Abstract

Synthesizing functionalized polyethylenes via ethylene coordination copolymerization with fundamental low-cost vinyl polar monomers provides a very attractive approach. However, it is also very challenging as the functional group (FG) to be introduced onto the polyolefin chain is directly derived from the corresponding vinyl polar monomers (CH2 = CH-FG), which often cause catalyst poisoning due to the FG coordination to active metal center and β-X elimination during catalysis, etc. It is especially true for the synthesis of cyano-functionalized polyethylenes (PEs) via ethylene/acrylonitrile copolymerization, which can only rely on Pd catalysis with low activity. Here we present an approach utilizing binuclear Ni catalysis for ethylene/acrylamide copolymerization and the synthesis of cyano-functionalized PEs (>99%) with great activity up to 4.1 × 106 g/(mol cat·h). Extensive polymer characterizations (NMR, GPC, model experiments, etc) confirm significant chain transfer and the conversion of amide to nitrile during catalysis. Mechanistic investigations, including comprehensive control experiments, deuterium labeling and computational studies, support an isomerization-mediated chain transfer polymerization (ICTP) mechanistic pathway, which include tandem acrylamide enchainment, amido group conversion into CN group, and active catalyst regeneration by Et2AlCl. Catalyst poisoning could be largely circumvented by this catalyst system.

Similar content being viewed by others

Introduction

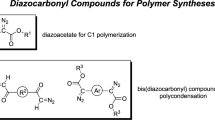

Polar-functionalized polyethylenes (PEs) often demonstrate enhanced properties and performances versus conventional polyolefins (POs)1,2,3. Ethylene/fundamental vinyl polar monomer copolymerizations offers an attractive method for their synthesis under mild conditions4,5,6,7,8,9,10. CH2=CHCN is such a polar comonomer with huge feedstock, low cost, and already used for industrial polymer production11,12,13, and hence its copolymerization with ethylene for the synthesis of cyano-functionalized PEs has garnered special attention. The copolymerization proved to be feasible via elegant catalysis with bisphosphine monoxide (BPMO) type14,15,16 and phosphine-sulfonate (sultam) type17,18,19,20,21 Pd complexes. Mainly because of the electron-deficient property of the double bond for the direct connection between the vinyl group and the functional group CN, undesired interactions/factors such as -CN coordination to the active metal center, β-H elimination as well as much reduced insertion reactivity after acrylonitrile enchainment could occur during catalysis, which severely impede the copolymerization process, the activities are still quite low, only up to 6.7 × 104 g/(mol cat·h) (Fig. 1a). And thus, the synthesis of cyano-functionalized polyethylenes via coordination polymerization remains one of the most challenging topics in this field and awaits new approach22,23,24,25,26.

We aim to explore novel approaches for olefin/polar monomer copolymerizations27,28,29 and have introduced a range of binuclear and tetranuclear Ni catalysts. These catalysts facilitate the efficient copolymerization of ethylene with short-chain protic monomers (such as vinyl acetic acid, acrylic acid, etc.), affording great activity, comonomer incorporation as well as molecular weight regulation30. Very recently, we tried to extend the polar monomers to acrylamide (AM) by employing binuclear Ni catalysts. Unexpectedly, we didn’t obtain the desired amide-functionalized PEs as reported in the literature31. Instead, we observed the formation of cyano-functionalized PEs with remarkably high activity in E/AM copolymerization (Fig. 1b). Thus, it provides an efficient approach for the synthesis of cyano-functionalized PEs using acrylamide as the starting vinyl polar monomer. Based on extensive mechanistic investigations, including control experiments, labeling experiments, and density functional theory (DFT), etc, an isomerization-mediated chain transfer polymerization (ICTP) mechanistic pathway was proposed, which involves sophisticated AM enchainment, chain transfer, amidate to nitrile conversion, and active catalyst regeneration. This catalytic pathway may account for the unusual conversion of acrylamide to nitrile as well as high activity (mitigated catalyst poisoning). In this article, we describe an approach utilizing binuclear Ni catalysis for the efficient synthesis of cyano-functionalized polyethylenes with great activity via ethylene/acrylamide copolymerization.

Results

Cyano-functionalized PEs from E/AM copolymerization

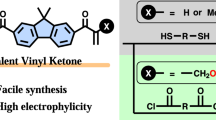

Based on our previous studies30, three Ni catalysts 1-3 with varied substituents (Fig. 1b) were chosen in this study. Cat.1 was first used for E/AM copolymerization at 30 °C under 1 atm of ethylene. AM was premixed with Et2AlCl (DEAC, 2.5 equiv.) in toluene for 12 h before precatalyst was introduced to initiate the polymerization (Table 1, run 1). The activity was 0.9 × 105 g/(mol cat·h) and the number-average molecular weight (Mn) of the resultant polymer was 1.3 kg/mol with a narrow dispersity (Đ = 1.7). The 1H NMR spectrum shows a clear triple peak at 2.35 ppm and a tiny triple peak at 2.24 ppm, which should be assigned to the CH2 adjacent to an FG (Supplementary Fig. 1). However, in the 13C NMR spectrum of the E/AM polymer (Supplementary Fig. 2), no signal attributable to C=O of the amide group was identified. Meanwhile, there was an obvious peak at around 119.5 ppm, which could be assigned to a cyano group32. While the formation of amide-functionalized PEs is reasonable, the formation of cyano-functionalized PEs is quite unexpected.

For further verifying the microstructure in the resultant polymer, we carried out ethylene copolymerization with hex-5-enenitrile and undec-10-enamide to obtain cyano- and amide- functionalized PEs, respectively, as reference polymers for comparative characterizations via 1H NMR, 1H-13C HSQC, 1H-13C HMBC. The 13C NMR chemical shift of the polymer (Table 1, run 1) at 119.5 ppm belongs to the cyano group, the proton chemical shift at 2.35 ppm belongs to that of the CH2 group attached to the nitrile. As this sample includes trace amount of amide group, we chose another typical polymer sample (Table 1, run 4; vide infra) for identification of the amide group. It indeed showed a proton chemical shift at 2.24 ppm, which is assignable to the CH2 attached to the amide group (Fig. 2b). FT-IR spectrum of the polymer shows an absorption band corresponding to the stretching vibration of cyano group (2247.7 cm-1; Supplementary Fig. 6). The above comparative characterizations by NMR and FT-IR clearly confirmed that the presence of both cyano and amide groups in the E/AM polymers.

a 1H and 13C NMR chemical shifts of the E/AM polymer obtained in run 1 of Table 1. b 1H and 13C NMR chemical shifts of the E/AM polymer obtained in run 4 of Table 1. c 1H and 13C NMR chemical shifts of the E/hex-5-enenitrile polymer obtained in run 1 of Supplementary Table 1 (1.6 mol% comonomer content; see Supplementary Figs. 25-27 and section 1.4 in Supplementary Information for synthesis and characterization). d 1H and 13C NMR chemical shifts of the E/undec-10-enamide polymer obtained in run 1 of Supplementary Table 2 (1.8 mol% comonomer content; see Supplementary Figs. 28-30 and section 1.4 in Supplementary Information for synthesis and characterization).

Besides the unexpected transformation of amide from monomer into nitrile in the resultant E/AM polymer, we also found a significantly increased number of polymer chains generated by each catalyst for the polymer (~12 chains/cat; Table 1, run 1) vs. ethylene homopolymer obtained under similar conditions (~1 chain/cat; Table 1, run 2). This remarkable chain transfer is likely associated with the polar monomer AM. Using CN/CONH2 ratio and chains/cat as the main parameters, we continued extensive catalytic studies of the effects of catalyst structure, DEAC/AM ratio, ethylene and AM loadings, as well as reaction time on the FG transformation and chain transfer processes.

Changing R1 of the Ni catalyst from -Me (run 1; cat.1) to bulkier -iPr (run 3; cat.2), we observed a ~1.6 times increase in activity from 0.9 × 105 g/(mol cat·h) to 1.4 × 105 g/(mol cat·h) while the CN/CONH2 ratio and chains/cat were kept constant. Further changing R2 of the Ni catalyst from -Me (run 3; cat.2) to -Et (run 4; cat.3), we observed a significantly reduced CN/CONH2 ratio as well as chains/cat. Thus, we decided to continue with cat.2.

Next, we assessed the effects of DEAC and AM loadings to verify their roles in the chain transfer copolymerization. With the same amount of AM, when the DEAC/AM ratio was increased from 1.5 to 6.0 equiv. at 30 °C, the copolymerization activity rose from 0.7 × 105 to 2.1×105 g/(mol cat·h), the chains/cat increased from 5 to 19 (Table 1, runs 5–9), and the CN/CONH2 ratio improved from 86/14 to 95/5. Interestingly, neither the AM incorporation nor the polymer molecular weight changed much, and a DEAC/AM ratio of greater than 2 seems necessary to ensure excellent overall results. Thus, DEAC promotes chain transfer process and the amide to nitrile conversion but is not involved in the chain transfer/chain propagation competition. When the AM loading increased from 2 mmol to 15 mmol while keeping a constant DEAC/AM ratio of 2.5, the polar monomer incorporation greatly increased from 0.4 mol% to 1.4 mol% at the expense of activity, and the CN/CONH2 ratio slightly increased from 82/18 to 94/6 with a simultaneous increase in chains/cat from 7 to 13 as well as Mn reduction from 5.7 kg/mol to 1.8 kg/mol (Table 1, runs 10−12). Thus, AM promotes chain transfer process and the amide to nitrile conversion, and, in contrast to DEAC, is directly involved in the chain transfer/chain competition.

The above results suggest AM gets enchained, which is followed by a reaction with DEAC to regenerate the active catalyst while completing a chain transfer. In other words, AM plays the role of chain transfer agent (CTA) with the assistance of DEAC. This finding is unusual in that vinyl polar monomer enchained often leads to catalyst poisoning without further initiating new polymer chains11,22,23,24,25,26,33. If this is the case, extending reaction time should, in principle, increase chains/cat while not influencing the polymer Mn in the presence of excess AM and DEAC. We indeed observed a gradually increased chains/cat from 10 to 27 by increasing the reaction time from 10 to 30 and then 60 min (runs 3, 13–14), and it was accompanied by an increased polymer yield from 0.464 g to 0.974 g and 1.458 g as well as a relatively constant Mn. The effects of time confirmed our reasoning, i.e., DEAC is not involved in the competitive monomer enchainment but circumvented the catalyst poisoning associated with vinyl polar monomer enchainment by achieving and promoting a chain transfer to regenerate the active catalyst. If AM plays the role of CTA, the resulting polymer is supposed to be cyano-capped PE. We were able to obtain PE-NH3+Cl- from run 14 in Table 1 by tandem reduction with LiAlH4 and acidification with HCl. The structure was identified by MALDI-TOF MS analysis (Supplementary Fig. 32).

We further assessed the E/AM copolymerization under 20 atm of ethylene and similar conditions vs. 1 atm, the activity significantly enhanced from 1.4 × 105 g/(mol cat·h) to 4.1 × 106 g/(mol cat·h) with a concomitant Mn enhancement from 2.4 to 48.5 kg/mol (Table 1, runs 3 and 16). Unsurprisingly, the polar monomer content declined from 1.1 mol% to 0.1 mol%. The CN/CONH2 ratio was similarly high, ~99/1 (trace CONH2 not detected), and the chains/cat was only slightly increased from 10 to 14. The results again confirmed tunable Mn and comonomer content in this chain transfer polymer system. Note that we also tried classical Brookhart α-diimine Ni complex (cat.4; Table 1, run 17) under parallel conditions to runs 1, 3 and 4, amide to nitrile conversion was also observed with a CN/CONH2 ratio of 77/23, which was close to the use of cat.3, but the activity was much lower, 0.2 × 105 g/(mol cat∙h).

Mechanistic investigations

The copolymerization of ethylene with AM gave cyano-functionalized polyethylenes but not the amido-functionalized copolymers, which are completely different from the known results31. The ratio of CN/CONH2 depends on the catalyst, the co-catalyst and its amounts, as well as the polymerization conditions. In such a polymerization, two distinct features are unambiguously identified in the E/AM copolymerization, i.e., extensive chain transfer but no chain unsaturation (β-H elimination), and the in situ amidate conversion into nitrile. This catalyst system achieved not only a highly efficient catalytic cycle having minimized catalyst poisoning associated with chelate binding of the enchained vinyl polar monomer, but also cyano-functionalized PEs using AM monomer. As both literature30,34 and our results35 suggest, Ni-R chain transfer with DEAC is highly unlikely, and instead, chain transfer/alkylation of Ni-X with main-group M-R is a relatively easy process36. We envisioned a Ni-R to Ni-X step (keto-enol tautomerization process) may be involved in the obviously multi-step mechanistic scenario, and the whole process is then an Isomerization-mediated Chain Transfer Polymerization (ICTP, Fig. 3a). Next, we attempted to carry out further studies to hopefully gain insight into and validate the proposed mechanistic pathway. Note that while the proposed ICTP catalytic cycle involves only the necessary fundamental steps, multiple species with complicated structures are involved. We tentatively proposed the intermediate structures based on literature and our DFT studies (vide infra) and focus on understanding the key catalytic steps: probing the roles of the catalyst, DEAC, and AM monomer in the catalytic cycle without ethylene; understanding the amide conversion to nitrile via the key metalated amidate intermediate.

a Proposed mechanistic pathway for the formation of nitrile group in E/AM copolymerization, including the catalytic cycle and the amidate conversion to nitrile. Note that the possible structure of AM reaction with DEAC is based on literature and DFT (vide infra). b Control experiments with and without catalyst in the absence of ethylene. c Control experiment with saturated amide instead of acrylamide monomer. d Proposed catalytic pathway for Ni mediated amidate conversion to nitrile.

First, we are curious if such ICTP process could be confirmed in small molecule control experiments by running the same experiments in the absence of ethylene. The presence of ethylene, related incorporation and polymer structure analysis could complicate the analysis. In principle, the absence of ethylene and related processes wouldn’t influence the catalytic cycle. Hence, model experiments were designed and run as follows: i) When cat.2 (0.02 mmol) was introduced into the premixed toluene solution of AM (10 mmol) and 2.5 equiv. of DEAC (25 mmol). Pentanenitrile was obtained in 2.0% GC yield (0.20 mmol) after reaction for 10 min; ii) No nitrile product was detected in the absence of Ni catalyst under otherwise identical conditions, likely suggesting AM insertion into Ni-C bond of the active species is required for the formation of nitrile product (Fig. 3b). As the acrylonitrile may be unstable during the process, we also tried the reaction of benzamide with DEAC without catalyst under identical conditions, no benzonitrile product was detected by GC either, confirming the observation with acrylamide substrate; iii) Pentanamide, instead of AM, was used under otherwise identical conditions for the reaction, no nitrile product pentanenitrile was detected (Fig. 3c). The corroborating evidence suggests that the insertion of AM into Ni-C bond is a necessary step of that catalytic cycle. In other words, the nitrile end group is not derived from other side reactions such as dehydration or Ni-free processes.

Besides, the amount of the obtained pentanenitrile product was 10 times the amount of the catalyst, suggesting that chain transfer occurred and the in situ formed Ni-Et can reinitiate another catalytic cycle to repeatedly afford pentanenitrile (Fig. 3d). In principle, the AM monomer can undergo either 1,2-insertion or 2,1-insertion, affording 2-methylbutanenitrile or pentanenitrile, respectively. However, only pentanenitrile was detected, suggesting exclusive 2,1-insertion. Hence, it can be reasonably inferred that each enchained AM invokes chain transfer and the conversion to nitrile, in which process the catalyst gets regenerated as well to initiate new polymer chains.

Our catalyst system distinguishes from other late transition metal-catalyzed olefin/vinyl polar monomer copolymerizations in that catalyst poisoning associated with the backbiting of enchained polar monomer was circumvented via keto-enol tautomerization/isomerization and chain transfer. Thus, it is important to understand this process and reveal the possible mechanistic pathway for the amidate conversion to nitrile (Fig. 4). It can be reasonably inferred that the amidate intermediate is formed (proposed species C), and then AlOAl elimination occurs to complete the conversion to nitrile. To examine the viability of the elimination reaction, we designed a set of control experiments (Fig. 4a). When pentanamide was treated with 5 equiv. of DEAC for 1 h, no pentanenitrile product was observed by GC. When pentanamide was treated with 2.17 equiv. of t-BuLi, 11% of pentanamide was converted to pentanenitrile as determined by GC. Furthermore, when pentanamide was treated with 2.17 equiv. of t-BuLi for 20 min and then 5 equiv. of DEAC for 1 h, 61% of pentanamide was converted to pentanenitrile as determined by GC (Fig. 4a; see also section 1.5 in the Supplementary Information for more details). In this reaction, t-BuLi abstracts both protons of N-H and the α-methylene C-H on pentanamide to form lithiated amidate species37,38,39. This lithiated amidate species is known to undergo [LiOLi] elimination to afford nitrile product (11% GC yield)37. Subsequent transmetalation with excess DEAC affords the aluminated amidate species, and the precipitation of the LiCl salt is likely the driving force for this salt metathesis reaction40,41,42. The resulting aluminated amidate resembles the proposed species D, which gave a much higher yield (61% GC yield), suggesting [AlOAl] elimination is much easier than [LiOLi] elimination.

a Control experiments mimicking the amidate conversion to nitrile with t-BuLi and DEAC. b The proposed mechanistic pathway in control experiments (Fig. 4a). c Deuterium labeling experiments on the amidate conversion to nitrile process. d The proposed mechanistic pathway in deuterium labeling experiments (Fig. 4c).

Ketenimine is a likely intermediate after [AlOAl] elimination, which is very unstable and rapidly isomerizes to afford the pentanenitrile (Fig. 4b)43. To further verify the reaction pathway, we also performed deuterium labeling experiments, following the same procedure of E/AM copolymerization (Table 1, run 3) except that deuterated monomer, CH2 = CHC(O)ND2, was used (Fig. 4c). The D NMR spectrum of the resulting polymer exhibited deuterium signal at 2.35 ppm (Supplementary Fig. 58), indicating that the D atom is located at the ɑ-position of cyano group. Based on the polymer’s 1H NMR spectrum (Supplementary Fig. 57), the ratios of the polymer products I, II and III were 74%, 19% and 7%, respectively. The D atom of a few ketenimine intermediates formed in the polymerization process could be deprotonated by DEAC, and after the N-Al species isomerized to nitrile, the Al could isomerize to the ɑ-position of cyano group. After quenching with acidified MeOH, the ɑ-position of the cyano group is H instead of D. This is indeed the case as confirmed by the copolymerization using regular AM but quenching with MeOD/DCl/D2O (Fig. 4c). In this case, around 20% was labeled with D atom at the ɑ-position of the cyano group. Thus, the experiment results suggest the ketenimine intermediate could undergo rapid isomerization to afford nitrile, and there is only a small amount of the unstable intermediate could possibly undergo deprotonation with DEAC before yielding nitrile as shown in Fig. 4d.

Computational studies

To gain further insights into the polymerization, combined with the experimental mechanistic studies, we also conducted DFT calculations aiming at a deeper understanding on the mechanistic scenarios of ICTP catalytic cycle and the amidate conversion to nitrile (Fig. 5). This is a complex catalyst system containing many species (catalyst, DEAC, ethylene, AM monomer) and multiple interactions (catalyst with DEAC, AM monomer with DEAC, catalyst with AM/DEAC adduct, etc), and thus it is challenging to gain a clear understanding of the structures of the species/intermediate as well as the multiple catalytic steps. As mentioned above, we envisioned starting with proposing chemically reasonable structures of the catalytically active species and AM/DEAC adduct before probing the mechanistic scenarios. The proposed structure of active species derived from cat. 2 and DEAC is shown in Fig. 5a. The second Ni in proximity and shared bridging O atom may have steric and electronic effects on the active Ni center, which were taken into consideration in the DFT calculations.

Regarding the AM/DEAC adduct, literature studies on amide reaction with alkylaluminium reagents44 suggest the presence of various coordination modes and coordination products. Initially, we attempted to obtain the crystal structure of the AM/DEAC adduct, but unfortunately, we were not successful. Therefore, we turned to computational studies for further investigation. In order to map out the possible AM/DEAC adducts model, we utilized the recently developed Stochastic Surface Walking (SSW) global optimization method based on density functional theory calculations to extensively explore the likely intermediate configurations, and finally were able to locate intermediate M as the most likely structure. Meantime, reliability of this advanced calculation method was verified by calculating the complex structure of N,4-di-tert-butylbenzamide with 2 equiv. of AlMe3. The intermediate structure obtained from the calculation (Supplementary Fig. 61) is consistent with the molecular structure by X-ray characterization given in the literature44. We further conducted DFT calculations and obtained a low ΔG (-42.2 kcal/mol; Fig. 5a) for adduct M, and thus this structure was used for subsequent mechanistic investigations by DFT.

Next, we calculated the key step of the ICTP catalytic cycle, i.e., keto-enol tautomerization/isomerization. Two insertion fashions of polar monomer species M, viz., 1,2 and 2,1, have been calculated (Fig. 5a). The computational results show that the 2,1- insertion pathway surmounts the lowest energy barrier (TS221, 5.5 kcal/mol) and is the most exergonic (with a relative energy of −111.2 kcal/mol) compared to the two insertion modes. This indicates that the 2,1-insertion of M is more favorable both kinetically and thermodynamically than 1,2-insertion, which aligns well with the experimental data in Fig. 3b. Afterwards, the energy barriers for ethylene coordination and Ni-C isomerization to Ni-N immediately after AM enchainment was calculated in comparison. Intermediate P221 could be stabilized by β-agostic interaction to afford P2-H. Based on P2-H, the Ni center can continue to undergo ethylene coordination or Ni-C bond isomerization to form Ni-N bond. According to the calculation results, the endotherm of the ethylene coordination process (P3’, −107.7 kcal/mol) is significantly higher than that of the Ni-C bond isomerization process (P3, −113.9 kcal/mol), thus Ni-C bond isomerization process is thermodynamically more favorable than ethylene coordination. Next, Ni could coordinate with a Cl atom to form intermediate P4. Subsequently, the species P4 undergoes chain transfer to alkyl aluminum (ion exchange), releasing the catalyst species and forming polymer-Al P5.

Besides, we also calculated the key AlOAl elimination process for amidate conversion to nitrile. The elimination of [AlOAl] from P5 produces enketoimide P6, which is finally isomerized to nitrile P7. The whole process is kinetically and thermodynamically feasible, with an energy barrier (ΔG‡DEAC) of 22.9 kcal/mol. Note that one amide group corresponds to at least two alkyl aluminum. Therefore, the DEAC/AM ratio should be greater than 2 to facilitate the whole process, which is also consistent with our experimental results (Table 1, runs 5−9).

So far, we have introduced the unexpected development of an efficient and selective E/AM copolymerization system, the selective synthesis of cyano-functionalized branched PEs, and distinct features, including extensive chain transfer but no chain unsaturation (β-H elimination), and the selective introduction of chain end nitrile group. Extensive experimental and theoretical studies have provided strong supports toward the proposed isomerization-mediated chain transfer polymerization (ICTP) catalytic pathway, which can reasonably account for all the experimental observations (Fig. 6). It includes a tandem acrylamide enchainment, isomerization, chain transfer, catalyst regeneration by Et2AlCl, and an amidate to nitrile transformation (yielding -CN group).

Discussion

Our study unveils an unusual strategy for ethylene/acrylamide copolymerization, utilizing binuclear Ni/DEAC catalysis to unexpectedly achieve excellent selectivity toward cyano-functionalized PEs as well as remarkably enhanced activity. Based on extensive experimental and theoretical studies, we proposed an isomerization-mediated chain transfer polymerization (ICTP) pathway coupled with amidate to nitrile transformation. This mechanistic pathway accounts for the unexpected synthesis of cyano-functionalized PEs from ethylene and acrylamide. The isomerization-mediated chain transfer allows active species to circumvent catalyst poisoning associated with back-biting and promote catalyst regeneration to initiate up to 27 polymer chains by each catalyst. Our findings not only advance our comprehension of polymerization mechanisms but also provide a useful method for the highly efficient synthesis of advanced functional POs. In principle, the synthesis of functionalized POs is currently the subject of ongoing investigation based on this unusual catalysis.

Methods

Materials

Toluene, n-hexane and tetrahydrofuran (THF) were dried over sodium still. Dichloromethane was dried over CaH2 before use. Acrylamide (99.9%) was purchased from Macklin Chemical Ltd. 1,1,2,2-Tetrachloroethane-d2 (99.5 atom %D) was purchased from J&K Chemical Ltd. Polymerization-grade ethylene was purified by passing through ethylene purification system (R&D by Dalian Institute of Chemical Physics, CAS). Diethylaluminum chloride (DEAC) was purchased from Jiangsu Yongjian Chemical Co., Ltd as a neat liquid and used as a 3.0 M toluene solution. Other commercially available reagents were purchased from Aladdin, Energy Chemical, or Sigma-Aldrich and used as received.

Instruments and characterizations

All air- and moisture-sensitive manipulations were carried out under high purity N2 using standard Schlenk technique or in a glovebox. 1H NMR,13C NMR, DEPT 135, H-H COSY, HSQC and HMBC spectra were recorded on the Agilent Technologies 600 MHz spectrometer. Elemental analysis was performed by the Analytical Laboratory of the Shanghai Institute of Organic Chemistry (CAS). Mn, Mw, and dispersity (Ð) were determined with Polymer Char GPC-IR5 at 150 °C (polystyrene calibration, 1,2,4-trichlorobenzene as solvent at 150 °C). IR spectra were acquired on Thermo Scientific Nicolet iZ10. MALDI-ToF mass spectrometry was performed using a Bruker 7.0 T SolariX Fourier transform ion cyclotron resonance mass spectrometry (Bruker Daltonics, Germany), equipped with MALDI ion source, this MALDI source has a pulsed smartbeam-II UV laser with an attenuator that allows fine adjustment of laser fluency (355 nm, Azura Laser AG, Berlin, Germany). GC-MS spectra were performed using Agilent 7890A-5977B.

Procedure for polymerization

Ethylene homopolymerization

A 250-mL Schlenk flask equipped with a stir bar was charged with toluene (21.7 mL) at 30 oC under 1 atm ethylene atmosphere. After 10 min, a 3.0 M toluene solution of DEAC (2.5 mmol, 0.8 mL) was added. The mixture was stirred for 10 min, and the polymerization was started by adding toluene solution (2.5 mL) of nickel catalyst (2 μmol). After 10 min, the polymerization was quenched with MeOH (1 mL), and then the mixture was poured into acidified MeOH (400 mL, 10 % HCl (v/v) in MeOH). The precipitated polymer was collected, washed with MeOH, and then dried under vacuum at 65 oC to constant weight.

Ethylene/acrylamide copolymerization

In a typical experiment (Table 1, run 1), a 250-mL Schlenk flask equipped with a stir bar was charged with the toluene solution of DEAC-pretreated acrylamide (acrylamide was premixed with DEAC for 12 h before polymerization) at 30 oC under 1 atm ethylene atmosphere. After 20 min, a toluene solution (5 mL) of cat.1 (20 μmol) was added to start the polymerization. The total volume of DEAC and toluene was 25 mL. After 10 min, the reaction mixture was poured into acidified MeOH (400 mL, 10 % HCl (v/v) in MeOH) cooled in an ice-water bath and stirred for 1 h. The precipitated polymer was collected, washed with MeOH, and then dissolved in n-hexane. The polymer solution was filtered through a syringe filter (pore size = 0.22 μm) and dried under vacuum. The polymer was further dried under vacuum at 65 oC to constant weight.

Ethylene/5-hexenenitrile copolymerization

To a solution of 5-hexenenitrile (2.3 mL, 20 mmol) in toluene (7.7 mL) was added a 3 M toluene solution of DEAC (30 mmol, 10 mL) at 30 oC under 1 atm ethylene atmosphere. The solution was stirred for 10 min. The polymerization was started by adding a toluene solution (5 mL) of nickel catalyst cat.1 (20 μmol). After 10 min, the reaction mixture was poured into acidified MeOH (400 mL, 10 % HCl (v/v) in MeOH) cooled in an ice-water bath and stirred for 1 h. The precipitated polymer was collected, washed with MeOH, and then dried under vacuum at 65 oC to constant weight.

Ethylene/10-undecenamide copolymerization

To a suspension of 10-undecenamide (0.55 g, 3.0 mmol) in toluene (18 mL) was added a 3 M toluene solution of DEAC (6 mmol, 2 mL) at 30 oC under 1 atm ethylene atmosphere. The solution was stirred for 10 min. The polymerization was started by adding a toluene solution (5 mL) of nickel catalyst cat.2 (5 μmol). After 5 min, the reaction was poured into acidified MeOH (400 mL, 10 % HCl (v/v) in MeOH) cooled in an ice-water bath, and stirred for 30 min. The precipitated polymer was collected, washed with MeOH, and then dried under vacuum at 65 oC to constant weight.

Data availability

All information relating to polymerization procedures, mechanistic studies, computational studies, polymer characterization (NMR, GPC), and GC-MS results are available in Supplementary Information. The cartesian coordinates of the optimized structures in this study are available as source data. All data are available from the corresponding authors upon request. Source data are provided with this paper.

References

Rünzi, T. & Mecking, S. Saturated Polar-Substituted Polyethylene Elastomers from Insertion Polymerization. Adv. Funct. Mater. 24, 387–395 (2014).

Zou, C. & Chen, C. Polar-Functionalized, Crosslinkable, Self-Healing, and Photoresponsive Polyolefins. Angew. Chem. Int. Ed. 59, 395–402 (2020).

Chen, J., Gao, Y. & Marks, T. J. Early Transition Metal Catalysis for Olefin–Polar Monomer Copolymerization. Angew. Chem. Int. Ed. 59, 14726–14735 (2020).

Ito, S. & Nozaki, K. Coordination–Insertion Copolymerization of Polar Vinyl Monomers by Palladium Catalysts. Chem. Rec. 10, 315–325 (2010).

Nakamura, A. et al. Ortho-Phosphonebenzenesulfonate: A Superb Ligand for Palladium-Catalyzed Coordination-Insertion Copolymerization of Polar Vinyl Monomers. Acc. Chem. Res. 46, 1438–1449 (2013).

Mu, H., Pan, L., Song, D. & Li, Y. Neutral Nickel Catalysts for Olefin Homo- and Copolymerization: Relationships between Catalyst Structures and Catalytic Properties. Chem. Rev. 115, 12091–12137 (2015).

Chen, C. Designing Catalysts for Olefin Polymerization and Copolymerization: Beyond Electronic and Steric Tuning. Nat. Rev. Chem. 2, 6–14 (2018).

Chen, Z. & Brookhart, M. Exploring Ethylene/Polar Vinyl Monomer Copolymerizations Using Ni and Pd α-Diimine Catalysts. Acc. Chem. Res. 51, 1831–1839 (2018).

Mecking, S. & Schnitte, M. Neutral Nickel(II) Catalysts: From Hyperbranched Oligomers to Nanocrystal-Based Materials. Acc. Chem. Res. 53, 2738–2752 (2020).

Zheng, H., Qiu, Z., Li, D., Pei, L. & Gao, H. Advance on Nickel- and Palladium-Catalyzed Insertion Copolymerization of Ethylene and Acrylate Monomers. J. Polym. Sci. 61, 2987–3021 (2023).

Nakamura, A., Ito, S. & Nozaki, K. Coordination-Insertion Copolymerization of Fundamental Polar Monomers. Chem. Rev. 109, 5215–5244 (2009).

Keyes, A. et al. Olefins and Vinyl Polar Monomers: Bridging the Gap for Next Generation Materials. Angew. Chem. Int. Ed. 58, 12370–12391 (2019).

Dau, H. et al. Linear Block Copolymer Synthesis. Chem. Rev. 122, 14471–14553 (2022).

Carrow, B. P. & Nozaki, K. Synthesis of Functional Polyolefins Using Cationic Bisphosphine Monoxide–Palladium Complexes. J. Am. Chem. Soc. 134, 8802–8805 (2012).

Mitsushige, Y. et al. Methylene-Bridged Bisphosphine Monoxide Ligands for Palladium-Catalyzed Copolymerization of Ethylene and Polar Monomers. ACS Macro Lett. 7, 305–311 (2018).

Mu, H.-L., Ye, J.-H., Zhou, G.-L., Li, K.-K. & Jian, Z.-B. Ethylene Polymerization and Copolymerization with Polar Monomers by Benzothiophene-bridged BPMO-Pd Catalysts. Chin. J. Polym. Sci. 38, 579–586 (2020).

Kochi, T., Noda, S., Yoshimura, K. & Nozaki, K. Formation of Linear Copolymers of Ethylene and Acrylonitrile Catalyzed by Phosphine Sulfonate Palladium Complexes. J. Am. Chem. Soc. 129, 8948–8949 (2007).

Nozaki, K. et al. Why Did Incorporation of Acrylonitrile to a Linear Polyethylene Become Possible? Comparison of Phosphine−Sulfonate Ligand with Diphosphine and Imine−Phenolate Ligands in the Pd-Catalyzed Ethylene/Acrylonitrile Copolymerization. J. Am. Chem. Soc. 132, 16030–16042 (2010).

Ota, Y., Ito, S., Kuroda, J.-i, Okumura, Y. & Nozaki, K. Quantification of the Steric Influence of Alkylphosphine–Sulfonate Ligands on Polymerization, Leading to High-Molecular-Weight Copolymers of Ethylene and Polar Monomers. J. Am. Chem. Soc. 136, 11898–11901 (2014).

Jian, Z. & Mecking, S. Short-Chain Branched Polar-Functionalized Linear Polyethylene via “Tandem Catalysis. Macromolecules 49, 4057–4066 (2016).

Xia, J. et al. Sterically Very Bulky Aliphatic/Aromatic Phosphine-Sulfonate Palladium Catalysts for Ethylene Polymerization and Copolymerization with Polar Monomers. Polym. Chem. 10, 546–554 (2019).

Philipp, D. M. et al. Computational Insights on the Challenges for Polymerizing Polar Monomers. J. Am. Chem. Soc. 124, 10198–10210 (2002).

Groux, L. F. et al. Insertion of Acrylonitrile into Palladium Methyl Bonds in Neutral and Anionic Pd(II) Complexes. J. Am. Chem. Soc. 127, 1854–1869 (2005).

Wu, F., Foley, S. R., Burns, C. T. & Jordan, R. F. Acrylonitrile Insertion Reactions of Cationic Palladium Alkyl Complexes. J. Am. Chem. Soc. 127, 1841–1853 (2005).

Yang, S.-Y. et al. The Exploration of Neutral Azoligand-Based Grubbs Type Palladium(II) Complex as Potential Catalyst for the Copolymerization of Ethylene with Acrylonitrile:A Theoretical Study Based on Density Functional Theory. Organometallics 24, 1242–1251 (2005).

Szabo, M. J. et al. Copolymerization of Ethylene with Polar Monomers: Chain Propagation and Side Reactions. A DFT Theoretical Study Using Zwitterionic Ni(II) and Pd(II) Catalysts. J. Am. Chem. Soc. 127, 14692–14703 (2005).

Yang, X.-H. et al. O-NSR]TiCl3-Catalyzed Copolymerization of Ethylene with Functionalized Olefins. Angew. Chem. Int. Ed. 48, 8099–8102 (2009).

Redshaw, C. & Tang, Y. Tridentate Ligands and Beyond in Group IV Metal α-olefin Homo-/Co-polymerization Catalysis. Chem. Soc. Rev. 41, 4484–4510 (2012).

Chen, Z. et al. Copolymerization of Ethylene with Functionalized Olefins by [ONX] Titanium Complexes. Macromolecules 46, 2870–2875 (2013).

Ji, G. et al. Direct Copolymerization of Ethylene with Protic Comonomers Enabled by Multinuclear Ni Catalysts. Nat. Commun. 12, 6283 (2021).

Marques, M. M. et al. Synthesis of Acrylamide/Olefin Copolymers by a Diimine Nickel Catalyst. Macromol. Chem. Phys. 201, 2464–2468 (2000).

Neiss, T. G. in Encyclopedia of Analytical Chemistry.

Schöbel, A., Winkenstette, M., Anselment, T. M. J. & Rieger, B. in Polymer Science: A Comprehensive Reference (eds Krzysztof Matyjaszewski & Martin Möller) 779-823 (Elsevier, 2012).

Hue, R. J., Cibuzar, M. P. & Tonks, I. A. Analysis of Polymeryl Chain Transfer Between Group 10 Metals and Main Group Alkyls during Ethylene Polymerization. ACS Catal. 4, 4223–4231 (2014).

Qu, B. et al. Norbornene Monomer Effects and Mechanistic Insights in Binuclear Nickel-Catalyzed Olefin Chain Walking Copolymerizations. ACS Catal., 12849–12858 (2023).

Johnson, J. B. & Rovis, T. Enantioselective Cross-Coupling of Anhydrides with Organozinc Reagents: The Controlled Formation of Carbon−Carbon Bonds through the Nucleophilic Interception of Metalacycles. Acc. Chem. Res. 41, 327–338 (2008).

Kaiser, E. M., Vaulx, R. L. & Hauser, C. R. Conversions of Certain Amides into Nitriles by Means of n-Butyllithium. J. Org. Chem. 32, 3640–3645 (1967).

Adam, W. & Takayama, K. α-Lithio-3-indolylacetate Synthons: Generation and Synthetic Utilization. J. Org. Chem. 45, 447–452 (1980).

Nodono, M., Tokimitsu, T., Tone, S., Makino, T. & Yanagase, A. Chain Transfer Polymerization of Methyl Methacrylate Initiated by Organolanthanide Complexes. Macromol. Chem. Phys. 201, 2282–2288 (2000).

Ishikawa, T., Ogawa, A. & Hirao, T. A Novel Oxovanadium(V)-Induced Oxidation of Organoaluminum Compounds. Highly Selective Coupling of Organic Substituents on Aluminum. J. Am. Chem. Soc. 120, 5124–5125 (1998).

Klis, T., Powell, D. R., Wojtas, L. & Wehmschulte, R. J. Synthesis and Characterization of Bulky Cationic Arylalkylaluminum Compounds. Organometallics 30, 2563–2570 (2011).

Saleh, M., Powell, D. R. & Wehmschulte, R. J. Catalytic Reduction of Carbon Dioxide Using Cationic Organoaluminum and -Gallium Compounds. Organometallics 36, 4810–4815 (2017).

Liu, R. Y., Bae, M. & Buchwald, S. L. Mechanistic Insight Facilitates Discovery of a Mild and Efficient Copper-Catalyzed Dehydration of Primary Amides to Nitriles Using Hydrosilanes. J. Am. Chem. Soc. 140, 1627–1631 (2018).

Huang, B.-H., Yu, T.-L., Huang, Y.-L., Ko, B.-T. & Lin, C.-C. Reactions of Amides with Organoaluminum Compounds: Factors Affecting the Coordination Mode of Aluminum Amidates. Inorg. Chem. 41, 2987–2994 (2002).

Acknowledgements

The authors are grateful for financial support by Youth Innovation Promotion Association CAS (No. 2020259, X.-Y.W.), the Strategic Priority Research Program of the Chinese Academy of Sciences (XDB1180000, Y.G., X.-Y.W.), the National Natural Science Foundation of China (U23A2084, X.-L.S., Y.T., Y.G.; 22271304, X.-Y.W.), Shanghai Rising-Star Program (21QA1411200, X.-Y.W.), Shanghai Science Foundation (23ZR1476300, X.-Y.W.), and Science and Technology Commission of Shanghai Municipality (23JC1404500, Y.Z., Y.G.).

Author information

Authors and Affiliations

Contributions

Y.T. and X.-L.S. conceived the project. Y.T. and Y.G. supervised the project. Y.T., S.-Y.Y., and Y.G. designed the experiments. S.-Y.Y. performed the experiments and analyzed the data. Y.Z. and Z.-P.L. performed computational studies. X.-S.N. and G.J. carried out the first synthesis of the binuclear Ni catalysts. Y.L. provided the ligands for the synthesis of binuclear Ni catalysts. J.Y. repeated some of the polymerization experiments. S.-Y.Y. and Y.G. wrote the initial manuscript draft. Y.T., X.-L.S., and X.-Y.W. edited and revised the manuscript. All the authors commented and approved the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yu, SY., Wang, XY., Sun, XL. et al. Cyano-functionalized polyethylenes from ethylene/acrylamide copolymerization. Nat Commun 16, 2461 (2025). https://doi.org/10.1038/s41467-025-57489-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-57489-z