Abstract

The thickness of X-ray detectors needs to reach hundreds of micrometers to absorb X-ray, and therefore, high voltages over tens or hundreds of volts should be applied to extract X-ray-generated carriers. Here, we propose a bulk Schottky junction for X-ray detection using interpenetrated macroporous-carbon electrodes and metal-halide perovskite networks. The X-ray-generated holes are extracted by the macroporous-carbon electrodes under the built-in electric field, while the electrons in the perovskite phase result in a high gain effect. A high sensitivity of 1.42×105 μC Gyair−1 cm−2 and a low detection limit of 48 nGyair s−1 at a low voltage of −1 V are achieved. We fabricated a dry battery-powered portable X-ray alarm prototype. The pixel detector shows a decent stability under X-ray exposure, and a spatial resolution of up to 5.0 lp mm−1, and the detector arrays also exhibit remarkable uniformity, demonstrating its potential application in X-ray imaging.

Similar content being viewed by others

Introduction

X-ray detectors are widely used in medical diagnosis, security and industrial material inspection, environmental radiation monitoring, etc1,2,3,4,5. Semiconductor X-ray detectors directly convert X-rays to electronic signals and have many advantages, such as high energy resolution, high spatial resolution, and high signal-to-noise ratio6,7,8,9,10. Good X-ray semiconductor materials should possess a high X-ray absorption coefficient, low defect density, high bulk resistivity, and large μτ product (where μ is the carrier mobility and τ is the carrier lifetime). Several semiconductor materials have been developed for radiation detection, including amorphous selenium (α-Se), mercury iodide (HgI2), cadmium zinc telluride (CZT), and metal-halide perovskites (MHPs). In particular, MHPs are emerging as promising materials for X-ray detectors due to their high atomic number, high tolerance to defects, and large μτ product11,12,13. In addition, MHPs are low-temperature solution-processed, which are preferred for large-area fabrication and imaging applications, as well as for integration with thin-film transistor readout circuits14,15,16,17,18,19,20.

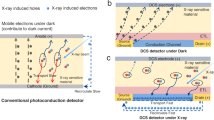

Two types of semiconductor X-ray detector structures have been reported, known as photoconductors and photodiodes, which are similar to conventional photodetectors21,22. In photoconductor detectors, electrons or holes are recirculated through symmetrical contacts before they recombine with the opposite charge, resulting in a high gain effect and large dark current23,24. In direct contrast, photodiodes extract equal amounts of holes and electrons and generally have no gain effect or low dark current25. Both types of detectors generally use a layered structure in which the X-ray absorbing layer is sandwiched between two electrodes with charge selecting/injecting layers at the perovskite/electrode interface. Therefore, the X-ray-generated carriers must be transported hundreds to thousands of micrometers to reach the electrodes. To suppress carrier recombination during transport and obtain high X-ray detection sensitivity, a large voltage of up to tens to hundreds of volts is usually needed to extract carriers7,26,27. However, high voltage causes several problems, such as current drift, performance degradation, and operation insecurity, which limit the use of X-ray detectors in portable applications11,28.

In this work, we develop a bulk Schottky junction (BSJ) for portable radiation detectors using an interpenetrated macroporous-carbon electrode and perovskite network. In the BSJ structure, the X-ray-generated holes are extracted by the nearby macroporous carbon electrode under the built-in field. The electrons are trapped in the perovskite layer, resulting in a high gain effect. The BSJ-based X-ray detectors using interpenetrated macroporous-carbon-perovskite (MCP) networks exhibit a high sensitivity up to 1.42 × 105 μC Gyair−1 cm−2 and a low detection limit of 48 nGyair s−1 at a low voltage of −1 V, which are comparable to those of perovskite single-crystal detectors operated at tens to hundreds of volts. The above advantages also enabled us to fabricate a dry battery-powered portable X-ray radiation alarm that exhibits the lowest limit of detection (LoD) at the level of nGyair s−1. The portable X-ray alarm responds 10 and 24 times faster and more sensitively to low-energy X-rays than the commercial silicon radiation detector and Geiger-Müller counter tube. The BSJ pixel detector shows a decent spatial resolution of up to 5.0 lp mm−1. The simple fabrication process of the large-area interpenetrated MCP network also enables us to construct detector arrays with remarkable uniformity for imaging. Furthermore, benefiting from the ultralow operating voltages and the self-encapsulation effect of the macroporous-carbon electrode, BSJ-based detectors exhibit excellent operational stability and long-term stability.

Results

Working principle of the BSJ detector

For conventional layered detectors, X-ray-generated electrons and holes must be transported through the perovskite layer, which is generally over hundreds to thousands of micrometers thick (Fig. 1a). In contrast, in the BSJ structure using interpenetrated MCP networks, the X-ray-generated holes need to be transported only across the pore radius, less than a few micrometers, to the macroporous-carbon electrode with the help of the built-in electric field (Fig. 1b). The built-in electric field is estimated to be approximately 0.03 V μm−1, and the width of the Schottky barrier is approximately 4.4 μm (Supplementary Note 1). It has been reported that the μτ product of MAPbI3 films can reach 10−4 cm2 V−1 (ref7,29.). Therefore, the carrier drift length driven by the built-in electric field of 0.03 V μm−1 exceeds hundreds of micrometers. The above calculations suggest that the built-in electric field is sufficient to drive X-ray-generated holes in the perovskite phase to the carbon electrode. Therefore, in the BSJ-based detector, the external bias needs to drive only hole injection and transport in the micrometer-thick compact perovskite layer, which is expected to be much smaller than that of the conventional layered structure. Due to the energy band bending at the perovskite/carbon interface, the X-ray-generated electrons tend to move toward the perovskite phase (Fig. 1c). The trapped electrons in the interpenetrated MCP network enhance the hole injection process. The difference between the hole extraction time and the electron recombination time results in a high photoconductive gain effect and high X-ray sensitivity22. Therefore, the device design and working mechanism of our BSJ detectors are different from the conventional layered structure detectors based on perovskite single crystals or thick compact film.

Fabrication and characterization of the BSJ structure

We compared the porosities of the macroporous carbon membranes prepared using ethanol, isopropanol, and acetone as exchange solvents (Methods section). We found that ethanol resulted in the largest carbon porosity (Supplementary Fig. 1), and it was used for the following study unless otherwise specified. Figure 2a shows a photograph of a large-area macroporous-carbon membrane with an area of 65 cm2 and thickness of 100 μm made by blade coating (Methods section). The surface and cross-sectional scanning electron microscopy (SEM) images demonstrate the macroporous nature of the membranes with a pore diameter of submicrometer (Fig. 2b–d). The pores are uniformly distributed in the macroporous-carbon membrane, which allows thorough infiltration of the precursor solution and uniform perovskite distribution. The porosity of the macroporous-carbon network is measured to be 63.6% and pore size diameters are around hundreds of nanometers, which are consistent with the SEM images in Fig. 2b–d (Supplementary Fig. 2). We used methylammonium lead iodide (MAPbI3) as perovskite composition in this work, and used volatile 2-methoxyethanol (2-ME) as solvent. In addition, we added 10 mol% of methylammonium chloride (MACl) to further increase the solubility of MAPbI3 in 2-ME. The MAPbI3 precursor solutions were infiltrated into macroporous-carbon membranes by applying a pressure of approximately 1.5 bar on top of the precursor. Three cycles of infiltration were performed via thermal annealing at 120 °C for two hours after each infiltration (Supplementary Fig. 3). The multiple cycles of infiltration make perovskite fully fill the macroporous carbon membrane, forming a continuous interpenetrated MCP network. It should be noted that the high-temperature annealing does not lead to the decomposition of MAPbI3 due to the self-encapsulation effect of the macroporous-carbon electrode (Supplementary Fig. 4). In addition, the interpenetrated MCP membrane exhibited excellent composition uniformity (Supplementary Fig. 5). The interpenetrated MCP network was constructed by blade coating a 3 μm thick compact perovskite layer on top (Supplementary Fig. 3). A saturated perovskite solution in 2-ME was used for blade coating to avoid redissolving the bottom MCP network. The top compact perovskite layer is flat and uniform (Fig. 2e, f and Supplementary Fig. 6), preventing devices from possible short circuits. We chose gold (Au) as the cathode and poly-TPD as the hole injection layer (poly-TPD: poly[N,N′-bis(4-butylphenyl)-N,N′-bis(phenyl)-benzidine]).

a Photograph of a large-area macroporous-carbon membrane. The scale bar is 2 cm. b–d Top view (b) and cross-sectional (c and d) SEM images of the macroporous-carbon membrane. The scale bars in b-d are 5 μm, 20 μm, and 4 μm, respectively. e Photograph of a large-area interpenetrated MCP networks. The scale bar is 2 cm. f-h Top view (f) and cross-sectional (g and h) SEM images of the interpenetrated MCP network. The scale bars in f-h are 1 μm, 20 μm, and 3 μm, respectively. i Elemental EDS mapping of carbon, lead, and iodine in the area in Fig. 2g. The scale bars are 20 μm. j Schematics of KPFM measurements of the interpenetrated MCP networks in the dark and under light. k-m Surface morphology (k), and the contact potential difference (CPD) images in the dark (l) and under light (m) of the cross-section of the interpenetrated MCP networks. The scale bars are 5 μm.

The cross-sectional SEM images of the interpenetrated MCP network demonstrate that the macroporous carbon membrane prepared with ethanol could load the most perovskite (Supplementary Fig. 1), and the perovskite was uniformly distributed within the 100 µm-thick macroporous-carbon membrane (Fig. 2g, h). In addition, there are no cracks in the cross-sectional SEM images of the MCP membrane, indicating the carbon membrane is well-connected after the infiltration. The cross-section sample was polished by an ion beam for characterization. We measured the weight changes of the membranes before and after perovskite infiltration to estimate the loading ratio (the ratio of perovskite volume to that of the MCP membrane). The loading ratio is estimated to be 80%, which is larger than the 63.6% porosity of the macroporous-carbon membrane (Methods section). This indicates that the pore size in the membrane increases by 26% during multiple infiltration and thermal annealing cycles30. The cross-sectional energy dispersive spectroscopy (EDS) results further demonstrate that the perovskite is uniformly infiltrated and distributed in the macroporous-carbon electrodes (Fig. 2i).

It has been reported that Schottky junctions can form at the carbon/perovskite interface31, which is also confirmed in our stacked bilayer carbon/perovskite film and lateral structure device (Supplementary Fig. 7). To prove the formation of the BSJ structure, we performed Kelvin probe force microscopy (KPFM) measurements on the cross-section of the interpenetrated MCP network both in the dark and under illumination. Under dark conditions, the CPD between perovskite and carbon shows only the Fermi level difference (Fig. 2j). The polished cross-section is relatively flat, which guarantees accurate characterization of the contact potential difference (CPD) of the sample (Fig. 2k). Thus, the perovskite and carbon regions can be distinguished from the potential difference (Fig. 2l). The carbon and perovskite phases in the interpenetrated MCP network can also be directly differentiated from the phase image (Supplementary Fig. 8). Under light conditions, the CPD of the perovskite phase decreases, suggesting that the Fermi level of the perovskite increases toward the conduction band (Fig. 2m). This result confirms the separation of X-ray-generated carriers and the electron trapping effect in the perovskite phase in the interpenetrated MCP network32. The electrostatic force microscope (EFM) measurement further confirmed the accumulation of electrons in perovskite phases (Supplementary Fig. 9).

Performance of the BSJ-based X-ray detectors

We fabricated X-ray photoconductive detectors using the conventional layered structure and the BSJ structure, as illustrated in Fig. 1a, b. The perovskite film of the layered structure was made by blade-coating (Methods section). Its morphology is consistent with that in the literature (Supplementary Fig. 10)7,29. The perovskite thickness of both types of detectors is approximately 100 μm to absorb enough X-ray photons, and the compositions are kept the same for fair comparison. We measured the photocurrent density (total current density subtracted from the dark current density) of both types of detectors at different dose rates. The sensitivity of the detectors with a device area of 0.04 cm2 under different biases was calculated by fitting the slope of the photocurrent density-dose rate curves (Supplementary Fig. 11). As shown in Fig. 3a, the BSJ-based detectors exhibit a maximum sensitivity (Sm) of 155,000 μC Gyair−1 cm−2 at a very low bias of −1.2 V. In contrast, the maximum sensitivity of the conventional layered structure detector reaches only 1750 μC Gyair−1 cm−2 even at a much larger voltage of -40 V (Fig. 3b). It should be noted that the BSJ detectors exhibited good reproducibility because the infiltration fabrication method of MCP membranes avoids the difficulty of controlling the crystallization of thick perovskite active layer (Supplementary Fig. 12). In addition, the sensitivity gradually increases while the gain factor remains similar with increasing perovskite loading ratios (Supplementary Fig. 13), indicating that increasing perovskite loading ratio would be an important way to further improve the sensitivity.

a, b Sensitivity of the BSJ detector (a) and conventional layered detector (b). c Signal-to-noise ratio of the detectors. d Dose rate measured by a thermoluminescent dosemeter and the X-ray response of the BSJ detectors. The shaded area shows the response range of the portable BSJ X-ray radiation alarm. e Prototype of the portable X-ray radiation alarm. f Response time of the BSJ detectors under −1 V. g Energy response of the BSJ detectors.

To examine the origin of the high sensitivity of the BSJ detector, we first examined whether the high sensitivity results from the compact perovskite layer in the BSJ detector. The calculation results show that the X-ray attenuation efficiency of 3 μm MAPbI3 reaches only 11%, which is very low (Supplementary Fig. 14). We also fabricated a thin layered detector with a 3 μm-thick perovskite layer, considering that the thickness of the compact perovskite layer in the BSJ detector is also 3 μm. Its sensitivity only reaches 370 μC Gyair−1 cm−2 (Supplementary Fig. 14). In addition, the BSJ still exhibited high sensitivity under high-energy X-rays up to 40 keV due to the effective absorption of thick MCP networks (Supplementary Fig. 15). These results demonstrate that the high sensitivity of BSJ detectors is attributed mostly to the interpenetrated MCP networks rather than the compact perovskite layer.

Inspired by the electron trapping effect in the BSJ structure and the high performance of the detector, we hypothesize that the photoconductive gain effect due to the trapped electrons in the perovskite phase contributed significantly to the high sensitivity. To test this hypothesis, we first calculated the theoretical Sm without considering photoconductive gain, which is approximately 190 μC Gyair−1 cm−2 (Supplementary Note 2). We also calculated the gain factor of BSJ detectors under different voltages and dose rates (Supplementary Note 3). The BSJ detectors exhibited a higher gain factor under a higher voltage and a lower dose rate (Supplementary Fig. 16). This trend is often observed in photoconductive detectors because the photogenerated carriers tend to gradually fill into shallow traps as the irradiation intensity increases, reducing the gain effect. We further analyzed the effect of the carrier trapping effect on the photoconductive gain. As shown in Supplementary Fig. 17, under visible light, the carriers are generated only in the compact perovskite layer without an electron trapping effect. External quantum efficiency (EQE) measurements at different voltages also reveal no gain effect. Thus, the response time under visible light (0.57 ms) is determined by the carrier transport time in the poly-TPD and the compact perovskite layer. In contrast, the response time under X-ray irradiation is determined by the electron trapping time in the perovskite of the interpenetrated MCP network and reaches 0.5 s. The significant difference in response time of the BSJ detector under visible light and X-rays further demonstrates the electron trapping effects in the MCP membrane. The trapping-detrapping process of the BSJ device measured by deep-level transient spectroscopy (DLTS) is 317.5 ms, which is much longer than the transmission time of 0.57 ms and the time constant of the device of 4.3 ms (Supplementary Fig. 18). The above results confirm that the electron trapping effect in the perovskite phase of the interpenetrated MCP network is the main reason for the gain and high sensitivity of the BSJ-based detector and is responsible for the response time of the detector. The trapping and detrapping processes may also lead to image lag and ghosting effects during dynamic imaging. However, the BSJ detector can be used in portable devices, such as radiation alarms, radiation dosimeters, and industrial nondestructive inspection devices, which will be discussed later.

The signal-to-noise ratio and the lowest LoD are critical parameters for evaluating detector performance. The noise current was calculated from the standard deviation of the photocurrent. The BSJ detector shows lower dark current and noise current than the layered detectors under working conditions (Supplementary Fig. 19), which should be due to their more compact perovskite film and lower working voltages. In contrast, the 100 μm-thick perovskite in the layered detector has a higher density of grain boundaries and voids, resulting in a higher dark current under a working voltage of −20 V. We further measured the response of the BSJ detector at dose rates below 1 μGyair s−1 (Supplementary Fig. 11c). With the noise current and photocurrent, we derived the signal-to-noise ratio (SNR) of both types of detectors under different dose rates (Fig. 3c). We observed a sublinear dependence of the photocurrent density on the dose rate for the BSJ detector. This is understandable because carriers tend to fill the longest-lived trap states, which results in high photoconductive gain at low irradiation intensities. We believe that the sublinear response of the BSJ detector is acceptable for the following two reasons. First, the sublinear range is <1 μGyair s−1, which is very small compared with the linear range over a few thousand μGyair s−1. Second, a one-to-one correspondence between the photocurrent and dose rate can still be obtained; therefore, an accurate dose rate can still be derived from the photocurrent. The sublinear response is absent in the layered detector, probably because the trap states have been fully filled at a dose rate below the lowest LoD of the layered detector. Impressively, the lowest LoD of BSJ detectors reaches 48 nGyair s−1 with an SNR equal to 3, which is two to three orders of magnitude lower than that of layered structure detectors.

Prototype of the portable X-ray detector

The high sensitivity of the BSJ detector at low voltages enables us to construct a portable X-ray radiation alarm prototype powered by a dry battery. To be used in portable dosimeters or radiation alarms, X-ray detectors should respond quickly and accurately to different dose rates. In the field of radiation safety surveys, silicon radiation detectors and Geiger-Müller (G-M) counter tubes are often used. However, both commercial devices suffer from long response times (6-12 s) and very weak or negligible responses to X-rays with energies <20 keV. To examine the response accuracy of our BSJ detectors to different dose rates, the dose rate profile produced by the Mini-X2 X-ray tube was first calibrated by commercial thermoluminescent dosimeters with a small diameter of 4.5 mm (Fig. 3d). The dose rate was measured by the BSJ detector was consistent with that measured by calibrated commercial thermoluminescent dosimeters (Fig. 3d). In particular, the BSJ detectors clearly identify a dose difference as low as 50 nGyair s−1, which meets the requirement of a portable radiation alarm.

We designed a semiconductor radiation alarm prototype based on the following principle. We used the current amplifier module to convert the small current of the BSJ detector to a voltage signal. A judgment module is used to compare the voltage signal with the control voltage to activate the alarm. The radiation alarm prototype can be powered by one 1.5 V dry-battery and weighs only 150 g (Fig. 3e). Our prototype shows excellent performance with an LoD in the range of nGyair s−1, as shown in Supplementary Movie 1. Due to the resolution of the current amplifier module (~1 nA), the lowest dose rate for triggering our portable X-ray alarm prototypes is approximately 500 nGyair s−1. Notably, no X-ray response was observed after replacing the BSJ detector with a commercial Si PIN diode due to its low sensitivity of 28 μC Gyair−1 cm−2 (Supplementary Figs. 20, 21). The response speed of BSJ detectors is much faster than that of commercial silicon semiconductor detectors and G-M counter tubes (Fig. 3f and Supplementary Fig. 20). We also compared the performance of BSJ detectors with silicon photomultipliers (SiPMs). The trigger dose rate of BSJ detectors is much lower than the detection limit of the SiPM detection circuit of 18 μGyair s−1, although their response time is slightly longer than that of SiPMs (Supplementary Fig. 22). In addition, both commercial portable detectors barely respond to X-rays with energies less than 20 keV. Thus, they are not suitable for radiation monitoring in many situations, such as X-ray diffraction (1-10 keV) and mammography (~20 keV)21. In contrast, BSJ detectors are much more sensitive to low-energy X-ray photons (Fig. 3g and Supplementary Fig. 20).

Imaging applications and stability of the BSJ detectors

The simple fabrication process of interpenetrated MCP networks also enables us to make BSJ detector arrays for imaging purposes. We tested a 6×6-pixel array with a pixel size of 500 μm and a pitch size of 500 μm (Fig. 4a). The standard deviations of the dark current and photocurrent under X-ray irradiation are 3.2% and 5.5%, respectively, demonstrating the good uniformity of the BSJ detector arrays (Fig. 4b and c). We further fabricated a detector with a pixel size of 130 μm to evaluate the imaging resolution. The pixel detector scanned a standard Pb line pair card along one direction with a step length of 10 μm, and we recorded the current response at each position to reproduce the image (Fig. 4d). We also calculated the modulation transfer function (MTF) to quantify the spatial resolution. As shown in Fig. 4e, the spatial resolution is approximately 5.0 lp mm−1 (defined as the spatial frequency value at MTF = 0.2), which is among the best values of perovskite-based direct conversion X-ray detectors and is higher than that of commercially used thallium-doped cesium iodide (CsI:Tl) flat-panel X-ray detectors (MTF of 0.36 at 2.0 lp mm−1)23,33. Although moving the pixel detector to characterize spatial resolution ignores pixel cross-talk, it is still an important reference for spatial resolution and represents the comprehensive performance of the BSJ detector. Theoretically, BSJ detectors can exhibit higher spatial resolution than conventional layered detector due to suppressed transverse diffusion (Supplementary Fig. 23). In our BSJ detector, the thickness of the compact perovskite layer (~3 μm) is much smaller than the pixel pitch, so transverse diffusion in the compact perovskite layer is minor compared with that in the conventional layered structure with much thicker perovskite layers. On the other hand, in interpenetrated MCP networks, X-ray-generated holes need to be transported across only the pore radius, less than a few micrometers, to the macroporous-carbon electrode.

a Photograph of the BSJ detector array using the interpenetrated MCP network. The scale bar is 1 mm. b, c Distribution of the normalized dark current (b) and X-ray photocurrent (c) at −1 V. d Photograph and X-ray imaging of a standard Pb phantom. lp, line pair. e The modulation transfer function for the BSJ detectors. f–i Dark current drift (f), antiradiation stability (g), operational stability under a constant bias of −1 V and pulsed X-ray radiation at a dose rate of 1600 μGyair s−1 (h), and long-term storage stability (i) of the BSJ detectors.

Finally, we examined the stability of the BSJ detectors during operation and under strong X-ray irradiation. The current drift caused by ion migration is an important reason for the poor operation stability of perovskite detectors, particularly for conventional layered structure detectors operating under high voltages13,34. In the BSJ detector, the tip-enhanced electric field effect can be neglected (Supplementary Fig. 24). In contrast, the low working voltages and compact perovskite films result in a relatively small current drift of 5% under working conditions of −1 V (Fig. 4f). According to the equation of carrier drift length L = μτE (where L is the carrier drift length, μ is the carrier mobility, τ is the carrier lifetime, and E is the electric field strength), it is understandable considering that the electric field needed in BSJ detectors is much smaller than that in conventional layered detectors due to the much smaller carrier drift length in BSJ detectors. The sensitivity of the BSJ detectors shows almost no degradation after exposure to X-rays at a dose rate of 1,600 μGyair s−1 for a total time of 5 hours (Fig. 4g), equivalent to 144,000 chest X-ray examinations30. Under pulsed X-ray radiation, the BSJ detectors also show remarkable operational stability (Fig. 4h). The shelf stability of the detector is also estimated. After being stored in a glovebox for nearly 5 months, the detector still maintained 92% of the initial sensitivity, demonstrating its excellent long-term stability (Fig. 4i). In addition, the BSJ detector maintained 83% of the initial sensitivity after being stored in the air without encapsulation for nearly one month (Supplementary Fig. 25). The low operation voltages and self-encapsulation effect of macroporous-carbon membranes should contribute significantly to their operation and shelf stability35.

Discussion

In conclusion, we have reported the formation of BSJs using interpenetrated carbon-perovskite networks. The perovskite phase absorbs X-rays and generates free electron-hole pairs, while the macroporous carbon electrode extracts and transports the holes. The structure is essentially different from the conventional layered structure mixing insulating polymers with perovskites. The BSJ overcomes the intrinsic trade-off in conventional X-ray detectors: increasing the thickness to absorb X-rays and reducing the carrier transportation length to reduce recombination. We have demonstrated its advantage of ultralow operation bias of −1 V. The BSJ X-ray detectors also exhibit excellent performance and stability compared with conventional layered structure devices using polycrystal films or single crystals (Supplementary Table 1). Although the BSJ detectors have a slow response due to the trapping-detrapping of carriers, the total dose needed for detection using BSJ detectors can be kept relatively low because of the low LoD compared with that of commercial photoconductive detectors (Supplementary Table 2). A photoconductive device with gain is often accompanied by a large dark current. Further reducing the dark current is highly needed for the BSJ detector to be applied in imaging. Reducing operation bias is an alternative way to reduce the dark current to match the TFT backplane in the future. For example, the BSJ detector exhibited higher sensitivity and comparable dark current compared with CZT detectors and a-Se detectors at ultralow bias (Supplementary Table 3). Improving the porosity of the macroporous carbon electrode to infiltrate more perovskites and composition engineering are possible ways of further improving the performance of the BSJ detector. Many advantages of the BSJ structure, such as self-encapsulation of the carbon network and the fabrication method of high-quality large-area ultra-thick perovskite active layer, also provided a different insight to improve the performance and stability of radiation detectors. Exploring the other advantages and radiation detection purposes of the BSJ structure is highly desirable.

Methods

Materials

The chemicals used in the experiments included lead iodide (PbI2; 99.999%, Alfa-Aesar), poly(N,N’-bis-4-butylphenyl-N,N’-bisphenyl)benzidine (poly-TPD; American Dye Source, Inc.), molybdenum trioxide (MoO3; Aladdin), 2-methoxyethanol (2-ME; J&K Scientific), and chlorobenzene (CB; 99.8%, Sigma-Aldrich). Carbon paste (DD-10) and diluent (Y-037) were purchased from Guangzhou Saidi Technology Co., Ltd. The main components of the carbon paste include curing resin, 2-(2-ethoxyethoxy) ethyl acetate, aromatic hydrocarbon and carbon black. The main components of the diluent include cyclohexanone and isophorone.

Methylammonium iodide (MAI) and methylammonium chloride (MACl) were synthesized by mixing methylamine (40 wt.% in H2O, Sigma-Aldrich) with equimolar amounts of aqueous hydriodic acid (HI; 57 wt.% in H2O, Sigma-Aldrich) and hydrochloric acid (HCl; 37% wt.% in H2O, Sinopharm Chemical Reagent Co., Ltd, stabilized), respectively, at 0 °C with constant stirring for 2 h. The solvent was removed using a rotary evaporator. The MAI and MACl were then recrystallized in a N2 glovebox by slowly cooling their ethanol solutions at a rate of 5 °C h−1. The large white crystals were then washed with diethyl ether and dried in a N2 glovebox at 60 °C for 24 h.

Carbon membrane preparation

The carbon paste and diluent were mixed at a weight ratio of 20:1. The mixture was then blade coated on an ITO (indium tin oxide) glass or polyethylene terephthalate (PET) substrate at a speed of 10 mm s−1 at room temperature. Compact carbon films were obtained by annealing the as-prepared wet carbon membranes at 120 °C for 2 hours. The macroporous carbon films were obtained by soaking the as-prepared wet carbon membranes in ethanol (or isopropanol or acetone) at room temperature for five hours. Then, the macroporous carbon membranes were peeled from the substrates and heated at 120 °C for 2 hours to remove the residual solvents.

Device fabrication

PbI2 (6.6 mmol), MAI (6.6 mmol), and MACl (0.66 mmol) were dissolved in 3 ml of 2-ME and stirred overnight before use. The perovskite solution was dropped onto macroporous carbon membranes, and an air pressure of 1.5 bar was applied on top of the precursor to improve its infiltration. The membranes were annealed at 120 °C under a pressure of 0.02 MPa for two hours. The above infiltration process was performed for three cycles. The perovskite-filled carbon membrane was then attached to the top of the compact carbon substrate, and the stacked membranes were annealed at 120 °C under a pressure of 0.02 MPa for two hours. A compact perovskite layer was prepared by blade coating the precursor solution (2.2 M) at room temperature with a coating speed of 50 mm s−1. The gap between the blade-coater and the substrate is 150 μm. The compact perovskite films were then annealed at 120 °C for 20 min. The poly-TPD solution was then spin-coated on the compact perovskite membrane at 1000 rpm for 30 s, followed by thermal annealing at 120 °C for 20 min. MoO3 and Au were sequentially evaporated on top of the poly-TPD layer with thicknesses of 8 nm and 25 nm, respectively. For the conventional layered structure detector, thick perovskite films were prepared using a similar blade-coating process as that used for compact perovskite films. The blade-coating process was repeated several times until the membrane reached the desired thickness.

Characterization of macroporous-carbon-perovskite network

The porosity and pore size diameters of the macroporous-carbon network were conducted using a mercury injection apparatus (Quantachrome, Poremaster33). The cross section of the interpenetrated MCP network was polished using an ion beam attenuator (Leica, EM TIC3X). SEM and EDS mapping were conducted using field-emission SEM (Hitachi, SU8220 and Zeiss, GeminiSEM 500). The KPFM measurements were conducted using a Bruker Dimension Icon system.

Characterizations of the X-ray detector

An Amptek Mini-X2 tube with an energy up to 50 keV and peak intensity at 10 keV was used as the continuous X-ray source. The dose rate of the X-ray source was tuned by changing the tube current and position, as well as by inserting Al foils of various thicknesses as filters. The dose rate was calibrated using an ion chamber dosimeter (PTW 30013 and PTW UNIDOS E). The response current of the detector under X-ray irradiation was measured using a semiconductor parameter analyzer (Keithley, 4200-SCS). The signal current (\({{\mbox{I}}}_{{\mbox{signal}}}\)) was obtained from subtracting the average total current (\({\bar{{\mbox{I}}}}_{{\mbox{total}}}\)) by the average dark current (\({\bar{{\mbox{I}}}}_{{\mbox{dark}}}\)). The sensitivity was derived from the slope between signal current density and dose rates. The noise current was measured with a dynamic signal analyzer (Agilent 35670 A) and a current preamplifier (Stanford Research System, SR 570). The EQE was measured using a xenon lamp-based system (Newport TLS260-300X, USA). DLTS measurements were performed using a Phystech FT-1230 HERA-DLTS system. The response time to visible light was measured by illuminating the devices with a 405 nm laser (Shanghai Raymount Optronics Technology, DL−405−100) from the Au cathode, and the response current was recorded with a current preamplifier and a digital mixed domain oscilloscope (Tektronix, MDO3104). The antiradiation stability of the devices was measured by exposing BSJ detectors to X-ray irradiation at a dose rate of 1,600 μGyair s−1 for approximately 1.5 h and turning off the X-ray source for 1 hour to cool the source. This procedure was repeated 4 times. The electric field distribution was simulated by COMSOL Multiphysics v6.1. The relative dielectric constants (ε) and electric conductivities (σ) of poly-TPD (ε = 2, σ = 2.6×10−3 S m−1), perovskite (ε = 6.5, σ = 7.7×10−6 S m−1), and carbon (ε = 30, σ = 10 S m−1) were taken from the literature.

X-ray imaging and modulation transfer function measurement

X-ray imaging was performed by moving a standard Pb line pair card through an X-Y linear stage between the X-ray source and the detector. The current signal of the detector was recorded with a current preamplifier and a digital mixed domain oscilloscope. The difference in photocurrent across the edge of the line pair card represents the contrast (∆μ). The difference in photocurrent across every line pair represents the effective contrast (∆μ0). The modulation function of the line pairs is expressed as [(∆μ0)/(∆μ)]36. Then, we fitted the MTF with a Gaussian function to obtain the spatial resolution of the detector.

Data availability

The data that support the findings of this study are provided in the main text and the Supplementary Information. Additional data supporting the findings can be requested from the corresponding authors. Source data are provided with this paper.

References

He, Y. et al. CsPbBr3 perovskite detectors with 1.4% energy resolution for high-energy γ-rays. Nat. Photon. 15, 36–42 (2021).

Wei, H. et al. Sensitive X-ray detectors made of methylammonium lead tribromide perovskite single crystals. Nat. Photon. 10, 333–339 (2016).

Zhuang, R. et al. Highly sensitive X-ray detector made of layered perovskite-like (NH4)3Bi2I9 single crystal with anisotropic response. Nat. Photon. 13, 602–608 (2019).

Zaffalon, M. L. et al. Extreme γ-ray radiation hardness and high scintillation yield in perovskite nanocrystals. Nat. Photon. 16, 860–868 (2022).

Song, Z. et al. Rheological engineering of perovskite suspension toward high-resolution X-ray flat-panel detector. Nat. Commun. 14, 6865 (2023).

Wei, H. & Huang, J. Halide lead perovskites for ionizing radiation detection. Nat. Commun. 10, 1066 (2019).

Kim, Y. C. et al. Printable organometallic perovskite enables large-area, low-dose X-ray imaging. Nature 550, 87–91 (2017).

Deumel, S. et al. High-sensitivity high-resolution X-ray imaging with soft-sintered metal halide perovskites. Nat. Electron. 4, 681–688 (2021).

Tailor, N. K. et al. Self-Powered X-ray Detection and Imaging using Cs2AgBiCl6 Lead-Free Double Perovskite Single Crystal. ACS Appl. Electron. Mater. 4, 4530–4539 (2022).

Yukta et al. Efficient and highly stable x-ray detection and imaging using 2D (BA)2PbI4 perovskite single crystals. ACS Photon. 9, 3529–3539 (2022).

He, Y., Hadar, I. & Kanatzidis, M. G. Detecting ionizing radiation using halide perovskite semiconductors processed through solution and alternative methods. Nat. Photon. 16, 14–26 (2022).

Gao, Y. et al. Ultrathin and ultrasensitive direct x-ray detector based on heterojunction phototransistors. Adv. Mater. 33, 2101717 (2021).

Liu, Y. et al. Triple-cation and mixed-halide perovskite single crystal for high-performance x-ray imaging. Adv. Mater. 33, 2006010 (2021).

Pan, W. et al. Cs2AgBiBr6 single-crystal X-ray detectors with a low detection limit. Nat. Photon. 11, 726–732 (2017).

Peng, J. et al. Ion-exchange-induced slow crystallization of 2D-3D perovskite thick junctions for X-ray detection and imaging. Matter 5, 2251–2264 (2022).

Qian, W. et al. An aerosol-liquid-solid process for the general synthesis of halide perovskite thick films for direct-conversion X-ray detectors. Matter 4, 942–954 (2021).

Wei, W. et al. Monolithic integration of hybrid perovskite single crystals with heterogenous substrate for highly sensitive X-ray imaging. Nat. Photon. 11, 315–321 (2017).

Sakhatskyi, K. et al. Stable perovskite single-crystal X-ray imaging detectors with single-photon sensitivity. Nat. Photon. 17, 510–517 (2023).

Yi, L., Hou, B., Zhao, H., Tan, H. Q. & Liu, X. A double-tapered fibre array for pixel-dense gamma-ray imaging. Nat. Photon. 17, 494–500 (2023).

Gandini, M. et al. Efficient, fast and reabsorption-free perovskite nanocrystal-based sensitized plastic scintillators. Nat. Nanotechnol. 15, 462–468 (2020).

García de Arquer, F. P., Armin, A., Meredith, P. & Sargent, E. H. Solution-processed semiconductors for next-generation photodetectors. Nat. Rev. Mater. 2, 16100 (2017).

Guo, F. et al. A nanocomposite ultraviolet photodetector based on interfacial trap-controlled charge injection. Nat. Nanotechnol. 7, 798–802 (2012).

Song, Y. et al. Elimination of interfacial-electrochemical-reaction-induced polarization in perovskite single crystals for ultrasensitive and stable x-ray detector arrays. Adv. Mater. 33, 2103078 (2021).

Jin, P. et al. Realizing nearly-zero dark current and ultrahigh signal-to-noise ratio perovskite X-ray detector and image array by dark-current-shunting strategy. Nat. Commun. 14, 626 (2023).

Tsai, H. et al. A sensitive and robust thin-film x-ray detector using 2D layered perovskite diodes. Sci. Adv. 6, eaay0815 (2020).

Li, M. et al. Oriented 2D Perovskite Wafers for Anisotropic X-ray Detection through a Fast Tableting Strategy. Adv. Mater. 34, 2108020 (2022).

Zhou, Y. et al. Heterojunction structures for reduced noise in large-area and sensitive perovskite x-ray detectors. Sci. Adv. 7, eabg6716 (2021).

Liu, Y. et al. Ligand assisted growth of perovskite single crystals with low defect density. Nat. Commun. 12, 1686 (2021).

Xia, M. et al. Compact and large-area perovskite films achieved via soft-pressing and multi-nctional polymerizable binder for flat-panel x-ray imager. Adv. Funct. Mater. 32, 2110729 (2022).

Zhao, J. et al. Perovskite-filled membranes for flexible and large-area direct-conversion X-ray detector arrays. Nat. Photon. 14, 612–617 (2020).

Wu, Z. et al. Highly efficient and stable perovskite solar cells via modification of energy levels at the perovskite/carbon electrode interface. Adv. Mater. 31, 1804284 (2019).

Yim, W. et al. Imaging spatial distribution of photogenerated carriers in monolayer mos2 with kelvin probe force microscopy. ACS Appl. Mater. Interfaces 14, 26295–26302 (2022).

Chen, Q. et al. All-inorganic perovskite nanocrystal scintillators. Nature 561, 88–93 (2018).

Yang, B. et al. Heteroepitaxial passivation of Cs2AgBiBr6 wafers with suppressed ionic migration for X-ray imaging. Nat. Commun. 10, 1989 (2019).

Mei, A. et al. A hole-conductor-free, fully printable mesoscopic perovskite solar cell with high stability. Science 345, 295–298 (2014).

Wu, X. et al. Ultrathin, transparent, and high density perovskite scintillator film for high resolution x-ray microscopic imaging. Adv. Sci. 9, 2200831 (2022).

Acknowledgements

Z.X. acknowledges the support from the National Key Research and Development Program of China (2022YFA1204800), the National Natural Science Foundation of China (62175226, 62234004), the University Synergy Innovation Program of Anhui Province (GXXT-2022-009), and funding from the Institute of Energy, Hefei Comprehensive National Science Center (Grant # 21KZS212). W.C. acknowledges the support from the National Natural Science Foundation of China (52302201), the China Postdoctoral Science Foundation (2022M723006), the fellowship of China National Postdoctoral Program for Innovative Talents (BX20230353). This work was partially carried out at the Center for Micro and Nanoscale Research and Fabrication, and Instruments Center for Physical Science, University of Science and Technology of China.

Author information

Authors and Affiliations

Contributions

Z.X. conceived the idea and supervised the project. Y.Z. fabricated and characterized the MCP membranes and detectors. Z.H. performed the theoretical simulation. N.G., C.Z., Y.Y., and X.X. calibrated the dose rate of the X-ray tube. Y.L. carried out the SEM and KPFM measurements. J.Y. and T.C. carried out the DLTS measurements. C.P. and W.C. synthesized the MAI and MACl materials. Z.X., J.Z., and Y.Z. analyzed the data and wrote the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Hsinhan Tsai and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, Y., Huang, Z., Peng, C. et al. A bulk Schottky junction for high-sensitivity portable radiation detectors. Nat Commun 15, 10311 (2024). https://doi.org/10.1038/s41467-024-54594-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-54594-3