demonstrations of SHINE fibers in pipelines and ferromagnetic soft robots. X.M.F., B.C.K.T., G.X.W., and H.C.G. analyzed all the data and co-wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Chi Hwan Lee who co-reviewed with Tianhao Yu and Sihong Wang who co-reviewed with Wei Liu for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Fu, X., Wan, G., Guo, H. et al. Self-healing actuatable electroluminescent fibres. Nat Commun 15, 10498 (2024). https://doi.org/10.1038/s41467-024-53955-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-53955-2

This article is cited by

-

Fluorescent Dye-Enhanced ACEL Fibers for Omnidirectional Luminescence and Voice-Interactive Human–Machine Interfaces

Advanced Fiber Materials (2025)