Abstract

In contrast to allyl palladium complexes, propargylic/allenylic palladium species display complex reactivities that limit their implementation in polymer chemistry, especially for chain-growth polymerizations. Here we report an example of controlled chain-growth polymerization via propargyl/allenyl palladium intermediates. Vinylidenecyclopropane 1,1-dicarboxylate (VDCP), a unique allenylic electrophile, selectively reacts via the σ-allenyl palladium complex rather than the more common π-propargyl pathway, thereby unlocking a chain-growth process. Based on this concept, precise synthesis of alkyne-backbone polymers is realized, featuring fast rate, high molecular weight, narrow dispersity, high chemoselectivity, and excellent end-group fidelity. We demonstrate preparation of unsaturated macromolecules with advanced sequences and architectures using this method, including block, gradient, and graft copolymers.

Similar content being viewed by others

Introduction

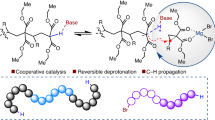

The palladium-catalyzed substitution reaction of allylic electrophiles has found numerous applications in synthetic organic chemistry1,2,3. Since the late 1980s, a number of polymerization methods leveraging this reactivity have been developed by Saegusa, Okada, Endo, Nomura, Leibfarth, and others, affording unsaturated carbon-chain and heterochain polymers via either a step- or chain-growth mechanism (Fig. 1a)4,5,6,7,8,9,10,11.

Despite of the structural similarity, analogous catalysis with propargylic/allenylic electrophiles remains underexplored in polymer science. Arguably, this is due to the dramatically increased complexity brought by an additional π-bond in the intermediate (Fig. 1b)12. In π-allyl catalysis, allylation is always the sole outcome. In contrast, nucleophilic trapping in propargylic/allenic systems can take place via three distinct and interconvertible Pd(II) species, namely the σ-allenyl, π-propargyl, and σ-propargyl palladium complexes, leading to allenylation (type A), alkenylation (type B), and propargylation (type C), respectively13,14,15. The reaction is thus subjected to subtle changes in the substrate-catalyst combination, and substantially less predictable and efficient16,17. To date, only a few attempts have been disclosed by Koizumi, where alkene-based polymers were synthesized in a step-growth fashion, mostly via type B trapping18,19,20.

A chain-growth method still remains unknown. While type B trapping is the most common and efficient, in particular for soft nucleophiles21,22, it virtually precludes a chain-growth reaction as it is followed by either a second nucleophilic attack23 or β-hydride elimination24. To overcome this problem, we became interested in a special allenylic electrophile, that is vinylidenecyclopropane 1,1-dicarboxylate (VDCP). It can be easily synthesized from commodity chemicals, butyne-1,4-diol and malonate in two steps. VDCP can oxidatively add to Pd(0) as reported by Shi and coworkers25,26,27,28. The resulting amphiphilic adduct drew our attention (Fig. 1c). The interaction between the enolate and the palladium center should lead to an unusually strong bias favoring the σ-allenyl complex ΙΙ over its π-propargyl isomer Ι. This might allow one to escape from the frustrating type B trapping if a facile exit is available via ΙΙ. With this consideration, a chain-growth process might become possible involving the terminal-selective nucleophilic attack of ΙΙ by a malonate chain-end, a typical soft nucleophile.

Here we report the Pd-catalyzed controlled ring-opening polymerization of VDCP (Fig. 1d). This reaction features high molecular weight (MW) (Mn up to 94.2 kg/mol), narrow dispersity (Đ ~ 1.1), ultrafast kinetics (full conversion in minutes), and excellent chemoselectivity. A broad scope of end-groups can be incorporated with high fidelity, such as terminal alkenes/alkynes, methacrylates, and even aryl halides, allowing the access to advanced macromolecular architectures. Leveraging the exceptional reactivity of VDCP, we demonstrated gradient pseudo-diblock copolymerization with vinylcyclopropanes (VCP). Experimental and computational evidence was found in support of propargyl/allenyl palladium intermediates.

Results and discussion

We initiated our study by evaluating the polymerization of dimethyl 2-vinylidenecyclopropane-1,1-dicarboxylate (M1) at 40 °C, in the presence of catalytic quantities of Pd2(dba)3 (2 mol% [Pd]) and a bidentate phosphine ligand, DPEPhos (Table 1). At the end of the reaction, trifluoroacetic acid was added to quench the enolates. The presence of an initiator (1a) and a small amount of sodium tert-butoxide base was necessary for a successful polymerization (entry 1). While leaving out the base led to only trace P1, polymerization without 1a took place in an uncontrolled manner, presumably via a sluggish self-initiation process (entries 2–4). No polymerization occurred in the absence of palladium (entry 5). Alternative tert-butoxide bases gave comparable results without observable counterion effect, whereas an organic base, 1,8-diazabicyclo(5.4.0)undec-7-ene (DBU), yielded only oligomers (entries 6–8). Acetonitrile was found a viable alternative solvent among others screened (entries 9–11).

We next evaluated the ligand bite angle effect. It was found that BINAP (93°) provided similar results with DPEPhos (108°) (entry 12). Yet, further reducing the angle to ~78° (dppe) or leave out the phosphine led to only low oligomers (entries 13–14). This is consistent with literature findings that small bite angle ligands favor type B trapping, which frustrates the polymerization16. A monophosphine, i.e., PPh3, promoted the polymerization in a slightly lower efficiency, whereas electron-rich phosphines completely shut down the polymerization (entries 15–16). The polymerization took place smoothly at ambient temperature (entry 17). Finally, varying the [Pd] loading had a minimal impact on the MW, and a narrower dispersity can be obtained at 0.5 mol% [Pd] (entry 18, Mn = 9.2 kg/mol, Đ = 1.08). In fact, full conversion was already achieved within 5 min under these conditions (entry 19).

Given the fast polymerization rate, kinetic profiling was performed under diluted conditions (Fig. 2a, b). The living characteristics the polymerization was evidenced by a linear increase of MW with respect to conversion. The controllability of the reaction was tested by varying the monomer-to-initiator ratio (Fig. 2c). The observed MW well matched the predicted values at [M1]:[1a] up to 200:1 (Mn = 32.2 kg/mol, Đ = 1.07). Going beyond this number led to MW that were lower than expected along with slightly higher dispersity (Mn = 94.2 kg/mol, Đ = 1.27 at 1000:1).

a, b Kinetic study ([M1]:[1a]:[Pd]:[NaOtBu] = 100:1:0.5:5, [M1] = 0.2 M). c MW control: Mn,Theo = MW(1a) + MW(M1) × conversion × ([M1]/[1a]) d, e Assigned 1H NMR (CDCl3, 400 MHz) spectrum and MALDI-TOF analysis of P1 (Table 1, entry 18).

The 1H and 13C NMR spectra of a sample of P1 (Table 1, entry 18) suggest complete ring-opening to give an alkyne-based backbone (Fig. 2d, Figs. S5, S6). The correct peak spacing was identified in matrix-assisted laser desorption/ionization time-of-flight (MALDI-TOF) mass spectroscopy (Fig. 2e). A single set of peaks was found, which is consistent with 1a incorporated at the α-end and protonation at the ω-end. This was corroborated by the 1H NMR end-group analysis. The MW of P1 estimated from NMR integrals, GPC, and mass spectrometry were in good agreement.

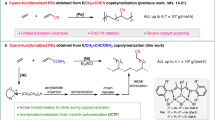

Having established the polymer structure, we set out to evaluate the scope of initiators with [M1]:[1] = 50:1 and 0.5% [Pd] (Fig. 3a). 2-Alkylated malonates all demonstrated high-efficiency initiation by giving predetermined MW and well-defined end-group signals on 1H NMR. Useful handles for postpolymerization-transformations can thus be incorporated at the chain-end, including allyls (1b), terminal propargyls (1c), and methacrylates (1d), which highlights the chemoselectivity of the palladium catalysis. Even an aryl bromide (1e) remained intact, indicating a highly selective oxidative addition process. The parent malonate (1f) and methylenes with a similar acidity (1g) are also competent initiators, providing chain growth in both directions29,30. We were able to expand this chemistry to initiators based on a sulfonamide (1h) and a 1,3-diketone (1i), however, the initiation efficiency for the former was moderate. A brief survey of monomer scope was next conducted (Fig. 3b). Notably, we challenged our reaction with bulky monomers that failed in the radical polymerization that we previously developed (M5-6)31. Decent polymerization results can still be obtained using the palladium-catalyzed protocol.

To further demonstrate the synthetic utility, chain extension, and graft polymerization were performed. Using isolated P1 as a macroinitiator, the synthesis of a diblock copolymer was supported by GPC and diffusion-ordered spectroscopy (DOSY), albeit a small shoulder peak in the GPC trace was observable (Fig. 3c, Fig. S47). Polymers with advanced topologies are important targets for synthesis32. To this end, we show that living radical polymerization of methacrylate 1e and subsequent Pd-catalyzed polymerization successfully produced a graft polymer bearing P1 as side-arms (Fig. 3d).

Without any modification, the same catalyst system enabled a copolymerization reaction of VDCP with its vinyl analog, vinylcyclopropane dicarboxylates (VCP) (Fig. 3e). Kinetic profiling revealed a remarkable reactivity difference between the two monomer classes. VDCP M1 was almost fully consumed within 5 min, at which point the conversion of VCP M7 was merely 8%. Therefore, a gradient copolymer P1-grad-P7 with a pseudo-diblock sequence was formed upon full conversion, which is supported by comparing its NMR spectra with the corresponding homopolymers (Fig. S61). This result again underscores the exceptionally high reactivity of VDCP in palladium-catalyzed polymerization.

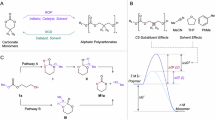

A plausible mechanistic hypothesis is depicted in Fig. 4a. The key steps involve the oxidative addition of Pd(0) with VDCP to generate the σ-allenyl complex ΙΙ, and the subsequent nucleophilic attack at the terminal carbon. The propagating chain-end would be most likely a malonate anion rather than an organopalladium33. This is consistent with the end-group structures found and the fact that the MW is independent on the [Pd] loading (Table 1). Besides literature small molecule reactions25,26,27,28, facile ring-opening of VDCP mediated by Pd(0) is supported by trace side product 2 formed in parallel with the polymerization, which was not detected in the absence of palladium. Either leaving out the base (Table 1, entries 2–3) or using electron-rich monophosphines, i.e., PCy3 (Table 1, entry 16), strongly promoted this ring-expansion pathway. This might be attributable to the rapid isomerization of ΙΙ to a η3-palladium enolate with such ligands34. In a stoichiometric experiment, Pd2(dba)3 was first mixed with DPEPhos to afford a red solution (Fig. 4b). An immediate color change occurred upon the addition of M1, which was also noticed in catalytic reactions (Figure S3). An aliquot of this mixture was analyzed by high-resolution mass spectrometry, and molecular ion peaks matching ΙΙ were identified35.

To further shed light on the key trapping step, density function theory (DFT) calculations at the SMD(1,4-dioxane)/M06-L-D3/def2-TZVP-SDD//B3LYP-D3(BJ)/6-31 G(d,p)-SDD level was employed. Indeed, the σ-allenyl palladium (INT2) is substantially more stable than its π-isomer (INT1), and the kinetic barrier for the palladium dancing is very low (TS1, 4.4 kcal/mol). We were able to identify the nucleophilic attack transition state for each complex, respectively. Type B trapping at the central carbon was found kinetically less facile (TS3, 6.9 kcal/mol) than the palladium dancing. Therefore, INT1 likely isomerizes to INT2 before π-propargyl trapping. Subsequently, INT2 undergoes nucleophilic attack by the initiator or polymer living chain end to yield an anionic chain end, enabling the chain growth process.

In conclusion, we present an example of controlled chain-growth polymerization via propargyl/allenyl palladium intermediates. The mechanistic key is a unique allenylic electrophile motif with high reactivity, VDCP, which enables selective trapping via the σ-allenyl palladium complex rather than the more common π-propargyl pathway. Using malonates as the initiators, we demonstrated the synthesis of high MW alkyne-based polymers with high precision, including block, gradient, and graft copolymers. The excellent chemoselectivity and ultrafast kinetics associated with this new method could open up new opportunities for building challenging macromolecular architectures.

Methods

General procedure for polymerization

An oven-dried 10 mL re-sealable screw-cap vial equipped with a Teflon-coated magnetic stir bar was charged with Pd2(dba)3 (1.0 mg, 0.25 mol%, 0.001 mmol), DPEPhos (1.6 mg, 0.75 mol%, 0.003 mmol) and NaOtBu (2.0 mg, 5.0 mol%, 0.02 mmol). The reaction vessel was evacuated and backfilled with nitrogen (this sequence was repeated a total of three times). The reaction vessel was taken into a nitrogen-filled glovebox. 1a (1.2 mg, 2.0 mol%, 0.008 mmol) in anhydrous dioxane (0.40 mL) was added to the reaction vessel. The tube was sealed and taken out of the glovebox. To the tube was added M (0.40 mmol, 1.0 equiv.) via syringe. The reaction mixture was vigorously stirred at r.t. till full conversion of M. The crude reaction mixture was quenched by the addition of a few drops of trifluoroacetic acid, dissolved in a minimal amount of THF, and precipitated by dropwise addition to vigorously stirred MeOH (or a mixture of MeOH/H2O). The precipitate was collected by centrifugation and then reprecipitated from MeOH. The obtained material was dried in vacuo at 40 °C overnight to afford the polymer, which was analyzed by gel permeation chromatography to determine its molecular weight and dispersity. The conversion of the monomer was determined by 1H NMR analysis of the crude reaction mixture.

Synthesis of M1-M6

A round bottom flask equipped with a magnetic stir bar was charged with cesium carbonate (2.5 equiv.) and THF (200–500 mL). A solution of bistosylate (1.0 equiv.) and malonate (1.0 equiv.) in THF (100 mL) was added to the flask dropwise using a constant pressure dropping funnel. The resulting slurry was stirred at 70 °C for 17–21 h. After being cooled to r.t., the reaction mixture was filtered through a plug of celite and eluted with ethyl acetate. The filtrate was dried over anhydrous Na2SO4 and concentrated in vacuo. The residue was purified by silica gel column chromatography to afford M1–M6.

Synthesis of M7

A round bottom flask equipped with a magnetic stir bar was charged with cesium carbonate (2.5 equiv.) and 1,4-dibromo-2-butene (1.0 equiv.), The reaction vessel was evacuated and backfilled with nitrogen (this sequence was repeated a total of three times). Dibenzyl malonate (1.0 equiv.) and THF (60 mL) were added to the flask via syringe. The resulting slurry was stirred at 60 °C for 17 h. After being cooled to r.t., the reaction mixture was filtered through a plug of celite and eluted with ethyl acetate. The filtrate was dried over anhydrous Na2SO4 and concentrated in vacuo. The residue was purified by silica gel column chromatography to afford M7.

Synthesis of 1e

A round bottom flask equipped with a magnetic stir bar was charged with sodium hydride (1.2 equiv.) and THF (50 mL). At 0 °C, add dimethyl malonate, and stir for thirty minutes. Then, add 1-bromo-2-bromomethyl-benzene and continue stirring at room temperature until the reaction is complete. Quench with saturated NH4Cl and extract with ethyl acetate. The filtrate was dried over anhydrous Na2SO4 and concentrated in vacuo. The residue was purified by silica gel column chromatography to afford 1e.

Synthesis of 1h

Tosyl chloride (1.1 equiv.) was slowly added as a solution in 20 mL dry THF to a solution of propargylamine (1.0 equiv.) and diisopropylethylamine 1.1 equiv.) in 100 mL dry THF at r.t., and the resulting mixture was stirred overnight. The reaction mixture was washed with saturated aqueous NH4Cl and brine. The organic phase was dried over Na2SO4 and concentrated. The residue was purified by silica gel column chromatography to afford 1 h.

Data availability

The data supporting the findings of this study are available within the article and its Supplementary Information. All data are available from the corresponding author upon request. Source data are available. Source data are provided with this paper.

References

Trost, B., Zhang, T. & Sieber, J. Catalytic asymmetric allylic alkylation employing heteroatom nucleophiles: a powerful method for C–X bond formation. Chem. Sci. 1, 427–440 (2010).

Pàmies, O. et al. Recent advances in enantioselective Pd-catalyzed allylic substitution: from design to applications. Chem. Rev. 121, 4373–4505 (2021).

Poli, G., Prestat, G., Liron, F. & Kammerer-Pentier, C. Selectivity in palladium-catalyzed allylic substitution. In: Kazmaier, U. (eds) Transition Metal Catalyzed Enantioselective Allylic Substitution in Organic Synthesis. Topics in Organometallic Chemistry, 38 (Springer, 2011).

Suzuki, M., Sawada, S. & Saegusa, T. New ring-opening polymerization via a π-allyl complex. 1. Polymerization of diethyl 2-vinylcyclopropane-1,1-dicarboxylate catalyzed by a palladium(0) complex. Macromolecules 22, 1505–1507 (1989).

Suzuki, M., Li, A. & Saegusa, T. Multibranching polymerization: palladium-catalyzed ring-opening polymerization of cyclic carbamate to produce hyperbranched dendritic polyamine. Macromolecules 25, 7071–7072 (1992).

Suzuki, M., Sawada, S., Yoshida, S., Eberhardt, A. & Saegusa, T. New ring-opening polymerization via a π-allylpalladium complex. 2. Novel proton-transfer polymerization of vinylcyclopropane derivatives having two electron-withdrawing substituents. Macromolecules 26, 4748–4750 (1993).

Suzuki, M., Yoshida, S., Shiraga, K. & Saegusa, T. New ring-opening polymerization via a π-allylpalladium complex. 5. Multibranching polymerization of cyclic carbamate to produce hyperbranched dendritic polyamin. Macromolecules 6, 1716–1719 (1998).

Koizumi, T., Sakamoto, J., Gondo, Y. & Endo, T. Novel palladium(0)-catalyzed polyaddition of bifunctional vinyloxiranes with 1,3-diketones. synthesis of new polymers bearing an allyl alcohol moiety via π-allylpalladium intermediates. Macromolecules 35, 2898–2902 (2002).

Nomura, N., Yoshida, N., Tsurugi, K. & Aoi, K. Versatile carbon−carbon bond-forming polycondensation between terpene derivatives and malonic esters via palladium-catalyzed allylic substitution reaction. Macromolecules 36, 3007–3009 (2003).

Nomura, N., Tsurugi, K., RajanBabu, T. & Kondo, T. Homogeneous two-component polycondensation without strict stoichiometric balance via the Tsuji−Trost reaction: remote control of two reaction sites by catalysis. J. Am. Chem. Soc. 126, 5354–5355 (2004).

Jagannathan, J. et al. Regioselective palladium-catalyzed chain-growth allylic amination polymerization of vinyl aziridines. J. Am. Chem. Soc. 146, 15264–15274 (2024).

Keinan, E. & Bosch, E. Palladium-catalyzed propargylic vs. allylic alkylation. J. Org. Chem. 51, 4006–4016 (1986).

Tsuji, J. & Mandai, T. Palladium-catalyzed reactions of propargylic compounds in organic synthesis. Angew. Chem. Int. Ed. 34, 2589–2612 (1995).

Ma, S. Pd-catalyzed coupling reactions involving propargylic/allenylic species. Eur. J. Org. Chem. 2004, 1175–1183 (2004).

O’Broin, C. & Guiry, P. Advances in decarboxylative palladium-catalyzed reactions of propargyl electrophiles. J. Org. Chem. 85, 10321–10333 (2020).

Daniels, D., Jones, A., Thompson, A. & Paton, R. Ligand bite angle-dependent palladium-catalyzed cyclization of propargylic carbonates to 2-alkynyl azacycles or cyclic dienamides. Angew. Chem. Int. Ed. 53, 1915–1920 (2014).

Locascio, T. & Tunge, J. Palladium-catalyzed regiodivergent substitution of propargylic carbonates. Chem. Eur. J. 22, 18140–18146 (2016).

Koizumi, T., Kiyonaga, O., Yamanaka, M. & Kawabata, S. Novel palladium-catalyzed polycondensation of propargyl carbonates and bisphenols. synthesis of polyethers having exomethylene groups. Macromolecules 37, 9670–9672 (2004).

Nishioka, N. & Koizumi, T. Pd(0)-catalyzed polycondensation of aryl-substituted propargylic carbonates with bifunctional nucleophiles promoted by aryl group on the acetylenic terminal carbon. J. Polym. Sci., Part A Polym. Chem. 49, 642–649 (2011).

Nishioka, N., Hayashi, S. & Koizumi, T. Palladium(0)-catalyzed synthesis of cross-conjugated polymers: transformation into linear-conjugated polymers through the Diels–Alder reaction. Angew. Chem. Int. Ed. 51, 3682–3685 (2012).

Tsuji, J., Watanabe, H., Minami, I. & Shimizu, I. Novel palladium-catalyzed reactions of propargyl carbonates with carbonucleophiles under neutral conditions. J. Am. Chem. Soc. 107, 2196–2198 (1985).

Guo, L.-N., Duan, X.-H. & Liang, Y.-M. Palladium-catalyzed cyclization of propargylic compounds. Acc. Chem. Res. 44, 111–122 (2011).

Ding, L., Gao, R.-D. & You, S.-L. Palladium(0)-catalyzed intermolecular asymmetric cascade dearomatization reaction of indoles with propargyl carbonate. Chem. Eur. J. 25, 4330–4334 (2019).

O’Broin, C. & Guiry, P. Synthesis of 2-amino-1,3-dienes from propargyl carbonates via palladium-catalyzed carbon–nitrogen bond formation. Org. Lett. 22, 879–883 (2020).

Niu, B., Wei, Y. & Shi, M. Palladium catalyzed divergent cycloadditions of vinylidenecyclopropane-diesters with methyleneindolinones enabled by zwitterionic π-propargyl palladium species. Chem. Commun. 57, 4783–4786 (2021).

Yang, Z.-R., Zhang, B., Long, Y.-J. & Shi, M. Palladium-catalyzed hydroamination of vinylidenecyclopropane-diester with pyrroles and indoles: an approach to azaaromatic vinylcyclopropanes. Chem. Commun. 58, 9926–9929 (2022).

Zhong, X.-H., Long, Y.-J., Wei, Y. & Shi, M. Palladium-catalyzed Sc(OTf)3/Cs2CO3-assisted C−O cross-coupling of vinylidenecyclopropane-diesters with phenolic compounds. Adv. Synth. Catal. 366, 3387–3396 (2024).

Long, Y.-J., Shen, J.-H., Wei, Y. & Shi, M. Substrate-controlled [8 + 3] cycloaddition of tropsulfimides and tropones with zwitterionic allenyl palladium species derived from vinylidenecyclopropane-diesters. J. Org. Chem. 89, 14831–14850 (2024).

Li, Y.-Y. et al. Organo-metal cooperative catalysis for C(sp3)−H alkylation polymerization. Nat. Synth. 2, 1232–1242 (2023).

Xie, T., Chen, S.-S., Li, Y.-Y. & Chen, D.-F. Leveraging electron push-pull effect for catalytic polymerization and degradation of a cyclobutane monomer system. Angew. Chem. Int. Ed. 63, e202405408 (2024).

Wu, B., Ding, Q.-J., Wang, Z.-L. & Zhu, R. Alkyne polymers from stable butatriene homologues: controlled radical polymerization of vinylidenecyclopropanes. J. Am. Chem. Soc. 145, 2045–2051 (2023).

Polymeropoulos, G. et al. 50th anniversary perspective: polymers with complex architectures. Macromolecules 50, 1253–1290 (2017).

Chen, J., Gao, S. & Chen, M. Cu-catalyzed silylation and borylation of vinylidene cyclopropanes. Org. Lett. 21, 8800–8804 (2019).

Albéniz, A., Catalina, N., Espinet, P. & Redón, R. Bonding modes in palladium(II) enolates: consequences for dynamic behavior and reactivity. Organometallics 18, 5571–5576 (1999).

Li, C., Zhou, Z., Li, Y., Guo, Y. & Ma, S. Reactivity of vinylidene-π-allyl palladium(ii) species. Chem. Commun. 59, 3727–3730 (2023).

Acknowledgements

Financial support was provided by the Natural Science Foundation of China (22350006, 22222101, 22171012), Beijing Natural Science Foundation (2242006), and BNLMS. Peking University Li Ge Zhao Ning Youth Research Fund for Life Sciences (LGZNQN202204) Computation was supported by high-performance computing platform of Peking University. The authors thank Jun-Jie Wang and Jing-Yao Bai (PKU) for discussions.

Author information

Authors and Affiliations

Contributions

R.Z. and Z.-L.W. proposed the transformation. Z.-L.W. carried out the experiments. R.Z. and Z.-L.W. wrote the manuscript. R.Z. directed the research.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Aiguo Hu, Toshio Koizumi, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, ZL., Zhu, R. Controlled chain-growth polymerization via propargyl/allenyl palladium intermediates. Nat Commun 16, 2506 (2025). https://doi.org/10.1038/s41467-025-57723-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-57723-8

This article is cited by

-

Artificial intelligence in polymer chemistry: opportunities and challenges

Chemical Papers (2026)

-

Palladium-catalyzed enantioselective dienylation of propargylic carbonates via sulfonimidamide desymmetrization

Nature Communications (2025)