Abstract

TAMOF-1 is a robust, highly porous metal–organic framework built from Cu2+ centers linked by a L-histidine derivative. Thanks to its high porosity and homochirality, TAMOF-1 has shown interesting molecular recognition properties, being able to resolve racemic mixtures of small organic molecules in gas and liquid phases. Now, we have discovered that TAMOF-1 also offers a competitive performance as solid adsorbent for CO2 physisorption, offering promising CO2 adsorption capacity ( > 3.8 mmol g–1) and CO2/CH4 Ideal Adsorbed Solution Theory (IAST) selectivity ( > 40) at ambient conditions. Moreover, the material exhibits favorable adsorption kinetics under dynamic conditions, demonstrating good stability in high-humidity environments and minimal degradation in strongly acidic media. We have identified the key interactions of CO2 within the TAMOF-1 framework by a combination of structural (neutron diffraction), spectroscopic and theoretical analyses which conclude a dual-site adsorption mechanism with the majority of adsorbed CO2 molecules occupying the empty voids in the TAMOF-1 channels without strong, directional supramolecular interactions. This very weak dominant binding opens the possibility of a low energy regeneration process for convenient CO2 purification. These features identify TAMOF-1 as a viable solid-state adsorbent for the realization of affordable biogas upgrading.

Similar content being viewed by others

Introduction

The presence of CO2 in gas streams is deleterious to the environment as emissions, but also problematic as an undesirable impurity in industrial feedstocks and in methane-based gas mixtures such as biogas and natural gas1,2. The former is a green replacement for the latter, where methane is obtained from the anaerobic fermentation of biological residues, as a renewable fuel3. Its exploitation offers a functional solution for the conversion of biowaste into usable renewable energy while reducing greenhouse gases. Biogas upgrading into biomethane to be used as a fuel (high calorific value) which can meet pipeline grade requirements is of great environmental, economic, and technological interest4,5. However, the separation and capture of the carbon dioxide (typically around 50% in biogas) is an extremely challenging process as (i) the CH4 and CO2 molecules have similar kinetic diameters making the separation of mixture difficult by kinetic/size exclusion; (ii) low-pressure operations are preferred, close to 1 bar (low driving force) to avoid high energy-consumption from compression work; and iii) it needs very high efficiency in CO2 removal (≥ 98%)6,7.

Gas-liquid absorption in chemical solvents (aqueous amine solution)8 is the most mature technology for large-scale CO2 capture9,10, including for methane purification11. However, this technology has three major drawbacks: high energy requirement for solvent regeneration, waste management (solid salts and traces of gaseous compounds due to amine degradation), and a large footprint. This calls for the development of alternative solutions based on novel and cutting-edge materials. In particular, the separation of CO2/CH4 mixtures directly in the gas phase would be highly desirable. In this context, a promising process for gas separation is physisorption12,13. Due to the physical nature of the interactions involved, this process typically demands lower energy consumption during the regeneration step when compared to processes ruled by strong chemical interactions such as chemisorption in solid or liquid adsorbents. Different technologies based on physisorption are available, such as pressure swing adsorption (PSA)14,15, vacuum swing adsorption (VSA)16, and thermal swing adsorption (TSA)17. These technologies involve at least two consecutive steps. First, CO2 is selectively adsorbed by the active component at high pressure and/or low temperature, and then the adsorbent is regenerated by CO2 desorption at lower pressure/vacuum (PSA/VSA) or/and at higher temperature (TSA).

Several types of porous materials have been investigated as physisorbents for CO2 removal18. Benchmark zeolites typically exhibit competitive separation performance, characterized by high adsorption capacity and equilibrium selectivity19. However, while advantageous for CO2 removal from dry emission or process streams, this selectivity is often compromised in the presence of water. Water molecules preferentially coordinate with exposed metal sites, outcompeting CO220. Furthermore, these materials necessitate high regeneration energy19,21,22, which consequently increases the operational expenditure (OPEX) in industrial plants striving for high CO215,20. Carbon-based materials offer the advantage of low cost and easy regeneration, although they are limited by a lower adsorption capacity and selectivity. Nowadays, the limitations of the adsorbents are also limiting the commercial use of carbon capture (CC) technologies just to niche applications, where there is no alternative. Suitable materials combining high adsorption capacity at low/moderate working pressures, able to discriminate CO2 against molecules with similar dimensions (e.g., CH4 and N2) with high selectivity, with low-energy regeneration and fast adsorption/desorption kinetics would offer plausible opportunities to realize CC not only for biogas upgrading but also in many additional fields. Especially if CC becomes economically competitive with current CO2 emission rights.

Metal-organic frameworks (MOFs) are crystalline and porous materials23,24 prepared by the self-assembly of metal ions or clusters with organic ligands or linkers to form reticular structures25,26. Due to their exceptional properties27 such as high accessible surface areas (up to 6200 m2g–1)28, extra high porosities (up to 90%)29, tunability in pore dimensions and morphology30, versatile functionality31 as well as thermal and chemical stability32, MOFs are recognized as promising materials for selective gas separations potentially able to overcome intrinsic limitations of common adsorbents33,34,35. Even though nowadays more than 70000 MOFs have been discovered, just a few of them have shown promising features into adsorption/desorption protocols or as membrane components for CO2 capture23,36. Some of the most remarkable candidates include CALF-20, a Zn-based oxalate-bridged framework with high performance in CO2 capture from flue gas, and an extraordinary robustness under humid conditions37; or Mg2(dobpdc), a Mg-based tetramine-functionalized framework with extraordinary cyclability and stability during CO2 capture from flue gas. However, this last material is characterized by chemical CO2 adsorption and needs a high operating temperature (100 °C)38. In the case of CO2/CH4 separations for biogas upgrading, the most relevant example is MUF-16 (Co(Haip)2, Haip = 5-aminoisophthalic acid)39. This MOF is able to capture carbon dioxide from hydrocarbons with exceptional selectivity although with moderate CO2 adsorption capacity40. Moreover, the low isosteric heat of adsorption allows for an easy regeneration step. Another interesting MOF is Qc-5-Cu-sql, a Cu- quinoline-5-carboxylic acid supramolecular network, also showing excellent CO2/CH4 selectivity via the molecular sieving mechanism. However, also in this case moderate CO2 adsorption capacity is reported41. Moreover, a thorough explanation of the selectivity of MOFs to adsorb CO2 is usually missing. Whereas chemisorption is easier to evaluate from structural data, the physisorption mechanism remains difficult to assess. In situ experiments are very rare to discriminate between: (i) size-exclusion principles, (ii) kinetically controlled processes, or (iii) thermodynamically controlled processes42.

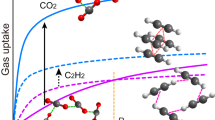

TAMOF-1 is the first in a series of homochiral MOFs based on natural amino acid derivatives, by transformation of the α-amino unit into a triazole group43,44. TAMOF-1 ([Cu(S-TA)2].xH2O, S–HTA = (S)-3-(1H-imidazol-5-yl)-2-(4H-1,2,4-triazol-4-yl)-propanoic acid) is easily synthesized at large scale from low-cost raw materials just by reaction of a copper(II) salt with L-histidine derivative (imidazole-5-ylmethyl)-(1,2,4–triazol-4-yl)acetate (L1) in water. This material has a 3D network, made from 10 Å wide, helicoidal, intercommunicated channels, decorated with multiple dangling functional groups carboxylate, triazole, and imidazole (Fig. 1) exhibiting a BET-specific surface area of 980 ± 50 m2 g–1 and a micropore volume of 0.38 cm3 g–1. TAMOF-1 exhibits exceptional water stability, withstanding both hydration/dehydration cycles without structural degradation or porosity loss44. Moreover, activation for gas separation is achieved under mild conditions (353–393 K under a sweep gas flow), preserving the MOF crystallinity—a rare feat for Cu-based MOFs and surpassing the requirements of typical MOFs and zeolites45,46.

In previous reports, we disclosed the performance of TAMOF-1 as a stationary phase for the chromatographic separation of racemic mixtures of organic substances thanks to its porosity and homochirality47. The latter was further exploited for the kinetic resolution of chiral substrates by catalytic coupling. Moreover, the characteristic shape and size of its channels and pores, as well as the Cu metal center, make TAMOF-1 a good candidate for separating also a wide variety of volatile organic compounds such as benzene−cyclohexane system and xylene isomers (positional isomers reconnection). The separation of these molecules has been proved in both the liquid and gas phases48. Furthermore, TAMOF-1 has been reported to be capable of separating C2H2/C2H4 and C2H2/CO2 mixtures49.

Here, we report that TAMOF-1 is a highly promising physisorbent to resolve CO2/CH4 mixtures and, in a broader context, aiming to capture CO2. In particular, this material has highly promising CO2 adsorption capacity and CO2/CH4 selectivity. Moreover, it allows for a low energy (ambient temperature) regeneration. When compared with other available adsorbents, including other MOFs, the TAMOF-1 performance appears very promising also in terms of operation costs. We anticipate that this material may help to bridge the gap between effective adsorption and affordable regeneration. Noteworthy, the adsorption/desorption performance remains durable over time, even in the presence of water, with only a small reduction observed when exposed to highly concentrated H₂S. By combining specific experimental (neutron diffraction and IR spectroscopy) and theoretical tools (Monte Carlo and molecular dynamics), we have thoroughly elucidated the molecular mechanism of the physisorption and transport properties of gas molecules within the TAMOF-1 network at the origin of its promising performance.

Results and discussion

Gas adsorption

Single gas (CO2, CH4, and N2) adsorption isotherms of TAMOF-1 powder up to 10 bars were measured in the 293–353 K temperature range (Fig. 2a). As a function of temperature, all isotherms maintain their characteristic shapes, with gas uptake increasing as the temperature decreases, typical of a physisorption process. Type I isotherms are obtained for CO2, without reaching a plateau (saturation) in the investigated pressure range. For example, at 298 K, CO2 adsorption capacities of 3.8 and 6.5 mmol g–1 are obtained at 1 and 10 bars, respectively. Linear isotherms are obtained for both CH4 and N2, with adsorption capacity following the order CO2 > > CH4 > N2, indicating selective preferential uptake of carbon dioxide.

a Adsorption/desorption isotherms of CO2, CH4 and N2 in a TAMOF-1 powder sample at 298 K up to 10 bar. b Adsorption isotherms of CO2 with a temperature range of 293–353 K up to 10 bar. c IAST selectivity of different CO2/CH4 gas mixtures with varying ratios at 25 °C up to 1 bar. d CO2 sorption capacity versus CO2/CH4 IAST selectivity for binary 50:50 v/v mixtures at 1 bar and 293 K (IAST selectivity values > 20), adapted from ref. 42. e Breakthrough curves of CO2 (solid line) and CH4 (dashed line) for binary mixtures with different CO2/CH4 ratios: 25:75(blue), 50:50(red), 75:25(green). f CO2 breakthrough curves in different inlet gas mixtures: 50:50 CO2/CH4 (red), 50:50 CO2/N2 (cyan), CO2/CH4/N2 = 50/25/25 (magenta). Measures in (e and f) were performed with 0.7 g of activated TAMOF-1 powder. TAMOF-1 was activated under vacuum (10−1 mbar) in both column top and bottom sides at 393 K for 15 h. g CO2/CH4 (50:50) breakthrough curves for activated TAMOF-1 (7.7 g) at 72% relative humidity (RH). TAMOF-1 was activated under vacuum (10-1 mbar) in both column top and bottom sides at 393 K for 15 h. h CO₂/CH₄ (50:50) breakthrough curves for activated TAMOF-1 (0.7 g) under acid gas conditions (0.9% H₂S, 2.5% H₂O). TAMOF-1 was activated under N2 flow (170 mil min–1 gTAMOF –1) at 393 K for 15 h. All breakthrough experiments were performed at 298 K and 1.05 bar. See Supplementary Tables 19–21 for detailed fixed-bed adsorption parameters.

From the different adsorption models available (See SI), the dual-site Langmuir-Freundlich model shows the best fitting for the CO2 adsorption isotherms (Supplementary Figs. 7–11). See, for instance, the comparison with the single-site Langmuir-Freundlich model in the logq vs. logP plot (Supplementary Fig 12). This indicates that at least two different adsorption sites are responsible for dominant CO2 uptake. Supplementary Tables 16, 17 show the isotherm parameters and regression coefficients.

The CO2/CH4 selectivity calculated by the ideal adsorption solution theory are reported in Fig. 2c and in the Supplementary Table 18. At 293 K and 1 bar, 45.9, 40.9, and 38.30 selectivity values are obtained for respectively 30:70, 50:50, and 70:30 CO2/CH4 gas mixtures (in the typical biogas composition range). Interestingly, data indicate that TAMOF-1 is capable of separating CO2/CH4 mixtures over a wide temperature range. For example, at 1 bar and 353 K, TAMOF-1 has a CO2 sorption capacity and 50:50 CO2/CH4 ideal selectivity of 1.8 mmol g–1 and 18, respectively. Another important feature is the complete adsorption/desorption reversibility obtained for all the gases (Fig. 2b) with no hysteresis observed. This behavior aligns with the physical nature of the gas adsorption phenomena within the TAMOF-1 network and underscores the structural rigidity of this material.

The isosteric enthalpy of adsorption, ΔHads was estimated via an indirect approach from the CO2 adsorption isotherms at the different temperatures using the Clausius-Clapeyron equation (for a detailed description of the calculations, see SI). Supplementary Fig. 13 shows the evolution of –ΔHads with CO2 uptake. A high –ΔHads is found at low pressure (zero coverage, –ΔH0ads=0), and then it rapidly decreases as CO2 uptake increases, approaching the bulk-phase sublimation heat of CO2, 26–27 kJ mol–1, at an adsorption capacity higher than 2 mmol g–1 50. This energy range points to a physical gas adsorption behavior and denotes a heterogeneous adsorption process occurring at multiple adsorption sites with different surface energies51.

Sahoo et al.42 conducted a preliminary comparison of mixed gas phase CO2 sorption capacity and separation selectivity for various MOFs using IAST (Fig. 2d). While many studies report only single gas sorption capacity (which is typically higher than the mixed gas capacity), the review focused on those that provided mixed gas CO2 data. Among the MOFs examined, MUF-16 and Qc-5-Cu-sql-β demonstrated both high CO2 sorption capacity (1.8 and 1.6 mmol g–1, respectively) and high CO2/CH4 separation selectivity (6690 and 3300, respectively). Interestingly, TAMOF-1 (this study) exhibited an even higher mixed CO2 sorption capacity (~ 3.1 mmol g–1) with acceptable separation selectivity (> 40). Given the lack of established performance benchmarks for industrial-scale biogas separation, it is premature to definitively assess the potential of these MOFs. We have also to mention that IAST parameters are calculated under idealized equilibrium conditions and do not represent the actual separation performance of adsorbents in dynamic conditions such as those obtained from breakthrough curves. Nevertheless, IAST analysis is usually reported and used to compare the gas separation performance of adsorbents valuable insights into the relative adsorption capabilities of TAMOF-1 with respect to other adsorbents.

Breakthrough measurements

In Fig. 2e, we report methane/carbon dioxide breakthrough curves through a TAMOF-1 powder bed at 1 bar and 298 K at different CO2/CH4 ratios. Gas separation parameters obtained from the breakthrough curves are reported in Supplementary Table 19 (See SI for details). Pure methane (≥ 99.9%) elutes first and speedily from the bed. Regular S-shaped curves were instead observed for CO2. Effective CO2/CH4 separation is achieved in all cases as CO2 is delayed. This confirms slower CO2 diffusion through the TAMOF-1 bed. By reducing CO2 molar flow, the related curves shift towards higher breakthrough times (Bt). Bt(CO2) increases from 16.4 to 18.7 min g–1 when the CO2/CH4 ratio is reduced from 50:50 to 25:75. In contrast, Bt(CH4) is almost constant, independent of the CH4 fraction. The CH4 concentration overshoots its equilibrium value (C/C0 > 1) before returning to equilibrium (C/C0 = 1). This roll-up effect indicates preferential adsorption of CO2, which displaces some of the initially adsorbed CH4. The precise shape of this overshoot depends on the methane flow rate, concentration, and adsorbent properties20. Adsorption capacities for both carbon dioxide and methane were also measured.

Nitrogen is a gas that can be present in combination with CO2 and CH4 in many gas streams, thus we also evaluated CO2/CH4/N2 separations through TAMOF-1 beds. For this purpose, fixed-bed column experiments were performed by varying the CH4/N2 ratio at constant CO2 concentration (50%) (Fig. 2f).

Carbon dioxide breakthrough curves perfectly overlap independently of the CH4/N2 ratio. This indicates that CO2 diffusion through TAMOF-1 is not affected by the type of other gas components (CH4 or N2) in the inlet gas mixture. These gases do not affect the adsorption capacity, which depends directly on the CO2 concentration, in agreement with isotherms measures (Fig. 2a). As a consequence, CO2 adsorption capacities (Supplementary Table 19) are similar (qb = 1.7 ± 0.06 mmol g–1, qs = 2.5 mmol g–1, CO2 = 50%). A similar CO2/CH4 selectivity was also observed for a binary CO2/CH4 (Ss = 6) or a CO2/CH4/N2 ternary (Ss = 4) inlet gas mixture with the same CO2 concentration (i.e., 50%). It is important to mention that N2, when present, exits as the first component and almost immediately from the column with elution time almost coincident with the dead time.

Breakthrough experiments at variable pressure conditions were also collected (Supplementary Table 19). By pressurizing the bed, Bt shifts to higher times with methane remaining always the first gas to elute. Increasing bed pressure from 1.2 to 6 bar at a constant flow rate, Bt(CO2) increases from 34 to 122 min g–1, and Bt(CH4) from < 4.7 to 32 min g–1. CO2 adsorption capacities increase from 0.42 to 1.24 mmol g–1, but CH4 adsorption also increases from < 0.06 to 0.33 mmol g–1. This results in a decrease in the CO2/CH4 selectivity as a function of increasing pressure, from > 7 to < 4 between 1.2 and 6 bar.

Higher temperatures accelerate the gas elution, and the CO2 concentration profiles sensibly shift toward lower Bt and lower adsorption capacity (Supplementary Table 19). This is in agreement with the weaker adsorbent-adsorbate interactions at higher temperatures, the faster molecular diffusion and the exothermic character of the adsorption process. A negligible temperature effect was instead observed for CH4, that speedily diffuses into the bed and almost immediately exits from the bed. Separation effectiveness decreases by increasing the temperature, and at temperatures similar to the activation one (393 K), CO2 and CH4 curves nearly overlap. Good separation capability (Sb > 0.9) was found up to 353 K, indicating applicability in a wide temperature range.

Regeneration and stability assessment of TAMOF-1

The regeneration step of a TAMOF-1 bed after saturation appears to be quite simple, avoiding the need for thermal heating. TAMOF-1 can be completely regenerated at a constant temperature just by passing through a sweep gas (N2). The corresponding CH4 and CO2 desorption curves after saturation by an N2 sweep gas stream were collected for different flow rates, temperatures, and pressures (Fig. 3)

TAMOF-1 desorption curves of CO2 (full line) and CH4 (dashed line) in a N2 sweep gas flow to regenerate the TAMOF-1 after CO2-CH4 breakthrough experiments for (a) different concentrations of equimolecular CO2-CH4 mixtures, (b) different pressures, (c) different flow rates and (d) different temperatures. In all cases, the processes were performed at constant pressure, temperature, and overall flow rate during both, the breakthrough and desorption steps. TAMOF-1 (0.7 g) was activated under N2 flow (170 mL min–1 gTAMOF–1) at 393 K for 15 h.

CH4 desorbs faster than CO2, as expected. The high CO2/CH4 selectivity in desorption allows for the recovery of a high purity CO2 fraction, which can be reused as a commodity. Moreover, the regeneration times are relatively short, when compared with the Bt times. The regeneration time can be accelerated by increasing the nitrogen flow rate, or reducing the pressure, or increasing the temperature. All these data highlight the potential of TAMOF-1 as an adsorbent for pressure/vacuum/thermal swing adsorption processes.

The presence of humidity is inherent in all raw biogas mixtures, typically reaching saturation levels under water20. From an engineering perspective, and particularly when employing adsorbents under vacuum conditions, partial removal of water from the inlet stream becomes crucial. This necessity arises from the potential for water condensation within the column, leading to obstructions that can diminish vacuum pressure during the desorption phase52. However, it is important to acknowledge that a certain degree of water vapor will invariably persist in the biogas mixture entering the adsorbent column. Previous investigations have demonstrated the structural robustness of TAMOF-1 under humid conditions, even in liquid water, with the material exhibiting complete reactivation. Here, we evaluate the competitive adsorption behavior of CO2 and H2O, as well as the adsorbent cyclic stability under dynamic adsorption conditions. As depicted in Fig. 2g, even in the presence of high humidity (~ 72% RH), TAMOF-1 retains its CO2 adsorption capacity (2.3 mmol g−1) with just a 15% reduction compared to the dry inlet mixture. The CO2/CH4 selectivity is also maintained within the range of 4–6. Subsequent to the adsorption step, regeneration was conducted under vacuum at a temperature of 80 °C. The separation performance of TAMOF-1 remained consistent over multiple adsorption-desorption cycles, as demonstrated by the overlapping CO2 and CH4 breakthrough curves (Supplementary Table 20). This stability indicates negligible degradation of the material after successive cycles and near-complete recovery of working capacity under the operating conditions investigated.

Hydrogen sulfide (H2S), a common impurity found in raw biogas (~ 0–100 ppm1), presents a significant challenge to biogas upgrading. H2S is a highly corrosive acid gas that can compromise the chemical stability of materials used in separation processes. For instance, H2S can disrupt the coordination bonds between organic ligands and metal centers in the MOFs, leading to structural degradation53. To assess the separation behavior of MOFs in the presence of hydrogen sulfide is therefore crucial for their effective application in biogas upgrading. Analysis of TAMOF-1 in humid (2.5 mol% H2O) and acidic gas (0.9 mol% H2S) conditions (Fig. 2h) demonstrates its ability to separate CO2/CH4 mixtures, even under these conditions. However, a reduction of adsorption capacities (16%) is observed between the first and the second cycle, while selectivity remains relatively constant (~ 3–5). We observed a reduction in the competitive adsorption between CO2 and CH4, with negligible co-adsorption of CH4. We assign this difference to the very high retention time found for H2S (no H2S was detected in the outlet stream not even after the CO2 equilibrium regime), which competes for adsorption sites. Importantly, this analysis was performed under accelerated conditions, with very high H2S concentration (9000 ppm), almost two order or magnitude higher than what is usually found in biogases. These data, therefore, demonstrate a relatively high robustness of the material also in strongly acid conditions. However, H2S removal is recommended prior to biogas upgrading with TAMOF-1 in order to increase material durability.

Structure determination with adsorbed CO2

We attempted to localize the preferential crystallographic position of the CO2 molecules when adsorbed in the TAMOF-1 framework by X-ray diffraction analysis. A single crystal was dehydrated, exposed to a CO2 stream, and then cooled down to 100 K. The analysis of the XRD structural data revealed residual densities in the channels that were compatible with the presence of CO2 in the crystal matrix. However, the poor selectivity under X-ray diffraction conditions between oxygen and carbon, in addition to the possible presence of residual water, precluded the successful location of CO2 molecules in the channels. For this reason, we turned to neutron diffraction54, where carbon and oxygen atoms can be properly identified thanks to their distinct neutron scattering lengths.

The neutron diffraction structure analysis of an activated TAMOF-1 single crystal confirms the crystal structure obtained by XRD (Fig. 4) with triangular empty channels running along the [111] direction, which is a 3-fold axis due to its cubic symmetry (Supplementary Tables 1–7). After exposure to CO2, and cooling down to 100 K, these channels are filled with CO2 molecules exhibiting moderate disorder (Fig. 4), indicating that weak interactions with the TAMOF-1 network are dominant (Supplementary Tables 8–15). Adjacent to this channel, three copper atoms self-assemble in two orientations that are rotated approximately 45° with respect to each other every 13.5 Å along the [111] axis, forming equilateral triangles of approximately 6.7 Å. This arrangement creates a narrower channel where CO2 molecules align themselves with the oxygen’s lone pairs located between the Lewis sites of two of the copper atoms in the triangle. These CO2 molecules are the only ones that exhibit a clear, directional interaction with any of the available TAMOF-1 sites. We associate this crystallographic position with the higher isosteric enthalpy of adsorption found at low coverage. The rest of the CO2 molecules are located along the channels of the structure with apparently random orientations.

a Detail of the CO2 positions within the Cu3 triangles in the largest void space of TAMOF-1. The distances O1C-Cu1(zxy) and O2C-Cu1 are 2.7726(1) and 2.7068(1) Å, respectively. The view direction is along [111]. Cu1, Cu1(zxy) and Cu1(yzx) are related by a crystallographic three-fold axis, which also relates the CO2 molecule at C1C to two others, which are not shown. C1C/O1C/O2C and its two congeners have site occupancy factors of 1/3 as a result of disorder about the symmetry axis. Color code: Cu, deep blue; O, red; N, light blue; C, gray; H, white. b View along [111] of the TAMOF-1 open framework (green stick representation) and the positions occupied by the guest CO2 molecules (red van der Waals’ radii representation) in the TAMOF-1 channels, with the two components shown together (left) and individually (right). View along [100] (c) and view along [111] (d), of parts of the complex void structure that accommodates the guest CO2 in TAMOF-1. The voids are represented as lighted areas for exterior surfaces and as shadowed areas for interior surfaces of the void boundaries.

The intermolecular interaction between CO2 molecules located in the channel is consistent with London dispersion forces in agreement instead with the lowest isosteric enthalpy of adsorption approaching the bulk-phase sublimation heat of CO2. The oxygen atoms in the CO2 molecules possess lone pairs that are directed toward the more positively charged carbon atoms, which are situated at distances ranging between 2.6 Å and 3.1 Å. Similarly, the carboxylate groups of the TAMOF interact in the same way with the CO2 molecules, as the oxygen atoms in the carboxylate groups exhibit lone pairs that are directed towards the carbon atoms in the CO2 molecule, which are positioned at a distance of 3.1 Å.

It is important to note that these neutron diffraction data were obtained at 100 K. Room temperature data collection resulted in a disordered model, indicating that room temperature is enough to break the dominant interactions between CO2 and TAMOF-1.

Spectroscopic analysis

To further investigate the interactions between CO2 and the TAMOF-1 framework at room temperature, we collected IR spectroscopy data. The IR spectra of CO2 when adsorbed on TAMOF-1 (Supplementary Fig. 4) show a band at 2335 cm–1, which, according with previous reports55,56, can be ascribed to physisorbed CO2. The less intense band at 2324 cm–1 has also been observed before and assigned to a combination band. These results suggest that there are not site-specific strong interactions and CO2 only physically interacts with the framework.

To confirm the validity of these results, we also investigated CO adsorption for comparison. Supplementary Fig. 4b shows the C-O stretching region of carbon monoxide adsorbed on TAMOF-1. Interaction of the metal-organic framework with adsorbed CO resulted in the formation of an IR absorption band at 2139 cm–1, which, according to literature, is assigned to (non-localized) physisorbed carbon monoxide57, indicating that the metal-organic framework TAMOF-1 does not present accessible coordinatively unsaturated metal centers.

Computational analysis and adsorption mechanism

We calculated the single-component adsorption isotherms for CO2, CH4, and N2 molecules in TAMOF-1 in the 263–333 K, and 1–107 Pa range. The good agreement between simulation and experiments validates our models (Fig. 5). Excess adsorption, following the protocol of Myers and Monson58, allows comparison with the experiment. Some energy parameters related to carbon capture were also calculated from the single-component isotherms of CO2 and N2. We estimate that TAMOF-1 exhibits low parasitic energy, a volumetric working capacity of 23.46 kg m–3, and a final CO2 molar purity of the mixture of 0.904, which are excellent features for carbon capture. The calculated adsorption isotherms were fitted to a dual-site (for CO2) and single site (for CH4 and N2) Langmuir-Freundlich model using the RUPTURA software59 (solid lines in Fig. 5). Subsequently, we proceeded to compute the binary isotherms and determine the adsorption selectivity for CO2:CH4 and 14 CO2: 84 N2 mixtures (representing the composition of dry post-combustion flue gas). The resulting adsorption selectivities are depicted in Fig. 5d. In all cases, the adsorption of CO2 surpasses that of CH4 or N2, primarily due to the stronger interactions between CO2 molecules and the adsorption surfaces.

a–c Calculated excess adsorption isotherm (empty circles) and experimental isotherms (solid points, see legend for more details) at 263.15, 303.15, 313, 323, and 333 K. Errors are estimated from the standard deviation in the adsorption processes. d, Selectivity \({s}_{j}^{i}={q}^{i}/\,{q}^{j},\) where i is CO2, and j is CH4 or N2.

Simulation shows that at low values of pressure (1–500 Pa) the molecules of carbon dioxide are located in the narrow channels formed by the triad of Cu atoms. There is a dominant interaction between CO2 and two Cu atoms (as shown in Fig. 4 and discussed in the SI, neutron diffraction analysis section), resulting in high values for the heat of adsorption, 50 kJ mol–1, in agreement with experimental results (\({Q}_{{{{\rm{st}}}}}\, \sim -\left\langle {U}_{{hg}}\right\rangle+{RT}\) where \(\left\langle {U}_{{hg}}\right\rangle\) is the mean interaction energy between the CO2 and the TAMOF-1 at very low pressure). However, as the CO2 pressure increases, the CO2-CO2 interactions become strong enough to displace some of the adsorbed CO2 molecules from these energetically favorable binding sites. This can be seen from radial distribution functions between CO2-CO2 and CO2-Cu atoms, displayed in Fig. 6.

Figure 6a shows that the interaction energy between the CO2 molecule and the adsorption surface remains stable at around – 45 kJ mol–1 up to 3 kPa and progressively decreases with pressure to – 23 kJ mol–1. Although this trend is qualitatively equivalent for CH4 and N2, the range of energies and pressures differs, and the effect on adsorption is neglected. For example, for CH4, the interaction energy varies from – 25 kJ mol–1 (low pressure) to – 12 kJ mol–1 (high pressure).

To conclude, the adsorption selectivity of CO2 over CH4 or N2 at intermediate pressures (Fig. 5d) is mainly explained by two causes: the electrostatic interactions between CO2 and the square planar Cu sites, and the confinement of CO2 inside the TAMOF-1 pocket-cages. The narrow pores formed by the triad of Cu atoms contribute to decrease this selectivity at high pressures.

The self-diffusivity coefficients (D) of CO2 and CH4 were calculated using MD simulations at various temperatures and adsorption loadings (Fig. 7). CO2 consistently exhibits lower diffusivity than CH4. At low loading (1 to 4 CO2 molecules per unit cell), the molecules of CO2 are confined in adsorption pockets formed by the triad Cu atoms, resulting in low diffusivity (i.e., DSCO2 ~ 10–10 m s–1). As pressure increases, the molecules of CO2 diffuse from the pocket adsorption site to the main channel. This leads to a maximum diffusivity at ~ 3 mol kg–1 of adsorption loading for all temperatures (e.g., at 333 K, the self-diffusivity is approximately DSCO2 ~ 10–9 m·s–1). Beyond this loading (three molecules per Cu triad), the molecules of CO2 are mainly adsorbed in the (chiral) channel, preventing transport and causing a progressively decreasing of diffusivity. In contrast to CO2, for CH4 molecules, self-diffusivity reaches its peak at infinite dilution for all temperatures (see Fig. 7b). The diffusion of CH4 decreases with the increase on adsorption. As an example, for 333 K and for 1 molecule per unit cell, the self-diffusivity coefficient is DSCH4 ~ 6 × 10–9 m s–1.

Breakthrough curves for CO2 and CH4 were computationally predicted to validate the experiments in a column bed length of 5.8 cm and a gas pressure of 1.05–1.3 bar at 298 K (Fig. 8). The fitted Langmuir-Freundlich parameters were used to predict this adsorption dynamic behavior. Helium was used as a carrier gas to ensure high gas velocity. Three distinct gas compositions were investigated: 95% He and 5% of a CO₂/CH₄ mixture with ratios of 1.5:3.5, 2.5:2.5, and 3.5:1.5 (v/v). Initially, the column was fully saturated with helium. The void fraction of the adsorbent bed was 0.3. Simulation data are in agreement with the experimental results (Fig. 8). The simulated elution gas behavior remains qualitatively and quantitatively consistent with experimental data across the range of gas mixture compositions investigated (3.75%, 2.5%, and 1.25% v/v CH4). Although a direct comparison with data reported in Fig. 2 is not accurate, the rapid elution of CH4 observed in this case may be attributed to its higher diffusivity at higher gas velocity (0.015 m s−1) and to its low gas partial pressure (Fig. 7b).

Calculated (lines) and experimental (square) breakthrough curves for CO2 and CH4 at 1 bar and 298.15 K for three composition ratios: 25 CO2: 75 CH4 (a), 50 CO2: 50 CH4 (b), and 75 CO2: 25 CH4 (c). Experiments performed with helium as the carrier gas (95% v/v). Experiments performed using 7.7 g of activated TAMOF-1. TAMOF-1 was activated under vacuum (10−1 mbar) in both column top and bottom sides at 393 K for 15 h.

In conclusion, TAMOF-1, a stable, robust, homochiral metal-organic framework (BET specific surface area = 980 ± 50 m2 g–1), has shown selective adsorption of CO2 from CO2/CH4 gas streams, offering a promising performance. Although comparing breakthrough data across studies is often challenging due to inconsistencies in experimental details, the performance parameters exhibited by TAMOF-1 appear competitive for CO2/CH4 separations when compared with state-of-the-art (Fig. 2d and Supplementary Table 22). As demonstrated by structural and theoretical data, CO2 uptake is dominated by a variety of weak interactions. At low coverage, the preferred binding sites are the square planar Cu2+ centers. Once these positions are full, the TAMOF-1 open channels accommodate additional CO2 molecules with weaker interactions with the dangling functional groups (carboxylate, triazole, imidazole) in the framework. Adsorption isotherms confirm the CO2 preferential uptake with respect to CH4 or N2 in a large pressure range, resulting in good separation parameters for CO2/CH4 gas mixtures. CO2/CH4 mixtures can be effectively separated with high selectivity in a wide CO2/CH4 concentration (1–75%), pressure (1–6 bar), and temperature range (293–353 K). Elution behavior of CO2 through the TAMOF-1 bed depends just on the CO2 molar flow and it is not affected by the presence of the other gases investigated (CH4 and/or N2).

TAMOF-1 retains separation performance, even under high humid conditions (~ 72% RH) showing no degradation and high cycling stability. Separation capability is observed also in extremely acidic conditions (9000 ppm H2S) although a small performance degradation is observed. These data demonstrate TAMOF-1 robustness, also in harsh acidic environments although H2S removal is preferred to increase material durability.

These properties are crucial for industrial-scale CO2 capture applications. The weak CO2–TAMOF-1 interactions facilitate facile, low-energy regeneration of the adsorbent bed. These attributes, coupled with high selectivity, render TAMOF-1’s performance in biogas upgrading superior to other reported materials42. Consequently, TAMOF-1 appears well-suited for integration into pressure/vacuum/thermal swing adsorption processes. A convenient regeneration protocol, adaptable to specific time and energy constraints through operational parameter tuning, is readily achievable. Current efforts are focused on scaling and pelletization of TAMOF-1, advancing the development of a CO2 capture and purification technology based on this promising material.

Methods

Materials

All reagents were of commercial grade and used without further purification: L-histidine (≥ 98%, Iris Biotech GmbH), thionyl chloride (SOCl2, ≥ 99%, Sigma Aldrich), hydrazine monohydrate (NH2NH2·H2O, reagent grade, 98%, Sigma Aldrich), sodium carbonate anhydrous (Na2CO3, ACS reagent, ≥ 99.5%, Sigma Aldrich). All solvents were of commercial grade and used without further purification: HPLC-grade ethanol, isopropanol, hexanes, acetonitrile and tert-butyl methyl ether (VWR, Chem-Lab and Sigma Aldrich), N,N-dimethylformamide (peptide grade, ≥ 99.9%, Iris Biotech GMBH) and diethyl ether (≥ 99%, VWR).

Synthesis

(E)-N’-((E)-(dimethyl-amino)methylene)-N,N-dimethylformohydrazonamide (2)

This reagent was prepared following a two-step synthesis:

Part I: In a 250 mL 3-neck round bottom flask (RBF), 150 mL DMF was added and cooled down in an ice-bath. Afterwards, 28.6 mL SOCl2 (0.39 mol) was slowly added under stirring with a syringe (dropwise). The reaction mixture was stirred for 24 h. After this time, the RBF was introduced in an ice bath, and once the mixture was cold, 5 mL NH2NH2·H2O (0.1 mol) dissolved in 15 mL DMF was added very slowly, under stirring, with a syringe (dropwise and carefully, CAUTION: very exothermic reaction!!). The reaction mixture was stirred at room temperature for 48 h. The precipitate was then filtered and washed with DMF (20 × 3 mL) and Et2O (10 × 3 mL) to yield 20.5 g (0.095 mol, 95% yield) of (CH3)2N(CH) = N-N = (CH)N(CH3)2·2HCl (1).

Part II: 20.5 g of 1 (0.095 mol) was weighted and dissolved in 100 mL H2O. In a different beaker, 10.6 g of Na2CO3 (0.1 mol) was dissolved in 100 mL H2O. Both water solutions were then mixed (the Na2CO3 on top of the azine solution), and the desired product (CH3)2N(CH) = N-N = (CH)N(CH3)2 (2) was purified by continuous extraction in 750 mL Et2O, at 50 °C during 2 days. The organic layer was concentrated in vacuo, and 12.95 g of 2 (0.09 mol, 96% yield) was obtained as an orange solid which was used without any further purification.

Synthesis of (S)-3-(1H-imidazol-5-yl)-2-(4H-1,2,4-triazol-4-yl)propanoic acid

2 (6.3 g, 0.044 mol) and L-histidine (3.1 g, 0.02 mol) were mixed together in 150 mL EtOH. The mixture was refluxed with stirring for 48 h. The final solution was filtered off from unreacted L-histidine, and the solvent was removed under reduced pressure to afford an orange gel that was washed with EtOH to yield a white precipitate of S-HTA, that was collected by filtration, washed with EtOH (15 × 3 mL), Et2O (15 × 3 mL) and dried in air. Yield: 3.5 g (0.017 mol, 85%).

Synthesis of [Cu(H2O)2(C8H8N5O2)2].6H2O (TAMOF-1)

CuII (CH3COO)2·H2O (0.48 g, 2.4 mmol) was dissolved in 50 mL of H2O, and the resulting solution was slowly added to a 100 mL aqueous solution of (S)-3-(1H-imidazol-5-yl)-2-(4H-1,2,4-triazol-4-yl)propanoic acid (1.0 g, 4.8 mmol). The solution was stirred for 30 min, allowing for the appearance of a precipitate. This blue polycrystalline powder (TAMOF-1) was filtered with a Nylon membrane filter (pore size: 0.45 μm, Filter-Lab), washed with H2O (50 × 3 mL), and dried in air. Yield: 1.1 g (70%). The structure and purity of the samples was confirmed by elemental analysis and powder X-ray diffraction (Supplementary Fig. 1). Anal. Calcd for C16H32CuN10O12: C 30.99, H 5.2, N 22.59; found: C 30.89, H 4.93, N 22.40. IR (ATR): ν = 3289, 1615, 1532, 1495, 1395, 1355, 1263, 1242, 1211, 1180, 1116, 1087, 1015, 979, 891, 845, 752, 701, 660, 647, 549, 511, 472 cm−1. TAMOF-1 thermal stability up to ≈ 473 K was confirmed by thermogravimetric analysis (TGA) performed using a TGA/SDTA851 Mettler in an air atmosphere (Supplementary Fig. 2). Single crystals of ≈ 1 mm3 dimensions, suitable for neutron diffraction experiments, were obtained by slow diffusion of the aqueous solution of Cu(OAc)2 and the aqueous solution of (S)-3-(1Himidazol-5-yl)-2-(4H-1,2,4-triazol-4-yl)propanoic acid in an H-Cell with the two compartments separated by a glass frit.

Single crystal neutron diffraction

Single-crystal neutron diffraction data was collected at 100 K on the four-circle diffractometer D19 at the Institut Laue-Langevin (ILL), Grenoble. The instrument was equipped with an Oxford Cryostream 700 Plus low-temperature device and was operated using a neutron wavelength of 1.4556(1) Å, provided by a flat Cu(220) monochromator (at 2θM = 69.91° take-off angle). A single crystal was selected from a batch of crystals of TAMOF-1 using an optical microscope. The selected specimen, with dimensions of approximately 1 × 0.8 × 0.6 mm3, was found to be suitable for single crystal neutron diffraction measurements using D19. The crystal was glued to a vanadium pin of 0.5 mm diameter and mounted on a standard goniometer head. Three short ω-scans were collected at room temperature (RT) to check the sample quality and obtain a preliminary orientation matrix. This yielded a cubic unit cell with a unique axis length of 20.19 (6) Å, further confirming that the TAMOF-1 structure remained intact. The cubic cell length determined by X-ray diffraction at T = 100 K was 20.120 (4) Å.

Two heating cycles were performed in order to activate (dehydrate) the crystal. The first cycle consisted of heating to T = 400 K (0.1 K min–1) in a stream of nitrogen gas, after which the crystal was kept at 400 K for slightly less than 30 min. The temperature of the sample, still in a stream of nitrogen gas, was lowered at a rate of 1 K min–1 to room temperature. Once at room temperature, the crystal was placed in an atmosphere of CO2 for 2.5 h, after which it was placed in the nitrogen gas stream on the diffractometer; and the temperature was lowered to T = 100 K for diffraction measurements (three omega scans of 80° each, with a step size of 0.07° and counting time of 25 sec/step). Structure analysis revealed that there was still water in the cavities of the MOF, so the activation cycle was repeated.

For the second dehydration cycle, the sample temperature was first raised to 400 K (ramp rate 0.1 K min–1). The crystal was kept at T = 400 K for 70 min, during which time a color change from turquoise to black was observed, but without loss of crystallinity. The nitrogen stream was then used to lower the sample temperature to 100 K. Once this temperature had been reached, the crystal was exposed to a current of CO2 for five minutes, while the N2 stream was simultaneously cut off using a purpose-built, one-use valve that permitted one of the two gases to impinge on the sample while blocking the other. At the end of the CO2 exposure, the flow was switched back to the N2 stream at T = 100 K.

Full data collection ensued, consisting of three omega scans, with an exposure time of approximately 45 s per image (5 × 106 monitor counts). The resulting data revealed that CO2 alone was present in the cavities of the TAMOF-1 sample, vide infra.

A regeneration step was then performed to evacuate the CO2 from the sample. This consisted of heating the sample once again to T = 400 K for 70 min, and then lowering the temperature to 100 K for data collection, which again consisted of 3 omega scans with a count time of approximately 45 s per image (5 × 106 monitor counts). Data analysis confirmed that all of the CO2 had been evacuated from the sample.

For full data collection, the measurement strategy consisted of a series of five ω-scans with steps of 0.07° at different χ and φ positions. The acquisition time was ca. 45 s per step, which corresponds to 500000 counts on the instrument monitor. The data collection was performed using the instrument control program NOMAD from ILL. We collected additional reciprocal space where no reflections were expected. We were able to do this thanks to the wide-angle solid-state detector at the D19 line in the Institut Laue-Langevin (ILL). We should have been able to detect any crystalline phase transition (by breaking of symmetry or appearance of domains) under the CO2 atmosphere. Indexing and unit-cell determination were done using the programs PFIND and DIRAX61. The integration of the raw data and refinement of the UB-matrix, including the offsets, were done using the programs RETREAT and RAFD19, respectively62; the Lorentz correction was applied to the intensities. Structure refinement was conducted using the program ShelxL2019/360. Neutron scattering lengths for structure analysis were taken from the Neutron Data Booklet, ILL Grenoble (2003) ISBN 0-9704134-7-4.

When the data collection was completed, the resulting structure model confirmed the cubic symmetry of the sample, in agreement with the preliminary X-ray diffraction data. The analysis also confirmed that the MOF was activated, with empty channels potentially capable of hosting guest molecules. We measured continuous sections of reciprocal space -- i.e., not just the expected positions for Bragg peaks -- using the wide angle 2D detector at the D19 beamline at the Institut Laue-Langevin (ILL). We are confident that we would have detected any crystalline phase transition (by breaking of symmetry, or appearance of domains) under the CO2 atmosphere. No deviation from the cubic symmetry was detected (Supplementary Tables 1 and 8). The average I/σ(I) for all merged reflections is 20.2. Any reflection violating the systematic absence conditions for the space group (P4332) was indistinguishable from the background. CCDC 2356946 and 2356947 contain the supplementary crystallographic data for this paper. These data can be obtained free of charge from The Cambridge Crystallographic Data Center via www.ccdc.cam.ac.uk/data_request/cif. Crystal structure representations were generated with OLEX263, Diamond64, and Mercury 4.065 visualization programs.

Infrared spectroscopy

Thin self-supported wafers of the TAMOF-1 were prepared and activated (outgassed) in a dynamic vacuum (residual pressure smaller than 10–4 mbar) at 423 K for 4 h inside a 2000-A-C AABSPEC cell that allowed us to perform: (i) in situ sample activation, (ii) gas dosage and (iii) variable-temperature IR spectroscopy of adsorbed molecules while simultaneously recording temperature and equilibrium pressure. A K-thermocouple (in contact with the sample wafer) connected to a digital thermometer (TEMP, XS Instruments) and a capacitance pressure gauge (MKS, Baratron) were used for that purpose; the precision of the measurements was about ± 2 K and ± 2 × 10–2 mbar for temperature and pressure, respectively.

After thermal activation of the sample wafer, the cell was dosed with the probe molecule and closed, and transmission FTIR spectra were recorded while simultaneously registering the spectrum. Transmission FTIR spectra were collected, at 3 cm–1 resolution on a Bruker Vertex 80 v spectrometer equipped with an MCT cryo-detector (Supplementary Fig. 4).

Gas isotherms

Adsorption isotherms of carbon dioxide, methane, and nitrogen up to 10 bar at different temperatures were carried out with iSorb HP1 200 (Anton Paar). Prior to analysis, the sample was degassed and dehydrated (activated) for 18 hours at 423 K, 10–6 Torr.

Breakthrough measurements

For the gas breakthrough experiments, different tubes loaded with different TAMOF-1 amounts were used as separation module. Noteworthy, the experiments gave consistent per-mass results. Two different columns were used: Column 1: 0.7 g TAMOF-1 (dehydrated), bed length: 1 cm; Column 2: 7.7 g TAMOF-1 (dehydrated), bed length: 18.3 cm. Scaling the system (about 18 times) did not affect TAMOF-1 performance. In both, TAMOF-1 was packed within the module with glass wool support at the top and the bottom of the column. TAMOF-1 powder has the following properties: random particle size between 0.2 and 10 μm44, bulk density = 0.689 g cm−3 (hydrated TAMOF-1) and 0.530 (dehydrated TAMOF-1), and porosity = 0.598.

Prior to breakthrough measurements, TAMOF-1 was activated in situ for water removal at 393 K for a 15 h vacuum (10−1 mbar) in both column top and bottom sides or a nitrogen flow (170 ml min–1 g–1(TAMOF)). Breakthrough data were collected by using the experimental set-up shown in Supplementary Figs. 5, 6. Gas cylinders of CH4 (Linde, 99.998%), CO2 (Air Liquide, 99.998%), CO2/CH4 mixture with composition of 50.3/49.7% (Messer) and N2 (Praxair, 99.999%) were used. The flows/compositions of the inlet gas stream were controlled upstream of the separation module by a set of calibrated mass flow controllers (Bronkhorst EL-FLOW). A manometer and a backpressure controller (Bronkhorst, EL-PRESS) were placed downstream of the separation module. A manometer was also used upstream of the bed to monitor the actual pressure at the bed inlet under no pressure control conditions. Unless otherwise stated, all pressure values are reported in units of absolute bar (bar). The separation module was heated by a linear power silicone heating wire (Ø 3 mm FOR-FLEX NORMAL, Electricfor) rolled around the column, the temperature was measured with a K-type thermocouple (Thermocoax) placed in between the module and the silicon heating wire, and in contact with both. It was controlled with a temperature controller EZ-Zone (Watlow). The outlet stream of the column was on-line analyzed by micro gas chromatograph (MGC, Agilent MicroGC 490) equipped with Molsieve MS5A, using Ar as carrier gas (99.999 % purity), and Poraplot U column, using He as carrier gas (99.999 % purity), along with thermal conductivity detectors (TCD).

In the experiments performed with a partial flow of N2 in the inlet gas mixture lower than 25 Nml min–1, a nitrogen flow of 30 Nml min–1 was mixed with the gas coming out from the separation module in order to meet the flow requirements of the GC. In this case, a non-return valve with negligible pressure drop was used to avoid reverse flow. The transit time or death time of the gas in the set-up was also evaluated and subtracted at each operation condition.

Regeneration assessment of TAMOF-1 (Fig. 3) was conducted flowing N2 sweep gas within the column (0.7 g). Several regeneration conditions were evaluated as: a) different concentrations of equimolecular CO2–CH4 mixtures, b) different temperatures, c) different flow rates, and d) different pressures. In all cases, the composition of the gas exiting the column was analyzed using the GC.

Gas adsorption experiments under humid conditions were conducted using a custom-built glass bubbler containing a known volume of water. A CO2/CH4 (50:50) gas mixture at a flow rate of 30 ml min−1 was passed through the bubbler and subsequently fed into the adsorption column. Temperature control was achieved using a chiller with ethylene glycol as the cooling fluid. A K-type thermocouple (Thermocoax) placed within the bubbler provided accurate temperature measurements. To prevent condensation within the analyzer, a nitrogen flow of 120 Nml min⁻¹ was used to dilute the gas exiting the separation column. Effluent gas composition (m/z) was continuously monitored via a quadrupole mass spectrometer (Pfeiffer OmniStar GSD 301 C1). Following CO2 saturation of the TAMOF-1 column, regeneration was performed under vacuum (10⁻² mbar) at 80 °C during 15 h. This adsorption–regeneration cycle was repeated 5 times to assess the stability of the material.

For the evaluation of the stability of TAMOF-1 under dynamic acid conditions, H2S was generated in situ by carbonation conversion of aqueous sodium sulfide66: NaHS(aq) + CO2(aq) + H20 \(\leftrightarrows {\mbox{H}}_2{\mbox{S}}({\mbox{g}})\,+{\mbox{NaHCO}}_3({\mbox{aq}})\). Experiments were conducted at 28 °C (room temperature) and 1 bar. The H2S concentration evaluated was 1% (v/v) (0.27 ml min⁻¹), corresponding to a water concentration of 2.3% (v/v) (0.725 ml min⁻¹). A total flow rate of 29 ml min⁻¹ was maintained, consisting of 16 ml min⁻¹ of a CO2/CH4 (50:50 v/v) gas mixture and the balance N2. Prior to the initial cycle, the MOF was activated. Between subsequent cycles, the MOF was purged with 250 ml min⁻¹ of N2 for at least 15 h.

Computational methods

Monte Carlo (MC) and Molecular Dynamics (MD) simulations were used to investigate the sorption and transport properties of carbon dioxide, methane, and nitrogen molecules both individually and as mixtures within the TAMOF-1 material. Our theoretical analysis focused on discerning the mechanisms that explain the separation process of mixtures of interest from a molecular perspective. In addition to sorption and transport properties, we also calculated the breakthrough curves. To conduct these simulations, we performed simulations at various temperatures, from 263.15 K to 333.15 K. We used a cubic supercell with dimensions of 2 × 2 × 2 for TAMOF-1. The initial relaxation of the atomic coordinates was achieved using an extended semi-empirical tight-binding model known as GFN2-xTB67, which was performed using DFTB + code (v. 22.2)68.

Our CO2 model comprises three Lennard-Jones sites with charges centered on each atom. The carbon-oxygen bonds remain fixed, while the Lennard-Jones parameters and the molecular structure of CO2 were derived from research conducted by García-Sánchez et al.69. For the N2 molecule, we adopted the model proposed by Potoff and Siepmann70, which incorporates three charged sites and two Lennard-Jones sites centered on each N atom. Regarding the CH4 molecule, we used an uncharged united atom model71, considering the CH4 group as a single interaction center with its own effective potential. We assumed the TAMOF-1 framework to be rigid during both the MC and MD simulations. To accurately capture the interactions between the adsorbates and framework, we employed van der Waals interactions. Furthermore, Coulombic interactions were considered for the CO2 and N2 molecules. The Ewald method was used in these cases. The Lennard-Jones parameters were derived from the well-established DREIDING potential72, except for the Cu atoms, for which we adopted parameters from the UFF potential73,74. The mixed Lennard-Jones parameters were calculated using Lorentz-Berthelot mixing rules.

To perform the MC and MD simulations, we used the reliable RASPA code75 and followed the established protocols. This protocol has been used successfully for other Cu-paddlewheel MOF (Cu-BTC)76. The adsorption isotherms were determined through MC simulations using a Grand Canonical ensemble (μVT). The pressure values were converted to fugacity using the Peng-Robinson equation of state. In our simulations, we conducted a minimum of 106 MC cycles. Within each MC cycle, the following trial MC moves were randomly selected for a given molecule: translation, rotation, reinsertion at random positions, and swapping (insertion or deletion). Binary isotherms and selectivities were calculated using IAST using the RUPTURA code59.

For the MD simulations, we used a time step of 0.5 fs to carry out 108 cycles of simulation. During the MD simulation, the radial distribution functions and atomic mean squared displacements were calculated. To study the transport properties of CO2 and CH4, we equilibrated the systems using a canonical ensemble (NVT). Subsequently, using the microcanonical ensemble (NVE), we measured the calculated self-diffusion coefficients for CO2 and CH4 from the measured mean-squared displacement at several concentrations and temperatures. Finally, we evaluated the TAMOF-1 features for carbon capture from the calculated sorption properties, following the work of Huck et al.77 and Ongari et al. by calculating energy parameters78.

Data availability

The supplementary crystallographic data generated in this study have been deposited in the Cambridge Crystallographic Data Center database under accession codes CCDC 2356946 and 2356947 [https://www.ccdc.cam.ac.uk/data_request/cif]. These data can be obtained free of charge. The relevant data associated with the computational study in this article, including the input and output files of the main simulations, as well as the scripts to reproduce the figures, are openly available online in the GitHub repository [https://github.com/salrodgom/data_TAMOF1_CO2_CH4] and at the Zenodo repository [https://doi.org/10.5281/zenodo.14826712]. Additional raw and processed data are available as supplementary data (aif files for isotherms) and at the Zenodo repository [https://doi.org/10.5281/zenodo.13126535]. Source data are provided in this paper.

References

Chuah, C. Y. et al. Harnessing filler materials for enhancing biogas separation membranes. Chem. Rev. 118, 8655–8769 (2018).

Cavenati, S., Grande, C. A. & Rodrigues, A. E. Removal of carbon dioxide from natural gas by vacuum pressure swing adsorption. Energy Fuels 20, 2648–2659 (2006).

D’Alessandro, D. M., Smit, B. & Long, J. R. Carbon dioxide capture: Prospects for new materials. Angew. Chem. Int. Ed. 49, 6058–6082 (2010).

Nocito, F. & Dibenedetto, A. Atmospheric CO2 mitigation technologies: carbon capture utilization and storage. Curr. Opin. Green. Sustain. Chem. 21, 34–43 (2020).

Chouikhi, N., Brandani, F., Pullumbi, P., Perre, P. & Puel, F. Biomethane production by adsorption technology: new cycle development, adsorbent selection and process optimization. Adsorption 26, 1275–1289 (2020).

Li, Z., Liu, P., Ou, C. & Dong, X. Porous metal-organic frameworks for carbon dioxide adsorption and separation at low pressure. ACS Sustain. Chem. Eng. 8, 15378–15404 (2020).

Gao, W. et al. Industrial carbon dioxide capture and utilization: state of the art and future challenges. Chem. Soc. Rev. 49, 8584 (2020).

Elfving, J. et al. Experimental comparison of regeneration methods for CO2 concentration from air using amine-based adsorbent. Chem. Eng. J. 404, 126337 (2021).

Chaffee, A. L. et al. CO2 capture by adsorption: Materials and process development. Int. J. Greenh. Gas Control 1, 11–18 (2007).

Peters, L., Hussain, A., Follmann, M., Melin, T. & Hägg, M.-B. CO2 removal from natural gas by employing amine absorption and membrane technology—A technical and economical analysis. Chem. Eng. J. 172, 952–960 (2011).

Angelidaki, I. et al. Biogas upgrading and utilization: Current status and perspectives. Biotechnol. Adv. 36, 452–466 (2018).

Liu, Y. et al. Multifunctional covalent organic framework (COF)-Based mixed matrix membranes for enhanced CO2 separation. J. Membr. Sci. 618, 118693 (2021).

Liu, R.-S. et al. Advances in post-combustion CO2 capture by physical adsorption: From materials innovation to separation practice. ChemSusChem 14, 1428–1471 (2021).

Majchrzak-Kucęba, I., Wawrzyńczak, D. & Ściubidło, A. Application of metal-organic frameworks in VPSA technology for CO2 capture. Fuel 255, 115773 (2019).

Danaci, D., Bui, M., Mac Dowell, N. & Petit, C. Exploring the limits of adsorption-based CO2 capture using MOFs with PVSA – from molecular design to process economics. Mol. Syst. Des. Eng. 5, 212–231 (2020).

Raganati, F., Miccio, F. & Ammendola, P. Adsorption of carbon dioxide for post-combustion capture: A review. Energy Fuels 35, 12845–12868 (2021).

Singh, G. et al. Emerging trends in porous materials for CO2 capture and conversion. Chem. Soc. Rev. 49, 4360–4404 (2020).

Pardakhti, M. et al. Trends in solid adsorbent materials development for CO2 capture. ACS Appl. Mater. Interfaces 11, 34533–34559 (2019).

Siriwardane, R. V., Shen, M.-S., Fisher, E. P. & Losch, J. Adsorption of CO2 on zeolites at moderate temperatures. Energy Fuels 19, 1153–1159 (2005).

Fitzgerald, S. A., Mukasa, D., Rigdon, K. H., Zhang, N. & Barnett, B. R. Hydrogen isotope separation within the metal-organic framework Cu(I)-MFU-4I. J. Phys. Chem. C. 123, 30427–30433 (2019).

Li, J.-R., Sculley, J. & Zhou, H.-C. Metal–organic frameworks for separations. Chem. Rev. 112, 869–932 (2012).

Siegelman, R. L., Kim, E. J. & Long, J. R. Porous materials for carbon dioxide separations. Nat. Mater. 20, 1060–1072 (2021).

Younas, M. et al. Recent progress and remaining challenges in post-combustion CO2 capture using metal-organic frameworks (MOFs). Prog. Energy Combust. Sci. 80, 100849 (2020).

Férey, G. Hybrid porous solids: past, present, future. Chem. Soc. Rev. 37, 191–214 (2008).

Ge, X. & Ma, S. in Materials for Carbon Capture (eds. Jiang, D., Mahurin, S. M. & Dai, S.) 5–27 (John Wiley & Sons, Ltd, 2020).

Bozbiyik, B. et al. Adsorption and separation of n-hexane and cyclohexane on the UiO-66 metal–organic framework. Microporous Mesoporous Mater. 183, 143–149 (2014).

Bazer-Bachi, D., Assié, L., Lecocq, V., Harbuzaru, B. & Falk, V. Towards industrial use of metal-organic framework: Impact of shaping on the MOF properties. Powder Technol. 255, 52–59 (2014).

Furukawa, H., Cordova, K. E., O’Keeffe, M. & Yaghi, O. M. The chemistry and applications of metal-organic frameworks. Science 341, 1230444 (2013).

Deng, H. et al. Large-pore apertures in a series of metal-organic frameworks. Science 336, 1018–1023 (2012).

Xue, D.-X. et al. Tunable rare earth fcu-MOF platform: Access to adsorption kinetics driven gas/vapor separations via pore size contraction. J. Am. Chem. Soc. 137, 5034–5040 (2015).

Czaja, A. U., Trukhan, N. & Müller, U. Industrial applications of metal–organic frameworks. Chem. Soc. Rev. 38, 1284–1293 (2009).

Hanikel, N. et al. Rapid cycling and exceptional yield in a metal-organic framework water harvester. ACS Cent. Sci. 5, 1699–1706 (2019).

Li, B., Wang, H. & Chen, B. Microporous metal–organic frameworks for gas separation. Chem 9, 1474–1498 (2014).

Abdelhameed, R. M., Emam, H. E., Rocha, J. & Silva, A. M. S. Cu-BTC metal-organic framework natural fabric composites for fuel purification. Fuel Process. Technol. 159, 306–312 (2017).

Kumar, S., Srivastava, R. & Koh, J. Utilization of zeolites as CO2 capturing agents: Advances and future perspectives. J. CO2 Util. 41, 101251 (2020).

Demir, H., Aksu, G. O., Gulbalkan, H. C. & Keskin, S. MOF Membranes for CO2 capture: Past, present and future. Carbon Capture Sci. Technol. 2, 100026 (2022).

Lin, J.-B. et al. A scalable metal-organic framework as a durable physisorbent for carbon dioxide capture. Science 374, 1464–1469 (2021).

Kim, E. J. et al. Cooperative carbon capture and steam regeneration with tetraamine-appended metal–organic frameworks. Science 369, 392–396 (2020).

Qazvini, O. T. & Telfer, S. G. MUF-16: A robust metal–organic framework for pre- and post-combustion Carbon Dioxide capture. ACS Appl. Mater. Interfaces 13, 12141–12148 (2021).

Qazvini, O. T., Barbarao, R. & Telfer, S. G. Selective capture of carbon dioxide from hydrocarbons using a metal-organic framework. Nat. Commun. 12, 197 (2021).

Chen, K.-J. et al. Tuning pore size in square-lattice coordination networks for size-selective sieving of CO2. Angew. Chem. Int. Ed. 55, 10268–10272 (2016).

Sahoo, R., Mondal, S., Mukherjee, D. & Das, M. C. Metal–organic frameworks for CO2 separation from flue and biogas mixtures. Adv. Funct. Mater. 32, 2207197 (2022).

Galan-Mascaros, J. R., Corella-Ochoa, N. & Lillo, V. A crystalline metal-organic framework. European Union Patent EP16382480.8. October 21st (2016).

Corella-Ochoa, M. N. et al. Homochiral metal-organic frameworks for enantioselective separations in liquid chromatography. J. Am. Chem. Soc. 141, 14306–14316 (2019).

Hamon, L., Jolimaître, E. & Pirngruber, G. D. CO2 and CH4 Separation by adsorption using Cu-BTC metal−organic framework. Ind. Eng. Chem. Res. 49, 7497–7503 (2010).

Asadi, T., Ehsani, M. R., Ribeiro, A. M., Loureiro, J. M. & Rodrigues, A. E. CO2/CH4 Separation by adsorption using nanoporous metal organic framework Copper-Benzene-1,3,5-tricarboxylate tablet. Chem. Eng. Technol. 36, 1231–1239 (2013).

Núñez-Rico, J. L. et al. TAMOF-1 as a Versatile and predictable chiral stationary phase for the resolution of racemic mixtures. ACS Appl. Mater. Interfaces 15, 39594–39605 (2023).

González-Galán, C. et al. Separation of volatile organic compounds in TAMOF-1. ACS Appl. Mater. Interfaces 14, 30772–30785 (2022).

Zhou, K. et al. Water-resistant, scalable, and inexpensive chiral metal–organic framework featuring global negative electrostatic potentials for efficient acetylene separation. Chem. Bio Eng. 1, 349–356 (2024).

Chickos, J. S. & Acree, W. E. Jr. Enthalpies of sublimation of organic and organometallic compounds. 1910–2001. J. Phys. Chem. Ref. Data 31, 537–698 (2002).

Nuhnen, A. & Janiak, C. A practical guide to calculate the isosteric heat/enthalpy of adsorption: Via adsorption isotherms in metal-organic frameworks, MOFs. Dalton Trans. 49, 10295–10307 (2020).

Nguyen, T. T. T., Lin, J.-B., Shimizu, G. K. H. & Rajendran, A. Separation of CO2 and N2 on a hydrophobic metal organic framework CALF-20. Chem. Eng. J. 442, 136263 (2022).

Martínez-Ahumada, E. et al. Capture of toxic gases in MOFs: SO2, H2S, NH3 and NOx. Chem. Sci. 12, 6772–6799 (2021).

Galan-Mascaros, J. R., Cabezas-Giménez, J., Escudero-Adan, E. C., Fabelo, O. R., & Falvello, L. R. In situ detection of adsorbed CO2 inside the channels of a CO2-selective metal organic framework (MOF). Institut Laue-Langevin (ILL) https://doi.org/10.5291/ILL-DATA.5-12-340 (2019).

Kauffman, K. L., Culp, J. T., Goodman, A. & Matranga, C. FT-IR Study of CO2 adsorption in a dynamic Copper(II) Benzoate−Pyrazine host with CO2−CO2 interactions in the adsorbed state. J. Phys. Chem. C. 115, 1857–1866 (2011).

Grissom, T. G. et al. Molecular-level insight into CO2 adsorption on the Zirconium-based metal–organic framework, UiO-66: A combined spectroscopic and computational approach. J. Phys. Chem. C. 123, 13731–13738 (2019).

Valenzano, L. et al. Computational and experimental studies on the adsorption of CO, N2, and CO2 on Mg-MOF-74. J. Phys. Chem. C. 114, 11185–11191 (2010).

Myers, A. L. & Monson, P. A. Adsorption in porous materials at high pressure: Theory and experiment. Langmuir 18, 10261–10273 (2002).

Sharma, S. et al. RUPTURA: simulation code for breakthrough, ideal adsorption solution theory computations, and fitting of isotherm models. Mol. Simul. 49, 893–953 (2023).

Sheldrick, G. M. Crystal structure refinement with SHELXL. Acta Crystallogr. Sect. C. 71, 3–8 (2015).

Duisenberg, A. J. M. Indexing in single-crystal diffractometry with an obstinate list of reflections. J. Appl. Crystallogr. 25, 92–96 (1992).

Wilkinson, C., Khamis, H. W., Stansfield, R. F. D. & McIntyre, G. J. Integration of single-crystal reflections using area multidetectors. J. Appl. Crystallogr. 21, 471–478 (1988).

Dolomanov, O. V., Bourhis, L. J., Gildea, R. J., Howard, J. A. K. & Puschmann, H. OLEX2: A complete structure solution, refinement and analysis program. J. Appl. Cryst. 42, 339–341 (2009).

Brandenburg, K. & Putz, H. Diamond – crystal and molecular structure visualization. Cryst. Impact https://www.crystalimpact.de/diamond (2025).

Macrae et al. Mercury 4.0: from visualization to analysis, design and prediction. J. Appl. Cryst. 53, 226–235 (2020).

Ng, S. H., Jia, C. Q. & Lu, W. K. Carbonation conversion of aqueous sodium sulfide to hydrogen sulfide. Environ. Sci. Technol. 27, 2158–2161 (1993).

Bannwarth, C., Ehlert, S. & Grimme, S. GFN2-xTB—An accurate and broadly parametrized self-consistent tight-binding quantum chemical method with multipole electrostatics and density-dependent dispersion contributions. J. Chem. Theory Comput. 15, 1652–1671 (2019).

Hourahine, B. et al. DFTB+, a software package for efficient approximate density functional theory based atomistic simulations. J. Chem. Phys. 152, 124101 (2020).

García-Sánchez, A. et al. Transferable force field for Carbon Dioxide adsorption in zeolites. J. Phys. Chem. C. 113, 8814–8820 (2009).

Potoff, J. J. & Siepmann, J. I. Vapor–liquid equilibria of mixtures containing alkanes, carbon dioxide, and nitrogen. AIChE J. 47, 1676–1682 (2001).

Martin, M. G. & Siepmann, J. I. Transferable potentials for phase equilibria. 1. United-atom description of n-Alkanes. J. Phys. Chem. B 102, 2569–2577 (1998).

Mayo, S. L., Olafson, B. D. & Goddard, W. A. DREIDING: a generic force field for molecular simulations. J. Phys. Chem. 94, 8897–8909 (1990).

Rappe, A. K., Casewit, C. J., Colwell, K. S., Goddard, W. A. I. & Skiff, W. M. UFF, a full periodic table force field for molecular mechanics and molecular dynamics simulations. J. Am. Chem. Soc. 114, 10024–10035 (1992).

Coupry, D. E., Addicoat, M. A. & Heine, T. Extension of the Universal force field for metal–organic frameworks. J. Chem. Theory Comput. 12, 5215–5225 (2016).

Dubbeldam, D., Calero, S., Ellis, D. E. & Snurr, R. Q. RASPA: molecular simulation software for adsorption and diffusion in flexible nanoporous materials. Mol. Simul. 42, 81–101 (2016).

Gutiérrez-Sevillano, J. J., Caro-Pérez, A., Dubbeldam, D. & Calero, S. Molecular simulation investigation into the performance of Cu–BTC metal–organic frameworks for carbon dioxide–methane separations. Phys. Chem. Chem. Phys. 13, 20453–20460 (2011).

Huck, J. M. et al. Evaluating different classes of porous materials for carbon capture. Energy Environ. Sci. 7, 4132–4146 (2014).

Ongari, D., Yakutovich, A. V., Talirz, L. & Smit, B. Building a consistent and reproducible database for adsorption evaluation in covalent–organic frameworks. ACS Cent. Sci. 5, 1663–1675 (2019).

Acknowledgements

The authors acknowledge the financial support from MCIN/AEI through projects PID2021-124796OB-I00, PID2021-124880NB-I00, PID2020-115658GB-I00, PDC2022-133214-I00; and from the Generalitat de Catalunya (SGR-2021-1154 and SGR-2021-01107). ICIQ is supported by the Ministerio de Ciencia e Innovación through the Severo Ochoa Excellence Accreditation CEX2021-001214-S; and by the CERCA Programme/Generalitat de Catalunya. This work was partially funded by the European Union’s Horizon Europe through the SUPERVAL project (The SUstainable Photo-ElectRochemical VALorization of flue gases), grant agreement no. 101115456. S.G.A. thanks AGAUR for a PhD industrial fellowship (2019 DI 73). S.R.G.B. thanks the Spanish Ministry of Science Innovation MCIN/AEI/10.13039/501100011033 (grants FJC2018-035697-I and RYC2022-036070-I), and the Consejería de Universidades, Investigación e Innovación, Junta de Andalucía (grant POSTDOC_21_00069). We also thank C3UPO (Centro de Cálculo Científico de la Universidad Pablo de Olavide) for providing high-performance computing facilities.

Author information

Authors and Affiliations

Contributions

J.R.G.M. proposed the concept. J.R.G.M., S.G., S.C., and A.V.-F. designed and supervised the research. J.C.G. and V.L. prepared TAMOF-1 as powder and single crystals. G.T.P., C.P.C., and P.R. carried out and analyzed the spectroscopic data. S.C.A., M.F.F., J.G.C., J.B.P., R.T.O., I.I.G.S., and S.G. performed and analyzed the gas adsorption and breakthrough experiments. J.C.G., O.F., E.C.E.A., and L.R.F. performed the neutron diffraction studies and structure refinement. S.R.G.B. and S.C. developed the computational methods and interpreted the data. All authors participated in the analysis of the results. J.R.G.M., S.C., and S.G. prepared the manuscript with contributions from all authors. All authors have given approval to the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare the following competing financial interest(s): V.L. and J.R.G.M. are inventors in European patent application No.: EP16382480.8, filed by ICIQ and ICREA (Priority date: 21/10/2016), protecting the chemical structure of TAMOF-1 and its derivatives and analogs, along with their applications, including but not limited to their use in CO2 separation and purification. This patent has been licensed to Orchestra Scientific S.L., a spin-off company founded and participated by J.R.G.M., ICIQ, and ICREA. S.G. is the CTO of Orchestra Scientific S.L. The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Wei Gong, Guang-Ping Hao, and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Capelo-Avilés, S., de Fez-Febré, M., Balestra, S.R.G. et al. Selective adsorption of CO2 in TAMOF-1 for the separation of CO2/CH4 gas mixtures. Nat Commun 16, 3243 (2025). https://doi.org/10.1038/s41467-025-58426-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-58426-w