Abstract

Direct electrochemical ethylene (C2H4) epoxidation with water (H2O) represents a promising approach for the production of value-added ethylene oxide (EO) in a sustainable way. However, the activity remains limited due to the sluggish activation of C2H4 and the stiff formation of *OH intermediate. This paper describes the design of a Ag/SnO2 electrocatalyst to achieve efficient electrochemical C2H4 epoxidation with a high faradaic efficiency of 39.4% for EO and a high selectivity of 91.5% at 25 mA/cm2 in a membrane electrode assembly. Results of in situ attenuated total reflection infrared spectra characterizations and computational calculations reveal that the Ag/SnO2 interface promotes C2H4 adsorption and activation to obtain *C2H4. Moreover, electrophilic *OH is generated on the catalyst surface through H2O dissociation, which further reacts with *C2H4 to facilitate the formation of *C2H4OH, contributing to the enhanced electrochemical epoxidation activity. This work would provide general guidance for designing catalysts for electrochemical olefin epoxidation through interface engineering.

Similar content being viewed by others

Introduction

Ethylene oxide (EO) is an important chemical that can generate ethylene glycol, ethylene glycol ethers, and ethanolamines, which is one of the major derivatives of ethylene (C2H4)1,2. Production of EO exceeds 35 million tons per year, and the demand for EO has been increasing in recent years3. Currently, EO is produced by the direct oxidation of ethylene with O2 on CsRe promoted Ag/Al2O3 catalyst in the industry at a relatively high temperature and high pressure (200–270°C and 1–3 MPa)4,5,6, which could cause significant carbon dioxide emissions (Fig. S1). To reduce carbon footprint, the use of electrified heating by renewable electricity could replace traditional heating systems from fossil fuel combustion7,8. Over recent years, electrothermal methods like joule-heat, induction-heat, microwave, and plasma have already attracted great attention9, which have been used in C2H4 epoxidation systems10. At the same time, direct C2H4 electro-oxidation is another important approach with the advantage of simplicity and variability11,12,13, and the epoxidation might replace the conventional oxygen evolution reaction (OER) to produce high-value product at the anode.

According to the varied reaction mechanisms, electrochemical C2H4 epoxidation can be categorized into different approaches. The halide-mediated method that generates Cl2 or Br2 to oxide alkene for epoxidation production has been demonstrated effective3,14,15,16. However, this method requires further development to mitigate halide corrosion and prevent leakage of Cl2/Br2. Recently, instead of using halide as a mediator, adopting H2O as the oxygen source for alkene epoxidation under mild conditions has shown great promise17,18,19,20,21,22. The method has been proved feasible by Holbrook and Wise in 197520, while the current density on Ag catalyst is rather low (~10−3 mA/cm2) and faradaic efficiency (FE) is not reported. Geng group investigates the facet effect on Ag3PO4 for C3H6 epoxidation21. Ag3PO4 cubes with (100) facets exhibit the highest propylene oxide FE of 18.7% with total current density of ~1.6 mA/cm2 at 2.2 V. The low current density remains a great challenge for industrial applications. Manthiram and coworkers use organic solvent to increase olefin solubility for epoxidation activity promotion22, while adding organic solvent may make separation difficult. To achieve high current density and faradaic efficiency for C2H4 epoxidation, we believe the design of an efficient electrocatalyst is essential.

Ag-based catalysts have been regarded as the most active industrial catalysts for aerobic epoxidation1. The moderate O-bonding strength on the Ag surface is believed to be essential for the high activity6, and the electrophilic oxygen promotes EO formation4. The suitable adsorption of oxygen species is also an important feature of catalysts for electrochemical epoxidation23,24,25,26. Therefore, Ag would be a potential candidate for electrochemical epoxidation21,27. However, during the electrochemical epoxidation by H2O, electrophilic oxygen species like OER intermediate should be formed by the dissociation of H2O molecules28, which could hardly be achieved by Ag catalyst only29,30. Meanwhile, the weak adsorption of C2H4 on Ag would further hinder electrochemical epoxidation20, as evidenced by its low binding energy of 0.06 eV on Ag(111) according to DFT calculations6. As a result, the key points to design catalysts for epoxidation with H2O are the promotion of H2O dissociation for the generation of electrophilic oxygen species31,32 and enhancing C2H4 adsorption.

The construction of metal/metal oxide heterojunction has proven to be an effective way to promote electrophilic species formation during OER by activating H2O on metal oxide33,34,35,36. Meanwhile, supported Ag with appropriate support interaction shows good catalytic performance for thermal epoxidation by enhancing C2H4 adsorption37,38,39. Therefore, adding suitable oxide support to the Ag catalyst could effectively promote electrochemical epoxidation performance. Among various metal oxides, SnO2 shows the capability to facilitate H2O adsorption and promote O-intermediate generation because of its high oxophilicity40,41. Besides, SnO2 itself is not so active in catalyzing the oxygen evolution reaction42. Thus, the side OER reaction could be prohibited for better selectivity toward EO. Moreover, the SnO2 combined with metal can adsorb organic molecules due to the abundant metal-oxide interface43,44,45. Considering these points, Ag/SnO2 catalyst would potentially facilitate the electrochemical epoxidation of C2H4.

Herein, we design a Ag/SnO2 catalyst with Ag nanoparticles supported on SnO2 for electrochemical epoxidation of C2H4. It shows a high faradaic efficiency of 39.4% for EO and a high selectivity of 91.5% at 25 mA/cm2 in a membrane electrode assembly (MEA) cell46,47. During the reaction, the MEA system overcame the low C2H4 solubility, and the C2H4 adsorbed on Ag reacted with the reactive electrophilic *OH species generated by SnO2, leading to enhanced electrochemical epoxidation activity.

Results and Discussion

Synthesis and characterization of catalysts

A series of Ag/SnO2 catalysts with different Ag loadings (i.e., 5 wt%, 10 wt%, and 20 wt% Ag/SnO2, denoted as 5Ag/SnO2, 10Ag/SnO2, 20Ag/SnO2, respectively) were synthesized by a NaBH4 reduction method (Supplementary Table 1). Transmission electron microscopy (TEM) and high-resolution TEM (HRTEM) were performed to illustrate the structure of the samples with different Ag loadings (Fig. 1a, b, and Fig. S2). The particle size of the SnO2 support is ~ 100 nm in 10Ag/SnO2. The uniform dispersion of the Ag nanoparticles at Ag/SnO2 with different loading was further supported by the energy dispersive X-ray spectroscopy (EDS) mappings (Fig. 1c, Figs. S3, and S4). Ag nanoparticles with the size of 20 nm are loaded on the SnO2 support regardless of the Ag loading. Therefore, a moderate amount of Ag-SnO2 interface could be formed in the 10Ag/SnO2 compared with the 5Ag/SnO2 and 20Ag/SnO2 samples. For the Ag/SnO2 catalysts, The HRTEM image of Ag nanoparticle displays a fringe distance of 0.24 nm, matching the (111) plane of Ag. For SnO2, the lattice fringes with a d-spacing of 0.26 nm and 0.33 nm correspond (101) and (110) plane of SnO2 (Fig. 1b and Fig. S2). X-ray photoelectron spectroscopy (XPS) was performed to study the surface state of Ag (Fig. 1d). The peaks at 368.1 eV and 367.2 eV of Ag 3 d XPS spectrum could be ascribed to Ag0 and Agδ+, respectively48. For the fresh 10Ag/SnO2 catalyst, the XPS spectrum indicates that the surface of Ag is predominately metallic. The phase structure investigation of 10Ag/SnO2 was performed by X-ray diffraction (XRD, Fig. 1e). For the fresh 10Ag/SnO2, the diffraction peaks match well with the metallic Ag (JCPDS# 04-0783) and SnO2 (JCPDS# 41-1445), which confirm the coexistence of Ag and SnO2.

a TEM image of fresh 10Ag/SnO2. b HRTEM image of fresh 10Ag/SnO2. c HAADF-STEM image and corresponding EDS element mapping of 10Ag/SnO2. d Ag 3 d XPS spectra of fresh 10Ag/SnO2 and spent 10Ag/SnO2. e XRD patterns of fresh 10Ag/SnO2 and spent 10Ag/SnO2. The a.u. stands for arbitrary units. Source data are provided as a Source Data file.

Catalytic performance of Ag/SnO2 for electrochemical epoxidation of C2H4

Linear sweeping voltammetry (LSV) tests of 10Ag/SnO2 were conducted in 0.05 M KOH electrolyte in an H-cell. As shown in Fig. 2a, 10Ag/SnO2 exhibits an oxidation peak at 1.05 V vs reversible hydrogen electrode (RHE, this reference is used throughout the article unless otherwise noted), which could be attributed to the oxidation of Ag to AgxO49. Meanwhile, 10Ag/SnO2 exhibits a higher current in C2H4 than in Ar, demonstrating that C2H4 oxidation is more favorable than OER on 10Ag/SnO2, and the overpotential of C2H4 oxidation is 0.6 V according to LSV test.

a LSV of 10Ag/SnO2 in C2H4 and Ar in 0.05 M KOH electrolyte at a scan rate of 50 mV/s. b FE of products and EO selectivity on Ag/SnO2 with different Ag loadings at 25 mA/cm2. c FE of EO for 10Ag/SnO2, Ag, and SnO2 at different current densities. d Stability test of 10Ag/SnO2 at cell voltage of 4.2 V. Error bars represent standard deviations from the mean of at least three repeated experiments. The experiments are conducted without iR compensation, and the loading of catalysts is 0.2 mg/cm2. Source data are provided as a Source Data file.

Considering the low solubility of C2H4 in water50, to overcome the mass transfer limitations of ethylene, MEA system was adopted (Figs. S5 and S6). The products accumulated in the anode chamber were collected and quantified immediately after the reaction by 1H nuclear magnetic resonance (NMR) spectroscopy (Figs. S7 and S8) and headspace gas chromatography (GC, Fig. S9). The gaseous products were quantified by online GC. The NMR results indicate that EO is the main liquid product of the C2H4 oxidation on 10Ag/SnO2. The catalytic performances of Ag/SnO2 with different Ag loadings were investigated (Fig. 2b). Particularly, 10Ag/SnO2 exhibits a notably enhanced catalytic activity compared with 5Ag/SnO2 and 20Ag/SnO2. An EO faradaic efficiency (FE) of 39.4% with 91.5% EO selectivity was achieved on 10Ag/SnO2 at 25 mA/cm2. The selectivity of 5Ag/SnO2 and 20Ag/SnO2 samples are 70.6% and 78.1% at 25 mA/cm2, respectively. The EO FE and selectivity first increased and then decreased with the increase in Ag loading for Ag/SnO2 catalysts. Considering the particle size does not change with the Ag loading, the varied performance of different samples indicates that the tuning of the metal-support interface is important to promote the activity. To further reveal the beneficial effect of the metal/metal oxide interface, control samples of Ag and SnO2 catalysts were tested for the epoxidation activity (Figs. S10 and S11). As shown in Fig. 2c and Fig. S12, 10Ag/SnO2 exhibits the highest EO FE compared to Ag and SnO2 at all applied currents. SnO2 is inert for electrochemical epoxidation. These results reveal the synergetic effect of Ag and SnO2 for the electrochemical epoxidation reaction. The selectivity of EO on 10Ag/SnO2 could reach 91.5% at 25 mA/cm2 (Fig. S13), which is at a similar level as the industrial catalysts for thermal catalytic epoxidation of C2H4 like AgReCs/Al2O34 and Ir1/α-MnO251. The catalysts were further tested by chronoamperometry experiments to evaluate the epoxidation performance. The EO FE of 10Ag/SnO2 is higher than Ag at different cell voltages, and 10Ag/SnO2 reaches about 2 times higher current density than Ag at 4.2 V cell voltage (Fig. S14). Simultaneously, As shown in Fig. S15, the full-cell energy efficiency of EO on 10Ag/SnO2 reaches 8.1% at 3.8 V, and achieves a maximum value of 9.4% as the cell voltage increases to 4.2 V, and decreases to 6.2% as the cell voltage increases to 5 V. The energy efficiency of EO on 10Ag/SnO2 is higher than Ag at all cell voltages. The electrochemical impedance spectroscopy (EIS) measurements were further carried out to further gain electrochemical information of catalysts42. As shown in Fig. S16, 10Ag/SnO2 shows smaller radius compared to Ag, indicating the good charge transfer process associated with electrochemical reaction. The uniform dispersion of the Ag nanoparticles on 10Ag/SnO2 remains uniform after reaction (Fig. S17), and the surface of the Ag particle is oxidized as evidenced by Ag 3 d XPS spectrum of spent 10Ag/SnO2 (Fig. 1d). The O 1 s XPS spectrum was deconvoluted into three peaks at 530.2, 531.1, and 532.3 eV, corresponding to oxygen lattice, oxygen vacancies, adsorbed molecular water, respectively52 (Fig. S18). The presence of oxygen vacancies would improve the conductivity of SnO253 and facilitate the dissociation of water54, thus promoting the reaction. In the deconvoluted Sn 3 d XPS spectrum (Fig. S19), the Sn 3d5/2 binding energy of SnO2 and SnO are located at 486.8 and 486.3 eV, respectively55, confirming Sn4+ is the dominant valence state with minor Sn2+. However, the XRD pattern of the spent catalyst still matches well with Ag and SnO2 (Fig. 1e), without the presence of the Ag oxide phase. This result indicates the bulk of Ag remains in a metal state during the reaction. This phenomenon is also confirmed by the XPS depth profiling of spent 10Ag/SnO2 (Fig. S20), which shows gradually intensified signals of Ag0 with the increase of sputtering depth. The XPS and XRD investigations reveal that Ag nanoparticles are partially oxidized at the surface during electrochemical epoxidation48. In addition, the long-term test was performed at 4.2 V cell voltage in the MEA system (Fig. 2d). The 10Ag/SnO2 shows a stable EO FE of about 39% for 8 hours and EO FE decreases slowly to 30% for 12 hours, and the EO selectivity shows the similar tendency while the current decreases slowly to 10.5 mA/cm2, after stability test no bulk silver oxide is detected by XRD (Fig. S21). Fig. S22 shows that the contact angle decreases from 95° to 72° after the reaction, indicating the loss of hydrophobicity. When the surface becomes hydrophilic, more water accumulates on the electrode and holds back the C2H4 reaction, which might be the cause of deactivation56.

Mechanisms for C2H4 adsorption study on Ag/SnO2

Room temperature infrared spectroscopy (IR) characterizations were performed at the gas-solid interface without applied polarization to investigate the adsorption behavior of C2H4 on pre-oxidized catalysts (details in supporting information). The catalyst powder was pre-oxidized by calcination in air to simulate the oxidation process on catalyst during electrochemical epoxidation. As shown in Figs. S23 and S24, the surface of pre-oxidized 10Ag/SnO2 is oxidized while the bulk remains metal, which indicates that the structure of pre-oxidized catalyst show a certain similarity with catalysts in electrochemical epoxidation. Thus the room temperature IR results could reflect the adsorption ability of C2H4 in some way. The characteristic bands could be assigned as follows57: out-of-plane wagging mode of gas-phase C2H4 (940 cm−1), scissoring mode of CH2 (1420 cm−1), combination mode of CH2 (1900 cm−1), and asymmetric stretching mode of CH2 (3100 cm−1). As shown in Fig. S25, the C2H4 peaks on Ag and SnO2 disappear after Ar purge. In contrast, 10Ag/SnO2 exhibits strong interaction between C2H4 and the catalyst after room temperature desorption. The C2H4 adsorption behaviors on catalysts were further characterized by real-time IR spectroscopy. The samples were purged with Ar after C2H4 adsorption. The time-dependent evolution of the surface species was monitored by the IR spectra (Fig. 3a, b, and Fig. S26). The normalized intensity of the CH band at 3100 cm−1 (Fig. 3c) is employed to reveal the behavior of C2H4 adsorption on the catalysts. The signal of C2H4 on 10Ag/SnO2 is higher than Ag and SnO2, demonstrating a more intense interaction between C2H4 and 10Ag/SnO2. Meanwhile, the temperature-programmed desorption (TPD) of C2H4 experiments were performed to elucidate the C2H4 adsorption behavior. As shown in Fig. 3d, the desorption temperature of C2H4 on Ag is about −50°C, while it is shifted to a higher temperature of −6°C on 10Ag/SnO2 with the desorption process ending at 30°C. This result reveals the enhanced C2H4 adsorption on 10Ag/SnO2. These observations demonstrate that the Ag/SnO2 interface promotes C2H4 adsorption, and increases the local concentration of C2H4 for epoxidation. The C2H4 IR and TPD results could reflect the C2H4 absorption behavior of the catalysts, while the C2H4 adsorption behavior might change during the electrochemical epoxidation because of the electrochemical environment.

Real-time C2H4 adsorption IR spectrum after Ar purge on a 10Ag/SnO2, and b Ag. c The time profile of the normalized intensity of C2H4 adsorption on 10Ag/SnO2, Ag, and SnO2. The normalization of the IR intensity was achieved by dividing the peak area of the band at 3100 cm−1 by the initial peak area of the band at 3100 cm−1. d C2H4-TPD of 10Ag/SnO2, Ag, and SnO2. The a.u. stands for arbitrary units. The powder was pre-oxidized before C2H4 adsorption IR and C2H4-TPD test. Source data are provided as a Source Data file.

In situ ATR-SEIRAS spectroscopy and DFT for mechanism study

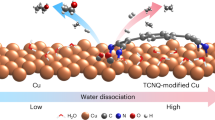

To gain insight into the electrochemical epoxidation mechanism, in situ electrochemical attenuated total reflection surface-enhanced infrared absorption spectroscopy (ATR-SEIRAS) was further employed to investigate the reaction mechanism (Fig. S27)58,59. The 10Ag/SnO2 shows a stable asymmetric stretching mode of CH2 at 3100 cm−1 in a broad potential range of 1.2 V to 1.7 V, which is attributed to adsorbed C2H4 (Fig. 4a). For comparison, such a band is absent on Ag and SnO2 (Fig. 4b and Fig. S28), further confirming the importance of the Ag/SnO2 interface for enhancing the adsorption of C2H4. XPS spectra show that the binding energy of Ag 3 d for 10Ag/SnO2 shifts to a lower binding energy compared to the reference Ag (Fig. S29), which indicates that the electron density of Ag on Ag/SnO2 decreases due to the strong interaction between Ag and SnO2 (Fig. S30). Bader charge analysis also shows that the interface of Ag on Ag/SnO2 lose 0.15 electron to Sn (Fig. S31). The Ag with electron deficiency could promote C2H4 adsorption and activation60. The bending band of adsorbed OH at 1155 cm−1 appears at 1.3 V on 10Ag/SnO2 and SnO261,62, and the peak increases from 1.3 V to 1.7 V. However, this band is not observed on Ag at all potentials. It is considered that the adsorbed H2O is consumed and *OH forms during the reaction on 10Ag/SnO2 and SnO2. This result is also confirmed in the Ar saturated solution that 10Ag/SnO2 and SnO2 facilitate *OH formation during the OER reaction (Fig. S32). The ATR-SEIRAS results illustrate that the Ag/SnO2 interface could enhance the adsorption of ethylene, and the addition of SnO2 promotes H2O activation to provide electrophilic *OH, which is expected to facilitate the epoxidation reaction. This is further demonstrated by differential electrochemical mass spectrometry (DEMS)23. The DEMS test was performed with a slow scan rate of potential (1 mV/s) to detect EO and O2. The m/z signal of 29 was monitored for EO, and the m/z signal of 32 was monitored for O2 (Fig. S33). The results shows that EO formation starts at potential of 1.4 V, which is lower than O2 evolution at potential of 1.5 V. These observations indicates that EO could generate before O2 generation, which indicates intermediate of OER might participate the epoxidation reaction, corresponding to the ATR-REIRAS results. Besides, the H2O2 reaction pathway is excluded by titration with KMnO4 (Fig. S34).

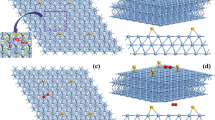

In situ ATR-SEIRAS of a 10Ag/SnO2, b Ag in 0.05 M KOH solution in C2H4 atmosphere, the band at 1250 cm−1 is assigned to SiO2 formation by Si substrate. The a.u. stands for arbitrary units. The experiments are conducted without iR compensation. c DFT calculation of the potential energy profile for the electrochemical epoxidation of C2H4 on Ag/SnO2 and Ag with *OH-mediated reaction pathway. d Schematic illustration of the mechanism of the enhanced C2H4 epoxidation activity on Ag/SnO2. The light gray, red, blue, black, and white spheres represent Ag, O, Sn, C, and H atoms, respectively. Source data are provided as a Source Data file.

To further elucidate the underlying reason for the high activity on Ag/SnO2 catalysts, density functional theory (DFT) calculations were performed63. According to XPS results, Ag with partly oxidized surface on SnO2, Ag with partly oxidized surface, and SnO2 were used as model (Fig. S35). The reaction is divided into three key stages21: adsorption and dissociation of H2O with ethylene adsorption, oxygenation of ethylene, and formation of EO. We first calculate the adsorption of C2H4 and H2O on Ag/SnO2, Ag, and SnO2. As shown in Figs S36 and S37, SnO2 shows inert ability to adsorb C2H4, while Ag/SnO2 strengthens the C2H4 adsorption. Besides, the addition of the SnO2 support in Ag/SnO2 promotes H2O adsorption. The adsorbed H2O could be oxidized to *OH or further oxidization to *O, which shows two epoxidation reaction pathways by *OH or *O. We investigate the reaction process along *OH-intermediate (Fig. 4c and Figs. S38–S41), the results show the formation of OH* is energetically favorable at Ag/SnO2 compared to Ag. Then, C2H4 adsorption occurs on Ag atoms and reacts with *OH to form *C2H4OH intermediate. Subsequently, the O-H bond in *C2H4OH is further dissociated and dehydrogenation to *C2H4O intermediate by two steps. Finally, the *C2H4O is transformed to *EO before desorption. During the reaction, the formation of all reaction intermediates on Ag/SnO2 is thermodynamically more favorable than Ag, indicating the occurrence of this reaction could be more readily on Ag/SnO2 for the high efficiency of EO production. With regard to *O-mediated reaction process, as shown in Figs S42 and S43, the formation of *O from *OH is difficult for both Ag/SnO2 (3.14 eV) and Ag (1.78 eV), indicating that the C2H4 epoxidation pathway might be preferred on *OH-intermediate on Ag/SnO2 and Ag. Thus, C2H4 is strongly adsorbed on Ag/SnO2 compared to Ag, and oxidized by *OH produced by SnO2 on Ag/SnO2, which could make the production of EO more efficient (Fig. 4d).

In summary, Ag/SnO2 catalysts are designed to promote electrochemical C2H4 epoxidation to ethylene oxide (EO). A notable enhancement in the activity is observed on Ag/SnO2, achieving an EO FE of 39.4%, and 91.5% selectivity. While the energy efficiency of EO could only reach 9.4%, and effort should be made to minimize the ohmic resistance to get superb voltammetric performance, increasing high energy efficiency for application value. Infrared spectroscopy elucidates the metal/metal oxide interface in Ag/SnO2 strengthens C2H4 adsorption to form *C2H4. Meanwhile, SnO2 promotes water dissociation to provide electrophilic *OH to react with *C2H4, enhancing epoxidation at the interface. This work offers a strategy to design high-performance catalysts for electrochemical epoxidation through the introduction of metal oxide support and tuning of the interface.

Methods

Material

AgNO3 (99.8%) and KOH (95%) were purchased from Aladdin Industrial Co., Ltd. SnO2 (99.9%) was purchased from 3 A Chemical Reagent Co., Ltd. NaBH4 (95%) was purchased from Adamas Co., Ltd. C2H5OH (GR), KMnO4 (AR), H2SO4 (GR) was purchased from Tianjin Kemiou Chemical Reagent Co., Ltd. The reagents were used without any purification process. Commercially available carbon-based gas diffusion layers (GDLs, AvCarb GDS3250) were purchased from Xima Laya Photo-Electric Technology Co., Ltd. Fumion FAA anion exchange resin and FAA-3-50 membranes with a thickness of 50 µm were purchased from SCI Materials Hub. H2 (≥99.99%), N2 (≥99.99%), Ar (≥99.99%), O2 (≥99.99%), and C2H4 (≥99.9%) were supplied by Air Liquide. Standards of EO solution was purchased from Shandong Jianpu Chemical Reagent Co. Deionized water (18.25 MΩ cm−1) was employed by a Millipore Direct-Q5 to prepare all aqueous solutions.

Catalyst preparation

0.5 g of commercial SnO2 was put into 20 mL of water in a beaker with vigorous stirring for 30 min, and 90 mg of AgNO3 was dissolved in this solution with another stirring for 1 h. Then, 3 mL of freshly prepared 0.5 M NaBH4 solution was added into the solution with stirring for 10 min. After the reaction, the product was collected with centrifugation and washed three times with water. Ag/SnO2 catalysts with different loadings were synthesized by adjusting the amounts of AgNO3.

Material characterizations

Transmission electron microscopy (TEM) and high-resolution TEM (HTREM) images were obtained on a JEM-2100 instrument (JEOL). X-ray photoelectron spectroscopy (XPS) measurements were performed on the ESCALAB Xi+ spectrometer (Thermo). The binding energy was calibrated using the C 1 s peak at 284.8 eV as the reference. The XRD pattern was acquired by Bruker D8 Focus (Cu Kα radiation). The ICP-OES tests were performed by Agilent 5800 ICP-OES, and SEM-EDS tests were performed by HITACHI Regulus 8100.

Room temperature IR

In room temperature IR experiments, samples were calcined in air at 150°C for 2 h to simulate the oxidation process in the reaction. The IR experiments were performed with a IS 50 instrument (Nicolet) equipped with a Harrick Scientific DRIFTS cell fitted with ZnSe windows. 40 mg of catalyst sample was loaded in the chamber and sealed. The backgrounds (4 cm−1 resolution, 32 scans) were collected after Ar purging for 15 min at a rate of 20 sccm. The spectra were collected after 30 min C2H4 flow at 20 sccm, and the desorption IR measurements were performed in Ar purge at 20 sccm. IR spectra were recorded continuously during the C2H4 adsorption and desorption process. Real-time IR tests were conducted similarly except for the scan rate changing from 32 to 4 for fast spectra collection.

TPD measurements

In TPD experiments, samples were calcined in air at 150°C for 2 h to simulate the oxidation process in the reaction. The TPD experiments were performed with a Micromeritics AutoChem 2920 apparatus with a liquid nitrogen pump. 100 mg of sample was heated at 200 °C for 0.5 h and cooled down to −70°C in flowing Ar. Then, C2H4 was adsorbed by introducing C2H4 to the catalyst at −70°C for 1 h. After that, the catalyst was purged with Ar for 1 h. The catalyst sample was then heated from −70°C to 150°C at a heating rate of 2°C/min. The signal of C2H4 was recorded by Hiden Qic-20 mass spectrometer (MS). MS signal of C2H4 (m/z = 26, not m/z = 28) was used to exclude CO2 and N2 signal.

Electrochemical measurements

Preparation of electrodes and membrane

10 mg of catalysts and 100 μL of FAA solution (5 wt%) were dispersed in 4.9 mL of ethanol, which was then sonicated for 30 min to form a homogeneous ink. To prepare the electrode, the ink was drop-casted on the carbon paper. The loading of catalysts was 0.2 mg/cm2. The FAA-3-50 was activated in 1 M KOH for 24 h, and washed by water for three times before use.

Preparation of KOH electrolyte solution

2.8 g of KOH was dissolved in water with stirring and diluted to 1 L. Then, the 0.05 M KOH solution was stored in a plastic bottle at room temperature and was used within 3 days. The pH of the 0.05 M KOH solution was 12.73 ± 0.09, which was tested by a pH meter (Mettler Toledo).

LSV test

The LSV test was performed in a H-cell. The H-cell contains a catholyte and an anolyte chamber, which was separated by FAA exchange membrane. Both sides of the cell contained 15 mL 0.05 M KOH solution. In the typical three-electrode system, an Ag/AgCl electrode (Gaoss Union, saturated KCl solution) and Pt foil (Gaoss Union, 99.9%) were used as reference electrode and counter electrode respectively, and carbon paper with catalyst was used as working electrode (1 × 2 cm2, 0.2 mg/cm2). The potentials were measured against Ag/AgCl electrode and were converted to the RHE scale using ERHE = EAg/AgCl + 0.197 + 0.0591 × pH. The reference electrode was calibrated in 0.5 M H2SO4 solution. The solution was saturated with H2 for 30 min before test, and Pt foil worked as both working electrode and counter electrode, and the Ag/AgCl electrode was set as reference electrode. The CV test was performed at a scan rate of 2 mV/s, and the onset potential of HER is the zero potential relative to the RHE.

Electrochemical epoxidation experiments

The reactions were carried out using an MEA system. GDE anode (2 × 2 cm2), FAA-3–50 membrane (3 × 3 cm2) and Ni mesh cathode (2 × 2 cm2) with Ti bipolar plate were assembled by a fixed tightening force (2.5 N ∙ m). During the reaction, 0.05 M KOH solution was served as catholyte and circulated at a flow rate of 10 mL/min. C2H4 was humidified before entering the MEA system, and the flow rate was 20 sccm. The cell voltage of MEA in this paper was full cell voltage. For the stability test, the catholyte solution changes every two hours.

EIS measurements

The EIS measurements were performed at the cell voltage of 2.2 V with a frequency range of 100000 to 0.01 Hz with an amplitude of 10 mV.

The data of electrochemical reaction were controlled by the Corrtest CS350M electrochemical workstation. All electrochemical measurements were conducted at room temperature and atmosphere. All electrochemical epoxidation measurements conduct in the H-cell and MEA were not corrected for iR compensation.

Contact angle measurements

The contact angle test was performed by a contact angle system (FCA2000AS, Shanghai AIFEISI precision instrument CO., Ltd.) at room temperature. 5 µL of water was spread by a needle on the electrode. The contact angles were measured by the side-view images after stabilizing the water on the surface.

Products analysis

The products were first put into an absorption bottle in the ice bath for EO collection. Considering that EO is volatile, the products were analyzed immediately. Beside the EO is not stable under acid and strong base condition, and it could be hydrolyzed to ethylene glycol. Thus near near-neutral store and reaction condition is recommended to inhibit EO hydrolysis. 1H NMR was performed using AVANCE III TM HD 400 MHZ NanoBAY with H2O suppression. 400 µL of solution was mixed with 100 µL of 10 mM DMSO in D2O used as internal stands for NMR analysis. Headspace gas chromatography (HS-GC) measurements were carried out using a BCHP HS-2 Headspace Sampler with GC 2060 gas chromatography. The product solution was put into a sealed sample vial. After heated at 70°C for 30 min, the sample was automatically injected into the GC with an HP-INNOWax column. The concentration of EO was quantified with the EO standard solution. The CO2 and O2 were detected by TCD gas chromatography.

The Faradaic efficiency (FE) of liquid product was calculated with the equation:

where n is the number of electrons transferred (e.g., 2 for EO), N is the amount of products. F is the Faraday constant (96485 C/mol−1). Q is the passed charge (C) during the reaction.

The Faradaic efficiency (FE) of the gas product was calculated with the equation:

where n is the number of electrons transferred (e.g., 4 for O2, 6 for CO2). V is the total molar flow rate of gas, x is the mole fraction of the product, F is the Faraday constant (96485 C/mol−1), and I is the total current.

The selectivity (S) of EO was calculated with the equation:

The energy efficiency of EO (EEEO) was calculated on the basis of the cathodic HER coupled with anodic C2H4 epoxidation reaction.

Where Eoxidation and Ereduction were the thermodynamic potential for C2H4 epoxidation to EO (1.01 V vs. RHE) and the HER (0 V vs. RHE), respectively.

ATR-SEIRAS Measurements

ATR-SEIRAS measurements were performed in a homemade ATR cell with Si prism. Si prism was polished by Al2O3 powder and cleaned in DI water for several times, then the Si prism was immersed in 40% NH4F solution following reacted with 4 mL of Au plating solution and 65% µL of 40% HF solution at 55°C for 5 min to form Au film64. Catalyst inks were dropped on it as the working electrode. A graphite rod and a saturated Ag/AgCl electrode were adopted as the counter electrode and reference electrode, respectively. The cell was integrated with the FTIR (IS 10, Nicolet) equipped with an MCT detector and a VeeMAX III accessory (PIKE Technology) to collect the data. All spectra were collected with a 4 cm−1 resolution and 8 scans.

DEMS test

DEMS is a powerful and quick tool for detecting gaseous and volatile species. The online DEMS measurement contains mass spectrometer connected to turbomolecular drag pumping station. The DEMS experiment was tested in 0.05 M KOH solution in home-made cell. The Ag/AgCl electrode and Pt foil were used as reference and counter electrode, respectively. The probe is immersed into solution with PTFE membrane on the top to avoid solution entering the vacuum system. The probe is set close to the working electrode. The background signals were pre-stabilized for at least 1 h, and the mass spectrometer was set up to monitor fragmentation pattern by mass to charge ratio (m/z). Note that the m/z of 29 (not 44) was monitored for EO, to exclude the effect of CO2, and m/z of 32 was monitored for O2. The test is used with LSV test, and the potential sweep rate was 1 mV/s to obtain near steady state behavior. In our reaction system, no ethylene glycol is detected in DEMS, because the PTFE membrane prevent penetration of ethylene glycol and the production of ethylene glycol is low in our system.

Titration method for H2O2

The generated H2O2 concentration was measured by titration method. 0.5 g KMnO4, 25 mL H2O, and 5 mL 20% H2SO4 was mixed and then diluted 10 times to get KMnO4 solution. The equation is the following equation:

After H2O2 has been entirely reacted, the solution keeps pinkish color at least 30 s, indicating complete titration.

The FE for H2O2 production is calculated using the following equation.

where n is the number of electrons transferred (2 for H2O2), N is the amount of H2O2. F is the Faraday constant (96485 C/mol−1). Q is the passed charge (C) during the reaction.

DFT calculations details

The spin-polarized calculations with the projector-augmented wave (PAW)65 method were performed using the Vienna ab initio simulation package (VASP, 5.4.4 version)66. The exchange and correlation effects were described by the Perdew–Burke–Ernzerhof functional67. The valence wave functions were expanded by plane wave with a cutoff energy of 400 eV. For partially oxidized Ag/SnO2 with covered *OH on the surface, a 3×3 SnO2 model containing three layers with the bottom layer fixed was first constructed. Then, the Ag nanorod with the introduction of oxygen atoms was loaded on the most stable site of SnO2 surface. A hydroxyl further adsorbed on the SnO2 surface, with possible adsorption sites calculated and the most stable one used. For partially oxidized Ag, oxygen atoms were introduced to 2×2 Ag model with four layers, during the structure optimizations, two bottom Ag layers were fixed while the top two Ag layers and oxygen atoms at the top layer were allowed to relax. For SnO2, 3×3 SnO2 model was set. The Brillouin zone was sampled using 3×2×1 k points mesh for geometry optimization. All the structures were optimized until the force on each atom was less than 0.02 eV Å−1. Atomic coordinates of the optimized computational structure are provided in Supplementary Data 1.

The adsorption energy for OH on the surface was described as:

Where E(slab + OH) is the total energy of the OH group on the substrate, E(slab), E(H2O), and E(H2) are the total energies of the substrate, H2O and H2, respectively.

The adsorption energies for C2H4 and C2H4OH on the surface were respectively described as:

Where E(slab + molecule) is the total energy of the molecule on the substrate, E(slab) and E(molecule) are the total energies of the slab model and molecule, respectively.

Data availability

The data that support the findings of this study are available within the paper and supplementary information. Additional data are available from the corresponding author on request. Source data are provided with this paper.

References

Pu, T. et al. Nature and reactivity of oxygen species on/in silver catalysts during ethylene oxidation. ACS Catal. 12, 4375–4381 (2022).

Chen, D. et al. Square-pyramidal subsurface oxygen [Ag4OAg] drives selective ethene epoxidation on silver. Nat. Catal. 7, 536–545 (2024).

Leow, W. R. et al. Chloride-mediated selective electrosynthesis of ethylene and propylene oxides at high current density. Science 368, 1228–1233 (2020).

Pu, T., Tian, H., Ford, M. E., Rangarajan, S. & Wachs, I. E. Overview of selective oxidation of ethylene to ethylene oxide by Ag catalysts. ACS Catal. 9, 10727–10750 (2019).

Kaichev, V. V. et al. The nature of electrophilic and nucleophilic oxygen adsorbed on silver. Kinet. Catal. 44, 432–440 (2003).

Li, H., Cao, A. & Nørskov, J. K. Understanding trends in ethylene epoxidation on group IB metals. ACS Catal. 11, 12052–12057 (2021).

Wismann, S. T. et al. Electrified methane reforming: A compact approach to greener industrial hydrogen production. Science 364, 756–759 (2019).

Idamakanti, M. et al. Electrified Catalysts for Endothermic Chemical Processes: Materials Needs, Advances, and Challenges. ACS Eng. Au 4, 71–90 (2024).

Dong, Q., Hu, S. & Hu, L. Electrothermal synthesis of commodity chemicals. Nat. Chem. Eng. 1, 680–690 (2024).

Ramírez, A., Hueso, J. L., Mallada, R. & Santamaría, J. Ethylene epoxidation in microwave heated structured reactors. Catal. Today 273, 99–105 (2016).

Sibal, A. P., Ghosh, R., Flaherty, D. W. & Stillwell, A. S. Setting benchmarks for ethylene and propylene oxidation via electrochemical routes: a process design and technoeconomic analysis approach. Green. Chem. 26, 9455–9475 (2024).

Li, A.-Z. et al. One-step electrochemical ethylene-to-ethylene glycol conversion over a multitasking molecular catalyst. J. Am. Chem. Soc. 146, 5622–5633 (2024).

Li, X., Yang, C. & Tang, Z. Electrifying oxidation of ethylene and propylene. Chem. Commun. 60, 6703–6716 (2024).

Li, Y. et al. Redox-mediated electrosynthesis of ethylene oxide from CO2 and water. Nat. Catal. 5, 185–192 (2022).

Huang, L. et al. Ethylene electrooxidation to 2-chloroethanol in acidic seawater with natural chloride participation. J. Am. Chem. Soc. 145, 15565–15571 (2023).

Xue, W. et al. Bromine-enhanced generation and epoxidation of ethylene in tandem CO2 electrolysis towards ethylene oxide. Angew. Chem. Int. Ed. 62, e202311570 (2023).

Zhang, P., Wang, T. & Gong, J. Advances in electrochemical oxidation of olefins to epoxides. CCS Chem. 5, 1028–1042 (2023).

Liu, C., Chen, F. & Zhao, B. -H., Wu, Y. & Zhang B. Electrochemical hydrogenation and oxidation of organic species involving water. Nat. Rev. Chem. 8, 277–293 (2024).

Tang, D. et al. Solar-driven green synthesis of epoxides. Sci. China Chem. 66, 3415–3425 (2023).

Holbrook, L. L. & Wise, H. Electrooxidation of olefins at a silver electrode. J. Catal. 38, 294–298 (1975).

Ke, J. et al. Facet-dependent electrooxidation of propylene into propylene oxide over Ag3PO4 crystals. Nat. Commun. 13, 932 (2022).

Chung, M. et al. Direct propylene epoxidation via water activation over Pd-Pt electrocatalysts. Science 383, 49–55 (2024).

Jirkovský, J. S., Busch, M., Ahlberg, E., Panas, I. & Krtil, P. Switching on the electrocatalytic ethene epoxidation on nanocrystalline RuO2. J. Am. Chem. Soc. 133, 5882–5892 (2011).

Chung, M., Jin, K., Zeng, J. S., Ton, T. N. & Manthiram, K. Tuning single-atom dopants on manganese oxide for selective electrocatalytic cyclooctene epoxidation. J. Am. Chem. Soc. 144, 17416–17422 (2022).

Li, H., Abraham, C. S., Anand, M., Cao, A. & Nørskov, J. K. Opportunities and challenges in electrolytic propylene epoxidation. J. Phys. Chem. Lett. 13, 2057–2063 (2022).

Lum, Y. et al. Tuning OH binding energy enables selective electrochemical oxidation of ethylene to ethylene glycol. Nat. Catal. 3, 14–22 (2020).

Gilbert, B. et al. Ag-based electrocatalysts for ethylene epoxidation. Electrochim. Acta 394, 139018 (2021).

Tao, H. B. et al. Revealing energetics of surface oxygen redox from kinetic fingerprint in oxygen electrocatalysis. J. Am. Chem. Soc. 141, 13803–13811 (2019).

Seitz, L. C., Hersbach, T. J. P., Nordlund, D. & Jaramillo, T. F. Enhancement effect of noble metals on manganese oxide for the oxygen evolution reaction. J. Phys. Chem. Lett. 6, 4178–4183 (2015).

Zhang, P. et al. Transition metal-doped α-borophene as potential oxygen and hydrogen evolution electrocatalyst: A density functional theory study. Catal. Commun. 144, 106090 (2020).

Tao, H. B. et al. A general method to probe oxygen evolution intermediates at operating conditions. Joule 3, 1498–1509 (2019).

Xie, Z. et al. Electrocatalytic methane oxidation to ethanol via Rh/ZnO nanosheets. J. Phys. Chem. C. 125, 13324–13330 (2021).

Zhou, W.-P. et al. Electrooxidation of methanol at SnOx–Pt interface: a tunable activity of tin oxide nanoparticles. J. Phys. Chem. Lett. 3, 3286–3290 (2012).

Fester, J. et al. The Structure of the cobalt oxide/Au catalyst interface in electrochemical water splitting. Angew. Chem. Int. Ed. 57, 11893–11897 (2018).

Li, S. et al. Interfacial synergistic effect in SnO2/PtNi nanocrystals enclosed by high-index facets for high-efficiency ethylene glycol electrooxidation. Nano Res 15, 7877–7886 (2022).

Du, D., Kang, F., Yang, S., Shao, B. & Luo, J. Co-electrolysis of ethylene glycol and carbon dioxide for formate synthesis. Sci. China Chem. 67, 1539–1544 (2024).

Chongterdtoonskul, A., Schwank, J. W. & Chavadej, S. Ethylene epoxidation activity over Ag-based catalysts on different nanocrystalline perovskite titanate supports. Catal. Lett. 142, 991–1002 (2012).

Chongterdtoonskul, A., Schwank, J. W. & Chavadej, S. Effects of oxide supports on ethylene epoxidation activity over Ag-based catalysts. J. Mol. Catal. A: Chem. 358, 58–66 (2012).

van den Reijen, J. E. et al. From qualitative to quantitative understanding of support effects on the selectivity in silver catalyzed ethylene epoxidation. Catal. Today 338, 31–39 (2019).

Deng, W. et al. Crucial role of surface hydroxyls on the activity and stability in electrochemical CO2 reduction. J. Am. Chem. Soc. 141, 2911–2915 (2019).

Kowal, A. et al. Ternary Pt/Rh/SnO2 electrocatalysts for oxidizing ethanol to CO2. Nat. Mater. 8, 325–330 (2009).

Xu, Y. et al. Strain-modulated Ru-O covalency in Ru-Sn oxide enabling efficient and stable water oxidation in acidic solution. Angew. Chem. Int. Ed. 63, e202316029 (2024).

Feng, B. et al. Synthesis of mesoporous Ag2O/SnO2 nanospheres for selective sensing of formaldehyde at a low working temperature. ACS Sens 7, 3963–3972 (2022).

Kumar, P. et al. Handheld crop pest sensor using binary catalyst-loaded nano-SnO2 particles for oxidative signal amplification. ACS Sens 9, 81–91 (2024).

Li, Y. et al. Activation of CO over ultrathin manganese oxide layers grown on Au(111). ACS Catal. 11, 849–857 (2021).

Fang, W. et al. Durable CO2 conversion in the proton-exchange membrane system. Nature 626, 86–91 (2024).

Wang, X. et al. Designing membrane electrode assembly for electrochemical CO2 reduction: a review. Trans. Tianjin Univ. 30, 117–129 (2024).

Pu, T. et al. Revealing the nature of active oxygen species and reaction mechanism of ethylene epoxidation by supported Ag/α-Al2O3 Catalysts. ACS Catal. 14, 406–417 (2024).

Holade, Y., Morais, C., Servat, K., Napporn, T. W. & Kokoh, K. B. Toward the electrochemical valorization of glycerol: fourier transform infrared spectroscopic and chromatographic studies. ACS Catal. 3, 2403–2411 (2013).

Davis, J. E. & McKetta, J. J. Solubility of ethylene in water. J. Chem. Eng. Data 5, 374–375 (1960).

Yang, H. et al. Heterogeneous iridium single-atom molecular-like catalysis for epoxidation of ethylene. J. Am. Chem. Soc. 145, 6658–6670 (2023).

Ye, F. et al. The role of oxygen-vacancy in bifunctional indium oxyhydroxide catalysts for electrochemical coupling of biomass valorization with CO2 conversion. Nat. Commun. 14, 2040 (2023).

Kılıç, Ç. & Zunger, A. Origins of coexistence of conductivity and transparency in SnO2. Phys. Rev. Lett. 88, 095501 (2002).

Zhu, K., Shi, F., Zhu, X. & Yang, W. The roles of oxygen vacancies in electrocatalytic oxygen evolution reaction. Nano Energy 73, 104761 (2020).

Mahmoudi, T. et al. Suppression of Sn2+/Sn4+ oxidation in tin-based perovskite solar cells with graphene-tin quantum dots composites in active layer. Nano Energy 90, 106495 (2021).

Niu, Z.-Z. et al. Hierarchical copper with inherent hydrophobicity mitigates electrode flooding for high-rate CO2 electroreduction to multicarbon products. J. Am. Chem. Soc. 143, 8011–8021 (2021).

Zhang, Y. et al. Highly selective adsorption of ethylene over ethane in a MOF featuring the combination of open metal site and π-complexation. Chem. Commun. 51, 2714–2717 (2015).

Dong, H. et al. Abundant Ce3+ ions in Au-CeOx nanosheets to enhance CO2 electroreduction performance. Small 15, 1900289 (2019).

Yuan, X. et al. Controllable Cu0-Cu+ sites for electrocatalytic reduction of carbon dioxide. Angew. Chem. Int. Ed. 60, 15344–15347 (2021).

Kokalj, A., Gava, P., de Gironcoli, S. & Baroni, S. Activated adsorption of ethylene on atomic-oxygen-covered Ag(100) and Ag(210): formation of an oxametallacycle. J. Phys. Chem. C. 112, 1019–1027 (2008).

Rizo, R. et al. Investigating the presence of adsorbed species on Pt steps at low potentials. Nat. Commun. 13, 2550 (2022).

Wang, H. & Abruña, H. D. Identifying adsorbed OH species on Pt and Ru electrodes with surface-enhanced infrared absorption spectroscopy through CO displacement. J. Am. Chem. Soc. 145, 18439–18446 (2023).

Linic, S. & Barteau, M. A. Formation of a stable surface oxametallacycle that produces ethylene oxide. J. Am. Chem. Soc. 124, 310–317 (2002).

Zhang, G. et al. Efficient CO2 electroreduction on facet-selective copper films with high conversion rate. Nat. Commun. 12, 5745 (2021).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B. 50, 17953–17979 (1994).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B. 47, 558–561 (1993).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Acknowledgements

The authors acknowledge the National Key R&D Program of China (2021YFA1501503), the National Natural Science Foundation of China (22121004, 22250008, 22361142838, 22108197), and the Xplorer Prize for financial support. The authors also thank Dr. Fengmin Jin for assisting with the TEM and HAADF-STEM characterizations.

Author information

Authors and Affiliations

Contributions

J.L.G. and P.Z. conceived and supervised the project. H.D., P.Z., T.W., and G.Z. carried out the experiments, analyzed the data and wrote the manuscript. Z.J.Z., R.L., and L.L.L. carried out the DFT calculations. C.X.W. helped with the in situ ATR-SEIRAS tests. G.D.S. helped with the C2H4-TPD tests. H.Y.W. and J.C.L. helped with the electrochemical test. All the authors participated in the writing of the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Stephan Steinmann, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.”

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Dong, H., Luo, R., Zhang, G. et al. Electrochemical epoxidation enhanced by C2H4 activation and hydroxyl generation at the Ag/SnO2 interface. Nat Commun 16, 1901 (2025). https://doi.org/10.1038/s41467-025-57223-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-57223-9