Abstract

The modulation of the electrostatic potential barrier at grain boundaries determines the performance of many ceramic-based electronics such as varistors. However, conventional protocols relying on complex doping and annealing processes inevitably increase the inhomogeneity of microstructure, which may jeopardize the performance stability and mechanical reliability in service. Instead of doping, herein we demonstrate an effective strategy to modulate the potential barrier in ZnO-based low-voltage varistors by exploiting internal stress-induced piezoelectric polarization. The local residual stress as large as ~1 GPa can be created in the ZnO matrix by incorporating ultra-stiff nanodiamond particles using a cold sintering process. As a result, the composite with only 2 wt% of nanodiamond exhibits a prominent nonlinear current-voltage response at a low switch voltage of 15.7 V/mm, which is ascribed to the depressed barrier height induced by the distinct effects of positively and negatively charged polarization on grain boundaries. More strikingly, the large internal stress can significantly enhance the strength of the composite by more than 230% compared with the monolith, owing to the highly strengthened grain boundaries and crack-tip bridging from prestressed nanodiamonds. These findings add internal stress as a new dimension to design mechanically robust ceramic electronics with high performance.

Similar content being viewed by others

Introduction

The trapped electrons and correspondingly formed potential barriers at grain boundaries (GBs) govern many physical properties of ceramic materials applied in varistors, thermoelectric materials, solar cells, and semiconducting technologies1,2. Typically, the modulation of potential barriers often requires complex design of GB composition via multiple-element doping and long-time annealing under reductive or oxidative atmosphere. As a critical electronic component that can provide a highly nonlinear current-voltage response to protect the electronics from surges in circuits, the ZnO-based varistor nowadays could contain more than five types of dopants to adjust the potential barrier (known as double Schottky barrier) at GBs3. Consequently, the inhomogeneity in microstructure is inevitably increased, which is detrimental for the stability of varistor performance, especially for low-voltage applications4. Compared with high-voltage applications, the demands for low-voltage varistors become increasingly strong in recent years due to the fast development of integrated circuits and semiconductor electronics. To largely depress the switch voltage in varistors, the ceramics with exaggeratedly grown grains usually have to be fabricated as thinly as possible5. However, the thin-layer design of ZnO ceramic results in not only increased sensitivity to microstructure due to very few GBs along the electrical field but also rising risks of mechanical failure with decreasing thickness.

Therefore, it is desirable to find an alternative strategy for engineering the potential barrier in ZnO-based low-voltage varistor. Besides the contribution from dopants, it has long been recognized that the piezoelectric effect also plays a role due to the non-central symmetric wurtzite structure of ZnO6. However, the effect is generally insignificant for most ZnO-based varistors because of the small internal stress generated via high-temperature sintering (HTS). In comparison, experiments on ZnO-based bicrystals with predetermined polarization vectors have revealed that large external compressive stress can greatly reduce the potential barrier height in a head-to-heat orientation of vectors along c axis, while increase the potential height in a tail-to-tail orientation7. Although these findings show the potential as piezotronic devices, the modulation of potential barrier via internal stress is far more preferred in practice, since varistors are rarely subjected to large external mechanical loadings.

Indeed, early works have shown that internal thermal stress could influence the distribution of barrier height8, but the change in current-voltage response is very limited compared with the response under external loading. In this work, we report a simple yet highly effective strategy to modulate the internal stress in undoped ZnO ceramic for achieving prominent nonlinear current-voltage response at low-voltage. In contrast to the small thermal stress (~100 MPa) generated by the difference of thermal expansion coefficient (TEC) through high-temperature sintering8, the local residual stress around 1 GPa can be created by the difference in elastic modulus between ZnO matrix and dispersed ultra stiff nanodiamond (ND) particles, which can be readily controlled by applied pressure during cold sintering process (CSP).

Distinct from HTS which relies on thermal diffusion at elevated temperatures, CSP can realize the densification at very low temperatures (200–300 °C) with the assistance of a transient liquid phase under high pressure (102−103 MPa)9,10,11. Among the oxides and nonoxides prepared by CSP12,13,14, ZnO is one of the most attractive ceramics for its prominent densification phenomenon. With various transient liquids and powder characteristics15,16, the sintering of ZnO ceramic with relative density above 96% can be achieved below 300 °C, which enables the fabrication of ZnO matrix composites with polymers17. Although some of these composites exhibit varistor-like behavior, the breakdown voltages are very high owing to the tunneling effect through penetrated insulating polymers18,19. In this work, the detrimental phase transformation of NDs is completely avoided by the low densification temperature of CSP, which allowed us to investigate the effect of large internal stress on potential barriers at GBs. In addition, the prestressed ND particles can also largely improve the strength of ZnO ceramic with high reliability. Together, our strategy provides a novel route to design electrically and mechanically reliable low-voltage varistors for future applications such as semiconductor electronics.

Results

Modulation of internal stress via cold sintering

Conventionally, the internal residual stress in ceramic is generated by HTS after cooling down to room temperature, which is ascribed to the anisotropic thermal expansion of grains as well as the different TECs between the matrix phase and the second phase. As a result, the residual stress in ZnO base varistors is generally small due to the insufficient TEC difference between the ZnO and interphases formed by dopants. In light of previous works of tuning I-V response by using external uniaxial or hydrostatic forces, we propose a novel strategy of exploiting applied pressure during sintering to create prestress between ZnO and rigid nanoparticles. To maximize the prestress generated by sintering pressure, the introduced nanoparticles should possess stiffness as large as possible with respect to the matrix (Fig. 1a). As a wide band gap semiconductor, the artificial ND exhibits giant Young’s modulus over 1000 GPa20, which makes it an ideal candidate for creating large internal stress. However, the surface of ND particles tends to graphitize at elevated temperatures (i.e. 600 °C above) due to their small size21, which could severely deteriorate the stiffness. In fact, the composite prepared by conventional pressureless sintering results in a complete loss of ND even with the protection of inert gas (Figs. S1–2 and Table S1). Therefore, we fully densified the ceramic composites by CSP at merely 300 °C to avoid degradation of ND while provide sufficient pressure for creating large residual stress. The conditions of densification were optimized to reach above 97% for the ZnO composites (Table S2 and Fig. S3), which is in consistent with the observed poreless feature on the fracture surface by SEM (Fig. 1b).

a Schematic diagram illustrating the thermal stress and prestress generated by HTS and CSP, respectively. b SEM image of a fractured surface of an ND/ZnO composite showing ND particles embedded in ZnO matrix, where embedded NDs are indicated by arrows. c TEM image of ND/ZnO composite, where the ND particles marked by arrows are located at GBs or triple junctions. d Normal strain distribution for monolithic ZnO (blue) and the region close to ND (red) along the εxx direction in the area marked in c, respectively; the insets are corresponding GPA images for the monolithic ZnO (left) and composite (right), respectively.

To obtain homogeneous microstructure in composites, the acid-treated ND particles (Fig. S4–7) and nanoscale ZnO powder were mixed by using a colloidal heteroaggregation strategy (Fig. S8-9) (see details in Methods). After CSP, the uniform dispersion of NDs with an average particle size of ~100 nm in ZnO matrix can be distinguished on the fracture surface by their sharp-edged morphology and brighter contrast with respect to the ZnO matrix (Fig. 1b and Fig. S10). All NDs are embedded at the grain boundaries of ZnO grains without exception according to SEM and TEM observations (Fig. 1c and Fig. S11). Compared with the monolithic ZnO (Fig. S12), the homogeneity of microstructure in the composite is improved by the incorporation of ND particles, which is critical for the reliability of electrical and mechanical properties. In addition, while the cold sintered monolithic ZnO shows obvious grain growth from ~30 nm (powder) to bulk (813 ± 68 nm), the addition of NDs greatly inhibits the grain growth to 325 ± 29 nm for 2 wt% ND composite and 237 ± 19 nm for 4 wt% ND composite (Fig. S12-13), which may have a great influence on the I-V nonlinearity of composite. More importantly, the pressure applied during CSP generated large residual stress around the ultrastiff NDs, which can be confirmed by the strain distribution of surrounding ZnO grains using geometric phase analysis (GPA) (Fig. 1d). It is observed that with the identical sintering conditions, the ZnO grains surrounding ND particle in composite (NZ-150) show much higher tensile strain compared with the grains in monolithic ZnO (Z-150), indicating the large local residual stress induced by NDs.

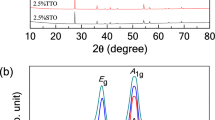

Since there is no apparent change in microstructure for the composites sintered under various pressures (Fig. S14–15), we resorted to the highly sensitive Raman spectra to unveil the residual stress in ND after densification quantitatively (Fig. 2a, b). It is found that the first-order Raman peak of ND in composite shows obviously higher wavenumbers compared to the pristine ND powder (1328 cm−1). Considering the constant size for ND before and after densification, the shifting of the Raman peak to a higher wave number should be ascribed to the compressive stress in NDs22. In addition, within the applicable range of Hooke’s law, the frequency shift and stress of phonons satisfy the relationship of \(\sigma=-k\times ({\omega }_{m}-{\omega }_{0})\), where k is a constant depending on the model of compression (uniaxial/triaxial), while ωm and ω0 is the measured and original Raman peak position without external stress for diamond, respectively23,24. Therefore, the stiffening of the Raman peak reflects the increased compressive stress in ND particles with increasing applied pressure during densification, which validates the capability of manipulating residual stress via sintering pressure. Accordingly, the calculated residual stress of ND in the composites prepared under different pressures is shown in Fig. 2f. With increasing applied pressure, the residual compressive stress of ND in composite increases continuously, which is generally higher than 1 GPa due to the high modulus of ND with respect to ZnO. Furthermore, the Finite Element Method (FEM) simulated stress distribution of a ND particle embedded in ZnO matrix indicates that the average surface stress of ND is greater than 0.5 GPa (Table S6) and the stress at the edges is about 1 GPa under a force field of 150 MPa (Fig. 2c), which is in agreement with the results estimated by Raman spectra. In comparison, the simulated results for ordinary rigid particle such as Al2O3 show much lower residual stress due to its smaller elastic modulus.

a Raman spectra for prestine ND and ND/ZnO composites with different sintering pressure. b High-resolution Raman spectra of diamond for ND powder and composites sintered with various pressures. c FEM simulated strain distribution from center to edge in second phases (ND and α-Al2O3) embedded in ZnO matrix under a force field of 150 MPa; inset shows the stress distribution mappings for ND and α-Al2O3, respectively. d XRD patterns of (213) peak for monolithic ZnO (blue) and composite NZ-150 (yellow) cold-sintered by using the same conditions. e XRD patterns at different azimuth angles for the composite NZ-150. f Calculation results of residual stress for monolithic ZnO and ND/ZnO composites under different sintering pressures.

Owing to the significant compressive stress in NDs, the stress field in the ZnO matrix has been changed correspondingly. Raman spectra for ZnO show that the residual stress varies greatly when measured on different areas in the composite (Fig. S16). While some areas have large Raman peak shift equal to the stress of ~1 GPa, some areas exhibit almost no peak shift, probably due to the far distance with respect to ND particles nearby. Therefore, we evaluated the residual stress of the ZnO matrix by using XRD to obtain more average information. First of all, the broadened (213) peak (Fig. 2d) in XRD data clearly demonstrate the increased micro stress of ZnO in the composite with respect to monolithic ZnO. Since the residual stress from surrounding NDs causes distortion of lattice and thus affects the diffraction angle (2θ), the internal stress can be determined by measuring the change of diffraction angle22,25. As shown in Fig. 2e, the shift of 2θ to a lower angle with increasing tilt angle (ψ) indicates that the average internal stress in the matrix is tensile, which can be understood by the requirement of compensating compressive stress for ND particles. The calculated average internal stress is 39 MPa for the composite sintered under 100 MPa, which increases continuously to 65 MPa for the one sintered under 150 MPa. In comparison, the internal stress is much lower (~30 MPa) and almost unchanged with increasing applied sintering pressure for the monolithic ZnO, indicating the effect from prestressed ND particles. However, as the applied pressure further increases to 175 MPa and above, the average residual stress of the ZnO matrix decreases reversely, which can be ascribed to the relaxed stress via plastic deformation or even micro-cracks formed under high pressure (Fig. S17).

Internal stress-induced nonlinear current-voltage behavior

Since we can modulate the internal stress in ND/ZnO composites by applied pressure during CSP, it is possible to effectively change the potential barriers in the ZnO matrix by piezoelectric charge generated at GBs. As shown in Fig. 3a, while the undoped ZnO ceramic shows very weak nonlinearity, the ZnO composite with only 2 wt% ND displays a prominent nonlinear I-V response at a very low switch voltage (Es= ~15.7 V/mm). In fact, the GBs of undoped ZnO ceramic also contain acceptor-type defects of low concentration that can form potential barriers with a certain height, as can be seen from the mild deviation of linear I-V response around 102.4 V/mm (Fig. 3a). Apparently, the addition of ND particles can largely decrease the switch voltage and improve the nonlinearity of undoped ZnO ceramic, suggesting a highly depressed potential barrier height. To prove the correlation between internal stress and potential barrier, we further tested the I-V behavior for the composites prepared with various sintering pressures. It can be seen that the switch voltage decreases continuously with increasing sintering pressure (Fig. 3a), indicating the decreased potential barrier with increasing internal stress. With the gradual increase of the residual stress of the sample, the relative permittivity of the samples tends to increase (Fig. S18)26. In addition, the measurement of impedance shows that the diameter of the Nyquist semicircle (Rb) is significantly reduced in the composites with respect to monolithic ZnO (Fig. 3d). More importantly, there is a clear dependence between reduced Rb and increasing sintering pressure, which reflects the modulation of barrier height by internal stress induced piezoelectric polarization7.

a Current density-electric field (I-V) curves of ZnO and composites under different sintering pressure, inset is the enlarged part of dashed square showing mild nonlinearity in monolithic ZnO. b I-V curve of cold sintered composites with α-Al2O3 and various ND contents. c Measured switch voltage (Es at 0.1 mA/mm2) and nonlinear coefficient for various samples prepared in this study. d Nyquist plots of cold sintered samples under different sintering pressures. e Experimentally determined potential barrier height as a function of internal stress of ZnO matrix; inset is the Arrhenius type plot of the resistivity ρ, where the values of ρ were extracted at a frequency of 10 Hz from temperature-dependent impedance measurements. f Comparison of performance for ZnO-based binary-system (single dopant) varistors and the ZnO composites with soft and rigid second phases18,19,36,37,38,39.

Intriguingly, when we added more ND particles into ZnO composites, the switch voltage slightly increased from 15.7 V/mm (2 wt% ND) to 26.2 V/mm (4 wt% ND), which can be ascribed to the increased concentration of GB with increasing content of ND. The incorporation of ND particles greatly limits the coarsening of ZnO grains (Fig. S12), resulting in the rapidly increased amount of GB by order of magnitudes. Indeed, the impedance measurement reveals a continuous increment of Rgb with increasing ND loading (Fig. S19-20 and Table S3) mainly due to the highly increased amount of GB despite additional regions influenced by prestressed NDs27. This phenomenon also clearly proves that the nonlinear I-V response is governed by GBs rather than the piezoresistive effect on grains. Thanks to the ultrafine microstructure with high homogeneity, the nonlinear coefficient of composites with 4 wt% ND is improved to ~8, which is among the best in ZnO-based binary varistors (Fig. 3f). Therefore, in contrast to the conventional strategy of fabricating thin layered ceramics with large grains, we have shown that the low-voltage varistors can be realized in bulk form without abnormally large grains. The validity of this strategy can be further proved by using other rigid nanoparticles such as α-Al2O3, as shown in Fig. 3b and Fig. S21. Similar to the composite with ND, the composite with α-Al2O3 nanoparticles also exhibit decreased switch voltage, though the Es value (35.7 V/mm) is much higher than that of ND/ZnO composite due to the low stiffness of α-Al2O3 with respect to ND. It is worth noting that distinct from conventional Al2O3 doped ZnO varistors, the solid reaction between Al2O3 and ZnO is completely prevented here due to the low densification temperature. The result unambiguously manifests the possibility of designing low-voltage varistors with on-demand properties by selecting a second phase with proper stiffness.

Although both increase and decrease of potential barriers in ZnO-based varistors via external stress have been demonstrated previously6, the above-discussed large depression of switch voltage induced by internal stress is rarely observed. Although we know that the ZnO matrix is under tensile stress in total, while some types of alignment of polarization vectors (e.g. tail-to-tail) can lead to lowering of the potential barrier, there are always some types of alignment (e.g. head-to-head) under which a raised potential barrier is expected. In addition, both tensile and compressive stresses exist under the influence of prestressed NDs (Fig. 4a and Fig. S23). Given the random distribution of equiaxed gains obtained here, there should be no preferred orientation of polarization vectors between adjacent grains in the ZnO composites. Therefore, the possibility of reduced and raised potential barriers induced by prestressed ND should be almost identical. However, our results show that the net influence of the modified potential barrier is always the significantly lowered barrier height without exception, suggesting the different effects of positive and negative polarization on the potential barrier.

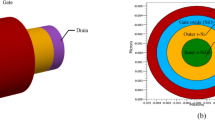

a FEM simulated internal stress-induced polarization in ND/ZnO composites; the arrows indicate the polarization vectors of grains. b Band structures of a potential barrier for head-to-head configuration under (i) compressive and (ii) tensile stress; the internal stress-induced polarization changes the potential barrier height as well as the negative interfacial charge density (Qi). FEM Simulated the distribution of current density in monolith (c) and composites with different sintering pressures (NZ-100 (d) and NZ-150 (e)) under the same voltage.

Considering the classic model of potential barrier in varistors (Fig. 4b), we infer that the difference stems from the limited empty defect states above the Fermi level at GB. When negative piezoelectric polarization is applied, more electrons are forced to fill the empty states and thus push up the barrier height. However, due to the limited unoccupied defect states, the increase of potential barrier is saturated quickly once all empty states are filled, even if under higher negative polarization. In comparison, the positive piezoelectric polarization leads to the release of trapped electrons from occupied states below the Fermi level, whose density is considerably higher than the unoccupied states above the Fermi level. As a result, the potential barrier height can be greatly reduced, along with decreased resistance at GBs (Fig. 4b). In fact, the potential barrier can be completely eliminated if the positive polarization is large enough, which has been verified in the ZnO bicrystals under large external stress7. Therefore, the decreasing of the potential barrier and corresponding resistance at GBs are always much more prominent than the opposite effect, leading to internal stress-dependent depression of switch voltage. The highly decreased switch voltage by prestressed ND particles can be simulated by using FEM, as shown in Fig. 4c–e. Compared to monolithic ZnO (Fig. 4c), some of GBs adjacent to the ND particle have much lower resistance, which can connect with low-resistance GBs surrounding another ND and finally form a path when the content of ND is high enough. As a result, the leakage of current in the ZnO composite occurs under sufficient voltage (Fig. 4d). With increased residual stress induced by NDs, more paths with low resistance can be formed in the ZnO matrix, and thus the leakage current increases (Fig. 4e).

Strengthening ceramic matrix with prestressed ND

The large internal stress induced by ultra-stiff ND particles also greatly enhances the flexural strength of ZnO composites, which is critical for the application of varistors. As evaluated by the biaxial bending test (see SI for details), the flexural strength for the ZnO composite with 4 wt% of NDs continuously increases with increasing pressure before the pressure reaches 200 MPa. Noting that the composites have almost the same relative density, the measured strength with increasing applied pressure reflects the effect of increased residual stress on the strengthening. In particular, the maximum flexural strength values is approaching 164 ± 15 MPa for the composite densified under 150 MPa (Fig. S22), which corresponds to a 234% increment over that of the monolithic ZnO prepared by CSP (Table S4), and also 53% higher than that of the composite prepared by conventional pressureless sintering (Table S1). This colossal strengthening effect has rarely been observed in ceramic composites reinforced by nanoparticles, as compared with other reported ceramic composites (Fig. 5e). Moreover, the reliability of the measured high strength was further analyzed by assuming the compliance of Weibull distribution (Fig. 5a). It is found a characteristic strength of σ0 = 48 MPa and Weibull modulus of m = 4.8 for the cold sintered monolithic ZnO, which is very similar to the results reported previously16. In contrast, the composite with prestressed NDs (NZ-150) possesses a Weibull modulus as large as 14.1, which is even higher than most ceramics prepared by hot-press sintering28,29,30,31. Therefore, the composite reinforced by prestressed NDs exhibits not only significantly higher strength but also much better reliability. In addition, owing to the giant stiffness of ND, the composite also exhibits highly improved Vickers hardness of 5.5 GPa compared with the monolith (3.2 GPa), which qualifies the composite as the most robust ceramic among varistors in terms of strength and hardness32,33.

a Weibull plots of flexural strength for ZnO and composites reinforced by NDs and α-Al2O3, respectively. b The fracture-resistance curves for ZnO and composites. Top view of Vickers indentation sites for ZnO and the ND/ZnO composite, respectively; insets are enlarged areas of polished surface marked by dot squares, and the scale bar in c and d are 1 μm and 0.5 μm, respectively. e Comparison of strengthening and hardening effects with other ceramic composites reinforced by nanoparticles40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55.

The significant strengthening effect can be understood from two aspects. On one hand, the prestressed ND particles can greatly strengthen the GBs in the region between neighboring NDs before crack initiation, due to the compressive stress in the direction normal to ND boundary. It has been known that the cold-sintered ceramics like ZnO usually show inferior strength compared with ceramic sintered at high temperatures, mainly due to the relatively weak GBs formed by dissolution-precipitation process34. The prestressed ND exerts large compressive stress on GBs relatively far from ND, leading to much higher tensile stress to break them. This effect can be seen from the indent created by the Vickers hardness test. The indent on monolithic ZnO shows severe spalling and pileup at the corners, and pullout of grains can be found on the polished surface due to the weak GBs (Fig. 5c). Under the same loading, the composite has much smaller and well-defined indent on the surface, where the stress concentration released in terms of cracks at corners rather than spalling (Fig. 5d). On the other hand, after crack initiation the prestressed ND particles give rise to prominent bridging effect for restraining the crack propagation. The local high compressive stress around the ND particles leads to a highly rising R-curve with increasing crack length35, while the slope of R-curve for Al2O3 reinforced ZnO ceramic is much lower compared with the composite reinforced by NDs (Fig. 5b), indicating larger fracture resistance induced by prestressed ND than Al2O3. In contrast, the monolithic ZnO shows almost no rising R-curve behavior due to the lack of crack-tip bridging effect.

Discussion

In summary, we proposed a novel strategy for modulating the potential barrier in varistor ceramics by introducing prestressed rigid nanoparticles. Different from the generally small thermal stress created by conventional high-temperature sintering, the local internal stress generated by the difference of stiffness between matrix and inclusions can be as large as 1 GPa in ZnO composite when incorporated with ultrastiff NDs. The corresponding piezoelectric polarization induced by internal stress leads to the decreased double Schottky barrier by 28% to 0.23 eV, which can be ascribed to the distinct effects of positively and negatively charged polarization on GBs. As a result, an ultralow Es of 26.2 V/mm and a nonlinear coefficient of 7.98 can be obtained, indicating the great potential as a low-voltage varistor. Furthermore, the prestressed ND nanoparticles strengthen the GBs with a prominent crack-tip bridging effect, leading to highly improved strength by 238% with respect to the monolith. Given the wildly existence of potential barriers in non-centrosymmetric oxide ceramics, we believe the regulation of GB potential barriers by prestressed rigid nanoparticles provides a new strategy for fabricating high-performance electronic ceramics that can be applied for not only varistors but also thermoelectrics and solid-state electrolytes, etc.

Methods

Acid treatment of ND

1 g ND particles were placed in a three-neck flask and mixed with a 100 ml concentrated acid solution of 98% sulfuric acid (H2SO4) and 68% nitric acid (HNO3) with volume ratio (3:1), respectively. The mixture was placed in the ultrasonic bath for 30 min, then vigorously stirred for 4 hours in an 80 °C water bath. After cooling it to room temperature, 200 ml of deionized water was added to dilute the mixture. The obtained ND particles were repeatedly washed by vacuum filtration with a large amount of deionized water until pH became neutral. Finally, the ND particles were dried for 12 h at 80 °C.

Preparation of ND/ZnO hybrid powder

The ZnO powder was uniformly mixed with ND via hetero-aggregation process. Firstly, 2.4 g of ZnO (Macklin, 99.9%, 30 ± 10 nm) was stirred with 240 ml of deionized water for half an hour, followed by ultrasonic treatment for 1 hour to form a stable ZnO colloidal solution. Secondly, the acid-treated ND dispersed in deionized water (0.5 mg/ml) and dropped into a well-dispersed ZnO suspension under magnetic stirring. ND and ZnO powders quickly assembled and precipitated to the bottom, leaving clear water as the supernatant. Collect the precipitated ND/ZnO mixture through vacuum filtration and dry it in a vacuum oven at 60 °C for 24 hours.

Sintering of ZnO and ND/ZnO composites

The densification process of monolith and composites was carried out using a hydraulic press (DP-308, Jingsheng Instrument Co., Ltd., China). 1.2 g of powder was mixed with 20 wt% 0.6 mol L−1 acetic acid aqueous solution and ground with a mortar and pestle for 6 mins. Subsequently, the wet powder was loaded into a stainless steel mold with an inner diameter of Φ10 mm and applied by a uniaxial pressure of 100-200 MPa. The heating rate given by the heat jacket integrated with the mold was 15 °C min−1, and held for 60 mins at 300 °C. After sintering, the pellet was cooled down to room temperature naturally.

Characterization

The constituent phases in pure ZnO and composites were identified by X-ray diffraction (XRD) (Smartlab) using Cu Kα radiation with a scanning range of 10−90°. The quality of ND was characterized by Raman spectroscopy (Tokyo Instruments Co.) (Spectral repeatability ≤ ± 0.1 cm−1, spectral resolution ≤ 1 cm−1, spatial resolution: horizontal≤1 μm, vertical ≤ 2 μm.). The fracture surface and polished surface of ZnO and ND/ZnO composites were observed by field emission scanning electron microscopy (FE-SEM, JEOL JSM-6700F). Transmission electron microscopy (TEM) (HRTEM, JEOL 200CX) was exploited to investigate the microstructure of the sample. Strain analysis of the HRTEM was carried out by using the commercial Geometric Phase Analysis package by HREM Research. The I-V curves were measured by an electrochemical workstation (PARSTAT 4000A, America). The impedance was measured by a broadband dielectric impedance spectrometer (NOVOCONTROL GmbH, Germany) with a frequency range from 10 Hz to 10 MHz.

The mechanical properties of ceramic were measured on an electronic universal testing machine (SHIMADZU AGS-X, Japan). Poisson’s ratio was determined by an advanced ultrasonic material characterization system (UMS-100, France). The Vickers hardness was determined by using a load of 0.5 Kgf for 10 s. The indentation fracture toughness was calculated by following the Anstis equation:

where E is young’s modulus, HV is Vickers indentation hardness, P is the load, and C is half crack length. The modified small punch (MSP) method was used to calculate the strength of ND/ZnO composite by the following equation:

where P is the load, the thickness of the sample is t, γ is the Poisson’s ratio, a and b are the radius of the hole of the mold and the radius of the tip of the cylindrical punch, respectively.

FEM simulations

Mechanical and electrical simulations are conducted using software, please refer to the supporting information for more details.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information files. Any additional requests for information can be directed to, and will be fulfilled by, the corresponding author. Source data are provided in this paper.

References

McKenna, K. P. & Shluger, A. L. Electron-trapping polycrystalline materials with negative electron affinity. Nat. Mater. 7, 859–862 (2008).

Huang, J. et al. Simultaneously breaking the double Schottky Barrier and Phonon transport in SrTiO3-based thermoelectric ceramics via two-step reduction. Acs Appl. Mater. Interfaces 12, 52721–52730 (2020).

Jiang, F., Peng, Z., Zang, Y. & Fu, X. Progress on rare-earth doped ZnO-based varistor materials. J. Adv. Ceram. 2, 201–212 (2013).

Clarke, D. R. Varistor ceramics. J. Am. Ceram. Soc. 82, 485–502 (1999).

Dursun, S., Tsuji, K., Bang, S. H., Ndayishimiye, A. & Randall, C. A. A route towards fabrication of functional ceramic/polymer nanocomposite devices using the cold sintering process. Acs Appl. Electron. Mater. 2, 1917–1924 (2020).

Raidl, N., Supancic, P., Danzer, R. & Hofstaetter, M. Piezotronically modified double Schottky barriers in ZnO varistors. Adv. Mater. 27, 2031–2035 (2015).

Keil, P. et al. Piezotronic tuning of potential barriers in ZnO bicrystals. Adv. Mater. 30, 1705573 (2018).

Verghese, P. M. & Clarke, D. R. Piezoelectric contributions to the electrical behavior of ZnO varistors. J. Appl. Phys. 87, 4430–4438 (2000).

Galotta, A. & Sglavo, V. M. The cold sintering process: A review on processing features, densification mechanisms and perspectives. J. Eur. Ceram. Soc. 41, 1–17 (2021).

Guo, J. et al. Cold sintering: progress, challenges, and future opportunities. In: Annual Review of Materials Research, 49 (2019).

Ndayishimiye, A., Bang, S. H., Spiers, C. J. & Randall, C. A. Reassessing cold sintering in the framework of pressure solution theory. J. Eur. Ceram. Soc. 43, 1–13 (2023).

Gao, J. et al. Realizing translucency in aluminosilicate glass at ultralow temperature via cold sintering process. J. Adv. Ceram. 11, 1714–1724 (2022).

Gao, J. et al. Cold sintering of highly transparent calcium fluoride nanoceramic as a universal platform for high-power lighting. Adv. Funct. Mater. 33, 2302088 (2023).

Gao, J. et al. Direct cold sintering of translucent gamma-Al2O3 ceramics. J. Eur. Ceram. Soc. 44, 4225–4231 (2024).

Nur, K. et al. Influence of powder characteristics on cold sintering of nano-sized ZnO with density above 99%. J. Eur. Ceram. Soc. 41, 2648–2662 (2021).

Jabr, A., Fanghanel, J., Fan, Z., Bermejo, R. & Randall, C. The effect of liquid phase chemistry on the densification and strength of cold sintered ZnO. J. Eur. Ceram. Soc. 43, 1531–1541 (2023).

Guo, J. et al. Recent Progress in Applications of the Cold Sintering Process for Ceramic-Polymer Composites. Adv. Funct. Mater. 28, 1801724 (2018).

Zhao, X. et al. Introducing a ZnO-PTFE (Polymer) Nanocomposite Varistor via the Cold Sintering Process. Adv. Eng. Mater. 20, 1700902 (2018).

Si, M. et al. Preparation of zinc oxide/poly-ether-ether-ketone (PEEK) composites via the cold sintering process. Acta Mater. 215, 117036 (2021).

Field, J. E. The mechanical and strength properties of diamond. Rep. Prog. Phys. 75, 126505 (2012).

Cebik, J. et al. Raman spectroscopy study of the nanodiamond-to-carbon onion transformation. Nanotechnology 24, 205703 (2013).

Ižák, T., Jirásek, V., Vanko, G., Dzuba, J. & Kromka, A. Temperature-dependent stress in diamond-coated AlGaN/GaN heterostructures. Mater. Des. 106, 305–312 (2016).

de Portu, G., Micele, L., Sekiguchi, Y. & Pezzotti, G. Measurement of residual stress distributions in Al2O3/3Y-TZP multilayered composites by fluorescence and Raman microprobe piezo-spectroscopy. Acta Mater. 53, 1511–1520 (2005).

Fan, Q. H., Grácio, J. & Pereira, E. Residual stresses in chemical vapour deposited diamond films. Diam. Relat. Mater. 9, 1739–1743 (2000).

Shang, C. H., van Heerden, D., Gavens, A. J. & Weihs, T. P. An X-ray study of residual stresses and bending stresses in free-standing Nb/Nb5Si3 microlaminates. Acta Mater. 48, 3533–3543 (2000).

El Desouky, F. G. & Abou-Helal, M. O. Synthesized nanostructures of Oxostannate Cs2Sn2O3 with a prospective study of structural, electrical, optical, and luminescence properties: effect of annealing temperature. J. Inorg. Organomet. Polym. Mater. https://doi.org/10.1007/s10904-024-03185-2 (2024).

Ismail, A. M. & ElDesouky, F. G. Facile assembly of flexible quaternary SnO2/SrSnO3/Fe3O4/PVDF nanocomposites with tunable optical, electrical, and magnetic properties for promising magneto-optoelectronic applications. Sci. Rep. 13, 4997 (2023).

Hidaka, N., Hirata, Y., Wang, X. H. & Tabata, S. Aqueous processing, hot-pressing and mechanical properties of silicon carbide with Al2O3 and Y2O3. J. Ceram. Soc. Jpn. 113, 143–148 (2005).

Schlup, A. P., Costakis, W. J., Youngblood, J. P. & Trice, R. W. Mechanical properties of hot-pressed transparent platelet alumina. Int. J. Appl. Ceram. Technol. 20, 3656–3665 (2023).

Wang, C. M. Microstructural homogeneity improvement in Si3N4 by a powder coating method. J. Mater. Sci. 31, 4709–4718 (1996).

Wang, X. H. & Hirata, Y. Influence of polyacrylic acid on rheology of SiC suspension and mechanical properties of densified SiC. Ceram. Int. 31, 677–681 (2005).

Yoshimura, H. N., Molisani, A. L., Narita, N. E., Manholetti, J. L. A. & Cavenaghi, J. M. Mechanical properties and microstructure of zinc oxide varistor ceramics. In: 5th International Latin American Conference on Powder Technology) (2005).

Ramirez, M. A. et al. Mechanical properties and dimensional effects of ZnO- and SnO2-based varistors. J. Am. Ceram. Soc. 91, 3105–3108 (2008).

Lowum, S., Floyd, R., Bermejo, R. & Maria, J.-P. Mechanical strength of cold-sintered zinc oxide under biaxial bending. J. Mater. Sci. 54, 4518–4522 (2019).

Ohji, T., Jeong, Y. K., Choa, Y. H. & Niihara, K. Strengthening and toughening mechanisms of ceramic nanocomposites. J. Am. Ceram. Soc. 81, 1453–1460 (1998).

Guo, J. et al. Altering interfacial properties through the integration of C60 into ZnO ceramic via cold sintering process. Carbon 190, 255–261 (2022).

Hng, H. H. & Tse, K. Y. Effects of MgO doping in ZnO-0.5 mol% V2O5 varistors. Ceram. Int. 34, 1153–1157 (2008).

Hong, Y.-W., Lee, Y.-J., Kim, S.-K., Paik, J.-H. & Kim, J.-H. Admittance Spectroscopy and Electrical Properties of Co3O4-Doped ZnO. Electron. Mater. Lett. 10, 903–906 (2014).

Wang, K., Xu, Z., Chu, R. & Li, G. Research method and mechanism analysis of a novel high-performance quaternary Zn-Sr-Co-Sb varistor ceramic. J. Mater. Chem. C. 12, 6999–7008 (2024).

Ahmad, I., Islam, M., Almajid, A. A., Yazdani, B. & Zhu, Y. Investigation of yttria-doped alumina nanocomposites reinforced by multi-walled carbon nanotubes. Ceram. Int. 40, 9327–9335 (2014).

Fan, Y. et al. Liquid-phase assisted engineering of highly strong SiC composite reinforced by multiwalled carbon nanotubes. Adv. Sci. 7, 2002225 (2020).

Jia, J. et al. Effects of CNTs content on microstructure and mechanical properties of Cnt/α-Al2O3 and Cnt-Csf/α-Al2O3 composites. Ceram. Int. 45, 19956–19961 (2019).

Kasperski, A. et al. Double-walled carbon nanotube/zirconia composites: Preparation by spark plasma sintering, electrical conductivity and mechanical properties. Ceram. Int. 41, 13731–13738 (2015).

Sun, J. et al. Developing high performance in titanium carbide nanocomposites containing hybrid SiC nanowire and CNT. J. Eur. Ceram. Soc. 43, 5466–5473 (2023).

Zhang, S. C., Fahrenholtz, W. G., Hilmas, G. E. & Yadlowsky, E. J. Pressureless sintering of carbon nanotube-Al2O3 composites. J. Eur. Ceram. Soc. 30, 1373–1380 (2010).

Chen, C. et al. Mechanical and thermal properties of graphene nanosheets/magnesia composites. Ceram. Int. 43, 10377–10385 (2017).

Gao, J. et al. Highly improved microwave absorbing and mechanical properties in cold sintered ZnO by incorporating graphene oxide. J. Eur. Ceram. Soc. 42, 993–1000 (2022).

Hu, Y. et al. Electrostatic self-assembly preparation of reduced graphene oxide-encapsulated alumina nanoparticles with enhanced mechanical properties of alumina nanocomposites. J. Eur. Ceram. Soc. 38, 5122–5133 (2018).

Liu, J., Yan, H. & Jiang, K. Mechanical properties of graphene platelet-reinforced alumina ceramic composites. Ceram. Int. 39, 6215–6221 (2013).

Donzel, L. & Roberts, S. G. Microstructure and mechanical properties of cubic zirconia (8YSZ)/SiC nanocomposites. J. Eur. Ceram. Soc. 20, 2457–2462 (2000).

Sternitzke, M., Derby, B. & Brook, R. J. Alumina/silicon carbide nanocomposites by hybrid polymer/powder processing: Microstructures and mechanical properties. J. Am. Ceram. Soc. 81, 41–48 (1998).

Sun, X. D. et al. Intragranular particle residual stress strengthening of Al2O3-SiC nanocomposites. J. Am. Ceram. Soc. 88, 1536–1543 (2005).

Tajima, K., Hwang, H. J., Sando, M. & Niihara, K. PZT nanocomposites reinforced by small amount of oxides. J. Eur. Ceram. Soc. 19, 1179–1182 (1999).

Wang, K. et al. Reactive hot pressing of SiC-ZrC composites at low temperature. J. Eur. Ceram. Soc. 37, 849–854 (2017).

Zhao, J. H. et al. Mechanical-Behavior Of Alumina Silicon-Carbide Nanocomposites. J. Am. Ceram. Soc. 76, 503–510 (1993).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 52350443, 52122203). The authors would like to thank Prof. Yiping Guo from Shanghai Jiaotong University for the assistance in sample measurements.

Author information

Authors and Affiliations

Contributions

This work was conceived and designed by P.Y., and Y.F. The samples were prepared by P.Y. Microstructures were characterized by P.Y. Varistor performance, and mechanical properties were tested by P.Y., and the data was processed by P.Y. assisted by Y.P.L., Y.R., and Q.D. The FEM model of samples were simulated and analyzed by P.Y. and M.M.S. The manuscript was drafted by P.Y., revised by Y.F., and discussed with W.J. and W.Z.J. All authors contributed to the data analysis and discussion.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Fawzy G. El Desouky, Aida Serrano, and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yan, P., Si, M., Liu, Y. et al. Large internal stress induced nonlinear current-voltage behavior in nanodiamond strengthened ZnO ceramics. Nat Commun 15, 9812 (2024). https://doi.org/10.1038/s41467-024-54279-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-54279-x