Abstract

The conversion of CO2 emissions into valuable 3D printed carbon-based materials offers a transformative strategy for climate mitigation and resource utilization. Here, we 3D print carbon nanocomposites from CO2 using an integrated system that electrochemically converts CO2 into CO, followed by a thermocatalytic process that synthesizes carbon nanotubes (CNTs) which are then 3D printed into high-density carbon nanocomposites. A 200 cm2 electrolyzer stack is integrated with a thermochemical reactor for more than 45 h of operation, cumulatively synthesizing 37 grams of CNTs from CO2. A techno-economic analysis indicates a 90% cost reduction in CNT production on an industrial scale compared to current benchmarks, underscoring the commercial viability of the system. A 3D printing process is developed that achieves a high nanocomposite CNT concentration (38 wt%) while enhancing composite structural attributes via CNT alignment. With the rapidly rising demand for carbon nanocomposites, this CO2-to-nanocomposite process can make a substantial impact on global carbon emission reduction efforts.

Similar content being viewed by others

Introduction

The escalating concentration of atmospheric carbon dioxide (CO2) is a critical issue confronting society, with significant implications for the global climate patterns and the ecological balance which dictate Earth’s habitability1,2. Current CO2 capture and conversion methodologies present substantial economic and logistical challenges, often rendering them impractical for widespread adoption3,4. Achieving sustainability in this context hinges on generating value-added products that can compensate for the costs associated with carbon capture. Among the suite of potential CO2 derivatives, functional solid carbon materials are attractive for a variety of reasons. The physical properties of solid carbon materials afford straightforward storage and transportation, making them a uniquely viable candidate for CO2 valorization. Converting CO2 into valuable carbon-based solid materials not only offers a pragmatic approach to carbon sequestration but also advances a commercially viable avenue for turning a pervasive environmental liability into an economic asset.

Carbon composites, known for their strength, thermal stability, and lightweight properties, offer a superior alternative to metals like aluminum and titanium in many applications due to facile processing. These composites are revolutionizing applications from transport to construction, enabling up to a 70% reduction in vehicle weight, enhancing fuel efficiency, and lowering emissions5,6,7,8,9. Advances in additive manufacturing, particularly filament fusion fabrication, have expedited the production of complex 3D structures. The integration of nanomaterials, such as carbon nanotubes (CNTs), into thermoplastic feedstock has yielded nanocomposites with enhanced properties10. These developments promise significant advancements in sustainable infrastructure and technology. Nonetheless, the prevalent reliance on fossil-derived carbon sources for producing these composites is a notable drawback. Transitioning the production of carbon materials like CNTs and carbon composites to a CO2 feedstock could significantly bolster the environmental credentials and sustainability of 3D-printed carbon nanocomposites.

Here, we present an integrated electrocatalytic-thermocatalytic system, specifically designed to convert CO2 into CNTs for use in the 3D printing of carbon nanocomposites. The system begins with an anion exchange membrane CO2 electrolyzer stack, which operates under ambient conditions to reliably produce carbon monoxide (CO). This electrochemically generated CO is then directly channeled into a thermochemical reactor for efficient CNT synthesis. Recent work has demonstrated the feasibility of this process for producing CNTs at the 100 mg-scale with 11 h of CO2 electrolyzer stability11. This work accelerates commercialization by improving the process scale by two orders of magnitude, increasing CO2 electrolyzer stability to >200 h, offering techno-economic analysis, and incorporating a 3D printing process for producing CO2-derived carbon nanocomposites with remarkable material properties. The CO2-derived CNTs in this study are effectively integrated into an advanced additive manufacturing process integrated with post-processing, enabling the creation of high-quality 3D thermoset carbon nanocomposites. A key achievement of this process is the high CNT content integrated into the structured nanocomposite material (~38 wt%) which is essential for maximizing CO2 utilization. This approach, developed by blending reaction engineering with innovative additive manufacturing techniques, presents a viable and promising method for generating high-value carbon composite materials from CO2.

Results

Design of CO2 conversion system for 3D printing composites

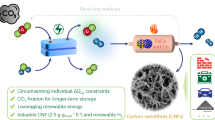

Figure 1 illustrates an innovative CO2-to-3D printed carbon nanocomposite process that operates under mild conditions, counteracting the thermodynamic challenges of directly converting CO2 to solid carbon, which typically requires high temperatures12,13,14. The process begins with the electrochemical reduction of CO2 to CO at ambient conditions, as shown in Eq. 1. This is achieved using a 200 cm2 CO2 electrolyzer stack, comprising Ag cathodes and Ir anodes, in combination with a 100 mM CsHCO3 electrolyte solution. In this setup, CO is generated at the cathode, whereas O2 is produced separately at the anode. The resulting CO is then channeled into a thermochemical reactor, where it interacts with a cost-effective steel wool catalyst. At a moderate temperature of 550 °C, the CO is transformed into carbon and CO2 (Eq. 2), and this CO2 can be easily recirculated to the initial CO2 electrolyzer.

In the thermochemical reactor, CO dissociation on the catalyst surface facilitates the formation of CNTs. The integrated electrochemical and thermocatalytic system ultimately produces carbon in the form of CNTs, along with O2, from the CO2 input (Eq. 3). The CO2-derived CNTs are subsequently utilized in an additive manufacturing process to create advanced carbon nanocomposites, suitable for many applications. These composites have notable applications in sectors like construction, transportation, and electronics (Fig. 1). In construction, they can replace high-emission steel for structural reinforcement, paneling, and repair of stressed structures. The application of carbon composites in transportation includes the fabrication of lightweight components for automobiles, aerospace, and marine vehicles. Furthermore, the electrical conductivity of carbon fiber makes carbon nanocomposites useful in manufacturing circuit boards, filaments, and batteries.

Synthesis of CO2-Derived CNTs

Thermochemical CNT formation takes place primarily via the Boudouard reaction (Eq. 2), but the following reaction may also take place:

A range of catalysts were evaluated for their efficiency in CNT formation. The tested materials included various grades of steel wool, stainless steel, and nickel wool. Among these, steel wool emerged as the most effective catalyst, significantly outperforming nickel wool and stainless steel which yielded negligible amounts of CNTs but did show a thin black film on all surfaces. This suggests strong binding of CO to produce carbon, but stainless steel (iron alloy with large quantities of nickel, chromium, etc.) and pure nickel wool lack the ideal catalytic properties to promote CNT growth. The superior performance of steel wool is attributed to its 3D Fe microfiber network, which provides an optimal structural environment for CNT growth along with the high iron content in steel wool which enabled the tip-growth mechanism for the formation of CNTs (Fig. S1)15. We experimented with different steel wool grades, characterized by varying microfiber diameters (35–75 μm). It was observed that Grade 0 steel wool, with a 50 μm fiber diameter, facilitated the highest CNT yield (~84%) with a production rate of 2.9 gCNT gcatalyst−1 h−1 (refer to Figs. S2, S3, and Supplementary Discussion 1 for detailed results). Energy-dispersive X-ray spectroscopy (EDS) analysis confirmed that the steel wool was predominantly comprised of iron, with only trace amounts of transition metals and carbon (Fig. S4).

The formation of CNTs, as described by the reactions shown in Equations 2 and 4, is exothermic. However, our findings indicate that a temperature range of 500–600 °C is essential to achieve high CNT yields (illustrated in Figs. 2a and S5, S6). This is due to the inherent tradeoff between reaction kinetics and thermodynamics given the exothermic nature of CNT production. The yield is highly sensitive to the composition of the gas feed into the thermochemical reactor, particularly the levels of hydrogen and CO2 (Figs. 2b and S7–S9). The absence of hydrogen resulted in no detectable CNT production, whereas a hydrogen concentration above 10 vol% significantly enhanced the yield. This finding was also supported by thermodynamic modeling (Fig. S10). Moreover, the presence of unreacted CO2 in the feed dramatically reduced CNT yield, an observation corroborated by both experimental data and thermodynamic modeling (Figs. 2c and S7–S9). Additionally, the humidity of the electrolyzer outlet gas stream also impacts performance with a lower humidity favoring higher CO conversion to CNTs (Fig. S11).

a Impact of thermochemical reactor temperature on CNT yield and CNT production rate (5 vol% H2, 95 vol% CO, 2 g catalyst, 500 sccm, 3 h test duration) (b) impact of H2 content on CNT yield (gas balance CO, 2 g catalyst, 500 sccm, 3 h test duration, 500 °C) c thermodynamic modeling of the effect of temperature and CO2 content on equilibrium and conversion of CO to CNTs (% CO2 represents vol% in feed to thermochemical reactor) (d) Impact of CO2 flowrate on CO2 electrolyzer outlet gas composition (e)>200 h high conversion CO2 electrolyzer stack stability testing (300 sccm CO2 inlet, 5 psi backpressure).

Comprehensive analysis using scanning electron microscopy (SEM) revealed that the highest quality CNTs were produced under conditions that maximized CNT yield, allowing for extended growth periods (Figs. S5, S8, S9). These insights have led to the identification of an optimal gas feed composition for the thermochemical reactor: high in CO, low in CO2, with more than 10 vol% hydrogen. Tailoring the CO2 electrolyzer to produce this specific gas mixture could significantly enhance the efficiency of CNT formation in the thermochemical reactor.

A membrane electrode assembly (MEA) configuration was employed to construct a CO2 electrolyzer, designed to produce an optimal gas mixture conducive to efficient CNT growth. The MEA-style CO2 electrolyzer, compared to a typical three-compartment microfluidic design, demonstrates greater potential for commercialization due to its ability to achieve higher energetic efficiency by minimizing internal resistances16,17,18,19,20,21. The cathode was constructed by depositing Ag particles on a carbon paper gas diffusion layer. For the anode, IrO2 particles (less than 10 nm in size) were deposited on a Ti felt, capitalizing on the known robustness of Ir as an anode catalyst in CO2 electrolysis under neutral conditions22. The cathode and anode were separated by PiperION anion exchange membranes. All tests employed a 100 mM CsHCO3 recirculating electrolyte.

To illustrate the system’s scalability, a 2-cell CO2 electrolyzer stack was constructed with a total electrode area of 200 cm2. The cathode featured a triple serpentine flow pattern to minimize pressure drop, whereas a parallel flow pattern was adopted for the anode to facilitate the efficient removal of oxygen bubbles. This 200 cm2 stack was operated in a parallel electrical circuit configuration, as depicted in Fig. S12.

Given that optimal CNT formation requires a minimal amount of CO2 in the inlet stream to the thermochemical reactor, the electrolyzer was operated at high CO2 conversion conditions to reduce the amount of unreacted CO2 in the gas outlet stream. Additionally, a hydrogen concentration above 10 vol% was necessary for effective CNT growth. While hydrogen evolution, a competing reaction on Ag catalysts during CO2 electroreduction23, is generally undesired24,25, it was beneficial in this context to produce the required hydrogen levels. Therefore, the 200 cm2 CO2 electrolyzer stack was tested across various inlet CO2 flow rates to tune the composition of the outlet gas (Fig. 2d). These flow rates were within the operational range required for the thermochemical reactor (Fig. S13). The impact of varying current densities and Ag catalyst loading on outlet gas composition was also studied revealing challenges in maintaining optimal gas composition >200 mA cm−2 and with a Ag catalyst loading <1 mg cm−2 (Figs. S14,S15). At 100 mA cm−2 and 1 mgAg cm−2 catalyst loading, the optimal inlet CO2 flow rate is 300 mL min−1 for the 200 cm2 electrolyzer. Under these conditions, a CO Faradaic efficiency of 90% can be achieved at ~3.2 V (Fig. S16). The additional cell voltage required at lower reactant CO2 flowrates results from non-Ohmic overpotential due to mass transport limitations. Future work should seek to overcome these mass transport limitations to improve cell voltage at high CO2 consumption rates.

A stability assessment was conducted on the 200 cm2 CO2 electrolyzer stack under optimized high conversion. The stack successfully delivered a stable performance for over 200 h under a total applied current of 20 A, as shown in Fig. 2e. During this stability test, the cell voltage stayed below 3.5 V and exhibited minimal fluctuation. A backpressure of 5 psi was applied during stability testing to simulate integration with a downstream thermochemical reactor which led to a slight improvement in CO2 consumption during initial operation attributed to improved CO2 surface coverage. Initial observations within the first 15 h included an increase in both H2 and CO2 fractions in the outlet gas mixture. These gas composition changes can be attributed to dry out and/or salt precipitation given the use of a non-humidified gas stream which was needed to promote the reaction shown in Eq. 4 and avoid suppressing CNT formation (Fig. S11). However, more in-depth studies using in operando neutron imaging are needed to elucidate this phenomenon. Some fluctuation in gas composition was observed around 125 h which can be attributed to either instability in the constant current sourced from the power supply or the previously discussed dry out and/or salt precipitation. However, these fluctuations in gas composition did not appear to impact CNT formation. Despite some dynamic behavior, the composition of the gas exiting the electrolyzer consistently met the target parameters (~20 vol% H2 and less than 20 vol% CO2) for the duration of the 200-h operation. This sustained performance within the desired compositional range underscores the system’s robustness and its potential for long-term operational stability.

Hybrid Electrocatalytic-Thermocatalytic reactor integration

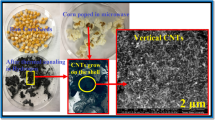

The successful development of the 200 cm2 CO2 electrolyzer stack was then integrated with the thermochemical reactor, shown in Fig. 3a. The outlet of the 200 cm2 electrolyzer stack was connected directly to the thermochemical reactor packed with steel wool catalyst. No separation unit was used to modify the gas composition before fed to the thermocatalytic reactor throughout all integrated testing. The electrolyzer stack was operated at a total current of 20 A (100 mA cm−2) with 3 L of 100 mM CsHCO3 electrolyte recirculated on the anode at ~20 ml min−1 and 300 sccm of CO2 fed to the cathode. The thermocatalytic reactor was heated to 550 °C and loaded with 2 g of steel wool catalyst. The integrated system was operated continuously for more than 45 h to produce ~37 g of CNTs (Fig. 3b). In a typical experiment with 2 g of steel wool catalyst, the average production rate of the CNTs is 0.79 g h−1.

Once the CNTs were produced, acid washing was conducted to remove any residual catalyst particles before 3D printing. EDS confirmed that the resulting CNTs are nearly pure carbon (Fig. S17). SEM analysis of the CO2-derived CNTs revealed a clean surface morphology, indicating high purity (Fig. 3C). Transmission Electron Microscopy (TEM) imaging provided more intricate details regarding the CNT structure, showing cylindrical nanostructures composed of multiple layers of carbon lattice rolled into concentric tubes (Fig. S18). These CNTs synthesized from CO2 exhibit an outer diameter of 261 (±24) nm and an average length of 3.519 (±1.531) μm, as characterized through image processing of SEM and TEM images. This analysis reveals a slightly larger diameter in comparison to commercially available large multi-walled carbon nanotubes (MWCNTs) with an outer diameter of ~107 nm and an average length of 1.25 μm26. However, the utilization of these larger diameter CNTs can lead to enhanced mechanical and functional properties, such as improved electrical and thermal conductivity, when employed as reinforcements in nanocomposite materials. Further exploration of these properties will be detailed in the section on carbon composite production.

The CNTs displayed a relatively dense packing, a characteristic likely influenced by the constricted growth environment provided by the steel wool catalyst’s microfiber network. Raman spectroscopy was utilized to draw a comparative analysis between the CO2-derived CNTs produced in the tandem system, CO-derived CNTs produced using only the thermochemical reactor, and commercially available MWCNTs (TCI, 60–100 nm). The results showed that the CO2-derived, CO-derived, and commercial CNTs exhibited similar properties. Raman spectra revealed comparable peak intensities in the D-band and G-band for all types of CNTs (Fig. S19). The CO2-derived CNTs exhibited a crystallinity of 71% while the CO-derived CNTs exhibited a crystallinity of 77% relative to the commercial CNTs. The D” band (1505–1520 cm−1) associated with amorphous carbon was undetectable in both the CO2-derived and CO-derived CNT samples suggesting a high degree of purity and lack of defects. Moreover, the prominent intensity of the D-band was indicative of the multi-walled structure of the CNTs.

Carbon composite production from CO2-derived CNTs

CO2-derived CNTs present a promising avenue for reinforcing structural components in additive manufacturing. The process of producing carbon nanocomposites from CNTs, which integrates 3D printing, polymer removal/carbonization, and thermoset matrix infiltration for mechanical components, creates structurally enhanced materials (Fig. 4a). Initially, a high-density (40 wt%) CNT nanocomposite filament is created by incorporating CO2-derived CNTs into thermoplastic polylactic acid (PLA) polymers, which serve as a binder for printing the green body of CNT structures. This carbon-dense composite feedstock enables the creation of 3D carbon structures that retain their structural integrity during post-polymer removal, attributed to the densely interconnected CNT network. The 3D printing process, conducted under high shear force, fabricates the green body of the carbon nanocomposite by aligning the CNTs in the printing direction, thereby enhancing the material’s strength in the aligned direction. Subsequently, through thermal treatment for binder removal, a 3D carbon scaffold is produced that preserves its preformed shape and CNT microstructure. A stable transition from the as-printed shape to the 3D carbon scaffold permits diverse infill of matrices within the structure, making it suitable for specific applications. For mechanical applications, the final step involves infiltrating this structure with an epoxy that offers superior mechanical properties, followed by curing, to create 3D CNT/epoxy nanocomposites. This method enables the fabrication of complex 3D CNT nanocomposites without requiring molds, and the CNT microstructure can be tailored through printing design and direction adjustments. The conventional approach to composite 3D printing, exemplified by direct 3D printing of CNT/epoxy nanocomposites27, faces obstacles in achieving a high CNT composite loading (>5 wt% CNTs) due to limited printability resulting from inadequate rheological properties of the feedstocks, such as the high viscosity of the epoxy ink mixture, when employing ink-state extrusion printing. This dependency on the polymer matrix introduces constraints on both the processability and functionality of the resulting product. In contrast, the 3D printing strategy presented here overcomes these hurdles by enabling a CNT composite loading of 40 wt%. Additionally, this approach offers the added benefit of not only maintaining the printability of the filament, but also ensuring that the mechanical and functional properties of the final product are not affected by the properties of the matrix material used for the filament.

a Manufacturing schematic from 3D printing CNT preform and polymer removal to 3D nanocomposite fabrication, b Characterization of 40 wt% CNT/PLA filament, showing a uniform distribution of the CNTs within the PLA, c Comparison photographs of carbon structure geometry according to the process step. d Surface geometry analysis by SEM images of as-printed, CNT scaffold, and CNT nanocomposite, e Comparison of tensile mechanical properties of epoxy and nanocomposites, f Thermal conductivity of synthesized CNT/PLA composites according to the printing direction [perpendicular (perp.) and parallel (par.)]. g Photographs demonstrating the design flexibility of 3D printing for complex 3D carbon structures.

For a lab-scale demonstration, rectangular epoxy/CNT nanocomposites were fabricated using 40 wt% CNT composite filaments, the highest achievable loading to make printable filaments with superior structural stability during post-processing. These filaments exhibited a uniform CNT dispersion within the polymer and were aligned longitudinally, facilitating smooth extrusion (Figs. 4b and S20). Figure 4c shows the transformation of the nanocomposite during various stages: 3D printing (Fig. S21), polymer removal, and matrix infiltration. The CNT samples, carbonized at 600 °C in a nitrogen atmosphere, retained their shape with minimal area reduction (~11%), without any visible defects or distortions. The interlinked CNT microstructure within the scaffold provided sufficient stability to endure vacuum pressure during the epoxy resin infiltration process via vacuum-assisted resin transfer molding (VARTM) (Fig. S22).

SEM analysis was employed to characterize the CNT distribution on the surfaces and cross-sections of both the composite and scaffold (Figs. 4d and S23). The as-printed composites showed a dense CNT distribution within the PLA, and the orientation of CNTs in the carbonized samples was evident. Approximately 40% of the CNTs were aligned within a 0° ± 20° range due to the high-shear force applied during 3D printing (Fig. S24). These aligned and interconnected CNTs were fully integrated into the epoxy matrix, comprising 37.6 wt% (27.9 vol%) of the final nanocomposites, as determined by TGA analysis (Fig. S25). The resultant CNT/epoxy nanocomposite demonstrated a Young’s modulus of 1.61 ± 0.11 GPa in the longitudinal direction, a significant improvement (~68%) over neat epoxy samples (0.96 GPa). This increase in Young’s modulus is attributed to the high load-bearing capacity of the longitudinally oriented CNTs (Fig. 4e). Moreover, such alignments contribute to improvements in electrical properties along the plane of alignment. Specifically, the electrical conductivity in the longitudinal direction exhibited a value of 757.57 S/m, representing a 200% enhancement relative to that observed in the transverse direction (252.53 S/m). The anisotropic nature of electrical conductivity holds promise for a wide array of applications spanning various industries, enabling precise control and utilization of electrical properties in specific directions.

By leveraging the high loading of large-diameter synthesized CNTs and the capability to manipulate the orientation of nanoparticles in 3D printing methodologies, the thermal properties of the carbon nanocomposites can be enhanced. Figure 4f shows the thermal conductivities of printed 30 wt% CNT/PLA samples in different printing directions, with CNTs aligned parallel and perpendicular to the heat flux. Both nanocomposites exhibit enhanced thermal conductivity compared to neat PLA polymer (0.097 W/mK)28 measured at 35 °C, as thermal reinforcement. Samples printed with CNTs oriented parallel to the heat flux demonstrate ~87% higher thermal conductivity (0.71 W/mK) compared to those printed with CNTs perpendicular to the heat flux (0.38 W/mK) at 35 °C. As the temperature escalates from 35 to 82 °C, the thermal conductivity of the composite increases correspondingly. This increase is attributed to the diminishing interfacial thermal resistance between the MWCNTs and the surrounding polymers as well as the effective heat conduction resulting from ballistic transport within the MWCNTs29. Moreover, these thermal conductivity properties surpass those of other MWCNT/PLA nanocomposites, which typically range from 0.3 to 0.575 W/mK28,30,31,32. These anisotropic thermal properties arise from the aligned orientation of high-loaded CNTs, offering potential applications as a heat dissipating material. Additionally, Fig. 4g illustrates the adaptability of this 3D printing in creating complex carbon structures, ranging from advanced lightweight materials like honeycombs to intricate hollow structures, exemplified by a 3D-printed pig head.

Techno-economics and market analysis

The conventional production method for industrial CNTs, primarily relying on chemical vapor deposition, uses hydrocarbon gases derived from fossil fuels. Methane pyrolysis is commonly used to produce CNTs at high temperatures ranging from 900 to 1400 °C33. Given the large amount of energy required to break C-H bonds, the current market price of multi-walled CNTs is $100 USD kg−1 (Fig. 5a)34. This study introduces a transformative approach, promoting the use of green syngas (CO and H2) produced electrochemically from CO2 and water at ambient conditions, as an alternative. Recent advancements in CO2 electrolysis have shown that CO, a viable product of electrochemical CO2 reduction, can be manufactured at a mere 0.29 USD per kg (Supplementary Discussion 3)35,36. This approach could feasibly reduce the cost of producing CNTs at an industrial scale down to $9.5 USD kg−1, well below the current market price (Fig. 5a). Further improvements in CO2 electrolysis could drive down this cost to $6.0 USD kg−1 by reducing cell voltage to 2.6 V and improving current density to 500 mA cm−2.

a techno-economic modeling of CO2-derived CNTs [pressure swing adsorption (PSA)] (b) 2022 composite material market revenue share breakdown42 (c) comparative market analysis of carbon utilization in construction materials (Table S1) (d) projected emission sequestration potential of CO2-derived carbon composites (Supplementary Discussion 4).

This advancement in the production of more economical CNTs promises to lower the cost of carbon nanocomposite materials, potentially revolutionizing their application across various industries. In 2022, the revenue from composite materials was largely driven by the construction industry, contributing ~38% to total sales (Fig. 5b). While current trends show a keen interest in incorporating carbon utilization in construction materials, much focus has been on CO2 sequestration in concrete through mineralization processes37,38,39. However, these processes often involve the conversion of CO2 into calcium or magnesium carbonates, leading to compromised compressive strength and a low carbon-to-cement weight ratio40. In contrast, CO2-derived carbon composites can integrate carbon without sacrificing material strength. When compared to other construction materials utilized for CO2 sequestration, CO2-derived carbon composites stand out, offering higher CO2 utilization efficiency by weight (Fig. 5c). These composites can incorporate up to ~38 wt% carbon from CO2, significantly outperforming other materials in terms of CO2 utilization. Moreover, the carbon composite market, with a valuation of $691 billion and a robust annual growth rate of 6.1%, represents a substantial economic opportunity. The high carbon density and market potential of these composites make them an attractive option for large-scale CO2 utilization.

The carbon composite market is projected to surpass $3.6 trillion by 2050, based on current growth trends (Fig. 5d). If CO2-derived composites can capture a significant market share, they could play a crucial role in achieving gigaton-scale CO2 sequestration by 2050 (Supplementary Discussion 4). The growth of this market has been limited by the elevated costs associated with traditional carbon composite production. However, utilizing CO2-derived CNTs could significantly accelerate market expansion, outpacing previous projections. This is where the revolutionary potential of 3D printing technology becomes evident. Not only does it facilitate the large-scale production of CO2-derived CNTs, but it also does so in a cost-effective manner, potentially leading to a seismic shift in the industry.

When carbon capture technologies are deployed at the gigaton scale needed for impactful environmental improvement, the role of carbon utilization technologies becomes critical. The CO2-to-3D printed nanocomposite system showcased in this study not only exemplifies the scalability required for such an endeavor but also highlights the economic feasibility of this innovative approach in CNT production. Its ability to create intricate structures with high precision further underscores the remarkable potential of this technology in contributing to CO2 emission mitigation on a global scale.

Discussion

In summary, we report a breakthrough system for 3D printing carbon nanocomposites directly from CO2 by integrating CO2 electrolysis with a thermocatalytic reactor. This innovative approach successfully produces CNTs for additive manufacturing, operating optimally with minimal residual CO2 and about 10 vol% H2 in the CO stream. The hybrid process, which maintained stability for over 45 h, resulted in the production of ~37 grams of CNTs. A notable 90% cost reduction in CNT production, compared to traditional fossil fuel-derived methods, was identified through our techno-economic analysis. The 3D printed nanocomposites, comprising around 38 wt% CO2-derived CNTs, achieved a Young’s modulus of 1.61 GPa along with enhanced thermal and electrical conductivity via CNT alignment. This development not only marks a significant advancement in carbon nanocomposite manufacturing but also holds immense potential for large-scale CO2 utilization and sequestration. By aligning with projected composite market demands, this technology could contribute significantly to global CO2 mitigation efforts, representing a crucial step toward addressing climate change.

Methods

Electrode preparation for CO2 electrolysis

To produce the cathodes, a commercial gas diffusion layer (Sigracet 39BB, Fuel Cell Store) was reinforced by air-spraying a TeflonTM dispersion (FEPD 121, Fuel Cell Store) with carbon black (Vulcan XC-72R, Fuel Cell Store). The reinforcement ink was prepared by adding 400 mg carbon black and 20% FEPD in 20 mL deionized water and 20 mL isopropyl alcohol. The ink was sonicated, vortexed, and then sprayed onto the gas diffusion layer (GDL) at 130 °C to achieve a 20 wt% loading relative to the fresh GDL. The reinforced GDL was then heated to 300 °C for 10 min in a furnace. After the reinforcement layer was applied and heat treated, Ag ink was prepared by mixing 400 mg Ag nanoparticles (<100 nm, 99.5% m Sigma-Aldrich) with 5 wt% carbon black (Vulcan XC-72R, Fuel Cell Store) and 5 wt% Sustainion Ionomer (Sustainion XA-9, Dioxide Materials) in 20 ml deionized water and 20 ml isopropyl alcohol. The Ag ink was then sonicated, vortexed, and air-sprayed onto the reinforced gas diffusion layers to achieve a 1 mg cm−2 loading.

To produce the anodes, IrO2 (99.99%, Alfa Aesar) was applied to Ti felt (Fuel Cell Store). The IrO2 ink was prepared by mixing 200 mg IrO2 with 15 wt% TeflonTM (FEPD 121) in 20 mL deionized water first, then adding 20 mL isopropyl alcohol second. After sonicating and vortexing, the catalyst ink was air-sprayed onto the Ti felt to achieve a loading of 2 mg cm−2. After the desired loading was achieved, the anode was heat-treated in a furnace at 300 °C for 1 h to complete the anode preparation.

Electrochemical experimentation

The CO2 electrolysis experiments were all conducted in a 200 cm2 MEA stack. The cathode was equipped with triple serpentine flow patterning to promote gas distribution and minimize pressure drop while the anode was equipped with parallel flow patterning to promote oxygen bubble removal (Fig. S26). PTFE gasketing (0.01”, McMaster-Carr) was used to seal the electrolyzer stack. PiperION-A60-HCO3 was used for the anion exchange membrane and was activated by soaking overnight in 0.1 M KHCO3. Ag catalyst was used on the cathode, PiperION (A60-HCO3, Versogen) was used as the anion exchange membrane, 100 mM CsHCO3 was used as the electrolyte, and an IrO2 catalyst was used on the anode. For stability testing, a 3 L reservoir of electrolyte was refreshed every 48 h. The electrolyte was recirculated at a flow rate of ~25 ml min−1. A power source (Cosel, PCA1500F) was used to supply current to the CO2 electrolyzer stack for all electrochemical experiments. Current was distributed to each cell using a busbar (Blue Sea Systems, PowerBar 1000). Inlet CO2 gas flow rate ranged from 250 to 500 sccm depending upon the experiment. All products at the outlet of the CO2 electrolyzer were quantified using a multiple gas analyzer no. 5 gas chromatograph (SRI Instruments) equipped with a MolSieve 5 A column, a HaySepD column, and a thermal conductivity detector. The outlet gas flow rate was monitored using an ADM flow meter (Agilent).

Thermochemical CNT production experiments

The thermochemical reactor is comprised of a 1” quartz tube in a Lindberg Blue tube furnace. 2 g of steel wool (McMaster) was submerged in 10% acetic acid for 5 min to remove oil coatings. The wool was subsequently rinsed in DI water and dried in a vacuum oven to obtain an accurate mass. The dried wool was then loosely packed into the center of the quartz tube and positioned in front of a thermocouple for accurate temperature measurement. The furnace was then heated to the desired operation temperature. Preliminary experiments investigating CNT formation utilized commercial inlet gases for characterization purposes. High-purity CO/H2/CO2 with desired flowrates were mixed and then entered the reactor. For integrated tests, the CO-rich product stream from the CO2 electrolyzer was fed directly into the thermochemical reactor. Due to the self-clogging nature of a CNT deposition reactor, care was taken to avoid backpressure build-up in the system by closely monitoring pressure upstream of the steel wool. For some experimental sets, the outlet gas from the thermochemical reactor was analyzed with an in-line gas chromatograph. After the experiment, the furnace was cooled to room temperature, and the steel wool and CNTs produced were collected and weighed to obtain an accurate measurement of the mass of CNTs produced. The CNTs were then sieved before acid leaching in 2 M hydrochloric acid for 2 days to remove leftover metals. This was followed by vacuum filtration of the CNT solution and drying in the vacuum oven to obtain pure CNTs for characterization and 3D printing.

Carbonizable carbon filament preparation

The CNT solution was prepared by dispersing 3.5 g of CO2-derived CNTs in 700 ml of dichloromethane (DCM) (Sigma-Aldrich) which was ultrasonicated for 30 min at a power of 60 W. Matrix solution was made by dissolving 5 g of PLA (LX175, Filabot) in 700 ml of DCM solvent using a magnetic stirrer until the PLA was completely melted. Once melted, 0.25 g of polyethylene glycol dimethyl ether 500 (PEGDE 500, Sigma-Aldrich) was added to the solution and mixed for 30 min to achieve better flexibility. Subsequently, the CNT and matrix solutions were mixed and ultrasonicated for an additional 10 min at a power of 60 W. The solution was dried overnight to produce a 40 wt% CNT/PLA film which was then cut into smaller pieces for a filament extrusion. A single extruder was used to make the continuous composite filament suitable for 3D printing.

Fabrication of the nanocomposite

The 3D preformed CNT structure was printed with an FDM printer (CarbonForm Inc.). To remove the matrix within the structure, the sample was heated in a furnace in nitrogen with the following parameters: heating from room temperature to 340 °C (10 °C min−1), heating up to 600 °C (2 °C min−1), maintaining at 600 °C for 30 min, and then cooling to room temperature (5 °C min−1). Once the CNT scaffold was obtained, thermoset resin (Epon 862/Epikure 3223, mixed at a weight ratio of 100:12) was infiltrated into the carbon scaffold through VARTM technique and cured overnight at room temperature.

CNT material characterization

Characterization of CNT structures was performed through the acquisition of SEM and TEM images, followed by detailed analysis such as diameter and length using image processing software, Fiji. Initially, the raw SEM/TEM images were converted into 8-bit format, and subsequently, Ridge Detection was applied with specific parameters (Line width: 14, High contrast: 100, Low contrast: (1) to accurately measure the outer diameter and length of the CNTs. The morphologies of the composite filaments, CNT scaffolds, and nanocomposites were examined using SEM (SEM/FIB Auriga 60 Cross Beam). To determine the ratio of the matrix and CNTs, thermogravimetric analysis (TGA, Discovery TGA) was used under nitrogen with a 10 °C min−1 ramp rate. The orientation of CNT was characterized through image processing using Fiji software. At first, the SEM images were converted to 8-bit and then analyzed orientation using ‘OrientationJ Distribution’’ and ‘OrientationJ Analysis’’ with Gaussian-shaped windows with 4 pixels. The volume fraction of CNTs was calculated based on TGA test results and the following formula41:

where \({m}_{f},{\rho }_{c},{{\rm{and}}} \, {\rho }_{m}\) are the mass fraction of CNTs, nanocomposite density, and resin density (1.20 g cm−3), respectively.

The relative CNT crystallinity was obtained via Raman spectroscopy using the following formula11:

where ID and IG represent the intensity of the D and G band, respectively.

CNT nanocomposite material characterization

The tensile properties of the CNT nanocomposites and thermoset references were evaluated using a Linkam Modular Force Stage machine equipped with a 200 N load cell with a 1.2 mm min−1 speed. For the measurement of thermal conductivity, a DTC-300 heat flow meter equipped with a guarded hot plate technique (TA Instruments) was utilized, and the thermal properties were measured under a steady-state condition. The electrical conductivity was measured through the four-point probe method.

Data availability

All data needed to evaluate the conclusions in the paper are present in the paper and/or the Supplementary Information. Additional data related to this paper are available from the authors by reasonable request. Source data are provided with this paper.

References

Intergovernmental Panel on Climate Change Sixth Assessment Report https://www.ipcc.ch/report/sixth-assessment-report-cycle/ (2023).

Friedlingstein, P. et al. Global carbon budget 2022. Earth Syst. Sci. Data 14, 4811–4900 (2022).

Sanz-Pérez, E. S., Murdock, C. R., Didas, S. A. & Jones, C. W. Direct capture of CO2 from ambient air. Chem. Rev. 116, 11840–11876 (2016).

Hepburn, C. et al. The technological and economic prospects for CO2 utilization and removal. Nature 575, 87–97 (2019).

Deng, K., Zhang, C. & Fu, K. (Kelvin). Additive manufacturing of continuously reinforced thermally curable thermoset composites with rapid interlayer curing. Compos. Part B Eng. 257, 110671 (2023).

Fu, K. et al. Graphene oxide-based electrode inks for 3D-printed lithium-ion batteries. Adv. Mater. 28, 2587–2594 (2016).

Fu, K., Yao, Y., Dai, J. & Hu, L. Progress in 3D printing of carbon materials for energy-related applications. Adv. Mater. 29, 1603486 (2017).

Azarov, A. V., Antonov, F. K., Golubev, M. V., Khaziev, A. R. & Ushanov, S. A. Composite 3D printing for the small size unmanned aerial vehicle structure. Compos. Part B Eng. 169, 157–163 (2019).

Smith, M. New developments in carbon fiber. Reinf. Plast. 62, 266–269 (2018).

Zhang, C. et al. Carbon additive manufacturing with a near-replica “Green-to-Brown” transformation. Adv. Mater. 38, e2208230 (2023).

Xie, Z. et al. CO2 fixation into carbon nanofibres using electrochemical–thermochemical tandem catalysis. Nat. Catal. 7, 98–109 (2024).

Chueh, W. C. et al. High-flux solar-driven thermochemical dissociation of CO2 and H2O using nonstoichiometric ceria. Science 330, 1797–1801 (2010).

Ackermann, S. et al. Kinetics of CO2 reduction over nonstoichiometric Ceria. J. Phys. Chem. C. 119, 16452–16461 (2015).

Han, X., Ostrikov, K. K., Chen, J., Zheng, Y. & Xu, X. Electrochemical reduction of carbon dioxide to solid carbon: development, challenges, and perspectives. Energy Fuels 37, 12665–12684 (2023).

Gao, J. et al. Revealing the role of catalysts in carbon nanotubes and nanofibers by scanning transmission X-ray microscopy. Sci. Rep. 4, 3606 (2014).

Overa, S., Ko, B. H., Zhao, Y. & Jiao, F. Electrochemical approaches for CO2 conversion to chemicals: a journey toward practical applications. Acc. Chem. Res. 55, 638–648 (2022).

Uǧuz, H. et al. 2022 Roadmap on low temperature electrochemical CO2 reduction. J. Phys. Energy 4, 042003 (2020).

Crandall, B. S., Overa, S., Shin, H. & Jiao, F. Turning carbon dioxide into sustainable food and chemicals: how electrosynthesized acetate is paving the way for fermentation innovation. Acc. Chem. Res. 56, 1505–1516 (2023).

Crandall, B. S. & Jiao, F. Knowledge transfer between liquid- and gas-fed CO2 electrolysis. Chem. Catal. 2, 2833–2834 (2022).

Hansen, K. U., Cherniack, L. H. & Feng, J. Voltage loss diagnosis in CO2 electrolyzers using five-electrode technique. ACS Energy Lett. 7, 4504–4511 (2022).

Weekes, D. M., Salvatore, D. A., Reyes, A., Huang, A. & Berlinguette, C. P. Electrolytic CO2 reduction in a flow cell. Acc. Chem. Res. 51, 910–918 (2018).

Vass, Á., Kormányos, A., Kószo, Z., Endrődi, B. & Janáky, C. Anode catalysts in CO2 electrolysis: challenges and untapped opportunities. ACS Catal. 12, 1037–1051 (2022).

Cave, E. R. et al. Trends in the catalytic activity of hydrogen evolution during CO2 electroreduction on transition metals. ACS Catal. 8, 3035–3040 (2018).

Thevenon, A., Rosas-Hernández, A., Fontani Herreros, A. M., Agapie, T. & Peters, J. C. Dramatic HER suppression on Ag electrodes via molecular films for highly selective CO2 to CO reduction. ACS Catal. 11, 4530–4537 (2021).

Bondue, C. J., Graf, M., Goyal, A. & Koper, M. T. M. Suppression of hydrogen evolution in acidic electrolytes by electrochemical CO2 reduction. J. Am. Chem. Soc. 143, 279–285 (2021).

Founda, A. N. & Almaqwashi, A. A. Synthesized partially unzipped carbon nanotubes and potential DNA/CNTs interactions. Phys. Scr. 98, 065955 (2023).

Jiang, Q., Zhang, H., Rusakov, D., Yousefi, N. & Bismarck, A. Additive manufactured carbon nanotube/epoxy nanocomposites for heavy-duty applications. ACS Appl. Polym. Mater. 3, 93–97 (2021).

Zhang, C., Deng, K., Li, X., Fu, K. K. & Ni, C. Thermally conductive 3D-printed carbon-nanotube-filled polymer nanocomposites for scalable thermal management. ACS Appl. Nano Mater. 14, 13400–13408 (2023).

Wu, M. C. H. & Hsu, J.-Y. Thermal conductivity of carbon nanotubes with quantum correction via heat capacity. Nanotechnology 20, 145401 (2009).

Ivanov, E. et al. PLA/Graphene/MWCNT composites with improved electrical and thermal properties suitable for FDM 3D printing applications. Appl. Sci. 9, 1209 (2019).

Spineli, G. et al. Nanocarbon/Poly(Lactic) acid for 3D printing: effect of fillers content on electromagnetic and thermal properties. Materials 12, 2369 (2019).

Kotsilkova, R. et al. Essential nanostructure parameters to govern reinforcement and functionality of poly(lactic) acid nanocomposites with graphene and carbon nanotubes for 3D printing application. Polymers 12, 1208 (2020).

Sánchez-Bastardo, N., Schlögl, R. & Ruland, H. Methane pyrolysis for CO2-free H2 production: a green process to overcome renewable energies unsteadiness. Chem. Ing. Tech. 10, 1596–1609 (2020).

Li, K. et al. Process simulation of diesel into aromatics and carbon nanotubes: a techno and economic analyses. ACS Omega 20, 17941–17947 (2023).

Jouny, M., Luc, W. W. & Jiao, F. A general techno-economic analysis of CO2 electrolysis systems. Ind. Eng. Chem. Res. 57, 2165–2177 (2018).

Shin, H., Hansen, K. U. & Jiao, F. Techno-economic assessment of low-temperature carbon dioxide electrolysis. Nat. Sustain. 4, 911–919 (2021).

Zevenhoven, R., Fagerlund, J. & Songok, J. K. CO2 mineral sequestration: developments toward large-scale application. Greenh. Gases Sci. Technol. 1, 48–57 (2011).

Winnefeld, F., Leemann, A., German, A. & Lothenbach, B. CO2 storage in cement and concrete by mineral carbonation. Curr. Opin. Green Sustain. Chem. 38, 100672 (2022).

Chang, R. et al. Calcium carbonate precipitation for CO2 storage and utilization: a review of the carbonate crystallization and polymorphism. Front. Energy Res. 5, 17 (2017).

Ravikumar, D. et al. Carbon dioxide utilization in concrete curing or mixing might not produce a net climate benefit. Nat. Commun. 12, 855 (2021).

Bradford, P. D. et al. A novel approach to fabricate high volume fraction nanocomposites with long aligned carbon nanotubes. Compos. Sci. Technol. 70, 1980–1985 (2010).

Composites Market Size & Trends. Grand View Res. https://www.grandviewresearch.com/industry-analysis/composites-market (2022).

Acknowledgements

This material is based upon work supported by the US Department of Energy under Award Number DE-FE0032147. Sagar Sourav is acknowledged for his Raman spectroscopy contribution.

Author information

Authors and Affiliations

Contributions

B.S.C., M.N., and S.P. contributed equally to this work. B.S.C. and M.N. conceived the experimental design, carried out the operation of the electrocatalytic-thermocatalytic system, performed data analysis, and wrote the first draft of this manuscript. S.P. carried out the 3D printing, analyzed the material properties, assisted with collecting SEM images, and wrote the first draft of the 3D printing section of this manuscript. J.Y. assisted with electrochemical experiments. C.Z. performed electrical and thermal properties characterization. S.M. assisted with 3D nanocomposite fabrication. K.W. and X.L. assisted with thermochemical experiments. F.J. and K.F. supervised the work. All authors edited and approved the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Ung Lee and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Crandall, B.S., Naughton, M., Park, S. et al. Transforming CO2 into advanced 3D printed carbon nanocomposites. Nat Commun 15, 10568 (2024). https://doi.org/10.1038/s41467-024-54957-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-024-54957-w

This article is cited by

-

Artificial synthesis of carbohydrates from electrochemically fixed carbon dioxide

Nature Synthesis (2026)

-

Progress in the integration of 3D printing technology with photothermal materials for osteosarcoma treatment

Advanced Composites and Hybrid Materials (2025)

-

A novel multi-method framework for 3D printed fiber-reinforced polymer concrete utilizing advance additive manufacturing techniques

Asian Journal of Civil Engineering (2025)