Abstract

The self-assembly of small molecules through non-covalent interactions is an emerging and promising strategy for building dynamic, stable, and large-scale structures. One remaining challenge is making the non-covalent interactions occur in the ideal positions to generate strength comparable to that of covalent bonds. This work shows that small molecule YAWF can self-assemble into a liquid-crystal hydrogel (LCH), the mechanical properties of which could be controlled by water. LCH can be used to construct stable solid threads with a length of over 1 meter by applying an external force on 2 µL of gel solution followed by water-regulated crystallization. These solid threads can support 250 times their weight. Cryogenic electron microscopy (Cryo-EM) analysis unravels the three-dimensional structure of the liquid-crystal fiber (elongated helix with C2 symmetry) at an atomic resolution. The multiscale mechanics of this material depend on the specificity of the molecular structure, and the water-controlled hierarchical and sophisticated self-assembly.

Similar content being viewed by others

Introduction

Self-assembly is a potential ability of an assortment of molecules, including proteins with molecular weights over kilos of Daltons and small molecules with molecular weights lower than a thousand Daltons. Spontaneous self-assembly typically relies on non-covalent interactions, including hydrogen bonding, π-π stacking, electrostatic force, etc1,2,3. Under appropriate conditions, these interactions build monomers into diverse structures that can be used for distinctive applications4,5,6,7. For example, insulin functions as monomers to balance the blood sugar level in the bloodstream8, whereas they are stored as zinc-binding hexamers in the pancreas9. Many polymers have also been used to build artificial silk via non-covalent interactions10,11,12,13,14. However, the materials constructed by self-assembled small molecules are usually reported to build nanoscale structures with molecular-scale dimensions15,16,17. They are rarely reported to build stable large-scale structures due to their weak intermolecular interactions18,19,20,21. Hence, small molecules with the self-assembly ability are usually designed and utilized for bio-applications22,23,24,25,26,27,28,29,30, such as drug delivery, controlled drug release, or 3D organoid culturing, where biocompatibility and biodegradability are the main goals. Although large-scale structures are hard to construct from self-assembled small molecules, they have many potential applications and advantages. For instance, if small molecule self-assembled structures were used to build artificial muscles or wearable electronics, these devices would be more sensitive toward different variations and have a lower cost31.

In order to construct large-scale structures, most of peptide materials are modified with alkyl chains or equipped with hydrophobic heads32,33,34,35. Here, we present a serendipitously observed tetrapeptide that consists of four amino acids: tyrosine (Y) – alanine (A) – tryptophan (W) – phenylalanine (F) (YAWF). This peptide contains three aromatic amino acids and an aliphatic amino acid that can be directly encoded by the human genetic code. The hydrogel built through the self-assembly of YAWF preserves an ultra-viscous characteristic (Supplementary Movie 1), and it owns a great anisotropic property, which is similar to liquid-crystal hydrogel (LCH). Cryogenic electron microscopy (Cryo-EM) was used to analyze the structure at the atomistic level to reveal the mechanisms of how YAWF monomers are arranged in the self-assembled nanostructure. The results show that YAWF monomers are precisely arranged in the nanotube as a y-shape, and any position change of amino acids in the sequence would break the balance in the molecule and cause the deformation of the nanotube.

In addition, LCH possesses some characteristics similar to those of human muscle36. Without applying any force to it, LCH is like a relaxed arm muscle. When applying an external force to LCH, the self-assembled nanotubes align more uniformly, similar to the arrangement of muscle fibers during a fist clench. If the LCH keeps being stretched, the bent sections of the nanotubes are straightened, as when extending muscle fibers. When LCH is stretched over its elastic range, some nanotubes are torn off and rebound to LCH if its water content is inappropriate (Supplementary Fig. 88 and Supplementary Movie 2), like when the muscle fibers are under high tension and finally break. However, if the stretching of LCH occurs in an ambient environment, some self-assembled nanotubes are aligned into stable large-scale solid threads via water-regulated crystallization. Moreover, through the entire process of stretching LCH, its elasticity is transferred to plasticity.

Results

Self-assembly of YAWF into ultra-viscous LCH

While exploring the gelation and self-assembly properties of different tetrapeptides, we serendipitously found that the peptide sequence YAWF can form an ultra-viscous hydrogel under optimized conditions. We tested the gelation ability of the synthesized peptides at 20 mM (11.7 mg mL−1, 1.2 wt%), 40 mM (23.4 mg mL−1, 2.3 wt%), and 80 mM (46.8 mg mL−1, 4.6 wt%). At 20 mM, YAWF fails (Supplementary Fig. 77) to form a stable hydrogel and cannot construct micro-threads. The 2.3 wt% concentration was chosen as it allows for stable hydrogel formation. Higher concentrations lead to solubility issues at pH 9.3, resulting in aggregates. Moreover, the presence of trifluoroacetic acid (TFA) anions does not significantly impact the gelation or self-assembly of YAWF. As confirmed by NMR analysis, YAWF-TFA shows consistent properties across different synthesis batches and purification methods (Supplementary Fig. 51). Both YAWF-TFA and YAWF-HCl produced similar liquid crystal hydrogels, indicating that the choice of counterion does not affect the hydrogels’ characteristics (Supplementary Figs. 78 and 93). Further studies demonstrated that the YAWF hydrogel exhibits high elasticity and can form micro-threads via the transition from elastic to plastic behavior, regulated by water content and an external force. The orientation pseudo image (Supplementary Fig. 95) shows highly birefringent domains, confirming the anisotropic properties of the nanofiber bundles and validating the classification of the YAWF hydrogel as an LCH. The uniform distribution of azimuth angles indicates the aligned orientations of the self-assembled nanotubes. In addition, variations in retardance between 0 and 16 nm further demonstrate the hydrogel’s birefringent characteristics, confirming its liquid crystalline property. The structural domain of the YAWF tetrapeptide contains all three non-essential aromatic amino acids: phenylalanine (F), tryptophan (W), and tyrosine (Y). Hence, we speculated that the building block YAWF could spontaneously self-assemble into nanostructures in water through π-π stacking-dominated intermolecular interactions3. Moreover, after observing the ultra-viscous property of YAWF, in order to investigate the significance of the amino acid’s position in the peptide self-assembly, 23 isomers of YAWF were prepared and then measured in the same conditions as YAWF (Fig. 1a and Supplementary Fig. 2). Solid-phase peptide synthesis (Supplementary Fig. 1) was used to synthesize these compounds37, while nuclear magnetic resonance and liquid chromatography – mass spectroscopy were used for validation (Supplementary Figs. 3–75 and Supplementary Table 1).

a Graph illustrating YAWF and its isomers. The position of R1, R2, R3, and R4 in the sequence is switchable. b Schematic diagram manifesting the gelation process of the LCH. c Cryo-EM images and scheme showing the self-assembly status of YAWF after heating at 68 °C and then cooling down at 22 °C for 0 min, 5 min, 10 min, and 20 min. d Scheme representing the energy barrier between the YAWF self-assembled nanotubes and the YAWF monodisperse products, which is around 95 kJ mol−1. e Optical photo of the clarifying of a hydrogel sample that was prepared for its rheological measurements. f Strain-dependent oscillatory rheology of LCH. g Viscosity information of LCH given by the flow ramp measurement. h Step–strain measurement with an applied oscillatory strain alternated between 1% and 100% for 30 s periods (ω = 10 rad/s, 20 °C). This process was repeated ten times, and the results indicated that the LCH undergoes fast dissociation-reformation processes and owns good recyclability.

After observing that YAWF could self-assemble into an ultra-viscous hydrogel, the conditions for its gelation were studied and modified to accelerate the gelation speed. Following the pathway illustrated in Fig. 1b, we obtained a clear transparent hydrogel (LCH, YAWF 23.4 mg mL−1). For the prepared sample, which had not undergone the heat-cooling process, we found that the ultra-viscous hydrogel was formed in less than an hour, but it contained precipitants inside it, indicating entropy-favorable hydrogel formation. Moreover, the formed LCH can be stored in a room environment for over two years (Supplementary Figs. 76 and 79). Under the same conditions, none of the YAWF isomers presented the same features as YAWF (Supplementary Fig. 80). Nevertheless, part of those isomers showed the ability to form hydrogels under an acidic environment (Fig. 2a–d and Supplementary Fig. 81). These results suggested the crucial roles of the peptide sequence in molecular self-assemblies, consisting with the melanin pigments formed by peptides38.

a Representative raw 300 KV micrograph of FAWY filament. The arrows point to the different types of filaments. Scale bar, 150 nm. b 2D averages of filaments. c Representative raw 300 KV micrograph of WAFY filament. The arrows point to the different types of filaments. Scale bar, 150 nm. d 2D averages of filaments.

Transmission electron microscopy (TEM) showed that YAWF can self-assemble to form long nanotubes with lengths over the measuring range (20 µm) of TEM (Supplementary Fig. 83). In comparison with other hydrogels built by short-peptides self-assembled nanofibers, the YAWF self-assembled nanotubes in LCH were well oriented (Supplementary Fig. 83)39. The concentration-dependent experiments (Supplementary Fig. 84) indicated that YAWF could not form long nanotubes at a concentration below or at 4 mg mL−1, whereas when the concentration was higher than this value the short nanofibers gained a tendency to elongate. The long nanofibers started to appear at a concentration of 6 mg mL−1, but their lengths were still much shorter than those observed at 23.4 mg mL−1. According to the Cryo-EM results, when the concentration of YAWF was increased to 11.7 mg mL−1, the nanotubes formed by YAWF did not change, but the number of the nanotubes got increased, making them easier to bundle together (Supplementary Fig. 85). Time-dependent Cryo-EM analysis (Fig. 1c) revealed that the YAWF monomers first self-assembled or pre-aggregated to form droplets through liquid-liquid phase separation (LLPS)40 at a higher temperature. When the sample was cooled down at room temperature, the YAWF monomers started to aggregate, and the nucleation occurred41 because of the energy transition between the solvent and the formed droplets. Along with time, nanotubes were observed through the transformation from droplets.

To reveal the energy transition in this phase transition, dynamic light scattering (DLS) was applied to evaluate the energy requirements for the disassembly of LCH to clear solution41,42. In this test, when the temperature is at 25 °C, LCH is supposedly under an ideal state and YAWF is supposed to totally self-assemble. The scattering rate alterations of the prepared samples were measured in a temperature range between 50 °C–75 °C (Supplementary Fig. 82a). Then, with the help of an Arrhenius plot (Supplementary Fig. 82b), the energy barrier was determined to be of 95 kJ mol−1 (Fig. 1d).

Mechanical properties of LCH

Figure 1e shows a prepared LCH hydrogel in a modified injector tube for rheological measurement because of the ultra-viscous property of LCH. The strain-dependent oscillatory rheology (Fig. 1f) of the LCH hydrogel shows a standard linear viscoelastic region with a hydrogel to solution cross-over point (strain value ~ 25.0%), indicating a moderate visco-elastic behavior of this hydrogel. The frequency-dependent oscillation shows that the elastic modulus (G’) is almost independent of the tested range of frequency, suggesting a structured and gel-like behavior (Supplementary Fig. 92). In comparison with other hydrogels that can be used to construct micro-threads or gel-noodles, LCH owns similar rheological properties as them (Supplementary Table 3)14,33,43. The viscosity of LCH was measured using flow ramp mode and is around 90.5 Pa s−1 (of the order of 105 times the viscosity of water) (Fig. 1g). Moreover, the recovery rate of LCH was measured using the step-strain mode. After the first round, both the loss modulus and the storage modulus of LCH decreased slightly and then remained steady for the last rounds (Fig. 1h). Overall, the results indicate that LCH is an ultra-viscous hydrogel with a good self-healing property.

Cryo-EM structures of LCH fibers at an atomistic level

Cryo-EM single-particle analysis was used to obtain the three-dimensional (3D) structure of the nanofibers formed by the peptides at an atomic resolution. The Cryo-EM sample was checked by 200 keV Cryo-EM (Fig. 3a), followed by data collection on 300 keV Cryo-EM. During the reference-free 2D classification, only one type of nanofiber was identified (Supplementary Fig. 87a). A final 3D reconstruction at 3.12 Å was obtained (Supplementary Fig. 87b). A trial-and-error process by testing all possible symmetries indexed from the ‘Symmetry Search Utility’ in cryoSPARC suggested that the overall structure of the nanofiber bears C2 symmetry44. The atomic model built into the 3D reconstruction exhibits an elongated helical structure (Fig. 3b, c) with an average helical rise of 4.6 Å and a twist of 5.15° (Supplementary Fig. 87c). A tunnel is observed in the center of the helical structure, with a diameter of 17 Å for the inner tunnel and a diameter of 45 Å for the outer shell, approximately (Fig. 3d). In this configuration, each YAWF molecule is arranged into a y-like shape (top-view), with tyrosine residues of the nanofiber pointing towards the inside and forming the surface of the central tunnel, tryptophan and phenylalanine residues constituting the outer shell, and alanine residues bridging the inner and outer surfaces (Fig. 3c, d). The cohesion of the peptides was mediated by extensive hydrogen bonding and aromatic-aromatic stacking interactions between the tyrosine, tryptophan, and phenylalanine residues (Fig. 3e–g). It is worth noting that these intermolecular hydrogen bonds and aromatic-aromatic stacking interactions not only confer a compact structure to the filaments but also provide them with a certain degree of stretchability along the helical axis. Since FAWY and WAFY could form hydrogels (not as transparent as LCH) under an acidic environment, we tried to investigate the self-assembling mechanisms of these tetrapeptides at an atomic resolution. However, when cryo-EM was utilized to disclose the FAWY and WAFY self-assembled nanostructures in their hydrogel samples, there were over nine types of nanostructures with different peptide densities in each sample (Fig. 2a–d). Hence, we were unable to reveal how the tetrapeptide monomers (FAWY and WAFY) were arranged in the nanostructures.

a Cryo-EM image illustrating the YAWF self-assembled nanostructure. The white arrow points to one of the nanostructures selected for analysis. b–d. Three-dimensional reconstruction of the YAWF arranged in the nanostructure (b). Side view (c), top view (d). e Molecular model showing the intermolecular interactions between YAWF molecules in different layers. f, g Molecular models illustrating the hydrogen bonding (f) and π-π stacking (g) between adjacent YAWF molecules, respectively.

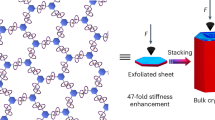

Alignment of nanotubes into threads

Conventionally, divalent counterions were used to help align self-assembled nanostructures to build macroscopic structures19,45. YAWF can self-assemble to form LCH after dissolving in an aqueous solution by simply adjusting its pH. After hydrogelation, an external force was applied on LCH, forming well-aligned solid threads. Once the structure of the nanotubes was distinguished, the crucial role that water plays in this hierarchical assembly was demonstrated. The C-terminal of YAWF is located at the outer surface of the nanotubes. When the pH is at 9.3 ± 0.1, the carboxylic acids exist in the system as -COO-, which interacts with water molecules via electrostatic forces. With the results obtained from the experiments, it is reasonable to derive the following conclusions. In LCH, self-assembled long nanotubes form a framework that traps water molecules inside. By applying a shear force, the orientation of the self-assembled nanotubes becomes more ordered and causes the imbalance between nanotubes and water molecules inside. Hence, the water molecules without interactions with -COO- on the surface of the nanotubes become bulk water molecules driven by entropy and are squeezed out from the LCH. This dehydration decreases the distances between nanotubes, followed by an elasticity increase of LCH. Then, if LCH keeps being stretched, with an increased internal shear force and accelerated water evaporation rate, more water molecules escape from the system. We speculate that water molecules would form a bridge between each two -COO-, and a large-scale solid thread would form in the end (Fig. 4b).

a Optical photos show micro-threads drawn from LCH using a rheometer. b Schematic illustration of a micro-thread constructs from the LCH through water-regulated crystallization. c Optical image shows a hand-made super-thin thread. d SEM image showing the morphological details of a hand-made thread. e AFM results revealing the height of a hand-made thread. Blue dot: the initial point of the test, red line: movement track. f POM pseudo-color image shows the thread has good anisotropic properties. g Optical image shows a micro-thread supports a weight over a hundred times heavier than itself. h Scheme shows FluidFM measure Young’s moduli of the threads (The nanopipette image courtesy of Cytosurge AG). i Optical image of the nanopipette and the thread before testing. j Graph shows the determined Young’s moduli of 12 threads using FluidFM. Data are presented as mean values +/− SD (Thread 1, n = 2; thread 2, n = 2; thread 3, n = 4; thread 4, n = 1; thread 5, n = 1; thread 6, n = 5; thread 7, n = 2; thread 8, n = 7; thread 9, n = 7; thread 10, n = 2; thread 11, n = 3; thread 12, n = 4). k Representation of the Young’s moduli of 9 YAWF micro-threads using DMA.

We observed that LCH has a materially stretchy property when removing the LCH sample from the sample-loading stage after the rheological test. A thread was drawn from LCH by a stainless plate (Fig. 4a). This phenomenon could be repeated many times, and many threads were obtained using the same procedure (Fig. 4b and Supplementary Fig. 97a and b), indicating that LCH has an excellent elasticity. When a rheometer was used to stretch LCH, the main part of the hydrogel was located at the sample loading stage and the stainless plate due to gravity and interactions between them (Supplementary Movie 3). A transparent hydrogel rod appeared as LCH was stretched to a length of 1 cm (Fig. 4a). As time passed, with the internal dehydration in the rod, the rod became thinner and more stable until it formed a large-scale plastic thread (crystallization). During dehydration, the elasticity of the thread constructed by nanotubes first increased, and then the behavior transition happened (from elasticity to plasticity). In one phase of the transition, the thin elastic thread could be split into many thin threads using tweezers (Supplementary Movie 4). In another approach to create thinner and regular threads, we first stretched LCH to a short length and then stabilized the short LCH rod through dehydration. With the increased elasticity of the material, it could be rapidly stretched to a long thread without tearing. During this process, the water was squeezed out of LCH (Fig. 4a and Supplementary Movie 5) with a much quicker water loss rate than that of natural water evaporation at room temperature. While the self-assembly of YAWF involves π-π stacking and hydrogen bonding, the structure of the nanotubes within the hydrogel is crucial for water retention. However, during the construction of micro-threads, the compression of LCH reduces its overall volume and water-trapping capacity. Besides, as the length of the constructed thread increases, the interface between the fibers and the air expands, which accelerates water-regulated crystallization. This crystallization process leads to the solidification of the thread, ultimately enhancing its dynamic stability (Fig. 4b). However, if the elasticity of the initially constructed short threads did not reach the ideal point, they could be torn off and retracted into the LCH when elongating them, whether it was towards the stage or the plate. The distance of the gap on a rheometer is limited (10 cm), and LCH possesses the potential ability to construct longer and thinner threads. During the test, LCH proved to have good adhesiveness with materials such as metal, plastic, glass, etc. Hence, two 10 µL pipette guns equipped with tips were used to draw micro-threads controlled by hands. A super thin thread was drawn with a length of over 10 cm, and it only utilized less than 2 µL of LCH (Fig. 4c and Supplementary Movie 6). Subsequently, many long threads were produced with lengths of nearly a meter. However, capturing them using a normal optical camera (Supplementary Movie 7) was very hard because their diameters were too thin. Only when a super-thin thread floating in the air was placed against the light, a video of the long thread was captured (Supplementary Movie 8).

Characterization of solid threads

From the SEM results, the threads produced by the rheometer are generally uniform in different sections, with diameters over 10 µm (Fig. 5a). The threads drawn by hands contained nodes due to the uneven forces applied to them (Supplementary Fig. 89). For the super-fine hand-made threads, although SEM could determine their widths, their heights were hard to measure using the same instrument due to the contrast (Fig. 4d). Thus, their heights were examined by AFM (Supplementary Fig. 90) and the height of one of the hand-made threads was 0.52 µm (Fig. 4e). In an ideal environment, 2 µL of YAWF hydrogel could be stretched by hands to form a thread with a length of over 1.2 m. Comparing the micro-threads made by the rheometer with the threads made by hand, we found that the YAWF self-assembled nanotubes align tidier in the rheometer-stretched micro-thread than in the threads drawn by hands because the stretch force of the rheometer is more stable than that of hands. Moreover, we observed that the self-assembled nanotubes aligned into bundles on the surface and inside the threads (Fig. 5a–d and Supplementary Fig. 86), supporting the hypothesis that the self-assembled nanotubes were the framework of the threads. To examine the stability of the solid threads built by LCH, different weights of materials were prepared to hang on it. Then, it was proven that the crystallized thread could support materials around 250 times over its weight. In accordance with the results provided by the dynamic mechanical analysis (DMA), Young’s moduli of the micro-threads (diameters between 20–50 µm) constructed using a rheometer were between 10–30 MPa (Fig. 4k). However, the threads (diameters between hundreds of nm to 10 µm) constructed by hands were too fine and hard to measure using the same method. Thus, we used FluidFM (Fig. 4h, i) to measure Young’s moduli of super-thin threads. We initially explored various equations to calculate Young’s moduli from FluidFM data, finding significant discrepancies in results. Ultimately, by comparing data from both DMA and FluidFM (Supplementary Table 4), we concluded that the Hertz equation best fits our samples, justifying its use for calculating the Young’s moduli of thinner micro-threads (Fig. 4j)46. To reveal the relationship between the mechanical strengths of the micro-threads and stretching rates. After preparing the LCH, it was set on an instrument, and different stretching rates (1 mm s−1, 2 mm s−1, 5 mm s−1) were applied on it to construct micro-threads. The AFM results (Supplementary Fig. 91) showed self-assembled YAWF nanotubes on the micro-thread surfaces. Notably, even threads constructed at the same stretching rate exhibited variations in Young’s moduli, which increased with higher stretching rates.

a–d. SEM photos reveal the morphology of a solid micro-thread at different scales. e POM image delineates that YAWF molecules are arranged in a solid thread. The red lines indicate the orientation of the slow axis. f Molecular model illustrates the angle in a turn in the YAWF self-assembled nanotubes. g Graphic representation of the YAWF self-assembled nanotubes in different statuses with the help of the spring models.

The Cryo-FIB/SEM (Supplementary Fig. 86a) and polarized optical microscope (POM) results showed that LCH exhibited an anisotropic property (Supplementary Fig. 95), which is the origin of its name. After the alignment of the nanotubes from LCH into solid threads, the threads exhibited a significant birefringent under polarized light (Fig. 3f and Supplementary Fig. 96b–f), indicating that the stretching of LCH to form solid threads is a water-regulated crystallization. Moreover, the POM results also indicated that the direction of the molecules arranged in the threads was perpendicular to the thread growth direction with an angle of around 33 degrees (Fig. 5e). Regarding the YAWF self-assembled nanotube, the angle in each turn was around 40 degrees with a half angle of 20 degrees (Fig. 5f). These results suggested that the deformation mechanism of the self-assembled nanotubes was similar to that of the stretching of a string (Fig. 5g) when stretching LCH. After stretching, the angle in each turn of the nanotubes increased from 40 to 66 degrees, and with the elongation of the nanotube, the diameter decreased.

Discussion

This work presents the unmodified short-peptide – YAWF that can simply self-assemble to LCH in water by adjusting its pH. LCH is able to construct dynamic, stable, and large-scale structures through water-regulated crystallization. LCH is recyclable, and after dehydration, it can be reformed by adding water to it and through a heat-cooling process. The solid threads constructed by LCH are mechanically strong (>10 MPa) and can support over 250 times their weight (Supplementary Fig. 97c and d). Moreover, the mechanisms of hierarchical and sophisticated self-assembly are also elucidated in this work from the singular molecule to the secondary structure (nanotube) threads. This result demonstrates that small molecules, such as short peptides, have enormous research potential for different applications, including building stable large-scale structures.

Methods

Materials & instruments

The details and instruments of this work are provided in the supplementary information.

Peptide synthesis

All the peptides that have been used in this project were synthesized through solid-phase peptide synthesis, with 2-chlorotrityl chloride resin as the anchoring37. Four of the protected amino acids N-(fluorenylmethoxycarbonyl)-L-alanine (Fmoc-Ala-OH), N-(fluorenylmethoxycarbonyl)-L-phenylalanine (Fmoc-Phe-OH), N-(fluorenylmethoxycarbonyl)-N1-(tert-butoxycarbonyl)-L-tryptophan (Fmoc-Trp(Boc)-OH), and N-(fluorenylmethoxycarbonyl)-O4-tert-butyl-L-tyrosine (Fmoc-Tyr(tBu)-OH were used. First, the carboxyl group of the first amino acid was conjugated to the resin. Before each amidation, 20% of piperidine in N,N’-dimethylformamide (DMF) was used to remove the Fmoc group. Then, 2-(1H-Benzotriazole-a-yl)-1,1,3,3-tetramethyluronium hexafluorophosphate (HBTU) and N,N-Diisopropylethylamine (DIPEA) were used to activate the carboxyl group on the other amino acid to couple with the free amino group. After the final coupling step, the Fmoc group on the N-terminus was removed. The excess reagent was rinsed with DMF, and washed 5 times by using dichloromethane (DCM). The peptides were cleaved from the resins by using the TFA (Trifluoroacetic acid) cleavage cocktail (95% trifluoroacetic acid, 2.5% trisopropyl silane, and 2.5% H2O) for 1 h. Besides, the protective groups on the side chain of the amino acids were also cleaved by using the TFA cleavage cocktail. After inspissation by a rotary vacuum evaporator, ethyl ether was used to separate peptides and impurities by precipitating the peptides. Later, the crude peptide products were purified by high-performance liquid chromatography (Agilent 1260 Infinity II Manual Preparative Liquid Chromatography system with a C18 RP column).

YAWF hydrogel preparation

23.4 mg YAWF powder were dissolved in 1.0 mL ultra-pure water, 1 M NaOH was used to aid in powder dissolution, to a final pH at 9.3 ± 0.1. After sonication for 5 min, the sample was heated at 68 °C for 30 min to clear the solution. The obtained solution was filtered using a 0.22 µm filter, and then, it was placed at room temperature overnight (around 12 h) to form the ultra-viscous hydrogel, of which YAWF is around 23.4 mg mL−1. For all the characterization in this project, this concentration (23.4 mg mL−1) was applied.

Rheology measurement

The rheological data of YAWF hydrogel were acquired using a rheometer (TA-Waters ARES-G2) at 20 °C equipped with a 25.0 mm parallel plate. During the oscillation strain test of the hydrogel, the angular frequency was set at 10 rad s−1. For testing the relationship between the shear rate and the viscosity of the hydrogel, the time of the test was 300 s. By measuring the recyclability of the hydrogel, the strain, and frequency were set at 1% and 10 rad s−1, respectively. Here, it is easy to break the YAWF hydrogel when transferring it to the rheometer using a pipette due to its ultra-viscous property. Hence, to prepare the sample for this experiment, the pre-prepared hydrogel was heated at 68 °C to the solution state, and the solution was transferred to a modified injector. Later, it was placed at room temperature for 12 h to form the hydrogel before the measurement (as shown in Fig. 1e).

DLS

The scattering rates of the 23.4 mg mL−1 YAWF samples (200 µL) under different temperatures (75–50 °C) were measured by a DLS instrument (Brukehaven instruments, BI-200SM/NanoBrook ZetaPALS/BI-DNDC) by adapting published methods42. As the models used by the mentioned DLS software are fitting for particles, and the self-assembled YAWF are nanofibers, in this test, the assembly sizes of the samples under different conditions were illustrated by the scattering rates. After LCH (1200 µL) was prepared, it was set at a constant temperature (25 °C). When the target temperatures (50 °C, 55 °C, 60 °C, 68 °C, 70 °C, 75 °C) were reached in the DLS, the 200 µL samples in the sample holders were each transferred into the instrument for the tests. For each temperature, the sample was set in the DLS for 30 min, and the scattering rates at different times were collected. Then, the energy barrier of the self-assembled YAWF hydrogel was calculated by the Arrhenius equation.

TEM

The morphology information of YAWF and its isomers were acquired using a TEM (Thermo Fisher, Talos L120C, Netherlands). After the same gelation process as that of YAWF, each sample (10 μL) was placed on 200 mesh carbon-coated copper grids and incubated for 1 min. The excess solution was removed using filter paper. The sample was stained with 2% (w/v) uranyl acetate (10 μL) solution and imaged on the TEM with an accelerating voltage of 120 kV.

Cryo-EM

100 holey carbon films coated grids (Quantifoil Micro Tools GmbH, 300 mesh, gold) were glow-discharged at 15 mA for 45 s. Subsequently, the sample was prepared using a plunge freezer (Thermo Fisher Vitrobot Mark IV). 3.0 µL samples were loaded onto the grid in a chamber, blotted for 3.5 s, and later dived into liquid ethane for vitrification, followed by relocation into liquid nitrogen. The sample was imaged on a 200 kV Cryo-EM (Thermo Fisher Glacios, objective lens: C-Twin, electron gun: X-FEG, Camera: Ceta, Falcon).

Cryo-EM and image processing for structure analysis

The peptide nanofiber sample was applied to glow-discharged lacey carbon grids and vitrified using a Vitrobot (Thermo Fisher). The grids were imaged on a Titan Krios (300 keV, Thermo Fisher) with a K3 camera (Gatan). 2110 micrographs were collected under the electron-counting mode at 1.087 Å per pixel, using a defocus range of − 1.5 to − 2 μm with ~ 50 e– Å–2 distributed into 40 fractions. Motion correction was done by MotionCor247, and contrast transfer function (CTF) estimations were done in cryoSPARCby patch CTF estimation (default parameters)44. The particles were auto-picked by a ‘filament tracer’ with a shift of ~ 24 pixels. Next, non-peptide junk particles were removed by multiple rounds of reference-free 2D classifications. Particles were kept if they had clear 2D average patterns. The selected particles were used to create an initial model by ‘Helical Refinement’. The possible helical symmetries were calculated based on the initial model, using ‘Symmetry Search Utility’. All the possible symmetries were then tested by trial and error in cryoSPARC until the recognized peptide features, such as the density of side chains, were observed. The resolution of the final reconstruction was estimated by both map:map (0.143) FSC and model:map (0.5) FSC. The final volumes were then sharpened with a negative B factor automatically estimated in cryoSPARC, and the statistics are listed in Supplementary Table 2.

SEM

SEM images were captured on a field emission scanning electron microscope (Hitachi Regulus 8230). Micro-threads with diameters smaller than 5 µm were created by manually stretching a small amount of hydrogel with pipettes. After crystallization, these threads were transferred to an electrically conductive tape-modified specimen holder. For thicker micro-threads (diameters higher than 5 µm), we intercepted crystallized threads drawn by the rheometer after recyclability testing and also transferred them to the conductive tape holder. Before testing by SEM, all samples were coated with 3.3 nm platinum using a high vacuum coating instrument (Leica EM ACE600). During the measurement, a 10 kV accelerating voltage were applied to resolve the high-order structure of the dried YAWF micro-threads. It is worth mentioning that the micro-threads were dry and hard before transferring them to the specimen holder, ensuring that the sample preparation procedure did not impact the structure of the assembly.

AFM

The heights of the YAWF threads were recorded on an environmental atomic force microscopy (Oxford Instruments, Cypher ES). 10 µL of the pre-prepared hydrogel were loaded on a silicon substrate, and then a pipette was used to draw micro-threads from the hydrogel. Here, when the micro-threads attached to the silicon substrate, they were not fully crystallized. After the threads were totally crystallized, the experiment was carried out at room temperature. The AFM images were obtained at 512 pixels × 512 pixels, and the scanning speed was 1 Hz.

DMA

The mechanical property of the coarse micro-threads was measured by using DMA (TA waters, Discovery DMA 850). A uniaxial bench-top tester equipped with a load cell was selected as shown in Supplementary Fig. 94. After this, the instrument was set to floating mode before loading our sample on the load cell. Then 1 µL of the pre-prepared hydrogel was transferred onto the load cell by pipettes for drawing micro-thread. As previously mentioned, the hydrogel was very sticky, so it did not need any glue to fix it on the load cell. A 5 min time period was applied here, for crystallization of the drawn micro-threads. Then different load forces were chosen for different samples, and the constant stretch velocity for every sample was 100 µm min−1. The diameters of the measured micro-threads were determined using an optical microscope after the measurements, which varied between 10 μm and 50 μm for all threads.

FluidFM

The Young’s modulus of the super-thin micro-threads drawn by pipettes were determined by FluidFM (Cytosurge, FluidFM OMNIUM). A 300 nm diameter aperture fluidFM nanopipette was equipped with the instrument whose nominal spring constant was 0.6 N/m, and the nanopipette was filled with 1 µL ultra-pure water. Before attracting the 1 µm diameter polystyrene bead with a 10-mbar force, the position of the laser on the cantilever was adjusted manually. Thereafter, the CCD sensor was adjusted to reach optimal light distribution between the sensor parts automatically. After attaching the bead, the spring constant was re-measured before indenting the micro-thread. Since the threads here are super thin, so some tests were not conducted on the threads. For all these 12 micro-threads: thread 1 (n = 2), thread 2 (n = 2), thread 3 (n = 4), thread 4 (n = 1), thread 5 (n = 1), thread 6 (n = 5), thread 7 (n = 2), thread 8 (n = 7), thread 9 (n = 7), thread 10 (n = 2), thread 11 (n = 3), thread 12 (n = 4).

POM

10 µL of the pre-prepared hydrogel were loaded on a microscope glass slide, and then a pipette was used to draw micro-threads from the hydrogel. Later, the constructed threads were measured on an Oosight imaging system (Hamilton, Lykos & Meta) equipped with polarization optics and a differential interference contrast (DIC) module (Olympus, IX73) in an ambient environment. Images were recorded using an optical microscope (Leica, M205 C POM).

Data availability

The cryo-EM maps have been deposited in the Electron Microscopy Data Bank (EMDB) under accession number EMD-60234, and the associated models have been deposited in the RSCB Protein Data Bank (PDB) under the accession number ID 8ZM0. All the data that support the findings are available within the main text and the Supplementary Information. Source data are provided in this paper.

References

Feng, Z., Zhang, T., Wang, H. & Xu, B. Supramolecular catalysis and dynamic assemblies for medicine. Chem. Soc. Rev. 46, 6470–6479 (2017).

Giuri, D., Marshall, L. J., Wilson, C., Seddon, A. & Adams, D. Understanding gel-to-crystal transitions in supramolecular gels. Soft Matter 17, 7221–7226 (2021).

A. Hill, R. J. et al. Alignment of aromatic peptide tubes in strong magnetic fields. Adv. Mater. 19, 4474–4479 (2007).

Chen, Z. et al. Solvent-free autocatalytic supramolecular polymerization. Nat. Mater. 21, 253–261 (2022).

Christoff-Tempesta, T. et al. Self-assembly of aramid amphiphiles into ultra-stable nanoribbons and aligned nanoribbon threads. Nat. Nanotechnol. 16, 447–454 (2021).

Fu, L. et al. Cartilage-like protein hydrogels engineered via entanglement. Nature 618, 740–747 (2023).

Webber, M. J., Appel, E. A., Meijer, E. W. & Langer, R. Supramolecular biomaterials. Nat. Mater. 15, 13–26 (2016).

Dunn, A. et al. Mechanism of action of insulin. Nature 183, 1123–1124 (1959).

Bentley, G., Dodson, E., Dodson, G. U. Y., Hodgkin, D. & Mercola, D. A. N. Structure of insulin in 4-zinc insulin. Nature 261, 166–168 (1976).

Brown, A. E. X., Litvinov, R. I., Discher, D. E., Purohit, P. K. & Weisel, J. W. Multiscale mechanics of fibrin polymer: Gel stretching with protein unfolding and loss of water. Science 325, 741–744 (2009).

Geng, Y., Kizhakidathazhath, R. & Lagerwall, J. P. F. Robust cholesteric liquid crystal elastomer fibres for mechanochromic textiles. Nat. Mater. 21, 1441–1447 (2022).

Li, J. et al. Spider silk-inspired artificial fibers. Adv. Sci. 9, 2103965 (2022).

Liu, Y. et al. Self-assembled supramolecular nanotube yarn. Adv. Mater. 25, 5875–5879 (2013).

Wu, Y. et al. Bioinspired supramolecular fibers drawn from a multiphase self-assembled hydrogel. Proc. Natl. Acad. Sci. USA 114, 8163–8168 (2017).

Deshmukh, S. A., Solomon, L. A., Kamath, G., Fry, H. C. & Sankaranarayanan, S. K. R. S. Water ordering controls the dynamic equilibrium of micelle–fibre formation in self-assembly of peptide amphiphiles. Nat. Commun. 7, 12367 (2016).

Zhang, J. et al. An all-in-one nanoprinting approach for the synthesis of a nanofilm library for unclonable anti-counterfeiting applications. Nat. Nanotechnol. 18, 1027–1035 (2023).

Thursch, L. J. et al. Influence of central sidechain on self-assembly of glycine-x-glycine peptides. Soft Matter 19, 394–409 (2023).

Freeman, R. et al. Reversible self-assembly of superstructured networks. Science 362, 808–813 (2018).

Yu, Z. et al. Simultaneous covalent and noncovalent hybrid polymerizations. Science 351, 497–502 (2016).

Wu, D. et al. Polymers with controlled assembly and rigidity made with click-functional peptide bundles. Nature 574, 658–662 (2019).

Wang, Q. et al. High-water-content mouldable hydrogels by mixing clay and a dendritic molecular binder. Nature 463, 339–343 (2010).

Cai, Y. et al. Supramolecular “Trojan Horse” for nuclear delivery of dual anticancer drugs. J. Am. Chem. Soc. 139, 2876–2879 (2017).

de Lázaro, I. & Mooney, D. J. Obstacles and opportunities in a forward vision for cancer nanomedicine. Nat. Mater. 20, 1469–1479 (2021).

Li, J. & Mooney, D. J. Designing hydrogels for controlled drug delivery. Nat. Rev. Mater. 1, 16071 (2016).

Guo, J. et al. Cell spheroid creation by transcytotic intercellular gelation. Nat. Nanotechnol. 18, 1094–1104 (2023).

Cheetham, A. G., Chakroun, R. W., Ma, W. & Cui, H. Self-assembling prodrugs. Chem. Soc. Rev. 46, 6638–6663 (2017).

Majumder, P. et al. Surface-fill hydrogel attenuates the oncogenic signature of complex anatomical surface cancer in a single application. Nat. Nanotechnol. 16, 1251–1259 (2021).

Wang, X. & Wang, Q. Enzyme-laden bioactive hydrogel for biocatalytic monitoring and regulation. Acc. Chem. Res. 54, 1274–1287 (2021).

Liu, M. et al. An insulin‐inspired supramolecular hydrogel for prevention of type 1 diabetes. Adv. Sci. 8, 2003599 (2021).

Mahler, A., Reches, M., Rechter, M., Cohen, S. & Gazit, E. Rigid, self-assembled hydrogel composed of a modified aromatic dipeptide. Adv. Mater. 18, 1365–1370 (2006).

Zhang, S. et al. Biomimetic spinning of soft functional fibres via spontaneous phase separation. Nat. Electron. 6, 338–348 (2023).

Zhang, S. et al. A self-assembly pathway to aligned monodomain gels. Nat. Mater. 9, 594–601 (2010).

Zhan, J. et al. Supramolecular silk from a peptide hydrogel. Mater. Chem. Front. 1, 911–915 (2017).

Marshall, L. J. et al. Hierarchical composite self-sorted supramolecular gel noodles. Adv. Mater. 35, 2211277 (2023).

Adler-Abramovich, L. et al. Bioinspired flexible and tough layered peptide crystals. Adv. Mater. 30, 1704551 (2018).

Matsuda, T., Kawakami, R., Namba, R., Nakajima, T. & Gong, J. P. Mechanoresponsive self-growing hydrogels inspired by muscle training. Science 363, 504–508 (2019).

Coin, I., Beyermann, M. & Bienert, M. Solid-phase peptide synthesis: from standard procedures to the synthesis of difficult sequences. Nat. Protoc. 2, 3247–3256 (2007).

Lampel, A. et al. Polymeric peptide pigments with sequence-encoded properties. Science 356, 1064–1068 (2017).

Zhou, J., Du, X., Gao, Y., Shi, J. & Xu, B. Aromatic–aromatic interactions enhance interfiber contacts for enzymatic formation of a spontaneously aligned supramolecular hydrogel. J. Am. Chem. Soc. 136, 2970–2973 (2014).

Yuan, C., Li, Q., Xing, R., Li, J. & Yan, X. Peptide self-assembly through liquid-liquid phase separation. Chem 9, 2425–2445 (2023).

Tantakitti, F. et al. Energy landscapes and functions of supramolecular systems. Nat. Mater. 15, 469–476 (2016).

Boekhoven, J. et al. Dissipative self-assembly of a molecular gelator by using a chemical fuel. Angew. Chem. Int. Ed. 49, 4825–4828 (2010).

Huang, R. et al. Charge screening wormlike micelles affects extensional relaxation time and noodle formation. Chem. Commun. 58, 10388–10391 (2022).

Punjani, A., Rubinstein, J. L., Fleet, D. J. & Brubaker, M. A. cryoSPARC: algorithms for rapid unsupervised cryo-EM structure determination. Nat. Methods 14, 290–296 (2017).

Hartgerink, J. D., Beniash, E. & Stupp, S. I. Self-assembly and mineralization of peptide-amphiphile nanofibers. Science 294, 1684–1688 (2001).

Norman, M. D. A., Ferreira, S. A., Jowett, G. M., Bozec, L. & Gentleman, E. Measuring the elastic modulus of soft culture surfaces and three-dimensional hydrogels using atomic force microscopy. Nat. Protoc. 16, 2418–2449 (2021).

Zheng, S. Q. et al. MotionCor2: anisotropic correction of beam-induced motion for improved cryo-electron microscopy. Nat. Methods 14, 331–332 (2017).

Acknowledgements

This project was supported by the National Key Research and Development Program of China (2022YFB3808300 to H.M.W.), Zhejiang Provincial Natural Science Foundation of China under Grant No XHD23C1001 (to H.M.W.), and the National Natural Science Foundation of China (82272145 to H.M.W.), and the Foundation of Westlake University. We thank the Instrumentation and Service Center for Molecular Sciences, Instrumentation and Service Center for Physical Sciences, General Equipment Core Facility, Biomedical Research Core Facilities, and Laboratory Animal Resource Center at Westlake University for their assistance with measurements.

Author information

Authors and Affiliations

Contributions

H.M.W. conceptually designed the strategy for this study, provided intellectual input, supervised the studies, and revised the manuscript. Y.F. designed the study and performed most of the experiments. J.S. and D.M. performed the cryo-EM experiments. J.L. characterized some peptides. H.M.W. and Y.F. wrote the manuscript with contributions from all authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Qigang Wang and the other anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Fang, Y., Shi, J., Liang, J. et al. Water-regulated viscosity-plasticity phase transitions in a peptide self-assembled muscle-like hydrogel. Nat Commun 16, 1058 (2025). https://doi.org/10.1038/s41467-025-56415-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-56415-7

This article is cited by

-

Robust reprocessable silicone-based adhesives via noncovalent cross-linking

Journal of Polymer Research (2025)