Abstract

Rechargeable magnesium batteries (RMBs) have emerged as a highly promising post-lithium battery systems owing to their high safety, the abundant Magnesium (Mg) resources, and superior energy density. Nevertheless, the sluggish kinetics has severely limited the performance of RMBs. Here, we propose an in-situ electrochemical activation strategy for improving the Mg-ion storage kinetics. We reveal that the activation strategy can effectively optimize surface composition of cathode that favors Mg-ion transport. Cooperating with lattice modifications, the CuSe | |Mg batteries exhibit a specific capacity around 160 mAh/g after 400 cycles with a capacity retention of over 91% at the specific current of 400 mA/g. Of significant note is the slight decay in specific capacity from 205 to 141 mAh/g has been observed with an increase in specific current from 20 to 1000 mA/g. This strategy provides insights into accelerating Mg-ion storage kinetics, achieving a promising performance of RMBs especially at high specific current.

Similar content being viewed by others

Introduction

The rapid development of large-scale energy storage power stations and electric vehicles, driven by global low-carbon and environmental protection imperatives, has placed heightened demands on battery systems1,2. While lithium-ion batteries (LIBs) have historically dominated due to their high energy density and extended cycle life, the scarcity of lithium resources has spurred exploration into post-lithium battery systems3,4,5,6. Among these, RMBs have garnered significant interest for their distinct advantages, such as the earth’s abundant reserves of Mg, the low price of primary Mg, and the superior safety and capacity characteristics of RMBs7,8. However, progress in RMBs development remains constrained by the absence of high-performance cathode materials9,10,11,12. Therefore, investigating the Mg-ion storage mechanism and improving the performance of Mg-ion storage cathodes are highly needed.

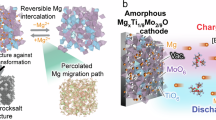

The large charge density of Mg2+ raised from its divalent nature and small ionic radius leads to the slow diffusion of Mg2+ in the solid phase, limiting the intercalation of Mg2+ in cathodes13. The slow diffusion contributes to large polarization and voltage lag in RMBs4. This sluggish Mg-ion storage kinetics not only limits charge-discharge rate but also accelerates capacity decay of the batteries. According to Pearson’s hard and soft acids and bases theory, the hard acid Mg2+ binds more strongly to O2−, which is a hard base, compared to soft chalcogen anions (S2− or Se2−)14. Consequently, the weak interaction between Mg2+ and chalcogen ions lowers the barrier for Mg2+ diffusion, producing rapid Mg-ion storage kinetics. While conversion-type metal chalcogenide cathodes have been extensively studied because of their high theoretical specific capacity compared to intercalation-type cathodes15,16,17, the Mg-ion storage capability still fall short of meeting the demands for fast kinetics, especially at high specific current9,18.

Tremendous methods have been implemented to improve the kinetics of Mg-ion storage, including strategies such as reducing the particle size, expanding the ion diffusion channel, and optimizing the solvation structure19,20,21,22,23,24,25,26,27,28,29,30. Nanoarchitecture cathodes can shorten the diffusion pathways and promote the electron and ion transport by increasing the electrode-electrolyte interface through a large specific surface area20,21,28. Moreover, expanding the interlayer spacing by introducing large molecules has proven effective for the intercalation-type cathodes21,22,24. The modification of the solvation structure of Mg2+ through electrolyte design significantly accelerates the charge transfer of the cathodes6,25,26,27,28,29. In fact, the typical electrode process is a tandem reaction that involves several elementary steps31, where Mg2+ in electrolyte first desolvates into independent Mg2+, followed by migrating to the interfacial layer, and finally inserts into the cathodes via charge transfer32,33. Consequently, the interfacial kinetics associated with the second step also significantly impacts the electrochemical performance of RMBs. While the recent advancements primarily focused on the structural impact of CuSe cathode materials on their electrochemical performance16,34,35, the contribution of CuSe cathode-electrolyte interface to the kinetics of RMBs is usually overlooked. Unlike the mostly used methods of introducing electrolyte additives that mainly affect the anode surface29,36,37, a strategy that effectively modifies the cathode interface is still lacking. The underlying mechanism that regulates the interfacial kinetics of cathodes for RMBs remain ambiguous. Therefore, exploring an effective method for improving the interfacial kinetics and reaction kinetics of the metal chalcogenides conversion-type cathode is essential to achieve high-performing RMBs.

Herein, we propose an in-situ electrochemical activation (ISEA) method, in which the batteries are charged to a cut-off capacity of 300 mAh/g in the first cycle. Compared with simple charge-discharge (SIM) method, ISEA significantly improves Mg-ion storage kinetics and cycling stability of the CuSe cathodes. Combining with a series of characterizations, we reveal that the formation of fluorine-containing on the surface of CuSe cathode through ISEA strategy contributes to rapid kinetics and high reversibility. Besides, the density functional theory (DFT) calculations indicate the expansion of (100) planes also accelerates the reaction kinetics of CuSe cathodes. As a result, the post-ISEA battery exhibits a reversible capacity of 170 mAh/g at the specific current of 100 mA/g, and maintains a capacity of around 160 mAh/g more than 400 cycles at a high specific current of 400 mA/g with a capacity retention of over 91%. Even when the specific current increases from 20 to 1000 mA/g, the specific capacity only experiences a moderate decrease of 31%. The capacity recovers to over 200 mAh/g upon reducing the specific current again, indicating a remarkable rate performance of the RMB.

Results

CuSe nanosheets with a hexagonal phase are synthesized via a colloidal approach reported previously with minor modifications38. As shown in Fig. 1a, X-ray diffraction (XRD) pattern of as-synthesized nanosheets matched well with hexagonal klockmannite CuSe phase (JCPDS No. 34-0171), consistent with the previous report34,38. In the Raman spectra (Fig. 1b and Supplementary Fig. 2), the strong peak appearing at around 260 cm–1 is attributed to the stretching mode of Se-Se (Se22–) bond, with an overtone peak observed at approximately 518 cm–1 (Fig. 1b and Supplementary Fig. 2)39,40. The CuSe cathodes are analyzed by X-ray photoelectron spectroscopy (XPS) to confirm the oxidation states (Fig. 1c, Supplementary Figs. 3 and 4). In Se 3 d spectrum, the characteristic peaks located at 55.4 eV and 56.3 eV correspond to Se22–, while the characteristic peaks located at 54.3 eV and 55.1 eV are attributed to Se2− 41. For Cu 2p spectrum, the peaks at 932.6 and 952.4 eV are ascribed to Cu 2p3/2 and Cu 2p1/2, suggesting the existence of Cu+. The peak observed in the Cu LMM spectrum (Supplementary Fig. 4) is consistent with the literature values of Cu+ and Cu2+ with a modified Auger parameter of 1850.4 eV42,43,44. The XPS results indicate the (Cu2)2+(Cu)2+(Se2)2–(Se)2– model of the as-synthesized CuSe nanosheets, consistent with (4/3)+ balance state of Cu as previously reported45,46,47. Scanning electron microscopy (SEM) images in Fig. 1d and Supplementary Fig. 5 reveal the hexagonal or triangular shape of 2D CuSe nanosheets, with the edge lengths ranging from around 600 nm to 1.8 μm. High-resolution TEM (HRTEM) image and selected area electron diffraction (SAED) pattern of a typical CuSe nanosheet manifested a klockmannite structure, with an observed interplanar spacing of 0.197 nm that corresponds to (110) planes (Fig. 1e, f)48. The low contrast of CuSe in TEM images indicates that the hexagonal nanosheets are quite thin. The corresponding elemental maps and quantitative energy dispersive X-ray spectroscopy (EDS) results confirm the colocation of Cu and Se signals with an atomic ratio of nearly 1: 1 (Fig. 1g–i, Supplementary Fig. 6 and Supplementary Table 1). The CuSe cathodes also exhibit a uniform distribution of Cu and Se elements in Supplementary Fig. 7.

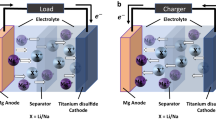

Two charge-discharge strategies have been employed and compared in this study. The SIM approach uses a cut-off voltage for both charge and discharge, as illustrated in Fig. 2a. In the SIM method, the discharge and charge cut-off voltages in all cycles remains constant at 0.4 V and 2.0 V, respectively. The ISEA approach is illustrated in Fig. 2b. In the ISEA method, the charge mode during the first cycle involves a capacity cut-off. To ensure the theoretical capacity (376 mAh/g) is not exceeded and avoid electrolyte decomposition, the cut-off capacity for charge is set at 300 mAh/g. The Coulombic efficiency (CE) observed in the first cycle of ISEA method is higher than that of the SIM method. Subsequent cycles in the ISEA method employed a voltage cut-off method during the charge-discharge process, and the cut-off voltages for discharge and charge set at 0.4 V and 2.0 V, respectively.

Schematic illustrations of (a) SIM and (b) ISEA methods. In-situ XRD patterns of CuSe cathode treated with (c) SIM and (e) ISEA methods, with the corresponding discharge-charge curves in (d) and (f), respectively. g STEM-HAADF image and h HRTEM image with elemental maps of Mg, Cl, and F of CuSe cathode after the first cycle of ISEA method. i In-situ Raman spectra of CuSe cathode treated with ISEA method during the second cycle with the corresponding discharge-charge curve in (j). XPS depth profile for (k) C 1 s, (l) F 1 s of CuSe cathode cycled with SIM method, and (m) C 1 s, (n) F 1 s of CuSe cathode cycled with ISEA method. Scale bars: (g) 1 nm, (h) 20 nm.

We first investigated the electrolyte after the first cycle of the ISEA method. Mg(TFSI)2 + MgCl2/DME electrolytes were used in this work, denoting as TFSI electrolyte. The LSV (Linear sweep voltammetry) curve of SS-Mg batteries in Supplementary Fig. 8 indicates that the electrolyte does not decompose at around 3.0 V vs. Mg2+/Mg. Nuclear magnetic resonance (NMR) spectra and Fourier transform infrared spectroscopy (FTIR) confirm that the electrolyte does not decompose violently after the first cycle of the ISEA method (Supplementary Figs. 9 and 10)25,49. The chemical shift of peaks in the NMR spectra is consistent with the previous report on TFSI electrolyte, without new peak appearing after ISEA49. Similarly, the FTIR spectra of the electrolytes are in line with the previous reports, with no shifting of peaks corresponding to DME and TFSI– after charging to 300 mAh/g in the first cycle25.

The phase evolution of CuSe cathode is analyzed by in-situ XRD pattern (Fig. 2c–f and Supplementary Fig. 1). Cu and MgSe are formed through a series of intermediates (Cu3Se2 JCPDS 47–1745, Cu2Se JCPDS 27–1131) during the discharge process of the CuSe cathode in the first cycle. The characteristic peaks of CuSe (30.4°, 31.1°, 50.0°) gradually diminish during the discharge of the first cycle disappearing after reaching the first platform at around 1.0 V. Concurrently, the intensity of the characteristic peaks for MgSe (JCPDS 18-0777, 47.0°) and Cu3Se2 (47.6°) gradually increases. At the second platform (around 0.8 V), the characteristic peaks of MgSe continue increasing while those of Cu3Se2 gradually disappear. Meanwhile, the characteristic peaks of Cu2Se (25.9°) emerged, with their intensity initially increasing, and then decreasing. A characteristic peak of Cu at 43.3° appears at the end of the discharge stage. Based on the above in-situ XRD analyses, the typical cathode conversion reactions of CuSe during the discharge process can be expressed by the Eqs. (1–3).

The phase evolution during the charge process is the reverse of the discharge process. For SIM method, the characteristic peaks of MgSe still exist at the end of the charge process in the first cycle, where the characteristic peaks of CuSe are not obvious, indicating an incompletely reversible electrode reaction. Therefore, the discharge capacity of the second cycle is significantly reduced. On the contrary, for ISEA method, the stronger signals of CuSe and near absence of characteristic peaks of MgSe after the first cycle manifest a more reversible reaction. We note that the CuSe peaks (30.4° and 31.1°) in the in-situ XRD patterns at the charging states appear to be obscure, which could be attributed to the particle morphology evolution. The existence of CuSe phase is also evidenced by the microscopic imaging (Fig. 2g, Supplementary Fig. 13). In addition to in-situ XRD measurements, XPS spectra, microscopic imaging and elemental maps also demonstrate the high reversibility of the post-ISEA CuSe/TFSI/Mg batteries (Supplementary Figs. 11–14). Notably, the HAADF-STEM image reveals that the hexagonal arrangements of Cu and Se atoms in CuSe nanosheets are preserved after the first cycle (Fig. 2g). The HRTEM image of Fig. 2h shows a hexagonal morphology of CuSe. The corresponding elemental maps suggest that the Mg content (5.9 at. %) in the post-ISEA cathode is lower compared to the cathode cycled via the SIM method (15.8 at. %), indicating a higher reversibility of cathode via ISEA method (Fig. 2h, Supplementary Fig. 12 and Supplementary Table 2). The cathode of ISEA-treated battery retains its single crystalline of CuSe after cycling, as manifested by the SAED pattern in Supplementary Fig. 13. However, the complex diffraction spots in SAED pattern of the cathode in SIM-treated battery indicate the coexistence of different structures, likely attributed to more irreversible electrochemical reactions. In-situ Raman spectroscopy of CuSe cathode (Fig. 2i) at the second cycle is employed to confirm the phase evolution of post-ISEA cathode. The Raman peak of the post-ISEA cathode locates at 260 cm−1 corresponds to the Se–Se bond stretching vibration of Se2 units, in a good agreement with the previous literatures39,40. During the discharge process, this characteristic peak gradually weakens and nearly disappears by the end of the first discharge platform. For the charging process, the characteristic peak reappears and gradually intensifies. The position and intensity of the peak persist after the second cycle. All these observations reveal that the CuSe cathode after ISEA treatment exhibits improved reversibility, which is conducive to the release of capacity in subsequent cycles.

The surface composition and morphology of the cathode is improved by ISEA strategy. The surface composition of CuSe cathode after 5 cycles of ISEA and SIM methods is analyzed by XPS depth profiling with etching time of 0 s, 100 s, and 300 s (Fig. 2k–n). The comparable electrolyte decomposition products on the surface of the CuSe cathodes after SIM and ISEA processes are observed, although their contents differ. In general, the outermost layer consists of electrolyte decomposition products (-C-H, -C = O, -C-F) and salt adsorption products (−CF3)25,50. The peaks at 284.9 eV and 286.5 eV correspond to -C-H and -C = O, respectively, while peaks observed at 292.4 eV and 688.9 eV are assigned to -CF3 and -C-F. These results indicate that the outermost layer of CuSe cathode after both processes contain minimal salt decomposition products. After 100 s etching, the characteristic peaks at 686.8 eV, which is the salt decomposition product of MgF2, appears in the F 1 s spectrum. The intensity of the peak decreases progressively with increasing etching time, along with the decreasing of the intensity of the characteristic peak of -C-F. After 300 s etching, the peak intensity of MgF2 is higher than that of -C-F, indicating a higher content of MgF2. This trend is consistent in both CuSe cathodes after SIM and ISEA processes, with the relative content of MgF2 being higher in the post-ISEA cathode. MgF2 has been shown to facilitate the Mg2+ transport between the electrode and electrolyte, thus improving the electrochemical performance36,51. Based on the above results, we propose that the surface on the CuSe cathode is composed of an outer organic product layer and an inner layer with a high content of inorganic MgF2. The element content of Cl at CuSe cathode by ISEA and SIM methods are 0.87 at. % and 1.11 at. %, respectively, indicating a similar level of electrolyte decomposition (Supplementary Fig. 14). In addition, the Mg content of CuSe cathode (2.07 at. %) after SIM treatment is higher than that of the ISEA method (1.14 at. %), consistent with the in-situ XRD results, which in turn, highlights the superiority of the ISEA method. This can be further supported by the morphology preservation of the cathode after ISEA treatment. As shown in Supplementary Fig. 15, it is apparent that the surface of the CuSe cathode in the SIM-treated battery exhibits pronounced unevenness and numerous cracks, which may impede electron transport and further cause sluggish kinetics. In contrast, the cathode surface of ISEA-treated battery appears smoother and exhibits fewer cracks. For anode side, it is apparent that post-SIM batteries display visible holes on the Mg anode surface (Supplementary Fig. 16), along with irregularly curly flaky deposits, potentially leading to short circuits within the batteries. In addition, the corresponding quantitative SEM-EDX results reveal less Cu element on Mg anode of ISEA-treated batteries than on SIM batteries (Supplementary Fig. 17), implying less Cu dissolution from the CuSe cathode.

In order to analyze the Mg-ion storage kinetics of CuSe cathode, galvanostatic intermittent titration technique (GITT), electrochemical impedance spectroscopy (EIS) and cyclic voltammetry (CV) tests were carried out, and the results are shown in Fig. 3. The diffusion coefficient (D) and IR drop of different state of charge (SOC) in the second cycle are obtained by GITT tests (Fig. 3a, b and Supplementary Fig. 18). The D values of CuSe/TFSI/Mg batteries treated with ISEA method during discharge process ranges from around 2.4 × 10−13 to 1.8 × 10−8 cm2/s, which are higher than that of batteries treated with SIM method (7.6 × 10−16 ~ 4.2 × 10−9 cm2/s). Similar observations occur during the charge process (Supplementary Fig. 19). The high D value indicates a rapid Mg-ion storage kinetics of the post-ISEA CuSe cathode. The IR drop describes a voltage drop due to the current flowing across the internal resistance of the battery52. The IR drop, which is closely related to ion diffusion kinetics, has been often overlooked and underestimated in previous studies53,54. During discharge process, the IR drop of post-ISEA batteries is around 0.1 V, which is more than 2 times lower than that in the post-SIM batteries (0.20 ~ 0.35 V). Similar observations occur during the charge process (Fig. 3b and Supplementary Fig. 20). Furthermore, the EIS results of the cycled CuSe/TFSI/Mg batteries show a significantly lower interfacial impedance and charge transfer impedance during both the charge and discharge stages in the post-ISEA battery compared to those for SIM-treated method (Fig. 3c), in line with the GITT results. CV tests were performed to further analyze the Mg-ion storage kinetics (Fig. 3d and Supplementary Fig. 21). The CuSe/TFSI/Mg batteries were discharged and charged for one cycle before the CV tests. During the first cycle in CV tests, two pairs of the redox peaks are observed 1.14/1.42 V and 0.85/1.88 V in post-ISEA batteries. The decreased voltage gap of the redox peaks upon cycling suggests reduced polarization and accelerated kinetics. By contrast, the polarization of the post-SIM CuSe/TFSI/Mg batteries is slightly increased and the peak currents are greatly decreased (Supplementary Fig. 21). Compared to the SIM method, the sharp and intense redox peaks in the post-ISEA CuSe/TFSI/Mg batteries manifest the significantly improved Mg-ion storage kinetics, which can be attributed to the high MgF2 content on the surface of CuSe cathodes (Fig. 2k–n). In addition, the CV curves of different scan rates also indicating the enhanced kinetics of ISEA-treated batteries (Supplementary Fig. 22).

a Diffusion coefficient and (b) IR drop of CuSe/TFSI/Mg batteries in the second cycle treated with different methods. c Comparison of EIS results of SIM and ISEA methods in the first cycle. d CV curves of post-ISEA battery. HRTEM images of CuSe cathodes cycled with (e) ISEA and (f) SIM methods. The blue balls represent the Cu atoms and is used to illustrate the change in lattice spacing of the (100) crystal planes. The Se atoms are omitted for presentation clarity. Scale bars: 5 nm, insets: 2 1/nm.

In addition to the contribution of interface, we propose that the Mg storage kinetics can be also regulated by the change in the lattice spacing of CuSe during the ISEA process. As shown in Fig. 3e,f and Supplementary Fig. 23, after the first cycle, the lattice spacing of (100) crystal planes of post-ISEA CuSe cathodes expand to 0.362 nm, compared to that of the CuSe cathodes after SIM treatment. The lattice variation has been shown to influence the adsorption, diffusion and incorporation of Mg2+, thereby affecting the Mg-ion storage kinetics55. DFT calculations were carried out to establish the relationship between the lattice spacing and the Mg-ion storage kinetics in the CuSe cathode (Fig. 4, Supplementary Table 3 and Supplementary Data 1). The surface energies (σ) of the typical (001), (100), and (110) crystal planes in the CuSe structure were calculated. The results show that the (001) crystal planes exhibit the lowest surface energy (0.39 J/m2), indicating their intrinsic stability in the CuSe unit cell. In contrast, the growth of (100) and (110) crystal planes is energetically favorable, thus producing a sheet-like morphology during the synthesis. To theoretically investigate the Mg-ion storage kinetics, we calculated the adsorption energy (Eads) of Mg and the formation energy (Ef) for the reaction of Mg-replace-Cu on the different crystal planes of CuSe. The corresponding structural models are shown in Fig. 4c–j. Among these planes, the (100) crystal planes possess the lowest Eads for Mg (Fig. 4b), indicating easier Mg adsorption on the (100) crystal planes of CuSe. The energy diagrams show that the subsequent Mg substitution step is more favorable on the (100) planes, while the positive values of Ef on other crystal planes indicate Mg substitution reactions are endothermic. After ISEA process, the values of Eads and Ef on (100) planes further reduce to −5.31 eV and −1.13 eV, respectively. This reduction suggests that the lattice expansion can benefit in the adsorption and substitution of Mg on (100) planes, thereby improving the Mg-ion storage kinetics of the CuSe/TFSI/Mg batteries.

DFT calculations of (a) the surface energies σ of (001), (100), and (110) planes of CuSe. b Energy diagrams for the adsorption energy Eads of Mg and the formation energy Ef for the reaction of Mg-replace-Cu on the different crystal planes of CuSe, with the corresponding structural models shown in (c–j). The expanded (100) planes denote as (100)*. The blue, green, and orange balls represent the Cu, Se, and Mg atoms, respectively.

The electrochemical performance of RMBs is significantly improved by employing ISEA treatment, especially in the aspects of cycling stability and rate performance (Fig. 5). The batteries are initially discharge-charged for 10 cycles at a low specific current of 20 mA/g. Figure 5a shows the cycling stability of the CuSe/TFSI/Mg batteries at a specific current of 100 mA/g. For SIM method, the specific capacity of the battery gradually decreases after about 90 cycles along with the decrease in CE. The battery finally fails after around 100 cycles with a discharge specific capacity of 152 mAh/g. By contrast, the battery subjected to ISEA treatment shows superior cycling stability at the same specific current. The initial discharge specific capacity is about 330 mAh/g. The battery exhibits a stable cycling with a specific discharge capacity up to 156 mAh/g for more than 250 cycles with a high CE. The corresponding charge-discharge profiles are provided in Fig. 5b and Supplementary Fig. 24. Two discharge platforms are observed in the first cycle at approximately 1.20 V and 0.85 V, respectively. In the second cycle, these two platforms slightly increase to 1.30 V and 0.95 V, in line with the CV curves (Fig. 3d). The rate performance of CuSe/TFSI/Mg batteries is evaluated in the range of specific current from 20 to 1000 mA/g.

a Cycling performance of CuSe/TFSI/Mg batteries with different ISEA and SIM methods at the specific current of 100 mA/g. b Charge-discharge curves of the post-ISEA CuSe/TFSI/Mg battery. The 1st and the 2nd cycle are at the specific current of 20 mA/g and the 50th cycle is at the specific current of 100 mA/g. c Rate performance of the post-ISEA CuSe/TFSI/Mg battery at the specific current ranges from 20 to 1000 mA/g. d Comparison of the rate performance of the previously reported Mg-ion storage cathodes with the post-ISEA CuSe cathode14,19,20,22,62,63,64,65,66,67,68,69,70,71. e Cycling performance of the post-ISEA CuSe/TFSI/Mg battery at the specific current of 400 mA/g. f Comparison of the electrochemical performances of previously reported Mg-ion storage cathodes with post-ISEA CuSe cathode19,22,23,63,66,72,73,74,75,76.

The battery after ISEA process also exhibits excellent rate performance (Fig. 5c). At the specific current of 20 mA/g, the average specific capacity reaches about 205 mAh/g. The battery still delivers a capacity of 141 mAh/g when operating at specific current as high as 1000 mA/g. When the specific current reduces from 1000 mA/g to 100 mA/g, the specific capacity of the battery can recover to over 200 mAh/g, surpassing the rate performance of state-of-the-art RMB cathodes reported (Fig. 5d). By contrast, the post-SIM battery displays inferior rate performance (Supplementary Fig. 25). The long-term stability at high specific current is one of the important descriptors of Mg-ion storage kinetics. As shown in Fig. 5e, CuSe/TFSI/Mg battery treated with ISEA achieves a long-life and stable cycling at the high specific current of 400 mA/g. Even after 400 cycles, the battery retains around 160 mAh/g of specific capacity with a capacity retention of 91%. By summarizing the performances including the specific capacity, specific current and cycling life, we highlight the superiority of post-ISEA CuSe cathodes compared with the previously reported cathodes of RMBs (Fig. 5f).

Discussion

In summary, CuSe nanosheets with a hexagonal phase are synthesized using a colloidal method. We demonstrate a ISEA approach to improve Mg-ion storage kinetics, as manifested by an increased diffusion coefficient and reduced interfacial impedance. Through the elaborate analyses of CuSe cathode evolution, we reveal that the ISEA treatment produces a more reversible crystal structure of CuSe and increased surface MgF2 content that favors Mg2+ transport, accelerating Mg-ion storage kinetics. By correlating the microscopic imaging and DFT calculations, we illustrate that the lattice expansion of the (100) crystal plane of post-ISEA CuSe cathode can promote the reaction kinetics. Consequently, the post-ISEA CuSe/TFSI/Mg battery archives promising cycling and rate performance. Notably, the post-ISEA battery attains a high specific capacity around 160 mAh/g over 400 cycles at the specific current of 400 mA/g. Our study not only offers a unique strategy to improve the Mg-ion storage kinetics but also provides more insights into the development of high-performance cathodes for RMBs.

Methods

Synthesis of the CuSe nanosheets

Chemicals

Copper chloride dehydrate (CuCl2·2H2O, ≥ 99.0%, Sigma-Aldrich), hydroxylamine hydrochloride (NH2OH·HCl, 99%, Sigma-Aldrich), selenium powder (−100 mesh, 99.99%, Sigma-Aldrich), oleylamine (OM, 70%, Sigma-Aldrich), 1-dodecanethiol (DDT, ≥ 98%, Sigma-Aldrich), toluene (99.8%, Sigma-Aldrich) and methanol (AR).

Synthesis method of CuSe nanosheets

Synthesis of the CuSe nanosheets was adapted from a previous reported method with modifications38,56. In a typical reaction, CuCl2·2H2O (1 mmol) was added to OM (20 mL) in a three-necked flask at room temperature. The slurry was heated to 80 °C with magnetic stirring for 15 min to obtain a deep blue solution. After added NH2OH·HCl (2 mmol), the solution was evacuated at 80 °C for about 5 min to remove the water and oxygen. The transparent yellow solution was obtained before the flask was purged with nitrogen. In a separate vial, the Se precursor was prepared by sonication of Se powder (2 mmol) in the mixture of OM (2 mL) and DDT (1 mL) at room temperature. The Se precursor solution was swiftly injected to the reaction solution, and the mixture was kept at 80 °C for 3 h. After air-cooled to room temperature, the products were collected by centrifugation at 2655 × g for 5 min. In order to completely remove the residual Se precursor and other unreacted impurities, the precipitate was first washed by the mixture of 6 mL OM and 0.4 mL DDT for one time, followed by the mixture of toluene and methanol for two times.

Structural characterizations

XRD

The crystallographic structure of cathode materials was investigated by ex-situ XRD (D8 Advance from Bruker) equipped with a Cu Kα radiation source (λ = 1.54 Å). The ex-situ XRD patterns were collected at 2θ between 10° and 80° every 30 min.

The cathode evolution was detected by in-situ XRD (D8 Advance from Bruker) equipped with a Cu Kα radiation source (λ = 1.54 Å). The schematic diagram of the in-situ XRD test device is shown in Supplementary Fig. 1. A customized CR 2032 button cell is equipped with an Al foil and polyimide tape. The hole diameter of the positive case is about 8 mm. The polyimide tape was used to separate the Al foil and electrolyte to avoid corrosion issues. The in-situ XRD patterns were collected at 2θ between 15° and 65° every 24 min.

SEM and TEM

The morphology and element distribution of the materials were acquired by scanning electron microscopy (SEM; Apreo S, Thermo Scientific) operating at 5 kV, energy dispersive X-ray spectroscopy (EDS) and high-resolution transmission electron microscope (HRTEM). The atomic imaging of the cathodes after cycling was collected by using high angle annular dark field scanning transmission electron microscopy (HAADF-STEM).

XPS

The valence states and depth distribution of elements on the surface of the CuSe cathodes were detected by X-ray photoelectron spectroscopy (XPS, Nexsa G2, Thermo Scientific). In order to eliminate the influence of surface impurities, the near-surface state was studied by XPS depth profile, and the etching time was set to be 0 s, 100 s and 300 s.

Raman spectra

Raman spectra tests were conducted on an inVia Qontor Raman spectrometer equipped with 532 nm filter at room temperature. In-situ Raman measurements were carried out with an in-situ Raman spectra electrochemical cell.

FTIR

The decomposition of the electrolyte was analyzed by Fourier transform infrared spectrometer (FTIR). The FTIR measurements were conducted on a Nicolet 6700 FTIR, Thermo Scientific.

NMR

The decomposition of the electrolyte was also measured by nuclear magnetic resonance (NMR). DMSO-d6 solvent was mixed the electrolyte samples. 1H NMR and 13C NMR spectra were collected to monitor the possible change in the electrolytes before and after cycling.

Density functional theory (DFT) calculations

The DFT calculations were conducted using the projected augmented wave (PAW) method57 as implemented based on the Vienna ab initio simulation package (VASP)58. To characterize the exchange and correlation effects, the Perdew-Burke-Ernzerhof (PBE) functional was chosen59. The plane-wave cut-off energy was set to 400 eV. The energy and force convergence criteria of the self-consistent iteration were set to 10–5 eV and 0.02 eV Å–1, respectively. A vacuum space of 15 Å was included in the z-direction to eliminate interactions between neighboring slabs. The k-point sampling was conducted using a Monkhorst-Pack grid of 2 × 2 × 1. Additionally, the DFT-D3 approach was implemented to incorporate van der Waals (vdW) interactions60. The (001), (100), and (110) surfaces of CuSe were modeled by using 3 × 3, 3 × 1, and 1 × 2 slabs, respectively. The bottom two atomic layers of CuSe were fixed, while the remaining atoms were allowed to fully relax.

-

i.

The surface energies (σ) of the reactive intermediates were calculated by σ = (Esub – n*Ebulk)/2 A, where Esub is the total energy of the slab model of the surface. Ebulk represents the average energy of a single atom in bulk, n is the number of atoms in the slab model. A is the area of the surface. 1 eV/Å2 = 16.02 J/m2 61.

-

ii.

The formation energies (Ef) of the Mg-CuSe systems were calculated by Ef = EMg-CuSe + ECu – ECuSe – EMg, where EMg-CuSe describes the total energies of the CuSe unit cell with a Cu atom replaced by a Mg atom. ECu, EMg and ECuSe are the energies of the single Cu and Mg atoms, and a CuSe unit cell, respectively55.

-

iii.

The adsorption energies (Eads) were calculated by Eads = E*Mg – EMg – Esub, where EMg and E*Mg represent the energies before and after the adsorption of Mg atom on the substrate, respectively. Esub is the energy of pristine surface of CuSe34.

Electrochemical measurements

The electrolyte was prepared in an Ar-filled (H2O < 0.01 ppm, O2 < 0.01 ppm) glovebox. 0.5 mmol magnesium bis(trifluoromethylsulfonyl)imide [Mg(TFSI)2] and 1 mmol MgCl2 were dissolved in 1 mL ethylene glycol dimethyl ether (DME), denoting as TFSI electrolyte.

The CuSe cathodes were made by the mixture of CuSe powder, Ketjenblack and polytetrafluoroethylene (PTFE) with a mass ratio of 6:2:2. CuSe powder and Ketjenblack were mixed in a mortar and ground for 30 min. The PTFE dispersion (10 wt.%) was then added into the mortar and ground for another 10 min. Finally, the mixture was rolled into films and stamped into circular sheets with a diameter of 10 mm. The cathodes were dried in a vacuum oven at 60 °C for 18 h. The loading of the active material of CuSe was 1.5 ~ 2.5 mg and the thickness was around 50 μm.

Mg metal circular plates with a diameter of 14 mm and thickness of 0.2 mm were used as anodes. The Mg anodes were polished with sandpaper in an Ar-filled (H2O < 0.01 ppm, O2 < 0.01 ppm) glovebox to remove the oxide layer on the surface before assembly. The polished anodes were rinsed three times with DME to remove residual Mg powder on the surface.

The electrochemical performance was tested by LAND test system (CT3002A) with CR2032 coin cells assembled in an Ar-filled (H2O < 0.01 ppm, O2 < 0.01 ppm) glovebox. The glass fibers (Whatman GF/D, thickness of 675 μm, diameter of 16 mm) were used as separators. All of the electrochemical tests were carried out at the room temperature. When testing the cycle performance of the battery at high specific current (100 mA/g and 400 mA/g), the battery was first cycled 10 times at the specific current of 20 mA/g. The cycling and rate performances of the full batteries were tested in the voltage range of 0.4 − 2.0 V at different charge and discharge specific current. The first cycle of the ISEA-treated battery is an exception, with a charge cut-off capacity of 300 mAh/g. Cyclic voltammetry (CV) curves were obtained at an electrochemical workstation (VMP-300, Bio-Logic) with the scanning rate of 0.05 mV s−1 at the potential range of 0.4 V to 2.0 V vs. Mg2+/Mg. Potentiostatic electrochemical impedance spectroscopy (PEIS) was carried out at room temperature over the frequency range from 1 MHz to 10 mHz by applying a sine wave with an amplitude of 10 mV.

Data availability

All data supporting the findings of this study are available within the article and its Supplementary Information files. Source data are provided with this paper.

References

Yoo, H. D. et al. Mg rechargeable batteries: an on-going challenge. Energy Environ. Sci. 6, 2265–2279 (2013).

Xu, K. Electrolytes and interphases in li-ion batteries and beyond. Chem. Rev. 114, 11503–11618 (2014).

Ruan, J. F. et al. Enhancing the whole migration kinetics of Na+ in the anode side for advanced ultralow temperature sodium-ion hybrid capacitor. Adv. Energy Mater. 13, 2301509 (2023).

Liang, Y., Dong, H., Aurbach, D. & Yao, Y. Current status and future directions of multivalent metal-ion batteries. Nat. Energy 5, 646–656 (2020).

Shah, R., Mittal, V., Matsil, E., Rosenkranz, A., Magnesium-ion batteries for electric vehicles: Current trends and future perspectives. Adv. Mech. Eng. 13, (2021).

Leong, K. W. et al. Next-generation magnesium-ion batteries: The quasi-solid-state approach to multivalent metal ion storage. Sci. Adv. 9, eadh1181 (2023).

Yang, Y. et al. Research advances of magnesium and magnesium alloys worldwide in 2022. J. Magnes. Alloy. 11, 2611–2654 (2023).

Aurbach, D. et al. Prototype systems for rechargeable magnesium batteries. Nature 407, 724–727 (2000).

Mohtadi, R., Tutusaus, O., Arthur, T. S., Zhao-Karger, Z. & Fichtner, M. The metamorphosis of rechargeable magnesium batteries. Joule 5, 581–617 (2021).

Li, Z. Y., Häcker, J., Fichtner, M. & Zhao-Karger, Z. Cathode materials and chemistries for magnesium batteries: challenges and opportunities. Adv. Energy Mater. 13, 2300682 (2023).

Blázquez, J. A. et al. A practical perspective on the potential of rechargeable Mg batteries. Energy Environ. Sci. 16, 1964–1981 (2023).

Shi, H.; et al. Understanding the cathode‐electrolyte interfacial chemistry in rechargeable magnesium batteries. Adv. Sci. 2401536 (2024).

Roy, A. et al. Improving rechargeable magnesium batteries through dual cation co-intercalation strategy. Nat. Commun. 15, 492 (2024).

Regulacio, M. D., Nguyen, D. T., Horia, R. & Seh, Z. W. Designing nanostructured metal chalcogenides as cathode materials for rechargeable magnesium batteries. Small 17, e2007683 (2021).

Liu, F. F., Wang, T. T., Liu, X. B. & Fan, L. Z. Challenges and recent progress on key materials for rechargeable magnesium batteries. Adv. Energy Mater. 11, 2000787 (2021).

Zhang, Z. H. et al. Self-established rapid magnesiation/de-magnesiation pathways in binary selenium-copper mixtures with significantly enhanced Mg-Ion storage reversibility. Adv. Funct. Mater. 28, 1701718 (2018).

Qu, X. et al. Charge‐compensation in a displacement Mg2+ storage cathode through polyselenide‐mediated anion redox. Angew. Chem. Int. Ed. 61, e202204423 (2022).

Mao, M. L., Gao, T., Hou, S. Y. & Wang, C. S. A critical review of cathodes for rechargeable Mg batteries. Chem. Soc. Rev. 47, 8804–8841 (2018).

Cheng, Y. W. et al. Facile synthesis of chevrel phase nanocubes and their applications for multivalent energy storage. Chem. Mater. 26, 4904–4907 (2014).

Shen, Y. et al. High‐energy interlayer‐expanded copper sulfide cathode material in non‐corrosive electrolyte for rechargeable magnesium batteries. Adv. Mater. 32, e1905524 (2019).

Xue, X. et al. One‐step synthesis of 2‐ethylhexylamine pillared vanadium disulfide nanoflowers with ultralarge interlayer spacing for high‐performance magnesium storage. Adv. Energy Mater. 9, 1900145 (2019).

Wu, C. L., Zhao, G. Y., Gong, S., Zhang, N. Q. & Sun, K. N. PVP incorporated MoS as a Mg ion host with enhanced capacity and durability. J. Mater. Chem. A 7, 4426–4430 (2019).

Yoo, H. D. et al. Fast kinetics of magnesium monochloride cations in interlayer-expanded titanium disulfide for magnesium rechargeable batteries. Nat. Commun. 8, 339 (2017).

Liang, Y. L. et al. Interlayer-expanded molybdenum disulfide nanocomposites for electrochemical magnesium storage. Nano Lett. 15, 2194–2202 (2015).

Hou, S. Y. et al. Solvation sheath reorganization enables divalent metal batteries with fast interfacial charge transfer kinetics. Science 374, 172–178 (2021).

Song, X. M. et al. Ternary eutectic electrolyte-assisted formation and dynamic breathing effect of the solid-electrolyte interphase for high-stability aqueous magnesium-ion full batteries. J. Am. Chem. Soc. 146, 7018–7028 (2024).

Shen, Y. L. et al. Anion-Incorporated Mg-Ion solvation modulation enables fast magnesium storage kinetics of conversion-type cathode materials. Adv. Mater. 35, 2208289 (2023).

Li, Z. Y. et al. Fast kinetics of multivalent intercalation chemistry enabled by solvated magnesium-ions into self-established metallic layered materials. Nat. Commun. 9, 5115 (2018).

Long, J. C. et al. Revealing the interfacial chemistry of fluoride alkyl magnesium salts in magnesium metal batteries. Angew. Chem.-Int. Ed. 62, e202301934 (2023).

Du, A. et al. An efficient organic magnesium borate-based electrolyte with non-nucleophilic characteristics for magnesium–sulfur battery. Energy Environ. Sci. 10, 2616–2625 (2017).

Huang, J. et al. Editors’ choice—review—impedance response of porous electrodes: theoretical framework, physical models and applications. J. Electrochem. Soc. 167, 166503 (2020).

Deng, L. et al. Self-optimizing weak solvation effects achieving faster low-temperature charge transfer kinetics for high-voltage Na3V2(PO4)2F3 cathode. Energy Storage Mater. 44, 82–92 (2022).

Yao, Y. X. et al. Regulating interfacial chemistry in lithium‐ion batteries by a weakly solvating electrolyte**. Angewandte Chemie International Edition 60, 4090–4097 (2020).

Zhang, Y. et al. Pulverization‐Tolerant CuSe Nanoflakes with High (110) planar orientation for high‐performance magnesium storage. Adv. Funct. Mater. 31, 2104730 (2021).

Jin, M. et al. Constructing Cu9S5@CuSe heterostructures under microwave irradiation for rechargeable magnesium batteries. Chem. Eng. J. 493, 152569 (2024).

Tang, K. et al. A stable solid electrolyte interphase for magnesium metal anode evolved from a bulky anion lithium salt. Adv. Mater. 32, 1904987 (2020).

Sun, Y. et al. A facile strategy for constructing high‐performance polymer electrolytes via anion modification and click chemistry for rechargeable magnesium batteries. Angew. Chem. Int. Ed. 63, e202406585 (2024).

Wu, X. J. et al. Two‐Dimensional CuSe nanosheets with microscale lateral size: synthesis and template‐assisted phase transformation. Angew. Chem. Int. Ed. 53, 5083–5087 (2014).

Shitu, I. G., Talib, Z. A., Chi, J. L. Y., Kechick, M. M. A. & Baqiah, H. Influence of tartaric acid concentration on structural and optical properties of CuSe nanoparticles synthesized via microwave assisted method. Results Phys. 17, 103041 (2020).

Tugarova, A. V., Mamchenkova, P. V., Dyatlova, Y. A. & Kamnev, A. A. FTIR and Raman spectroscopic studies of selenium nanoparticles synthesised by the bacterium. Spectrochimica Acta Part a-Mol. Biomolecular Spectrosc. 192, 458–463 (2018).

Chen, X. Q., Li, Z. & Dou, S. X. Ambient facile synthesis of gram-scale copper selenide nanostructures from commercial copper and selenium powder. ACS Appl. Mater. Interfaces 7, 13295–13302 (2015).

Wang, P., Ng, Y. H. & Amal, R. Embedment of anodized p-type Cu2O thin films with CuO nanowires for improvement in photoelectrochemical stability. Nanoscale 5, 2952–2958 (2013).

Berg, I., Amit, E., Hale, L., Toste, F. D. & Gross, E. N‐heterocyclic carbene based nanolayer for copper film oxidation mitigation. Angew. Chem. Int. Ed. 61, e202201093 (2022).

Biesinger, M. C. Advanced analysis of copper X‐ray photoelectron spectra. Surf. Interface Anal. 49, 1325–1334 (2017).

Kumar, P., Nagarajan, R. & Sarangi, R. Quantitative X-ray absorption and emission spectroscopies: electronic structure elucidation of Cu2S and CuS. J. Mater. Chem. C. 1, 2448–2454 (2013).

Oppong-Antwi, L., Huang, B. & Hart, J. N. Electronic properties of transition and alkaline earth metal doped CuS: A DFT Study. ChemPhysChem 24, e202300417 (2023).

Bhatt, V., Kumar, M. & Yun, J.-H. Unraveling the photoconduction characteristics of single-step synthesized CuS and Cu9S5 micro-flowers. J. Alloy. Compd. 891, 161940 (2022).

Koren, B. et al. Sample preparation induced phase transitions in solution deposited copper selenide thin films. RSC Adv. 12, 277–284 (2022).

Salama, M. et al. Structural analysis of magnesium chloride complexes in dimethoxyethane solutions in the context of Mg batteries research. J. Phys. Chem. C. 121, 24909–24918 (2017).

Yu, Y. et al. Instability at the electrode/electrolyte interface induced by hard cation chelation and nucleophilic attack. Chem. Mater. 29, 8504–8512 (2017).

Li, B. et al. Kinetic surface control for improved magnesium-electrolyte interfaces for magnesium ion batteries. Energy Storage Mater. 22, 96–104 (2019).

Oelßner, W., Berthold, F. & Guth, U. The iR drop - well-known but often underestimated in electrochemical polarization measurements and corrosion testing. Mater. Corros. 57, 455–466 (2006).

Blount, B., Juarez, G., Wang, Y. & Ren, H. iR drop in scanning electrochemical cell microscopy. Faraday Discuss. 233, 149–162 (2022).

Xu, L. et al. In-situ determination of onset lithium plating for safe Li-ion batteries. J. Energy Chem. 67, 255–262 (2022).

Lin, F. et al. Surface reconstruction and chemical evolution of stoichiometric layered cathode materials for lithium-ion batteries. Nat. Commun. 5, 3529 (2014).

Wang, Y. & Tongying, P. Local photocatalytic H2 generation on individual microscale two-dimensional CdSe nanosheets. Appl. Surf. Sci. 487, 253–259 (2019).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple [Phys. Rev. Lett. 77, 3865 (1996)]. Phys. Rev. Lett. 78, 1396–1396 (1997).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

He, Q., Yu, B., Li, Z. & Zhao, Y. Density functional theory for battery materials. Energy Environ. Mater. 2, 264–279 (2019).

Li, X. et al. A high‐rate rechargeable Mg battery based on AgCl conversion cathode with fast solid‐state Mg2+ diffusion kinetics. Energy Technol. 7, 1900454 (2019).

Pan, B. et al. Polyanthraquinone‐based organic cathode for high‐performance rechargeable magnesium‐ion batteries. Adv. Energy Mater. 6, 1600140 (2016).

Wang, Y. R. et al. Highly Branched VS4 Nanodendrites with 1D Atomic-Chain Structure as a Promising Cathode Material for Long-Cycling Magnesium Batteries. Adv. Mater. 30, e1802563 (2018).

Cao, Y. H. et al. Anionic Te-substitution boosting the reversible redox in CuS nanosheet cathodes for magnesium storage. ACS Nano 16, 1578–1588 (2022).

Chen, D. et al. CoSe2 hollow microspheres, nano-polyhedra and nanorods as pseudocapacitive Mg-storage materials with fast solid-state Mg2+ diffusion kinetics. Nanoscale 11, 23173–23181 (2019).

Zhou, L. M. et al. Nickel-iron bimetallic diselenides with enhanced kinetics for high-capacity and long-life magnesium batteries. Nano Energy 54, 360–366 (2018).

Zhou, L. et al. Interlayer‐spacing‐regulated VOPO4 nanosheets with fast kinetics for high‐capacity and durable rechargeable magnesium batteries. Adv. Mater. 30, 1801984 (2018).

Wang, Y. et al. Atomic substitution enabled synthesis of vacancy-rich two-dimensional black TiO2–x nanoflakes for high-performance rechargeable magnesium batteries. ACS Nano. 12, 12492–12502 (2018).

Chen, D. et al. Ni0.85Se hexagonal nanosheets as an advanced conversion cathode for Mg secondary batteries. J. Energy Chem. 48, 226–232 (2020).

Zhang, Y. J. et al. a-MoS3@CNT nanowire cathode for rechargeable Mg batteries: a pseudocapacitive approach for efficient Mg-storage. Nanoscale 11, 16043–16051 (2019).

He, D. et al. Flower-like CoS with nanostructures as a new cathode-active material for rechargeable magnesium batteries. J. Power Sources 294, 643–649 (2015).

Cheng, Y. W. et al. Molecular storage of Mg Ions with vanadium oxide nanoclusters. Adv. Funct. Mater. 26, 3446–3453 (2016).

Li, Z. Y. et al. Multi-electron reactions enabled by anion-based redox chemistry for high-energy multivalent rechargeable batteries. Angew. Chem.-Int. Ed. 59, 11483–11490 (2020).

Shen, Y. L. et al. A pyrite iron disulfide cathode with a copper current collector for high-energy reversible magnesium-ion storage. Adv. Mater. 33, e2103881 (2021).

Ha, J. H. et al. Silver chalcogenides (Ag2X, X=S, Se) nanoparticles embedded in carbon matrix for facile magnesium storage via conversion chemistry. Energy Storage Mater. 27, 459–465 (2020).

Acknowledgements

Y.L acknowledges the financial support from the Science and Technology Commission of Shanghai Municipality (23ZR1405000 and 22YF1401900) and the National Natural Science Foundation of China (No.52471224 and No.52301298). F.W. acknowledges the financial support from the Science and Technology Commission of Shanghai Municipality (23TS1401700) and the National Natural Science Foundation of China (No.52472192, No. 52261135631, No. 52103335, and No. 52071083).

Author information

Authors and Affiliations

Contributions

Y.L., F.W. and D.S. supervised and conceived the project. X.Q. conducted electrochemical experiments and material characterizations. G.L. provided suggestions on the in-situ XRD measurements. X.Q. and FM.W. performed SEM measurements. X.Q. and Y.Z. performed Raman measurements. T.G., Y.L., Y.S. and F.F. contributed to the data analysis and discussions. All authors contributed to the writing of the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Yanna NuLi, and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Qu, X., Li, G., Wang, F. et al. In-situ electrochemical activation accelerates the magnesium-ion storage. Nat Commun 16, 1310 (2025). https://doi.org/10.1038/s41467-025-56556-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-56556-9

This article is cited by

-

A Simple and Scalable Method for Preparing Natural Molybdenite-Based MoS2–Graphene Oxide Composite Anodes via Ultrasonic Exfoliation Combined with a Solvothermal Process

Journal of Electronic Materials (2026)

-

Stereoisomerism of multi-functional electrolyte additives for initially anodeless aqueous zinc metal batteries

Nature Communications (2025)