Abstract

The interfacial electron interactions in heterogeneous catalysts are critical in determining the adsorption strengths and configurations of reaction intermediates, which are essential for the efficiency of multistep tandem catalytic processes. Amorphous-crystalline (a-c) heterostructures have garnered significant interest due to their unusual atomic arrangements, adaptable electron configurations, and exceptional stability. Here, we introduce a mesoporous a-c heterojunction catalyst featuring enriched amorphous-crystalline Ni(OH)2/Pt boundaries (ac-Ni(OH)2@m-Pt), designed for efficient acidic oxygen reduction reaction (ORR). This catalyst enables electron redistribution at the heterogeneous interface, thereby enhancing both catalytic activity and durability. As anticipated, the ac-Ni(OH)2@m-Pt delivers a high mass activity (MA) of 0.95 A mgPt−1 and maintains good durability (89.8% MA retention) over 15000 cycles. Advanced characterization and theoretical calculations reveal that the catalyst’s high performance stems from the dynamic heterogeneous-interface electron redistribution at the a-c interface. This dynamic-cycling electron transfer, driven by the applied potential, promotes O2 activation and accelerates the protonation of *O intermediate during ORR. This work offers a promising avenue for improving the design of electrocatalysts using a-c interface engineering.

Similar content being viewed by others

Introduction

Developing and utilizing green energy conversion technology, such as proton-exchange membrane fuel cells (PEMFCs), is an important approach to break out the dependence on fossil energy1,2. Oxygen reduction reaction (ORR), as the cathode reaction of PEMFC, involves intricate four-electron transfer processes that lead to sluggish kinetics, becoming the bottleneck of improved efficiency3. To date, nanostructured platinum (Pt)-based materials are still identified as the most active electrocatalyst for the ORR in PEMFCs4,5. However, the widespread commercialization of PEMFC systems remains hindered by the substantial Pt content required to compensate for the sluggish oxygen reduction kinetics occurring at the devices’ cathode, which is far from the ultimate cost target of US$30 kW−1 for the fuel cell stack6. Recently, alloying Pt with cheap transition metals (noted as M) has emerged as an effective approach to improve ORR mass activity and reduce catalyst costs. This is achieved through the ligand and stress effect created by incorporating M atoms into the Pt lattice, as well as minimizing the consumption of noble Pt. Nevertheless, these activity enhancements are often not accompanied by high durability. The leaching of transition metals not only deteriorates catalytic activity but also shortens the lifespan of Pt-based alloy catalysts7,8. As a result, designing electrocatalysts that simultaneously improve mass activity and catalytic stability is urgently needed.

Currently, significant research achievements focus on the use of atomic doping9, morphology regulation10, and surface functionalization strategies11,12 to modulate the electronic structure of active sites in Pt-based catalysts. These modifications directly influence the adsorption and deionization of reactive species, thereby affecting catalytic activity. Notably, the construction of atomic-level heterostructure offers an alternative avenue to modulate the electron distribution of metal sites13,14. When two distinct components form a heterostructure, interfacial electronic interactions trigger electron transfer, leading to electron redistribution and surface polarization. This, in turn, facilitates charge transport to reactants on the surface of catalysts for enhanced electrocatalytic performance15,16,17. However, most studies on heterojunction catalysts focus on crystalline–crystalline (c-c) complexes. The inherent lattice mismatch between different interfaces would result in limited contact interfaces, poor electron transfer efficiency, and interfacial instability in an acidic medium, which ultimately reduces catalytic effectiveness18,19,20. In this context, establishing amorphous–crystalline (a-c) heterostructures that exhibit unconventional atomic arrangements at heterostructure interfaces can mitigate the issues associated with lattice mismatches in c-c heterostructures, and also display satisfactory potential in electrocatalytic applications21,22. Furthermore, the scarcity of active sites at the catalyst interface and constrained mass transfer become the bottleneck of improving reaction kinetics. This issue is exacerbated when scaling up from laboratory-scale thin-film rotating disk electrode (RDE) experiments to practical cell devices, as the catalyst thickness in real-world applications often surpasses that used in experimental setups. Li et al.23 showed that mass transfer and ORR kinetics could be improved by integrating an open-pore architecture into the catalyst design. Given the demands for efficient mass transport and accessible active sites during reactions, developing heterostructure catalysts with high-density a-c interfaces and ordered mesoporous structures is of great value but challenging.

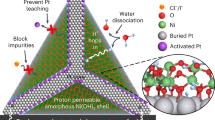

In this work, we report a unique design of an amorphous-crystalline heterojunction, combining amorphous Ni(OH)2 and crystalline mesoporous Pt (denoted as ac-Ni(OH)2@m-Pt), to effectively modulate heterogeneous-interface electron redistribution under the potential driven state, significantly boost ORR performance of Pt in acidic medium. At the atomic level, the incorporation of amorphous Ni(OH)2 can enhance the electron interactions at the a-c interface, promoting electron transfer from Pt to the Ni site to form a relatively high oxidation state Pt site, which optimizes adsorption energies and lower the overpotential to accelerate ORR kinetics, leading to high-efficient ORR process. As expected, the ac-Ni(OH)2@m-Pt displays good activity for electrocatalytic ORR, with a half-wave potential of 0.91 V versus reversible hydrogen electrode (vs. RHE) and a four-electron selectivity of 98% in 0.1 M HClO4. Besides, the encapsulated amorphous Ni(OH)2 is stabilized within the structure due to interactions with Pt. Consequently, the ac-Ni(OH)2@m-Pt undergoing 15000 accelerated durability tests (ADTs) shows undetectable structural deformation and less than 11% loss of mass activity. In situ X-ray absorption fine structure (XAFS) reveals that amorphous Ni(OH)2 acquires electrons from Pt, activating Pt sites to adsorb and activate oxygen molecules at a low overpotential, and then donate electrons to Pt at a high overpotential for promoting its ORR process. Combined with synchrotron infrared (SRIR) and density of functional theory (DFT) calculations, we observe that the synergistic a-c interface could accelerate the formation of *OH on the catalyst surface, contributing to the rapid 4-electron ORR process. This work deepens our understanding of the role of a-c heterogeneous interface in electrocatalytic reactions and provides a promising strategy for designing improved electrocatalysts for diverse chemical transformations.

Results and Discussion

Preparation and characterization of ac-Ni(OH)2@m-Pt

The uniformly dispersed ordered mesoporous nanoparticles (ac-Ni(OH)2@m-Pt) with abundant amorphous-crystalline boundaries were successfully prepared using a meticulously designed “template-solvent” strategy (Fig. 1a). Mesoporous KIT-6 was initially chosen as a rigid, stable template to adsorb Pt2+ and Ni2+ precursors into its well-ordered mesoporous under vacuum conditions. The resulting orange powder was transferred to ascorbic acid (as a reducing agent), to yield a black product, which was subsequently designated PtNi@KIT-6. During this step, Ni cations were gradually inserted into the Pt nanocrystals, preserving the mesoporous structure of KIT-6. The template was finally removed by washing the product with a 2 M NaOH solution under 80 °C, which simultaneously removed the KIT-6 template and formed amorphous Ni(OH)2, resulting in ac-Ni(OH)2@m-Pt. Both the KIT-6 template and the etching solvent played pivotal roles in creating the mesoporous structure and the amorphous-crystalline boundaries. The ORR performance was greatly influenced by the transition metal content, with an optimal Pt/Ni atomic ratio of 3: 1, as determined by inductively coupled plasma mass spectrometry (ICP-MS) results, displaying the best catalytic activity (Supplementary Fig. 1). For comparison, mesoporous Pt (m-Pt) and commercial PtC were employed as reference samples.

a Schematic illustration of synthesizing ac-Ni(OH)2@m-Pt catalyst. (b) XRD patterns of m-Pt and ac-Ni(OH)2@m-Pt. (c) TEM, (d) local enlargement of (c) (the yellow circles represent mesoporous structures), and (e) HRTEM images of ac-Ni(OH)2@m-Pt. f, g Enlarged images and the corresponding FFT patterns of the selected regions marked by the blue and orange squares, respectively, in (e). h EDX element mappings of ac-Ni(OH)2@m-Pt catalyst.

The crystal structure of the synthesized samples was verified through X-ray diffraction pattern (XRD) results, as seen in Fig. 1b. Three characteristic XRD peaks in the 2θ range of 35–70° were observed for ac-Ni(OH)2@m-Pt and m-Pt catalysts, corresponding to the typical Fm3̅m phase structure of a face-centered cubic Pt (PDF#04-0802)24. Notably, no Ni-related species peaks were observed for ac-Ni(OH)2@m-Pt, suggesting that Ni species exist within Pt in an amorphous form. The refinement XRD peaks match well with Pt (Supplementary Fig. 2), further supporting the presence of predominantly crystalline Pt and amorphous Ni species in ac-Ni(OH)2@m-Pt. Moreover, compared with m-Pt, all diffraction peaks of ac-Ni(OH)2@m-Pt display a slight positive shift, indicating strong interfacial interaction between Ni species and Pt, leading to the shrinkage of the Pt lattice25. Low-magnification transmission electron microscopy image (TEM) in Fig. 1c reveals that the ac-Ni(OH)2@m-Pt nanoparticles are morphologically polyhedral in shape, with sizes ranging from 100 to 120 nm. There are abundant meso-channels penetrated within the entire sample (Fig. 1d). Similarly, m-Pt exhibits a comparable morphology and distinct lattice fringes (Supplementary Fig. 3), confirming the successful design of mesoporous structures. Meanwhile, the nitrogen sorption experiment exhibits a slightly higher surface area of ac-Ni(OH)2@m-Pt compared to m-Pt (Supplementary Fig. 4). Through high-resolution TEM (HRTEM) observations (Fig. 1e), the ac-Ni(OH)2@m-Pt shows a mixed structure of amorphous and crystalline domains with abundant phase boundaries. Within the blue square region (Fig. 1f), a distinct lattice fringe corresponding to a d-spacing of 0.212 nm is identified, which is consistent with the (111) crystallographic plane of Pt. In contrast, the area highlighted by the orange square (Fig. 1g) exhibits no discernible lattice fringes. The associated Fast Fourier Transform (FFT) pattern reveals only a faint reflection halo devoid of sharp diffraction spots, indicating the amorphous nature of the Ni species. Such amorphous phases commonly have numerous lattice disorders, which can further facilitate ionic diffusion, therefore abundant amorphous-crystalline boundaries may enhance the electrocatalytic performances. The energy-dispersive X-ray spectroscopy (EDX) characterization indicates a homogeneous distribution of Pt, Ni, O elements in ac-Ni(OH)2@m-Pt, as shown in Fig. 1h. Moreover, the atomic ratio of Pt to Ni in the ac-Ni(OH)2@m-Pt was calculated to be approximately 2.9: 1 in Supplementary Fig. 5 by the energy-dispersive X-ray spectroscopy (EDX), which is consistent with the ICP result.

Electronic properties of catalysts

The surface components and chemical states of the catalysts were carefully analyzed using X-ray photoelectron spectroscopy (XPS). The ac-Ni(OH)2@m-Pt survey spectrum verifies the presence of both Pt and Ni, as illustrated in Supplementary Fig. 6. High-resolution XPS spectra, depicted in Fig. 2a, b and Supplementary Fig. 7, reveal that the surface Pt predominantly exists in a metallic state, while the Ni species are mainly in the form of Ni(OH)226,27. We speculate it as amorphous Ni(OH)2, which is consistent with our XRD observations28. Additionally, the k3χ (k) oscillation curve for the Ni K-edge in ac-Ni(OH)2@m-Pt (Supplementary Fig. 8) closely resembles that of Ni(OH)2, indicating similar structural characteristics. Notably, the binding energy of Pt in ac-Ni(OH)2@m-Pt exhibits a positive shift compared to m-Pt, implying a modification of Pt’s electronic properties due to electron redistribution at the a-c heterogeneous interface induced by the introduction of amorphous Ni species. To further elucidate the local electronic and coordination structural information of ac-Ni(OH)2@m-Pt and m-Pt, X-ray absorption fine structure (XAFS) measurements were employed (Supplementary Fig. 9). Note that the XAFS signal is an average of all the targeted atoms, thus the change of the X-ray absorption near-edge structure (XANES) absorption energy resulting from the charge transfer between the interfacial atoms is diluted by the bulk signal from non-interfacial atoms and thus is always not very obvious. The XANES spectra (Fig. 2c) exhibit that the average electronic state of Ni in ac-Ni(OH)2@m-Pt is slightly lower than the +2 oxidative state of Ni(OH)2, which may be attributed to electron donation from Pt and the presence of less metallic component. Concurrently, the Pt XANES spectra in Fig. 2d display a slightly higher valence state of ac-Ni(OH)2@m-Pt relative to the initial m-Pt and Pt foil, indicating partial charge transfer from Pt to the neighbor amorphous Ni(OH)2.

a, b High-resolution XPS spectra of (a) Ni 2p, and (b) Pt 4 f of m-Pt and ac-Ni(OH)2@m-Pt (Sat. is the abbreviation of Satellite). c, d XANES spectra at the (c) Ni K-edge, and (d) Pt L3-edge (XANES is the abbreviation of X-ray absorption near-edge structure). The inset is an enlarged white-line peak. e EXAFS spectra at the Pt L3-edge and Ni K-edge (EXAFS is the abbreviation of extended X-ray absorption fine structure). (f-h) WT-EXAFS plots of the Pt L3-edge for (f) Pt foil, (g) m-Pt, and (h) ac-Ni(OH)2@m-Pt.

To determine the local coordination structure of Pt and Ni sites at the atomic scale, the Fourier-transformed extended X-ray absorption fine structure (EXAFS) of Pt and Ni in ac-Ni(OH)2@m-Pt was performed in Fig. 2e. The prominent peak located at 2.52 Å of the Pt L-edge for ac-Ni(OH)2@m-Pt and m-Pt is ascribed to the Pt-Pt bond, and the Pt-O scattering peak at 1.63 Å is absent in the ac-Ni(OH)2@m-Pt, likely due to its minimal percentage. The significant reduction in the intensity of Pt-Pt peak reveals a decrease in the coordination number of Pt, attributed to the formation of an ordered mesoporous structure. The EXAFS spectrum of Ni K-edge demonstrates two major peaks: one located at ~1.61 corresponding to the Ni-O coordination in the first shell, and another at ~2.64 Å representing the Ni-O-Ni coordination in the second shell. These features are similar to those observed in standard Ni(OH)2, but the intensity of Ni-O-Ni peaks is considerably lower, suggesting a high degree of structural disorder in the amorphous Ni(OH)227. Additionally, the wavelet-transformed (WT) EXAFS spectra of ac-Ni(OH)2@m-Pt and reference samples were further performed to distinguish the bonding between Pt and other elements (Fig. 2f–h), the Pt foil displays a main signal in the k-space at about 10.2 Å−1. The negative shift of the maxima in the k space from Pt foil to ac-Ni(OH)2@m-Pt reveals that Pt is coordinated with a lighter transition metal29, which should be Pt-O-Ni configuration, suggesting the a-c heterogeneous interface electron interaction through Pt-O-Ni structure.

Electrochemical characterization in acidic electrolyte

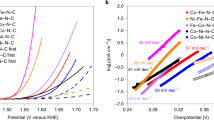

To elucidate the electrochemical ORR properties of ac-Ni(OH)2@m-Pt arising from the amorphous-crystalline boundaries, electrocatalytic measurements were conducted using the rotating disk electrode (RDE) technique, along with m-Pt and commercial PtC (20%) catalysts for comparison. The cyclic voltammetry (CV) curves (Fig. 3a) were initially recorded in a N2-saturated 0.1 M HClO4 electrolyte to obtain the electrochemically active surface area (ECSA) of catalysts according to the hydrogen underpotential deposition (Hupd). The ac-Ni(OH)2@m-Pt displays the largest ECSA of 88.7 m2 g−1 (Supplementary Fig. 10), substantially surpassing that of m-Pt (70.4 m2 g−1) and PtC (67.2 m2 g−1), confirming more accessible active sites in ac-Ni(OH)2@m-Pt. Linear sweep voltammetry (LSV) curves of the samples were then required in Fig. 3b, ac-Ni(OH)2@m-Pt delivers the optimal ORR activity with a half-wave (E1/2) potential of 0.912 V vs. RHE (subsequent potentials are all relative to RHE), which is 36 and 57 mV than those of m-Pt (0.876 V) and PtC (0.855 V). This high performance may benefit from its fast mass transfer in mesoporous structure and interface electron redistribution at the a-c boundaries. Aside from the half-wave evaluation of catalysts, the Pt mass normalized data comparison offers a more accurate picture of catalyst activity (Fig. 3c and Supplementary Table 1). The ac-Ni(OH)2@m-Pt exhibits high activity, with a mass activity (MA) of 0.95 ± 0.006 A mgPt−1 at a potential of 0.9 V, surpassing m-Pt (0.27 ± 0.005 A mgPt−1) and PtC (0.12 ± 0.006 A mgPt−1) by 3.5 and 7.9 times, respectively. Remarkably, the MA achieved by ac-Ni(OH)2@m-Pt in this work also exceeds the DOE 2025 target and most recently reported catalysts (Supplementary Table 2)30. Meanwhile, the specific activity (SA) for ac-Ni(OH)2@m-Pt is determined to be 1.07 ± 0.005 mA cm−2, presenting approximately 2.7 and 6.3 times higher than that of m-Pt (0.39 ± 0.005 mA cm−2) and PtC (0.17 ± 0.006 mA cm−2), respectively. Tafel plots of these catalysts (Fig. 3d) obtained under the same condition further confirm the better performance of the ac-Ni(OH)2@m-Pt, showing a much lower slope (65.8 mV dec−1) compared to m-Pt (82.4 mV dec−1) and PtC (77.9 mV dec−1), probably indicative of its faster charge transfer ability induced by amorphous-crystalline boundaries.

a CV curves with a sweep rate of 50 mV s−1), (b) Non-iR corrected ORR polarization curves with a sweep rate of 10 mV s−1 and rotation rate of 1600 rpm, c Mass activity and specific activity (error bars are the standard deviations of three individual calculation), and (d) Tafel slopes of ac-Ni(OH)2@m-Pt, m-Pt, and PtC. e Non-iR corrected ORR LSV curves with a sweep rate of 10 mV s−1 of ac-Ni(OH)2@m-Pt at different rotation rates (400 – 2500 rpm) (inset: the corresponding K-L plots under different potentials). f Electron transfer number (n) and H2O2 yield of catalysts. g BOL and EOL LSV curves with a sweep rate of 10 mV s−1 of ac-Ni(OH)2@m-Pt and m-Pt. BOL and EOL (h) ECSA, (i) Mass activity of ac-Ni(OH)2@m-Pt, PtC, and m-Pt, in which BOL and EOL represent before-of-life and end-of-life.

Moreover, The Koutecky–Levich (K–L) plots of samples derived from the polarization curves at varying rotating rates illustrate good linearity and parallelism in the potential range of 0.4 – 0.6 V (Fig. 3e, Supplementary Figs. S11 and 12). The average electron transfer number (n) is calculated to be 3.98 for ac-Ni(OH)2@m-Pt, 3.84 for m-Pt, and 3.82 for PtC, confirming an efficient 4-electron reaction process in ac-Ni(OH)2@m-Pt. In addition, the yield of H2O2 on the three samples during the ORR was further monitored by the rotating ring disk electrode (RRDE) measurements. As shown in Fig. 3f and Supplementary Fig. 13, the H2O2 yield of ac-Ni(OH)2@m-Pt in the potential range from 0.2 – 0.8 V is consistently below 4%, giving an electron transfer number of ~4.0. The above results suggest that ac-Ni(OH)2@m-Pt catalyst exhibits high selectivity towards the four electrons pathway. Moreover, the crystalline PtNi-calcination exhibits a lower E1/2 (0.867 V) than ac-Ni(OH)₂@m-Pt (Supplementary Fig. 14), further verifying the synergistic promoting effect of a-c interfaces. To evaluate the ORR stability of the catalysts, accelerated degradation testing (ADT) was conducted. The changes of CV curves for the catalysts before and after 15000 cycles are shown in Supplementary Fig. 15. Surprisingly, ac-Ni(OH)2@m-Pt exhibits satisfactory long-term stability, with only a 7 mV attenuation in E1/2 after 15000 cycles of ADT (Fig. 3g). This outperforms me-Pt and PtC, which show an E1/2 loss of 20 and 45 mV, respectively (Supplementary Fig. 16). The improved stability of ac-Ni(OH)2@m-Pt is further validated by a high ECSA retention of approximately 92% after ADT operations (Fig. 3h), surpassing the ECSA retention of m-Pt ( ~ 87%) and PtC (72%). More importantly, the mass-normalized data analysis shows a more meaningful comparison, where ac-Ni(OH)2@m-Pt exhibits better stability with a less than 11% decline in MA after 15000 ADT cycles. In contrast, commercial PtC shows a significant MA attenuation of over 50% (Fig. 3i). The SA values of ac-Ni(OH)2@m-Pt and m-Pt decay by 11% and 21%, respectively, which are much lower than that of PtC (58%) (Supplementary Fig. 17). Given the critical dependence of catalyst durability on its structural and compositional integrity, we conducted a detailed analysis of the post-stability-test structural and compositional alterations to gain deeper insights into the catalyst’s long-term performance. Supplementary Figs. 18–23 show that the microstructure and electronic structure of ac-Ni(OH)2@m-Pt remain largely intact after electrochemical testing, with negligible alterations in the oxidation state and coordination of Pt and Ni sites. Furthermore, the Pt/Ni atomic ratio is determined to be 79:21, suggesting some degree of Ni(OH)2 dissolution in the acidic ORR process. However, post-stability testing characterization confirms the retention of Ni(OH)2 and abundant a-c heterogeneous interfaces. These findings demonstrate that the amorphous Ni(OH)2 at the a-c interface maintains good stability during the ORR, and the synergistic electronic effect of the a-c heterogeneous interface in ac-Ni(OH)2@m-Pt favors both ORR activity and stability. In addition, the membrane electrode assembly (MEA) performance of the ac-Ni(OH)2@m-Pt catalyst was further evaluated in a hydrogen fuel cell under H2-air conditions. The ac-Ni(OH)2@m-Pt cathode delivers a maximum power density of 1.07 W cm−2 (Supplementary Fig. 24).

Exploration of the mechanism via in situ characterization

To deeply investigate the origin of enhanced activity for ac-Ni(OH)2@m-Pt, we probed the dynamic changes in the oxidation state and local coordination environment at ORR-relevant potentials using in situ XAFS measurements (Supplementary Fig. 25). Figure 4a shows the potential-dependent Pt-L edge XANES of ac-Ni(OH)2@m-Pt, emphasizing the change in the oxidation state of Pt at applied potentials31. Upon applying a potential of 1.00 V, the white-line peak intensity of Pt shows a slight increase compared to the initial condition (electrode in solution without applied voltage). This enhancement stems from the elevated oxidation state induced by the formation of Pt sites coordinated with oxygen species. Notably, under oxygen reduction potentials, the white-line peak intensity experiences a slight decline. Such valence state oscillation of Pt sites may be ascribed to the strong interaction with oxygen-involving intermediates for enhanced ORR activity32. To accurately capture the a-c heterogeneous-interface electronic interaction between Ni(OH)2 and Pt, the Ni K-edge XAFS was also conducted to study the dynamic electron interaction behavior during the reaction process. Interestingly, for the Ni K-edge XANES (Fig. 4b), the oxidation state of Ni sites changes oppositely compared to Pt, indicating the obvious electron transfer behavior between Pt and Ni sites. Compared to initial conditions, the energy of the absorption edge has shifted negatively when a potential of 1.0 V is applied to the sample. With decreasing potentials to 0.85 V and then to 0.55 V, the absorption edge location moves first positively, then negatively, illustrating a dynamic cyclic evolution of oxidation states of the Ni cations. This variable oxidation state of Ni sites is further confirmed by the energy position of the first derivative maximum from XANES spectra (Fig. 4c).

a, b In situ XANES spectra for the (a) Pt L-edge, and (b) Ni K-edge for ac-Ni(OH)2@m-Pt. c The first derivative of the Ni K-edge XANES spectra, and (d) calculated oxidation state of Ni under in situ potentials based on the absorption edge of Ni K-edge XANES spectra for ac-Ni(OH)2@m-Pt. Error bars are the standard deviations of three replicate calculations. e In situ EXAFS spectra of Pt L-edge (up) and Ni K-edge (down) during ORR conditions.

To further quantify the change in the oxidation state of metal sites, the average valence state was fitted based on Ni K-edge XANES (Fig. 4d). The average valence state for Ni is 1.88 at an applied potential of 1.0 V, indicating that Ni receives electrons from Pt by bridged oxygen, activating Pt sites for oxygen molecule adsorption and activation. As the potential decreases to 0.55 V, the increasing valence state of Ni elevates from 2.07 (0.85 V) back to 1.85, revealing that amorphous Ni(OH)2 is involved in oxygen reduction, which may act as a promotor in the decomposition of water molecules to provide sufficient protic hydrogen. This implies that Pt and Ni are synergistic active sites, facilitating the adsorption of reactive species. In addition, a detailed local coordination environment can be further determined by EXAFS spectra (Fig. 4e). No apparent variation is found for the coordination peaks located at 2.64 and 2.52 Å for Ni K-edge and Pt L3-edge, confirming the desirable structural stability of ac-Ni(OH)2@m-Pt, which can be attributed to the strong interaction between amorphous Ni(OH)2 and crystalline Pt structure. Note that the Ni - O peak moves toward a positive direction when potentials decrease to 0.55 V, which could be attributed to absorbed and dissociated water molecules over Ni sites33. The above results reveal that a-c heterogeneous-interface electron redistribution actuated by potentials promotes oxygen molecular adsorption and evolution at the Pt site, achieving high-efficiency ORR activity.

Deciphering reaction mechanism from in situ SRIR and computational studies

To visualize the catalytic reaction pathways and mechanisms of ac-Ni(OH)2@m-Pt, surface-sensitive in situ synchrotron radiation infrared (SRIR) spectroscopy measurements were employed using a homemade cell (Supplementary Fig. 26). As illustrated in Fig. 5a, three distinct infrared peaks located at 1087, 848, and 3024 cm−1 are identified for ac-Ni(OH)2@m-Pt during the ORR process, with their intensities varying with the applied potentials. These characteristic peaks could be referred to as the stretching vibrations of *OOH, *O and *OH intermediates, respectively25,34. This indicates a typical four-electron ORR pathway occurs at ac-Ni(OH)2@m-Pt. This pathway is associated with a low H2O2 byproduct yield (less than 4%) and a high electron transfer number of 3.98. Meanwhile, the in situ SRIR measurement was also conducted for the m-Pt and PtC to make a comparison (Fig. 5b and Supplementary Fig. 27). Only two infrared vibration peaks located at ~1080 and 844 cm−1 can be assigned to *OOH and *O intermediates, and no *OH intermediates were detected, suggesting slow protonation of oxygen-containing species in the ORR reaction for m-Pt and PtC catalysts. This also infers the amorphous Ni(OH)2 could act as a collaborative catalytic center to supply abundant protonic hydrogen for a fast protonation of *O in the ORR process for ac-Ni(OH)2@m-Pt. To further examine the reaction process, we analyzed the potential-dependent SRIR signal variations in the bands of *OOH, *O and *OH intermediates (Fig. 5c). As the applied potential decreases, the appearance of *OOH species and *O on the ac-Ni(OH)2@m-Pt surface precedes that on the m-Pt surface by ~100 mV. Moreover, the amplitude of the *O SRIR signal of ac-Ni(OH)2@m-Pt is enhanced much more than that of m-Pt, which is attributed to the fast decomposition of more *OOH to *O over the Pt sites in ac-Ni(OH)2@m-Pt. More interestingly, when the potential drops below 0.75 V, the amplitude of *OH gradually increases over the ac-Ni(OH)2@m-Pt surface while not detected on the m-Pt surface. Concurrently, in situ SRIR results of ac-Ni(OH)2@m-Pt under both cathodic and anodic scans (Supplementary Fig. 28) reveal a dynamic evolution process of reaction intermediates with applied potential. Above all, the in situ SRIR and XAFS results jointly reveal that a dynamic cyclic evolution of oxidation states in the Ni cations can promote Pt sites to adsorb and activate oxygen molecules at a low overpotential. The synergistic effect between the a-c interface accelerates the formation of *OH on the catalyst surface, contributing to enhanced ORR activity and stability.

Theoretical investigations were further conducted based on density function theory (DFT) calculations to investigate the differences in performance between m-Pt and ac-Ni(OH)2@m-Pt (Fig. 5d and Supplementary Fig. 29). The construction of the model follows the guidance of XRD and XAFS results, with amorphous Ni(OH)2 combined with crystalline Pt (111) to form a heterostructure (Supplementary Data 1). Since catalytic activity is directly correlated with surface electronic states, the study focuses on analyzing the free energy changes of the elementary steps involved in ORR. The ORR process is divided into four main steps, encompassing hydrogenation and O - O bond breaking (Supplementary Figs. 30 and 31). Two electrocatalysts exhibit downhill trends in all reaction steps at a potential of U = 0 V (Supplementary Fig. 32), implying they were spontaneous. Free energy diagrams at U = 1.23 V display a comparable trend in free energy changes. The most positive ΔG of 0.53 eV for m-Pt is the protonation process of *O into *OH, demonstrating it is the rate-determining step (RDS) for electrocatalytic ORR35. After introducing a-c boundaries in m-Pt, ΔG of this process reduces to 0.23 eV, suggesting that synergistic a-c boundaries and redistribution electrons over the heterogeneous interfaces lower the energy barrier of the protonation reaction, which matches strongly with the SRIR data. The differential charge distribution and the shift in the d-band center (Supplementary Figs. 33 and 34) further verify the electron interactions at the a-c heterogeneous interface, leading to enhanced ORR performance of ac-Ni(OH)2@m-Pt.

In summary, we have reported an ordered mesoporous Pt-based electrocatalyst featuring abundant amorphous-crystalline boundaries (ac-Ni(OH)2@m-Pt), in which the amorphous Ni(OH)2 functions as a modulator to tailor the heterogeneous-interface electronic structure, resulting in long-term acidic ORR activity. Mechanistic studies employing in situ XAFS and SRIR spectroscopies reveal that the in situ a-c heterogeneous-interface electron redistribution actuated by potentials was realized. Specifically, the amorphous Ni(OH)2 captures electrons from Pt, thereby activating the Pt sites, and subsequently donates electrons back to Pt to promote its ORR process. Furthermore, theoretical investigations highlight that a faster four-electron conversion of intermediates can be achieved in ac-Ni(OH)2@m-Pt by lowering the energy barrier for the protonation of oxygen species. As a result, the ac-Ni(OH)2@m-Pt delivers enhanced ORR performance with a half-wave of 0.912 V in the acid electrolyte, the lowest Tafel slope of 65.8 mV dec−1, and enhanced stability compared to m-Pt. Despite a gap in stability compared to the requirements of industrial applications, this work provides valuable insights for designing platinum-based acidic ORR catalysts through interface engineering. Future efforts should focus on enhancing the stability of Pt-based catalysts, employing strategies such as multi-atom doping, interface engineering, electrode optimization, and iterative device improvements.

Methods

Chemicals

Potassium tetrachloroplatinate (K2PtCl4, 99.9%), Nickel chloride hexahydrate (NiCl2·6H2O, 99.9%), Nafion solution (5 wt%), and perchloric acid (HClO4, 70%) were purchased from Sigma-Aldrich. KIT-6 molecular sieves were purchased from Jiangsu Xianfeng Nanomaterials Technology Co., Ltd. Sodium hydroxide (NaOH, 96%) and L-ascorbic acid (AA, 99.7%) were purchased from Aladdin. Commercial PtC was purchased from Johnson Matthey Corp (20 wt%). All the chemicals were used as received without further purification.

Synthesis of ac-Ni(OH)2@m-Pt

Typically, K2PtCl4 (80 mg) and NiCl2·6H2O (20 mg) were dispersed in deionized water (2 mL) and ultrasound for 30 min to disperse evenly. Following this, 0.3 g KIT-6 was added to the above solution, and the mixture was sonicated for an additional hour. The resulting solution was then dried under vacuum to yield a solid powder, referred to as precursor@KIT-6. Next, 2 mL of a 1 M ascorbic acid (AA) solution was added dropwise to the powder and left undisturbed for 24 h. Subsequently, the percursor@KIT-6 was treated with 2 M hot NaOH while stirring continuously to remove the KIT template. Afterward, the black powder was centrifuged and washed with distilled water. In addition, 30 mg and 40 mg were selected for NiCl2·6H2O during the synthesis process to prepare samples with different Pt/Ni.

Synthesis of m-Pt

Typically, K2PtCl4 (80 mg) was dispersed in deionized water (2 mL) and ultrasound for 30 min to disperse evenly. 0.3 g KIT-6 was added to the above solution, ultrasound for another 1 h and further dried under vacuum to obtain a powder (percursor@KIT-6). After that, 2 mL of 1 M AA solution was added dropwise to the powder and kept undisturbed for 24 h. Finally, the percursor@KIT-6 was added into 2 M hot NaOH for continuous stirring to remove the KIT template. Black powder was centrifuged and washed with distilled water.

Material characterization

Transmission electron microscopy (TEM), high-resolution transmission electron microscopy (HRTEM), as well as energy dispersive X-ray spectroscopy (EDX) was performed on a Talos F200X instrument. The powder X-ray diffraction (XRD) patterns were measured in a Philips X’Pert Pro Super X-ray diffractometer with Cu Kα radiation (λ = 1.54178 Å). Inductively coupled plasma mass spectrometry (ICP-MS) was performed on PlasmaQuad 3 (VG Instruments). The Brunauer-Emmett-Teller (BET) surface areas of the samples were obtained using an ASAP 2020 analyzer and an automated N2 gas adsorption system. ThermoFisher-VG Scientific (ESCALAB250X) was applied to gather the X-ray photoelectron spectroscopy (XPS), and all the binding energies obtained in XPS spectra analysis were corrected by C 1 s at 284.8 eV. The Pt L-edge and Ni K-edge X-ray absorption spectra were measured at the 1W1B station in the Beijing Synchrotron Radiation Facility (BSRF, China).

Electrochemical measurements

Electrochemical evaluations of the ORR performance were performed on a standard three-electrode system by an electrochemical workstation (CHI760E, CH instruments) with a rotating ring-disk electrode (RRDE, Pine). The reference and counter electrodes used were a saturated Ag/AgCl (saturated KCl) and a carbon rod, respectively. To calibrate the reference electrode, a three-electrode configuration is employed, with the reference electrode requiring calibration as the reference, a platinum sheet functioning as the counter electrode, and a platinum mesh serving as the working electrode. Before the test, hydrogen gas is bubbled through 0.1 M HClO4 for over 30 min to ensure the electrolyte becomes saturated with dissolved hydrogen. Hydrogen is continually passed over the working electrode, and LSV testing is performed. The voltage corresponding to the current zero is the calibration potential. The potentials relative to the reversible hydrogen electrode (E(vs. RHE)) were calculated by E(vs. Ag/AgCl) + 0.256 V. The resistance (Rs) was measured by the current interrupt method of the electrochemical workstation. For electrode preparation, electrocatalysts were dispersed in a mixture solution (730 µL deionized water, 250 µL ethanol, and 20 µL Nafion) and then sonicated for 20 min to form homogeneous inks. The as-prepared ink was dropped onto the glassy carbon (GC) disk of the rotating disk electrode (RDE, disk diameter of 5 mm) or rotating ring disk electrode (RRDE, disk diameter of 5.61 mm) to obtain a loading of 12.5 µgPt cm−2 for all the catalysts. The electrolyte was prepared by mixing 808 μL HClO4 with deionized water, and adjusting the total volume to 100 mL to obtain 0.1 M HClO4 electrolyte. The electrolyte should be stored away from light and used promptly. The CV test was conducted at a potential sweep of 50 mV s−1 in N2-saturated 0.1 M HClO4 electrolyte. The ORR polarization curves were recorded in O2-saturated 0.1 M HClO4 under various rotating speeds from 400 to 2500 rpm with a sweep rate of 10 mV s−1. For the accelerated durability test, the potential cycling was measured in the voltage range of 0.6–1.1 V with a scan rate of 100 mV s−1. All potentials stated are relative to the reversible hydrogen electrode (versus RHE). The ECSA is calculated using the following Eq. (1):

Where QH-adsorption is the hydrogen desorption charge obtained by integrating the area in CVs, LPt is the actual Pt loading, and Ag is the geometric surface area of the glassy carbon electrode.

The electron transfer number (n) for oxygen reduction can be calculated according to the Koutecky-Levich Eqs. (2) and (3):

In the equation, J is the measured current density, JK and JK are the kinetic and diffusion current densities, ω is the rotating speed of the electrode, n is the number of electrons transferred by a single oxygen molecular, F is the Faraday constant, D0 is the diffusion coefficient of O2 in 0.1 M HClO4, C0 is the concentration of O2, and V is the kinematic viscosity of the electrolyte.

The hydrogen peroxide yield (H2O2%) and average electron transfer number based on RRDE measurements can be determined by the following Eqs. (4) and (5):

where Id is the disk current, Ir is the ring current, and N = 0.37 is the current collection efficiency of the Pt ring.

In situ XAFS measurements

In situ XAFS analysis was carried out using a custom-built electrochemical cell with a three-electrode setup, where catalyst-coated carbon cloths were immersed in an acidic medium. Specifically, a homogeneous catalyst ink was prepared by dispersing 5 mg of the sample in a 1 mL mixture containing 0.5 mL ethanol, 0.5 mL deionized water, and 20 µL Nafion. This ink was then applied to a carbon paper working electrode ( ~ 1 cm × 1 cm), with the backside sealed using Kapton film to ensure uninterrupted contact between the electrocatalysts and the electrolyte. Before commencing the measurements, the 0.1 M HClO4 electrolyte was oxygen-saturated by purging with oxygen for 30 min, and a steady oxygen flow was maintained throughout the experiment to uphold saturation. To investigate the dynamic behavior of active sites under electrochemical conditions, a sequence of voltages (1.00–0.55 V) was applied. The absorption edge positions (E0) for Pt L3-edge and Ni K-edge spectra were calibrated against Pt and Ni foil standards, respectively. All XAFS data were recorded in a single beamtime session and processed using standard methods via the ATHENA module in the IFEFFIT software suite36. The k2-weighted and k3-weighted χ(k) data, spanning k-space ranges of 2.2–11.9 Å−1 and 2.4–11.1 Å−1, respectively, were converted to real space through Fourier transformation employing a Hanning window (dk = 1.0 Å−1). This approach facilitated the isolation of EXAFS contributions from different coordination shells for both Pt and Ni samples.

Valence state fitting

The absorption edge positions are determined as the maximum of the first derivative of the XANES spectra. Using the Ni foil (3d84s2) and NiO (3d84s0) standards, the calibration line with a slope of 6.55 eV per electron is obtained from the absorption edge positions versus the oxidation state. The absorption edge position is shown as a function of the oxidation state, thus the valence state can be calculated for ac-Ni(OH)2@m-Pt under different working conditions. We repeat the derivative of the absorption edge three times and get the error of the maximum absorption edge in ± 0.06 eV, so the valence state error obtained by spectra fitting is ± 0.01 (valence state).

In situ SRIR measurements

In situ SRIR spectra were conducted to investigate the reaction intermediates and pathways at the infrared beamline (BL01B) of the National Synchrotron Radiation Laboratory (China). The experimental setup included an infrared (IR) spectrometer (Bruker 66 V s−1), which was equipped with a KBr beam splitter, a liquid nitrogen-cooled MCT detector, and an IR microscope (Bruker Hyperion 3000) that had a 16×objective lens. Notably, the distance between the electrode and the window can be adjusted at the microscale level, helping to minimize water interference in the IR signal. To ensure consistent results and eliminate variations due to sample shedding, infrared spectra were recorded after applying a constant potential to the catalyst electrode for 15 min. To mitigate the influence of water and the active site on the infrared signal, a comparable metal loading was used, alongside a specialized in situ cell used in the infrared test. Additionally, to accurately obtain the intermediate signal, the infrared spectrum immersed in the electrode liquid without applying voltage was recorded as the background reference. This approach provided a more reliable basis for analyzing the infrared signal under potential during the SRIR measurements of different sample surfaces. Ultimately, the final infrared spectrum obtained in the subsequent tests was the result of background subtraction using the new SRIR spectra.

Density functional theory (DFT) calculation

All DFT calculations were performed using the Vienna Ab-initio Simulation Package (VASP). The Perdew-Burke-Ernzerhof (PBE) function of the Generalized Gradient Approximation (GGA) was used to describe the exchange-correlation energy, and the ion-electron interactions was represented using the projector-augmented wave (PAW) method. The Kohn-Sham valence states were expanded in a plane-wave basis set, with a cut-off energy of kinetic energy cutoff of 450 eV. Geometry optimization was performed until the force convergence criterion fell below 0.02 eV/Å, with an electronic relaxation threshold of 10−5 eV. The calculated Fermi energy was set to zero for all the DOS plots. In addition, the calculation of the amorphous/crystalline boundary was conducted using ab initio molecular dynamics (AIMD).

Data availability

The data supporting this study are available in the article and its Supplementary Information section. Source data are provided in this paper. Source data are provided with this paper.

References

Xiao, F. et al. Atomically dispersed Pt and Fe sites and Pt–Fe nanoparticles for durable proton exchange membrane fuel cells. Nat. Catal. 5, 503–512 (2022).

Huang, J. et al. Experimental Sabatier plot for predictive design of active and stable Pt-alloy oxygen reduction reaction catalysts. Nat. Catal. 5, 513–523 (2022).

Kodama, K., Nagai, T., Kuwaki, A., Jinnouchi, R. & Morimoto, Y. Challenges in applying highly active Pt-based nanostructured catalysts for oxygen reduction reactions to fuel cell vehicles. Nat. Nanotechnol. 16, 140–147 (2021).

Tian, X. et al. Engineering bunched Pt-Ni alloy nanocages for efficient oxygen reduction in practical fuel cells. Science 366, 850–856 (2019).

Bu, L. et al. Biaxially strained PtPb/Pt core/shell nanoplate boosts oxygen reduction catalysis. Science 354, 1410–1414 (2016).

Setzler, B. P., Zhuang, Z., Wittkopf, J. A. & Yan, Y. Activity targets for nanostructured platinum-group-metal-free catalysts in hydroxide exchange membrane fuel cells. Nat. Nanotechnol. 11, 1020–1025 (2016).

Ma, Z. et al. Enhancing oxygen reduction activity of Pt‐based electrocatalysts: from theoretical mechanisms to practical methods. Angew. Chem. Int. Ed. 59, 18334–18348 (2020).

Tian, X., Lu, X. F., Xia, B. Y. & Lou, X. W. Advanced electrocatalysts for the oxygen reduction reaction in energy conversion technologies. Joule 4, 45–68 (2020).

Nie, Y. et al. Low‐electronegativity Mn‐contraction of PtMn nanodendrites boosts oxygen reduction durability. Angew. Chem. Int. Ed. 136, e202317987 (2024).

Wang, Y., Zhang, X. Y., He, H., Chen, J. J. & Liu, B. Ordered mesoporous high‐entropy intermetallics for efficient oxygen reduction electrocatalysis. Adv. Energy Mater. 14, e202303923 (2023).

Yuan, H. et al. Surface engineering of Pt aerogels by metal phthalocyanine to enhance the electrocatalytic property for oxygen reduction reaction. Mater. Today Energy 37, 101379 (2023).

Xin, L. et al. Understanding Pt nanoparticle anchoring on graphene supports through surface functionalization. ACS Catal. 6, 2642–2653 (2016).

Chen, Y. et al. Enhancing oxygen reduction activity via tailoring microstrain in PdMo nanoalloy through repetitive hydrogen absorption–release. ACS Catal. 14, 9354–9363 (2024).

He, T. et al. Deposition of atomically thin Pt shells on amorphous palladium phosphide cores for enhancing the electrocatalytic durability. ACS Nano 15, 7348–7356 (2021).

Chen, A. et al. Structure of the catalytically active copper–ceria interfacial perimeter. Nat. Catal. 2, 334–341 (2019).

Chen, G. et al. Interfacial electronic effects control the reaction selectivity of platinum catalysts. Nat. Mater. 15, 564–569 (2016).

Zhu, W. et al. Taming interfacial electronic properties of platinum nanoparticles on vacancy-abundant boron nitride nanosheets for enhanced catalysis. Nat. Commun. 8, 15291 (2017).

Xue, J. Y. et al. Engineering multiphasic MoSe2/NiSe heterostructure interfaces for superior hydrogen production electrocatalysis. Appl. Catal. B: Environ. 312, 121434 (2022).

Zhou, X. et al. Design and epitaxial growth of MoSe2–NiSe vertical heteronanostructures with electronic modulation for enhanced hydrogen evolution reaction. Chem. Mater. 28, 1838–1846 (2016).

Feng, J. X., Wu, J. Q., Tong, Y. X. & Li, G. R. Efficient hydrogen evolution on Cu nanodots- decorated Ni3S2 nanotubes by optimizing atomic hydrogen adsorption and desorption. J. Am. Chem. Soc. 140, 610–617 (2018).

Liu, Y. et al. Enhancing the d/p‐band center proximity with amorphous‐crystalline interface coupling for boosted pH‐robust water electrolysis. Adv. Energy Mater. 13, 2203797 (2023).

Sun, P. et al. Constructing amorphous‐crystalline interfacial bifunctional site island‐sea synergy by morphology engineering boosts alkaline seawater hydrogen evolution. Adv. Sci. 11, 202309927 (2024).

Li, J. et al. Metal–Organic Framework-derived graphene mesh: a robust scaffold for highly exposed Fe–N4 active sites toward an excellent oxygen reduction catalyst in acid media. J. Am. Chem. Soc. 144, 9280–9291 (2022).

Wang, H. et al. Shape- and size-controlled synthesis in hard templates: sophisticated chemical reduction for mesoporous monocrystalline platinum nanoparticles. J. Am. Chem. Soc. 133, 14526–14529 (2011).

Liu, M. et al. Tracking the role of compressive strain in bowl-like Co-MOFs structural evolution in water oxidation reaction. Appl. Catal. B: Environ. Energy 354, 124114 (2024).

Mansour, A. Characterization of β-Ni(OH)2 by XPS. Surf. Sci. Spectra 3, 239–246 (1994).

Wan, C. et al. Amorphous nickel hydroxide shell tailors local chemical environment on platinum surface for alkaline hydrogen evolution reaction. Nat. Mater. 22, 1022–1029 (2023).

Nai, J., Wang, S., Bai, Y. & Guo, L. Amorphous Ni(OH)2 nanoboxes: fast fabrication and enhanced sensing for glucose. Small 9, 3147–3152 (2013).

Wu, G. et al. In-plane strain engineering in ultrathin noble metal nanosheets boosts the intrinsic electrocatalytic hydrogen evolution activity. Nat. Commun. 13, 4200 (2022).

Zaman, S. et al. Scalable molten salt synthesis of platinum alloys planted in metal–nitrogen–graphene for efficient oxygen reduction. Angew. Chem. Int. Ed. 61, 202115835 (2021).

Su, H., Soldatov, M. A., Roldugin, V. & Liu, Q. Platinum single-atom catalyst with self-adjustable valence state for large-current-density acidic water oxidation. eScience 2, 102–109 (2022).

Liu, M. et al. In situ modulating coordination fields of single-atom cobalt catalyst for enhanced oxygen reduction reaction. Nat. Commun. 15, 1675 (2024).

Liu, M. et al. Self-nanocavity-confined halogen anions boosting the high selectivity of the two-electron oxygen reduction pathway over Ni-based MOFs. J. Phys. Chem. Lett. 12, 8706–8712 (2021).

Su, H. et al. Tensile straining of iridium sites in manganese oxides for proton-exchange membrane water electrolysers. Nat. Commun. 15, 95 (2024).

Yan, W. et al. PCTS‐controlled synthesis of L10/L12‐typed Pt‐Mn intermetallics for electrocatalytic oxygen reduction. Adv. Funct. Mater. 34, 202310487 (2023).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchro. Rad. 12, 537–541 (2005).

Acknowledgements

This work was supported by the Postdoctoral Fellowship Program of CPSF under Grant Number GZB20240859 (M.L.), the National Natural Science Foundation of China (12405377 (M.L), 12074435 (J.P.) and 12205300 (H.S.)), China Postdoctoral Science Foundation (2024M763694 (M.L.), Science and Technology Planning Project of Yunnan Province (202302AH36001 (J.P.)), and the Natural Science Foundation of Hunan Province (2024JJ4027 (H.S.)). The authors thank the 1W1B station at the Beijing Synchrotron Radiation Facility (BSRF) and the BL14W1 as well as BL20U at the Shanghai Synchrotron Radiation Facility (SSRF) for providing the beam time. The authors thank the infrared beamline (BL01B) of the National Synchrotron Radiation Laboratory for providing the beam time.

Author information

Authors and Affiliations

Contributions

J.P., H.S., and M.L. conceived the project. M.L. conducted the experiments, including catalyst synthesis, catalytic tests and data analysis. H.S., M.L., and X.L. designed the in situ XAFS experiments. X.H. performed TEM tests. P.T. and F.L. performed catalytic activity. The manuscript was written by M.L., H.S., and J.P. All authors discussed the results and commented on the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Xueqiang Qi, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, M., Su, H., Liu, X. et al. Dynamic modulation of electron redistribution at the heterogeneous interface nickel hydroxides/platinum boosts acidic oxygen reduction reaction. Nat Commun 16, 2826 (2025). https://doi.org/10.1038/s41467-025-58193-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-58193-8