Abstract

Self-remodeling material can change their physical properties based on mechanical environment. Recently, mechanically controlled polymerization using mechanoredox catalyst enabled composite materials to undergo a permanent structural change, thereby enhancing their mechanical strength. However, a significant delay in material’s response was observed due to the sluggish activation of the bulk catalyst for polymerization. Herein, we report a fast, mechanically controlled radical polymerization of water soluble monomers using 2D MoS2 as the mechanoredox catalyst, studied under various mechanical stimuli, including ultrasound, ball milling and low frequency vibrations. Our strategy enables complete polymerization within several minutes of work. This accelerated process can be utilized to create composite hydrogels with the ability to alter their mechanical and electrical properties in response to mechanical stimuli. This strategy has potential for applications in smart materials such as hydrogel sensors, artificial muscles, and implantable biomaterials.

Similar content being viewed by others

Introduction

In nature, cells demonstrate the capacity to sense mechanical forces and transduce these stimuli into intricate biochemical signals, thereby orchestrating diverse facets of cellular behaviors, a process known as mechanotransduction1. It allows the body to optimize its structure and function and ultimately leads to stronger bones and muscles2. By contrast, mechanical force often plays a destructive role in synthetic materials, leading to the occurrence of material damage3,4,5. For example, polymer network can gradually lose its ability to withstand further force, when subjected to cyclic loading or repetitive stress. This can manifest as microcracks that propagate and eventually lead to failure, even under relatively low levels of stress6. The development remodeling strategies via mechanochemistry enables the construction of self-strengthening and self-growth materials through the activation of mechanophore by stretching long polymer chains7,8,9,10,11,12,13,14. However, it is still a challenge to trigger a constructive response under low levels of mechanical changes.

Piezoelectric materials can serve as artificial mechanotransducers that adeptly capture minuscule mechanical changes from the surrounding environment and effectively convert it into electric signal15. This concept has already found applications in various fields, particularly in energy harvesting and sensing16. More recently, piezoelectric materials also showed the ability to catalyze organic reaction, such as arylation of aryl diazonium salts17, atom transfer radical cyclization (ATRC)18, CO2 reduction19 and H2O2 production20. This breakthrough has also led to their utilization in the creation of self-strengthening materials, achieved through the development of a series of mechanically controlled polymerization and mineralization21,22,23,24.

In 2017, Esser Kahn et al. reported the catalytic role of BaTiO3 nanoparticles in the atom transfer radical polymerization (ATRP) by facilitating the reduction of divalent copper ions under ultrasound (US)25. We and others have also showed the success of mechanically controlled reversible-deactivation radical polymerization (RDRP) using ZnO and BaTiO3 nanoparticles26,27,28,29. Recently, a self-strengthening organogel, capable of responding to low frequency vibrations, has been developed using thiol-ene and disulfide chemistry24,30. To date, ZnO and BaTiO3 nanoparticles are two extensively utilized bulk mechanoredox catalyst, but they demonstrate suboptimal catalytic efficiency for polymerization30,31. Although BaTiO3 displays enhanced catalytic efficiency under ball milling conditions, the polymerization process still necessitates several hours, resulting in a significantly delayed response for materials remodeling29,32,33. Thus, the rate of material property change is relatively slow compared with other stimuli-responsive materials34.

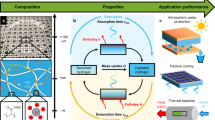

ZnO and BaTiO3 nanoparticles were reported to show slow activation in catalyzing polymerization. We hypothesized that the slow electron migration rate within the three-dimensional crystals and the obstruction of interface electron transport by organic solvents have led to the delayed response in the current system35. By contrast, few layered two-dimensional (2D) MoS2, an n-type semiconductor with non-centrosymmetric structure, can undergo spontaneous polarization under mechanical force and efficiently separate the electron and hole36. Herein, we proposed the application of 2D MoS2 as a highly efficient mechanoredox catalysts for aqueous and bulk free radical polymerization and crosslinking of water soluble monomers. We studied this polymerization under various mechanical stimuli, including US, ball milling and cyclic vibrations. Our strategy enables the complete polymerization within several minutes of work (Fig. 1). This accelerated process can be utilized to create smart material that spontaneously provoke crosslinking, thereby modifying the mechanical and electrical characteristics of the composite hydrogel. The resulting composite hydrogel showed a 13-fold increase in storage modulus under mechanical vibration (500 Hz) for 60 min. Meanwhile, the strengthening event also led to an increase in ion conductivity, thereby enhancing its potential in various sensing applications.

Under mechanical stimulation, 2D MoS2 forms a piezoelectric potential (arrow symbol P shows the direction of polarization) to produce electrons (green ball) and holes (yellow ball), which promote the decomposition of the initiator. Vinyl monomers (blue ball) polymerize rapidly under strong mechanical forces. The PVA hydrogels undergo secondary cross-linking of acrylamide within the PVA hydrogels under mechanical stimulation, and the degree of cross-linking increases as the mechanical force (purple lightning symbol) increases. PVA/PAM: polyvinyl alcohol/polyacrylamide hydrogel.

Results

Mechanically controlled polymerization

2D MoS2 were successfully synthesized utilizing the hydrothermal method37. Scanning electron microscopy (SEM) images revealed that the MoS2 exhibited a size range of ~500–600 nm with the flower-like morphology (Fig. 2a). The lattice spacing measured at the edge position was found to be 0.66 nm, which aligns well with previously reported values (Fig. 2b)38. Notably, a few-layered structure of the 2D MoS2 was evidenced by the high-resolution transmission electron microscope (HRTEM) image (Fig. 2c). Furthermore, the corresponding element mapping results further confirmed the presence of Mo and S elements, which were found to be evenly distributed throughout the MoS2 sample (Supplementary Fig. 1). The phase structure of MoS2 sample was precisely determined through X-ray diffraction (XRD) analysis (Fig. 2d). All characteristic peaks can be attributed to the stable hexagonal phase of MoS2 (JCPDS card No. 37–1492). We have also characterized the as-synthesized MoS₂ sample using Raman spectroscopy, which revealed two prominent peaks at ~378 and 404 cm−1. These peaks correspond to the E12g and A1g vibrational modes of 2H-MoS2, respectively (Supplementary Fig. 2). The chemical states of Mo and S elements in the MoS2 sample were characterized by X-ray photoelectron spectroscopy (XPS) (Supplementary Fig. 3). The XPS spectrum exhibited two distinct set of peaks positioned at 232.5 eV, 229 eV, 163.3 eV and 162.1 eV, corresponding to the Mo 3d5/2 and Mo 3d3/2 peaks, S 2p1/2 and S 2p3/2 peaks. We also employed piezoelectric force microscope (PFM) to further assess the morphological and piezoelectric features of the MoS2 (Fig. 2e, f). The undulating portions of the topographic image confirmed the morphology of the sample. The piezoelectric potential image demonstrated that the as-synthesized 2D MoS2 exhibit a relatively high piezoelectric response at the edge of the sample, enabling an enhanced catalytic performance (Fig. 2f).

a SEM image showing the morphology of 2D MoS2. Scale bar: 500 nm. b HRTEM image showing the measured lattice spacing of few-layered structure of 2D MoS2. Scale bar: 5 nm. c HRTEM image showing the presence of single layer and few-layered structure. Scale bar: 5 nm. d XRD pattern of 2D MoS2. e 3D topographic image of 2D MoS2. f The output piezoelectric potential image of 2D MoS2.

Subsequently, we investigated the mechanically controlled polymerization using different piezoelectric materials and mechanochemical conditions (Fig. 3a). The apparatus used for US and ball milling experiments were shown in Supplementary Fig. 4. First, we compared the commercial available hexagonal wurtzite ZnO and tetragonal BaTiO3 nanoparticles with the as-synthesized 2D MoS2 under US condition. The morphology and structure of ZnO and BaTiO3 were confirmed by SEM and XRD analysis (Supplementary Fig. 5). PFM analysis was conducted on ZnO and BaTiO3 (Supplementary Fig. 6). Notably, ZnO exhibits a relatively low piezoelectric potential response, while the piezoelectric potential of BaTiO3 is significantly higher than that of MoS2 and ZnO. It is important to note the catalytic performance of catalyst is also associated with other parameters, such as morphology and surface characteristics of the material39. N,N-dimethylacrylamide (DMA) and peroxymonosulfate (PMS) were selected as the monomer and initiator, respectively. The degassed reaction mixture was then immersed in an US bath (40 kHz,110 W). The conversion of monomer was determined using 1H NMR of an aliquot of reaction mixture (Supplementary Fig. 7). Figure 3b suggested that an induction period of 2 h for polymerization using ZnO or BaTiO3 nanoparticles. By contrast, no induction period was observed for polymerization using 2D MoS2. The polymerization demonstrated a high monomer conversion of 99% within just 45 min. BaTiO3 achieved a conversion of 82% in 10 h, while ZnO only reached a conversion of 50% in 12 h. This is consistent with the piezoelectric catalytic properties of BaTiO3 and ZnO reported in the literature20,21,22. Gel permeation chromatography (GPC) analysis suggested the BaTiO3 and ZnO system produced polymers with relatively low molecular weights (Fig. 3c). It is important to note that our investigation utilized a high initiator concentration. Consequently, high molecular weight polymers were achieved after reducing the initiator concentration (Supplementary Fig. 8). By contrast, GPC analysis revealed that 2D MoS2 system formed high molecular weight polymers (Mn = 212.6 kDa, Ɖ = 2.0) after 30 min with a high monomer conversion. We believed that this is associated with the rapid generation of a large amount free radicals, which leads to a fission-based polymerization process. These results emphasized the excellent performance of MoS2 in promoting free radical polymerization under US conditions. We will discuss the kinetics analysis of free radical generation later in the paper.

a Mechanically controlled polymerization under US or ball milling conditions. b The comparison of polymerization kinetics under US and using different piezoelectric materials. c GPC traces for polymerization of DMA under US and using different piezoelectric materials. The measurements were performed using DMF as eluent and PMMA as calibration standard. PNP: piezoelectric nanoparticles. d The comparison of polymerization kinetics under ball milling and using different piezoelectric materials. e Photograph of reaction mixture inside the ball milling jar and temperature changes before and after reaction. f Comparison of polymerization kinetics at different ball milling frequencies.

In addition, our investigation encompassed other water soluble monomers, including 2-hydroxyethyl acrylate (HEA) and acrylamide (AM). Both of the monomers displayed high conversions within 30 min (Supplementary Fig. 9). The 1H NMR analysis of the reaction mixture confirmed the complete monomer conversion after 60 min of US (Supplementary Figs. 10–12). In the absence of piezoelectric materials, no polymerization was observed even after 12 h of US, ruling out the potential influence of cavitation on the polymerization process. In addition, no polymerization was observed when control experiments were conducted without the presence of US or PMS. This observation further supported the crucial roles play by US and PMS in facilitating the polymerization process (Supplementary Table 1). XPS was utilized to identify the hydroxyl groups on the surfaces of different catalysts, including non-piezoelectric TiO2, ZnO, BaTiO3, and 2D MoS2. The O1s spectra presented in Supplementary Fig. 13a–d confirm the presence of hydroxyl groups on the surfaces of all materials. Subsequently, we introduced a very low catalyst loading (0.012 wt%) into the polymerization system while keeping all other components unchanged. No polymerization was observed across all systems after 1 h reaction, indicating that the reduced amount of catalysts had a detrimental effect on the polymerization process (Supplementary Table 2, Entries 1–3). After 8 h, polymerization occurred only in the system with 2D MoS2 (Supplementary Table 2, Entries 4–6). More importantly, no polymerization was observed when persulfate was excluded from the system, demonstrating that hydroxyl groups on the catalyst surface alone is insufficient to initiate polymerization (Supplementary Table 2, Entries 7–9).

Mechanochemical reaction using ball milling showed high reactivity. We hypothesized that ball milling would facilitate polarization of MoS2, thereby generating free electron (e−) and hole (h+) through the piezoelectric mechanism. The decomposition of persulfate produces sulfate radical, which subsequently react with water to form hydroxyl radicals. Meanwhile, the generated holes also readily react with water to form hydroxyl radicals. These free radicals can initiate the polymerization of vinyl monomers (Supplementary Fig. 14). To test this hypothesis, we used potassium persulfate (KPS), a more thermally stable initiator, in the ball milling condition. We examined the polymerization of different vinyl monomer in the presence of oxygen, including HEA, N-isopropylacrylamide (NIPAM), and DMA, and measured their Mn and Ɖ using GPC. (Supplementary Fig. 15). Surprisingly, solid polymers were observed for all monomers after only 1 min of ball milling. Taking NIPAM as an example, the 1H NMR result showed a near-quantitative monomer conversion (99%) within 5 min (Supplementary Fig. 16). The Mn of the resulting polymer was determined to be 254 kDa by GPC. By contrast, ZnO and BaTiO3 catalytic system did not exhibit any signs of polymerization before 30 min (Fig. 3d).

We employed the Brunauer-Emmett-Teller (BET) method to measure the specific surface area of ZnO (16.8 m2/g), BaTiO3 (2.3 m2/g) and 2D MoS2 (25.6 m2/g) (Supplementary Fig. 17). Although ZnO has a higher specific surface area than BaTiO3, the polymerization was even slower in the presence of ZnO, indicating that the surface area is not the determining factor for catalytic activity. However, owing to its two-dimensional nature, 2D MoS2 exhibits a relatively high piezoelectric potential and specific surface area, which contribute to its high catalytic activity. To ascertain the crucial role of piezoelectricity in polymerization, we also performed the polymerization using cubic phase BaTiO3 (C-BTO) with reduced piezoelectric properties (Supplementary Fig. 18a). To rule out the interference of size effect, the tetragonal phase BaTiO3 (T-BTO) with the same diameter can be prepared by thermal annealing of the C-BTO at 800 °C in a muffle furnace. As shown in Supplementary Fig. 18b, no polymerization was observed for C-BTO, whereas the formation of a viscous polymer was noted in the case of T-BTO (Supplementary Fig. 18c, d). Additionally, the temperature of the milling jar remained at room temperature, experiencing only minor fluctuations within the range of 24.1 °C to 24.6 °C (Fig. 3e). This observation suggests that the reaction did not significantly impact the thermal conditions within the experimental setup. Other acrylamides monomers and acrylic monomers all exhibited high conversions within 5 minutes (Supplementary Table 3). To demonstrate the recyclability of the catalyst, we conducted the experiment in which washed and reused the MoS2 from the grinding mixture, employing it in ball milling conditions up to three times. The conversion during each polymerization process remained relatively unchanged (Supplementary Fig. 19). SEM results further confirmed the morphological changes of MoS2 before and after the reaction (Supplementary Fig. 20). While a minor portion of the structure exhibited damage, the overall structure remained intact to a significant extent.

Mechanistic study of mechanically controlled polymerization

In order to further understand the polymerization process, we delved into the influence of different ball milling frequencies (Fig. 3f). At a frequency of 30 Hz, nearly 90% conversion was achieved within 1 min. Conversely, only a viscous solution with a conversion of 58% was observed at 20 Hz condition. Furthermore, even slower polymerization was observed at 10 Hz. These findings suggest that the use of high frequency ball milling could facilitate the further polarization of the catalyst and enhance catalytic performance. According to the literature, we have estimated that the applied stress at ball milling condition of 30 Hz, 20 Hz, and 10 Hz are 1800 MPa, 1200 MPa, and 600 MPa, respectively40. We employed finite element analysis (FEM) to further assess the piezoelectric potential distribution of MoS2 using the conditions mentioned above. Figure 4a–c illustrated the FEM results, showing the piezoelectric potential distribution of a single layered MoS2 when subjected to stress along the X-axis. The peak piezoelectric potential of MoS2 at 30 Hz reached up to 5.66 V exceeding that observed at lower frequencies. This result further validates our conjecture that ball milling at higher frequency could enhance polarization of MoS2, leading to the separation of electrons and holes and the formation of active sites. This, in turn, results in a higher piezoelectric response, promoting the decomposition of KPS and accelerates the polymerization process. While the simulation results provide valuable qualitative insights, it should be noted that they may not fully capture the behavior of materials at the nanoscale.

FEM simulation of the piezoelectric potential distribution of a single layered MoS2 under ball milling frequencies of a 10 Hz. b 20 Hz. c 30 Hz. d EPR spectra of different control experiments under ball milling: MoS2 and KPS, only MoS2 and only KPS. e EPR spectra of free radicals obtained by ball milling of KPS and different piezoelectric materials. f Hydroxyl radical concentration vs milling time using different catalysts.

To further explore the initiation mechanism, electron paramagnetic resonance (EPR) analysis was applied to identify the reactive intermediates (i.e., ·OH and SO4·-,) using DMPO (5,5-dimethyl-1-pyrroline-N-oxide) as spin-trapping agents. As depicted in Fig. 4d, the MoS2 system exhibited distinct signals corresponding to DMPO-·OH, characterized by a peak intensity ratio of (1:2:2:1)41. These results indicated 2D MoS2 induced the decomposition of KPS to generate ·OH. By contrast, no signals were observed in the absence of KPS or MoS2, confirming the essential role of both KPS and MoS2 in the radical generation process. Furthermore, signals associated with DMPO-SO4·- were also not observed in the MoS2 system. The absence of DMPO-SO4·- signals can be attributed to the rapid conversion of sulfate radicals into ·OH radicals upon reaction with water. We carried out a parallel experiment to examine the generation of these free radicals under US conditions. Our observations revealed the presence of a significant amount of ·OH, along with a minor signal peak of SO4·- (Supplementary Fig. 21). These findings provide further validation of the proposed radical process. In addition, the complete inhibition of polymerization was observed when adding ethanol as the free radical inhibitor. By contrast, the reduced monomer conversion (69%) was obtained when using IPA as the ·OH scavenger (Supplementary Fig. 22). These results further demonstrate the collaborative role of SO4·- and ·OH in the polymerization process. We also examined the performance of ZnO and BaTiO3. As depicted in Fig. 4e, ZnO and BaTiO3 piezoelectric nanoparticles exhibited weaker signal of ·OH radicals. This finding demonstrated that the application of MoS2 enables the generation of a higher amount of ·OH radicals compared to other piezoelectric nanoparticles. Lastly, we quantify the ·OH concentration during reaction by utilizing terephthalic acid (TA) as the fluorescent probe (Supplementary Fig. 23). As shown in Fig. 4f, a linear relationship between ·OH generation and ball milling time was observed, giving a fast radical generation rate at 0.55 μM/min. By contrast, both ZnO and BaTiO3 system exhibited significantly slower ·OH generation kinetics.

Synthesis and characterization of self-remodeling hydrogels

After establishing the rapid mechanically controlled polymerization, we examine its potential in construction of self-remodeling hydrogel under low-frequency mechanical forces (Fig. 5a). To verify the piezoelectric response of piezoelectric materials under low-frequency mechanical forces, we performed piezoelectric current response tests in the condition of magnetic stirring (Fig. 5b). ZnO and BaTiO3 nanoparticles exhibited delayed and weak current responses when the stirrer was turned on. In contrast, 2D MoS2 produced an intensive current signal immediately upon turn on the stirrer. These findings confirmed that 2D MoS2 exhibits a more sensitive piezoelectric response under low-frequency mechanical forces than ZnO and BaTiO3 nanoparticles. Subsequently, we conducted a study on the crosslinking polymerization of AM and N,N’-methylidene bisacrylamide (MBA), and validated its feasibility over a period of 60 min using an electrodynamic vibration system (500 Hz, 70 W) (Supplementary Fig. 24). The results revealed that only the sample containing 2D MoS2 was able to undergo crosslinking on the electrodynamic shaker (Supplementary Fig. 25). Furthermore, the storage modulus (G’) of MoS2-PAM hydrogels exhibited a continuous increase upon 60 min of vibration, demonstrating a significant faster response than ZnO based system (Supplementary Fig. 26).

a Schematic illustration of construction of self-remodeling hydrogel. MBA: N,N’-methylidene bisacrylamide. b Piezoelectric response of ZnO, BaTiO3 and MoS2 under magnetic stirring. c Left inset: PVA hydrogels SEM images. Scale bar: 20 μm. Center inset: PAM hydrogels SEM images. Scale bar: 20 μm. Right inset: MoS2-DN hydrogels SEM images. Scale bar: 20 μm.

Following that, poly(vinyl alcohol) (PVA) was selected as the target hydrogel for our investigation. The strengthening event was achieved through crosslinking polymerization of AM and MBA within the MoS2-PVA hydrogel (0.3 wt% MoS2) by cyclic loadings from an electrodynamic shaker (1000 Hz, 70 W) for 60 min. The resulting MoS2 based double network hydrogel (MoS2-DN hydrogel) demonstrated a decrease in pore size compared with the individual PVA and PAM hydrogel (Fig. 5c). The presence of Mo and S elements in the DN hydrogel, as well as the existence of nitrogen (N) element, were evidenced by energy-dispersive X-ray spectroscopy (EDS) mapping analysis (Supplementary Fig. 27). As mentioned earlier, this method is applicable to various acrylate and acrylamide-based monomers. We plan to explore the application of this 2D MoS2-based method for other gel systems in future publications.

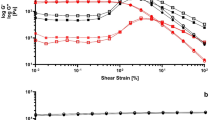

ZnO has been reported as a piezoelectric material capable of strengthening organogels under mechanical force30. However, its dynamic response exhibits considerable delay and the use of organic solvents poses limitations on its biomedical application. We also prepared a ZnO based hydrogel as the control, employing the same condition as preparation of MoS2-DN hydrogel. The fast response of hydrogel is crucial in order to ensure a timely adaptation. Therefore, we characterized the MoS2-DN hydrogel and ZnO hydrogel by a rheometer, employing the G’ to describe the enhancement contribution from mechanical vibration (Fig. 6a). After 60 min, the G’ of the MoS2-DN hydrogels increased by 27.3 kPa, while the ZnO hydrogels only showed a slight increase of 2.7 kPa. Furthermore, we conducted rheological experiments on C-BTO, T-BTO and the non-piezoelectric TiO2. The results indicate that hydrogels containing TiO2 and C-BTO did not undergo crosslinking under mechanical stimulation, hence there was no increase in the storage modulus. Furthermore, continuous vibration of TiO2 and C-BTO containing hydrogels led to a slight decrease in the storage modulus, which may be attributed to the mechanical deconstruction of the hydrogel. In contrast, T-BTO demonstrated a slow increase in the storage modulus. This phenomenon may be attributed the slow generation of free radicals by T-BTO, which results in a less cross-linked network structure and consequently reduced mechanical properties42. The temperature of the sample during vibration was monitored by infrared thermometer to exclude the influence from thermal contribution (Supplementary Fig. 28). We used Fourier infrared spectroscopy (FTIR) to explore the degree of cross-linking over time (Supplementary Fig. 29). The absorption peak at 1669 cm−1 corresponded to the characteristic carbonyl groups of acrylamide. The decrease in the peak at 1613 cm-1, a characteristic peak of the vinyl group, indicated an increase in the degree of crosslinking. After 60 min of mechanical stimulation, the disappearance of the double bond peak confirmed the successful establishment of the second PAM network.

a The G’ change of MoS2-DN hydrogels and ZnO hydrogels at different reaction times. b Stress-strain curves of MoS2 and ZnO hydrogels before and after reaction. c The tensile stress-strain curves of MoS2-DN hydrogel and control sample without 2D MoS2 (PVA/PAM hydrogel). d The G’ of MoS2-DN hydrogels as a function of shaker power (500 Hz, 60 min). Control experiment: MoS2 hydrogel without vibration. Data with error bars are presented as mean ± Standard Error of the Mean (SEM) of three independent experiments. e Measurement of the ion conductivity of PVA, PVA/PAM hydrogel, and MoS2-DN hydrogels containing 0.1 mol/L NaCl. f The ion conductivity variation in hydrogels under low-frequency mechanical vibration conditions. Error bars represent standard deviation based on three replicate data.

Figure 6b showed the representative stress-strain curves of ZnO hydrogels and MoS2-DN hydrogels (before and after reaction) obtained by dynamic mechanical analysis (DMA). The compressive stress of MoS2-DN hydrogels was significantly higher than that demonstrated by ZnO hydrogels. Notably, the MoS2 DN hydrogel showed a compressive stress of 1.2 MPa at strain of 37%, whereas ZnO hydrogels exhibited a compressive stress of 0.18 MPa under the same strain condition. Supplementary Fig. 30 displayed a photograph illustrating the deformation of MoS2-DN hydrogel and ZnO hydrogel when subjected to a compression stress of 1.2 MPa. The MoS2-DN hydrogel exhibited significantly less deformation than the ZnO hydrogel, indicating the successful formation of the second network structure. More importantly, we prepared the dumbbell-shaped hydrogel samples and subjected them to uniaxial tensile testing (Supplementary Fig. 31a). Supplementary Fig. 31b displayed the stretching process of hydrogel samples on a universal test machine. As shown in Fig. 6c, the MoS2-DN hydrogel exhibited a tensile stress and strain at break of 1.453 MPa and 304 %, which are 1.1 and 1.7 times higher than those of the control sample without 2D MoS2 (PVA/PAM hydrogel). The incorporation of 2D MoS2 significantly enhanced the mechanical properties, resulting in an increase in elastic modulus from 460.1 to 534.9 kPa and an improvement in toughness from 4.4 to 6.33 MJ/m3. The improvement in the mechanical properties of the hydrogel can be attributed to the incorporation of 2D MoS2, which provides additional noncovalent cross-linking points. To rule out the interference of piezoelectrically mediated process on the hydrogel structure, we also prepared the hydrogel samples with various 2D MoS2 content using a thermal initiation method (Supplementary Fig. 32). The hydrogel samples demonstrate a higher strain at break and a decrease in tensile stress as the 2D MoS2 content increases, indicating that inorganic filler content also influences the tensile properties of the hydrogel43.

The effect of vibration energy on the strengthening behavior was explored under a constant frequency of 500 Hz. We altered the vibration energy by changing the input power from 50 W to 80 W. Parallel experiments were repeated three times to ensure the reliability of our findings. As depicted in Fig. 6d, a slightly increase in the storage modulus was observed at 50 W, compared to the control sample without vibration. By contrast, a significant increase of 39 kPa in G’ was observed at 80 W. We speculated that subjecting the hydrogel to increased stress under higher power conditions would promote the crosslinking reaction.

To explore the potential sensing application of our remodeling strategy, we conducted a preliminary investigation on the changes of ion conductivity from PVA hydrogel to PVA/PAM DN hydrogel. The PVA/PAM DN hydrogel exhibited an enhanced ionic conductivity compared to the PVA hydrogel (Fig. 6e). The formation of second PAM network could enhance the ion transportation through the DN hydrogel network struture44. Furthermore, the incorporation of MoS2 further elevated the conductivity. This enhancement can be attributed to its inherent electrical conductivity and alteration of hydrogel’s microstructure45. We also compared the change in ion conductivity during the strengthening process (Fig. 6f). After 60 min of vibration, the conductivity was found to be 3 times higher than before reinforcement. We speculate that this may be due to the interactions between PVA and PAM that affect the pore structure and ion mobility of the hydrogel46. Further experiments to elucidate the mechanism of the observed change in conductivity will be reported in future publications.

Discussion

In summary, we reported a highly efficient mechanically controlled polymerization that enable the construction of self-strengthening hydrogel with fast and permanent structure modification. In our investigation, 2D MoS2 exhibited enhanced performance in catalyzing free radical polymerization of water soluble monomers compared with previously used ZnO and BaTiO3 materials. We examined the polymerization under typical mechanochemical conditions, including US and ball milling. The ball milling method, with its ability to enhance the polarization of piezo-catalysts, enables the full conversion of monomer within a few minutes. Furthermore, 2D MoS2 exhibited a fast mechanical activation even under low levels of cyclic loading, triggering the formation of a second cross-linked network within the hydrogel and ultimately resulting in the distinct mechanical properties. Additionally, the strengthening of hydrogel also leads to a 3-fold increase in ion conductivity. We believe that this strategy will provide an additional opportunity for smart material applications such as hydrogel sensors, artificial muscles and implantable biomaterials.

Methods

Hydrothermal synthesis of 2D MoS2

The 2D MoS2 were synthesized by the hydrothermal process. The Na2MoO4·2H2O (0.72 g) and the CH4N2S (0.69 g) powder was dissolved in the 1-butyl-3-methylimidazolium chloride (BMIM [Cl], 1 M, 1 mL) to prepare the precursor. Then, 1 mL HCl was diluted in 60 mL of the deionized water. Next, the diluted HCl solution was slowly titrated into precursor and stirred for 12 h. The solution was then transferred into the Teflon-lined stainless container and allowed to react at 220 °C for 24 h. The black powder of the 2D MoS2 was then collected after the autoclave was cooled to room temperature.

Synthesis of cubic BTO (C-BTO) nanoparticles

The C-BTO nanoparticles were synthesized by the solvothermal method using Ba(OH)₂·H₂O and Ti[O(CH₂)₃CH₃]₄ as materials. In a typical preparation procedure of C-BTO nanoparticles: Initially, 17.018 g of tetrabutyl titanate was dissolved in 20 mL of ethanol. Subsequently, 7 mL of ammonium hydroxide solution was introduced into the mixture. In parallel, 14.204 g of Ba(OH)₂·H₂O was dissolved in 25 mL of deionized water. This aqueous solution was then combined with the ethanol mixture. The final suspension was transferred into a 100 mL Teflon-lined stainless steel autoclave and subjected to hydrothermal treatment at 200 °C for 48 h. After reaction, the product was repeatedly washed with acetic acid and ethanol, followed by drying in an oven at 80 °C for 24 h.

Synthesis of tetragonal BTO (T-BTO) nanoparticles

A simple thermal anneal was conducted to convert BTO from cubic to tetragonal. For thermal treatment, the required amount of C-BTO powder was weighed, placed in an alumina crucible, and heated at 800 °C for 10 h in air in a tube furnace, followed by natural cooling. After annealing, the agglomerated powder was ground in a pestle and mortar to produce a fine powder.

General procedure for mechanically controlled polymerization in an ultrasound bath

DMA (0.2 g, 2.8 mmol), PMS (23 mg, 37.4 μmol), 10 mg (1.2 wt%) mechanoredox catalyst and 0.6 mL deionized water were added to a 20 mL Schlenk flask. The flask was sealed and degassed via three freeze-pump-thaw cycles. The flask was transferred to the ultrasound bath (25 °C, 40 kHz, 110 W) to start the polymerization.

The monomer conversion was determined by 1H NMR and the resulting polymer was characterized by GPC to obtain the number-average molecular weight (Mn) and diffusion coefficient (Ɖ). A small amount of the sample was dissolved in 0.55 ml D2O to prepare the sample for 1H NMR. The remaining sample was subjected to freeze drying. Subsequently, the obtained samples were dissolved in chromatographic grade DMF or aqueous buffer for GPC analysis.

General procedure for mechanically controlled polymerization in a ball mill

In a typical experiment, NIPAM (0.3 g, 2.7 mmol), KPS (10 mg, 37.0 μmol), 10 mg (2.9 wt%) mechanoredox catalyst and 20 μl deionized water were added into a 1.5 mL stainless steel milling jar equipped with a 5 mm stainless steel milling ball. The jar was sealed in the air, fixed in a ball mill and shaken at a frequency of 30 Hz for 1–5 min.

The monomer conversion was determined by 1H NMR, while the Mn and Ɖ were obtained by GPC characterization. A small amount of the sample was dissolved in 0.55 mL D2O to prepare the sample for 1H NMR. The remaining sample was subjected to freeze drying. Subsequently, the obtained samples were dissolved in chromatographic grade DMF or aqueous buffer for GPC analysis.

Synthesis of MoS2-PAM Hydrogel

To obtain a MoS2-PAM hydrogel, 0.3 g of AM, 10 mg of MoS2, 10 mg of KPS, 10 mg MBA were added to 1 mL deionized water. The reaction mixture was then transferred to a 10 mL ampoule and placed on an electrodynamic shaker (1000 Hz) for 1 h.

Synthesis of MoS2-DN Hydrogel

To obtain a MoS2-DN hydrogel, dissolve 1 g PVA and 10 mg of MoS2 in 8 mL of deionized water. Heat the mixed solution at 95 °C for 1 h to dissolve the PVA. After the PVA is completely dissolved, cool the solution to room temperature, then add 1 g of acrylamide, 10 mg of KPS, and 30 mg of MBA. After subjecting the hydrogel to three cycles of freezing and thawing to form a physical hydrogel, place the hydrogel on an electrodynamic shaker for 1 h to obtain the MoS2-DN hydrogel.

Preparation of thermally initiated hydrogel without 2D MoS2 (PVA/PAM hydrogel)

First, dissolve 1 g of PVA in 8 mL of deionized water by heating at 95 °C to obtain a PVA solution. After cooling, add 1 g of AM, 10 g of KPS, and 30 mg of MBA. After the hydrogel has completed three cycles of freezing and thawing to form a physical hydrogel, heat it at 65 °C for 4 h to obtain the control sample. Uniaxial tensile hydrogel samples were fabricated using a dumbbell-shaped cutting mold.

Preparation of thermally initiated hydrogel (PVA/PAM-MoS2 hydrogel)

PVA/PAM-MoS2 (0.3 wt%) hydrogel: First, dissolve 1 g of PVA and 30 mg of MoS2 (0.3 wt%) in 8 mL of deionized water by heating at 95 °C to obtain a PVA solution. After cooling, add 1 g of AM, 10 g of KPS, and 30 mg of MBA. After the hydrogel has completed three cycles of freezing and thawing to form a physical hydrogel, heat it at 65 °C for 4 h to obtain the control sample. Uniaxial tensile hydrogel samples were fabricated using a dumbbell-shaped cutting mold.

Experimental procedure for DMPO trapping and EPR measurement

10 mg of mechanoredox catalyst, 37.0 μmol KPS were mixed in 20 μl deionized water and loaded into stainless steel milling jar. Then 0.3 mmol of DMPO was added into the reaction mixture. The reaction mixture was milled at 30 Hz for 1 min. Following this, it was diluted with 0.18 mL of deionized water. The reaction liquid was then extracted using a capillary pipette for EPR testing.

Electron paramagnetic resonance (EPR) spectroscopic measurements were performed at room temperature using a JEOL JES-X320 X-band to detect radicals spin-trapped by 5,5′-dimethyl-1-pyrroline-N-oxide (DMPO). The parameters for ESR measurements of all samples were tested as follows: center field 326 mT, sweep time 30 s, modulation frequency 100 kHz, Mod width 0.35 × 0.1, amplitude 3.00 × 100, time costs 0.03, microwave frequency 9.2 GZ, microwave power 0.998 mW.

Quantification of free radical concentrations using fluorescence spectroscopy.

Fluorescence spectroscopy measurements

Fluorescence spectroscopy measurements were conducted on FLS920 fluorescence spectrometers with excitation and emission slit sizes set to 10 nm. Mix 6 mg of MoS2, 4 mg of terephthalic acid (TA) and 50 μL of a 20 mg/mL KPS solution together. Place this mixture into a 1.5 mL stainless steel jar along with a 5 mm diameter stainless steel milling ball. Seal the jar and mill the reactants using an MM400 mill for a period of 1 to 30 min. After milling, dissolve the product in 4 mL of PBS buffer by sonication and vigorous stirring. Finally, centrifuge the mixture at 13528 × g for 10 min to obtain the supernatant. Load the supernatant into a 4 cm path length, 3 cm3 quartz colorimetric dish for fluorescence analysis of the OH adduct, 2-hydroxyterephthalic acid. Set the excitation wavelength (λexcitation) to 315 nm and measure the fluorescence (λemission) across the range of 375–550 nm, with the maximum emission wavelength (λmax) at 425 nm. Compare the results with the standard curve of 2-hydroxyterephthalic acid.

Catalyst recycling experiments

To validate the recyclability of the catalyst, three cycles of NIPAM polymerization were performed. The polymerization conditions are the same as the general procedure for mechanically controlled polymerization carried out in a ball mill. After the first cycle, the resulting polymer was dissolved in DMF. Subsequently, the MoS2 was successfully recovered through three centrifugations and washing steps with water, and dried under vacuum for the subsequent recycling experiments.

Free radical scavenging test

To verify the role of different free radicals in the polymerization process, three experiments were designed: Experiment 1 without adding any scavenger, Experiment 2 with 10 mM ethanol (EtOH) as a free radical scavenger, and Experiment 3 with 10 mM isopropyl alcohol (IPA) to specifically capture hydroxyl radicals. The reaction system also consisted of 10 mg of 2D MoS2, 10 mg of KPS, 300 mg of NIPAM, 10 mM scavenger and 20 μL of water. The results were observed after a 1 min.

Rheology measurements

Rheology measurements were conducted using an DHR rheometer (TA, USA). The frequency sweep experiment was performed over the frequency range of 0.1–100 rad s−1 at a fixed strain of 1% at 25 °C. Compression test of hydrogel was performed on Discovery DMA 850 at a speed of 1 mm/min. The hydrogel samples were cut into cylinder shape with a diameter of 10 mm and a height of 10 mm. The temperature was kept at 25 °C.

Piezoelectric response test

Piezoelectric response of ZnO, BaTiO3 and MoS2 under magnetic stirring conditions were tested using a three-electrode system. Add 2.5 mg of the mechanoredox catalyst into 1 mL of perfluorinated resin solution (Nafion 117). Next, subject the mixture to ultrasound for 30 min to ensure the uniform distribution of the catalyst within the solution. The ratio of the volume of Nafion 117 solution to deionized water is 1:99. Subsequently, apply 5 μl of the resultant suspension onto the surface of a pristine glassy carbon electrode with a diameter of 3 mm. Place the electrode in a desiccator to dry, thereby obtaining an electrode loaded with the test sample, designated as the working electrode. Finally, utilize a three-electrode system to evaluate the current response under magnetic stirring conditions. In the experimental setup, a platinum wire was employed as the counter electrode, with a saturated calomel electrode (SCE) serving as the reference electrode. A glassy carbon electrode was utilized as the working electrode. The electrolyte used was a 0.2 M Na2SO4 solution, and the initial bias potential at the working electrode was set to zero during the measurement period. The solution was magnetically stirred at a frequency of 1500 rpm. The experiments were conducted in the following sequence: A blank experiment was performed without the addition of any piezoelectric catalyst at the glassy carbon electrode. A mixed solution containing ZnO was added to the electrolyte at the working electrode. Subsequently, a mixed solution containing BaTiO3 was introduced to the electrolyte at the working electrode. Finally, a mixed solution containing MoS2 was dripped into the electrolyte at the working electrode. Each test was conducted to evaluate the effect of the respective piezoelectric catalysts on the electrochemical reactions.

Ionic conductivity test

The ionic conductivity of the hydrogel was measured by the impedance spectrum in a frequency range of 1 to 1 × 106 Hz. Hydrogels were prepared into a sheet with a cross sectional area (A) of 1 cm2 and a thickness (d) of 2 mm. The hydrogel sheets were sandwiched between two pieces of foamed nickel mesh. The resistance (R) was the intercept through the horizontal axis in the EIS diagram. The conductivity (σ) was calculated by the following formula:

Materials characterizations

Morphology of MoS2 was characterized by SEM (Hitachi SU8010). HRTEM (Talos F200S). Structure analysis of the MoS2 was carried out on D8 Advance XRD. XPS was measured with the Thermo Fisher Scientific ESCALAB 250 Xi, Al Ka source (MA, USA). The piezoelectric properties of MoS2 are obtained by piezoresponse force microscopy (PFM) Bruker Dimension Icon. Fourier transform infrared spectroscopy spectra (FT-IR) were obtained using a Thermo Nicolet-is5 transform infrared spectrometer. NMR spectroscopy was carried out on a Varian Unity 300 MHz spectrometer operating at 300 MHz. Deuterated solvent (D2O or CDCl3) was employed as reference and sample concentrations were approximately 10 mg/mL. Gel permeation chromatography (GPC) data were obtained using a TOSOH HLC-8320 SEC equipped with a TSK gel Multipore HZ-N (3) 4.6 × 150 mm column at 40 °C. DMF served as the eluent with a flow rate of 0.35 mL min−1. GPC samples were injected using the TOSOH HLC-8320 SEC plus autosampler. The molecular weights were calibrated with PMMA standards. GPC data of polymerization of AM was obtained using a DAWN HELEOS II/Waters1515 system at 30 °C. Aqueous buffer (0.2 M NaNO3, 0.01 M Na3PO4 in Milli-Q water with 200 ppm NaN3, pH 8) served as the eluent with a flow rate of 0.5 mL min−1. The molecular weight of polyacrylamide was calibrated with PEG standards.

Data availability

All the data that support the findings are available within the main text and the Supplementary Information. Source Data are available with this paper. Source data are provided with this paper.

References

Seetharaman, S. et al. Microtubules tune mechanosensitive cell responses. Nat. Mater. 21, 366–377 (2022).

Silver, J. S. et al. Injury-mediated stiffening persistently activates muscle stem cells through YAP and TAZ mechanotransduction. Sci. Adv. 7, eabe4501 (2021).

Hsu, T. G. et al. A polymer with “Locked” degradability: superior backbone stability and accessible degradability enabled by mechanophore installation. J. Am. Chem. Soc. 142, 2100–2104 (2020).

May, P. A. & Moore, J. S. Polymer mechanochemistry: techniques to generate molecular force via elongational flows. Chem. Soc. Rev. 42, 7497–7506 (2013).

Yang, J. & Xia, Y. Mechanochemical generation of acid-degradable poly(enol ether)s. Chem. Sci. 12, 4389–4394 (2021).

Awaja, F., Zhang, S. N., Tripathi, M., Nikiforov, A. & Pugno, N. Cracks, microcracks and fracture in polymer structures: Formation, detection, autonomic repair. Prog. Mater Sci. 83, 536–573 (2016).

Wang, S. et al. Facile mechanochemical cycloreversion of polymer cross-linkers enhances tear resistance. Science 380, 1248–1252 (2023).

Matsuda, T., Kawakami, R., Namba, R., Nakajima, T. & Gong, J. P. Mechanoresponsive self-growing hydrogels inspired by muscle training. Science 363, 504–508 (2019).

Li, X. & Gong, J. P. Design principles for strong and tough hydrogels. Nat. Rev. Mater. 9, 380–398 (2024).

Zhang, K. et al. Shape morphing of hydrogels by harnessing enzyme enabled mechanoresponse. Nat. Commun. 15, 249 (2024).

Zhang, Y. et al. Modulus adaptive lubricating prototype inspired by instant muscle hardening mechanism of catfish skin. Nat. Commun. 13, 377 (2022).

Lei, Z., Wang, Q., Sun, S., Zhu, W. & Wu, P. A bioinspired mineral hydrogel as a self‐healable, mechanically adaptable ionic skin for highly sensitive pressure sensing. Adv. Mater. 29, 1700321 (2017).

Zheng, Y. & Li, C. Photothermally-driven oxazine hydrogel actuators at the water-air interface. Giant 16, 100192 (2023).

Fan, F. et al. Converting “sliding” to “rolling” design for high-performance lubricating hydrogel. Giant 9, 100296 (2024).

Yu, D. et al. Enhanced catalytic performance by multi-field coupling in KNbO3 nanostructures: Piezo-photocatalytic and ferro-photoelectrochemical effects. Nano Energy 58, 695–705 (2019).

Guo, T. M. et al. Chiral two-dimensional hybrid organic-inorganic Perovskites for Piezoelectric ultrasound detection. J. Am. Chem. Soc. 145, 22475–22482 (2023).

Kubota, K., Pang, Y. D., Miura, A. & Ito, H. Redox reactions of small organic molecules using ball milling and piezoelectric materials. Science 366, 1500–1504 (2019).

Schumacher, C., Hernández, J. G. & Bolm, C. Electro‐mechanochemical atom transfer radical cyclizations using Piezoelectric BaTiO3. Angew. Chem. Int. Ed. 132, 16499–16502 (2020).

Tian, W. et al. Vibration‐driven reduction of CO2 to acetate with 100 % Selectivity by SnS nanobelt Piezocatalysts. Angew. Chem. Int. Ed. 62, e202306964 (2023).

Zhang, Y. et al. Enhanced piezo-catalytic H2O2 production over Bi0.5Na0.5TiO3 via piezoelectricity enhancement and surface engineering. Chem. Eng. J. 465, 143043 (2023).

Wang, Z., Ayarza, J. & Esser-Kahn, A. P. Mechanically initiated bulk-scale free-radical polymerization. Angew. Chem. Int. Ed. 58, 12023–12026 (2019).

Ayarza, J. et al. Bioinspired mechanical mineralization of organogels. Nat. Commun. 14, 8319 (2023).

Orrego, S. et al. Bioinspired materials with self-adaptable mechanical properties. Adv. Mater. 32, e1906970 (2020).

Ayarza, J., Wang, Z., Wang, J. & Esser-Kahn, A. P. Mechanically promoted synthesis of polymer organogels via disulfide bond cross-linking. ACS Macro Lett 10, 799–804 (2021).

Mohapatra, H., Kleiman, M. & Esser-Kahn, A. P. Mechanically controlled radical polymerization initiated by ultrasound. Nat. Chem. 9, 135–139 (2016).

Ding, C. et al. Piezoelectrically mediated reversible addition–fragmentation chain-transfer polymerization. Macromolecules 55, 4056–4063 (2022).

Zhou, M. et al. Mechanically driven atom transfer radical polymerization by piezoelectricity. ACS Macro Lett 12, 26–32 (2023).

Padmakumar, A. K., Singha, N. K., Ashokkumar, M., Leibfarth, F. A. & Qiao, G. G. Ultrasound-Assisted RAFT polymerization in a continuous flow method. Macromolecules 56, 6920–6927 (2023).

Chakma, P. et al. Mechanoredox catalysis enables a sustainable and versatile reversible addition-fragmentation chain transfer polymerization process. Angew. Chem. Int. Ed. 62, e202215733 (2023).

Wang, Z. et al. Bio-inspired mechanically adaptive materials through vibration-induced crosslinking. Nat. Mater. 20, 869–874 (2021).

Tu, S. et al. Piezocatalysis and Piezo‐Photocatalysis: catalysts classification and modification strategy, reaction mechanism, and practical application. Adv. Funct. Mater. 30, 2005158 (2020).

Nothling, M. D., Daniels, J. E., Vo, Y., Johan, I. & Stenzel, M. H. Mechanically activated solid-state radical polymerization and cross-linking via piezocatalysis. Angew. Chem. Int. Ed. 62, e202218955 (2023).

Zeitler, S. M., Chakma, P. & Golder, M. R. Diaryliodonium salts facilitate metal-free mechanoredox free radical polymerizations. Chem. Sci. 13, 4131–4138 (2022).

Zhu, C. N. et al. Reconstructable gradient structures and reprogrammable 3D deformations of hydrogels with coumarin units as the photolabile crosslinks. Adv. Mater. 33, 2008057 (2021).

Liu, K. et al. Dimensional optimization for ZnO-based mechano-ATRP with extraordinary activity. J Phys Chem Lett 13, 4884–4890 (2022).

Wu, W. et al. Piezoelectricity of single-atomic-layer MoS2 for energy conversion and piezotronics. Nature 514, 470–474 (2014).

Wu, J. M., Chang, W. E., Chang, Y. T. & Chang, C. K. Piezo-catalytic effect on the enhancement of the ultra-high degradation activity in the dark by single- and few-layers MoS2 nanoflowers. Adv. Mater. 28, 3718–3725 (2016).

Hu, Z. et al. MoS2 nanoflowers with expanded interlayers as high-performance anodes for sodium-ion batteries. Angew. Chem. Int. Ed. 53, 12794–12798 (2014).

Bößl, F. & Tudela, I. Piezocatalysis: can catalysts really dance? Curr. Opin. Green Sustain. Chem. 32, 100537 (2021).

Nwoye, E., Raghuraman, S., Costales, M., Batteas, J. & Felts, J. R. Mechanistic model for quantifying the effect of impact force on mechanochemical reactivity. Phys. Chem. Chem. Phys. 25, 29088–29097 (2023).

Peng, F. et al. Kinetics and mechanisms of enhanced degradation of ibuprofen by piezo-catalytic activation of persulfate. Chem. Eng. J. 392, 123818 (2020).

Ge, Q. et al. 3D printing of highly stretchable hydrogel with diverse UV curable polymers[J]. Sci. Adv. 7, eaba4261 (2021).

Lee, K. M. et al. Multifunctional role of MoS2 in preparation of composite hydrogels: radical initiation and cross-linking. ACS Appl. Mater. Interfaces. 12, 8642–8649 (2020).

Zhang, Y. et al. Fabrication of flexible accelerated-wound-healing chitosan/dopamine-based bilayer hydrogels for strain sensors. Int. J. Biol. Macromol 253, 127395 (2023).

Deo, K. A. et al. Nanoengineered ink for designing 3D printable flexible bioelectronics. ACS Nano 16, 8798–8811 (2022).

Ye, Y., Zhang, Y., Chen, Y., Han, X. & Jiang, F. Cellulose nanofibrils enhanced, strong, stretchable, freezing-tolerant ionic conductive organohydrogel for multi-functional sensors. Adv. Funct. Mater. 30, 2003430 (2020).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (22471185 to Z.W.), Science and Technology Program of Suzhou (ZXL2022480 to Z.W.).

Author information

Authors and Affiliations

Contributions

J.W. and Z.W. conceived the concept; J.W., C.D., and K.C. designed the experiments; J.W., Z.H., L.Z., and R.D. performed the experiments and analyzed the data; J.W. conducted the finite element simulation. All authors participated in writing the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, J., Han, Z., Zhang, L. et al. Two dimensional MoS2 accelerates mechanically controlled polymerization and remodeling of hydrogel. Nat Commun 16, 1689 (2025). https://doi.org/10.1038/s41467-025-57068-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-57068-2

This article is cited by

-

Progress in the integration of 3D printing technology with photothermal materials for osteosarcoma treatment

Advanced Composites and Hybrid Materials (2025)