Abstract

Two-dimensional (2D) nanomaterials display unique characteristics owing to their ultrahigh surface-to-volume ratio and quantum confinement effects. Nonetheless, seeking a versatile and facile method to rationally shape ultrathin 2D frameworks is still an appealing challenge. Herein, a series of ultrathin 2D metal oxide crystals (2D MOs), including 3d transition metals (Ti, Cr, Mn, Fe, Co, Ni, Cu, Zr, W), lanthanide (Ce) and nontransition metal (In, Sn, Bi) oxides, were created through a confined interlayer growth strategy in combination with melt infiltration, in which no complicated chemistry or sophisticated equipment was needed. The 2D oxides presented lamellar constructions with high crystallinity, and the thickness was strictly limited to ~ 1 nm. The crystallization process, including the Frank-van der Merwe mode and the Volmer-Weber mode, was described. The defects and distortions of 2D TiO2 reduced the optical band gap and improved the sunlight utilization efficiency, thus accelerating the photocatalytic activity. This method could be extended to the preparation of 2D polymetallic oxides, metal sulfides etc., which enables the development of versatile systems for ultrathin 2D frameworks, especially for nonlayered structures originally.

Similar content being viewed by others

Introduction

Two-dimensional (2D) solids are distinguished from bulk solids because of their constrained longitudinal dimensionality1. With very high aspect ratios and thicknesses corresponding to a few atomic layers, the 2D materials including graphene, oxides, hydroxides, sulfides and boron nitrides have been reported with interesting properties and promising applications2,3,4. Among them, 2D metal oxides (MOs) are a large family with unique combinations of redox chemistry, abundant defect sites, rapid mass transport and high earth abundance, endowing them with widespread applications ranging from catalysts and energy-storage devices to semiconductors. Mechanical/chemical/ultrasonic exfoliation5,6,7, chemical vapor deposition (CVD)2,8, template method9, solvo-/hydrothermal methods10 etc., have been used to fabricate novel 2D architectures.

Similar with the fabrication of graphene by exfoliating layered graphite, some types of 2D metal oxide nanosheets have been produced via the “top-down” strategy. For instance, nine types of 2D hexagonal metal oxide monolayers (TiO2, MnO, Fe2O3 etc.) have been prepared via exfoliation method5. The bulk metal surface could be polished and oxidized to layered metal oxide in oxygen-deficient environment, which was easily obtained after mechanical exfoliation. Meanwhile, liquid-phase exfoliation also was used in metal oxide sheets production11. Ultrasonic waves could break the van der Waals (vdW) forces between the metal oxide layers, following the liquid-phase exfoliation and stabilization in liquids. It is clear that exfoliation is suitable for cleavage those original frameworks contain a layered structure, which rely on weak vdW forces to maintain the interlayer interaction. Considering that most metal oxides are not intrinsically layered, the formation of 2D metal oxide nanosheets via exfoliation is quite limited.

The “bottom-up” strategy has also been developed for the 2D metal oxides synthesis. Although CVD is more flexible, its large-scale application is extremely restricted by its high energy intensity, limited product types and low yield. The wet-chemical synthesis method benefits from low-cost, high-yield and simple operation. By wet-chemical system, Zhao et al. 9 synthesized ultrathin 2D metal oxides including MgO, Al2O3, SnO2, ZrO2, TiO2, and Sb2O5 using graphene oxide (GO) as template. The metal cations was adsorbed on the GO surface, and hydrolyzed gradually in the liquid-phase reaction with precisely controlled temperature and pH. Notably, it is restricted by the solution pH, solubility and hydrolysis of precursors. A strategy involving the use of surfaces of water-soluble salt crystals as growth substrates to synthesize 2D transition metal oxides such as MoO3, MoO2, MnO, and WO3 from solution has been discovered12. It remains a challenging task if the precursors are hydrolyzed violently or refractorily. Seeking a versatile and facile method to fabricate 2D metal oxide crystals is an appealing endeavor.

Confinement synthesis in a fixed interlayer is the transverse growth of 2D target guest species by utilizing the layer spacing of lamellar framework in combination with template. Due to the fixed spacing between the layers of template, the longitudinal dimension of target products can be strictly limited. Very recently, Guo’s group13 reported the solution preparation of free-standing nitrogen-doped amorphous monolayer carbon within the interlayer cavity of layered double hydroxides (LDHs), indicating the feasibility of confined polymerization using solid templates. Herein, we developed the confined interlayer growth strategy in combination with a melt infiltration method under dry-chemical conditions, achieving the synthesis of various ultrathin 2D metal oxide crystals (2D MOs), including 3d transition metal (Ti, Cr, Mn, Fe, Co, Ni, Cu, Zr, and W) oxides, lanthanide (Ce) oxides and nontransition metal (In, Sn, and Bi) oxides. The synthesized 2D MOs presented ultrathin monolayer structures, which perfectly inherited the layer morphology of the parent compound RUB-15. All the 2D MOs exhibited high crystallinity through modulation of the growth conditions. Each MO monolayer was held by vdW forces rather than ionic bonds, which was distinctly different from those in the bulk phase. The ultrathin 2D crystals exposed large surfaces and edge regions, which formed multiple defects and strains that led to lattice distortions. The obtained 2D TiO2 nanosheets demonstrated outstanding degradation efficiency for various persistent organic pollutants, including phenolic compounds and antibiotics, in 120 min. Moreover, five kinds of 2D transition metal sulfides (MSs), including FeS2, CoS, NiS2, Cu9S5, and SnS2 have been synthesized in this strategy. The method is flexible for the construction of other ultrathin 2D frameworks, such as binary MOs, sulfide/phosphide or metallene nanosheets, which highlights the multidisciplinary exploration of 2D crystals with unique properties.

Results and discussion

Synthesis and characterization of 2D MOs/MSs

The principle of the confined interlayer growth strategy coupled with the melt infiltration is illustrated in Fig. 1a. The layered silicate RUB-15 is introduced as a nanotemplate, and the composition of the unit cell is [N(CH3)4]8[Si24O52(OH)4]·20H2O. The framework possesses hemihedral cavities, and each cavity contains a tetramethylammonium (TMA+) ion with one methyl group pointing inwards, leading to an ideal space-filling arrangement14,15. With a thickness of each silicate layer of approximately 0.6 nm and a stable basal distance (1.4 nm), an interlayer space of ~ 1.0 nm can be used as a confined nanoreactor14. Compared with those of other layered compounds, such as 0.34 nm of graphite16, 0.62 nm of bulk-MoS217 and layered double hydroxides (LDHs, 0.46 nm of Co-Fe LDH18, 0.66 nm of ZnTi-LDH and 0.75 nm of MgAl-LDH19), the spacing of RUB-15 is significantly larger, which favors the insertion of diverse molecules. The selection of hydrated metal halides as precursors was a key factor, as the low melting point of the metal halide could facilitate the subsequent insertion process. The metal precursor was gradually inserted into the interlaminated template at a slow heating rate under Air or Ar atmosphere. With continuous heating, the inserted precursor gradually grew and crystallized into 2D framework with a restricted thickness. Finally, by removing the template, well-defined 2D MO/MS crystals were obtained. Sodium hydroxide solution or ammonium hydrogen fluoride was selected to etch RUB-15. By adopting this strategy, we successfully synthesized 13 kinds of ultrathin 2D MOs and 5 kinds of 2D MSs, including 3d transition metals (TiO2, Cr2O3, Mn2O3, Fe2O3, Co3O4, NiO, CuO, ZrO2, and WO3), lanthanides (CeO2), nontransition metals (In2O3, SnO2, Bi2O3) and MSs (FeS2, CoS, NiS2, Cu9S5, and SnS2). The entire synthesis was processed under dry-chemical conditions, avoiding the hydrolysis of metal ions. The yields of 2D MOs/MSs were close to the theoretical value corresponding to metal salt precursors, thus the solvent-free production process could be scaled up easily by amplification of the raw materials, favoring large-scale production for potential industrial applications.

Specifically, 8 kinds of monocrystalline 2D MOs (Cr2O3, Mn2O3, Fe2O3, Co3O4, NiO, CeO2, WO3, and Bi2O3) are shown in Fig. 2, whereas 5 kinds of polycrystalline 2D MOs (TiO2, CuO, ZrO2, In2O3, and SnO2) are listed in Fig. 3. All the transmission electron microscopy (TEM) images of the 2D MOs presented ultrathin lamellar morphology, which were flexible nanosheets with lateral dimensions of up to several micrometers. The inset corresponding energy dispersive X-ray spectroscopy (EDS) maps recorded the uniform spatial distribution of metal and oxygen in the 2D MOs. The high-resolution TEM images (HRTEM, Fig. 2a3−h3) and selected-area electron diffraction patterns (SAED, Fig. 2a4−h4) revealed that all the 2D MOs in Fig. 2 presented good monocrystallinity, which were consistent with the X-ray diffraction (XRD, Fig. 2a5−h5) results. The measured lattice spacing of 2.54 Å for 2D Cr2O3 (Fig. 2a3) was in good agreement with the (110) interplanar distance of the rhombohedral Cr2O3 phase. The corresponding SAED pattern (Fig. 2a4) also revealed the single-crystalline nature of 2D Cr2O3, which is characteristic of a hexagonal system20. Moreover, a series of neat lattice stripes could also be observed in 2D Mn2O3, 2D Fe2O3, 2D Co3O4, 2D NiO, 2D CeO2, 2D WO3, and 2D Bi2O3, and the lattice spacings of ca. 2.75 Å, 2.69 Å, 2.45 Å, 2.39 Å, 1.91 Å, 3.65 Å, and 1.41 Å were assigned to the (222) plane of bixbyite, the (104) plane of Fe2O3, the (311) plane in 2D Co3O4, the (111) plane in 2D NiO, the (220) plane in 2D CeO2, the (200) plane in 2D WO3 and the (−411) plane in 2D Bi2O3. These ultrathin 2D oxide crystals were perfectly indexed to those of chromium oxide (JCPDS 01-1294)21, Mn2O3 (JCPDS 41-1442)22, hematite (JCPDS 33-0664)23, cobalt oxide (JCPDS 42-1467)24, nickel oxide (JCPDS 47-1049)25, ceric dioxide (JCPDS 34-0394)26, monoclinic WO3 (JCPDS 72-0677)27 and α-bismuth trioxide (JCPDS 41-1449)28, respectively. For comparison, the corresponding template-free counterparts (denoted as bulk MOs) obtained through the same processing protocol are also provided in Supplementary Figs. 1−8. Without a template, the obtained corresponding bulk MOs presented as agglomerates and irregular particles. The size of the bulk MOs ranged from tens of nanometers to microns. Undoubtedly, the RUB-15 template played an indispensable role in the formation of laminar 2D MOs. The morphology of the 2D MOs was further verified to be ultrathin lamella from the atomic force microscopy (AFM) images (Fig. 2a6−h6). The thickness of each lamella was ~ 1.0 nm in all the 2D MOs, which could be considered as monolayer. The N2 adsorption-desorption isotherms exhibited characteristic type-I isotherms at low relative pressures and type-IV isotherms at medium relative pressures, revealing the microporosity and mesoporosity of the 2D MOs (Supplementary Figs. 1h−8h). The pore size distribution curves centered at 1.18 ~ 1.48 nm corresponded to the layer spacing of 2D metal oxides, further verifying the intercalation fabrication. The corresponding atomic structures are shown in Fig. 2a7–h7.

The TEM images (Fig. 3a 1 − e 1) indicated that 2D TiO2, 2D CuO, 2D ZrO2, 2D In2O3, and 2D SnO2 had similar nanosheet morphologies composed of polycrystalline nanograins. The lattice spacings of 3.52 Å, 2.51 Å, 3.06 Å, 4.15 Å, and 3.33 Å correspond to the (101), (002), (−111), (211), and (110) planes of TiO2, CuO, ZrO2, In2O3 and SnO2, respectively, in the HRTEM images (Fig. 3a3–e3). The corresponding SAED diffraction pattern (Fig. 3a4–e4) exhibited multiple bright electron diffraction polycrystalline rings, suggesting that the nanosheet was formed by stacked crystal particles. For example, the electron diffraction rings of 2D TiO2 in Fig. 3a4 were indexed to the (101), (103), (200), (105) and (213) planes of anatase and rutile. These ultrathin 2D oxide crystals were perfectly indexed to those of anatase (JCPDS 21-1272)29, cupric oxide (JCPDS 45-0937)30,31, zirconium dioxide (JCPDS 37-1484 and 42-1164)32,33, indium oxide (JCPDS 06-0416)34 and cassiterite SnO2 (JCPDS 41-1445)35. Interestingly, mixed-phase oxide crystals were observed in both 2D TiO2 and 2D ZrO2. According to the AFM images (Fig. 3a6−e6), the thicknesses of these five oxide nanosheets were between 0.92 and 1.12 nm. X-ray photoelectron spectroscopy (XPS, Supplementary Fig. 1e,f−13e,f) was used to analyze the surface states of the 13 kinds of 2D MOs and their corresponding bulk counterparts. Generally, the O 1s spectra located at low binding energy belong to the M − O − M bond, whereas the higher binding energy refer to the O atoms adjoining the defect position and bridging hydroxyls, etc36,37,38,39. The peaks at higher energy region of most 2D MOs (e.g., Cr2O3, Mn2O3, Fe2O3, NiO, CeO2, Bi2O3, CuO, ZrO2 and In2O3) were markedly elevated compared with those of the bulk MOs, while the corresponding metal peaks (2p, 3 d and 4 f) position had also been shifted slightly. The thickness of 2D MOs was further characterized by spherical aberration-corrected scanning transmission electron microscopy (STEM) from a cross-sectional view, taking 2D TiO2 as an example (Supplementary Fig. 14a,b). The atomic structure of monolayer 2D TiO2 was clearly observed, with some regions consisting of two or three layers of bright titanium atoms, proving that the ultrathin nanosheets indeed follow the confined interlayer growth mode within RUB-15.

In addition to metal oxides, five 2D metal sulfide ultrathin nanosheets, namely, FeS2, CoS, NiS2, Cu9S5 and SnS2, were prepared via incorporating sulfur powder precursors and processed in the same procedure. The TEM and HRTEM images demonstrated that all the 2D MSs were ultrathin, flexible, and highly crystallized, with sizes of several micrometers (Fig. 4). All the 2D MS data in Fig. 4a−e presented good monocrystallinity. The measured lattice spacing of 2.20 Å for 2D FeS2 in Fig. 4a3 was in good agreement with the (211) interplanar distance of cubic-system pyrite40. Moreover, a series of neat lattice stripes could also be observed in 2D CoS, 2D NiS2, 2D Cu9S5, and 2D SnS2, and the lattice spacings of 2.99 Å, 2.57 Å, 3.24 Å and 3.20 Å were assigned to the (100) plane of CoS41, the (210) plane of NiS242, the (0015) plane of 2D Cu9S543 and the (100) plane of 2D SnS244. The corresponding atomic structures of the 2D MS data are shown in Fig. 4a7–e7.

Confined interlayer growth mechanism of 2D MOs

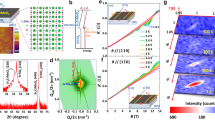

The synthesis mechanism of ultrathin MOs was further investigated with 2D TiO2 as an example. In-situ XRD (Fig. 5a) and in-situ Raman spectroscopy (Fig. 5b) revealed the phase change of TiCl4 in RUB-15 interlamination under temperature programming. At 25 °C, the diffraction peaks at 2θ values of 4.5°, 6.6°, 19.2°, and 24.6° correspond to the RUB-15 template. Except for the peak at 6.6°, the majority of the diffraction peaks disappeared gradually as the heating process progressed. The major peak at 2θ = 6.6° corresponds to the interlayer distance of RUB-15 (1.4 nm)45, which did not shift at all during the whole intercalation process, indicating that the maintenance of the RUB-15 structure and the intercalation metal compound propped up the interlayer. Upon heating, the characteristic (110), (200), (211), and (222) planes of silica sodalite located at 14.1°, 20.0°, 25.1° and 34.7° were enhanced with increasing temperature, corresponding to the generation of sodalite. The appearance of the crystal phase of anatase began from 300 °C, and highly crystallized TiO2 formed at 500 °C. The in-situ Raman spectra were perfectly consistent with the in-situ XRD results, confirming that the vibrational activity of the disappeared TMA+ ions and H2O molecules accompanied the generation of TiO2 nanocrystals during calcination. The frequencies at 365 cm−1 (E, C−N deformation), 752 cm−1 (A1, C−N symmetric stretch), 949 cm−1 (T2, C−N asymmetric stretch), 1451 cm−1 (E, CH3 asymmetric deformation), 2926 cm−1 (T2, CH3 symmetric stretch), 2983 cm−1 (A1, CH3 symmetric stretch), 3031 cm−1 (T2, CH3 asymmetric stretch) and 3360 cm−1 (OH stretching vibrations) completely vanished at 300 °C, demonstrating the decomposition of TMA+ ions and H2O in the interlayer of RUB-1546. The generated peaks at frequencies of approximately 141 cm−1 (Eg), 194 cm−1 (Eg), 395 cm−1 (B1g), 515 cm−1 (A1g) and 637 cm−1 (Eg) matched well with the Raman-active modes of anatase29. These peaks continuously became stronger at 300 °C, revealing the production of anatase nanocrystals. The gradually increasing peak with frequency at 141 cm−1 (Eg) accounted for the enhanced (101) facet exposed on 2D TiO229. Above 500 °C, the peaks at 141 cm−1 (Eg), 194 cm−1 (Eg), 395 cm−1 (B1g), 515 cm−1 (A1g) and 637 cm−1 (Eg) increased significantly with rising thermal treatment, which confirmed the further crystallization and regularity of the 2D TiO2 surface. The XRD Rietveld refinement of 2D TiO2 in Fig. 5c revealed a space group of I41/amd and lattice parameters of a = b = 3.7929(3) Å, c = 9.5264(3) Å and α = β = γ = 90° with a unit cell volume of 137.049 Å3. Compared with the lattice information of standard anatase TiO2 (a = b = 3.771 Å, c = 9.430 Å and α = β = γ = 90° with a unit cell volume of 134.1 Å3)47, the lattice of 2D TiO2 was enlarged along three axes, particularly in the c-axis direction. This expansion in the c-axis showed a maximum relative distortion of 1.02%, foreshadowing the potential properties arising from the ultrathin structure.

a, b In-situ XRD and in-situ Raman patterns of the confined interlayer growth process during interlamination in RUB-15. c XRD Rietveld refinement of 2D TiO2. d Growth details of ultrathin 2D MOs in a confined interlayer. e, f Stacking faults and inversion domains in the atomic-resolution STEM images of 2D TiO2.

On the basis of the above discussion, Fig. 5d shows the growth process in detail in the confined interlayer of RUB-15, which can be inferred as three steps: (1) Below 300 °C, with increasing reaction temperature, volatile metal chlorides, such as CrCl3 or TiCl4 molecules, gradually diffuse into the interlamination of RUB-15 and exchange with the counterion TMA+, and this process is accompanied by the decomposition of TMA+ ions. (2) At 300 ~ 500 °C, tiny crystals of metal oxides were generated. The difference in whether single crystals or polycrystals were produced was determined by the different nucleation rates of the metal chlorides. Most metal chlorides (e.g., CrCl3 and CoCl2) were stable in the RUB-15 interlayer below 300 °C, whereas TiCl4, SnCl2 or ZrCl4 were hydrolyzed quickly with the lattice water molecules in RUB-15 and converted to nanocrystals immediately as follows:

Compared with the growth rate, the nucleation rate was lower for even and thin fewer atomic layers of Cr2O3 at 300 °C. In contrast, the fast nucleation rate of TiO2 produces numerous crystal islands with anisotropic growth orientations. (3) Above 500 °C, the MO nanocrystals further crystallized into large 2D nanosheets, and the crystallinity increased with calcination. The first route was called the Frank-van der Merwe mode. The single-layered crystal clusters generated at 300 ~ 500 °C (such as Cr2O3) gradually linked and formed a crystal layer before the second layer started growing. This layer-by-layer growth mode results in single crystals, such as the eight 2D MOs (Cr2O3, Mn2O3, Fe2O3, Co3O4, NiO, CeO2, WO3, and Bi2O3) shown in Fig. 2. The other route was the Volmer-Weber mode (island growth mode), in which the TiO2 microcrystal islands expand and finally assemble into 2D polycrystalline nanosheets, including polycrystalline 2D TiO2, CuO, ZrO2, In2O3, and SnO2, as shown in Fig. 3. The interlayer of ca. 1.0 nm controlled the critical layer thickness of the MOs within ~ 1 nm in both growth modes. Atomic-resolution STEM was employed to visualize the strain and deficiencies on the 2D TiO2 surface. There were several lattice defects, such as stacking faults, inversion domains and lattice tortuosity, in the (111), (221) planes of TiO2, and the structural models could account for the observed defect structures in Fig. 5e, f. Considering the narrow spacing between the RUB-15 layers and the long diffusion distance of volatile metal ions along the silicate layer (up to tens of microns), the preparation process was of diffusion control and the tendency to generate defects was high due to diffusion obstruction. Meanwhile, the 2D TiO2 nanosheets were composed of nanocrystals. There were many lattice heterojunctions at the crystal interfaces in polycrystalline TiO2, and dislocations and defects existed at the polycrystal junction. The crystal phase structure, oxidation state and defect concentration of the target 2D MOs could be modulated by the calcination atmosphere, temperature, heating rate and proportion of the metal halide precursor to the RUB-15 template. In a previous study, the defect content of Fe3O4 was modulated by the ratio of ferric chloride hexahydrate to template23. The calcination atmosphere, such as Ar or Air, also impacts the formation of oxygen vacancies48. Therefore, this solvent-free confined growth strategy has flexible manoeuvrability for adjusting the physical and chemical properties of ultrathin 2D MOs and could be applied in many technical fields, such as transistors, sensors, topological insulators, battery electrodes and catalysts.

Optical and catalytic properties of 2D TiO2

In the UV-vis diffuse reflectance spectra (Fig. 6a), bulk TiO2 exhibited a sunlight response in the UV region at ~ 393 nm, whereas the response range of 2D TiO2 was extended into the visible region at ~ 434 nm, proving that the utilization of sunlight was effectively enhanced on the ultrathin 2D surface. The corresponding optical bandgap energies (Eg) were calculated on the basis of Tauc plots (Fig. 6b) derived from UV-vis spectra. The bandgap of bulk TiO2 was 2.96 eV, which was slightly smaller than that of anatase in the literature (3.2 eV)49, whereas the bandgap of 2D TiO2 (2.44 eV) was significantly narrower. The smaller bandgap might be due to the abundant defects at the 2D interface, which has been demonstrated in previous reports50. Moreover, the valence-band XPS spectra (Fig. 6c) revealed that the valence-band edges of 2D TiO2 and bulk TiO2 were both located at 2.75 eV. Low-temperature electron paramagnetic resonance (EPR, Fig. 6d) confirmed that a much stronger oxygen vacancy (OV) signal of 2D TiO2 was located at g = 2.004 than that of bulk TiO251. The confined interlayer growth of the 2D geometry inevitably resulted in many defects at the 2D TiO2 interface. Owing to the ultrathin nature of 2D TiO2, oxygen vacancies are located predominantly on the surface rather than in the bulk, which trap photogenerated electrons and hinder charge recombination52, thus effectively boosting the photocatalytic activity (the photoluminescence spectra further verified this viewpoint in Supplementary Fig. 16).

a UV-vis spectra, b corresponding Tauc plots. c Valence-band XPS spectra. d Low-temperature EPR spectra (77 K). e, f Calculated total and partial density of states of 2D TiO2 and 2D TiO2 (OV). g Degradation curves of BPA on 2D TiO2 and bulk TiO2 under simulated sunlight illumination. h, i EPR spectra of TEMPO-h+ and DMPO-·O2− adducts for 2D TiO2 and bulk TiO2.

Subsequently, spin-polarized density functional theory (DFT) calculations offer theoretical insight into the influence of thickness and oxygen vacancies on the electronic characteristics of TiO2. The highest exposed (101) plane of anatase was employed, and the optimized details are shown in Supplementary Figs. 17−19. The total and partial density of states (TDOS and PDOS) of the four TiO2 systems are shown in Fig. 6e, f and Supplementary Fig. 20. The decrease in the layer thickness of intrinsic anatase led to a broader bandgap, of which the pure 2D TiO2 and bulk TiO2 were calculated to be 2.83 eV and 2.42 eV, respectively. Notably, the incorporation of OV on 2D TiO2 introduced additional states near the Fermi energy level. The band gap of 2D TiO2 (OV) (Fig. 6f) was estimated to be 2.40 eV, much narrower than that of pristine 2D TiO2, which was conducive to light adsorption. Consequently, featuring oxygen vacancy defects on less layered structures could effectively accelerate charge transfer, improve light adsorption and thereby enhance the photocatalytic performance of anatase. TiO2-based photocatalysts are the most representative materials that exhibit excellent degradation activity toward organic compounds. The photocatalytic activities of 2D TiO2 and bulk TiO2 were evaluated via the degradation of bisphenol A (BPA) under simulated sunlight irradiation. As shown in Fig. 6g, the conversion of BPA degradation reached 98.3% in 120 min on 2D TiO2 and reached only 26.3% on bulk TiO2. According to the pseudo-first-order kinetics fitting in the inset of Fig. 6g, the rate constant k of 2D TiO2 (k = 0.0364 min−1) was approximately 15 times greater than that of bulk TiO2 (k = 0.0024 min−1). Compared with commercial P25 and other reported TiO2-based catalysts, the degradation efficiency was also outstanding (Supplementary Fig. 21 and Supplementary Table 2). In addition, 2D TiO2 exhibited superior degradation efficiency for various persistent organic pollutants (Supplementary Table 3). In addition to the phenolic compounds, various antibiotics were oxidized in 120 min, confirming that ultrathin 2D TiO2 exhibited good universality in terms of pollutant photodegradation. The EPR trap signals of the TEMPO-h+ (Fig. 6h) and DMPO-·O2− (Fig. 6i) adducts in the dark and after light irradiation confirmed efficient radical generation. The enlarged EPR spectra in Fig. 6h reveal the difference in the signals of the TEMPO-h+ adduct between 0 and 15 min. The typical peaks of h+ on the 2D TiO2 system reflected its effective product, whereas no photogenerated hole features were observed on the bulk TiO2. Moreover, the DMPO-·O2− adduct signals were markedly enhanced in the 2D TiO2 system during photocatalysis compared with those of bulk TiO2. Since ·O2− radicals are produced by the reduction of O2 through photogenerated e−, the DMPO-·O2− adduct signals indicate that more photogenerated electrons are generated at the 2D interface53. The OV was verified as the capture center of e−, thus accelerating separation and inhibiting the interface recombination of electron-hole pairs54, thus the ultrathin 2D interface featuring with OV could effectively promote the separation and transmission of photogenerated carriers. Simultaneously, OVs accelerated the adsorption of O2 molecules and participated in the formation of ·O2− radicals. This was further verified by the obvious activity inhibition in the 2D TiO2 system when it was injected with N2 (Supplementary Fig. 24). Finally, the defective ultrathin 2D structure produced more active sites and shortened the migration of photogenerated carriers, simultaneously inhibiting the recombination of electron-hole pairs and effectively increasing the photodegradation activity.

By introducing RUB-15 as a template, a series of molecularly 2D ultrathin metal oxide nanosheets, including 3d transition metal (Ti, Cr, Mn, Fe, Co, Ni, Cu, Zr, and W) oxides, lanthanide (Ce) oxides and nontransition metal (Sn and Bi) oxides, were successfully fabricated through a confined interlayer growth strategy in combination with the melt infiltration method. The successful synthesis of 5 kinds of metal sulfides proved that this strategy was not only limited to the production of MOs but also expanded to other ultrathin 2D polymetallic oxides, metallic sulfur/nitrogen/boron/phosphide, organic polymers and so on. The obtained 2D MOs/MSs presented a lamellar structure with a complete crystalline phase with high crystallinity and featured defects at the interface. When 2D TiO2 was used as a photocatalyst, ultrathin nanosheets significantly improved the sunlight utilization efficiency and accelerated the degradation rate of various organic contaminants. The confined growth mechanism, including the Frank-van der Merwe mode and the Volmer-Weber mode, was proposed. The limited space in the template promoted the stepwise reaction of melt infiltration, microcrystal generation and 2D assembly of MO units. This simple solvent-free synthetic strategy could significantly improve the bottom-up fabrication of 2D nanosheets, which are expected to play a crucial role in many fields beyond catalysis, such as electronic, magnetic, optical, and energy storage.

Methods

Chemicals and reagents

All chemicals were used as received without further experimental purification. Metal halide, S (99.99%, powder), NaOH, NH4HF2 were purchased from Aladdin Company. Acetone was purchased from Sinopharm Co., Ltd. Edetate disodium (EDTA-2Na), tert-butyl-alcohol (TBA), p-benzoquinone (p-BQ), bisphenol A (BPA), 2-chlorophenol, 4-chlorophenol, 2,4-dichlorophenol, 2,4,6-trichlorophenol, phenol, ibuprofen, ofloxacin, ciprofloxacin, diphenhydramine, phenytoin and atrazine were all purchased from Aladdin Company. All the experimental water was Milli-Q water (18.25 MΩ/cm).

Synthesis of 2D metal oxide nanosheets

Specifically, 1.0 g of metal halide and 1.0 g of RUB-15 template were mechanically mixed uniformly. The resulting mixture was subsequently heated to target temperature at a rate of 1 °C/min in a tube furnace and then held at target temperature for 360 min (Air atmosphere). After naturally cooling, the calcined mixture was washed with acetone several times and then freeze-dried. The final product was leached into NaOH solution (1 M) or NH4HF2 solution (1 M) for 24 h to etch the template, washed with copious amounts of Milli-Q water until neutral, then freeze-dried and named 2D MOs. For comparison, the corresponding template-free sample was named bulk MOs, and the synthesis protocol for the thermal and etching treatments was exactly the same as that for the 2D MOs. Details of the synthesis of the various metal oxides are listed in Supplementary Information.

Synthesis of 2D metal sulfide nanosheets

Specifically, 3 mM metal halide, 12 mM sulfur powder and a certain mass of RUB-15 template (the mass equal to the sum of metal halide and sulfur powder) were mechanically mixed homogeneously. The resulting mixture was subsequently heated in a tube furnace to 450 °C at a rate of 5 °C/min and kept at 450 °C for 60 min (Ar atmosphere). After natural cooling, the product was soaked in a 1 M NaOH solution (1 M) for 24 h to remove the template, then rinsed to neutrality with large amounts of ultrapure water, and finally freeze-dried thoroughly. Details of the synthesis are listed in Supplementary Information.

Characterization

Crystallographic information about the fabricated samples were acquired by using powder X-ray diffraction (XRD), which was conducted on SmartLab SE (Rigaku) equipped with Cu-Kα (λ = 1.54 Å) radiation. And the XRD scan of 2D TiO2 was further analyzed by the Rietveld refinement method, using the FULLPROF code. In-situ XRD patterns were recorded on Bruker D8 Advance. Raman and In-situ Raman data were collected from Renishaw invia reflex. Transmission electron microscopy (TEM), selected-area electron diffraction (SAED) images and the corresponding energy dispersive X-ray spectroscopy (EDS) maps of 2D MOs/MSs were conducted on Tecnai G2 F20 microscope. Spherical aberration-corrected scanning transmission electron microscopy (STEM) images were conducted on Titan Cubed Themis G3 300. Morphology and thickness characteristics were acquired by atomic force microscope through 5500AFM microscope (AFM, Aglient Keysight), as the samples were deposited on polished silicon wafers for test. Field-emission scanning electron microscopy (FESEM) images of bulk MO and the corresponding EDS maps were taken on Hitachi SU8010 microscope. X-ray photoelectron spectroscopy (XPS) and valence-band XPS spectra were recorded on 250xi (Thermo ESCALAB) by utilizing a monochromatic Al Kα X-ray source. All calibrations were referenced to the surface adventitious carbon (C 1s = 284.8 eV). Specific surface area (SBET) was calculated based on N2 adsorption-desorption isotherms record on a Micromeritics ASAP2460 instrument at 77 K. Optical property was detected with ultraviolet-visible (UV-vis) diffuse reflectance spectra (UV-3600, Shimadzu). Photoluminescence (PL) spectra were measured by a CARY ECLIPSE fluorescence spectrophotometer with the excitation light at 320 nm. Low-temperature electron paramagnetic resonance (EPR) of solid sample was taken on Bruker-A300-10/126 spectrometer and measured at 77 K. In addition, the EPR signals of radicals were also examined on Bruker-A300-10/126 spectrometer at room temperature.

DFT calculation details

Spin-polarized density functional theory (DFT) calculations were performed to probe the effect of thickness and OVs on the electronic characteristics of anatase (101) within Vienna Ab initio Simulation Package (VASP) code. The Perdew-Burke-Ernzerhof (PBE) functional within Generalized Gradient Approximation (GGA) was employed to depict the exchange-correlation energy. The electron-ion interactions were described by the projector augmented-wave (PAW) potentials with energy cutoff of 400 eV. Grimme’s method (DFT-D3) was applied to consider the van der Waals interactions, and the convergence criterion is set to 1 × 10−5 eV/cell in energy and 0.02 eV/Å in force. The Brillouin zone is sampled by 3 × 3 × 1 k and 7 × 7 × 1 k grid mesh with Monkhorst-Pack scheme for structural optimization and electronic properties, respectively.

Data availability

The data supporting the findings of the study are available in the paper and its Supplementary Information. Source data are provided with this paper.

References

Naguib, M., Mochalin, V. N., Barsoum, M. W. & Gogotsi, Y. 25th anniversary article: MXenes: a new family of two-dimensional materials. Adv. Mater. 26, 992–1005 (2014).

Amontree, J. et al. Reproducible graphene synthesis by oxygen-free chemical vapour deposition. Nature 630, 636–642 (2024).

Kang, J. et al. Valence oscillation and dynamic active sites in monolayer NiCo hydroxides for water oxidation. Nat. Catal. 4, 1050–1058 (2021).

Falin, A. et al. Anomalous isotope effect on mechanical properties of single atomic layer boron nitride. Nat. Commun. 14, 5331 (2023).

Zhang, B. Y. et al. Hexagonal metal oxide monolayers derived from the metal-gas interface. Nat. Mater. 20, 1073–1078 (2021).

Chung, J.-Y. et al. Structure and exfoliation mechanism of two-dimensional boron nanosheets. Nat. Commun. 15, 6122 (2024).

Gao, W. et al. Vacancy-defect modulated pathway of photoreduction of CO2 on single atomically thin AgInP2S6 sheets into olefiant gas. Nat. Commun. 12, 4747 (2021).

Zhou, J. et al. A library of atomically thin metal chalcogenides. Nature 556, 355–359 (2018).

Zhao, H. et al. A generalized strategy for the synthesis of large-size ultrathin two-dimensional metal oxide nanosheets. Angew. Chem. Int. Ed. 56, 8766–8770 (2017).

Lan, K. et al. Uniform ordered two-dimensional mesoporous TiO2 nanosheets from hydrothermal-induced solvent-confined monomicelle assembly. J. Am. Chem. Soc. 140, 4135–4143 (2018).

Tan, C. et al. Recent advances in ultrathin two-dimensional nanomaterials. Chem. Rev. 117, 6225–6331 (2017).

Xiao, X. et al. Scalable salt-templated synthesis of two-dimensional transition metal oxides. Nat. Commun. 7, 11296 (2016).

Bai, X. et al. Nitrogen-doped amorphous monolayer carbon. Nature 634, 80–84 (2024).

Moteki, T., Chaikittisilp, W., Sakamoto, Y., Shimojima, A. & Okubo, T. Role of acidic pretreatment of layered silicate RUB-15 in its topotactic conversion into pure silica sodalite. Chem. Mater. 23, 3564–3570 (2011).

Oberhagemann, U., Bayat, P., Marler, B., Gies, H. & Rius, J. A layer silicate: synthesis and structure of the zeolite precursor RUB-15—[N(CH3)4]8[Si24O52(OH)4]·20H2O. Angew. Chem. Int. 35, 2869–2872 (1996).

Wen, Y. et al. Expanded graphite as superior anode for sodium-ion batteries. Nat. Commun. 5, 4033 (2014).

Hu, Z. et al. MoS2 nanoflowers with expanded interlayers as high-performance anodes for sodium-ion batteries. Angew. Chem. Int. Ed. 53, 12794–12798 (2014).

Ma, R. et al. Synthesis and exfoliation of Co2+-Fe3+ layered double hydroxides: an innovative topochemical approach. J. Am. Chem. Soc. 129, 5257–5263 (2007).

Zou, J. et al. Photocatalytic selective oxidation of benzyl alcohol over ZnTi-LDH: the effect of surface OH groups. Appl. Catal. B Environ. 260, 118185 (2020).

Sackey, J. et al. Biosynthesized black α-Cr2O3 nanoparticles; experimental analysis and density function theory calculations. J. Alloys Comp. 850, 156671 (2020).

Bumajdad, A., Al-Ghareeb, S., Madkour, M. & Al Sagheer, F. Non-noble, efficient catalyst of unsupported α-Cr2O3 nanoparticles for low temperature CO oxidation. Sci. Rep. 7, 14788 (2017).

Pan, T. et al. In-depth understanding of the oxidative compatibility of volatile organic compounds with Mn2O3 and Pt-loaded catalysts. Environ. Sci. Technol. 58, 9381–9392 (2024).

Wang, W. et al. The confined interlayer growth of ultrathin two-dimensional Fe3O4 nanosheets with enriched oxygen vacancies for peroxymonosulfate activation. ACS Catal. 11, 11256–11265 (2021).

Wang, J. et al. Accurate control of multishelled Co3O4 hollow microspheres as high performance anode materials in lithium-ion batteries. Angew. Chem. Int. Ed. 52, 6417–6420 (2013).

Gong, W. et al. A step-scheme mechanism in a NiO/CdS heterojunction nanoarray for visible light-activated gas sensing at room temperature. Inorg. Chem. Front. 11, 5997–6009 (2024).

Wang, F. et al. A photoactivated Cu-CeO2 catalyst with Cu-[O]-Ce active species designed through MOF crystal engineering. Angew. Chem. Int. Ed. 59, 8203–8209 (2020).

Wei, Z.-Q. et al. Unexpected boosted solar water oxidation by nonconjugated polymer-mediated tandem charge transfer. J. Am. Chem. Soc. 142, 21899–21912 (2020).

Zhang, Q. et al. Bifunctional oxygen-defect bismuth catalyst toward concerted production of H2O2 with over 150% cell faradaic efficiency in continuously flowing paired-electrosynthesis system. Adv. Mater. 36, 2408341 (2024).

Zhang, H. et al. Unusual facet and cocatalyst effects in TiO2-based photocatalytic coupling of methane. Nat. Commun. 15, 4453 (2024).

Bai, S., Xu, Y., Wang, P., Shao, Q. & Huang, X. Activating and converting CH4 into CH3OH via CuPdO2/CuO nanointerface. ACS Catal. 9, 6938–6944 (2019).

Duan, Y. et al. Optically active chiral CuO “Nanoflowers”. J. Am. Chem. Soc. 136, 7193–7196 (2014).

Luo, J. et al. Removal of antimonite (Sb(III)) and antimonate (Sb(V)) from aqueous solution using carbon nanofibers that are decorated with zirconium oxide (ZrO2). Environ. Sci. Technol. 49, 11115–11124 (2015).

Zhao, Y. et al. Two-step carbothermal welding to access atomically dispersed Pd1 on 3D zirconia nanonet for direct indole synthesis. J. Am. Chem. Soc. 141, 10590–10594 (2019).

Sun, L. et al. Rationally designed double-shell dodecahedral microreactors with efficient photoelectron transfer: N-doped-C-encapsulated ultrafine In2O3 manoparticles. Chem. Eur. J 25, 3053–3060 (2019).

Zhou, Y. et al. Surface defect and wettability engineering of porous SnOx for reliable bioassays with high selectivity and wide linear dynamic range. J. Am. Chem. Soc. 146, 16581–16589 (2024).

Li, Y. et al. Plasmonic hot electrons from oxygen vacancies for infrared light-driven catalytic CO2 reduction on Bi2O3−x. Angew. Chem. Int. Ed. 60, 910–916 (2021).

Yang, F. et al. Boosting hydrogen oxidation activity of Ni in alkaline media through oxygen-cacancy-rich CeO2/Ni heterostructures. Angew. Chem. Int. Ed. 58, 14179–14183 (2019).

He, Y. et al. Hydrophobic CuO nanosheets functionalized with organi adsorbates. J. Am. Chem. Soc. 140, 1824–1833 (2018).

Qi, Y. et al. Photoinduced defect engineering: Enhanced photothermal catalytic performance of 2D black In2O3−x nanosheets with bifunctional oxygen vacancies. Adv. Mater. 32, 1903915 (2020).

Zhang, G., Wang, G., Wan, Y., Liu, X. & Chu, K. Ampere-level nitrate electroreduction to ammonia over monodispersed bidoped FeS2. ACS Nano 17, 21328–21336 (2023).

Lu, B. et al. Steering the orbital hybridization to boost the redox kinetics for efficient Li-CO2 batteries. J. Am. Chem. Soc. 146, 20814–20822 (2024).

Wang, T. et al. NiFe (Oxy) hydroxides derived from NiFe disulfides as an efficient oxygen evolution catalyst for rechargeable Zn-Air batteries: The effect of surface S residues. Adv. Mater. 30, 1800757 (2018).

Fang, Y., Yu, X.-Y. & Lou, X. W. Bullet-like Cu9S5 hollow particles coated with nitrogen-doped carbon for sodium-ion batteries. Angew. Chem. Int. Ed. 131, 7826–7830 (2019).

Ma, X. et al. Sulfur-vacancy-engineered two-dimensional Cu@SnS2−x nanosheets constructed via heterovalent substitution for high-efficiency piezocatalytic tumor therapy. J. Am. Chem. Soc. 146, 21496–21508 (2024).

Moteki, T., Chaikittisilp, W., Shimojima, A. & Okubo, T. Silica sodalite without occluded organic matters by topotactic conversion of lamellar precursor. J. Am. Chem. Soc. 130, 15780–15781 (2008).

Dutta, P. K., Del Barco, B. & Shieh, D. C. Raman spectroscopic studies of the tetramethylammonium ion in zeolite cages. Chem. Phys. Lett. 127, 200–204 (1986).

Weirich, T. E., Winterer, M., Seifried, S. & Mayer, J. Structure of nanocrystalline anatase solved and refined from electron powder data. Acta Cryst. 58, 308–315 (2002).

Bai, W. et al. Crystallinity regulation-induced organic degradation on ultrathin 2D Co3O4/SiO2 nanosheets: the critical trigger of oxygen vacancies. Environ. Sci. Nano 11, 2507–2520 (2024).

Zhang, P., Lu, X. F., Luan, D. & Lou, X. W. Fabrication of heterostructured Fe2TiO5-TiO2 nanocages with enhanced photoelectrochemical performance for solar energy conversion. Angew. Chem. Int. Ed. 59, 8128–8132 (2020).

Xiong, J., Di, J., Xia, J., Zhu, W. & Li, H. Surface defect engineering in 2D nanomaterials for photocatalysis. Adv. Funct. Mater. 28, 1801983 (2018).

Elimian, E. A. et al. Construction of Pt-mTiO2/USY multifunctional catalyst enriched with oxygen vacancies for the enhanced light-driven photothermocatalytic degradation of toluene. Appl. Catal. B-Environ. 307, 121203 (2022).

Esmat, M. et al. Nitrogen doping-mediated oxygen vacancies enhancing cocatalyst-free solar photocatalytic H2 production activity in anatase TiO2 nanosheet assembly. Appl. Catal. B Environ. 285, 119755 (2021).

Zhang, S. et al. Enhanced photodegradation of toxic organic pollutants using dual-oxygen-doped porous g-C3N4: mechanism exploration from both experimental and DFT studies. Appl. Catal. B Environ. 248, 1 (2019).

Li, H., Li, J., Ai, Z., Jia, F. & Zhang, L. Oxygen vacancy-mediated photocatalysis of BiOCl: reactivity, selectivity, and perspectives. Angew. Chem. Int. Ed. 57, 122–138 (2018).

Acknowledgements

The authors acknowledged the financial support from the National Natural Science Foundation of China No. 22306024 (W.W.), No. 21976055 (Z.C.), No. U2067215 (X.W.) and No. 22327807 (X.W.).

Author information

Authors and Affiliations

Contributions

Z.C. conceived and designed the experiments. W.W. performed the syntheses, characterizations, data collection and analysis. Z.C. and W.W. cowrote the manuscript. Y.L. and Y.A. carried out the theoretical calculations. X.D. assisted in the acquisition of electron micrographs. H.W. contributed to the optical property analysis. X.W, Z.C, and Q. L helped with article revisions. All the authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Lin Guo and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, W., Liu, Y., Du, X. et al. Solvent-free fabrication of ultrathin two-dimensional metal oxides/sulfides in a fixed interlayer by geometric confinement. Nat Commun 16, 1623 (2025). https://doi.org/10.1038/s41467-025-56912-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-56912-9

This article is cited by

-

Growth of non-layered 2D transition metal nitrides enabled by transient chloride templates

Nature Communications (2026)

-

Salt-Assisted Synthesis of 2D Materials for Electrochemical Applications

Electrochemical Energy Reviews (2026)