Abstract

Amine-assisted two-step CO2 hydrogenation is an efficient route for methanol production. To maximize the overall catalytic performance, both the N-formylation of amine with CO2 (i.e., first step) and the subsequent amide hydrogenation (i.e., second step) are required to be optimized. Herein, a class of Al2O3-supported Ru catalysts, featuring multiple activated Ru species (i.e., metallic and oxidized Ru), are rationally fabricated. Density functional theory calculations suggest that metallic Ru forms are preferred for N-formylation step, whereas oxidized Ru species demonstrate enhanced amide hydrogenation activity. Thus, the optimal catalyst, containing unique Ru clusters with coexisting metallic and oxidized Ru species, efficiently synergize the conversion of CO2 into methanol with exceptional selectivity (>95%) in a one-pot two-step process. This work not only presents an advanced catalyst for CO2-based methanol production but also highlights the strategic design of catalysts with multiple active species for optimizing the catalytic performances of multistep reactions in the future.

Similar content being viewed by others

Introduction

The anthropogenic emissions of greenhouse gases, primarily carbon dioxide (CO2), are widely believed to be responsible for a range of adverse environmental issues1,2. The facile catalytic reduction of CO2 into value-added secondary carbon feedstocks (i.e., hydrocarbons, alcohols, and carboxylic acids) exhibits excellent potential for mitigating the excessive accumulation of CO23,4,5,6. As one of the most attractive chemical products generated via CO2 reduction, methanol (CH3OH) has a variety of attractive potential applications, including serving as a basic industrial feedstock, functioning as a liquid organic hydrogen carrier (LOHC), and being utilized in direct CH3OH fuel cells (DMFCs)7,8,9,10,11. The thermal-driven CO2 hydrogenation is a promising pathway for the scale-up production of CH3OH, which commonly employs H2 as the reductant, ideally sourced from renewable green hydrogen, thus contributing to a sustainable future12,13,14. In the past decades, remarkable researches have been conducted on the selective production of CH3OH via traditional one-step CO2 hydrogenation15,16,17,18,19,20,21, mainly focusing on metal oxides (e.g., In2O3, ZnO-ZrO2, In2O3-ZrO2)22,23,24 and metal/metal oxides (e.g., Cu/ZnO/Al2O3, Cu/In2O3, Cu/ZrO2, Pd/ZnO)25,26,27,28,29,30,31. However, the traditional CO2 hydrogenation based on metal oxides is encumbered by the necessity of high catalytic temperature (>300 °C)22,23,24, resulting in excessive energy consumption. Although the introduction of metal components into metal oxides promotes the activation of H2 and thus achieves enhanced catalytic performance at relatively lower temperature (<250 °C)26,27,28, this modification simultaneously leads to a trade-off with the decrease in CH3OH selectivity, owing to the increased production of the by-products CH4 and CO32,33,34.

Compared to the traditional one-step CO2 hydrogenation16,17,18,19,20, the process of amine-assisted CO2 hydrogenation to CH3OH consists of two sequential steps, i.e., the N-formylation of amine with CO2 (i.e., first step) and the subsequent amide hydrogenation (i.e., second step). In the presence of homogeneous catalysts35,36,37,38, especially ruthenium complexes35,36,37, amine-assisted CO2 hydrogenation demonstrates superior catalytic activity and selectivity at mild condition (<180 °C), thus making it to be a promising alternative for CH3OH production. However, the inherent difficulties in separation and recycling of homogeneous catalysts, coupled with the inferior stability, hinder their widespread application and the scaling up of this amine-assisted CO2-to-MeOH route. Furthermore, to maximize the overall catalytic performance of the amine-assisted two-step CO2 hydrogenation, both the N-formylation step and the subsequent amide hydrogenation are required to be optimized. Due to the distinct requirements of the preferred catalytic species for different steps in sequential reactions, catalysts featuring multiple activated species are theoretically deemed essential39,40,41. Therefore, the existent homogeneous catalysts with a single designated activity structure may not provide the optimum catalytic activity for both steps of the sequential CO2 hydrogenation process. In this context, the immobilization of homogeneous catalysts onto stable heterogeneous matrix (e.g., Al2O3, In2O3, ZrO2) can be the most straightforward strategy, as it offers the benefit of easy separation. More importantly, the atomic-scale heterogeneity of supported metal catalysts is almost unavoidable, resulting in diverse structural morphologies or/and local coordination environments for the active components42,43, but this heterogeneity precisely offers the potential to optimize each step of the sequential CO2 hydrogenation reaction and thus fine-tune the overall catalytic performance.

Based on the aforementioned considerations, a series of Al2O3-based heterogeneous catalysts containing distinct Ru species, labeled as Ru-1, Ru-2, and Ru-3, were systematically synthesized via an impregnation-annealing method. Specifically, upon annealing in argon, Ru-1 showcased atomically dispersed Ru species (Ru1). In contrast, Ru-2, annealed in air, featured a combination of Ru1 and Ru clusters (Ruc), while Ru-3, annealed in a 10% H2-argon mixture, featured a hybrid of Ru1 and Ru nanoparticles (Rup). Notably, Ruc is a special active center, where the top site, Ruc-top, exhibits metallic characteristics similar to Rup, while the edge site, Ruc-edge, interacts with the Al2O3 matrix, displaying oxidized states comparable to that of Ru1. Experimental investigations reveal that the catalytic activities of Ru species in the morpholine N-formylation step (Eq. (1)) follow the order of Ruc > Rup > Ru1, whereas in the amide (i.e., N-formylmorpholine, NFM) hydrogenation step (Eq. (2)), the sequence is Ruc > Ru1 > Rup. As a result, Ru-2, featuring dominant morphological distribution of Ruc, presented optimal catalytic performance in the one-pot two-step hydrogenation of CO2 to CH3OH with morpholine as the amine assistant (Eq. (3), selectivity of CHO3H > 95%, regeneration of morpholine >99%). Density functional theory (DFT) results reveal that the metallic Ru species (i.e., Ruc-top and Rup) and oxidized Ru species (i.e., Ruc-edge and Ru1) are favorable for amine N-formylation and the subsequent amide hydrogenation, respectively, consistent with the experimental results. This work presents a heterogeneous catalysis protocol for amine-assisted hydrogenation of CO2 towards CH3OH production with superior selectivity and stability, highlighting the significance of active species heterogeneity in enhancing the catalytic performance for multistep sequential reactions.

Results

Synthesis and characterizations of Al2O3-based Ru catalysts

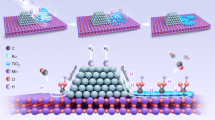

A series of Al2O3-supported Ru catalysts (i.e., Ru-1, Ru-2, Ru-3) were rationally synthesized via an impregnation-annealing method, with Ru-Macho and α-Al2O3 being employed as metal precursor and support, respectively. According to the different calcination conditions, Ru-1 and Ru-2 were identified as catalysts annealed in argon or air at 200 °C for 2 h, respectively, while Ru-3 was synthesized by annealing in a 10% H2-argon mixture at 300 °C for 2 h (see Method section for details). The powder X-ray diffraction (PXRD) patterns exhibited no diffraction peaks related to Ru or RuO2 phase in the three catalysts (Supplementary Fig. 1), which might be ascribed to the low contents (Supplementary Table 1) or/and small sizes of the Ru species. Transmission electron microscopy (TEM) images show that the morphologies of the synthesized catalysts with loaded Ru species remained consistent with the original Al2O3 matrix (Supplementary Fig. 2). Moreover, N2 adsorption experiments reveal that the BET values of the above three Ru catalysts are comparable to that of the pristine α-Al2O3 (Supplementary Fig. 3), implying that the influence of Ru loading on the specific surface area of the α-Al2O3 matrix is negligible. To identify the differences in atomic-scale structures among the three Ru catalysts, the aberration-corrected high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) technique was adopted. The Ru species in Ru-1 catalysts were atomically dispersed (Fig. 1a and Supplementary Fig. 4), while Ru clusters (~0.8 nm) emerged in Ru-2 and these clusters grew into larger nanoparticles (~2.9 nm) in Ru-3 (Fig. 1b, c and Supplementary Figs. 5, 6). Notably, the size of formed Ru species is not only related to the annealing conditions but also to the coordination structure of the Ru precursor. In contrast to Ru-2, the catalyst obtained by replacing Ru-Macho with ruthenium acetylacetonate (labeled as Ru-4) demonstrated a notable enlargement in the size of resulting Ru species (Supplementary Fig. 7), suggesting that the P/N-Ru coordination in the Ru-Macho precursor serves to stabilize the Ru species and mitigate Ru agglomeration during the annealing process.

Aberration-corrected HAADF-STEM images of a Ru-1, b Ru-2, and c Ru-3. d Ru K-edge XANES spectra of Ru foil, Ru-1, Ru-2, Ru-3 and RuO2. e Ru k3-weighted Fourier transform of the EXAFS spectra of Ru foil, Ru-1, Ru-2, Ru-3 and RuO2. f CO-probe DRIFTS results of CO-absorbed Ru-1, Ru-2 and Ru-3. Ru ensembles (Rue) including Ruc and Rup.

Additional spectroscopic characterizations were conducted to elucidate the electronic structure and coordination environment of the catalysts. X-ray photoelectron spectroscopy (XPS) measurements revealed the presence of the elements Al, O, P, and Ru, excluding N, suggesting that the coordinated N species in the Ru-macho precursor was eliminated during the annealing process (Supplementary Fig. 8a). The high-resolution Ru 3p spectrum of Ru-1 exhibited two prominent peaks at the binding energies of 485.0 eV (Ru 3p1/2) and 462.2 eV (Ru 3p3/2), similar to those of Ru oxides44, indicating the partially oxidized valence state of Ru species in Ru-1 (Supplementary Fig. 8b, c). In contrast, the binding energies of Ru species in Ru-3 at 483.7 eV (Ru 3p1/2) and 461.8 eV (Ru 3p3/2) showed a striking resemblance to the characteristic signals of metallic Ru45, consistently supporting the presence of nanoparticles as observed via HAADF-STEM. Similarly, Ru-2 also demonstrated an average valence state that closely aligns with metallic Ru, but slightly elevated compared to Ru-3. The observed elevation might be attributed to the presence of partially oxidized Ru species within the small-sized Ruc in Ru-2, as opposed to the metallic Rup in Ru-3. In addition, the XPS spectra signal intensities of the P species, originating from the metal precursor (i.e., Ru-Macho), decreased in the sequence of Ru-1 > Ru-2 > Ru-3 as the size of Ru species increased (Supplementary Fig. 9), suggesting that the P species may assist in mitigating the Ru agglomeration during the annealing process.

To probe the local microstructure of Ru species with enhanced precision, X-ray absorption spectroscopy (XAS) was employed. As shown in Fig. 1d, X-ray absorption near edge structure (XANES) analysis showed that the energy absorption thresholds of Ru-1, Ru-2 and Ru-3 were located between those of Ru foil and RuO2, arranged in the order of Ru-3 <Ru-2 <Ru-1, where Ru-1 being closest to that of RuO2, while Ru-3 approximating to that of Ru foil. This sequence illustrated an increase in the valence states from the Ru foil to Ru-3, Ru-2, Ru-1 and RuO2, which is consistent with the XPS observation results. The extended X-ray absorption fine structure (EXAFS) spectrum of Ru-1 only exhibited one main peak at ~1.4 Å, and no fingerprinting signal peak of Ru-Ru interactions (~2.3 Å) can be observed, verifying the atomic dispersion of Ru in Ru-1. The best fitting result of the obtained EXAFS data revealed that each Ru atom was coordinated by ~3 O atoms and ~1 P atom on average (Fig. 1e, Supplementary Fig. 10a, b and Table 2). For the Ru-2 catalyst, in addition to the prominent peak at ~1.4 Å, assigned to Ru-O3P1 motif, a relatively weak peak at ~2.3 Å that corresponds to Ru-Ru first coordination shell could be identified. The low Ru-Ru coordination number (C.N.) of 3.0 ± 1.0 determined for Ru-2 suggested the presence of tiny Ruc, which agrees well with the HADDF-STEM results (Fig. 1e, Supplementary Fig. 10c, d and Table 2). Compared with Ru-2, the fingerprinting signal of Ru-Ru observed at ~2.3 Å in Ru-3 emerges as the prominent peak, suggesting the aggregation of Ru species into Rup, consistent with TEM observation results. The fitting result further confirmed the presence of Rup with a high Ru-Ru coordination number (C.N.) of 10.0 ± 0.6, similar to that of metallic Ru foil (Fig. 1e, Supplementary Fig. 10e, f and Table 2).

To gain an in-depth understanding of the Ru species distribution in the catalysts, a CO-probe diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) experiment was conducted to acquire semiquantitative information about the proportions of the surface Ru species. The red characteristic peaks in the DRIFTS spectra (Fig. 1f, Supplementary Fig. 11), corresponding to bicarbonyl species (i.e., two linearly adsorbed CO molecules) on partially oxidized Ru1 species, decreased in intensity with increasing size of Ru from the Ru-1 catalyst to the Ru-3 catalyst, while the characteristic peaks for adsorbed monocarbonyl species (i.e., one linearly adsorbed CO molecule) on metallic Ru species (blue) increased in intensity. The statistical percentages of Ru1 and Ruc/Rup, determined by integrating the characteristic peaks, revealed that the Ru1 contents in Ru-1, Ru-2 and Ru-3 are 100%, 61.9%, and 55.9%, respectively (Supplementary Table 3). The metal dispersion (i.e., available Ru active sites) was further calculated on the basis of the CO adsorption determined from CO-pulse adsorption experiments (Supplementary Table 4). The metal dispersion decreased with the increasing proportion of metallic Ru species, which is consistent with the results of the CO-probe DRIFTS experiment.

Catalytic performance of Al2O3-based Ru catalysts towards the morpholine-assisted sequential CO2 hydrogenation

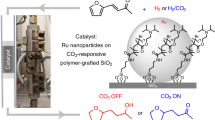

Compared to the Ru catalyst derived from ruthenium acetylacetonate as the precursor (i.e., Ru-4), the Ru catalysts (Ru-1, Ru-2, and Ru-3) with small-sized Ru species, using Ru-Macho as the precursor, exhibited superior catalytic performance in both the N-formylation of amines with CO2 and the subsequent amide hydrogenation reaction (Fig. 2a–c, Supplementary Fig. 12). Remarkably, significant differences in the catalytic performance among Ru-1, Ru-2, and Ru-3 were also observed. In the morpholine N-formylation step to generate NFM, both Ru-2 and Ru-3 demonstrated superior catalytic performance. The turnover frequencies (TOFs) values of Ru-2 and Ru-3 were about 81% and 50% higher than that of Ru-1, respectively (Fig. 2d). In addition, the catalytic generation of amide reached a state of equilibrium after 36 h for Ru-2 and Ru-3, while twice the time was required for Ru-1 (Fig. 2b). Furthermore, Ru-2 and Ru-3 exhibited superior selectivity (>95%) for the amide compared to Ru-1 (~83%), with slight formic acid detected (Supplementary Fig. 13).

a Schematic illustration of Ru-catalyzed independent N-formylation and amide hydrogenation and a one-pot sequential CO2 hydrogenation reaction. b Catalytic yield in N-formylation of morpholine over different catalysts. c Catalytic yield of NFM hydrogenation over different catalysts. d TOF values of Ru-1, Ru-2 and Ru-3 toward morpholine N-formylation and NFM hydrogenation, respectively. e Yield-time profile of the one-pot two-step tandem process catalyzed by Ru-2. Reaction conditions: 120 °C, 10 mmol substrate, 15 mL 1,4-dioxane as a solvent, 100 mg catalyst, 0.5 mmol Cs2CO3; for the N-formylation process: P (CO2): P (H2) = 1: 1 with a total pressure of 4 MPa; for amide hydrogenation, P (H2) = 4 MPa.

The NFM hydrogenation for CH3OH production was conducted within an alkaline system, where Ru-2 exhibited superior activity with TOF values of ~301 h−¹ (Fig. 2c, d), significantly exceeding the TOF values achieved by Ru-1 ( ~ 207 h−¹) and Ru-3 ( ~ 181 h−¹). To determine whether the performance of the Ru-2 has been optimized, refined adjustments to the annealing time in the Ru-2 catalyst preparation process were conducted, resulting in the production of Ru-5 and Ru-6 with shortened (1 h) or extended (3 h) annealing time, respectively (see Method section for details). To our delight, the catalytic performance of Ru-2 still maintains the superiority in comparison to both Ru-5 and Ru-6 (Supplementary Fig. 14). Moreover, an Al2O3-based catalyst with only metallic Ru was also fabricated (labeled as Ru-7, see Method section for details). Evidently, the yield of CH3OH over Ru-7 is inadequate (Supplementary Fig. 15), indicating that the metallic Ru species is unfavorable for the amide hydrogenation reaction. Furthermore, the assessment of the catalytic performance of Al2O3 matrix revealed its inert in both the amine N-formylation and amide hydrogenation reactions, implying that the primary catalytic activities are ascribable to the Ru species (Supplementary Table 5). In addition to the catalysts, Cs2CO3 also exerted a notable impact on the catalytic performance. The CH3OH yield over NFM hydrogenation step was significantly inhibited when Cs2CO3 was removed from the catalytic system or replaced with organic bases such as piperidine (Supplementary Table 5), indicating the necessity of Cs2CO3, which might facilitate the polarization of the N atom within NFM, thereby promoting the activation of the C-N bond and accelerating the C-N cleavage46,47.

To more clearly identify the contributions of Ru1, Ruc, and Rup in N-formylation and amide hydrogenation processes, we normalized the catalytic performance of these three Ru species (see Section 3 in Supplementary Information (SI) for details). The results showed that the activities of Ru species in the N-formylation step follow the sequence Ruc > Rup > Ru1, while in the amide hydrogenation step, they follow the order Ruc > Ru1 > Rup (Supplementary Fig. 16). Encouraged by the exceptional performance of Ru-2 with dominant morphological distribution of Ruc, we decided to investigate its potential utilization in a one-pot two-step tandem process. In three consecutive reaction cycles over 144 h (Fig. 2e), Ru-2 exhibited superb activity (CH3OH turnover number, TON = 3300) and selectivity (>95%), which is among the highest in all reported catalysts (Supplementary Tables 6, 7). To our delight, the Ru leaching was negligible and both the morphology and the valence state of Ru species are well-preserved, as evidenced by the HAADF-STEM images and XPS results (Supplementary Figs. 17, 18 and Table 8).

Catalytic mechanism of sequential CO2 hydrogenation over Al2O3-based Ru catalysts

To confirm the catalytic reaction pathways of sequential CO2 hydrogenation, a series of mechanistic experiments were performed using the optimal Ru-2 catalyst. The influence of excess CO2 during the N-formylation of morpholine was investigated (Fig. 3a), in which zwitterionic carbamates were spontaneously produced by morpholine in an aprotic solvent. In batch 2, the reaction was initiated after CO2 saturation (without additional CO2 input during the catalytic reaction), in contrast to the original batch 1, while in batch 3, the excess CO2 was evacuated after CO2 saturation and replaced with 2 MPa N2. The absence of excess CO2 led to a higher formic acid selectivity with similar conversion levels (Fig. 3b), indicating the significant role of high-concentration CO2. We proposed that a high concentration of CO2 is capable of enhancing the content of the critical intermediate (i.e., zwitterionic carbamate), which potentially facilitates the improvement of amide selectivity during the N-formylation process.

a Schematic illustration of the influence of an excess CO2 atmosphere during the N-formylation of morpholine. b Catalytic conversion and selectivity of Ru-2 within 2 h over the batches shown in a, where the conversion was controlled ~20%. c H2-TPR profiles of the three catalysts. d Catalytic yield in two reactions with hydrogen and deuterium and the corresponding KIE values.

The H2 temperature-programmed reduction (H2-TPR, Fig. 3c) profiles of the three catalysts revealed different H2 affinities, where Ru-2 and Ru-3, possessing abundant Ruc and Rup sites, was prone to reduction at a lower temperature, thus manifesting the stronger H2 activation ability compared with Ru-1. To investigate the influence of H2 activation in both steps of sequential CO2 hydrogenation, hydrogen was replaced with deuterium (Fig. 3d). Obviously, the reaction rate of N-formylation sharply decreased when hydrogen was replaced with deuterium, with a primary KIE value of 2.45 (2 < KIE < 7), indicating that the rate determining step (RDS) in the N-formylation reaction is a step in which hydrogen is involved48,49.

However, this phenomenon was not observed in the amide reaction process, in which nearly identical reaction rates were obtained with hydrogen and deuterium (KIE = 0.98). Thus, the RDS in the amide hydrogenation reaction was speculated to be cleavage of the C-N bond. Notably, the NFM hydrogenation process leading to the production of CH3OH can be delineated into two stages: the cleavage of the C-N bond in NFM, resulting in the generation of formaldehyde and the regeneration of morpholine, and the subsequent hydrogenation of formaldehyde to yield CH3OH36,50,51. In order to be more intuitive, a comparative experiment was carried out. As shown in Supplementary Fig. 19, the hydrogenation of formaldehyde to CH3OH can be completed within 3 h (yield >99%), whereas the yield of CH3OH over NFM hydrogenation is only ~46% and no formaldehyde intermediate can be detected, highlighting that the primary bottleneck in NFM hydrogenation lies in the cleavage of the C-N bond.

DFT calculations were further conducted to gain insights into the reduction mechanism. Based on the experimental observations, three simulation models incorporating the structural features of Ru1, Ruc, and Rup species were constructed (see Method section for structural details), labeled as S-Ru1, S-Ruc, and S-Rup, respectively (Supplementary Fig. 20). As shown in Supplementary Fig. 21, the Bader charge analysis revealed two distinct types of charged Ru atoms within the S-Ruc, where the top site of S-Ruc (S-Ruc-top) possesses an atomic charge of -0.15, close to that of metallic S-Rup (-0.05). In comparison, the edge site of S-Ruc (S-Ruc-edge) that binds to Al2O3 matrix owns atomic charge as +0.91, approaching that in the oxidized S-Ru1 (+1.09). This observation suggested that both the metallic and oxidized states of Ru atoms coexist within the Ruc, which was consistent with the assumption derived from XPS (i.e., the presence of partially oxidized Ru species within the small-sized Ruc).

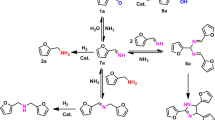

The free energy profile and the relevant structures of intermediates are plotted in Fig. 4a, b, respectively. Due to the facile dissociation of H2 on the Ru sites (Supplementary Fig. 22), the energy barriers for H2 dissociation are not depicted in the energy profile. The adsorbed hydrogen atom is directly placed at the reaction site and the energy of the gaseous hydrogen is taken as the reference. The highest barrier of amine N-formylation is 2.01 eV for the metallic S-Rup, whereas a notable increment to 3.17 eV is observed in the presence of oxidized S-Ru1 (Supplementary Table 9), suggesting that the metallic Ru forms may be the more favorable catalytic species for the N-formylation process (see Supplementary Figs. 23, 24 for structural details). In contrast, the key barrier of the amide hydrogenation process for metallic S-Rup is higher than that for oxidized S-Ru1 (1.24 eV vs. 1.49 eV), indicating that the oxidized Ru species possess higher catalytic activity for amide hydrogenation reaction. However, the key energy barriers for either S-Ru1 or S-Rup are higher than that for S-Ruc.

a Energy profile of the catalytic process. Energy barriers of key steps are labeled. S-Ru1: red line; S-Ruc-top: green line; S-Ruc-edge site: purple line; S-Rup site: blue line. b Structures of the key intermediates in the reaction pathways over S-Ruc. The asterisk denotes the adsorption site. Color code: Ru: green; Al: pink; N: blue; C: gray; O: red; H: white. For clarity, the Al2O3 matrix was depicted in a line model.

In the case of S-Ruc, there are multiple Ru species that include top-site metallic Ru (i.e., S-Ruc-top) and edge-site oxidized Ru (i.e., S-Ruc-edge). The calculated energy barrier of the first step on the S-Ruc-top site was 1.01 eV for the reduction of carbonyl group to C-O single bond. Further protonation leads to elimination of the hydroxyl group, thus forming a formamide intermediate coupled with the production of H2O, which requires overcoming an energy barrier of 1.14 eV (see Supplementary Fig. 25 for structural details). Despite the relatively low energy barriers over S-Ruc-top site in catalyzing the hydrogenation of the formamide intermediate (i.e., (CH3)2NCH2O), the subsequent step to form a hemiaminal (an intermediate of formamide hydrogenation) over S-Ruc-top requires overcoming a high energy barrier of 1.45 eV, resulting in a sluggish rate to obtain the final product (Supplementary Fig. 26). Considering that the oxidized site may facilitate the amide hydrogenation, the migration of the (CH3)2NCH2O intermediate towards the S-Ruc-edge site is simulated, with a kinetic barrier of 1.06 eV (Supplementary Fig. 27), comparable to the barriers of formamide hydrogenation (1.10 eV). Upon migration, the overall barrier of formamide hydrogenation over the S-Ruc-edge site reduces to 1.00 eV (purple lines in Fig. 4a). Herein, not only the hydrogenation step but also the migration of the intermediate determines the whole amide hydrogenation process.

Based on the results of our experiments and DFT simulations (Supplementary Fig. 28), we proposed a potential catalytic reaction pathway for the morpholine-assisted two-step CO2 hydrogenation (Fig. 5 and Supplementary Fig. 29). Initially, morpholine (A) absorbs CO2 to yield zwitterionic carbamates (B). Active hydrogen species generated via metallic Ru species (i.e., Ruc-top and Rup) then reduce these carbamates to form intermediate C. The gem-diol like intermediate C readily eliminate a hydroxyl group to generate NFM. The released OH¯ further reacts with the morpholinium cation to yield morpholine and H2O. In addition, the electronegative oxygen in intermediate C can also coordinate to the Ru1 site to form intermediate D’ (Supplementary Fig. 29), which undergoes hydrogenolysis to form formic acid and morpholine. This process is probably the primary source of formic acid by-product formation, which might be suppressed by accelerating the catalytic rate of the competing reaction (i.e., the reaction of OH¯ with the morpholine cation), consistent with the experimental results of the CO2 concentration adjustment (Fig. 3a, b). In the amide hydrogenation step, the C-N cleavage of NFM was more favorable occurred over the oxidized Ru species (i.e., Ruc-edge and Ru1) to generate the adsorbed formaldehyde and regenerating morpholine (Supplementary Fig. 29b). The adsorbed formaldehyde is prone to hydrogenation, leading to the formation of CH3OH.

Discussion

In summary, we prepared a series of active heterogeneous Ru catalysts with multiple active Ru species, including Ru1, Ruc and Rup. The critical roles of the active metal species in the reaction process were revealed by combining experiments and theoretical calculations and a possible reaction pathway was proposed, which suggested that the metallic Ru forms (i.e., Ruc-top and Rup) are superior catalytic species for the N-formylation step, whereas the oxidized Ru species (i.e., Ruc-edge and Ru1) exhibit higher amide hydrogenation activity. Due to the coexistence of metallic and oxidized species within the Ruc, the Ru-2 catalyst, with dominant morphological distribution of Ruc, demonstrated excellent performance in both the N-formylation and amide hydrogenation reactions, enabling efficient one-pot two-step CH3OH production under relatively mild conditions. This work provides a potential candidate catalyst for selective reduction of CO2 to CH3OH. The strategy of rationally designing multiple optimized active species within a single catalyst paves the way for enhancing the catalytic performance in various multistep sequential reactions in the future.

Methods

Preparation of Ru-1

The synthesis method of the catalyst is a typical impregnation method. Firstly, 1 g of α-Al2O3 was dispersed in 20 mL of acetone with continuous stirring. Then, 60 mg of Ru-Macho was weighed and dispersed in 20 mL of acetone by ultrasonic treatment for half an hour. After that, the latter was added into the acetone solution containing the α-Al2O3 support, and stirred at room temperature for 4 h. The mixture was then heated to 60 °C and stirred until the acetone was completely evaporated. The resulting light yellow solid was grounded and placed in a ceramic boat. The boat was placed in a tube furnace and gas replacement was carried out for 1 h in a nitrogen atmosphere (80 mL/min) to remove air. The sample was then heated to 200 °C at a rate of 5 °C/min and kept there for 2 h in a nitrogen atmosphere (80 mL/min), followed by natural cooling to room temperature to obtain the Ru-1 catalyst.

Preparation of Ru-2

The preparation method of the Ru-2 catalyst was similar to that of Ru-1, except that it is calcined in air using a muffle furnace. Typically, 1 g of α-Al2O3 was dispersed in 20 mL of acetone with continuous stirring. Then, 60 mg of Ru-Macho was weighed and dispersed in 20 mL of acetone by ultrasonic treatment for half an hour. After that, the latter was added into the acetone solution containing the α-Al2O3 support, and stirred at room temperature for 4 h. The mixture was then heated to 60 °C and stirred until the acetone was completely evaporated. The resulting light yellow solid was grounded and placed in a ceramic boat. The boat was placed in a muffle furnace. The sample was then heated to 200 °C at a rate of 5 °C/min and kept there for 2 h, followed by natural cooling to room temperature to obtain the Ru-2 catalyst.

Preparation of Ru-3

Typically, 1 g of α-Al2O3 was dispersed in 20 mL of acetone with continuous stirring. Then, 60 mg of Ru-Macho was weighed and dispersed in 20 mL of acetone by ultrasonic treatment for half an hour. After that, the latter was added into the acetone solution containing the support, and stirred at room temperature for 4 h. The mixture was then heated to 60 °C and stirred until the acetone was completely evaporated. The resulting light yellow solid was grounded and placed in a ceramic boat. The boat was placed in a tube furnace and gas replacement was carried out for 1 h in a nitrogen atmosphere (80 mL/min) to remove air. The sample was then heated to 300 °C at a rate of 5 °C/min and kept there for 2 h in a 10% H2/Ar atmosphere (200 mL/min), followed by natural cooling to room temperature to obtain the Ru-3 catalyst.

Preparation of Ru-4

Ru-4 catalyst was prepared using ruthenium acetylacetonate as a precursor. Typically, 1 g of α-Al2O3 was dispersed in 20 mL of acetone and stirred evenly to obtain solution A. Then, 39.4 mg of ruthenium acetylacetonate (equivalent amount of Ru within 60 mg of Ru-Macho) were dissolved in 20 mL of acetone to obtain solution B. The solution B was then added to solution A and continuously stirred at room temperature for 4 h. The mixture was then heated to 60 °C and stirred until the acetone was completely evaporated. The ground solid was placed in a ceramic boat. Subsequently, the ceramic boat was placed in a muffle furnace, and the sample was heated to 200 °C at a rate of 5 °C /min and maintained for 2 h, finally cooled naturally to room temperature.

Preparation of Ru-5 and Ru-6

The Ru-5 and Ru-6 catalysts were prepared similarly to the Ru-2 catalysts, except for the annealing time. The Ru-5 catalyst was annealed in air at 200 °C for 1 h, while the Ru-6 catalyst was c annealed in air at 200 °C for 3 h. The other preparation processes remained unchanged.

Preparation of Ru-7

The synthesis of Ru nanoparticles was carried out according to the reported procedure with minor modifications52. Firstly, 21 mg of RuCl3, 105 mg of PVP and 8 mL of H2O were added to a 100 mL beaker and stirred for 20 min to obtain solution A, then 135 mg of sodium borohydride was dissolved in 3 mL of H2O to form solution B. Solution A was then placed in an ice-water bath, while solution B was added. During this addition, a gradual darkening of solution A was observed. Stirring was maintained until no further bubbles were observed. Following this, the resultant black Ru nanoparticles were isolated through simple centrifugal washing. The obtained Ru nanoparticles were dispersed in H2O, and then 1 g of α-Al2O3 was added into the re-dispersed solution. The mixture was stirred for 4 h and then evaporated to dryness, yielding the Ru-7 catalyst.

Computational details

Density Functional Theory (DFT) calculations were performed using the Vienna Ab-initio Simulation Package (VASP). The calculations employed the generalized gradient approximation (GGA) with the Perdew-Burke-Ernzerhof (PBE) functional to calculate the exchange and correlation energy. The projector augmented wave (PAW) method was employed to describe ion-electron interactions. A plane-wave cut-off energy of 450 eV was used. The DFT-D3 correction was included to account for van der Waals (vdW) interactions. Three models were constructed in this study, including Ru8 cluster supported on Al2O3 (0001) surface (marked as S-Ruc), a single Ru atom supported on the Al2O3 (0001) surface coordinated with trimethylphosphine ((CH3)3P) (marked as S-Ru1), and Ru (0001) surface simulating the Ru nanoparticle (marked as S-Rup). The (3 × 3) Al2O3 (0001) facet, cleaved from the α-Al2O3 bulk, was used as the substrate due to its low surface energy53. The exposed Al sites in Al2O3 surface were covered with hydroxyl group to be passivated. For the Al2O3 (0001) model, a vacuum layer of 20 Å in the z direction was used to prevent interaction between periodic images. For the construction of Ru8 cluster, a nearly spherical Ru10 cluster was cleaved from the metal Ru bulk, and 2 atoms were removed from the cluster to form an interface in contact with Al2O3. Then the Ru8 cluster was placed on the passivated Al2O3 (0001) surface to construct the S-Ruc mode. The average Ru-Ru coordination number (C.N.) for S-Ruc is 3.6, which was consistent with the experimentally determined C.N. of 3.0 ± 1.0 for the synthesized Ruc. The S-Ru1 model was constructed by incorporating a single Ru atom into the passivated Al2O3 (0001) facet, and coordinating it with a trimethylphosphine ((CH3)3P) ligand, resulting in a model featuring one Ru-P bond and three Ru-O bonds to simulate the experimental Ru1 site characterized by the Ru-O3P1 motif. To simulate the surface of the relatively large Ru nanoparticles (S-Rup), a slab model consisted of 4 layers of the (5 × 5) Ru (0001) facet were constructed and a 20 Å vacuum layer in the z-direction was set to prevent interaction between periodic images. During the relaxation process, for structure relaxation, the convergence criteria for force and energy were set to 0.02 eV Å−1 and 10−6 eV, respectively. The CI-NEB method was employed to locate the transition state and calculate the reaction barrier.

Data availability

The data supporting the findings of this study are available within the article and its Supplementary Information Files. Extra data are available from the author upon request.

References

Artz, J. et al. Sustainable Conversion of carbon dioxide: an integrated review of catalysis and life cycle assessment. Chem. Rev. 118, 434–504 (2018).

Aresta, M., Dibenedetto, A. & Quaranta, E. State of the art and perspectives in catalytic processes for CO2 conversion into chemicals and fuels: The distinctive contribution of chemical catalysis and biotechnology. J. Catal. 343, 2–45 (2016).

Huang, J. E. et al. CO2 electrolysis to multicarbon products in strong acid. Science 372, 1074–1078 (2021).

Velty, A. & Corma, A. Advanced zeolite and ordered mesoporous silica-based catalysts for the conversion of CO2 to chemicals and fuels. Chem. Soc. Rev. 52, 1773–1946 (2023).

Yang, Y. et al. Operando studies reveal active Cu nanograins for CO2 electroreduction. Nature 614, 262–269 (2023).

Sun, R. et al. Heterogeneous catalysts for CO2 hydrogenation to formic acid/formate: from nanoscale to single atom. Energy Environ. Sci. 14, 1247–1285 (2021).

Bai, S.-T. et al. Homogeneous and heterogeneous catalysts for hydrogenation of CO2 to methanol under mild conditions. Chem. Soc. Rev. 50, 4259–4298 (2021).

Zhong, J. et al. State of the art and perspectives in heterogeneous catalysis of CO2 hydrogenation to methanol. Chem. Soc. Rev. 49, 1385–1413 (2020).

Xie, Y., Hu, P., Ben-David, Y. & Milstein, D. A reversible liquid organic hydrogen carrier system based on methanol-ethylenediamine and ethylene urea. Angew. Chem. Int. Ed. 58, 5105–5109 (2019).

Fernández-Alvarez, F. J. & Oro, L. A. Cover feature: homogeneous catalytic reduction of CO2 with silicon-hydrides, state of the art. ChemCatChem 11, 5–5 (2019).

Appel, A. M. et al. Frontiers, Opportunities, and challenges in biochemical and chemical catalysis of CO2 fixation. Chem. Rev. 113, 6621–6658 (2013).

Khaselev, O. & Turner, J. A. A monolithic photovoltaic-photoelectrochemical device for hydrogen production via water splitting. Science 280, 425–427 (1998).

Luo, J. et al. Water photolysis at 12.3% efficiency via perovskite photovoltaics and Earth-abundant catalysts. Science 345, 1593–1596 (2014).

Zhai, P. et al. Engineering single-atomic ruthenium catalytic sites on defective nickel-iron layered double hydroxide for overall water splitting. Nat. Commun. 12, 4587 (2021).

Navarro-Jaén, S. et al. Highlights and challenges in the selective reduction of carbon dioxide to methanol. Nat. Rev. Chem. 5, 564–579 (2021).

Zhao, H. et al. The role of Cu1–O3 species in single-atom Cu/ZrO2 catalyst for CO2 hydrogenation. Nat. Catal. 5, 818–831 (2022).

Li, H. et al. Synergetic interaction between neighbouring platinum monomers in CO2 hydrogenation. Nat. Nanotech. 13, 411–417 (2018).

An, B. et al. Confinement of ultrasmall Cu/ZnOx nanoparticles in metal–organic frameworks for selective methanol synthesis from catalytic hydrogenation of CO2. J. Am. Chem. Soc. 139, 3834–3840 (2017).

Hu, J. et al. Sulfur vacancy-rich MoS2 as a catalyst for the hydrogenation of CO2 to methanol. Nat. Catal. 4, 242–250 (2021).

Lam, E. et al. CO2 Hydrogenation on Cu/Al2O3: Role of the metal/support interface in driving activity and selectivity of a bifunctional catalyst. Angew. Chem. Int. Ed. 58, 13989–13996 (2019).

Prieto, G., Zečević, J., Friedrich, H., de Jong, K. P. & de Jongh, P. E. Towards stable catalysts by controlling collective properties of supported metal nanoparticles. Nat. Mater. 12, 34–39 (2013).

Martin, O. et al. Indium oxide as a superior catalyst for methanol synthesis by CO2 hydrogenation. Angew. Chem. Int. Ed. 55, 6261–6265 (2016).

Wang, J. et al. A highly selective and stable ZnO-ZrO2 solid solution catalyst for CO2 hydrogenation to methanol. Sci. Adv. 3, e1701290 (2017).

Frei, M. S. et al. Mechanism and microkinetics of methanol synthesis via CO2 hydrogenation on indium oxide. J. Catal. 361, 313–321 (2018).

Beck, A. et al. Following the structure of copper-zinc-alumina across the pressure gap in carbon dioxide hydrogenation. Nat. Catal. 4, 488–497 (2021).

Bahruji, H. et al. Pd/ZnO catalysts for direct CO2 hydrogenation to methanol. J. Catal. 343, 133–146 (2016).

Behrens, M. et al. The active site of methanol synthesis over Cu/ZnO/Al2O3 industrial catalysts. Science 336, 893–897 (2012).

Wu, C. et al. Inverse ZrO2/Cu as a highly efficient methanol synthesis catalyst from CO2 hydrogenation. Nat. Commun. 11, 5767 (2020).

Shi, Z. et al. CO2 hydrogenation to methanol over Cu-In intermetallic catalysts: Effect of reduction temperature. J. Catal. 379, 78–89 (2019).

Li, K. & Chen, J. G. CO2 hydrogenation to methanol over ZrO2-containing catalysts: insights into ZrO2 induced synergy. ACS Catal. 9, 7840–7861 (2019).

Samson, K. et al. Influence of ZrO2 structure and copper electronic state on activity of Cu/ZrO2 catalysts in methanol synthesis from CO2. ACS Catal. 4, 3730–3741 (2014).

Kattel, S., Liu, P. & Chen, J. G. Tuning selectivity of CO2 hydrogenation reactions at the metal/oxide interface. J. Am. Chem. Soc. 139, 9739–9754 (2017).

Studt, F. et al. Discovery of a Ni-Ga catalyst for carbon dioxide reduction to methanol. Nat. Chem. 6, 320–324 (2014).

Yin, Y. et al. Pd@zeolitic imidazolate framework-8 derived PdZn alloy catalysts for efficient hydrogenation of CO2 to methanol. Appl. Catal. B Environ. 234, 143–152 (2018).

Bai, S.-T., Zhou, C., Wu, X., Sun, R. & Sels, B. Suppressing dormant Ru states in the presence of conventional metal oxides promotes the Ru-MACHO-BH-catalyzed integration of CO2 capture and hydrogenation to methanol. ACS Catal. 11, 12682–12691 (2021).

Kar, S. et al. Mechanistic insights into ruthenium-pincer-catalyzed amine-assisted homogeneous hydrogenation of CO2 to methanol. J. Am. Chem. Soc. 141, 3160–3170 (2019).

Zhang, L., Han, Z., Zhao, X., Wang, Z. & Ding, K. Highly efficient ruthenium-catalyzed N-formylation of amines with H2 and CO2. Angew. Chem. Int. Ed. 54, 6186–6189 (2015).

Jayarathne, U., Hazari, N. & Bernskoetter, W. H. Selective Iron-catalyzed N-formylation of amines using dihydrogen and carbon dioxide. ACS Catal. 8, 1338–1345 (2018).

Zecevic, J., Vanbutsele, G., de Jong, K. P. & Martens, J. A. Nanoscale intimacy in bifunctional catalysts for selective conversion of hydrocarbons. Nature 528, 245–248 (2015).

Jiao, F. et al. Selective conversion of syngas to light olefins. Science 351, 1065–1068 (2016).

Cheng, K. et al. Direct and highly selective conversion of synthesis gas into lower olefins: design of a bifunctional catalyst combining methanol synthesis and carbon–Carbon coupling. Angew. Chem. Int. Ed. 55, 4725–4728 (2016).

Zhang, J. et al. Importance of species heterogeneity in supported metal catalysts. J. Am. Chem. Soc. 144, 5108–5115 (2022).

Liu, L. & Corma, A. Identification of the active sites in supported subnanometric metal catalysts. Nat. Catal. 4, 453–456 (2021).

Qadir, K. et al. Intrinsic relation between catalytic activity of CO oxidation on Ru nanoparticles and Ru oxides uncovered with ambient pressure XPS. Nano Lett. 12, 5761–5768 (2012).

Meng, Z. et al. Electron-rich ruthenium on nitrogen-doped carbons promoting levulinic acid hydrogenation to γ-valerolactone: effect of metal–support interaction. ACS Sustain. Chem. Eng. 7, 16501–16510 (2019).

John, J. M., Takebayashi, S., Dabral, N., Miskolzie, M. & Bergens, S. H. Base-catalyzed bifunctional addition to amides and imides at low temperature. a new pathway for carbonyl hydrogenation. J. Am. Chem. Soc. 135, 8578–8584 (2013).

Wang, Y. et al. Structure, reactivity and catalytic properties of manganese-hydride amidate complexes. Nat. Chem. 14, 1233–1241 (2022).

Li, Z. et al. Covalent triazine framework supported non-noble metal nanoparticles with superior activity for catalytic hydrolysis of ammonia borane: from mechanistic study to catalyst design. Chem. Sci. 8, 781–788 (2016).

Li, L. et al. Accelerating chemo and regioselective hydrogenation of alkynes over bimetallic nanoparticles in a metal–organic framework. ACS Catal. 10, 7753–7762 (2020).

Townsend, D. et al. The roaming atom: straying from the reaction path in formaldehyde decomposition. Science 306, 1158–1161 (2004).

Kothandaraman, J. et al. Efficient reversible hydrogen carrier system based on amine reforming of methanol. J. Am. Chem. Soc. 139, 2549–2552 (2017).

Zhu, Q.-L., Li, J. & Xu, Q. Immobilizing metal nanoparticles to metal–organic frameworks with size and location control for optimizing catalytic performance. J. Am. Chem. Soc. 135, 10210–10213 (2013).

Yue, Y. et al. Structure and Reactivity of α-Al2O3 (0001) Surfaces: How Do Al-I and Gibbsite-like Terminations Interconvert? J. Phys. Chem. C. 126, 13467–13476 (2022).

Acknowledgements

This work is supported by the Natural Science Foundation of Zhejiang Province (LQ22B010005, Q.Y. and LD21E020001, L.C.), the National Natural Science Foundation of China (22101288, Q.Y.), the “From 0 to 1” Innovative Program of CAS (NO.ZDBS LYJSC021, L.C.), the Ningbo Yongjiang Talent Introduction Programme (2021A-036-B, Z.L.), the Science and Technology Innovation 2025 Program in Ningbo (2022Z205, Z.L.), Youth Innovation Promotion Association, Chinese Academy of Sciences (Q.Y.).

Author information

Authors and Affiliations

Contributions

These authors contributed equally: D. Su, Y. Wang, and H. Sheng. Q. Yang conceived the experimental idea. D. Su and Y. Wang collaboratively designed the experiments and carried out material synthesis and characterization, as well as performance testing. H. Liu assisted in interpreting the experimental results. S. Dai contributed to the aberration-corrected electron microscopy characterization and analysis. H. Sheng and D. Pan carried out the theoretical calculations and analysis. Z. Tian and Q. Zhang provided guidance on theoretical calculations. The manuscript was drafted by Q. Yang, D. Su, Y. Wang, and H. Sheng. Z. Lu and L. Chen supervised and directed the project and revised the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Su, D., Wang, Y., Sheng, H. et al. Efficient amine-assisted CO2 hydrogenation to methanol co-catalyzed by metallic and oxidized sites within ruthenium clusters. Nat Commun 16, 590 (2025). https://doi.org/10.1038/s41467-025-55837-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-55837-7

This article is cited by

-

Light-induced heterolytic hydrogen dissociation for CO2 hydrogenation to single C2 hydrocarbon

Science China Chemistry (2026)