Abstract

Relaxor antiferroelectrics are considered promising candidate materials for achieving excellent energy storage capabilities. However, the trade-off between high recoverable energy density and high efficiency remains a major challenge in relaxor antiferroelectrics for practical applications. Herein, guided by phase-field simulation, we propose a strategy of designing polymorphic heterogeneous shell in core-shell dual-phase dielectrics to synergistically control micro and local heterostructures, resulting in comprehensive improvements in breakdown electric field, polarization fluctuation and saturation behaviors. Leveraging the core-shell effect and polarization heterogeneity, an ultrahigh recoverable energy density of 12.7 J cm-3 and an impressive efficiency of 87.2% are achieved in lead-free relaxor antiferroelectrics, making a performance breakthrough in core-shell dielectrics. This work opens up a new avenue to efficiently develop high-performance energy storage dielectrics and is expected to be popularized in other fields.

Similar content being viewed by others

Introduction

Dielectric capacitors, known for their high power density (PD), rapid discharge rate (t0.9), and excellent reliability, are widely applied in advanced pulse power electronic systems1,2. Recently, environmentally friendly lead-free ceramic capacitors have become a hot topic in research and application3. However, the generally low recoverable energy density (Wrec) and efficiency (η) hinder their advancement towards device miniaturization and integration4,5. The energy storage parameters of dielectric capacitors can be calculated by \({W}_{{total}}={\int }_{0}^{{P}_{m}}{EdP},{W}_{{rec}}={\int }_{{P}_{r}}^{{P}_{m}}{EdP},{{{\rm{and\; \eta }}}}=\frac{{W}_{{rec}}}{{W}_{{total}}}\), where Wtotal, Pm, Pr, and E represent the total energy density, maximum polarization, remanent polarization, and applied electric field, respectively (Supplementary Fig. 1). To achieve excellent overall energy storage properties, it is necessary to simultaneously obtain high breakdown electric field (Eb), large polarization fluctuations (high Pm and low Pr), and delayed polarization saturation.

It is widely recognized that microstructure modulation in dielectrics plays a key role in enhancing Eb. Initially, strategies such as grain size engineering and sintering aids were adopted to reduce grain size and strengthen compactness for improving breakdown features by increasing the content of high resistance grain boundaries and reducing voids6,7. However, the significant reduction in grain size makes it difficult to maintain high compactness of the material, thereby deteriorating Eb, which is a challenge in preparing ceramics. Realizing structural heterogeneity at the microscale can effectively alleviate the aforementioned contradiction. For example, introducing a second phase to form dual-phase dielectrics can fill the gaps or voids between the parent perovskite grains, diminishing the possibility of local discharge breakdown8,9. Unfortunately, the second phase is typically accompanied by a lower dielectric constant than the parent perovskite, which can cause a significant decrease in polarization10,11. Another dual-phase heterogeneous structure of core-shell has been demonstrated to be perfectly compatible with high polarization and high breakdown through forming endogenous strongly polar cores and core-shell heterogeneous interfaces12,13. Although high Wrec (>7.0 J cm-3) can be achieved in core-shell dielectrics, the strong polarization reversal in cores and large polarization response mismatch behavior between cores and shells under external electric fields result in significant polarization hysteresis, making it difficult to break through the performance constraint between Wrec (≥10.0 J cm-3) and η (≥85%)14,15.

Designing local heterogeneous and diverse polarization configurations in dielectrics is a fascinating and effective approach to control the desired polarization evolution behaviors under external electric fields. Local polarization configurations can be controlled by various methods such as high-entropy and supercritical state to form polymorphic nanoclusters or polarization heterogeneity, significantly decreasing Pr and polarization hysteresis (η ≥ 85%)5,16,17,18. However, the regulation of local polarization configurations is primarily concentrated in the single-phase solid solutions, lacking efficient control of Eb (dominated by microstructure) and high polarization maintained by large-sized domains19,20. According to the research progress of dielectric energy storage ceramics, controlling local heterostructures or local polarization configurations based on micro heterostructure dielectrics poses significant challenges, especially in lead-free (relaxor) antiferroelectrics. If the collaborative design of micro and local scale heterostructures is achieved in dielectrics, the comprehensive energy storage properties are expected to be further improved, promoting the development and widespread application of advanced dielectric capacitors.

In this work, inspired by the heterogeneous polarization control in single-phase solid solutions and guided by phase-field simulation, we propose a polymorphic heterogeneous shell strategy to design core-shell dielectrics, achieving the synergistic regulation of micro and local heterostructures. According to the phase diagram, equal molar quantities of NaNbO3 (NN) with high bandgap (Eg) and (Bi0.5Na0.5)TiO3 (BNT) with high spontaneous polarization can be selected as the implementation targets to design relaxor antiferroelectrics (0.5NN-0.5BNT)16,21. The large differences in sintering temperature (1400 °C for NN and 1150 °C for BNT) and element diffusion behavior are considered and utilized to efficiently and easily establish core-shell heterostructures and control heterogeneous polarization configurations, respectively14,22. Furthermore, high-energy ball milling program is reasonably designed to reduce the proportion of core in the parent material for minimizing the impact of strong polarization reversal in the core and polarization response mismatch. Benefiting from the synergistic effect, we achieve an ultrahigh Wrec of 12.7 J cm-3 and a high η of 87.2% in 0.5NN-0.5BNT core-shell relaxor antiferroelectrics (0.5NN-0.5BNT-cs), leading to a performance breakthrough in core-shell dielectrics.

Results and discussion

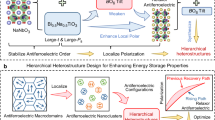

Phase-field simulation for designing polymorphic heterogeneous shell

We first conduct phase-field simulation to theoretically predict the potential of designing polymorphic heterogeneous shells for improving energy storage properties. To enhance the feasibility of the simulation, we choose NN with the coexistence of ferroelectric and antiferroelectric phases as the core, which is simplified into a long-range ordered ferroelectric polarization configuration owing to the irreversible transformation of the unstable antiferroelectric phase into ferroelectric phase under electric fields23. NN is gradually dissolved into BNT, as the parent material of the shell, for controlling the domain structure or local polarization configuration of the shell. As shown in Fig. 1a, core-shell dielectrics with long-range ordered ferroelectric polarization exhibit large polarization hysteresis and rapid polarization saturation behaviors. With the gradual introduction of NN in the shell, domain size significantly decreases and the long-range polarization order is broken, resulting in enhanced local polarization heterogeneity (Fig. 1b, c). Ultimately, the polar core with polymorphic heterogeneous shell can be established in dielectrics (Fig. 1c). It is recognized that the enhancement of local polarization heterogeneity can significantly reduce the energy barrier and stress of polarization rotation and decrease polarization hysteresis, revealing a gradual slimmer P-E loop with smaller Pr and more delayed polarization saturation2. Notably, there is no significant decrease in Pm, which can be attributed to the influence of the internal strongly polar core and the enhancement of polarization texture along the electric field direction in polymorphic heterogeneous shell5,14. As a result, large polarization fluctuations and delayed polarization saturation can be achieved by designing polymorphic heterogeneous shell in core-shell dielectrics, resulting in significant increases in Wrec and η of 85% and 35% from the simulated P-E loops under the same electric field, respectively, compared to the dielectrics with polar core and microdomain shell structure. These demonstrate the enormous potential of this strategy to enhance comprehensive energy storage performance.

Comparative display of domain structures, polarization configurations, and normalized P-E loops with different heterostructures including a Polar core with microdomain shell, b Polar core with nanodomain shell, and c Polar core with polymorphic heterogeneous shell. The light green rectangles represent the enlarged domain structure or local polarization configuration in the shell.

Micro core-shell heterostructure

To validate our design ideas, scanning electron microscope (SEM) and transmission electron microscopy (TEM) are performed to reveal the microstructure of 0.5NN-0.5BNT-cs ceramics. As shown in Fig. 2a and Supplementary Fig. 2, the sample exhibits good sintering quality with a dense microstructure and no obvious voids. A distinct microscopic heterostructure with dark core regions of hundreds of nanometers inside grains can be proven to be core-shell structure. Notably, a pure perovskite structure can be observed in 0.5NN-0.5BNT-cs sample by high-resolution synchrotron X-ray diffraction (XRD), indicating that the internal cores are not formed by impurities (Supplementary Fig. 3). Combining the previous studies, temperature-dependent dielectric spectra and synchrotron XRD results can confirm that the nature of 0.5NN-0.5BNT-cs should be relaxor antiferroelectric (Supplementary Fig. 4)21,24. The evident core-shell heterostructures can also be further analyzed through TEM (Fig. 2b–d and Supplementary Fig. 5). As shown in Fig. 2b, typical striped domains with widths varying several dozen nanometers can be clearly found in the core regions, demonstrating strong polarity. In contrast, no obvious domain morphology is observed in the shell regions and the contrast is weak, indicating a lack of long-range ferroelectric order. According to the results of selected area electron diffraction (SAED) patterns along [100]c, [110]c, and [111]c (Fig. 2c,d and Supplementary Fig. 6), the pure perovskite structure can also be verified in the core and shell regions25. The (ooe)/2 and (ooo)/2 (o is odd and e is even) superlattice diffraction spots found in the core and shell regions suggest the existence of in-phase and anti-phase oxygen octahedral tilts based on the conclusions by Glazer, respectively, which is also reflected by the synchrotron XRD result (Supplementary Fig. 3)26. Furthermore, as shown in Fig. 2c, two distinct satellite peaks are found around the (001)/2 superlattice diffraction point in the shell region, which is an important feature of antiferroelectrics, once again indicating the relaxor antiferroelectric nature of 0.5NN-0.5BNT-cs ceramics27.

a SEM images of polished and thermally etched 0.5NN-0.5BNT-cs. b Room-temperature bright-field TEM images of 0.5NN-0.5BNT-cs and SAED patterns recorded along the c [100]c, and d [110]c for the core and shell regions, where red arrows point to superlattice diffraction points and yellow arrows point to satellite diffraction points. e EDS mapping images and f EDS line scan across core and shell in 0.5NN-0.5BNT-cs by TEM. Simulation of g Electrical field distribution, and h Electric tree evolution for 0.5NN-0.5BNT, 0.5NN-0.5BNT-s, and 0.5NN-0.5BNT-cs.

It is recognized that the formation of core-shell structure is affected by many factors such as phase formation temperature12, sintering temperature15, diffusion rates of elements14,28,29, and the synergistic diffusion effect of multiple ions13,30,31. To analyze the origin of the core-shell structure and different ferroelectric nature between them, energy dispersive X-ray spectroscopy (EDS) is performed on 0.5NN-0.5BNT-cs sample by TEM and SEM (Fig. 2e, f and Supplementary Fig. 7). Na and Nb are mainly concentrated in the core regions to form NN solid solutions, where Bi and Ti are almost absent, contributing to the visible striped domains with a long-range ordered polarization. In contrast, the distribution of Na, Bi, Nb and Ti in the shell regions is diffuse and disordered, exhibiting larger compositional disorder than that of cores, which causes a strong random field manifested as the speckle domain morphology with weak contrast. There is a diffusion transition region of approximately 150 nm between the core and shell, suggesting that the core region formed by incomplete diffusion of BNT into the NN matrix (Fig. 2f). The sintering temperature of 0.5NN-0.5BNT-cs sample is chosen at 1160 °C in this work, which is very close to that of pure BNT (1150 °C) and far from that of pure NN (1400 °C). Based on the above analysis results and the sintering characteristics of ceramics, it can be speculated that the small calcined BNT particles can diffuse and dissolve with each other, and combine into large particles, while NN particles are difficult to melt with each other and can only partially diffuse into BNT to form shell regions. Furthermore, we subject the calcined BNT and NN particles to long-term high-energy ball milling treatment for significantly reduce the particle size, which can accelerate the melting kinetics process of BNT and NN particles to form obviously large shells but small cores during sintering.

The breakdown characteristics are closely related to the microstructure of the ceramics. According to the statistical results, the average grain sizes (Ga) of 0.5NN-0.5BNT without core-shell structure and 0.5NN-0.5BNT-cs are about 3.66 μm and 4.05 μm (Supplementary Fig. 8), which means that there is no significant difference in grain boundary density. To better understand the advantage of the core-shell microstructure during the dielectric breakdown process, 2D finite-element method is used to simulate the electric field distribution and electric tree evolution of 0.5NN-0.5BNT, 0.5NN-0.5BNT-s (neglecting the existence of cores), and 0.5NN-0.5BNT-cs by combining the intrinsic properties (dielectric constant) and extrinsic structural features (grains, grain boundaries, cores, shells, and core-shell interfaces) of the ceramics (Fig. 2g, h and Supplementary Fig. 9)32,33. It is known that a strong electric field is concentrated in the grain boundaries owing to the lower dielectric constant than that of grains. Similar electric field distribution and electric tree evolution behavior with close breakdown time can be obviously discovered in 0.5NN-0.5BNT and 0.5NN-0.5BNT-s samples. The emergence of the core-shell structure significantly reduces the electric field on grain boundaries and makes the electric field distribution more uniform, avoiding the occurrence of large local electric fields and premature breakdown. It can also be found that core-shell interfaces can hinder the propagation of electric trees. When 0.5NN-0.5BNT ceramic experiences breakdown, exhibiting that an electric tree penetrates the entire sample, the electric tree of 0.5NN-0.5BNT-cs only propagates about 2/3 (Fig. 2h). Consequently, the establishment of micro core-shell heterostructures is realized in 0.5NN-0.5BNT-cs ceramic, which can significantly improve dielectric breakdown characteristics and enhance Eb.

Local heterogeneous polarization configuration

To further explore the local polarization information of the core and shell regions, atomic-resolution high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) is performed on 0.5NN-0.5BNT-cs ceramic along [110]c. As shown in Fig. 3a, c, long-range ordered polarization configuration can be clearly obtained in the core region, which contributes to the visible striped domains. However, long-range disordered but locally ordered chaotic polarization configurations are found in the shell region (Fig. 3b, c), which can be defined as a polymorphic heterogeneous shell, revealing the speckle domain morphologies with weak contrast under TEM. According to the polarization vector analysis and two-dimensional contours of polarization angles, the locally ordered regions with a similar polarization direction can form polymorphic polar nanoregions (PNRs) with a size of only ~1-3 nm34. Combining the wider distribution range of polarization angles in the shell region (Fig. 3d), higher activity and flexible external electric field response can be provided by smaller polymorphic PNRs, resulting in small Pr and decreased polarization hysteresis35. Furthermore, the polarization magnitudes in the shell region also exhibit a more disordered distribution behavior compared to the core region (Fig. 3e, f). The regions with near-zero polarization magnitude in the shell can be considered as the cubic phase matrix, presenting a landscape where island-shaped polymorphic PNRs float in a cubic ocean, which can be collectively referred to as the coexisting polymorphic nanoclusters and cannot be observed in the core region. The higher average polarization magnitude (Mave) of 7.5 pm can be counted in the core region than that of the shell region (Mave = 5.8 pm), demonstrating the existence of strongly polar cores and weakly polar shells. However, it should be noted that the Mave of the shell region is also comparable to that of some reported perovskite relaxors with high polarization16,36. This distinctive polarization configurations in core-shell dual-phase 0.5NN-0.5BNT-cs ceramic is expected to efficiently maintain large polarization fluctuations and small hysteresis while delaying polarization saturation.

Atomic-resolution HAADF images and the corresponding atomic displacement vectors of the a Core region and b Shell region in 0.5NN-0.5BNT-cs recorded along [110]c. c Polarization angle distribution along [110]c in the core and shell regions. d The statistic of calculated polarization angle distribution along [110]c. e Polarization magnitude distribution along [110]c in the core and shell regions. f The statistic of calculated polarization magnitude distribution along [110]c. g B-site atomic column intensity distributions in [110]c-viewed HAADF-STEM images of the core and shell regions.

As shown in Fig. 3g and Supplementary Fig. 10, the intensity distributions of A-site and B-site atomic columns are also extracted in 0.5NN-0.5BNT-cs ceramic to qualitatively analyze the distribution behavior of elements and their relationship with polarization configurations. It is known that the intensity of atomic columns is positively correlated with atomic number (Z)37. The core region with polarization vectors along the [1-10] direction corresponds to weaker A-site and stronger B-site atomic column intensity, indicating that this region is enriched with Na and Nb atoms to form an orthorhombic phase zone owing to ZNa < ZBi and ZNb > ZTi. The stronger A-site and weaker B-site atomic column intensities can be observed in the core region with polarization vectors along the [001] or [00-1] direction. It can be speculated that some Bi and Ti elements also diffuse into the NN matrix and drive the transformation of internal polarization configuration. The absence of Bi and Ti elements in the core regions may be attributed to their limited diffusion and difficulty in being detected by low-resolution EDS. It is precisely because of the minimal diffusion of Bi and Ti that the long-range ordered polarization configuration of the core region has not been severely disrupted. In the shell region, both A-site and B-site atomic column intensities exhibit a significantly disordered distribution state, indicating a strong component disorder, which can cause local polarization heterogeneity. Therefore, the distribution behavior of different elements may be an important origin for the simultaneous formation of long-range ordered strongly polar core and polymorphic heterogeneous shell in 0.5NN-0.5BNT-cs ceramic.

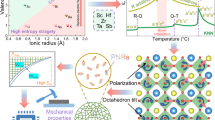

Energy storage performance of 0.5NN-0.5BNT-cs ceramic

To evaluate the energy storage potential of 0.5NN-0.5BNT-cs ceramics, we measure the unipolar P-E loops until breakdown (Fig. 4a and Supplementary Fig. 11). The slim P-E loops with low Pr and small hysteresis can be clearly found in 0.5NN-0.5BNT-cs ceramic under different electric fields. During the electric field loading process, the η remains almost unchanged and always exceeds 85.0% (Fig. 4b), indicating that the impacts of strong polarization reversal in cores and polarization response mismatch between cores and shells on hysteresis have been effectively suppressed, even under a high electric field of 70 kV mm-1. Encouragingly, a high Wrec of 12.7 J cm-3 and an impressive η of 87.2% can be realized in 0.5NN-0.5BNT-cs ceramic by designing a polymorphic heterogeneous shell. On the basis of improving η, Wrec increases by 2.7 times compared to the reported 0.5NN-0.5BNT relaxor antiferroelectric ceramic (Wrec = 4.7 J cm-3) without core-shell structure16. Furthermore, as summarized in Fig. 4d, e and Supplementary Fig. 12, the excellent comprehensive energy storage properties achieved in 0.5NN-0.5BNT-cs ceramics show breakthrough progress in the recently reported core-shell dielectric ceramics13,14,38,39, which also demonstrates great competitiveness compared to other lead-free energy storage ceramics.

a Room-temperature unipolar P-E loops of 0.5NN-0.5BNT and 0.5NN-0.5BNT-cs. b Wrec, η, c Pm, and Pr of 0.5NN-0.5BNT-cs and 0.5NN-0.5BNT as a function of the electric field up to Eb. d Comparisons of Wrec versus η between 0.5NN-0.5BNT-cs and reported core-shell heterostructure ceramics. (BT: BaTiO3, ST: SrTiO3, KNN: K0.5Na0.5NbO3) e Comparisons of Wrec between 0.5NN-0.5BNT-cs and recently reported core-shell heterostructure ceramics. f Temperature- and g Frequency-dependent energy density and η of 0.5NN-0.5BNT-cs at 50 kV mm-1. h The changes of PD during underdamped discharge and WD and t0.9 during overdamped discharge under different electric fields. Partial data in a–c are adapted with permission from Ref. 16. Copyright 2022 Wiley-VCH GmbH.

The improvement of energy storage performance for 0.5NN-0.5BNT-cs ceramics should be attributed to the largely enhanced Eb, improved polarization fluctuations, and delayed saturation behavior with small hysteresis. In terms of breakdown characteristics, the bandgap (Eg) of 0.5NN-0.5BNT-cs (2.94 eV) is larger than that of 0.5NN-0.5BNT (2.62 eV) (Supplementary Fig. 13), making it difficult for electrons to jump from the top of the valence band to the bottom of the conduction band, which serves as an intrinsic contribution to enhance Eb 40. The appearance of core-shell structure and core-shell interface makes the electric field distribution more uniform and avoids the occurrence of high local electric fields at grain boundaries, which also hinder the propagation of electric trees. In addition, benefiting from the core-shell structure, the resistance value at 450 °C of 0.5NN-0.5BNT-cs is almost twice that of 0.5NN-0.5BNT (Supplementary Fig. 14). The above factors significantly enhance Eb from 38 to 70 kV mm-1. From the perspective of polarization, compared to 0.5NN-0.5BNT, large Pm, small Pr, and approximate polarization saturation delay degree can be achieved in 0.5NN-0.5BNT-cs ceramic (Fig. 4a, c). Firstly, large Pm can be attributed to the internal strongly polar cores with large-sized domains and the enhancement of polarization texture along the electric field direction in polymorphic heterogeneous shells under high electric field5,14. The diffusion of antiferroelectric-ferroelectric phase transition in relaxor antiferroelectrics can also contribute to large polarization under electric fields16. Moreover, a higher room temperature dielectric constant can be observed in 0.5NN-0.5BNT-cs (Supplementary Fig. 4), leading to a larger polarization response under the same applied electric field. Secondly, higher activity and flexible external electric field response can be provided by ultra-small polymorphic PNRs in shells, which can decrease Pr and polarization hysteresis. The effects of strong polarization reversal in cores and polarization response mismatch between cores and shells have been effectively suppressed through long-term high-energy ball milling to reduce the core size, maintaining low Pr and small polarization hysteresis. Finally, based on the large random field caused by compositional disorder, polymorphic heterogeneous shells can also suppress the fast polarization saturation behavior of small-sized polar cores, achieving delayed polarization saturation. Therefore, outstanding overall energy storage properties can be realized 0.5NN-0.5BNT-cs core-shell dual-phase dielectrics.

Stability and charge-discharge properties of 0.5NN-0.5BNT-cs ceramic

Temperature, frequency, and cycling stability are crucial indicators to ensure stable operation of dielectric capacitors in harsh environments. The slim temperature-, frequency- and cycling-dependent unipolar P-E loops can be found in 0.5NN-0.5BNT-cs ceramics under a high electric field of 50 kV mm-1 (Supplementary Fig. 15). In a wide temperature range, 0.5NN-0.5BNT-cs ceramics exhibit excellent temperature stability with high Wrec about 8.2 ± 0.1 J cm-3 and high η above 85.0% (Fig. 4f), which is related to the temperature insensitive phase structure (Supplementary Fig. 16) and dielectric spectra (Supplementary Fig. 4). The excellent frequency stability of energy storage performance can also be obtained in 0.5NN-0.5BNT-cs ceramics, in which Wrec fluctuates slightly around 7.5 J cm-3 with η exceeding 80.0% (Fig. 4g). Furthermore, when the 0.5NN-0.5BNT-cs sample is subjected to 106 cycles of electric fields, Wrec and η can be well stabilized near 7.6 J cm-3 and 80.0%, respectively, indicating outstanding cycling stability (Supplementary Fig. 15c, d). The charge-discharge properties of 0.5NN-0.5BNT-cs ceramics are also been tested to measure the application potential. Both underdamped and overdamped discharge waveforms with decent regularity can be observed under different electric fields (Supplementary Fig. 17). As shown in Fig. 4h, the PD and discharge energy density (WD) of 0.5NN-0.5BNT-cs ceramic grow with increasing electric field, achieving an ultrahigh PD of 418.5 MW cm-3 and high WD of 2.9 J cm-3. It should be noted that the stored energy density can be rapidly released up to 90% at the nanosecond level of 58.1 ns. Therefore, 0.5NN-0.5BNT-cs ceramics exhibit excellent comprehensive performance with preferable stability, making promising application potential for advanced capacitors.

In summary, we propose a polymorphic heterogeneous shell strategy to develop high-performance energy storage dielectrics through synergistically control micro and local heterostructures. The core-shell structure has been established with different polarization landscapes to enhance breakdown characteristics and improve polarization evolution behaviors. As a consequence, boiling energy storage properties with a high Wrec of 12.7 J cm-3 and an impressive η of 87.2% have been achieved in 0.5NN-0.5BNT-cs relaxor antiferroelectrics, along with good stability and charge-discharge behavior. This strategy has been demonstrated to efficiently design new dielectrics with excellent energy storage performance, which can provide guidance for multi-scale heterostructure design in other fields.

Methods

Sample preparation

The 0.5NaNbO3-0.5(Bi0.5Na0.5)TiO3 ceramic with core-shell structure (abbreviated as 0.5NN-0.5BNT-cs) was synthesized by a solid-state reaction method using raw materials Na2CO3 (Aladdin, 99.99%), Nb2O5 (Aladdin, 99.9%), Bi2O3 (Aladdin, 99.9%) and TiO2 (Aladdin, 99.8%). The raw powders were baked at 220 °C for 24 hours and then weighed according to the stoichiometry of NaNbO3 and (Bi0.5Na0.5)TiO3, respectively. The mixtures were ball-milled by a planetary ball mill with alcohol for 12 hours. After drying, BNT and NN powders were calcined at 850 °C and 950 °C for 4 hours, respectively. The calcined NN and BNT powders were subjected to high-energy ball milling for 12 hours, dried, and weighed at a stoichiometric ratio of 0.5NaNbO3-0.5(Bi0.5Na0.5)TiO3, and the resulting powders were mixed by high-energy ball milling for 20 minutes. Subsequently, the dried powders were mixed with 8 wt% polyvinyl alcohol (PVA) binder and pressed into 10 mm diameters pellets. The pellets were held in a crucible with sacrificial powder of the same composition at 550 °C for 2 hours to expel the PVA binders, followed by sintering at 1160 °C for 2 hours. Ordinary 0.5NaNbO3-0.5(Bi0.5Na0.5)TiO3 ceramic (abbreviated as 0.5NN-0.5BNT) was prepared by a conventional solid-phase reaction method16.

Structural characterization

Temperature-dependent XRD spectra were obtained using an X-ray diffractometer (Cu kα1, 1.54059 Å, X’pert PRO, PANalytical, the Netherlands). High-resolution synchrotron XRD experiments (λ = 0.42 Å) were performed at Spring-8. The surface grain morphologies of the samples were observed by a scanning electron microscope (SEM, LEO1530, ZEISS SUPRA 55, Oberkochen, Germany). The finely polished sample below 40 μm was thinned for TEM measurement using an ion milling system with a liquid nitrogen cooled stage (PIPS, Model 691, Gatan Inc., Pleasanton, CA, USA). SAED and domain morphologies were performed on a field-emission TEM (JEM-2100, JEOL, Japan) with an accelerating voltage of 200 kV. The element distribution was obtained through SEM and TEM as described above. Atomic-scale images were acquired with an aberration-corrected Hitachi HF5000 microscope, operating at atomic resolution in the high-angle annular dark-field (HAADF) mode. The polarization vector, magnitude, and angle were computed using tailored MATLAB scripts.

Electrical performance measurement

The sintered pellets were thinned and polished to a thickness of 50–70 μm and coated by silver electrodes with an area of 0.78 mm2 for measuring energy storage and charge-discharge properties. Room-temperature unipolar P-E loops at a frequency of 10 Hz were measured with a ferroelectric analyzer (aix ACCT, TF Analyzer 1000, Aachen, Germany). Temperature-, frequency-, and cycling-dependent unipolar P-E loops were also measured using the same equipment. The charge-discharge properties were measured under different applied electric fields by a commercial charge-discharge platform (CFD-001, Gogo Instruments Technology, Shanghai, China). Dielectric and impedance spectra as functions of temperature and frequency were measured using a precision LCR meter (Keysight E4990A, Santa Clara, CA) with an applied voltage of 500 mV and a heating rate of 3 °C min−1. The thickness of the test sample was 0.6 mm and the electrode area was 50 mm2.

Optical performance measurement

To compare the bandgap of the samples, the optical absorption properties of the samples were measured in the wavelength range of 200–800 nm using a UV-vis spectrophotometer with an integrating sphere (UV−3600Plus, Shimadzu, Japan).

Phase-field simulation

The details of phase-field simulation about domain structure and polarization configuration are elaborated in the Supplementary information.

Finite element simulation

The dielectric breakdown process of electric field distribution and electric tree evolution were simulated by finite element methods with 2D models using COMSOL software. The detailed finite element simulation processes are elaborated in the Supplementary Information.

Data availability

All data supporting this study and its findings are available within the article and its Supplementary Information. Any data deemed relevant are available from the corresponding author upon request.

References

Li, J. et al. Grain-orientation-engineered multilayer ceramic capacitors for energy storage applications. Nat. Mater. 19, 999–1005 (2020).

Pan, H. et al. Ultrahigh-energy density lead-free dielectric films via polymorphic nanodomain design. Science 365, 578–582 (2019).

Qi, H. et al. Local structure engineered lead-free ferroic dielectrics for superior energy-storage capacitors: a review. Energy Storage Mater. 45, 541–567 (2022).

Jayakrishnan, A. et al. Are lead-free relaxor ferroelectric materials the most promising candidates for energy storage capacitors? Prog. Mater. Sci. 132, 101046 (2023).

Chen, L. et al. Giant energy-storage density with ultrahigh efficiency in lead-free relaxors via high-entropy design. Nat. Commun. 13, 3089 (2022).

Liu, B. et al. Grain size effect and microstructure influence on the energy storage properties of fine-grained BaTiO3-based ceramics. J. Am. Ceram. Soc. 100, 3599–3607 (2017).

Niu, Z. et al. Bi0.5K0.5TiO3-based lead-free relaxor ferroelectric with high energy storage performances via the grain size and bandgap engineering. Mater. Today Chem. 24, 100898 (2022).

Xiong, X. et al. Ultrahigh energy-storage in dual-phase relaxor ferroelectric ceramics. Adv. Mater. 36, 2410088 (2024).

Shu, L. et al. Partitioning polar-slush strategy in relaxors leads to large energy-storage capability. Science 385, 204–209 (2024).

Ren, P. et al. Energy storage density and tunable dielectric properties of BaTi0.85Sn0.15O3/MgO composite ceramics prepared by SPS. J. Eur. Ceram. Soc. 37, 1501–1507 (2017).

Yang, B. et al. Design of high-entropy relaxor ferroelectrics for comprehensive energy storage enhancement. Adv. Funct. Mater. 34, 2409344 (2024).

Xue, G. et al. Core-shell structure and domain engineering in Bi0.5Na0.5TiO3-based ceramics with enhanced dielectric and energy storage performance. J. Materiomics 9, 855–866 (2023).

Huang, W. et al. Superior energy storage performances achieved in (Ba,Sr)TiO3-based bulk ceramics through composition design and Core-shell structure engineering. Chem. Eng. J. 444, 135523 (2022).

Dong, X. et al. (1-x)[0.90NN-0.10Bi(Mg2/3Nb1/3)O3]-x(Bi0.5Na0.5)0.7Sr0.3TiO3 ceramics with core-shell structures: a pathway for simultaneously achieving high polarization and breakdown strength. Nano Energy 101, 107577 (2022).

Zhou, X. et al. Optimized dielectric energy storage performance in ZnO-modified Bi0.5Na0.5TiO3-Sr0.7Bi0.2□0.1TiO3 ceramics with composite structure and element segregation. Chem. Eng. J. 458, 141449 (2023).

Chen, L. et al. Local diverse polarization optimized comprehensive energy-storage performance in lead-free superparaelectrics. Adv. Mater. 34, 2205787 (2022).

Xie, A. et al. Supercritical relaxor nanograined ferroelectrics for ultrahigh-energy-storage capacitors. Adv. Mater. 34, 2204356 (2022).

Yang, B. et al. High-entropy enhanced capacitive energy storage. Nat. Mater. 21, 1074–1080 (2022).

Pan, H. et al. Ultrahigh energy storage in superparaelectric relaxor ferroelectrics. Science 374, 100–104 (2021).

Duan, J. et al. High-entropy superparaelectrics with locally diverse ferroic distortion for high-capacitive energy storage. Nat. Commun. 15, 6754 (2024).

Qi, H. et al. Emerging antiferroelectric phases with fascinating dielectric, polarization and strain response in NaNbO3-(Bi0.5Na0.5)TiO3 lead-free binary system. Acta Mater. 208, 116710 (2021).

Zhang, M. et al. Enhanced electric-field-induced strains in (K,Na)NbO3 piezoelectrics from heterogeneous structures. Mater. Today 46, 44–53 (2021).

Mishra, S. et al. Competing antiferroelectric and ferroelectric interactions in NaNbO3: Neutron diffraction and theoretical studies. Phys. Rev. B 76, 024110 (2007).

Qi, H. et al. Linear-like lead-free relaxor antiferroelectric (Bi0.5Na0.5)TiO3-NaNbO3 with giant energy-storage density/efficiency and super stability against temperature and frequency. J. Mater. Chem. A 7, 3971–3978 (2019).

Li, Y. et al. High energy storage performance in Ca-doped PbZrO3 antiferroelectric films. J. Eur. Ceram. Soc. 40, 1285–1292 (2020).

Glazer, A. Simple ways of determining perovskite structures. Acta Cryst. A 31, 756–762 (1975).

Chen, L. et al. Compromise optimized superior energy storage performance in lead-free antiferroelectrics by antiferroelectricity modulation and nanodomain engineering. Small 20, 2306486 (2024).

Shen, Z. et al. Nb-doped BaTiO3-(Bi0.5Na0.5)TiO3 ceramics with core-shell structure for high-temperature dielectric applications. Adv. Appl. Ceram. 115, 435–442 (2016).

Chen, L. et al. High permittivity and excellent high-temperature energy storage properties of X9R BaTiO3-(Bi0.5Na0.5)TiO3 ceramics. J. Am. Ceram. Soc. 103, 1113–1120 (2020).

Chazono, H. et al. Sintering Characteristics in the BaTiO3-Nb2O5-Co3O4 Ternary System: II, Stability of So-called “Core-Shell” Structure. J. Am. Ceram. Soc. 83, 101–106 (2000).

Chazono, H. et al. Sintering characteristics in BaTiO3-Nb2O5-Co3O4 ternary system: I, Electrical properties and microstructure. J. Am. Ceram. Soc. 82, 2689–2697 (1999).

Cai, Z. et al. Grain-size-dependent dielectric properties in nanograin ferroelectrics. J. Am. Ceram. Soc. 101, 5487–5496 (2018).

Cai, Z. et al. Dielectric response and breakdown behavior of polymer-ceramic nanocomposites: The effect of nanoparticle distribution. Compos. Sci. Technol. 145, 105–113 (2017).

Tang, Y. et al. Observation of a periodic array of flux-closure quadrants in strained ferroelectric PbTiO3 films. Science 348, 547–551 (2015).

Zhang, M. et al. Ultrahigh energy storage in high-entropy ceramic capacitors with polymorphic relaxor phase. Science 384, 185–189 (2024).

Chen, L. et al. Near-zero energy consumption capacitors by controlling inhomogeneous polarization configuration. Adv. Mater. 36, 2313285 (2024).

Zhou, X. et al. Lead-free ferroelectrics with giant unipolar strain for high-precision actuators. Nat. Commun. 15, 6625 (2024).

Huan, Y. et al. Achieving excellent energy storage reliability and endurance via mechanical performance optimization strategy in engineered ceramics with core-shell grain structure. J. Materiomics 8, 601–610 (2022).

Wang, H. et al. Preparation of BaTiO3@NiO core-shell nanoparticles with antiferroelectric-like characteristic and high energy storage capability. J. Eur. Ceram. Soc. 41, 4129–4137 (2021).

Kim, C. et al. Machine learning assisted predictions of intrinsic dielectric breakdown strength of ABX3 perovskites. J. Phys. Chem. C 120, 14575–14580 (2016).

Acknowledgements

This work was supported by the National Key R&D Program of China (grant no. 2023YFB3508200 (H.Q.)), the National Natural Science Foundation of China (grant nos. 22235002 (J.C.), 52172181 (H.Q.), and 22205016 (H.Q.)), the China National Postdoctoral Program for Innovative Talents (grant no. BX20230040 (L.C.)), and the China Postdoctoral Science Foundation (grant no. 2023M740208 (L.C.)). High-resolution synchrotron XRD experiments were conducted at the BL02B2 beamline of Spring-8, following approval from the Japan Synchrotron Radiation Research Institute.

Author information

Authors and Affiliations

Contributions

This work was conceived and designed by L.C. and H.Q. H.Y. fabricated the samples, tested the energy storage, structure, stability and other properties, and processed related data, assisted by L.C. The phase-field simulation was processed by H.W. and X.S. The finite element simulation was processed by H.Y. The dielectric spectra, optical absorption spectrum and impedance spectra were collected by H.Y., R.Z., and J.W. The SEM images were filmed and processed by H.Y. and W.F. The TEM and STEM images were filmed and processed by L.C., T.H., and Z.F. The manuscript was drafted by H.Y. and L.C., and revised by H.Q. and J.C. All authors participated in the data analysis and discussions.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yu, H., Hu, T., Wang, H. et al. Design of polymorphic heterogeneous shell in relaxor antiferroelectrics for ultrahigh capacitive energy storage. Nat Commun 16, 886 (2025). https://doi.org/10.1038/s41467-025-56316-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-56316-9

This article is cited by

-

Ultrahigh energy storage density and efficiency in AgNbO3-based ceramics by percolating interaction between antipolar regions and defect pairs

Nature Communications (2026)

-

Non-polar nanocluster confinement engineering realizes high capacitive energy storage in Pb-free high-entropy relaxors

Nature Communications (2026)

-

Structural order differentiation unlocks the energy storage performance of commensurate antiferroelectric ceramics

Nature Communications (2025)

-

Magnetoelectric regulation in multiferroic double perovskite heterojunction thin films

Journal of Materials Science (2025)