Abstract

Transition metal carbide shows excellent performance in selective hydrogenation of acetylene, however, the carburization of Pd-based intermetallic compounds remains infeasible. Here we report the successful synthesis of an unprecedented Pd3ZnCx intermetallic carbide, via co-infiltration of zinc and carbon in one-step carburization by syngas. Utilizing state-of-the-art in situ characterizations and theoretical calculation, we unveil the dynamic evolution of Pd3ZnCx during carburization, forming a Pd3Zn like cubic phase carbide structure. A unique transitional state (Pdt) with low content of Zn/C co-infiltration is clearly identified facilitating phase transition and sustain incorporation of carbon and zinc at elevated temperatures. The Pd3ZnCx carbide shows by far the best catalytic performance in the selective hydrogenation of acetylene with a high selectivity (>90%) even at a high H2/C2H2 ratio. Our results therefore provide a co-infiltration strategy and dynamic insights for the one-step synthesis of Pd based intermetallic carbides, towards high-performance intermetallic compound for selective hydrogenation of acetylene.

Similar content being viewed by others

Introduction

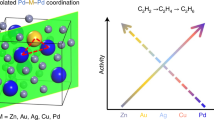

Selective hydrogenation of acetylene is an important process widely used in ethylene industry for removing acetylene impurities1,2. Pd is the most active component for this reaction yet suffers low selectivity at high acetylene conversions and poor stability for long-term operations1. To address these challenges, various Pd-based alloys and intermetallic compounds (Pd–Ag, Pd–Au, Pd–Cu, Pd–Ga, Pd–Zn)3,4,5,6,7 have been developed. The isolation of Pd sites by a second relatively inert metal substantially improves the ethylene selectivity and suppresses the side reactions of oligomerization/coking as the C–C coupling requires at least four contiguous Pd sites8. For example, the spatial arrangement of Pd atoms in PdZn alloy allows moderately strong σ-bonding of acetylene, which bridges over the two Pd atoms in the Pd–Zn–Pd linkage7, and weak π-bonding with ethylene that facilitates high selectivity in acetylene semi-hydrogenation.

Various surface/subsurface carbon species can be generated in situ from alkynes/alkenes and have been reported to play an important role during selective hydrogenation. The coke formation is one major reason for deactivation2,8,9, while the subsurface or interstitial carbon can greatly suppress the deep hydrogenation which improves the selectivity10. Recently, transition metal carbides (Pd10 or Ni11,12) have attracted tremendous interests due to their excellent performance in selective hydrogenation of acetylene. The interstitial carbon can significantly suppress the formation of hydride species (PdHx)10,12 and strongly modulate the geometric and electronic structure of the active metal atom. The modified electronic state of the central atom by interstitial carbon11 thus weakens the adsorption of acetylene on the surface and alleviates catalyst deactivation by suppressing polymerization products. To date, however, the carburization of Pd-based intermetallic compounds by alkynes/alkenes remains infeasible likely due to their excellent structural stability and fully occupied interstitial sites, which is thus highly desirable but of grand challenges.

Carbon monoxide as a process modifier can usually exist or be intentionally added in trace amounts in acetylene hydrogenation reaction gas in the industrial operating condition for front-end or tail-end process1,9,13,14. Carbon monoxide can improve the selectivity of ethylene by poisoning the active center and weakening the adsorption of ethylene. Meanwhile, CO has been validated to enable a variety of structural changes on binary alloys, e.g. segregation15, phase separation16,17, carburization18,19,20,21, under a reaction environment. However, the role of carbon monoxide as a structural assistant in the dynamic carburization of Pd-based intermetallic catalysts remains elusive.

Herein, we developed a co-infiltration strategy via one-step carburization by syngas (CO + H2) and reported an unprecedented Pd3ZnCx intermetallic carbide in Pd-based intermetallic compound family, as high-performance catalyst for selective hydrogenation of acetylene. Utilizing state-of-the-art in situ characterizations and theoretical calculation, we revealed a significant role of CO in dynamic formation of Pd3ZnCx intermetallic carbides. A unique transitional state (Pdt) with multi-domain structures was identified that evolved continuously from 120 to 350 °C as a critical intermediate facilitating the sustained insertion of Zn and C at elevated temperatures. The catalytic testing and theoretical calculations further revealed that Pd3ZnCx was the highly active phase for the selective hydrogenation of acetylene, significantly higher than the highest reported value of PdZn intermetallic compound at high selectivity (>90%) by lowering the initial hydrogenation barrier and promoting ethylene desorption.

Results

Preparation and identification of Pd3ZnCx intermetallic carbide

The carburization of PdZn intermetallic compounds (β1-PdZn) by alkynes/alkenes remains infeasible likely due to its excellent structural stability and weak C–H bond dissociation on Pd–Zn–Pd fragments7. Instead, we proposed a co-infiltration strategy via one-step carburization using syngas (10%CO–50%H2–40%He) to achieve the Pd3ZnCx intermetallic carbides (see preparation procedure in Fig. 1a). It is worth noting that the stepwise heating procedure (up to 400 °C) is very critical since the transition of palladium and other interstitial species, i.e. H, C and Zn has a relatively narrow temperature window (see detailed temperature ramps in Supplementary Discussion).

a Preparation procedure of Pd3ZnCx by syngas. b STEM images of Pd3ZnCx and the corresponding particle size distribution. c Aberration-corrected HAADF-STEM image of Pd3ZnCx; the corresponding EDS line scan (d), and the EDS elemental mapping of Pd L-edge (green) (e), Zn K-edge (purple) (f), C K-edge (yellow) (g). Quasi in situ XPS spectra of Pd 3d (h) and C 1s (i) core levels for PdO/ZnO/Al2O3 fresh sample, PdZn/ZnO/Al2O3 and Pd3ZnCx/ZnO/Al2O3. j Enlarged XRD patterns of Pd3ZnCx/ZnO/Al2O3, Pd3Zn/Al2O3 (α-PdZn), PdZn/ZnO/Al2O3 (β1-PdZn), PdCx/Al2O3 and Pd/Al2O3 for comparison. k Linear correlation between the C:Pd ratio and shift of (111) diffraction peak relative to that of Pd3Zn, predicted by DFT calculation (Diffraction peak shift = −5.88 × C − 0.01; R2 = 0.999).

The aberration-corrected high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) reveals the atomic structure of Pd3ZnCx nanoparticles (NPs) after syngas treatment (Fig. 1b–g). As shown in Fig. 1b, the as-formed NPs are uniformly distributed on the Al2O3 support with an average particle size of 16.1 ± 1.4 nm (Fig. 1b inset). The energy dispersive spectroscopy (EDS) mapping (Fig. 1e–g) reveals a uniform distribution of Pd (L-edge), Zn (K-edge) and C (K-edge) within the selected NP. The EDS line scan (Fig. 1d and Fig. S3c) further confirms the presence of both zinc and carbon on the selected NP. The average atomic ratio of Pd:Zn is ~3:1 based on the quantitative analysis results (Fig. S3b, d), while the carbon content from EDS can be less accurate due to the interference with surface carbon deposit. Therefore, we denoted the new intermetallic carbide phase as Pd3ZnCx, and the carbon content can be determined by the XRD peak shift as discussed in the latter section. The lattice spacing of the Pd3ZnCx NPs is 0.222 nm (Fig. 1c), which is slightly larger than 0.220 nm of (111) plane in cubic phase Pd3Zn alloy (α-PdZn), and 0.219 nm of (101) plane in tetragonal β1-PdZn alloy (see detailed analysis in Fig. S1). The lattice expansion is observed quite often in transition metal carbides as the carbon atoms are filled into the interstitial position in the alloy NPs11,22. The EEL spectrum in Fig. S5 also reveals a similar feature (280–300 eV) to previously reported Ni3ZnC0.711, suggesting its carbide nature rather than amorphous carbon deposit.

Quasi in situ XPS experiments (Fig. 1h, i) further reveal the formation of Pd3ZnCx intermetallic carbides. The PdO/ZnO/Al2O3 fresh sample (denoted as PdO–ZnO) was pretreated at 400 °C in hydrogen (denoted as PdZn) and in syngas (denoted as Pd3ZnCx) respectively and then directly transferred for XPS analysis without exposure to the air. The Pd 3d XPS spectra (Fig. 1h) show a prominent reduction of PdO (fresh sample) after H2 reduction at 400 °C and the PdZn intermetallic alloy is evidently identified with a typical Pd 3d5/2 binding energy of 335.9 eV, in agreement with the reported value of multilayer PdZn alloy23, along with emerging metallic Zn signal in Zn LMM Auger spectra (Fig. S6). By contrast, the Pd3ZnCx sample obtained by syngas pretreatment shows a Pd 3d5/2 binding energy of 335.4 eV, slightly lower than that for PdZn phase, but higher than that of Pd metal, suggesting its alloy composition. The carbide phase is unambiguously confirmed by C 1s spectra (Fig. 1i), with a characteristic carbide component at 283.6 eV24.

The phase structure of Pd3ZnCx was further validated by XRD, as shown in Fig. 1j and Supplementary Fig. S8. The as-formed Pd3ZnCx intermetallic carbide shows a cubic structure with (111) and (200) diffraction peaks similar to that of Pd3Zn (α-PdZn), suggesting a carburization on cubic Pd3Zn (α-PdZn) rather than tetragonal β1-PdZn. The slight shift to lower diffraction angle is thus attributed to the carbon infiltration into Pd3Zn alloy, similar to the XRD shift between Pd and PdCx. The content of carbon in Pd3ZnCx can thus be quantified by the shift of Pd3Zn (111) diffraction peak in XRD, similar to the previously reported method for PdCx24,25. Accordingly, the average carbon content in the bulk carbide can be estimated to be Pd3ZnC0.03. Based on DFT calculations, there is a clear linear correlation between the C:Pd ratio and the shift of (111) diffraction peak relative to that of Pd3Zn (Fig. 1k and Table S1). Specifically, when the C:Pd ratio is 0.01, the calculation predicted shift in the diffraction peak of (111) between Pd3ZnC0.03 and Pd3Zn is 0.07°, which is very close to the 0.05° of the shift observed experimentally between Pd3ZnCx and Pd3Zn (Fig. 1j). According to the XRD results, Pd3Zn shift to higher diffraction angle (lattice contraction) than Pd metal due to Zn replacement, while Pd3ZnCx shifts to lower diffraction angle than Pd3Zn which is attributed to the lattice expansion due to interstitial carbon insertion. The overall effect thus results in a similar Pd–Pd distance of Pd3ZnCx to Pd metal. This is in line with the EXAFS fitting results (Figs. S11–14) that Pd3ZnCx shows the Pd–Pd(Zn) distance of 2.73 Å which is closer to Pd metal and PdCx, rather than β-PdZn (2.85 Å)7(Supplementary Table S2).

In situ observation of dynamic phase transition during carburization

In situ, XRD experiments were performed to gain insights into the dynamic phase transition during Pd3ZnCx formation. As shown in Fig. 2a and Fig. S15, PdO phase was initially observed on the fresh PdO/ZnO/Al2O3 sample after calcination in air, with characteristic diffraction peaks at 41.93° and 54.79° for PdO(110) and (112), respectively. Upon heating (rate: 5 °C/min) in a syngas atmosphere to 90 °C, a phase transition from PdO to PdHx hydrides (β-PdHx) was clearly observed, exhibiting a characteristic β-PdHx(111) diffraction at 38.92°22. The hydrogen content in β-PdHx can be estimated by the peak shift through Vegard’s law26 which is around x = 0.489~0.583. With increasing temperature, the β-PdHx hydrides became thermodynamically unstable, and decompose into α-PdHx, characterized by the upshift of XRD peak to 39.98° due to lower hydrogen content in α-PdHx27. Meanwhile, a transitional state (Pdt) emerged at above 120 °C showing continuous upshifts of XRD diffraction peak to a higher degree. It thus implied a sustained process for carbon and Zn infiltration in a wide temperature window (120–350 °C). Eventually at 400 °C, a complete formation of Pd3ZnCx was achieved showing a typical diffraction peak at 40.25°, to a slightly lower angle of Pd3Zn (40.30°) (see typical XRD patterns in Fig. 1j and Fig. S8). The thermal effect during this process can also be ruled out as thermal expansion usually leads to an opposite shift to lower angle (Fig. S16).

a In situ XRD patterns of PdO/ZnO/Al2O3 sample under syngas atmosphere at elevated temperatures ranging from 30 to 400 °C. Quasi in situ XPS spectra of Pd 3d (b) and Zn LMM (c) of PdO/ZnO/Al2O3 sample under syngas atmosphere at elevated temperatures. The BE of Pd 3d5/2 for Pd0 is 334.8 eV in this work.

Using quasi in situ XPS, we further track the evolution of Pd and Zn chemical state during carburization in syngas. For Pd 3d core level (Fig. 2b), the fresh PdO/ZnO/Al2O3 sample shows a typical PdO state with Pd 3d5/2 at 336.6 eV. At above 90 °C, the PdO was initially reduced showing a prominent metallic Pd component emerging at 334.8 eV, and remained metallic state up to 200 °C. The upshift of Pd 3d5/2 to 335.4 eV was observed at 400 °C which is attributed to the formation of Pd alloy23 at this critical temperature. In the case of Zn, here we employ Zn LMM Auger band (Fig. 2c) because of high sensitivity to its chemical nature28,29. The fresh sample presents a typical ZnO feature with Zn LMM at 989.4 eV. Initial reduction of ZnO occurs at 120 °C exhibiting a characteristic twin-peak feature of Zn metal at 993.5 and 996.7 eV. The small fraction of the metallic Zn component suggests a low content of Zn insertion in the intermediate Pdt phase at this temperature. The gradually intensified signal of Zn metal (twin-peak feature) thus reflects a sustained infiltration of Zn with increasing temperature, which is in line with the consecutive upshift in XRD results. Until 400 °C, complete alloying/carburization of Pd3ZnCx was thus obtained as an indicator of abundant Zn metal (Fig. 2c) and carbide formation (Fig. 1i). It should be noted that ZnO is excess during this process, as indicated by the prominent diffraction peak of ZnO in the XRD (Fig. 2a and Fig. S15) and quasi in situ XPS results (Fig. 2c). Only a small amount of Zn is reduced, and co-infiltrated into the Pd3ZnCx, reflecting a inhibitive role of syngas in forming β1-PdZn alloy.

Environmental TEM was carried out to directly visualize the phase transition of the PdO/ZnO/Al2O3 during carburization (Fig. S17). Initially, PdO NPs were observed in the fresh sample under high vacuum conditions at 30 °C (Fig. S17a), with an average d-spacing of 0.260 nm for PdO(101). The formation of PdHx was observed immediately after introducing a syngas at 30 °C, with a characteristic d-spacing of 0.236 nm for β-PdHx(111), which remained stable up to 80 °C (Fig. S17b). Compared to metallic Pd NPs the lattice spacing was expanded attributed to the incorporation of H into the Pd NPs. Further increasing the temperature (80–120 °C) leads to a contraction of Pd lattice to 0.226 nm (Fig. S17c), which is very close to the lattice constant of transitional Pdt species determined by XRD. After fully carburized at 400 °C, the Pd3ZnCx phase was eventually formed, showing a typical d-spacing of 0.222 nm for Pd3ZnCx as observed ex situ in Fig. S17d.

Combining the in situ XRD, quasi in situ XPS and ETEM results, we unambiguously demonstrated phase transition of PdO → PdHx → Pdt → Pd3ZnCx during the carburization with syngas. The PdO NPs were first reduced at 40–90 °C and transformed to β-PdHx hydrides due to H infiltration. Further increasing temperature, the β-PdHx became thermally unstable up to 120 °C and decomposed gradually to α-PdHx. Along with the α-PdHx formation, the growth of intermediate Pdt species simultaneously occurred at 120 °C with initial insertion of a small amount of metallic Zn as verified by quasi in situ XPS. The gradual upshift of XRD peaks thus indicates the slow and sustained process of Zn/C infiltration that evolves continuously in a temperature range from 120 to 350 °C. The fully carburized Pd3ZnCx phase will not be achieved until 350 °C when intense insertion of zinc and carbon occurs.

The critical role of intermediate Pdt species in promoting Pd3ZnCx formation

The intermediate Pdt transitional state obtained by pretreating the PdO/ZnO/Al2O3 with syngas at 200 °C was further characterized. The HAADF-STEM image in Fig. 3a resolves a polycrystalline state of Pd NPs, with co-existence of multi-domains of α-PdHx (D(111) = 0.233~0.235 nm)27 and Pdt (D(111) = 0.223~0.225 nm) growing in between α-PdHx domains. Although the lattice of Pdt is very close to that of Pd metal or Pd3Zn, the incorporation of both carbon and zinc can be validated by EDS line scan (Fig. S18) despite a low amount. The initial incorporation of Zn was also verified by Zn LMM Auger spectra (Fig. 2c). Therefore, we can conclude that the Pdt species is an intermediate state during transition from PdHx to Pd3ZnCx with low Zn and C infiltration.

a High-resolution STEM images of Pdt at 200 °C and the corresponding local FFTs are displayed; crystal planes assigned to α-PdHx (red dots), the crystal plane indexed to Pdt (blue dots); yellow dash lines indicate the α-PdHx/Pdt interface; black arrows show the growth direction of Pd3ZnCx, which is perpendicular to the α-PdHx(111) planes. b In situ XRD patterns of PdO/ZnO/Al2O3 (i) and PdO/Al2O3 (ii) treatment by syngas from 100 to 400 °C. c TPSR characterization for PdO/ZnO/Al2O3 (red line) and PdO/Al2O3 (gray line) under syngas atmosphere monitored by XRD-MS. d Schematic diagram of the continuous growth of Pdt at the α-PdHx domain boundaries. The silver ball represents the Pd with the H coordination environment. The royal blue ball represents the Pd with the Zn coordination environment. The lake blue ball represents the Pd with the Zn and C coordination environment.

This initial formation of Pdt intermediates was clearly resolved occurring on the boundaries between polycrystalline α-PdHx domains, as depicted by yellow dots in Fig. 3a. The five different domains (R1~R5) on the surface can be identified as face-centered cubic (FCC) structured α-PdHx hydrides by fast Fourier transform (FFT), showing interplanar spacing D(111) = 0.233~0.235 nm characteristic for α-PdHx(111) with slightly varied H content. Between the two neighboring crystal boundaries, the belt-like Pdt domain (highlighted by blue) was clearly resolved which separates the adjacent α-PdHx territories. This strongly indicates the incorporation of carbon and zinc initiated on the domain boundaries of polycrystalline α-PdHx, and preferentially grows along PdHx<111> direction (marked with black arrows) when the Pdt domain expanded. This continuing transition of polycrystalline α-PdHx to Pdt and eventually to Pd3ZnCx also explains the consecutive upshift of Pd diffraction peak in XRD, rather than a trade-off of two crystalline phases.

At 120 °C, the abundant grain boundaries of α-PdHx were formed during the decomposition of β-PdHx hydrides that facilitated the subsequent insertion of Zn and carbon (α-PdHx + H2 + ZnO → α-Pd3Zn + H2O). The Zn LMM Auger spectra (Fig. 2c) validated the surface enrichment of reduced Zn with the increase of temperature. During this process, α-PdHx and Pdt domains coexisted until a fully carburized Pd3ZnCx formed at 350 °C.

To elucidate the critical role of Pdt in the carburization, we designed a control experiment by treating a PdO/Al2O3 catalyst (without ZnO) by syngas with the identical procedure. As shown by in situ XRD in Fig. 3b (ii), the phase transition of PdO/Al2O3 catalyst can be identified as PdO → β-PdHx → α-PdHx. Specifically, after Pd hydride was decomposed at 130 °C, the diffraction peak remained at 40.00°, suggesting the preference and stability of Pd metal rather than carbides under this condition. Herein, the formation of PdCx carbide is not favored in the absence of Zn, which can be rationalized by the higher capability of H2 dissociation on metallic Pd surface that inhibits the formation of surface/subsurface C* species from CO30. In contrast, the Zn infiltration during initial carburization of PdO–ZnO (Pdt phase), despite in a very small amount, can further open the channel for the infiltration of interstitial carbon.

On the other hand, carburization of the pre-synthesized PdZn intermetallic alloy (β1-PdZn) is also greatly inhibited due to excellent structural stability of PdZn alloy in syngas and semi-hydrogenation reaction conditions, as revealed by in situ XRD results (Fig. S15). Fully occupied interstitial site by Zn incorporation can substantially suppress the infiltration of C* species, which explains the infeasibility of previous attempts for the carburization of PdZn alloy7,31. Our results thus provide a co-infiltration strategy of both zinc and carbon during initial stage, promoting carbon infiltration on Pd3Zn (α-PdZn) as a practical approach to synthesize Pd-based intermetallic carbide.

To trace the origin of interstitial carbon, we further performed temperature-programmed surface reaction (TPSR) by coupling a mass spectrometer to the XRD setup (XRD-MS, see “Methods” section). The gaseous products of CO2 (m/z 44), H2O (m/z 18), CH4 (m/z 15), CO (m/z 28) were monitored in real-time during carburization by syngas, as shown in Fig. 3c and Supplementary Figs. S19, 20. Different from monometallic Pd/Al2O3, a prominent peak of CO2 formation was found on PdO/ZnO/Al2O3 catalyst in a rather low-temperature regime at 120–200 °C during the initial formation of Pdt. It thus suggests the source of carbon for the initial infiltration, likely via disproportionation reaction of CO, i.e. 2 CO→CO2 + C. CO dissociation (disproportionation) on Pd has been earlier reported on stepped Pd(112)32 and undercoordinated Pd sites20,21. We thus speculated that the enriched dislocations at Pd–Znsurface/PdHx phase boundaries could plausibly serve as active sites for this low-temperature CO disproportionation, promoting abundant surface C* species for co-infiltration into Pdt intermediates. Besides, the CO2 signal at high-temperature range (>300 °C) can be attributed to the side reaction (water–gas shift reaction) during CO hydrogenation (see Fig. S19).

To further validate the feasibility of the low-temperature disproportionation reaction, we employed DFT calculations to evaluate the reaction-free energies for the formation of Pd3ZnCx by reacting Pd3Zn with CO via Pd3Zn + 2x CO → Pd3ZnCx + x CO2, with variable carbon content (x, 0.01~1). As shown in Supplementary Table S3, by decreasing C:Pd ratio from 1 to 0.01, a trend becomes evident where lower C:Pd ratio renders the disproportionation reaction more favorable. Notably, at a C:Pd ratio of 0.13, the reaction becomes spontaneous with free energy of −0.18 eV. Particularly for our experimental results where the C:Pd ratio is 0.01, the reaction-free energy is only −0.26 eV that further underscores the thermodynamic feasibility of the new phase formation (Pd3ZnC0.03).

Based on the above-mentioned results, we can thus depict an overall picture for the formation of Pd3ZnCx intermetallic carbide (Fig. 3d). In syngas, PdO reduction first occurs to generate thermodynamically stable β-PdHx species (Eq. 1). With increasing temperature (>120 °C), the formation of polycrystalline α-PdHx species during β-PdHx decomposition facilitates the reduction of a small amount of vicinal ZnO, forming Pd–Znsurface surface alloys (likely Pd3Zn) initiated on the α-PdHx domain boundaries (Eq. 3)27. The enriched dislocations at Pd–Znsurface/PdHx boundaries thus catalyze the low-temperature CO disproportionation reaction (Eq. 4) providing carbon source for Pdt intermediates (Eq. 5). The intermediate Pdt continuously expands starting from the domain boundaries and opens up the channel for sustained infiltration of both Zn and C toward Pd3ZnCx (Eq. 6). Besides, a semi-quantitative calculation of trend comparisons from PdH to Pd3Zn and then Pd3ZnCx for each transition was carried out by DFT simulation. Figure S21 shows that it is thermodynamically spontaneous for the formation from PdH to Pd3Zn, and Pd3Zn to Pd3ZnC, which further validates the rationality of Pd3ZnCx generation.

Enhanced catalytic performance of Pd3ZnCx in acetylene hydrogenation

The catalytic performance of the unprecedented Pd3ZnCx intermetallic carbides was tested for selective hydrogenation of acetylene in an excess of ethylene under two conditions with different H2/C2H2 ratios, by comparing with the conventional PdZn catalyst (Fig. 4). In the tail-end method, the H2/C2H2 ratio is close to the stoichiometric ratio, as presented in Fig. 4a. The Pd3ZnCx shows significantly higher activity (acetylene conversion) than PdZn in a wide range of temperature (40 °C~120 °C), while maintaining high ethylene selectivity (>90%). In the front-end method, the hydrogen content is relatively higher, and we choose H2/C2H2 = 4 as shown in Fig. 4b. Notably at high H2/C2H2 ratio of 4 (Fig. 4b), the Pd3ZnCx still exhibits superior activity in low-temperature range (40 °C~120 °C), and maintains high ethylene selectivity (>80%) at high acetylene conversion (120 °C~160 °C). As can be seen, the Pd3ZnCx has excellent ethylene selectivity under both tail-end and front-end conditions. In contrast, the PdZn catalyst, however, has a sharp decline in ethylene selectivity below 30% at high acetylene conversion under the front-end condition.

Acetylene conversion (bar plot) and ethylene selectivity (line plot) of the Pd3ZnCx (red) and PdZn (black) catalysts in selective hydrogenation of acetylene in an excess of ethylene, with different H2/C2H2 ratio. a 2% C2H2, 2.2% H2 and 80% C2H4 in balance with He (H2/C2H2 = 1); b 2% C2H2, 8% H2 and 80% C2H4 in balance with He (H2/C2H2 = 4). Reaction conditions: space velocity = 5000 mL g−1 h−1; pressure = 0.5 MPa. c Durability test on Pd3ZnCx for 200 h at 120 °C, and STEM images after the durability test as inset. Pd loading: 0.08 wt%. Feed gas: 2% C2H2, 2.2% H2 and 80% C2H4 in balance with He. Reaction conditions: space velocity = 5000 mL g−1 h−1; pressure = 0.5 MPa. d Catalytic performance of Pd3ZnCx and other reported transition metal catalysts in literatures for the semi-hydrogenation of acetylene (Data from Table S4). e DFT calculated surface model of PdZn and Pd3ZnCx (top view). f Free energy profiles of acetylene hydrogenation on PdZn and Pd3ZnCx catalysts.

Furthermore, the mass activity of Pd3ZnCx catalyst was calculated using the method proposed by Osswald et al.33, and compared with other transition metal catalysts in the literature34,35,36,37,38,39,40,41. As displayed in Fig. 4d and Table S4, Pd3ZnCx showed the highest selectivity at high acetylene conversions far beyond a vast variety of transition metal catalysts. Meanwhile, Pd3ZnCx also exhibits strikingly high activity-per-mass, 1.4 times that of the PdZn intermetallic compounds, which is among the highest reported values under the acetylene-hydrogenation industrial condition operating <120 °C, and remarkably higher turnover frequencies (TOF), ~2.9 times that of conventional PdZn catalyst (Table S5).

The durability of the Pd3ZnCx catalyst was further evaluated at 120 °C for 200 h, as shown in Fig. 4c. An excellent durability was observed showing only a slight decrease in selectivity from 97% to 91% after the 200 h time-on-stream test with stable acetylene conversion as high as 94%. Both fresh (Fig. 4c) and spent (Fig. S22) Pd3ZnCx catalysts present an excellent structural stability after long-term durability test, showing 0.222 nm spacing for Pd3ZnCx(111). Compared with PdZn alloy and other Pd catalysts in literatures, this unprecedented Pd3ZnCx intermetallic carbide has shown superior activity, selectivity and stability for the selective hydrogenation of acetylene.

The superior activity of Pd3ZnCx can be attributed to its excellent H2 dissociation ability. The H2–D2 exchange experimental results (Fig. S23) showed the formation of HD (deuterium hydride) over the Pd3ZnCx at as low as 25 °C, implying a favored hydrogen dissociation even at room temperature. On the contrary, the production of HD was not favored and rapidly declined for PdZn at the same temperature. Figure S24 showed the formation of HD over the Pd3ZnCx at the whole test temperature range from 25 to 200 °C, implying a favored hydrogen dissociation on Pd3ZnCx sample. The enhanced H2 dissociation ability of Pd3ZnCx can be attributed to the electron-rich Pd sites in Pd3ZnCx42,43, and thus facilitates hydrogenation of acetylene.

DFT calculations further reveal the catalytic superiority of Pd3ZnCx in the acetylene hydrogenation reaction. Free energy profiles in Fig. 4f demonstrate that the first hydrogenation barrier on Pd3ZnCx (0.58 eV) is lower than that of PdZn (0.77 eV), promoting the hydrogenation activity. The desorption of ethylene on Pd3ZnCx is spontaneous, which accounts for its high selectivity of ethylene. Furthermore, the higher barrier for deep hydrogenation on Pd3ZnCx (0.93 eV) also inhibits further reactions, thereby further enhancing the selectivity toward ethylene. Calculations of the reaction pathways were also conducted for other comparative catalysts, including Pd and Pd3Zn (Fig. S25). The results similarly underscore the exceptional catalytic performance of Pd3ZnCx. Besides, high H2/C2H2 ratio condition was also considered for Pd3ZnCx catalyst with H* coverage calculation in Fig. S28 (Pd3ZnCx–H catalyst). Based on the thermodynamically preferred reaction pathway (Fig. S29), we performed calculations of the complete acetylene hydrogenation reaction profiles on Pd3ZnCx–H catalyst (Fig. S30), which reveals that under H* coverage, the reaction barrier of Pd3ZnCx–H for the first hydrogenation step is still lower than PdZn, proving the superior catalytic performance of Pd3ZnCx. It should be mentioned that a common disproportionation elementary step in the hydrogenation of acetylene, that is, the instead of generating CH2CH2, the hydrogenation of *CHCH2 to *CHCH3, is also computationally compared (Fig. S31). Both thermodynamic and kinetic results show that for Pd3ZnCx, *CHCH2 will prefer to generate CH2CH2 rather than *CHCH3. Higher barrier of C–C coupling was also found on Pd3ZnCx (Figs. S32, S33), suggesting its high resistance to coke formation. Moreover, the energy barrier for H2 dissociation on Pd3ZnCx (Fig. S34) is significantly lowered compared to PdZn. This indicates that Pd3ZnCx is also conducive to facilitating H2 dissociation, thereby promoting the occurrence of selective hydrogenation of acetylene44.

The origin of the superior catalytic performance of Pd3ZnCx was further investigated. Due to the electronegativity differences among Pd (2.20), Zn (1.65) and C (2.55), there is a significant charge transfer from Zn to Pd, resulting in an electron enrichment of 0.16 e− for Pd in Pd3Zn, and from Pd to C, adding 0.09 e− upon carbon incorporation. This charge redistribution is also confirmed by charge density difference (Fig. S35), leading to an increased electron density on Pd and a lower d-band center (−2.23 eV) in Fig. S36, weakening C2H4 adsorption. Projected Density of States (PDOS) analysis (Fig. S34) indicates a broadened d-band and more active electrons near the Fermi level in Pd3ZnCx, enhancing acetylene hydrogenation and H2 dissociation. The adsorption configurations are shown in Fig. S37. Geometrically, the most stable C2H2 adsorption configuration is at the fcc site on Pd3ZnCx surfaces, with each C atom bridging two Pt sites, enhancing C2H2 adsorption. C2H4 shows a favorable π-bonding mode, similar to PdZn (Fig. S38), indicating geometric favorability for Pd3ZnCx.

Discussion

Using co-infiltration strategy, we reported an unprecedented intermetallic carbide of Pd3ZnCx in one-step carburization of PdO–ZnO via syngas. State-of-the-art in situ characterizations explicitly revealed a dynamic phase transition as PdO → PdHx → Pdt → Pd3ZnCx. The initial formation of Pdt transitional state with low Zn and C content was identified as a crucial intermediate promoting phase transition and sustainable infiltration of zinc and carbon toward Pd3ZnCx formation. Comparing to conventional PdZn intermetallic catalysts and other reported Pd-based catalysts, the Pd3ZnCx intermetallic carbide shows by far the best catalytic performance for the selective hydrogenation of acetylene, maintaining high selectivity (>90%) and excellent stability (~200 h) at high acetylene conversion. The insertion of interstitial C enables the electron enrichment of Pd3Zn sites that further facilitate ethylene desorption and the hydrogen dissociation resulting in its enhanced catalytic performance. Our results thus developed a co-infiltration strategy for one-step synthesis of Pd3ZnCx intermetallic carbide, as a practical approach to synthesizing high-performance Pd-based intermetallic carbide toward selective hydrogenation of acetylene.

Methods

Chemicals and materials

Palladium (II) diacetylacetonate (34.7 wt% Pd) was purchased from Alfa Aesar Shanghai Co., Ltd.; zinc nitrate hexahydrate was purchased from Damao Tianjin Co., Ltd.; toluene was purchased from Sinopharm Chemical Reagent Co., Ltd.; α-Al2O3 (surface area of 5.4 m2 g−1) was purchased from Aluminum Industry Shangdong Co., Ltd. All the reagents were of analytical grade and used as-received without further purification.

Sample preparation

ZnO/Al2O3 catalyst was synthesized by incipient wet impregnation of Al2O3 powder with Zn(NO3)2 as precursor. Briefly, 546.0 mg Zn(NO3)2·6H2O was dissolved in 1.3 g DI H2O to form a clear solution, and to this solution 2.0 g Al2O3 powder was added. The resultant slurry was allowed for standing at room temperature overnight, and then dried at 120 °C for 12 h and calcined at 400 °C for 3 h. The Zn loading of the ZnO/Al2O3 was determined to be 5.5 wt% by inductively coupled plasma atomic emission spectrometry (ICP-OES).

The Pd was supported on ZnO/Al2O3 through a wet impregnation method. In detail, 286.5 mg (5 wt% Pd) or 4.6 mg (0.08 wt% Pd) palladium diacetylacetonate was dissolved in 60 g toluene under ultrasonication for several minutes. Then, 2.0 g ZnO/Al2O3 powder was added to the solution and stirred for 30 min to obtain a homogeneous dispersion. After removing toluene by vacuum distillation with a rotary evaporator at 60 °C, the samples were calcined at 400 °C for 3 h and served as the fresh catalyst for further treatment or testing. The low-loading sample (0.08 wt% Pd) with an average particle size of 5 nm was used for catalytic testing and H2–D2 exchange reaction, while the high-loading sample (5 wt%) with an average particle size of 16 nm was used for in situ experiments to gain a satisfied signal/noise ratio. ZnO was excessive compared with Pd.

Material characterizations

Aberration-corrected HAADF-STEM

Aberration-corrected HAADF-STEM imaging was performed on a JEOL JEM-ARM200F equipped with a probe Cs-corrector working at 200 kV. For the HAADF imaging, a convergence angle of ~23 mrad and a collection angle range of 68–174 mrad were adapted for the incoherent atomic number imaging. The elemental composition as well as distribution were analyzed with an energy dispersive X-ray analyzer (EDS, EX-230 100 m2 detector) equipped on the microscope. The sample was ultrasonically dispersed in ethanol for 15–20 min, and then a drop of the suspension was dropped on a copper TEM grid coated with a thin holey carbon film.

Environmental TEM

Environmental TEM experiments were carried out on the Titan Themis G3 ETEM (Thermo Scientific Company) in the electron microscopy center at the Dalian Institute of Chemical Physics Chinese Academy of Sciences, which was working at 300 kV with a Cs corrector for parallel imaging (CEOS GmbH) and a measured resolution of better than 1.0 Å. The sample was loaded on a Si3N4 membrane and heated in situ using a micro-electromechanical system (MEMS) based sample holder (FEI NanoEX).

Inductively coupled plasma optical emission spectrometer (ICP-OES)

Pd and Zn contents of the samples were determined by ICP-OES. Before the experiment, a microwave digestion system (Anton Paar Multiwave 3000) was used to dissolve ~100 mg of PdO/ZnO/Al2O3 sample, which was then analyzed with the ICP-OES method (PerkinElmer 7300DV) to obtain the loading of Pd and Zn.

In situ X-ray diffraction (XRD)

In situ XRD measurements were conducted on a PANalytical Empyrean diffractometer with in situ reactor (XRK900) using CuKα radiation, operated at 40 kV and 40 mA. The PdO/ZnO/Al2O3 sample with 5 wt% Pd was transferred to an in situ reactor with the beryllium window. Then the syngas (10%CO–50%H2–40%He) or 50%H2–50%He flow at 50 mL min−1 was introduced after the inert gas flushing, with a heating rate of 5 °C min−1 from room temperature to 400 °C. The XRD patterns were recorded at desired temperatures from 36° to 60°. All XRD data were measured multiple times on different batches of samples which were consistent and reproducible.

XRD-MS setup

The gas composition during in situ XRD was monitored by an online mass spectrometer (Pfeiffer OmniStar) to the outlet of the in situ reactor. The detection point of mass spectrometry was located 150 cm down flow of the XRD in situ reactor, and excess exhaust gas was discharged from the exhaust pipe through a three-way valve.

Quasi in situ X-ray photoelectron spectroscopy (XPS)

Quasi in situ XPS was performed on a ThermoFisher ESCALAB 250Xi+ equipped with a gas cell directly mounted to the sample chamber. The quasi in situ measurements enable direct sample transfer under UHV condition for XPS analysis after a certain treatment without exposure to air. All the spectra were recorded using monochromated X-ray irradiation Al Kα (hv = 1486.7 eV) at room temperature. The peak positions were calibrated by adjusting the C 1s peak to 284.8 eV and Al 2p peak to 74.5 eV. All the samples were treated in the gas cell with syngas (10%CO–50%H2–40%He) or 50%H2–50%He flow at 50 mL min−1.

X-ray absorption fine structure (XAFS) spectra

XAFS spectra at Pd K-edge of the samples were measured at beamline 14 W of the Shanghai Synchrotron Radiation Facility (SSRF) in China. The output beam was selected by Si (311) monochromator. The energy was calibrated by the Pd foil. Before measurement, the samples were reduced at 400 °C under syngas (Pd3ZnCx) or under hydrogen (PdZn), and cooled to room temperature. Then the samples were transferred to glove box without exposure to air. The samples were sealed in Kapton films in the glove box before XAFS measurement. The data were collected at room temperature under transmission mode by using solid state detector. Athena software package was employed to process the EXAFS data.

H2–D2 exchange reaction

H2–D2 exchange reaction was evaluated at a Micromeritics Chemisorption Analyzer AutoChem II equipped with a Pfeiffer OmniStar mass spectrometer. In total, 100 mg catalyst was first reduced in 10%CO–50%H2–40%He or 50%H2–50%He at 400 °C for 2 h and then was cooled down to room temperature in He. The catalyst was then tested for H2–D2 exchange reaction under a standard condition: a gas mixture of H2 and D2 with a flow rate of 18 and 14 mL/min, respectively.

Catalytic testing

The selective hydrogenation of acetylene over Pd-based catalysts was tested in a fixed-bed flow reactor. The total flow rate was kept at 4.17 ml min−1. The amount of Pd-based catalysts was 50 mg. Before the reaction test, all the catalysts were reduced in 10%CO–50%H2–40%He or 50%H2–50%He at 400 °C for 2 h, and then cooled down to reaction temperature. The catalytic performance was evaluated in a gas feed of 2% C2H2, 2.2% H2 and 80% C2H4 in balance with He for H2/C2H2 = 1; and 2% C2H2, 8% H2 and 80% C2H4 in balance with He for H2/C2H2 = 4. Space velocity = 5000 mL g−1 h−1; pressure = 0.5 MPa. Both the inlet and outlet gases were analyzed online with an Agilent Technologies 7890B gas chromatograph equipped with a flame ionization detector (FID) packed with a capillary column (Agilent HP-PLOT Al2O3 S; 50 m × 0.530 mm). To accurately quantify the concentration of gas components, the relatively inert CH4 gas was used as the internal standard doped in the reaction atmosphere. The acetylene conversion and ethylene selectivity were calculated according to equations:

C2H2(in) and C2H2(out) are the concentrations of acetylene at the inlet and outlet of the reactor, respectively. C2H6(in) and C2H6(out) are the concentrations of ethane at the inlet (unavoidable impurity in feed gas) and outlet of the reactor, respectively.

The TOF value was calculated based on the surface moles of Pd. The metal dispersion of Pd for Pd3ZnCx and PdZn samples was 24.7 and 21.1%, respectively, detected by CO pulse chemisorption.

Calculation methods

We conducted calculations using the Vienna ab initio Simulation Package with the projector augmented wave method and the generalized gradient approximation in the form of the Bayesian error estimation functional with van der Waals corrections (BEEF–vdW) for periodic boundary conditions45,46,47. The phase structures were built with different C ratios, optimized, and analyzed using XRD spectra. The cutoff energy for the plane-wave basis set was 400 eV, with fixed bottom two layers and a 15 Å separation along the Z direction to minimize slab interactions. A 0.02 eV/Å criterion was used for atomic force convergence during geometry optimization. K-point sampling was done with a 3 × 3 × 1 mesh using the Monkhorst–Pack method48. The basic modeling structures are provided on GitHub (https://github.com/TJU-ECAT-AI/Pd3ZnCx-DFT-Structures).

Transition states (TS) were found using the CI-NEB technique with six intermediate images, followed by refinement using the dimer method with a force tolerance of 0.02 eV/Å49,50. A normal mode analysis confirmed the TS structures. Free energy reaction profiles were calculated to include entropy and ZPE. We used the equation Sads = 0.7Sgas − 3.3R to calculate the adsorbate entropy51, with Sgas obtained from a thermodynamic database using heat capacity extrapolation for unlisted temperatures.

Data availability

All the data supporting the findings of this study are available within the article and its Supplementary Information files or from the corresponding authors upon reasonable request. Source data are provided with this paper.

References

McCue, A. J. & Anderson, J. A. Recent advances in selective acetylene hydrogenation using palladium containing catalysts. Front. Chem. Sci. Eng. 9, 142–153 (2015).

Borodziński, A. & Bond, G. C. Selective hydrogenation of ethyne in ethene-rich streams on palladium catalysts. Part 1. Effect of changes to the catalyst during reaction. Catal. Rev. 48, 91–144 (2006).

Pei, G. X. et al. Ag alloyed Pd single-atom catalysts for efficient selective hydrogenation of acetylene to ethylene in excess ethylene. ACS Catal. 5, 3717–3725 (2015).

Pei, G. X. et al. Promotional effect of Pd single atoms on Au nanoparticles supported on silica for the selective hydrogenation of acetylene in excess ethylene. New J. Chem. 38, 2043–2051 (2014).

Pei, G. X. et al. Performance of Cu-alloyed Pd single-atom catalyst for semihydrogenation of acetylene under simulated front-end conditions. ACS Catal. 7, 1491–1500 (2017).

Armbrüster, M. et al. Pd-Ga intermetallic compounds as highly selective semihydrogenation catalysts. J. Am. Chem. Soc. 132, 14745–14747 (2010).

Zhou, H. R. et al. PdZn intermetallic nanostructure with Pd–Zn–Pd ensembles for highly active and chemoselective semi-hydrogenation of acetylene. ACS Catal. 6, 1054–1061 (2016).

Vignola, E. et al. Evaluating the risk of C–C bond formation during selective hydrogenation of acetylene on palladium. ACS Catal. 8, 1662–1671 (2018).

Molnár, A., Sárkány, A. & Varga, M. Hydrogenation of carbon-carbon multiple bonds: chemo-, regio- and stereo-selectivity. J. Mol. Catal. A Chem. 173, 185–221 (2001).

Teschner, D. et al. The roles of subsurface carbon and hydrogen in palladium-catalyzed alkyne hydrogenation. Science 320, 86–89 (2008).

Niu, Y. M. et al. Manipulating interstitial carbon atoms in the nickel octahedral site for highly efficient hydrogenation of alkyne. Nat. Commun. 11, 9 (2020).

Wang, Y., Liu, B. Y., Lan, X. C. & Wang, T. F. Subsurface carbon as a selectivity promotor to enhance catalytic performance in acetylene semihydrogenation. ACS Catal. 11, 10257–10266 (2021).

Borodziński, A. & Bond, G. C. Selective hydrogenation of ethyne in ethene-rich streams on palladium catalysts, Part 2: Steady-state kinetics and effects of palladium particle size, carbon monoxide, and promoters. Catal. Rev. 50, 379–469 (2008).

Rahimpour, M. R. et al. A novel configuration for Pd/Ag/α-Al2O3 catalyst regeneration in the acetylene hydrogenation reactor of a multi feed cracker. Chem. Eng. J. 198-199, 491–502 (2012).

Zhang, X. B. et al. Reversible loss of core–shell structure for Ni–Au bimetallic nanoparticles during CO2 hydrogenation. Nat. Catal. 3, 411–417 (2020).

Ouyang, M. Y. et al. Directing reaction pathways via in situ control of active site geometries in PdAu single-atom alloy catalysts. Nat. Commun. 12, 1549 (2021).

Ahmadi, M., Cui, C. H., Mistry, H., Strasser, P. & Cuenya, B. R. Carbon monoxide-induced stability and atomic segregation phenomena in shape-selected octahedral PtNi nanoparticles. ACS Nano 9, 10686–10694 (2015).

Xu, M. W. P. & Brown, J. J. Mechanism of iron catalysis of carbon monoxide decomposition in refractories. J. Am. Ceram. Soc. 72, 110–115 (1989).

Niu, L. W. et al. Genesis of an Fe5C2@Fe3O4 core/shell structure during CO carburization of metallic iron nanoparticles. J. Catal. 407, 97–103 (2022).

Maciejewski, M. & Baiker, A. Incorporation of carbon into palladium during low-temperature disproportionation of carbon monoxide over palladium/zirconia prepared from glassy palladium-zirconium. J. Phys. Chem. 98, 285–290 (1994).

Gredig, S., Tagliaferri, S., Maciejewski, M. & Baiker, A. Oxidation and disproportionation of carbon monoxide over Pd/ZrO2 catalysts prepared from glassy Pd-Zr alloy and by coprecipitation. Stud. Surf. Sci. Catal. 96, 285–295 (1995).

Shao, L. D. et al. Improved selectivity by stabilizing and exposing active phases on supported Pd nanoparticles in acetylene-selective hydrogenation. Chem. Eur. J. 18, 14962–14966 (2012).

Rameshan, C. et al. Subsurface-controlled CO2 selectivity of PdZn near-surface alloys in H2 generation by methanol steam reforming. Angew. Chem. Int. Ed. 49, 3224–3227 (2010).

Liu, Y. N. et al. Adsorbate-induced structural evolution of Pd catalyst for selective hydrogenation of acetylene. ACS Catal. 10, 15048–15059 (2020).

Ziemecki, S. B., Jones, G. A., Swartzfager, D. G. & Harlow, R. L. Formation of interstitial palladium-carbon phase by interaction of ethylene, acetylene, and carbon monoxide with palladium. J. Am. Chem. Soc. 107, 4547–4548 (1985).

Denton, A. R. & Ashcroft, N. W. Vegard’s law. Phys. Rev. A 43, 3161–3164 (1991).

Niu, Y. M. et al. Visualizing formation of intermetallic PdZn in a palladium/zinc oxide catalyst: interfacial fertilization by PdHx. Angew. Chem. Int. Ed. 58, 4232–4237 (2019).

Antonides, E., Janse, E. C. & Sawatzky, G. A. LMM auger spectra of Cu, Zn, Ga, and Ge. I. Transition probabilities, term splittings, and effective Coulomb interaction. Phys. Rev. B 15, 1669–1679 (1977).

Biesinger, M. C., Lau, L. W. M., Gerson, A. R. & Smart, R. S. C. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Sc, Ti, V, Cu and Zn. Appl. Surf. Sci. 257, 887–898 (2010).

Velasco-Vélez, J. J. et al. The role of adsorbed and subsurface carbon species for the selective alkyne hydrogenation over a Pd-black catalyst: an operando study of bulk and surface. Top. Catal. 61, 2052–2061 (2018).

Iwasa, N., Masuda, S., Ogawa, N. & Takezawa, N. Steam reforming of methanol over Pd/ZnO: effect of the formation of PdZn alloys upon the reaction. Appl. Catal. A 125, 145–157 (1995).

Wille, A., Nickut, P. & Al-Shamery, K. Low temperature dissociation of CO at reactive step sites of Pd(112). J. Mol. Struct. 695-696, 345–352 (2004).

Osswald, J. et al. Palladium-gallium intermetallic compounds for the selective hydrogenation of acetylene Part II: Surface characterization and catalytic performance. J. Catal. 258, 219–227 (2008).

Huang, F. et al. Low-temperature acetylene semi-hydrogenation over the Pd1–Cu1 dual-atom catalyst. J. Am. Chem. Soc. 114, 18485–18493 (2022).

Ayodele, O. B., Shittu, T. D., Togunwa, O. S., Yu, D. & Tian, Z.-Y. XAS and DFT investigation of atomically dispersed Cu/Co alloyed Pt local structures under selective hydrogenation of acetylene to ethylene. Chem. Eng. J. 479, 147496 (2024).

Ballesteros-Soberanas, J. et al. A MOF-supported Pd1-Au1 dimer catalyses the semihydrogenation reaction of acetylene in ethylene with a nearly barrierless activation energy. Nat. Catal. 7, 452–463 (2024).

Wu, Q., Shen, C., Sun, K., Liu, M. & Liu, C.-j Selective hydrogenation of acetylene over Pd/In2O3@SiO2: the effect of the catalyst reduction temperature. Chem. Eng. J. 486, 150333 (2024).

Yurpalova, D. V. et al. Design of efficient supported Pd-Co catalysts for selective hydrogenation of acetylene. J. Catal. 432, 115417 (2024).

Zhai, P., Cullen, D. A. & Ding, K. The role of surface chemistry in the synthesis of supported CuPd bimetallic/intermetallic catalysts for selective hydrogenation reactions. Chem. Eng. J. 480, 148238 (2024).

Zhou, S. et al. Partial carbon encapsulation synthesis of separated Ni-Ag catalyst for efficient selective hydrogenation of acetylene: synergizing hydrogen spillover and steric hindrance. Appl. Catal. A 673, 119590 (2024).

García-Mota, M., Bridier, B., Pérez-Ramírez, J. & López, N. Interplay between carbon monoxide, hydrides, and carbides in selective alkyne hydrogenation on palladium. J. Catal. 273, 92–102 (2010).

Harris, J. & Andersson, S. H2 dissociation at metal surfaces. Phys. Rev. Lett. 55, 1583–1586 (1985).

Zhang, L. L., Zhou, M. X., Wang, A. Q. & Zhang, T. Selective hydrogenation over supported metal catalysts: from nanoparticles to single atoms. Chem. Rev. 120, 683–733 (2020).

Wang, S. et al. Activation and spillover of hydrogen on Sub-1 nm palladium nanoclusters confined within sodalite zeolite for the semi-hydrogenation of alkynes. Angew. Chem. Int. Ed. 58, 7668–7672 (2019).

Mortensen, J. J. et al. Bayesian error estimation in density-functional theory. Phys. Rev. Lett. 95, 216401 (2005).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Hafner, J. Ab initio molecular-dynamics simulation of the liquid-metal-amorphous-semiconductor transition in germanium. Phys. Rev. B 49, 14251–14269 (1994).

Monkhorst, H. J. & Pack, J. D. Special points for Brillonln-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000).

Henkelman, G. & Jónsson, H. A dimer method for finding saddle points on high dimensional potential surfaces using only first derivatives. J. Chem. Phys. 111, 7010–7022 (1999).

Campbell, C. T. Bimetallic surface-chemistry. Annu. Rev. Phys. Chem. 41, 775–837 (1990).

Acknowledgements

This work was financially supported by the National Key R&D Program of China (No. 2023YFA1506603), National Natural Science Foundation of China (Nos. 22132006, 22072151, 22121004), the NSFC Center for Single-Atom Catalysis (No. 22388102), China Postdoctoral Science Foundation (No. 2023M733452) and B.Y. acknowledges the CAS Project for Young Scientists in Basic Research (YSBR-022), and Dalian Institute of Chemical Physics (DICP I202107). We also acknowledge generous computing resources at High Performance Computing Center of Tianjin University.

Author information

Authors and Affiliations

Contributions

T.Z., A.W. and B.Y. conceived and designed the project. H.C. prepared the catalysts and performed the catalytic testing, the in situ XRD experiments, the XRD–TPSR experiments, H2–D2 exchange experiments, and data analysis. J.G., Z.Z. and L.L. performed the theoretical calculations. Y.Z. performed STEM/ETEM imaging and data analysis. Q.G. performed quasi in situ XPS measurements. X.L. and Z.Y. conducted the XAFS experiments and data analysis. H.C., B.Y. and A.W. wrote the paper. X.Y. participates in discussion and manuscript writing. All authors contributed to the discussion and edited the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chen, H., Li, L., Zhao, ZJ. et al. Co-infiltration and dynamic formation of Pd3ZnCx intermetallic carbide by syngas boosting selective hydrogenation of acetylene. Nat Commun 15, 9850 (2024). https://doi.org/10.1038/s41467-024-54274-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-024-54274-2