Abstract

Mechanoluminescence platforms, combining phosphors with elastic polymer matrix, have emerged in smart wearable technology due to their superior elasticity and mechanically driven luminescent properties. However, their luminescence performance often deteriorates under extreme elastic conditions owing to a misinterpretation of polymer matrix behavior. Here, we unveil the role of the polymer matrices in mechanoluminescence through an interface-triboelectric effect driven by elasticity, achieving both high elasticity and brightness. By investigating interactions between elastic polymers and copper doped zinc sulfide microparticles, we reveal that elasticity significantly governed triboelectric effects for mechanoluminescence. In particular, high negative triboelectricity emerged as the key to overcoming poor triboelectric effect in extreme elastic conditions. This led to the discovery of polybutylene adipate-co-terephthalate silane and polycarbonate silane, achieving remarkable elasticity over 100% and a brightness of 139 cd/m2. These findings offer fundamental insights to select the optimal polymer matrix based on systematic parameters for various smart wearable applications.

Similar content being viewed by others

Introduction

Since the first report in 1605, mechanoluminescence (ML) phosphors have emerged as unique candidates for an in-situ strain sensors1, owing to repeatable and mechanically-driven light-emitting property attributed to crystal recovery2,3 of various solids such as titanates4, gallates5, aluminates6, silicates7, and stannates8. In particular, a novel type of ML platform with both phosphors and specific elastic polymers showcased another big step in a variety of applications9,10 such as pressure-sensitive light-emission sensors11,12,13, wind-driven displays14, and power-free light emission systems15, owing to outstanding ML performance with self-recoverability and exceptional elasticity9.

To achieve these performances of ML platform, elastic polydimethylsiloxane (PDMS), which is effective force converter to overcome the difficulty of direct force apply into micro-sized individual ML particles, plays a critical role as an unrivaled component16,17,18 by integration with most case of ML phosphors such as CaZnOS19, Sr3Al2O5Cl2:Dy3+ 20, Y3Al5O12:Ce3+, Ba0.5Sr0.5Si2O2N2:Eu2+ 21, and ZrO2:Ti4+ 22, along with ZnS-based materials. Specifically, essential factors of PDMS are known to be excellent elasticity23 (elastic modulus: 1.32–2.97 MPa, tensile strength: 3.51–5.13 MPa) and negative surface charge density24,25 (−110 µC/m2), which can provide not only flexibility for the ML platform but also a superior interface triboelectric effect, which is known to be crucial driving force for high ML performance26,27,28,29.

Notwithstanding the importance of polymer matrix, challenge to investigate the role of fundamental parameters to achieve both high elasticity and superior ML brightness is an open question. One of the main challenges for this performance lie in enhancing the triboelectric effect based on natures of polymer, which is known to be generated in interface of pores between ML phosphor and polymer matrix as a result of the elasticity. However, a significant paradox exists between the elastic- and luminance performance, which means that elevating the elasticity of the polymer matrix not only reduces the pore gap size but also can minimize the triboelectric effect by loss of charge accumulation that hinders high ML performance under the identical mechanical load30. Given the use of polymer with identical surface charge density, increasing flexibility of polymer matrix with high elasticity might lead to unexpected result such as dramatic ML degradation. On the other hand, while efforts to regulate PDMS elasticity by adding SiO2 nanoparticles to address rigid elastic condition or introducing other polymers with relatively negative triboelectricity, like polyvinylidene difluoride (PVDF)31, result in strong ML brightness, it may fail to ensure the high flexibility of ML platform11. Thus, clear strategy to systematically reveal the fundamental parameters of polymer matrix to avoid triboelectrically loss and thereby enhance both the high elasticity and ML brightness under extreme strain is imperative to solve these kinds of paradox.

While some of investigations on improving the ML performance based on polymer nature have been reported to date, most of the studies were solely paid on the enhancing triboelectric effect based on negative triboelectricity despite the potential contribution of polymer elasticity. Even, the interaction of ML performance with the fundamental parameters of polymer has been left unexplored to date.

Here, by exploiting a series of five elastic polymer matrices, we shed light on the principle of interaction between the ML brightness of ZnS:Cu2+@AlOX microparticle (denoted as ZnS:Cu) and individually screened fundamental parameters such as elasticity and triboelectricity. We investigate the trends of ML brightness based on the main parameters of both elasticity and triboelectricity of each polymer matrix while considering one of the factors being held constant. Given that the triboelectricity of polymer is held constant, it reveals that ML brightness decreases approximately lineally with elevating trends of elasticity. In contrast, we find that even though the elasticity of the polymer is not uniformly defined, the ML brightness of ZnS:Cu can be proportional to the increasing trends of triboelectricity. It is shown that ML brightness is governed not directly by elasticity, but rather by the triboelectric effect generated at the interface pore gap, which is determined by elasticity.

Based on these findings, we focus in on the microscopic landscape at the ZnS:Cu single particle level to uncover the role of pore gap interaction with the elasticity and triboelectricity of polymers in determining ML brightness. Indeed, we confirm that outstanding ML performance by endowing polymers with high negative triboelectricity, which maximizes surface charge accumulation on polymers with ZnS:Cu, despite the expected minimization of triboelectricity due to small pore gap sizes resulting from high elasticity. This allows us to realize important fundamental guideline to choose the efficient polymer matrix for achieving both high elasticity and superior ML brightness at the same time. We suggest three key factors: (1) Essentially, transparency should be considered a priority for emitting ML light out of the polymer32,33 (2) And then elasticity should be considered to withstand various mechanical stresses, ensuring flexibility of ML platform11. (3) Lastly, we suggest that high negative triboelectricity is the most important factor in determining ML brightness, which can maximize the interface charge accumulation in unforeseen environments29,30.

Our rational guideline led to the discovery of novel polymer matrices, polybutylene adipate-co-terephthalate silane (Eco Flex, EF) and polycarbonate silane (Dragon Skin, DS), which not only provide high elastic performance of over 100% attributed to elasticity of polymers but also show remarkable ML brightness of 139 cd/m2 by efficient charge accumulation, which is highest brightness in extreme strain region over the 60% to date. As a result, fabric-type ML textile sensors with EF and DS for human motion detection demonstrate outstanding ML brightness up to 90% strain regions on body locations such as the knee and elbow, making the detail signal resolution according to the motion of human body. We believe that our study provides not only a novel type of efficient polymer matrices for ML applications but also fundamental insights for many scientists conducting ML research to discover new kinds of polymer matrices for various ML applications.

Results

Characterization of the elastic polymer matrices for the ML platform

In this study, we used a typical ML platform consisting of ZnS:Cu phosphor and an elastic polymer matrix (Fig. 1a). Basically, the ML effect is randomly created in single particle landscape attributed to triboelectric effect, well-known to be a fundamental mechanism of ML, at the pore gap in interface between solid ZnS:Cu and polymer formed by elastic deformation under the mechanical stress (Fig. 1b)34,35. To systematically ascertain specific factors affecting this ML effect, we screened five potential polymer matrices—ethylene propylene diene monomer rubber (epoxy resin, ER), polyurethane (PU), PDMS, EF and DS—as candidates based on the fundamental parameters of transparency, elasticity, and triboelectricity, which could be attributed to inherent chemical structure of monomers (Fig. 1c). We first considered the amorphous structure of the candidates to ensure maximum transparency due to the disordered polymer chain that can reduce the light scattering in the visible region compared to more crystalline analogs. We first evaluated the average visible transmittance (AVT, from 360 to 780 nm) of five selected candidates to confirm the absorption of visible range, which could decrease the ML brightness (Fig. 1d). Since the ML effect independently occurs in ZnS:Cu particles, we suggest that the high AVT values could be a crucial factor bestowing a rational light pathway without emission loss from the ZnS:Cu phosphor to human eyes. We then considered the elasticity of our candidates, which could be defined by their polymerization ability and the chemical structure of their monomers, and it varies depending on the degree of cross-linking. Based on each chemical structure (shown in Fig. 1c), we focused on the inherent elasticity regarding each monomer under the optimal reaction ratio between main materials and curing agent (see the experimental section). To confirm the elasticity of all candidates, we accessed the analysis of strain-stress characteristics of pure polymer matrices by use of force meter (Fig. 1e) and focused on the yield point as a main factor in determining elastic nature of polymers. The evaluated strain tolerances (maximum strain range enabling full recovery to original state) increase with the following trends against stress before reaching the failure position: ER < PU < PDMS < DS < EF on the order of strain ~% (Supplementary Fig. 1a and Supplementary Table 1). Additionally, the elastic limit as a yield point also exhibits the same trends, which is known to play an important role in determining not only the effective flexibility but also ML effect of the ML platform to exclude ML loss with unrecoverable polymer elongation. For the trend of elasticity of polymers, ER exhibits the most rigid properties, which could be attributed to the high cross-linking ability by its C=C double bonds. For PU, while the urethane bonds by means of the reaction of isocyanate (-N=C=O) and polyol (-OH) groups provide greater flexibility than ER, strong intermolecular interactions could limit the movement of polymer chains. In contrast, high yield points of PDMS, EF, and DS can be ascribed to the siloxane (Si-O-Si) backbone, which is known to provide high flexibility compared to carbon-based bonds (C-C, C-O, C=C) due to the large bond angle and length of them, allowing for free movement of the polymer chains. In particular, DS and EF stand out for their elasticity (high yield point), which can be ascribed to silane modification in DS, resulting in higher cross-linking than in PDMS, and to the polybutylene adipate (PBA) and terephthalate-based structure, along with silane groups, providing much more free movement of chains in EF, respectively.

a Schematic structure (inset: ML image under the stretching motion with human hands) and b working process of the ML platform containing ZnS:Cu in the elastic polymer matrix. c The screening method of polymer matrices based on three key factors, and structure of selected five candidates. d Transmittance of the thin film as coated by each pure polymer matrix. The inset photo in d exhibits the superior transmittance of all polymer candidates by clearly identifying the word “HYU”. e Stress-strain graphs indicating the yield points of the selected polymer matrices.

Based on these results, we first applied all candidates to ZnS:Cu to make the ML platform, and then we preferentially confirmed the stable formation of the ML platform without any detrimental reactions such as emission loss or structural deformation during the thermal or UV curing process with ZnS:Cu particles. The ZnS:Cu is uniformly incorporated into all selected polymer matrices, as evidenced by scanning electron microscopy (SEM) (Supplementary Figs. 2–6). While the polymer structure may be indistinguishable due to dimensions below the SEM instrumental resolution, the distributed Si elemental signal in the energy-dispersive X-ray spectroscopy (EDS) mapping image indicates successful polymer matrix formation with ZnS:Cu. This suggests the ML platforms morphologically well-formed with all candidates. Additionally, the X-ray diffraction (XRD) patterns (Supplementary Fig. 7) and homogeneous photoluminescence (PL) features across the entire area (Supplementary Fig. 8) bestow not only stable exist of ZnS:Cu by wurtzite indicators without any thermally structural distortion but also feasibility of our hypothesis of lossless emission performance of ZnS:Cu during the process. This indicates that all polymer candidates can solely manifest their fundamental characteristics in confirming ML performance, irrespective of the optical damage of ZnS:Cu.

ML brightness depending on the elasticity of the polymer matrix

Based on the above results, we accessed the strain tolerances for determining the elasticity of ML platforms incorporating ZnS:Cu microparticles. To determine the optimal amount of ZnS:Cu in polymer matrix, we preferentially confirmed the elasticity-ML relationship depending on the weight ratio of ZnS:Cu (Supplementary Fig. 9 and Supplementary Table 2). Indeed, the overall elasticity of the ML platform, which should be bestowed by the polymer property, was directly regulated according to the loading ratio of ZnS:Cu microparticles. Furthermore, since the ZnS:Cu microparticles play the role of the main emitter, the amount of ZnS:Cu particles (loading ratio) also determines the total ML brightness. As shown in Supplementary Fig. 9a, the elasticity of all ML platforms decreases according to the loading ratio from 0% to 80% due to the physical reduction of the polymer volume in the global system. To optimize the suitable loading ratio between ZnS:Cu and polymer matrix for ML performance, we evaluated the ML intensity depending on the ZnS:Cu content (Supplementary Fig. 9b). As a normal condition of ML at 60% strain, while ER and PU cannot exhibit effective ML due to their poor elasticity, increasing trends of ML intensity from 10% to 70% can be observed in PDMS, EF, and DS, respectively. However, the 80% loading ratio indicates ML degradation, which can be attributed to polymer damage caused by the excessively high content of ZnS:Cu in the polymer matrix. This proves that the 70% of ZnS:Cu in polymer matrix is a suitable condition for the highest ML performance. From this optimal condition, we accessed strain-stress characteristics of ML platform. Despite the overall reduction of elasticity is observed, the elasticity trends approximately equal with pure polymer matrices (Fig. 2a), meaning that determining elasticity of ML platform based on the level of the polymer matrix is rational. For the choice of polymer matrix in ML platforms, the ER not only exhibits a smaller failure point at 11% than other candidates but also demonstrates an unidentified yield point in determining elasticity. While the failure point of PU is observed at 300% without destruction, it fails to return to its original state after exceeding a 40% stretch, meaning that the effective elasticity (yield point) of PU is only 40% under mechanical stress. This low yield point could not only interrupt the formation of the pore in the ML process (Fig. 1b) but also limits the ML performance owing to loss of elasticity when strain range is above 40%. In contrast, we need to pay attention to EF and DS, which bestow their outstanding failure points of 140–250% compared to PDMS (at 60%), making the superior yield point over the 100 % as a high elasticity. Regardless of ML brightness, these results suggest that EF and DS are rational candidates for ML platforms, indicating outstanding applicability in real environments requiring extreme elastic regions.

a Stress-strain graphs of the ML platforms depending on each polymer matrix. b ML brightness by strain depending on each polymer matrix. c ML brightness by stress at 60% and 70% strain for PDMS, EF, and DS. Error bars in b and c represent 5% and 3% errors, respectively. d ML brightness and e ML spectra of PDMS, EF, and DS depended on strain at 40%, 50%, 60%, and 70%, respectively. The inset in d shows the actual ML phenomenon with PDMS, EF, and DS under 70% strain.

From these results, we then estimated ML brightness based on both strain and stress to access its relationship with elasticity as shown in Fig. 2b. As trends of elasticity, the ML platforms with ER and PU are limited effective ML across the entire strain region attributed to poorly elastic region. It strongly demonstrates that the absence of elasticity of pure polymer matrices results in weaker ML brightness of the ML platform. As shown in Fig. 2b, while ER cannot generate any ML due to the lowest elasticity, PU still shows short-term ML in the effective elastic region in 40% strain, even though lead to rapid ML failure due to polymer damage29. In contrast, PDMS, EF, and DS exhibit the increasing tendency of ML brightness in their effective elastic region owing to outstanding elasticity of polymer matrix. We note that ML brightness of PDMS can increase before the 40% strain, but eventually tends to saturate or decrease owing to a shorter yield point around 45%, as a result of polymer damage. In the same context, the ML brightness of EF and DS also monotonically increases in their effective elastic region before reaching the yield point around 100% strain, as well as continuously enhanced brightness, even surpassing PDMS beyond 60% strain. This result implies that ML platforms with PDMS, EF, and DS provide not only longer effective elastic region for ML effect but also possibility of ML process before reaching the yield point of polymer matrix, attributed to their excellent elasticity. Furthermore, ML platforms with EF and DS not only exhibited high strains of 60% and 70% at relatively low stress levels, ranging from 1 to 3 MPa and 6 to 8 MPa, respectively (Fig. 2c), but also achieve the highest ML brightness at the 70% strain with values of 119, 124, and 139 cd/m² (Fig. 2d,e). Thus, taken collectively, we suggest that the elasticity of the polymer strongly contributes to ML brightness in three aspects: (1) providing an effective elastic region, which determines the ML range depending on the stress-strain relationship, (2) enabling the ML process, and (3) enhancing sensitive responsiveness to stress.

In these results, we discovered the intriguing phenomenon of outstanding ML brightness with EF and DS despite their superior elasticity, prompting a revisiting of the principles of ML. In accordance with previous reports, the ML brightness tends to decrease owing to increasing elasticity, which decides pore gap size contributed to triboelectric effect as a driving force of ML effect30. To ascertain this hypothesis, we examined the relationship between ML brightness and the varying elasticity of PDMS. It shows that the reducing trends of ML brightness were observed for the increasing three elasticity settings (regarding the failure points; low: 24%, middle: 36%, high: 55%) by adjusting the curing conditions of PDMS (Supplementary Fig. 10, Supplementary Table 3). Given all samples are under identical strain conditions, we confirmed that higher elasticity corresponds to lower ML brightness due to the ability to form pores (average values of pore gap with more than 20 particles) between ZnS:Cu and PDMS, which is attributed to elasticity (low elasticity—large pore gap size, high elasticity—small pore gap size), as shown in Supplementary Fig. 11a, b. In other words, in an ML platform with EF and DS, which have significantly higher elasticity than PDMS, lower brightness would have been expected, but they exhibited even more noticeable brightness performance than PDMS. We need to understand more this unprecedented result that contradicts the existing paradox.

ML brightness depending on the triboelectricity of the polymer matrix

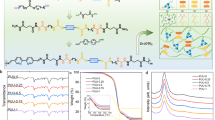

As evidence of the above results, we suggest one more significant factor of polymer matrix as triboelectricity, which is not only well known to be driving force of ML effect but also expected interaction with elasticity in determining ML brightness. However, probing the independent interaction between ML brightness and triboelectricity, irrespective of other factors, is not straightforward due to the concurrent ML process with all other relevant factors. To solve this impossibility, we preferentially developed novel setup to independently assess the luminescence performance of ZnS:Cu in conjunction with the triboelectricity of all polymer candidates. As shown in Fig. 3a, we coated a pure polymer film on a 6-in. silicon wafer and connected with Al tape as an electrode. On the other hand, we composed a ZnS:Cu single layer in PDMS between ITO electrodes (1.5 × 1.5 cm) with a thickness of 30 µm given the average ZnS:Cu size scale of 20–30 µm (to exclude the random characteristics caused by a thick layer) (Supplementary Fig. 12). In this setup, we successfully divide two prime parts: (1) pure polymer matrix to achieve effective triboelectricity and (2) the ZnS:Cu single layer to verify luminescence performance depending on this triboelectricity without elastic nature, and then lie on electrical connection these two parts (Supplementary Fig. 13). Five pure polymer matrices can offer effective triboelectricity to the ZnS:Cu single layer regardless of elasticity, thereby achieving luminescence performance likely reliant solely on triboelectricity.

a Home-made set-up for analysis AC-EL brightness of ZnS:Cu single layer attributed to independent triboelectricity of pure polymer matrices. b The output voltage and surface charge density of the polymer matrices. c AC-EL spectra of a ZnS:Cu single layer attributed to the output voltage of polymer matrices. The inset shows the AC-EL image of ZnS:Cu single layer attributed to output voltage of DS. d ML spectra according to the polymer matrices under the stretching, releasing, bending, scratching, and tearing, respectively. Inset images indicate the ML phenomenon under each mechanical motion.

To define the triboelectricity, we initially evaluated the surface charge density of all candidates, which contributes to the effective charge accumulation by mechanical action, capable of the triboelectric effect on the surface of polymer (Fig. 3b). As a series of polymer matrices, the observed charge density monotonically increases with the following trend: ER < PU < PDMS < EF < DS (−15.9, −21.3, −31.9, −102.1, and −146.7 nC/cm2), which could be attributed to the electron withdrawing ability of polymers in contacting surface (Supplementary Fig. 14). It is proved that all polymer candidates basically indicate the negatively charged surface potential by evidence with Kelvin probe force microscopy (KPFM), indicating identical trend with surface charge density (Supplementary Fig. 15). This strongly suggests that negatively charged polymer matrix can easily contribute the surface electron to alternative positively charged material to achieve the charge separation and accumulation for triboelectric effect. Based on these results, we then accessed oscilloscope analysis to verify the output voltage attributed to the surface triboelectricity of all polymer candidates. The latex glove is exploited as an alternative material instead of ZnS:Cu surface (positive surface charge density +11 nC/cm2) and apply tapping motion to generate triboelectric effect against polymer interfaces. As shown in Fig. 3b, the trend of the output voltage follows the results of surface charge density from 10 V to 195 V with identical tendency of a series of all polymers, by means of triboelectric effect, which is likely to match with ML process. As expected, the trends of surface charge density are clearly proportional to the output voltage as an ability of triboelectric effect in polymers. Particularly, it is noteworthy that EF and DS (124 and 195 V) stand out here due to their highly negative triboelectricity compared to traditional PDMS (109 V), which leads us to expect remarkable luminescence performance.

To confirm the relationship between triboelectricity and the luminance performance of ZnS:Cu, we directly supplied the generated output voltage above to the ZnS:Cu single layer (Fig. 3c). As expected in our setup, we successfully observed blinking luminescence of ZnS:Cu single layer as shown in inset of Fig. 3c, which can be ascribed to the alternating current electroluminescence (AC-EL) from the triboelectric effect of polymer matrices. Remarkably, the detected AC-EL spectra and relative intensity linearly increase following the triboelectricity trend, also manifesting the luminescence of ER and PU, which failed to emit ML due to poor elasticity. Furthermore, as expected, EF and DS display higher AC-EL performance than classic PDMS owing to higher triboelectricity. This strongly suggests that the triboelectricity of polymer matrices is not only the most important factor to consider in an ML platform but also solely contributes to the luminescence performance regardless of elasticity. Further evidence for this interaction is also found by examining the PL of the ML platform with all polymer candidates (Supplementary Fig. 7). While the PL intensity corresponding to all polymer candidates provides the negligible difference regarding the spectrum shape and relative intensity, the AC-EL intensity shows the trends, proving the role of triboelectricity of polymer matrices. That is, in the ML process, the brightness is solely affected by effective triboelectric field of polymer matrix in interface of ZnS:Cu regardless of elasticity.

To ascertain this hypothesis in ML process, we focused on the high-strain region of the ML platform to define the approximately identical environment to generate triboelectricity. Given that the high strain region over 60% provides them with sufficient conditions to gain effective triboelectricity, we characterized ML spectra under mechanical stress, including stretching, releasing, bending, scratching, and tearing (Fig. 3d). Regarding the PDMS, EF, and DS, we find similar ML trends with AC-EL, matching the tendency of output voltage above, as well as ER and PU also join the trend in banding, scratching, and tearing condition due to polymer fracture in interface with ZnS:Cu. It means that these polymer matrices under high strain region may influence the possibility of triboelectric effect. Briefly, in high-strain environments, while the brightness of ZnS:Cu is influenced by the triboelectricity of the polymer matrix, it may be hindered in lower-strain regions below 60% due to a weaker triboelectric effect. From these facts, we realized that the elasticity of the polymer matrix always involves ML brightness in ML process, despite the clear insight that triboelectricity dominantly contributes to ML brightness. Thus, we strongly suggest addressing the pore gap in microscopic landscape engaged by both elasticity and triboelectricity simultaneously in determining ML brightness.

ML performance based on both the elasticity and triboelectricity of the polymer matrix at the ZnS:Cu single particle level

To gain insight into the simultaneous ML interaction of elasticity and triboelectricity, it is necessary to theoretically and experimentally find microscopic evidence capable of probing single-particle levels in the local landscape of ML effects. Since the ML effect always arises in the pore gap between the ZnS:Cu and polymer matrix, we focused on this landscape to confirm their interaction between ML brightness and both polymer factors. Note that the ML process involves three primary steps simultaneously under mechanically stressed environments: (1) creating pores between ZnS:Cu and the polymer, (2) generating the effective triboelectric field corresponding to pore gap, and (3) activating ZnS:Cu for emission from this triboelectric field.

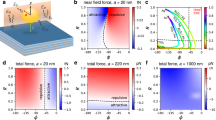

We accessed the finite-difference time-domain (FDTD) two-dimensional (2D) static electric field simulation to gain theoretical insight into interaction with pore gap (dgap) and triboelectric effect in the single particle level. We preferentially assigned the evaluated positive or negative surface charge density of ZnS:Cu (σ2 = 10 nC/cm2) and three polymers (σ1-PDMS = −31.9 nC/cm2, σ1-EF = −102.1 nC/cm2, σ1-DS = −146.7 nC/cm2), modeling the semi-circular and semi-elliptical surfaces of particles from the center of ZnS:Cu (Supplementary Table 4). Note that we only focused on the PDMS, EF, and DS among all candidates to consider the possibility of ML process. To satisfy charge balance, the net positive charges at the dgap boundaries are associated with the negative surface charge density, assuming a charge distribution across the entire contact interface (Supplementary Fig. 16). Given a uniform charge distribution over 1/20 of the hemisphere area (theoretical, θ = 18°) in a dgap of 10 µm, the electric field (E-field) on the ZnS:Cu interface is calculated to be 2.3 × 106, 3.3 × 106, and 3.7 × 106 V/m, respectively, depending on the PDMS, EF, and DS (Fig. 4a–c). These values not only manifest the effective threshold voltage on ZnS:Cu (106–107 V/m) in the AC-EL process36,37,38, but also bestow the possibility of ML activation in aspect of single particle level. Since the dgap held in constant at a 10 µm, the trend of E-field, by means of the triboelectric effect, linearly increase according to the elevating trend of surface charge density in order of PDMS > EF > DS, which strongly support our hypothesis that triboelectric effect is ascribed to surface charge density when elasticity held in constant. This result also leads us to realize that elasticity only contributes to the ability to regulate the dgap, not the triboelectric effect, hence, the ML brightness may seem to be regulated by elasticity, but it is for the charge accumulation ability depending on the dgap. To verify this hypothesis, we calculated additional E-fields for different dgap of 10, 20, 30, and 40 µm, respectively, which could be attributed to the elasticity of the polymer matrix in real ML process (Supplementary Fig. 17). As suggested, the E-fields of each polymer matrix are clearly increased proportionally with dgap, as well as exhibit the elevating trend depending on tendency of polymer matrix: PDMS < EF < DS. In particular, we focused on the E-fields of EF and DS at 10 µm (3.3 × 106 and 3.7 × 106 V/m), which are higher than those of PDMS at 30 µm, attributed to superior triboelectric properties. From this fact, we strongly suggest that outstanding ML brightness can be manifested despite of smaller dgap ascribed to high elasticity of polymer matrices.

FDTD simulation of the triboelectric field in the interfacial gap at 10 µm between ZnS:Cu and polymer matrix as a PDMS, b EF, and c DS, where the surface charge density is distributed over one-tenth of the total area (θ = 18°). d SEM image and e average dgap values between ZnS:Cu single particle and each polymer matrix under the strain of 60%. Error bars in e indicate 11% error. f ML images and g ML spectra of ZnS:Cu single particle depending on the polymer matrices, under the strain of 60%.

Based on these simulation results, we confirmed our suggestion through an experimental method capable of probing an identical landscape compared with the simulation window. We first performed an SEM analysis to assess the average dgap in ML platforms with PDMS, EF and DS under the 60% strain (Fig. 4d). As expected, while we cannot identify available dgap in ER and PU owing to poor elasticity (rigid feature), other candidates manifest clear dgap at the interface depending on their elasticity tendency: PDMS < DS < EF (average dgap with more than 20 particles: 10, 6, and 2 µm, respectively), proving our hypothesis that elasticity contributes to dgap (Fig. 4e and Supplementary Fig. 19). At the same time, to monitor the ML intensity attributed to this dgap, we designed an in-situ system by utilizing a spectrometer and an optical microscope (OM). The optical fiber and microscope objective are placed at identical positions on the samples to access both spectral information and ML images simultaneously (Supplementary Fig. 20). Remarkably, we successfully confirmed the ML intensity of single particles in terms of images (Fig. 4f) and relative ML intensity (Fig. 4g), and it aligns well with the trend based on the triboelectricity of polymer matrices, attributed to surface charge density (−15.9, −21.3, −31.9, −102.1, and −146.7 nC/cm2). However, since the ER and PU cannot form the dgap, we do not observe any ML effect in the microscopic image and spectrum despite outstanding ML effect in PDMS, EF, and DS. Notably, EF and DS provide outstanding ML despite smaller dgap (2, 6 µm) compared with PDMS (10 µm). These results lead us to realize the important ML interaction between elasticity and triboelectricity. As discussed in above section, there is serious paradox in ML performance that the lower dgap by high elasticity led to weaker triboelectric effect attributed to identical triboelectricity. However, from our results, we suggest rational solution that even if selecting a polymer with small dgap due to its high elasticity, implementing strong triboelectric properties can still achieve outstanding ML performance. In the same context, since the hyperspectral PL of single particle depending on the polymer matrices indicates identical spectral information (representing random regions for each particle, Supplementary Fig. 21), we strongly suggest that the strategy of interface control between ZnS:Cu and polymer matrices is most important to determine ML performance.

Human motion-detecting ML textile sensors with super elastic, negative triboelectric polymer matrix manifesting high ML performance

We now show a fabric-type ML textile sensor specifically designed for human motion detection to validate the practical utility of the ML platforms with the selected polymer matrices. Figure 5a provides a schematic illustration of the ML textile featuring a super-elastic polymer matrix strategically affixed to a human elbow and knee for real-time monitoring of motion. The ML textile was prepared in a zigzag pattern using individual ML platforms with PDMS, EF, and DS. These clearly demonstrate the bright ML under weak stretching motion of human hands (Fig. 5b). The ML performance at the maximum strain distance is significantly higher in the order of PDMS, EF, and DS, attributed to their triboelectricity and higher elastic features, as demonstrated in our work. Furthermore, EF and DS fibers exhibited remarkable strain performance compared with PDMS (Fig. 5c). To further verify the importance of polymer selection in this human motion detection sensor, we accessed the stability test for luminescent intensity of the ML fibers with polymer candidates ER, PU, PDMS, EF, and DS over the strain ranges of 40%, 60%, and 90%, respectively, up to 10,000 cycles (Supplementary Fig. 22). Since the stretching-releasing speed may cause the destruction of the polymer, we also considered frequency of stretching releasing motion at 100, 300, and 700 cycles per minute (CPM) in all condition. In all tests, we do not observe the ML stability of ER due to sample fracture at all strain levels, attributed to its low yield point of 11%. At 40% strain as a lowest condition for stability test, PU, PDMS, EF, and DS showed superior stability up to 75% after 10,000 cycles, with PDMS, EF, and DS maintaining over 90% intensity due to their high elasticity. However, ML intensity of PU decreased with increasing frequency and failed to demonstrate stability at 60% and 90% strain due to its low elasticity. Furthermore, while PDMS does not show ML at 90% despite its superior stability as shown in 40% and 60%, EF and DS stand for stability over the 90% across all strain and frequency conditions. It proves again that elasticity of polymer is important factor in determining the stability performance to apply real wearable applications.

a Schematic illustration for human motion (arm and knee bending) detection based on the ML platform. b The photo of an ML textile sensor with DS, and ML working image under the weak stretching motion with human hands. c ML working images of five strands of fiber with PDMS, EF, and DS, respectively. CIE color coordinates as a motion signal of ML textile sensor with d PDMS, e EF, and f DS according to human motion of the knee corresponding to strain greater than 40%.

Based on this fiber samples, we performed Commission Internationale de I’áclairge (CIE) color coordinate measurements during the sitting-to-standing transition, which involves a strain range of 40% to 90%, to obtain the human motion signal from the ML textile on the knee. The CIE coordinates revealed an independent motion signal attributed to distinct ML intensity and spectrum information related to human motion during a sitting-to-standing transition. Within the systematically defined strain range of 40–90%, each ML textile sensor provided distinct indicators discernible through shifts in CIE coordinates. In the strain range of 40–70% (moderate sitting behavior), PDMS maintained a high ML brightness, providing exceptional signals. However, it reached a failure limit at 70%, preventing it from delivering signals during the complete sitting motion. As we proved in the stability test, EF, and DS consistently provided stable independent indicators during all human movements of the sitting-standing transition and did not reach a failure limit due to their superior elasticity, maintaining high ML brightness. This demonstrates the superior impact of polymer selection based on elasticity and triboelectric capabilities in ML applications. The movie, which demonstrates the ML performance of the fibers used in our application (Supplementary Fig. 23) corresponding to PDMS, EF, and DS, provides further insight into their human motion sensing capabilities (Supplementary Movie 1).

This feature enables the visual quantification of angular displacement of the joint through ML. Our findings emphasize the importance of the polymer matrix for harnessing the transformative potential of next-generation ML platforms in capturing and visually representing human motion. Following further refinements, these novel ML platforms are poised to revolutionize a range of sectors, including wearable technology, healthcare monitoring, and human-computer interfaces.

Fundamental guidelines for selection of polymer matrices in ML applications

Based on the theoretical and experimental insights of our research, we propose three fundamental factors to consider when selecting a polymer matrix for super-elastic, high-performance ML platforms: transparency, elasticity, and negative triboelectricity. (1) the polymer matrix must possess sufficient transparency to allow light emission of the phosphor to reach the external environment. (2) the elasticity of the polymer matrix contributes to ML stability under mechanical stimuli and can regulate the dgap associated with the charge accumulation ability at the ZnS:Cu interface. (3) negative triboelectricity emerges as the pivotal determinant of ML brightness, capable of overcoming the ML degradation associated with high elasticity.

Considering these factors (Fig. 6a), we discovered EF and DS as viable polymer matrices for ML platform applications. Our research revealed superior negative triboelectric properties of the EF and DS matrices compared to the conventional PDMS matrix. Furthermore, ML platforms utilizing EF and DS demonstrated outstanding performance with high transmittance, excellent super-elasticity, and exceptional stability against mechanical stress. We integrated these novel polymer matrices, which exhibit enhanced negative triboelectricity, into the existing triboelectric series39 (Fig. 6b) to inform the design and fabrication of ML platforms. This triboelectric series, including the new polymer matrices, will serve as a valuable guide in the field of ML research for selecting suitable polymer matrices for ML platforms.

a Strategy of selecting the polymer matrix based on three key factors for the ML platform. b Updated triboelectric series with newly discovered polymer matrices for the ML platform. The green dots, representing the results of our work, highlight higher triboelectricity relative to previous ML polymer matrices.

Discussion

In summary, we provide a rational guideline for selecting the polymer matrix for a high-quality ML platform with both elastic and luminance performance. By exploiting series of polymer matrices, we unveil the role of the polymer matrix in the ML process, based on elasticity and triboelectricity as crucial fundamental factors independently determining ML brightness. As a primary fundamental factor, elasticity not only regulates the pore gap size (dgap) between ZnS:Cu and the polymer matrix but also provides the possibility of the triboelectric effect in determining ML brightness. As for the secondary fundamental factor, triboelectricity is crucial in determining ML brightness attributed to the negative surface charge density, enabling charge accumulation at the interface for ML activation. Collectively, by utilizing the in situ microscopic analysis of ML effect in single particle level, we suggest that ML brightness is governed not directly by elasticity, but rather by the triboelectric effect generated at the interface pore gap, which is determined by elasticity. Our guideline led to discovery of novel polymer matrices, polybutylene adipate-co-terephthalate silane (Eco Flex, EF) and polycarbonate silane (Dragon Skin, DS), which not only provide high elastic performance of over 100% attributed to elasticity of polymers but also show remarkable ML brightness of 139 cd/m2 by efficient charge accumulation, which is highest brightness in extreme strain region over the 60% to date. Furthermore, fabric-type ML textile sensors with discovered novel EF and DS for human motion detection reveal the outstanding ML brightness up to 90% strain regions by body motion at the knee and elbow, making the superior signal resolution. Our study provides well-understood fundamental insight to select the novel type of ML polymer matrix in various smart wearable ML applications.

Methods

Materials

The ZnS:Cu2+@AlOx microparticles (D502) as a main phosphor for the ML platform was purchased from Keyan Phosphor Technology Co.,Ltd (KPT). The average particle size of the ZnS:Cu2+@AlOx was from 20 to 30 μm. For the external polymer matrices, the epoxy resin was purchased from Donyang Epoxy Co. LTD, and polydimethylsiloxane (PDMS) was purchased from the Sylgard 184. The polyurethane 30 (PU), Dragon skin 30 (DS), and Eco-flex 30 (EF) were purchased from the Smooth-On Inc.

Fabrication of samples

Fabrication of pure polymer film

To make the pure polymer film, we used a homemade template to ensure the film formed with dimensions of 70 mm in length, 10 mm in width, and 2 mm in thickness. All pure polymer precursors of ER, PU, PDMS, EF, and DS were poured into this template and vacuum-sealed to remove the air, then cured according to their optimal curing processes. For the ER, we used a single precursor solution and applied UV irradiation at 360 nm for 10 min to cure it. For the PU, EF, and DS film, we used A (main polymer solution) and B solution (curing agent) and mixed them at a 1:1 weight ratio (wt%). The mixed precursor of PU was then placed in a furnace at 80 °C for 15 h, and EF and DS precursor were placed in a furnace at 100 °C for 20 min. For the pure PDMS film, PDMS A and B were mixed at a 9:1 weight ratio and cured in furnace at 100 °C for 20 min. The weight ratio between main polymer solution and curing agent was used of provided condition from the company, which is considered optimal chemical reaction ratio of materials.

Fabrication of ML platform

ZnS:Cu microparticles were incorporated into each polymer precursors of ER, PU, PDMS, EF, and DS, respectively, at a weight ratio of 7:3 of ZnS:Cu microparticles:polymer matrix. The mixed composite solution with polymer matrix was poured into a homemade template (see the above context) and cured according to each method of polymer matrices following above curing condition to get an ML platform.

Fabrication of triboelectric-induced electroluminescence setup

To fabricate the triboelectric nanogenerators using pure polymer matrices of ER, PU, PDMS, EF, and DS, we prepared precursor solutions in 20 ml vials. We then used the doctor blading method to coat 2 ml of each precursor onto a 6-in. silicon wafer and follow each curing process (see the above curing method). Fabricated pure polymer films were connected with Al tape as an electrode. On the other hand, we made a ZnS:Cu single layer with PDMS between ITO electrodes (1.5 × 1.5 cm area) with a thinckness of 30 µm given the average ZnS:Cu size scale of 20–30 µm (to exclude the random characteristics caused by a thick layer) (Supplementary Fig. 12). Thereby, we successfully divide two prime parts: (1) pure polymer matrix to achieving effective triboelectricity and (2) the ZnS:Cu single layer to verify luminescence performance depending on this triboelectricity without elastic nature, and then lie on electrical connection these two parts (Supplementary Fig. 13).

Characterization

All PL spectra were measured using an Edinburgh Instruments FLS1000 fluorimeter, equipped with a 450 W continuous xenon arc lamp. The ML spectra were measured using a Tristan optical emission spectrometer (MUT GmbH). ML properties were measured using a homemade stretching-relaxing apparatus subject to a constant stress (500 cycles per minute, 2 cm elongation). Transmittance spectra were obtained using a UV-vis spectrophotometer (Shimadzu UV-2600 240 V EN). To measure transmittance, each polymer was spin-coated onto a glass substrate at 4000 rpm for 30 s. Stress-strain curves were measured using a force meter (Puyan Co., LTD). The X-ray diffraction pattern (XRD) of ZnS:Cu2+@AlOx were conducted on the Bruker D8 Advance powder X-ray diffractometer, Anton Paar, operated with a Cu Kα beamline. The surface roughness of the films was measured using an XE-100 AFM operating in non-contact mode. To measure the output voltage of each polymer matrix, samples were fabricated in the form of a triboelectric nanogenerator, and the generated voltage and current upon friction were measured using an oscilloscope from Tektronics Co. (TBS 2000B). Surface charge was measured using an electrostatic voltmeter model 876 from Trek Co., LTD. Scanning electron microscopy (SEM) was used to see identify the morphology of the film and the dispersion form of the phosphor, and energy dispersion X-ray spectroscopy (EDS) was performed to confirm the composition of the film and the phosphor. SEM images were obtained using a low-voltage, high-resolution scanning electron microscope (Carl Zeiss (sigma 300)).

Data availability

The data used in this study are available from the corresponding author upon request due to ongoing patent preparation and intellectual property considerations associated with the research collaboration with LG Display.

References

Bacon, F. The Advancement of Learning. In The Fourth Book (ed Devey, J.) (P. F. Collier & Son, 1901).

Xu, C.-N., Watanabe, T., Akiyama, M. & Zheng, X.-G. Direct view of stress distribution in solid by mechanoluminescence. Appl. Phys. Lett. 74, 2414–2416 (1999).

Xu, C. N., Watanabe, T., Akiyama, M. & Zheng, X. G. Artificial skin to sense mechanical stress by visible light emission. Appl. Phys. Lett. 74, 1236–1238 (1999).

Wang, X., Xu, C.-N., Yamada, H., Nishikubo, K. & Zheng, X.-G. Electro-mechano-optical conversions in Pr3+-Doped BaTiO3-CaTiO3 ceramics. Adv. Mater. 17, 1254–1258 (2005).

Matsui, H., Xu, C.-N., Akiyama, M. & Watanabe, T. Strong mechanoluminescence from UV-irradiated spinels of ZnGa2O4:Mn and MgGa2O4:Mn. Jpn. J. Appl. Phys. 39, 6582 (2000).

Li, C. S. et al. Dynamic visualization of stress distribution by mechanoluminescence image. Key Eng. Mater. 388, 265–268 (2008).

Chandra, V. K., Chandra, B. P. & Jha, Piyush Models for intrinsic and extrinsic elastico and plastico-mechanoluminescence of solids. J. Lumine 138, 267–280 (2013).

Kamimura, S., Yamada, H. & Xu, C.-N. Strong reddish-orange light emission from stress-activated Srn+1SnnO3n+1:Sm3+ (n = 1, 2, ∞) with perovskite-related structures. Appl. Phys. Lett. 101, 091113 (2012).

Jeong, S. M., Song, S., Lee, S.-K. & Choi, B. Mechanically driven light-generator with high durability. Appl. Phys. Lett. 102, 051110 (2013).

Wang, X., Peng, D., Huang, B., Pan, C. & Wang, Z. L. Piezophotonic effect based on mechanoluminescent materials for advanced flexible optoelectronic applications. Nano Energy 55, 389–400 (2019).

Qian, X. et al. Printable skin-driven mechanoluminescence devices via nanodoped matrix modification. Adv. Mater. 30, e1800291 (2018).

Liu, J. et al. A multifunctional composite material with piezoresistivity and mechanoluminescence properties for a wearable sensor. Compos. Sci. Technol. 236, 109993 (2023).

Hou, B. et al. An interactive mouthguard based on mechanoluminescence-powered optical fibre sensors for bite-controlled device operation. Nat. Electron. 5, 682–693 (2022).

Jeong, S. M. et al. Bright, wind-driven white mechanoluminescence from zinc sulphide microparticles embedded in a polydimethylsiloxane elastomer. Energy Environ. Sci. 7, 3338–3346 (2014).

Jeong, S. M. et al. Battery-free, human-motion-powered light-emitting fabric: mechanoluminescent textile. Adv. Sustain. Syst. 1, 1700126 (2017).

Jeong, S. M., Song, S., Lee, S.-K. & Ha, N. Y. Color manipulation of mechanoluminescence from stress-activated composite films. Adv. Mater. 25, 6194–6200 (2013).

Monette, Z., Kasar, A. K. & Menezes, P. L. Advances in triboluminescence and mechanoluminescence. J. Mater. Sci. Mater. Electron. 30, 19675–19690 (2019).

Jeong, H. I. et al. Quantum dot‐in‐mechanoluminescent matrix for full‐color implementation. Adv. Opt. Mater. 11, 2202088 (2022).

Liu, S. et al. Near‐infrared mechanoluminescence of Cr3+ doped gallate spinel and magnetoplumbite smart materials. Adv. Funct. Mater. 33, 2209275 (2023).

Bai, Y. et al. Self‐charging persistent mechanoluminescence with mechanics storage and visualization activities. Adv. Sci. 9, 2203249 (2022).

Ma, Z. et al. Mechanics-induced triple-mode anticounterfeiting and moving tactile sensing by simultaneously utilizing instantaneous and persistent mechanoluminescence. Mater. Horiz. 6, 2003–2008 (2019).

Kim, H. J. et al. Detection of cracked teeth using a mechanoluminescence phosphor with a stretchable photodetector array. NPG Asia Mater. 14, 26 (2022).

Ariati, R., Sales, F., Souza, A., Lima, R. A. & Ribeiro, J. Polydimethylsiloxane composites characterization and its applications: a review. Polymers 13, 4258 (2021).

Shin, E.-C., Ko, J.-H., Lyeo, H.-K. & Kim, Y.-H. Derivation of a governing rule in triboelectric charging and series from thermoelectricity. Phys. Rev. Res. 4, 023131 (2022).

Zou, H. et al. Quantifying and understanding the triboelectric series of inorganic non-metallic materials. Nat. Commun. 11, 2093 (2020).

Li, J., Zhang, Z., Luo, X., Zhu, L. & Wang, Z. L. Triboelectric leakage-field-induced electroluminescence based on ZnS:Cu. ACS Appl. Mater. Interfaces 14, 4775–4782 (2022).

Zhou, J. et al. An ultra-strong non-pre-irradiation and self-recoverable mechanoluminescent elastomer. Chem. Eng. J. 390, 124473 (2020).

Li, L., Wondraczek, L., Peng, M., Ma, Z. & Zou, B. Force-induced 1540 nm luminescence: Role of piezotronic effect in energy transfer process for mechanoluminescence. Nano Energy 69, 104413 (2020).

Wang, W. et al. Contact electrification induced mechanoluminescence. Nano Energy 94, 106920 (2022).

Park, H.-J. et al. Self-powered motion-driven triboelectric electroluminescence textile system. ACS Appl. Mater. Interfaces 11, 5200–5207 (2019).

Li, H. et al. A self-powered porous ZnS/PVDF-HFP mechanoluminescent composite film that converts human movement into eye-readable light. Nanoscale 10, 5489–5495 (2018).

Yang, F., Yuan, Y., Sijbesma, R. P. & Chen, Y. Sensitized mechanoluminescence design toward mechanically induced intense red emission from transparent polymer films. Macromolecules 53, 905–912 (2020).

Banishev, A. F. & Banishev, A. A. Deformation stimulated luminescence of a composite produced on the basis of polymethylmethacrylate transparent in the visible region and finely dispersed powder of SrAl2O4:(Eu2+, Dy3+) phosphor. Inorg. Mater. Appl. Res. 10, 647–651 (2019).

Matsui, H., Xu, C.-N., Liu, Y. & Tateyama, H. Origin of mechanoluminescence from Mn-activated ZnAl2O4: triboelectricity-induced electroluminescence. Phys. Rev. B 69, 235109 (2004).

Lee, G. et al. Interfacial triboelectricity lights up phosphor‐polymer elastic composites: unraveling the mechanism of mechanoluminescence in zinc sulfide microparticle‐embedded polydimethylsiloxane films. Small 2307089 https://doi.org/10.1002/smll.202307089 (2024).

Ono, Y. A. Electroluminescent Displays (World Scientific, 1995).

Vij, D. R. Luminescence of Solids (Plenum Press, 1998).

Yen, W. M. Shionoya S., Yamamoto H. Phosphor Handbook (CRC Press, 2007).

Zhang, X., Chen, L., Jiang, Y., Lim, W. & Soh, S. Rationalizing the triboelectric series of polymers. Chem. Mater. 31, 1473–1478 (2019).

Acknowledgements

H.I.J. acknowledges support from the Institute of Information & Communications Technology Planning & Evaluation (IITP), funded by the Korean government (MSIT) (No. 2020-0-01373, Artificial Intelligence Graduate School Program, Hanyang University), and the research fund of Hanyang University (HY-2023). H.S.J., H.S., W.H.J., and H.C. acknowledge funding from the National Research Foundation of Korea (NRF) (Grant No. NRF-2023R1A2C1003824, NRF-2022R1A2C1002764, NRF-2021M3H4A1A02049634, and RS-2024-00436187). H.I.J., H.S.J., and H.C. acknowledge support from LG Display under the LGD-Hanyang University Incubation Program (Grant No. C2022008311). S.D.S. acknowledges funding from the Royal Society and Tata Group (Grant No. UF150033).

Author information

Authors and Affiliations

Contributions

H.I.J. and H.S.J. equally contributed to this work. H.I.J. conceptualized this work. H.S.J. and H.I.J. characterized polymers and ML. M.D. and H.I.J. analyzed PL and ML for each ML platforms. G.K. and J.W.Y. conducted the FDTD simulation of the ML platform at the single-particle level depending on the triboelectricity of polymer matrices. Y.L., S.B., and H.K. analyzed the surface charge density for triboelectricity of each polymer matrix. S.D.S. analyzed PL and ML at the film and single particle levels. H.I.J., M.D., and H.S.J. wrote and revised the manuscript. W.H.J., H.S., and B.R.L. characterized ML platform to demonstrate surface properties. J.L., H.C., S.M.J., and S.D.S supervised this work. All the authors contributed to the discussion and validated the manuscript.

Corresponding authors

Ethics declarations

Competing interests

H.I.J. and H.C. are named on a pending patent related to the research conducted in collaboration with LG Display. The other authors declare no financial or non-financial competing interests.

Peer review

Peer review information

Nature Communications thanks Shuo Chen, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jeong, H.I., Jung, H.S., Dubajic, M. et al. Super elastic and negative triboelectric polymer matrix for high performance mechanoluminescent platforms. Nat Commun 16, 854 (2025). https://doi.org/10.1038/s41467-025-56007-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-56007-5

This article is cited by

-

Multi-stimulated far-UVC luminescence for solar-blind imaging

Nature Communications (2025)

-

A Robust Core–Shell Structured Fabric with Integrated Personal Protection and Visualized Monitoring for Smart Protective Textiles

Advanced Fiber Materials (2025)