Abstract

Reducing green hydrogen production cost is critical for its widespread application. Proton-exchange-membrane water electrolyzers are among the most promising technologies, and significant research has been focused on developing more active, durable, and cost-effective catalysts to replace expensive iridium in the anode. Ruthenium oxide is a leading alternative while its stability is inadequate. While considerable progress has been made in designing doped Ru oxides and composites to improve stability, the uncertainty in true failure mechanism in acidic oxygen evolution reaction inhibits their further optimization. This study reveals that proton participation capability within Ru oxides is a critical factor contributing to their instability, which can induce catalyst pulverization and the collapse of the electrode structure. By restricting proton participation in the bulk phase and stabilizing the reaction interface, we demonstrate that the stability of Ru-oxide anodes can be notably improved, even under a high current density of 4 A cm‒2 for over 100 h. This work provides some insights into designing Ru oxide-based catalysts and anodes for practical water electrolyzer applications.

Similar content being viewed by others

Introduction

Water electrolysis is one of the most promising ways for scaling up green hydrogen production. Among various electrolyzers, PEMWEs have garnered particular attention due to their high current density, quick response, and compact size, making them well suited for integration into renewable energy systems. However, state-of-the-art PEMWEs with Ir-based anodes and platinum (Pt) cathodes suffer from high costs due to the limited global reserves and high prices of these precious metals, especially Ir. This fact has led to an urgent demand for alternative, cost-effective electrocatalysts, particularly for replacing Ir in the anode1. Ru oxide has been found to be intrinsically more active than Ir-based catalysts in OER, while the price of Ru is only one-tenth of that of Ir. Therefore, it is considered highly promising to reduce the current dependence on Ir and decrease the capital cost of electrolyzers. Unfortunately, the durability of Ru oxides for their application in PEMWEs has been challenged2,3.

Current research primarily attributes the instability of Ru oxides to lattice oxygen participation and Ru dissolution from over-oxidation4. It was reported that the dissolution rate of Ru oxide in acidic and oxidative environments is approximately an order of magnitude higher than that of Ir oxide5,6. However, the details of lattice oxygen participation and Ru dissolution in the failure of Ru oxide anodes in PEMWE operation remain not fully understood, which greatly inhibits the optimization of Ru oxide-based catalysts. In recent years, research efforts have been largely focused on the doping strategy to modify the electronic structure of Ru oxides. For instance, introducing electron-donating elements into the Ru oxide lattice aims to lower the oxidation state of Ru7,8, stabilize the lattice structure9, or alert the OER mechanism10. However, dopants could also reduce the number of active sites and may adversely affect the intrinsic activity of the Ru oxide. Moreover, some metal dopants, such as Co, Na, Mn, Cr, Cu and Ni, may be prone to dissolution in acid, which can negatively impact the conductivity of Nafion membranes due to their cation exchange capability. From these aspects, non-doping methods that enable the stability of Ru oxide anodes will be favorable.

Very recently, some controversial results about the stability of Ru oxides in acidic OER have appeared in literature, suggesting that the failure mechanisms of Ru oxide anodes under PEMWE operation conditions are not yet fully understood. Some fundamental studies have pointed out that the assumed dissolution-relative species RuO4 has not been spectroscopically identified11. The dissolution rates reported also vary a lot12. For example, Ru oxides obtained through thermal annealing was reported to have distinguished corrosion resistance compared to metallic Ru13. Additionally, the acidic OER on oriented facets of RuO2 has been observed without lattice oxygen exchange14. Recently, local coordination modulation of undoped RuO2 has demonstrated stable performance in practical PEMWE conditions for up to 100 h at 60 °C and 1 A cm–2 15. As research into the mechanism deepens, there is growing attention to the possibility that the failure of Ru oxides in OER may involve more complex mechanisms, potentially including the participation of CUS in the adsorption and dissociation of water molecules16,17. However, due to the scarcity of direct experimental evidence, there remains a significant gap in systematic research on the actual stability and failure mechanisms of Ru oxide anodes in PEMWE applications.

In this study, we demonstrate distinct stabilities in Ru oxides during OER and provide direct evidence suggesting factors beyond lattice oxygen participation and Ru site over-oxidation contribute to Ru oxide anode degradation. Specifically, proton participation notably impacts the stability of Ru oxides in acidic OER. Hydrous RuOx (h-RuOx), containing large amount of CUS in the bulk phase that are chemically complexed with ‒OH, which will induce water dissociation in the bulk phase during the OER. This causes rapid pulverization of catalyst particles and collapse of the anode structure, rather than over-oxidation of Ru sites. The PEMWE with the h-RuOx anode thus experiences rapid failure during the operation. Conversely, anhydrous, highly crystalline RuO2 (anh-RuO2) without CUS presented in the bulk phase shows satisfying stability without doping. The PEMWE with the anh-RuO2 anode exhibits only a slow decay rate when operating at 1 A cm‒2 for >500 h. Pre- and post-stability characterizations of the anh-RuO2 catalyst and electrode structures suggest stable Ru valence state and lattice oxygen coordination. The slow performance decay is reasonably attributed to the reorganization of the catalyst-ionomer reaction interface. Therefore, we propose that the stability improvement of Ru oxides for acidic OER can be realized by prohibiting proton participation in the bulk phase and eliminating CUS, while inhibiting the reaction interface reconstruction. By introducing an additional binder to provide extra catalyst fixation in the anh-RuO2 anode, we achieve stable operation of undoped RuO2 at a high current density of 4 A cm‒2 for >100 h. This work will provide some insights for the development of Ru oxide-based catalysts and anodes aiming for PEMWE applications.

Results

The activity and stability of the two Ru oxides (h-RuOx and anh-RuO2) are evaluated as anodes in PEMWEs and compared with those of the commercial IrO2 catalyst. From the polarization performance curves (Fig. 1a) and a direct comparison of voltages for delivering different electrolysis current densities (Fig. 1b), both Ru oxides demonstrate significant advantages over commercial IrO2 with the controlled same precious metal loading of 1 mg cm‒2. Due to their higher intrinsic catalytic activity, the PEMWEs with the Ru oxide anodes exhibit overall better performance in both the small-current-density regions, which are controlled by reaction kinetics, and the large-current-density regions, dominated by the ohmic resistance of the electrolyzer. The polarization curve with the h-RuOx anode features a notably lower onset potential, exhibiting only 1.38 V for an initial current density of 0.2 A cm‒2, compared to 1.46 V for the anh-RuO2 anode and 1.50 V for the commercial IrO2 anode. Furthermore, both Ru oxide anodes show comparable performance in high-current-density operation, achieving an electrolysis current density of 3.9 A cm‒2 with the anh-RuO2, and 3.0 A cm‒2 with the h-RuOx at 1.8 V, compared to the 2.4 A cm‒2 for the IrO2. Galvanostatic electrochemical impedance spectroscopy (EIS) measurements reveal that the PEMWE with the anh-RuO2 anode exhibits lower high-frequency resistance (Fig. 1c), thereby benefiting high-current-density performance. Despite both Ru oxides showing outstanding polarization performance compared to commercial IrO2, the PEMWEs fabricated with these Ru oxides exhibit markedly different stability under identical operating conditions (Fig. 1d, e). During operation at an electrolysis current density of 1 A cm‒2 with deionized water circulated as the anode feedstock at 80 °C, the anh-RuO2 exhibits satisfactory stability, maintaining operation for over 550 h with a gradual performance decay rate of ~133 µV h‒1. In stark contrast, the h-RuOx fails abruptly within just 1 min of operation. The distinct stability results observed in PEMWE present to be similar to those observed in the rotating disk electrode (RDE) systems (Fig. 1f, Fig. S1 and S24). We also observe that the anode circulating water during PEMWE operation with the h-RuOx anode quickly turns light blue and returns to colorless after filtration, leaving dark particles (Fig. 1g, and Fig. S2). This suggests that the light blue anode circulating liquid is a particle suspension rather than a dissolved metal ion solution. The anode circulating water with the anh-RuO2 anode remains colorless for a considerable period of hundreds of hours of operation. Inductively coupled plasma mass spectrometry (ICP-MS) is applied to detect dissolved Ru ions in the filtered anode circulating liquid after stability tests in both cases, which were both at the ppb level and can be considered negligible, as shown in Tab. S1 (an Ru concentration of 13.3 ppm can be expected assuming full dissolution). These phenomena suggest that the performance degradation of Ru oxide anodes in the acidic OER process may not result from Ru dissolution. A recent study also observed that the carbon paper-supported RuO2 did not lose much catalyst quantity after the OER, and no significant dissolved Ru ions were detected in the electrolyte12. However, due to the lack of comparative studies, the mechanism has not been explored.

a The PEMWE performance curves with the anh-RuO2 anode, h-RuOx anode and the commercial IrO2 anode. The electrolyzer performance curves are presented as non-iR corrected. b A comparison of voltages for operating the PEMWEs at different current densities. c Nyquist plots from the galvanostatic EIS measurements at 100 mA cm‒2. PEMWE stability test with (d), the anh-RuO2 anode, and (e), the h-RuOx anode for operating at 1 A cm‒2. f Chronoamperometric tests conducted under RDE system at 10 mA cm‒2. g Pictures showing the color of the anode circulating water before and after filtration as collected from the failed PEMWE with the h-RuOx anode. Source data are provided as a Source Data file.

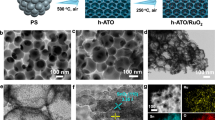

To understand the origin of the significant difference in operational stability of the two Ru-oxide anodes, characterizations regarding their chemical and physical properties are performed. The X-ray diffraction (XRD) patterns (Fig. 2a) demonstrate a high crystallinity of ~94.75% with characteristic diffraction peaks referring to the rutile phase (PDF 04-009-7842) detected from the anh-RuO2, and an average coherent crystallite domain size of ~19.8 nm is calculated based on the Scherrer equation18. Whilst the broadened diffraction pattern and the missing characteristic peaks indicate the amorphous structure of the h-RuOx with possible smaller particle size. The Brunauer–Emmett–Teller (BET) surface area obtained from N2 adsorption-desorption isotherms (Fig. S3) of the anh-RuO2 is characterized to be 18.7 m2 g‒1, and the h-RuOx is much larger of 34.4 m2 g‒1. The structure of anh-RuO2 and h-RuOx is further visually investigated by high resolution transmission electron microscopy (HR-TEM). The anh-RuO2 demonstrates well-defined crystalline structure (Fig. 2b). The interplanar spacings of 0.317 nm and 0.255 nm as measured from fringes can be assigned to the (110) and (101) lattice planes of rutile RuO2, while the inserted fast Fourier transform (FFT) pattern also reflects the crystalline nature of the anh-RuO2. In contrast, the h-RuOx exhibits amorphous phase. The surface chemical composition and Ru valence state are characterized by X-ray photoelectron spectroscopy (XPS). The high-resolution O 1 s spectra (Fig. 2c) show three fitted peaks at binding energy of 530.19, 531.77, and 533.00 eV respectively, typically representing the lattice oxygen (O2‒), oxygen vacancy (Vo), and adsorbed oxygen (from coordinated water). The h-RuO2 exhibits an obviously larger proportion of adsorbed oxygen ( ~ 54.4%) that may originate from coordinated water, whereas the anh-RuO2 surface is observed to be dominated by lattice oxygen, comprising 40.5% of the total content. Correspondingly, a lower valence state of Ru is observed on the h-RuOx as evidenced by a negative shift of Ru 3p3/2 and Ru 3p1/2 peaks at 463 and 485.1 eV compared to that of the anh-RuO2 by 0.2 eV (Fig. S4). The X-ray absorption near-edge structure (XANES) spectra of Ru-K is collected to explore the Ru valence state in anh-RuO2 and h-RuOx, respectively (Fig. 2d)19. The lower adsorption energy at the normalized position observed with the h-RuO2 compared to that with the crystalline anh-RuO2 indicates a lower Ru valence state of less than +4 in the h-RuO2. For both the anh-RuOx and the h-RuOx, the analysis of Ru‒O and Ru‒Ru bonds are conducted via the Ru K-edge extended x-ray absorption fine structure (EXAFS). According to Fig. 2e, the anh-RuO2 exhibits two peaks corresponding to the first shell of the Ru‒O bond at 1.5 Å and the second-shell Ru‒Ru bond at 3.2 Å. Notably, the intensity of both shells for the h-RuOx is much weaker, particularly for the second-shell Ru‒Ru bond, suggesting a lower coordination number of Ru‒O and poor crystallinity of the h-RuOx. The O K-edge X-ray absorption spectroscopy (XAS) under total electron yield (TEY) is used to examine the Ru‒O covalency as shown in Fig. 2f. A negatively and enhanced shifted pre-edge peak at 529.4 eV for the anh-RuO2 compared to 529.6 eV for the h-RuOx indicates a higher Ru‒O covalency corresponding to a higher Ru valence state in the anh-RuO2. These results are consistent with the XPS and XRD characterizations, indicating a lower Ru valence state, more O vacancies, and poor crystallinity of the h-RuOx. Clarifying the contribution of these factors to the stability differences in acidic OER will greatly aid in the improvement of Ru-oxide catalytic stability.

a XRD patterns of the anh-RuO2 and the h-RuOx showing the crystallinity. b HR-TEM images and FFT patterns showing the phase structure. c High-resolution O 1 s spectra and the deconvoluted peaks. d Ru K-edge XANES spectra with an inset showing the enlarged region. e Ru K-edge EXAFS, and (f) O K-edge XAS collected from the two Ru oxide anodes showing the electronic structure. Source data are provided as a Source Data file.

Recent progresses on improving the stability of Ru oxide-based catalysts for acidic OER under real PEMWE operating conditions are summarized in Tab. S29,20,21,22,23,24,25,26,27,28,29,30. It has been generally recognized that metal doping is effective in improving the stability of Ru oxide-based catalysts through two main mechanisms: inhibiting the participation of the lattice oxygen or preventing the over-oxidation of Ru sites. However, the origin of the instability of Ru oxide remains controversial. For instance, specific stability of lattice oxygen in RuO2 has been observed without exchange during the OER catalysis14. Most recently, it was demonstrated that the presence of metallic Ru‒Ru interaction could enable pure RuO2 to operate stably at 1 A cm‒2 for 100 h15. Due to the lack of standardized stability testing conditions—where some studies introduce additional liquid acid environments, and others conduct evaluations only under small current densities—there remains a gap in the understanding of the true failure mechanisms of Ru oxides. Therefore, to gain insights into the markedly different stabilities exhibited by the two Ru-oxide anodes for the operation at 1 A cm‒2 under standard PEMWE conditions (80 °C, pure water), we first analyze the chemical-state changes and the electrode-structure transformations of the Ru-oxide anodes through characterizations at the beginning of life (BoL) and end of life (EoL). As shown in Fig. 3a, b, the Ru K-edge XANES and EXAFS spectra confirm that both the Ru valence state and local structure remain unchanged in the anh-RuO2 anode after a 550-h stability test at 1 A cm‒2. Even when operating at a higher current density of 3 A cm‒2 for 100 consecutive hours, this stability is not compromised (Fig. S5). The results exclude the over-oxidation of the Ru centre and the participation of lattice oxygen in the highly-crystalline anh-RuO2 during the OER process, providing evidence of its observed stability in PEMWE. Unexpectedly, the Ru valence state in the h-RuOx is observed with negligible change as well after the complete failure for operating at 1 A cm‒1, as evidenced by the Ru K-edge XANES spectra (Fig. 3c). Additionally, a substantial decrease in the Ru‒O coordination number as evidenced by the decreased intensity of the Ru‒O scattering path in the Ru K-edge EXAFS spectra (Fig. 3d) indicated the pulverization of catalyst particles and changes of the local structure. The results suggest that the cause of Ru oxide anodes failure may stem from other factors, instead of Ru centre over oxidation. The decreased intensity of the Ru‒Ru scattering path further indicates the deterioration of the crystallinity, suggesting a possible reconfiguration of the local atomic structure of Ru.

a Ru K-edge XANES spectra with an inset showing the enlarged region and (b) EXAFS spectra collected from the anh-RuO2 anode at the start and after the stability tests at 1 A cm‒2 and 4 A cm‒2 for 100 h, respectively. c Ru K-edge XANES spectra with an inset showing the enlarged region and d, EXAFS spectra collected from the h-RuOx anode prior and after the failure at 1 A cm‒2. EDS elemental mapping of the Pt, Ru and F distribution in the CCMs with (e) anh-RuO2 anode, and (f), h-RuOx anode after the stability tests. Source data are provided as a Source Data file.

Microstructures of catalysts coated membrane (CCM) fabricated with the anh-RuO2 anode and the h-RuOx anode are studied by cross-section scanning electron microscopy (SEM) imaging and energy dispersive spectroscopy (EDS) elemental mapping. As shown in Fig. 3e and Fig. S6, S7, the anh-RuO2 anode exhibits slight delamination after the 550 h operation at 1 A cm-2. A morphologically denser layer composed of Ru oxide is observed to form at the contact interface between the anode and the membrane, while the anode structure remains intact. The EDS mapping depicts the distribution of elements such as Ru, Pt, and F in the CCM after the operation and provides additional confirmation that no discernible dissolution or migration of Ru is observed, resulting in an undisturbed and Ru contaminant-free Pt/C cathode. This delamination occurred in the anh-RuO2 anode is likely responsible for the slow performance degradation. Notably, severe collapse of the h-RuOx anode structure is observed after even 1 min stability test. The reformed RuO2 particles are detected at the cathode side as evidenced by both the EDS elemental mapping (Fig. 3f) and the line scanning of the Ru distribution across the CCM (Fig. S8).

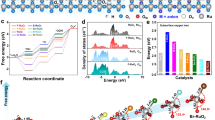

Apparently, there are two distinct degradation mechanisms at play in the Ru-oxide anodes during the OER process. Regarding the commonly accepted adsorbate evolution mechanism (AEM) and the lattice oxygen oxidation mechanism (LOM) for oxygen evolution, in addition to the transfer and participation of oxygen, proton involvement is also crucial, however, it is generally recognized that proton transfer occurs only in reaction environment, and thus its transport is not directly connected to the reaction or stability mechanisms. For the Ru oxides with actively bounded ‒OH that can exhibit proton conductivity in the bulk phase under specific circumstance, the mechanism may differ. Hydrous ruthenium oxide (RuOxHy) has been found to be a mixed proton and electron conductor that innately expresses Ru−OH speciation31, and the proton conductivity has been demonstrated to be related to the coordinated water content in the bulk phase. Previous research also assumed that the pronounced dissolution of Ru oxide can happen with the presence of coordinately unsaturated Ru sites16, or with the formation of RuO2(OH)2 intermediates32,33. These phenomena suggest that when unsaturated Ru sites are coordinated with −OH, protons are allowed to insert, follow the reaction \({Ru}{O}_{X}{({OH})}_{y}+{\delta H}^{+}+{\delta e}^{-}\leftrightarrow {Ru}{O}_{x-\delta }{({OH})}_{y+\delta }\) under OER potentials. To verify this assumption, we first examine the pseudocapacitive behaviors involving the proton redox and intercalation of the two Ru oxides by using them as a cathode of supercapacitor. As shown in Fig. 4a, Fig. S9–12, and Fig. S23, cyclic voltammetry (CV) is conducted in the potential range of 0.0 to 1.0 V at 5.0 mV s‒1 in 1 M H2SO4, the h-RuOx electrode exhibits a broad rectangular-like shape in the potential window, indicating that protons can be reversibly intercalated into h-RuOx resulting in a high area-specific capacitance of 16.5 F m‒2 (corresponding to a mass-specific capacitance of 417.8 F g–1). In contrast, the anh-RuO2 electrode exhibits much lower proton storage capacity of only 2.0 F m-2 (24.2 F g‒1) with negligible variation with scan rates, suggesting that the highly crystalline bulk phase is incapable of proton insertion. To further explore the differences in the existence of −OH between the anh-RuO2 and the h-RuOx, we also analyze the H2O and O2 desorption signals by mass spectroscopy (MS) of the two Ru oxides under temperature programmed desorption (TPD) treatment. As depicted in Fig. 4b, c, the h-RuOx displays a broad desorption peak for H2O (m/z = 18), starting at around 71 °C and peaking at around 250 °C. The onset and peak temperatures for H2O desorption can reflect the binding energy and quantity of structural water in different forms. Simultaneously, segmented O2 desorption peaks are observed, with the initial desorption slightly lagging behind that of H2O at around 120 °C. These findings support that protons are distributed not only on the surface of h-RuOx but also in the bulk phase and might exist as chemically complexed ‒OH. The O2 desorption peak appearing in the temperature range of 400–500 oC is generally attributed to the oxidation of lattice oxygen which should be accompanied with the valence state change of the Ru, indicating that the lattice oxygen in h-RuOx is also active. In comparison, neither obvious desorption peaks of H2O nor O2 are observed for the anh-RuO2, suggesting a proton intercalation-free nature of the bulk phase, and a high stability of the lattice oxygen in the highly crystalline anh-RuO2. Time-of-flight secondary-ion mass spectrometry (TOF-SIMS) is utilized to further investigate the distribution of bulk protons and the stability of lattice oxygen in the Ru oxides. The mass spectra in Fig. 4d exhibit notably stronger ion signals corresponding to O2‒ (m/Q = 16) and OH‒ (m/Q = 17) from the h-RuOx compared to the anh-RuO2. A depth profiling of OH‒ distribution (Fig. 4e–g) reveals a thorough distribution of coordinated −OH throughout the bulk phase of the h-RuOx, whereas the anh-RuO2 exhibits an anhydrous phase with potentially only some adsorbed water on the surface.

a CV curves collected from the two Ru oxides in 1 M H2SO4 at a scan rate of 5 mV S‒1. TPD-MS profiles of H2O-18 and O2-32 for (b) the h-RuOx, and (c) the anh-RuO2. d Ion signals of O2‒ (m/Q = 16) and OH‒ (m/Q = 17) from TOF-SIMS acquired data. X-Z depth imaging of the OH‒ gradient distribution in (e) the h-RuOx, and (f) the anh-RuO2. g A comparison of the depth profiling of OH‒ distribution obtained from the two Ru oxides. The electron-density isosurface from DFT calculation of h, the h-RuOx, and i, the anh-RuO2. The color bar inset illustrates the electrostatic potential (Vs(r) in eV) scale corresponding to different shading colors, and the isosurfaces are plotted at the 0.001 e bohr−3 level. The gray ball represents Ru atom, and red ball represents O atom. Source data are provided as a Source Data file.

The above results demonstrate that proton participation notably impacts the stability of Ru oxide anodes during the OER process. Specifically, this behavior encompasses proton redox and intercalation onto the Ru oxide surface, which differs notably between various Ru oxide materials. During the electrode reaction, if proton transfer and oxygen exchange occur only on the catalyst surface, the primary effect is the reconstruction of the interface between the catalyst and the ionomer, leading to a slow performance decay, as observed with the anh-RuO2 anode. Conversely, the insertion of protons can generate bound water in the bulk phase, and induce hydrolysis occurring at the internal Ru CUS sites. The water dissociation in the bulk phase is then accompanied by proton and electron conduction, as well as oxygen exchange, leading to immediate disintegration of catalyst particles and subsequent rapid electrode structure collapse and swift performance failure.

Density functional theory (DFT) calculations were conducted to provide a side support of the stability difference observed. Based on the four elementary steps of the acidic OER process34, H2O molecules initially fill oxygen vacancies by forming OH* species, accompanied by proton removal through a one-electron oxidation step35,36. For the h-RuOx with its amorphous bulk phase, we utilized ab initio molecular dynamics (AIMD) simulations. For the anh-RuO2, we selected the (110) surface in this calculation (Supplementary Data 1). We recognize that selecting an appropriate model for DFT theoretical calculations to thoroughly analyze the stability observed in PEMWE is challenging due to the complex, multi-factor electrode reactions occurring within the device, therefore, the results obtained here serve solely as supporting evidence. The absorption energy of OH* was calculated to be -1.1 eV, compared to -0.3 eV on the anh-RuO2, suggesting that water coordination in the bulk h-RuOx is notably more active. Considering the subsequent generation of O* species, where lattice oxygen within the catalyst structure facilitates HOO* formation to regenerate oxygen vacancies, the calculated lattice oxygen vacancy formation energy in anh-RuO2 (2.9 eV) is much higher than in h-RuOx (0.4 eV). Figure 4h, i present the electron-density isosurface of the h-RuOx and anh-RuO2, indicating that h-RuOx exhibits a more positive electrostatic potential compared to anh-RuO2, suggesting a greater affinity for the adsorption of negatively charged OH species. This observation aligns with the calculated adsorption energies, further supports the observed activity and stability differences between the two Ru oxide catalysts in PEMWE.

To verify the proposed mechanism, we treated the h-RuOx at various temperatures in air for 2 h to remove the intercalated water before applying them in PEMWE again for stability testing. The XRD patterns and Ru K-edge EXAFS spectra results (Fig. 5a, c, and Tab. S3) exhibit an increase in crystallinity and growth in particle size of the h-RuOx with increased thermal treatment temperature. The Ru K-edge XANES spectra in Fig. 5b exhibit an obvious increase in the Ru oxidation state after the thermal treatments. In the thermal treatment range of 300–600 °C, as the temperature increases, the oxidation state of Ru also increases. This phenomenon suggests the presence of chemically bonded ‒OH rather than crystal water incorporated within the Ru particles. However, even after treating h-RuOx at 600 °C (labeled as h-RuOx-600), the Ru valence in the h-RuOx-600 is still found to be lower than that of untreated anh-RuO2 with Ru4+, indicating the remained CUS in the bulk phase. This may be due to the internal oxygen vacancies left after the removal of the ‒OH that are not fully oxidized, and proton insertion is still able to occur. The Ru valence state and lattice structure remain extremely stable after the same thermal treatments conducted for the anh-RuO2 (Fig. S13 and S14), indicating that there is no chemically bonded ‒OH presented in the anh-RuO2, leaving an almost CUS-free bulk phase. The results are also in good consistency of the TPD-MS profiles.

a XRD patterns of the h-RuOx after thermal treatments. b Ru K-edge XANES spectra with an inset showing the enlarged region, and (c) Ru K-edge EXAFS spectra of the h-RuOx after thermal treatments showing the electronic structure changes after removing the coordinated water. d PEMWE stability test with the h-RuOx-300 anode for operating at 1 A cm‒2. e PEMWE stability test with the anh-RuO2-S anode for operating at 4 A cm‒2, and (f) Nyquist plots collected at the BoL and EoL from galvanostatic EIS measurements at 100 mA cm‒2. Source data are provided as a Source Data file.

We further examine the stability of h-RuOx-300 after the treatment at 300 °C (h-RuOx-300) compared to that of the untreated h-RuOx (Fig. 5d). We choose 300 °C for the thermal treatment since most Ru-oxide based catalysts reported in the literature have been synthesized or modified at this temperature, making it a good control sample for comparison. When tested under the same operating conditions in PEMWE at 1 A cm‒2, the stability of h-RuOx-300 is drastically improved compared to the less-than-1-min failure of the h-RuOx anode. A stable operation for >200 h without any performance decay is demonstrated. This result is even comparable to many reported doped-Ru-oxide catalysts aimed at improving stability. To further evaluate the improved stability, we accelerate the stability testing by operating the PEMWE at 4 A cm‒2. The generation and release of O2 bubbles under such high current density operation at around 2 V could magnify the degradation caused by the interface loss due to the catalyst-ionomer interface destruction. We observe a PEMWE performance degradation with the h-RuOx-300 anode within 15 h operation by operating at 4 A cm‒2 (Fig. S15), at a decay rate of 24.6 mV h‒1 for the first 10 h and an even higher 54 mV h‒1 for the next 5 h. This may be due to the presence of oxygen vacancies inside the h-RuOx-300 particles can re-coordinate water, leading to catalyst particle pulverization and catalyst-ionomer interface destruction during the OER. EIS measurements at the BoL and EoL show an increase in both ohmic resistance and electrode reaction impedance of the PEMWE after the test, indirectly reflecting the performance decrease caused by the catalyst-ionomer interface destruction.

Based on above results, we can conclude that the stability improvement of Ru-oxide catalysts in PEMWE applications needs to meet two additional requirements besides the active sites: the inhibition of catalyst bulk phase participation and the stabilization of reaction interface. Eliminating the bulk proton participation requires the removal of coordinately unsaturated Ru sites. When the anode consists only of Ru oxide particles and Nafion ionomer, the ionomer serves as both a proton-conducting medium and a binder. The intense proton exchange at the catalyst-ionomer interface during the OER process causes the catalyst to lose its fixed sites and fall off when surface reconstruction occurs. Therefore, besides inhibiting internal proton participation in catalyst bulk phase, further stabilizing the reaction interface to reduce the impact of surface reconstruction is crucial for improving stability.

To address this, we introduce additional styrene-butadiene rubber (SBR) binder into the h-RuOx-300 and anh-RuO2 anodes, respectively. This SBR addition is controlled at the same weight ratio as the ionomer to provide extra catalyst fixation alongside the Nafion ionomer, thereby stabilizing the catalyst particles, without contributing to proton conduction. We then compare the stability of the two stabilized anodes under 4 A cm‒2 accelerated testing, as shown in Fig. 5e, f and Fig. S16. Surprisingly, the stabilized anh-RuO2 anode (anh-RuO2-S) can even go through >100 h operation at 4 A cm‒2 without any performance decay. This is a notable stability reported among both doped Ru oxides and undoped Ru oxides catalysts to date by inhibiting the anh-RuO2 catalyst surface reconstruction. HR-TEM images (Fig. S17) clearly show the retention of the crystalline bulk phase of the anh-RuO2 catalyst particles after the stability test. While by operating at 4 A cm‒2, the stabilized h-RuOx-300 anode (h-RuOx-300-S) also exhibits improved stability within the first 10 h operation with a much smaller decay rate of 2.4 mV h‒1. However, due to the unresolved bulk participation, the PEMWE with the SBR added h-RuOx-300-S anode is still observed with accelerated performance degradation after 10 h operation. Based on the above results, we can conclude that in addition to inhibiting proton participation in the bulk phase, maintaining an effective reaction interface during the surface reaction is also critical for stabilizing Ru oxide anodes in the OER process.

In conclusion, we have investigated the stability differences observed with undoped Ru oxides for acidic OER and propose potential failure mechanisms of Ru-oxide anodes in practical PEMWE applications. Through synchrotron characterization, we demonstrate that lattice oxygen exhibits a certain stability in highly crystalline RuO2 for catalyzing the OER, a finding that has also been reported through theoretical simulations but remains controversial. When unsaturated Ru coordination is present inside Ru oxides, especially when bonded with chemically complexed ‒OH, the anodic OER process involves proton insertion, leading to water dissociation in the bulk phase. This results in proton and electron conduction and oxygen exchange through separate percolation paths, causing rapid PEMWE performance failure due to catalyst disintegration and electrode structure collapse. When the participation of the bulk phase is inhibited with fully coordinated Ru sites, the proton conduction and oxygen exchange occur only at the Ru oxide-ionomer interface during the OER. This would not cause rapid anode failure but could lead to a slow decline in performance by loosening the catalyst-ionomer interface during long-term operation, especially under high current densities. In this case, surface modification is desired to further improve the stability of the OER electrode. We hope this work may inspire future development of Ru oxide-based catalysts and anodes for PEMWEs.

Methods

Membrane electrode assembly preparation. Nafion™ NR212 (~50 μm) and Nafion™ dispersion (D521, 1100 EW, 5 wt.%) were purchased from Chemours, the United States, and used as received. Premion™ Ru oxide (electronic grade, 99.95% metals basis) from Thermo Scientific and anhydrous Ru(IV) oxide (99.9 % trace metals basis) from Sigma Aldrich were used to prepare the anodes. Commercial high-surface-area IrO2 catalyst was from Fuel Cell Store, the United States. The anode catalyst layers were formed onto the NR212 membrane first by spraying coating with the precious metal loading measured to be 1.1 mg cm‒2. First, the anode oxide catalyst was mixed with D521 ionomer dispersion at a weight ratio 10 wt.% for preparing the catalyst ink, and isopropyl alcohol/water solution (2:1 v/v) was used as the solvent for catalyst dispersion. At specific circumstance, the SBR was added as additional binder at an oxide/SBR ratio of 10 wt.%. The catalyst ink was treated under ultrasonic water bath for 1 h with the temperature controlled at 5 °C during this process. The spraying process was conducted using a manual spray gun (HD131, 0.2-micron diameter), with the hot plate temperature maintained at 98 °C throughout the procedure to ensure uniform deposition. The formation of the cathode catalyst layers based on Pt/C catalyst (HiSPEC 8000, nominally 50 wt.%, Alfa Aesar) on the other side of the membrane followed the similar procedures. An ionomer to carbon (I/C) ratio of 60 wt.% was applied in the preparation of cathode catalyst ink. The CCM with a demarcated area of 2 \(\times\) 2 cm2 covered by uniform catalyst layers was dried in an oven heated up to 80 °C for 1 h before hot pressing. Hot pressing was conducted based on a lab setup as shown in Fig. S22, which exerted a pressure of about 42 kPa for 30 s to the CCM as prepared before making it ready for PEMWE assembly.

PEMWE performance tests. The fabrication of the PEMWE electrolyzer was carried out as follows: the as-prepared CCM was coupled with Toray 090 carbon paper (5 wt.% wet-proof, Fuel Cell Store) as the cathode gas diffusion layer, and platinized titanium fiber (0.27 mm, Fuel Cell Store) as the anode, with both components cut to 2 × 2 cm2 to form the membrane electrode assembly. PTFE gaskets, 0.3 mm thick, were used for sealing. The single-cell electrolyzer was assembled by applying 2.5 Nm of torque to fasten the bolts. During the PEMWE performance tests, deionized water heated to 80 °C was supplied to the anode side at a flow rate of 80 mL min‒1, with both the electrolyzer and circulating water temperatures stabilized at 80 °C. The polarization curves were obtained on a Keysight DC power supply (30 V, 20 A) by incrementally stepping the voltage from 1.2 V to 1.8 V at intervals of 10 mV. The corresponding currents were recorded after 10 s of equilibrium at each voltage point. EIS measurements were performed on Zahner, ZENNIUM under galvanostatic mode, a DC current of 100 mA cm‒2 was applied to the electrolyzer. After stabilizing under the applied current, an AC perturbation amplitude of 10% of the DC current was added. Impedance responses of Nyquist plots were recorded stepwise from 10 kHz to 100 mHz. The stability tests were conducted under standard PEMWE operation at high current densities of 1 A cm‒2 and 4 A cm‒2 with the voltage changes over time recorded.

Electrochemical measurements. The performance of Ru oxide catalysts was evaluated using a conventional three-electrode setup, consisting of a pre-polished RDE coated with thin-film catalyst layer as the working electrode, a carbon counter electrode, and an Ag/AgCl reference electrode. The potential can be converted to RHE via the following equation:

Standard LSV, CA and EIS measurements were conducted on a CHI660E electrochemical workstation. O2-saturated 0.5 M H2SO4 applied as the electrolyte to mimic acidic OER conditions, and a rotation speed of 2400 rpm was controlled to eliminate mass transportation. Capacitance of the Ru oxides was evaluated on a potentiostat (Ivium Technologies B.V., Netherlands). CV curves were recorded in a potential range of 0 to 1 V at different scan rates from 5–100 mV s‒1. For these measurements, 1 M H2SO4 was used as the electrolyte, and the working electrode catalyst loading was controlled to be 5 mg. 0.5 M H2SO4 and 1 M H2SO4 solutions were purchased from Sigma Aldrich, and stored in cabinet without direct sunlight before use.

Material characterizations. XRD measurements were conducted on a Brucker D8-Advance X-ray diffractometer with a Cu anode (Kα = 1.5405 Å) powered at 40 kV and 40 mA. Phase identification and crystallinity calculation were carried out using Bruker EVA 6.0 with the PDF4 + ICDD database. The crystallographic information file (CIF) file of ruthenium oxide was exported from the PDF4 + ICDD database and used for whole pattern fitting by Rietveld refinement using TOPAS 6.0. The crystallite size was calculated in accordance with the double-Voigt approach adopted in TOPAS. XPS was performed on a Kratos AXIS Ultra DLD equipment to study the surface chemical state of the Ru oxide powers. ICP-MS was conducted on a Thermo Scientific™ Element™ 2 to detect any dissolved Ru ion in the anode circuiting water. The BET surface area was obtained through nitrogen adsorption-desorption measurements on Micromeritics TriStar II at 77 K. The SEM images of the CCMs after stability tests were characterized using a field emission scanning electron microscope (FESEM, Tescan Clara) at an accelerating voltage of 5 kV with a secondary electron detector. EDS mapping was conducted to analyze the elemental distribution of Ru, Pt, and F in the CCMs, with carbon coating performed on samples in advance. The TPD was conducted on Quantachrom ChemBet 3000 equipped with a MS (OmniStar™) for detecting the signals of H2O and O2. Pure argon (Ar) was used as the carrier gas at a constant flow rate of 20 mL min−1 [STP], with the temperature ramped from 25 °C to 900 °C at 15 °C min−1 for TPD-MS analysis. ToF-SIMS was conducted on an IONTOF M6 to investigate the surface and depth distribution of coordinated water in Ru oxides, using a Cs+ source for acquiring negative ion profiling. Synchrotron Ru K-edge hard XAS, and O K-edge soft XAS were performed at the National Synchrotron Radiation Research Center (NSRRC) in Taiwan, with TPS BL44A, and TLS BL20A. The ATHENA module in the IFEFFIT software package was used for EXAFS data analysis.

DFT calculations. All DFT calculations for periodic material systems were conducted using the Vienna Ab initio Simulation Package (VASP) with the projector-augmented wave (PAW) method37,38. The exchange-correlation interactions were described by the generalized gradient approximation (GGA) using the Perdew-Burke-Ernzerhof (PBE) functional39. To account for van der Waals (vdW) interactions, the DFT-D3 approach based on Grimme’s scheme was applied40,41. A plane-wave basis set with an energy cutoff of 500 eV was employed, and the interaction between atomic cores and electrons was represented through the PAW method. The Brillouin zone was sampled using a 2 × 2 × 1 k-point mesh centered at the gamma (Γ) point for structural relaxation. A vacuum region of ~15 Å was introduced to prevent lateral interactions between adsorbates, and the lower half of the slab models was constrained in their lattice positions during relaxation. Structural optimization was performed by fully relaxing dynamic magnetic moments without restrictions until convergence criteria were satisfied, with total energy differences below 1 × 10‒6 eV and residual forces under 0.02 eV/Å.

Data availability

The main data supporting the findings of this study are available within the published article and its Supplementary Information and source data files. Additional data are available from the corresponding author on request. Source data are provided with this paper.

References

Tang, J., Guo, K., Guan, D., Hao, Y. & Shao, Z. A semi-vapor electrolysis technology for hydrogen generation from wide water resources. Energy & Environmental Science 17, 7394–7402 (2024).

Yang, M. et al. Degradation mechanisms and stabilization strategies of ruthenium-based catalysts for OER in the proton exchange membrane water electrolyzer. Proc. Natl Sci. Mater. Int. 34, 207–222 (2024).

Tang, J., Zhong, Y., Su, C. & Shao, Z. Silver compositing boosts water electrolysis activity and durability of RuO2 in a proton-exchange-membrane water electrolyzer. Small Sci. 3, 2300055 (2023).

Fan, R.-Y. et al. The promising seesaw relationship between activity and stability of Ru-based electrocatalysts for acid oxygen evolution and proton exchange membrane water electrolysis. Small 20, 2304636 (2024).

Cherevko, S. et al. Oxygen and hydrogen evolution reactions on Ru, RuO2, Ir, and IrO2 thin film electrodes in acidic and alkaline electrolytes: a comparative study on activity and stability. Catal. Today 262, 170–180 (2016).

Escudero-Escribano, M. et al. Importance of surface IrOx in stabilizing RuO2 for oxygen evolution. J. Phys. Chem. B 122, 947–955 (2018).

Liu, H. et al. Eliminating over-oxidation of ruthenium oxides by niobium for highly stable electrocatalytic oxygen evolution in acidic media. Joule 7, 558–573 (2023).

Zhang, D. et al. Construction of Zn-doped RuO2 nanowires for efficient and stable water oxidation in acidic media. Nat. Commun. 14, 2517 (2023).

Wu, Z.-Y. et al. Non-iridium-based electrocatalyst for durable acidic oxygen evolution reaction in proton exchange membrane water electrolysis. Nat. Mater. 22, 100–108 (2023).

Jin, H. et al. Dynamic rhenium dopant boosts ruthenium oxide for durable oxygen evolution. Nat. Commun. 14, 354 (2023).

Over, H. Fundamental studies of planar single-crystalline oxide model electrodes (RuO2, IrO2) for acidic water splitting. ACS Catal. 11, 8848–8871 (2021).

Tang, Y., Lin, Y., Zhang, Y., Deng, M. & Chen, L. Revisiting the degradation mechanism of ruthenium oxide for oxygen evolution reaction in acidic media. Mater. Today Energy 43, 101603 (2024).

Roy, C. et al. Trends in activity and dissolution on RuO2 under oxygen evolution conditions: particles versus well-defined extended surfaces. ACS Energy Letters 3, 2045–2051 (2018).

Stoerzinger, K. A. et al. Orientation-dependent oxygen evolution on RuO2 without lattice exchange. ACS Energy Lett. 2, 876–881 (2017).

Zhao, G. et al. Metallic Ru─Ru interaction in ruthenium oxide enabling durable proton exchange membrane water electrolysis. Adv. Mater. 36, 2404213 (2024).

Raman, A. S. & Vojvodic, A. Providing atomistic insights into the dissolution of rutile oxides in electrocatalytic water splitting. J. Phys. Chem. C 126, 922–932 (2022).

Rao, R. R. et al. Surface orientation dependent water dissociation on rutile ruthenium dioxide. J. Phys. Chem. C 122, 17802–17811 (2018).

Jirkovský, J., Hoffmannová, H., Klementová, M. & Krtil, P. Particle size sependence of the electrocatalytic activity of nanocrystalline RuO2 electrodes. J. Electrochem. Soc. 153, E111 (2006).

Zhu, Y. et al. Facilitating alkaline hydrogen evolution reaction on the hetero-interfaced Ru/RuO2 through Pt single atoms doping. Nat. Commun. 15, 1447 (2024).

Liu, Y. et al. Construction of Pd-doped RuO2 nanosheets for efficient and stable acidic water oxidation. Green Energy Environ. 9, 937–948 (2023).

Wang, Y. et al. Unraveling oxygen vacancy site mechanism of Rh-doped RuO2 catalyst for long-lasting acidic water oxidation. Nat. Commun. 14, 1412 (2023).

Shi, Z. et al. Customized reaction route for ruthenium oxide towards stabilized water oxidation in high-performance PEM electrolyzers. Nat. Commun. 14, 843 (2023).

Huang, H. et al. Structure engineering defective and mass transfer-enhanced RuO2 nanosheets for proton exchange membrane water electrolyzer. Nano Energy 88, 106276 (2021).

Li, L. et al. Optimizing the electronic structure of ruthenium oxide by neodymium doping for enhanced acidic oxygen evolution catalysis. Adv. Funct. Mater. 33, 2213304 (2023).

Wang, J. et al. Single-site Pt-doped RuO2 hollow nanospheres with interstitial C for high-performance acidic overall water splitting. Sci. Adv. 8, eabl9271 (2022).

Jin, H. et al. Safeguarding the RuO2 phase against lattice oxygen oxidation during acidic water electrooxidation. Energy Environ. Sci. 15, 1119–1130 (2022).

Chen, F.-Y. et al. Ruthenium-lead oxide for acidic oxygen evolution reaction in proton exchange membrane water electrolysis. Nano Res. 17, 8671–8677 (2024).

Hao, S. et al. Dopants fixation of Ruthenium for boosting acidic oxygen evolution stability and activity. Nat. Commun. 11, 5368 (2020).

Wang, Y. et al. Breaking the Ru−O−Ru symmetry of a RuO2 catalyst for sustainable acidic water oxidation. Angew. Chem. Int. Edition 63, e202316903 (2024).

He, W. et al. Grain-boundary-rich RuO2 porous nanosheet for efficient and stable acidic water oxidation. Angew. Chem. Int. Edition 63, e202405798 (2024).

Rolison, D. R., Hagans, P. L., Swider, K. E. & Long, J. W. Role of hydrous ruthenium oxide in Pt−Ru direct methanol fuel cell anode electrocatalysts: the importance of mixed electron/proton conductivity. Langmuir 15, 774–779 (1999).

Chaudhary, P., Zagalskaya, A., Over, H. & Alexandrov, V. Strain-dependent activity-stability relations in RuO2 and IrO2 oxygen evolution catalysts. ChemElectroChem 11, e202300659 (2024).

Klyukin, K., Zagalskaya, A. & Alexandrov, V. Role of dissolution intermediates in promoting oxygen evolution reaction at RuO2(110) surface. J. Phys. Chem. C 123, 22151–22157 (2019).

Ping, X. et al. Locking the lattice oxygen in RuO2 to stabilize highly active Ru sites in acidic water oxidation. Nat. Commun. 15, 2501 (2024).

Rong, C., Dastafkan, K., Wang, Y. & Zhao, C. Breaking the activity and stability bottlenecks of electrocatalysts for oxygen evolution reactions in acids. Adv. Mater. 35, 2211884 (2023).

Shan, J., Zheng, Y., Shi, B., Davey, K. & Qiao, S.-Z. Regulating electrocatalysts via surface and interface engineering for acidic water electrooxidation. ACS Energy Lett. 4, 2719–2730 (2019).

Kresse, G. & Furthmüller, J. Efficiency of Ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953 (1994).

Ernzerhof, M. & Scuseria, G. E. Assessment of the perdew–Burke–Ernzerhof exchange-correlation functional. J. Chem. Phys. 110, 5029–5036 (1999).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate Ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Guan, D. et al. Identifying a universal activity descriptor and a unifying mechanism concept on perovskite oxides for green hydrogen production. Adv. Mater. 35, 2305074 (2023).

Acknowledgements

This work was supported by the Resources Technology & Critical Minerals Trailblazer Program. The authors would like to acknowledge the support from the Max Planck-POSTECH-Hsinchu Center for Complex Phase Materials.

Author information

Authors and Affiliations

Contributions

Z.S. supervised the project. J.T. designed and performed the electrolyzer tests, analyzed the data, and wrote the original manuscript. D.G., C.W.P., and Z.H. coordinated the synchrotron tests. L.Z. conducted the XPS tests, while M.K. facilitated the XRD tests. T.Z. carried out the BET experiments. H.X. performed the DFT calculations. U.A., Z.F., and J.G. contributed to data discussions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Peer review

Peer review information

Nature Communications thanks Xue Feng Lu and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Tang, J., Guan, D., Xu, H. et al. Undoped ruthenium oxide as a stable catalyst for the acidic oxygen evolution reaction. Nat Commun 16, 801 (2025). https://doi.org/10.1038/s41467-025-56188-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-56188-z

This article is cited by

-

Durable acidic water oxidation ruthenium based electrocatalyst by fluorination induced symmetry breaking

Nature Communications (2025)

-

Research On the Treatment of Phenol Wastewater By Persulfate Activation Based On Heterogeneous Catalyst CoFe2O4

Water, Air, & Soil Pollution (2025)