Abstract

Conversion electrodes offer higher reversible capacity and lower cost than conventional intercalation chemistry electrodes, but suffer from kinetic limitation and large volume expansion. Despite significant efforts, developing conversion electrodes with fast charging capability and extended lifespan remains challenging. Here, by leveraging the advantages of high-entropy doping and morphology tailoring, we develop a high-entropy hierarchical micro/nanostructured sulfoselenide Cu0.88Sn0.02Sb0.02Bi0.02Mn0.02S0.9Se0.1 electrode with entropy-driven fast-charging capability. When used as a negative electrode material for sodium-ion batteries, it achieves a stable cycle life of 10,000 cycles at 30 A g−1 and a high reversible capacity of 365.7 mAh g−1 under fast charging in 13 seconds at 100 A g−1. Moreover, high-entropy sulfoselenide also demonstrates stable cycling and good rate capability as a positive electrode material for lithium metal batteries, achieving a fast-charging capability of 37 seconds that is comparable with state-of-the-art layered cathodes. High-entropy sulfoselenide is characterized by its robust crystal structure, low ion diffusion barrier, and effective suppression of side reactions with electrolytes during cycling. Importantly, transmission X-ray microscopy affirms the chemical stability of HESSe, which underpins its fast-charging performance.

Similar content being viewed by others

Introduction

Intercalation-based lithium-ion batteries (LIBs) currently dominate the electric vehicle market due to their high energy density and long cycle life. However, serious concerns arise due to the ever-increasing energy demand and the supply chain risk of critical materials (e.g., Cobalt, graphite, etc.) in LIBs1,2. Sodium-ion batteries (SIBs) have emerged as a promising candidate due to their abundant raw materials, cost-effectiveness, and safety3,4,5. However, their widespread adoption in electric vehicles faces two major challenges: prolonged charging times and low energy density (<160 Wh kg−1)6. To tackle these challenges, significant efforts have been dedicated to the development of fast-charging negative electrode materials that exhibit fast Na+ diffusion and reaction kinetics. In recent years, transition metal chalcogenides (TMCs) have attracted considerable attention as negative electrode materials for SIBs, due to their high specific capacities via multi-electron transfer conversion mechanism7,8,9. Additionally, TMCs effectively mitigate dendrite formation due to their elevated working voltage, thereby enhancing safety. On the other hand, the conversion TMCs are also a class of promising negative electrode materials that offer comparable energy density and lower cost compared to the existing Ni-rich layered cathodes10. However, serious problems such as volumetric expansion, side reactions, kinetic limitations, and structural instability still exist. These issues, which arise from the significant structural restructuring caused by the conversion reaction, severely limit the development of TMCs. These processes significantly reduce the lifespan and impedes the development of fast-charging battery technologies11.

In recent years, a class of materials known as high-entropy materials has emerged, typically comprising five or more elements and forming a single-phase crystal lattice structure12. The increased chemical complexity associated with these materials results in a diverse array of intriguing properties13,14. To date, this strategy has been widely adopted and has been proven to significantly enhance the stability of various intercalation negative electrode materials15,16,17,18. For example, rock-salt Co0.2Cu0.2Mg0.2Ni0.2Zn0.2O has demonstrated the effectiveness of high-entropy design in overcoming the structural instability of conversion negative electrodes19. This concept was further extended to the design of high-entropy spinel oxide and perovskite oxide positive electrodes20 as well as sulfide negative electrodes21,22,23. Nevertheless, recent mechanistic studies revealed that the improved electrochemical performance cannot be exclusively explained by the cocktail effect of multi-cations24,25, but also highly depends on the selection of electrochemical active and inert cations that enabled a semi-coherent metallic and oxide phase at the nanoscale26. As a result, the reported high-entropy conversion negative electrodes not only suffer from the use of critical elements such as Co and Ni to facilitate electron transport, but also undergo a significant initial irreversible capacity loss19,21,23,27. The elimination of Ni and Co in high-entropy conversion electrodes unfortunately leads to decreased cycle life and rate capability22,23.

In this study, we draw inspiration from the high-entropy strategy and morphology tailoring to develop high-entropy hierarchical micro/nanostructured sulfoselenide Cu0.88Sn0.02Sb0.02Bi0.02Mn0.02S0.9Se0.1 (HESSe) as fast-charging negative electrodes. The introduction of multiple cations has improved the physical and chemical properties of HESSe materials, showing enhanced cocktail effects. Specifically, HESSe exhibits a reversible specific capacity of 325 mAh g−1 after 10,000 cycles at a current density of 30 A g−1 when used as negative electrode material for sodium-ion batteries. Notably, at a high current density of 100 A g−1, HESSe still attains a specific capacity of 365.7 mAh g−1 with a fast-charging time of only 13 s. Additionally, HESSe exhibits potential in lithium-metal batteries, demonstrating a rapid charging capability of 37 s at a specific current of 30 A g−1. Comprehensive structural characterization and electrochemical tests confirmed the origin of the cocktail effect, which is the Na+ rapid kinetics, low diffusion energy barrier, stable crystal structure, and chemical stability HESSe, suppressing the side reactions and alleviating the lattice stress, thus exhibiting the entropy stabilization and entropy-driven fast-charging effects in a comprehensive manner.

Results

Structural and morphological characterization

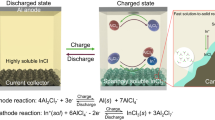

The material design concept diagram is shown in Fig. 1a, CuS structure was used as the basis to introduce Se to form CuS0.9Se0.1 (LESSe), and further converted into Cu0.88Sn0.02Sb0.02Bi0.02Mn0.02S0.9Se0.1 (HESSe) using a high-entropy strategy. The calculation of configurational entropy for the above three samples and the properties of the selected metal are detailed in Supplementary Tables 1 and 2. The crystalline structure and phase purity of the samples were investigated using X-ray diffraction (XRD) and Rietveld refinement. As depicted in Fig. 1b–d, HESSe, LESSe, and CuS exhibit a single-phase structure with a hexagonal structure that characterized by the space group of P63/mmc (PDF#78-0876). The lattice parameters of HESSe, obtained by Rietveld refinement, are a = b = 3.80670 Å, c = 16.54448 Å and α = β = 90°, γ = 120°, V = 207.63 Å3. More details on Rietveld refinements and structural parameters of HESSe, LESSe and CuS are shown in Supplementary Tables 3–5. The increase in configurational entropy results in a reduction in the cell volume of the sample, which can be ascribed to the incorporation of metal elements with higher electronegativity into the entropy structure, thereby strengthening electrostatic attraction and inducing unit cell shrinkage. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) show that HESSe exhibits a hierarchical micro/nanostructured nanoflower-like morphology comprising numerous nanosheets with an average size of approximately 1 μm (Fig. 1e, f and Supplementary Fig. 1). LESSe and CuS has similar nanoflower-like morphology, though with thicker nanosheets due to decreased entropy. The results indicate that high-entropy configuration reduces the surface formation energy, thereby leading to formation of more uniform thin-layer nanoflower morphologies. The high-resolution TEM (HRTEM) images of HESSe show a lattice fringe of (100) plane with a d-spacing of 3.775 Å (Fig. 1g). The selected electron diffraction (SAED) image exhibits a multitude of regularly dispersed diffraction spots, providing evidence for the single-crystal nature of HESSe (Fig. 1h). EDS-mapping analysis (Fig. 1i) reveals that the multi-component HESSe particles possess a uniform distribution of elements without any segregation or enrichment of cations/anions. EDS-mapping of LESSe sample also confirms the uniform element distribution of Cu, S and Se (Supplementary Fig. 2). The element stoichiometry analysis of HESSe, as determined by inductively coupled plasma-mass spectrometry (ICP-MS), demonstrates that the metallic ratio of multiple dopants shows no discernible difference (Supplementary Table 6). The electronic conductivity was measured via four-point probe method, where HESSe exhibits a higher electronic conductivity due to the high-entropy doping (Supplementary Fig. 3)28. A comprehensive examination of the valence states of the HESSe sample was conducted using X-ray photoelectron spectroscopy (XPS), as shown in Supplementary Fig. 4. The Brunauer–Emmett–Teller (BET) experimental results for the three materials are presented in Supplementary Fig. 5. The specific surface area of HESSe (13.3 m2 g−1) is higher than that of LESSe (5.1 m2 g−1) and CuS (3.1 m2 g−1). Additionally, HESSe exhibits a larger specific surface area and pore diameter (Supplementary Fig. 5b), which facilitates sodium ion transport and electrolyte infiltration.

Sodium storage performances

A comprehensive evaluation was performed to assess the entropy effect on the de/sodiation capabilities. Electrochemical performance was tested using CR2032-type coin cells, with metallic sodium serving as both counter and reference electrode. Supplementary Fig. 6 presents the Cyclic Voltammetry (CV) profiles of the initial three cycles, measured at a scanning rate of 0.2 mV s−1 between 0.1 to 3.0 V (vs. Na/Na+) for the three electrodes. The second and third curves of HESSe exhibit significant overlap, indicating good reversibility for sodium storage. By contrast, both LESSe and CuS show poor reversibility, with CuS undergoing more severe side reactions. Figure 2a displays the cycling performance of the three electrodes at a specific current of 0.4 A g−1. HESSe delivers an initial discharge/charge capacity of 687.8/566.4 mAh g−1, with an initial coulombic efficiency (ICE) of 82.3%. This outperforms LESSe (555.3/446.3 mAh g−1, ICE of 80.4%) and CuS (586.3/426.6 mAh g−1, ICE of 72.8%). As displayed in Supplementary Fig. 7, the higher ICE of HESSe can be attributed to the ether-based electrolyte, which exhibits a stable solvation structure that promotes the formation of a thin and stable SEI29,30,31. After 2000 cycles, HESSe retains a high capacity of 534.2 mAh g−1, corresponding to a capacity retention of 94.3%, with centralized voltage plots upon cycling (Fig. 2b). In contrast, the cycling lifespan and charge-discharge voltage stability of LESSe and CuS deteriorate more rapidly (Supplementary Fig. 8). The rate capability test (Fig. 2c) of HESSe delivers specific capacities of 583.4, 534.7, 515.7, 500.8, 492.5, and 479.1 mAh g−1 at specific density of 0.2, 0.5, 1.0, 2.0, 3.0, and 6.0 A g−1, respectively, outperforming both LESSe and CuS. The galvanostatic charge-discharge curves (GDC) of HESSe at various specific density confirm low polarization compared to LESSe and CuS electrode (Supplementary Fig. 9). Additionally, a more detailed rate capability test (Supplementary Fig. 10) reveals that HESSe shows a high specific capacity of 365.7 mAh g−1 even at a high specific current of 100 A g−1. Subsequently, a long-term cycling performance test was conducted. At a specific current of 6.0 A g−1, HESSe exhibits a specific capacity of 463.2 mAh g−1 over 8000 cycles with 95.8 % capacity retention (reference activated third cycle) as shown in Fig. 2d and Supplementary Fig. 11. Notably, during fast-charging capability measurements, HESSe negative electrode maintains a reversible charge capacity of 325.1 mAh g−1 at 30 A g−1 after 10,000 cycles (Fig. 2e, f) while sustaining a Coulombic efficiency of ~99.8% (Supplementary Fig. 12). This performance is comparable to other high-performing sodium-ion battery negative electrode materials reported in recent studies (Fig. 2g and Supplementary Table 7). Even at a high loading of 4.65 mg cm−2, the HESSe electrode exhibits high specific capacities of 408.9 mAh g−1 at specific current of 0.2 A g−1 (Supplementary Fig. 13a, b). The stable rate performance of the HESSe electrode at 0 °C suggests its potential for applications in low-temperature environments (Supplementary Fig. 13c, d). The cycling performance of HESSe underscores its stable structure and fast Na+ diffusion kinetics during the repetitive cycles, attributed to the dual effects of entropy stabilization and entropy-driven fast charging. On one hand, the larger selenium ions doping expands the diffusion path of sodium ions, and the M-Se bond energy is weaker than M-S, which facilitates the conversion reaction, thus enabling higher specific capacity and better kinetic performance of LESSe than CuS. On the other hand, the high-entropy doping of multiple cations significantly increases the configurational entropy and achieves the entropy stabilization effect. This is because different metal elements undergo electrochemical reactions in sequence, effectively preventing the instantaneous collapse of the structure and thereby enhancing electrochemical stability32. Therefore, the coexistence of cations and anions in the high-entropy structure significantly enhances the overall performance. These factors contribute to the enhanced cocktail effect observed in HESSe, and additionally, a variety of characterization techniques are employed to investigate the underlying mechanisms.

a Cycling performance and c rate capability of Na||HESSe, Na||LESSe and Na||CuS cells with filled and unfilled circles denoting charge and discharge processes, respectively. b Charge/discharge profiles of Na||HESSe cell at 0.4 A g−1. Cycling performance of Na||HESSe cell at d 6.0 A g−1 and e 30 A g−1. f Charge/discharge profile of Na||HESSe cell at 30 A g−1. g Comparison of Na||HESSe cell with other reported transition metal chalcogenides positive electrodes; detailed electrochemical data are provided in Supplementary Table 7.

Theoretical calculations and analysis of kinetic behavior

The electronic properties and structures of three sulfides were investigated by Density Functional Theory (DFT) calculations to understand the influence of high-entropy on their electrochemical properties. As shown in the total density of states (TDOS) and partial density of states (PDOS) results in Fig. 3a–c, HESSe has a fully occupied state at the Fermi level, indicating its multi-metallic nature. The higher TDOS and integrated DOS values of HESSe (Supplementary Fig. 14) indicate an increased number of states (electrons) at the Fermi level, leading to higher carrier concentration, which explains the higher conductivity of HESSe compared to LESSe and CuS due to the high-entropy structure of multi-metal cations. The atomic coordinates used for DOS calculations are shown in Supplementary Table 8. Figure 3d, e and Supplementary Fig. 15 the diffusion paths of Na⁺ in HESSe and CuS, with atomic coordinates listed in Supplementary Table 9. As shown in Fig. 3f, all sodium ion diffusion barriers in HESSe are lower than those in CuS, with the highest barrier being only 0.10 eV, significantly lower than that of CuS (0.19 eV). Additionally, the calculated adsorption energies (inset in Fig. 3f) reveal that HESSe exhibits higher adsorption energy compared to CuS, further demonstrating that the high-entropy structure imparts stronger sodium ion adsorption capability to the electrode material, thereby improving its sodium storage performance. In summary, these theoretical calculations fully validate the storage performance of Na||HESSe and underscore the effectiveness of the high-entropy strategy in optimizing energy storage materials. CV tests at different scan rates were employed to investigate the fast charging and discharging mechanism of the HESSe electrode, as shown in Fig. 3g. When the scan rate is increased, Peak 4 of LESSe and CuS exhibits more severe polarization (Fig. 3h, i), whereas Peak 4 of HESSe maintains a more stable peak current, further demonstrating the fast-charging behavior and cycling stability of HESSe. According to the formula (1 and 2)33,34:

where i represents peak current, a is a constant, and v is the scan rate. Specifically, b close to 0.5 represents the diffusion-controlled behavior while b close to 1 indicates the capacitive-controlled behavior. In addition, the capacitive contribution percentage for given CV curves can be quantified using the following equation35:

where, i (mA) is current at a particular potential (V), v (mV s−1) is scan rate, k1 and k2 and are fitting parameters for capacitive and diffusion-controlled contributions. As the scan rate increased, the curves maintained similar shapes. For the HESSe electrode, the b value of Peak 1 is close to 0.5 (Fig. 3j–l), indicating that the formation of the intercalation compound NaₓHESSe is primarily diffusion-controlled. The b values for Peaks 2–5 are all greater than 0.5 and approach 1, suggesting that the subsequent conversion processes are predominantly capacitive in nature. More importantly, the capacitive contribution percentage of HESSe increases from 92.6% to 96.7% (Fig. 3m), significantly higher than that of LESSe and CuS (Fig. 3n, o).

a–c Density of states (DOS) of the three materials. d, e Schematic illustration of the Na+ diffusion paths in Na||HESSe and Na||CuS cells, respectively, along with the corresponding (f) diffusion energy barrier curves, the insets show Na⁺ adsorption energy. g–i Cyclic voltammetry curves at different scan rates ranging from 0.2 to 1.0 mV s−1; j–l Log i vs Log v plots at each peak; The percentage of capacitive contribution of the m Na||HESSe, n Na||LESSe and o Na||CuS cells.

The Galvanostatic Intermittent Titration Technique (GITT) results show the DNa+ values of HESSe are higher than those of CuS (Fig. 4a–c and Supplementary Fig. 16). As shown in Fig. 4d, HESSe displays smaller voltage polarization compared to LESSe and CuS. This enhanced Na+ transport can be attributed to the diverse elements within high-entropy configuration, which synergistically improve electron/ion conductivity and reduce Na+ diffusion energy barriers. In situ electrochemical impedance spectroscopy (EIS) measurements were conducted at different states of the first cycle (Fig. 4e–k), with the calculated fitting results provided in Supplementary Table 10 and the corresponding equivalent circuit shown in Supplementary Fig. 17. During the initial discharge processes (OCP-D1.3 V), the resistance increases rapidly for LESSe and CuS, due to the growth of SEI layer and the occurrence of side reactions. After fully charging to 3.0 V, the LESSe and CuS exhibit higher resistance than HESSe due to their poor conductive network. Overall, as depicted in Fig. 4k, HESSe maintains lower and more stable resistance during de/sodiation processes compared to LESSe and CuS, which can be attributed to the high-entropy structural ability to enhance electronic conductivity36,37,38. In addition, a detailed discussion of the EIS fitting values and distribution of relaxation times (DRT) method for analyzing the impedance process is presented in Supplementary Fig. 18.

GITT potential profiles and corresponding Na+ diffusion coefficients of a Na||HESSe, b Na||LESSe and c Na||CuS cells in the first two cycles, d polarization curves of GITT at 1st discharge process. Nyquist plots of e, f Na||HESSe, g, h Na||LESSe and i, j Na||CuS cells in first cycle (solid lines represent fitting results) and k Impedance comparison diagram of three electrodes; detailed fitting data are provided in Supplementary Table 10.

Sodium-ion storage mechanism

In situ XRD was employed to investigate the crystal structure evolution of HESSe during charge/discharge cycles. The in situ cells were tested at 100 mA g−1 within 0.1–3.0 V during the initial two cycles and the mass loading was 7.6 mg cm−2. As shown in Fig. 5a, red dashed lines mark the relevant diffraction peaks of HESSe. These peaks are clearly observed after the first and second cycles. At stage I (from OCP to 0.9 V), the intensities of all diffraction peaks gradually weaken, and new diffraction peaks corresponding to NaxHESSe (021) emerge at 34.5° as Na+ integrates into HESSe. Additionally, HESSe (110) diffraction peak at 47.8° slightly shifts to a low angle, attributed to the increase of lattice parameter due to the intercalation reaction39,40,41. At stage II (from 0.9 V to 0.1 V), the characteristic diffraction peak of HESSe diminishes, indicating a conversion reaction. The diffraction peaks of 22.7°, 30.5°, 38.3° are indexed to Na2S (PDF #47-1698) and Na2Se (PDF #47-1699). The new diffraction peak at 43.3° is indexed to Cu (PDF#85-1326). At stage III (from 0.1 V to 2.0 V), the peaks corresponding to Cu, Na2S and Na2Se disappear due to the de-conversion reaction and the peak of NaxHESSe reformation appears at 34.5°. During stage IV of de/sodiation process (from 2.0 V to 3.0 V), HESSe diffraction peaks reappear, though with weaker intensity compared to OCP state owing to the crystal size becomes smaller39,42. Subsequently, the second cycle likewise proceeded through stages I–IV, further confirming the reversibility of the de/sodiation processes in HESSe. Overall, HESSe exhibits phase transition reversibility. The relevant redox reactions are as follows (3–8):

Stage I (intercalation, OCP-0.9 V):

Stage II (conversion and alloying, DC0.9 V-DC0.1 V)

(Stage III de-alloying and de-conversion C0.1 V-C2.0 V)

(Stage IV de-sodiation, C2.0 V-C3.0 V)

To further elucidate the mechanism of HESSe during the initial de/sodiation process, ex situ XPS measurements were conducted at the OCP, fully discharged, and final charged states (Fig. 5b). The XPS spectra reveal a peak shift for the copper element: Cu 2p3/2 (932.07 eV to 931.70 eV to 931.95 eV), Cu 2p1/2 (952.04 eV to 951.42 eV to 951.73 eV), indicating a reduction from Cu2+ to Cu0 upon discharge and subsequent re-oxidation to Cu2+ upon charging to 3.0 V43,44. This observation aligns with the theoretical conversion-type mechanism and confirms the high reversibility of the reaction. Furthermore, the characteristic doublet peaks at 162.14 and 163.25 eV represent the 2p3/2 and 2p1/2 orbitals of S2- for the pristine electrode of HESSe. In the first cycle, the binding energies of S 2p orbitals decrease (2p3/2 at 159.82 and 2p1/2 at 160.59 eV) and return to the original values (2p3/2 at 162.37 and 2p1/2 at 163.6 eV) at the DC0.1 V and C3 V state, respectively, attributed to the formation and disappearance of Na2S45. The Se 3p and Se 3 d orbits exhibit a similar trend with the formation of Na2Se species46,47. At the fully discharged state, TEM elemental mapping demonstrates the homogeneous distribution of all cations and anions (Fig. 5c). In addition, the valence state changes of Sn, Sb and Mn during the first de/sodiation process were analyzed in detail, as shown in Supplementary Fig. 19. All these elements undergo a process of reduction followed by oxidation. As illustrated in Supplementary Fig. 20a, at the fully sodiation state (DC0.1 V), distinct lattice fringes associated with Na2S, Na2Se, Na9Sn4, Na3Sb, Na3Bi, Cu and Mn can be observed. Furthermore, the lattice fringes of HESSe reversibly recover at the fully desodiation state (Supplementary Fig. 20b, c).

Stability characteristics and morphological evolution

To evaluate the chemical stability of HESSe during cycling, we conducted three-dimensional (3D) full-field transmission X-ray microscopy (TXM) that combined with X-ray absorption near-edge structure (XANES, Cu K-edge). The Cu K-edge white-line (WL) energy was utilized to compare the chemical states of Cu in different electrodes. Figure 6a, b presents the 3D TXM-XANES results for the pristine and cycled HESSe electrodes. The cycled cell was charged to 3.0 V before being disassembled for characterization. For each electrode, we cut three slices at different depths (slice 1 to slice 3) of the tested samples and generated corresponding 3D chemical maps of each slice based on color-coded Cu WL energy. The 3D computed tomography (CT, weighted attenuation) results obtained from the TXM datasets show that the particle morphology is well maintained during cycling. The 3D Cu WL energy maps in Fig. 6a, b indicate that the Cu WL energy for both the pristine and cycled samples (3.0 V charged state) is predominantly around 8998.5 eV, demonstrating the electrochemical reversibility of the HESSe electrode during cycling. The morphological evolution of the cycled HESSe, LESSe and CuS electrodes was investigated by SEM to evaluate structural stability after long-term cycling. The nanoflake morphology of the HESSe electrode is also well maintained during the repetitive de/sodiation process (Fig. 6c and Supplementary Fig. 21), indicating the satisfactory stability and reversibility of high-entropy structure. Conversely, both the LESSe and CuS electrodes exhibit significant damage, including severe expansion and fracture, as shown in Fig. 6d, e. Additionally, notable thickening is observed for the CuS electrode. These findings suggest that the change in configurational entropy significantly influences morphological evolution. The incorporation of multi-component elements into high-entropy structures induces lattice distortion due to variations in ion radii and electronegativity, consequently improving mechanical properties48. Geometric Phase Analysis (GPA) was carried out based on HRTEM to image the internal stress of three samples after 100 cycles (Supplementary Fig. 22). For LESSe and CuS, significant non-uniform internal strains exist around the regions with lattice distortion, which can be attributed to the severe volume expansion during the charge-discharge process, thereby increasing the lattice strain. Such intense internal stress can lead to the formation and propagation of cracks. For the HESSe electrode, the strain area significantly reduces, indicating its structural stability during the long-term cycling process and effectively suppressing the lattice stress caused by volume expansion. As a result, HESSe demonstrates enhanced mechanical tolerability, effectively mitigating structural deterioration such as grain swelling and rupture. Subsequent XRD tests were conducted to investigate the crystalline evolution after 50, 75 and 100 cycles. For the pristine state of the HESSe electrode (Supplementary Fig. 23a), multiple diffraction peaks at around 30° can be clearly observed. Due to the reduced particle size and increased unit cell parameters in the de/sodiation processes, the diffraction peak of HESSe electrode exhibits broadening and shifts towards lower angles. Conversely, the XRD diffraction peak of the LESSe sample exhibits a significant attenuation after 75 cycles and nearly vanishes after 100 cycles under identical experimental conditions (Supplementary Fig. 23b). For the CuS electrode, after 50 cycles, the XRD diffraction peak almost disappears, and a Cu1.92S phase emerges. Subsequently, the primary phase of the electrode becomes Cu1.92S accompanied by more irreversible Na2S and NaxCuS intermediate residues after 100 cycles (Supplementary Fig. 23c). The poor cycling performance of CuS may be attributed to the collapses of its fragile crystal structure during cycling. As shown in Supplementary Fig. 24, EIS test and Nyquist plot fitting confirm that HESSe exhibits stable and low resistance compared to LESSe and CuS, consistent with the fast-charging capability of HESSe. To investigate the composition of the SEI layer on the electrodes after long-term cycling, XPS etching tests were performed on HESSe, LESSe, and CuS electrodes following 100 cycles (Supplementary Fig. 25). The fitting results of the C 1s and F 1s spectra for the HESSe electrode reveal a weaker C-F and a stronger NaF intensity compared to those of LESSe and CuS. It is consistent with the atomic percentage analysis, confirming that the SEI layer of HESSe consists of a thinner organic outer layer and an inorganic inner layer (rich NaF). In contrast, the SEI layers of LESSe and CuS exhibit lower fluorine content and higher atomic percentages of C and O, indicating a thicker organic outer layer. Notably, NaF possesses a low Na⁺ diffusion barrier and high electronic insulation properties, which facilitates rapid Na⁺ transport within the SEI while effectively preventing electron penetration through the SEI layer49. These characteristics of the NaF-rich inorganic layer contribute to the fast-charging performance of the HESSe negative electrode and ensure its stability during long-term cycling. After 100 cycles, obvious by-products such as SOx and Na2Sx appear on the LESSe and CuS electrodes (Supplementary Fig. 26).

Electrochemical performance at sodium-ion full cell

To further explore the practical application of HESSe, coin-type full cells were assembled with HESSe negative electrode and Na3V2(PO4)3 (denoted as NVP) positive electrode. The specific capacity of full cells was calculated based on the mass of positive electrode. As depicted in Fig. 7a, the specific discharge capacity in the first cycle is 107.8 mAh g−1 at a specific current of 0.2 A g−1, with an ICE of 95.7 %. After 100 cycles, the cell exhibits a high reversible specific capacity of 98.3 mAh g−1. The corresponding voltage profiles are shown in Supplementary Fig. 27a. Furthermore, the HESSe||NVP delivers a capacity of 83.6 mAh g−1 after 1000 cycles at 1 A g−1 (Fig. 7b Supplementary Fig. 27b). More appealingly, HESSe||NVP also exhibits outstanding rate performance that is comparable to that of a Na||HESSe cell. At the specific density of 0.05, 0.1, 0.2, 0.4, 0.6, 0.8, 1.0, 1.5 and 2.0 A g−1, it delivers specific capacities of 106.2, 105.0, 104.0, 103.3, 102.4, 101.7, 101.1, 100.2, and 99.3 mAh g−1, respectively (Fig. 7c, d). In addition, as shown in Supplementary Fig. 28, the sodium-ion pouch cell HESSe||NVP successfully illuminates the HQU logo pattern composed of LED bulbs. At a specific current of 0.05 A g−1, the pouch cell demonstrates an initial discharge specific capacity of 105.4 mAh g−1 (calculated based on the mass of the positive electrode active material). Moreover, it exhibits a specific capacity of 68.4 mAh g−1 at a specific current of 1 A g−1.

Working as positive electrode for Lithium metal batteries

Conversion-type positive electrode materials, such as transition metal halides, chalcogenides, and oxides, have demonstrated high operational voltages and high specific capacities, offering high energy densities for rechargeable lithium-metal batteries10. In consideration of their potential advantages, low cost, environmental benignity, easy synthesis, insensitivity to moisture, and high energy density, these Li-free positive electrodes could become competitive candidates compared to Li-contained positives. After a detailed discussion of the electrochemical performance and reaction mechanism of Na||HESSe, we further explored its potential in lithium metal batteries, aiming to leverage its advantages of high energy density and fast charging capability. For Li||HESSe, the electrochemical performance are presented in Fig. 8a, where the reversible specific capacity at a specific current of 0.1 A g−1 remains 487.5 mAh g−1 after 100 cycles. The voltage curve indicates that the discharge platform lies within the range of 1.5–2.0 V (Fig. 8b). At specific densities of 0.4 A g−1 and 1.0 A g−1, HESSe exhibits specific capacities of 472.6 mAh g−1 and 421.6 mAh g−1 after 400 and 500 cycles, respectively (Fig. 8c, d). Furthermore, rate capability was conducted and shown in Fig. 8e and Supplementary Fig. 29 at a high rate of 10 A g−1, HESSe still delivers a specific capacity of 305.9 mAh g−1 with corresponding charging time within 4 min. Furthermore, at a high specific current of 30 A g−1, the HESSe positive electrode can be fully charged in just 37 s, demonstrating an promising application prospect (Supplementary Fig. 30). To investigate the structural evolution of the HESSe positive after 100 cycles, XPS depth-profiling measurements were performed on the samples to analyze the composition of the SEI layer (Supplementary Fig. 31). In the HESSe-Li electrode after 100 cycles, as cycling progresses, the atomic percentages of F and S gradually increase, while the C content steadily decreases, and the O content remains largely unchanged. This phenomenon suggests that the solid electrolyte interface (SEI) layer of the HESSe-Li electrode is primarily composed of organic components and inorganic components (such as LiF). Notably, the inorganic layer rich in LiF plays a crucial role in SEI stability by not only facilitating efficient lithium-ion transport but also inhibiting lithium dendrite growth, thereby enhancing the long-term cycling stability of the electrode50. Drawing from these results, high-entropy conversion-type electrodes demonstrate potential as positive electrode materials to address the pressing demand for fast-charging in contemporary society.

Discussion

In this study, we integrated the conversion-type electrode with a high-entropy strategy to develop rechargeable batteries featuring fast-charging capability and long-term lifespan. The structural advantages of high-entropy and its compositional benefits significantly enhance the conductivity and mechanical strength of crystal structure. In SIBs, the HESSe negative electrode exhibits a specific capacity of 534.2 mAh g−1 after 2000 cycles at a specific current of 0.4 A g−1, achieving a capacity retention of 94.3 %. HESSe exhibits high specific capacity and cycling stability at 30 A g−1, attributed to the multi-electron transfer mechanism of the conversion-type reaction and the stable crystal structure of high-entropy. Notably, HESSe achieves a fast-charging time of only 13 s at 100 A g−1. Comprehensive characterization revealed that HESSe maintains low and stable impedance while forming a stable SEI layer that improves interface compatibility between the electrode and electrolyte and reducing Na+ diffusion barriers. Furthermore, TXM testing confirmed that chemical stability of HESSe underpins its fast-charging capabilities. Additionally, HESSe effectively mitigates the substantial volume expansion, mechanical cracking, and surface side reactions that occur during long-term cycling. When employed as a positive electrode material in lithium metal batteries, HESSe delivers a specific capacity of 312 mAh g−1 at a specific current of 30 A g−1, along with a fast-charging capability of 37 s.

Methods

Materials synthesis

The Cu0.88Sn0.02Sb0.02Bi0.02Mn0.02S0.9Se0.1 (HESSe) was synthesized via a solvothermal method. 0.8068 g Cu(CH3COO)2·H2O, 0.0225 g Sn(CH3COO)2, 0.0277 g Sb(CH3COO)2, 0.0436 g Bi(NO3)3·9H2O, 0.0223 g Mn(CH3COO)2·4H2O and 1.3502 g thiourea were mixed in 50 mL of ethylene glycol (beaker A). In another beaker (beaker B), 0.0420 g selenium dioxide and 30 mL of ethylene glycol were added. After magnetic stirred for 4 h, the solution from beaker B was slowly dripped into beaker A and then stirred for an additional 30 min. Afterward, the mixture was put into 100 mL Teflon-lined autoclaves and heated at 180 °C for 12 h. After completion of the reaction, the precipitate was separated by centrifugation and washed six times with absolute ethanol and deionized water. Finally, the obtained powder (HESSe) underwent vacuum drying at 80 °C for 24 h. CuS0.9Se0.1 (LESSe) and CuS were prepared similarly without the addition of other metal ions or selenium dioxide.

X-ray diffraction

X-ray diffraction (XRD) was performed with a Bruker D8 Discover X-ray diffractometer (Cu Kα radiation, λ = 1.5406 Å). Rietveld refinement was conducted with FullProf software. In situ XRD (Bruker D8 Advance) measurement was conducted by in situ battery (BAT-XRD-HT, Ivan Zhitong Co., Ltd., China) at the first cycle over the 2θ range of 20° to 60° with a 0.01° step size, employing carbon paper (12 mm in diameter) as current collector. During the measurement, the specific current was set to 0.2 A g−1 in the voltage range of 0.1–3.0 V. For ex situ XRD measurements, the cells were disassembled in an argon-filled glove box after cycling at a specific current of 1.0 A g−1. The electrodes were rinsed with dimethyl glycol (DME) solvent and vacuum-dried at 40 °C for 6 h. The dried electrodes were transferred from the glove box to a sealed sample holder, and XRD measurements were conducted in air with the exposure time strictly limited to less than 1 h.

Morphology and microstructural information

Scanning electron microscopy (SEM, JEOL-7500F) and Transmission electron microscopy (TEM, JEOL JEM-F200) with energy dispersive X-ray (EDX) spectrometer. The powder samples were uniformly dispersed in anhydrous ethanol via ultrasonication for 20 min. A homogeneous suspension was obtained and subsequently deposited onto a silicon wafer using a micropipette. The specimens were vacuum-dried at ambient temperature for 10 h and then mounted on an SEM stage for morphological characterization. For post-cycled battery analysis, cells were disassembled in an argon-filled glovebox (H2O < 0.1 ppm, O2 < 0.1 ppm). The electrodes were repeatedly washed with DME to eliminate residual electrolytes, followed by 10 h vacuum drying prior to characterization. For TEM, the powder sample was ultrasonically dispersed in ethanol for 20 min to ensure homogeneity. A colloidal suspension was drop-casted onto a gold TEM grid (300 mesh) using a calibrated micropipette, followed by 10 h vacuum drying at 40 °C. For electrode characterization, surface-active materials were scraped from cycled electrodes in the argon glovebox, thoroughly ground in an agate mortar, and processed using identical specimen preparation protocols.

X-ray photoelectron spectroscopy

X-ray photoelectron spectroscopy (XPS) tests were conducted using ESCALAB 250Xi instrument. For ex situ XPS characterizations, carbon paper was used as current collectors and the ex situ electrodes were obtained by disassembling the coin cells at different de/sodiation states in an Ar-filled glove box, then dried for at least 10 h to remove the remaining electrolyte. The dried electrodes were first placed into a vacuum transfer vessel in glove box and then transferred into the XPS vacuum chamber (base pressure: 8 mbar). The electrodes were etched for 0, 20, and 40 s, corresponding to etching depths of 0, 5, and 10 nm, respectively.

Inductively coupled plasma-mass spectrometry experiments

Element content was analyzed by inductively coupled plasma-mass spectrometry (ICP-MS, Agilent 7800). The sample digestion was performed using a freshly prepared aqua regia system (nitric acid/hydrochloric acid, 1:3 by volume). An accurately measured volume of aqua regia was added to the sample, followed by continuous thermal digestion at 90 °C for 6 h under constant temperature conditions. After complete digestion, the reaction system was cooled to ambient temperature and subsequently subjected to stepwise dilution with deionized water (with resistivity of 18.2 MΩ·cm at 25 °C) to achieve appropriate detection concentrations. The processed samples were then analyzed by ICP-MS for simultaneous multi-element quantitative determination.

TXM experiments

TXM data was collected at beamline 18-ID (FXI) of National Synchrotron Light Source II (NSLSII), Brookhaven National Laboratory. The reconstruction, registration, and fitting of the 3D TXM-XNAES datasets were implemented by TXM-Sandbox package (https://github.com/xianghuix/TXM_Sandbox)51. Segmentation and visualization of the TXM results were carried out by the dragonfly software (version 2022.2, Comet technologies Canada Inc., Montreal, Canada. https://www.theobjects.com/dragonfly).

Brunauer–Emmett–Teller surface area and porosity

The Brunauer–Emmett–Teller (BET) specific surface area and pore structure parameters were characterized using a Micromeritics 3Flex surface characterization analyzer. Approximately 0.18 g of powdered sample was precisely weighed and loaded into a dedicated sample tube for analysis. The sample tube was subsequently connected to a vacuum degassing system and subjected to thermal pretreatment at 110 °C for 6 h under continuous vacuum to eliminate physisorbed contaminants. The specific surface area was calculated through multi-point BET model analysis, while the pore size distribution and pore volume were derived from the adsorption branch using the Barrett-Joyner-Halenda (BJH) method. All textural parameters including BET surface area, total pore volume, and pore size distribution were automatically generated by the integrated analysis software.

Density functional theory calculations

The structural and electronic properties of HESSe, LESSe and CuS were studied by the density functional theory (DFT) calculations implemented in the VASP code. The generalized gradient approximation (GGA) of Perdew-Burke-Ernzerhof (PBE) was applied as the exchange correlation function. The Grimme’s DFT-D3 method with the zero damping function was used to integrate van der Waals interactions. The plane-wave cutoff energy was set to 500 eV and a 3 × 3 × 2 k mesh was applied. Geometry optimization was carried out by using a conjugate gradient minimization until all the forces acting on ions were less than 0.02 eV Å−1 per atom. VESTA software was used to draw the three-dimensional structures of the crystal structures52.

Electrochemical characterization

Na||HESSe cells

The active material (70 wt.%) and acetylene black (20 wt.%) were manually ground for 10 minutes in an agate mortar under dry conditions at 25 °C. The mixture was then transferred to a 10 mL vial, where polyvinylidene fluoride (PVDF, 10 wt.%, HSV900, Arkema) binder and N-methyl-2-pyrrolidone (NMP, 99.9%, Aladdin) solvent were added, followed by magnetic stirring for 4 h. The slurry was uniformly coated onto pristine copper foil (14 μm in thickness, 99%, Hefei Kejing) without pretreatment using an automatic coating machine and vacuum-dried at 110 °C for 12 h, yielding electrodes with an active material mass loading of 0.7–1.7 mg cm−2. Thick electrodes (60 μm in thickness, 1.13 cm2 in area and 4.65 mg cm−2 in mass loading) were fabricated by homogenizing active material (80 wt.%), acetylene black (10 wt.%), and binder (10 wt.% carboxymethyl cellulose (CMC)/styrene-butadiene rubber (SBR) mixture at a 1:1 mass ratio in deionized water. All the dried electrodes were punched into 12 mm diameter discs and stored in an argon-filled glove box (H2O < 0.1 ppm, O2 < 0.1 ppm). The CR2032-type coin cells (Canrd Technology Co., Ltd) were assembled in an Ar-filled glove box using one stainless steel spacer (15.8 mm × 0.8 mm) and one spring (15.4 mm × 1.1 mm), with 200 μL of electrolyte added to each cell. The electrolyte was a solution of 1 M NaPF6 in DME (Battery grade, H2O < 20 ppm, Suzhou Dodochem Ltd. NP-035). Using 19 mm diameter porous glass fiber (Whatman, GF/D 1823-125, 675 μm in thickness, 2.7 μm in aperture) as separator and high-purity Na metal as counter electrode. The sodium foil (1.5 mm in thickness) was fabricated from sodium chunks (99.5%, Sinopharm Chemical Reagent Co., Ltd.) stored in petroleum-based protective medium. All procedures were conducted in an argon-filled glove box: Surface oxides were mechanically polished off using a ceramic knife, followed by pressing the sodium into uniform sheets under 5 MPa pressure. The sheets were then precisely punched into 16 mm diameter metallic discs for subsequent coin cell assembly. The galvanostatic charge/discharge were carried out on a LAND battery-test instrument (CT3002A) within 0.1–3.0 V. Capacity retention was determined by normalizing the charge capacity to the initial charge capacity of the first cycle. For specific currents of 6.0 A g−1 and 30 A g−1, the capacity retention values were referenced to the capacity after activation (3rd cycle). The first discharge and charge process are categorized as one complete cycle, and the coulombic efficiency is calculated based on the ratio of the charge capacity to the discharge capacity during this cycle.

Li||HESSe cells

The lithium metal cells employed a CR2025-type coin cell (without spacer or spring) featuring HESSe as the positive and lithium metal foil (16 mm × 1.0 mm) as the negative electrode. 200 μL of 1 M LiTFSI in DOL: DME = 1:1 v/v (Guangdong Canrd New Energy Technology Co., Ltd) was used as the electrolyte, and glass fiber was used as separator. The voltage range for constant current charge and discharge testing is 1.0–3.0 V.

Galvanostatic intermittent titration technique

The Galvanostatic Intermittent Titration Technique (GITT) tests were carried out on a LAND battery-test instrument (CT3002A). GITT was conducted at specific current of 50 mA g−1 for 15 min followed by a 3 h rest. The recording interval for each data point is 20 s.

Cyclic voltammetry experiments

Cyclic voltammetry (CV) test was measured on a CHI760E electrochemical workstation (Chenhua, Shanghai China) at a scanning rate of 0.2 mV s−1. CV measurements for investigating kinetic behavior were systematically conducted at sequential scan rates of 0.2, 0.4, 0.6, 0.8, and 1.0 mV s−1.

Electrochemical impedance spectroscopy experiments

Electrochemical impedance spectroscopy (EIS) measurements were conducted with an electrochemical workstation (Metrohm-Autolab, PGSTAT 302 N), employing a sinusoidal AC perturbation of 5 mV amplitude across the frequency spectrum from 0.1 Hz to 100 kHz. In situ EIS characterization was systematically integrated with potentiostatic intermittent titration technique (PITT) protocols, where impedance scans were initiated upon completion of each PITT step. The potential stepping sequence featured 0.4 V increments maintained for 3600 s equilibration periods. All EIS acquisitions comprised 50 logarithmically distributed frequency points per measurement cycle, ensuring consistent spectral resolution throughout the electrochemical interrogation process. The EIS data fitting was performed using ZView software (Version 2.70, Scribner Associates Inc.).

HESSe||NVP cells

For preparing the HESSe||NVP coin cells, the Na3V2(PO4)3 positive electrode (denoted as NVP, Shenzhen Kejing Star Technology Co., Ltd.) was prepared with active material (80 wt.%), acetylene black (10 wt.%), and PVDF (10 wt.%). The mixture was coated onto an Al foil (99% purity, 16 μm in thickness, Hefei Kejing), vacuum-dried at 110 °C for 12 h, and punched into 12 mm diameter discs (mass loading about 5.4 mg cm−2). After pre-cycling the Na||HESSe coin cells for five cycles at a specific current of 0.1 A g−1, the HESSe electrode was retrieved and paired with a pristine NVP electrode to assemble HESSe||NVP coin cells in an argon-filled glovebox. The N/P ratio is about 1.1, where the mass loading measured 5.4 mg cm−2 for NVP and 1.2 mg cm−2 for HESSe. The HESSe||NVP coin cells were constructed using a glass fiber separator with 200 μL of 1 M NaPF6 in DME electrolyte precisely injected into each cell.

The single-layer HESSe||NVP pouch cell was assembled using a 5.5 × 4.5 cm2 positive, 6.0 × 5.0 cm2 negative electrodes, and 6.5 × 5.5 cm2 polypropylene separator (Celgard 2500), where the areal mass loadings were measured to be about 2.6 mg cm−2 and 0.8 mg cm−2 for the positive and negative electrodes, respectively. Aluminum and nickel tabs were welded to the positive and negative electrode, respectively. During pouch cell assembly, 2 mL of 1 M NaPF6 in DME electrolyte was injected, and the cell was placed under continuous vacuum for 10 minutes to remove excess electrolyte, followed by immediate hermetic sealing. The HESSe||NVP pouch cells were subjected to galvanostatic charge-discharge testing after a 24 h resting period, under an external pressure of 32 kPa. None of the electrodes in the pouch cells underwent pre-activation processes. HESSe||NVP coin or pouch cells are tested in incubator (30 °C ± 0.5 °C) and the voltage range of 1.0–3.5 V, and the specific capacity is calculated based on the mass of the positive electrode. The coulombic efficiency is calculated based on the ratio of the discharge capacity to the charge capacity.

Data availability

The authors declare that all the relevant data are available within the paper and its Supplementary Information file or from the corresponding author upon request. Source data are provided with this paper.

References

Park, G. T. et al. Introducing high-valence elements into Cobalt-free layered cathodes for practical lithium-ion batteries. Nat. Energy 7, 946–954 (2022).

Li, M. & Lu, J. Cobalt in lithium-ion batteries. Science 367, 979–980 (2020).

Li, Y. et al. Interfacial engineering to achieve an energy density of over 200 Wh kg−1 in sodium batteries. Nat. Energy 7, 511–519 (2022).

Li, X. et al. An encapsulation-based sodium storage via Zn-single-atom implanted carbon nanotubes. Adv. Mater. 34, 2202898 (2022).

Li, W. et al. Synergetic Sn incorporation-Zn substitution in Copper-based sulfides enabling superior Na-ion storage. Adv. Mater. 36, 2305957 (2024).

He, Z. et al. Anode materials for fast charging sodium-ion batteries. Nano Energy 129, 109996 (2024).

Wan, Y. et al. Fast-charging anode materials for sodium-ion batteries. Adv. Mater. 36, 2404574 (2024).

Yue, X. et al. Layered metal chalcogenide based anode materials for high performance sodium ion batteries: A review. Renew. Sustain. Energy Rev. 185, 113592 (2023).

Shi, Y., Yang, B., Guo, X., Wu, X. & Pang, H. Copper sulfides and their composites for high-performance rechargeable batteries. Mater. Today Chem. 23, 100675 (2021).

Wang, L. et al. Li-free cathode materials for high energy density lithium batteries. Joule 3, 2086–2102 (2019).

Qiao, S. et al. Advanced anode materials for rechargeable sodium-ion batteries. ACS Nano 17, 11220–11252 (2023).

Yeh, J. W. et al. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299–303 (2004).

Li, C. et al. High entropy anodes in batteries: From fundamentals to applications. Energy Storage Mater. 71, 103468 (2024).

Liang, L. et al. High-entropy doping promising ultrahigh-Ni Co-free single-crystalline cathode toward commercializable high-energy lithium-ion batteries. Sci. Adv. 10, eado4472 (2024).

Zhao, C. et al. Suppressing strain propagation in ultrahigh-Ni cathodes during fast charging via epitaxial entropy-assisted coating. Nat. Energy 9, 345–356 (2024).

Fu, F. et al. Entropy and crystal-facet modulation of P2-type layered cathodes for long-lasting sodium-based batteries. Nat. Commun. 13, 2826 (2022).

Zhang, R. et al. Compositionally complex doping for zero-strain zero-cobalt layered cathodes. Nature 610, 67–73 (2022).

Ding, F. et al. Tailoring planar strain for robust structural stability in high-entropy layered sodium oxide cathode materials. Nat. Energy 9, 1529–1539 (2024).

Sarkar, A. et al. High entropy oxides for reversible energy storage. Nat. Commun. 9, 3400 (2018).

Liu, X. et al. High-entropy oxide: A future anode contender for lithium-ion battery. EcoMat 4, e12261 (2022).

Lin, L. et al. High‐entropy sulfides as electrode materials for Li‐ion batteries. Adv. Energy Mater. 12, 2103090 (2022).

Zhao, J. et al. Entropy‐change driven highly reversible sodium storage for conversion‐type sulfide. Adv. Funct. Mater. 32, 2206531 (2022).

Cheng, W. et al. Pressure-stabilized high-entropy (FeCoNiCuRu)S2 sulfide anode toward simultaneously fast and durable lithium/sodium ion storage. Small 19, 2301915 (2023).

Liu, C., Bi, J., Xie, L., Gao, X. & Rong, J. High entropy spinel oxides (CrFeMnNiCox)3O4 (x = 2, 3, 4) nanoparticles as anode material towards electrochemical properties. J. Energy Storage 71, 108211 (2023).

Wang, J. et al. Ultra-sleek high entropy alloy tights: Realizing superior cyclability for anode-free battery. Adv. Mater. 36, 2308257 (2024).

Wang, K. et al. Synergy of cations in high entropy oxide lithium ion battery anode. Nat. Commun. 14, 1487 (2023).

Li, S., Tong, L., Zhang, B. & Fu, X. First-principles study of high-entropy sulfides and their alkali metal-doped modification as cathode material for sodium-ion batteries. ChemPhysChem 25, e202300999 (2024).

Yue, X. et al. A novel vanadium-mediated MoS2 with metallic behavior for sodium ion batteries: Achieving fast Na+ diffusion to enhance electrochemical kinetics. Chem. Eng. J. 417, 128107 (2021).

Li, E. et al. VS2/Bi2S3 spring-type heterointerfaces hollow microspheres with spatial confinement and vacancy defects for fast-charging and ampere-hour scale pouch sodium-ion hybrid capacitors. Adv. Energy Mater. 14, 2405674 (2024).

Zheng, T., Hu, P., Wang, Z. & Guo, T. 2D amorphous Iron selenide sulfide nanosheets for stable and rapid sodium-ion storage. Adv. Mater. 35, 2306577 (2023).

Li, Y. et al. Ether-based electrolytes for sodium ion batteries. Chem. Soc. Rev. 51, 4484–4536 (2022).

Li, H., Su, Y., Sun, W. & Wang, Y. Carbon nanotubes rooted in porous ternary metal sulfide@N/S-doped carbon dodecahedron: Bimetal-organic-frameworks derivation and electrochemical application for high-capacity and long-life lithium-ion batteries. Adv. Funct. Mater. 26, 8345–8353 (2016).

Zhao, W. et al. Hierarchical architecture engineering of branch-leaf-shaped cobalt phosphosulfide quantum dots: Enabling multi-dimensional ion-transport channels for high-efficiency sodium storage. Adv. Mater. 36, 2305190 (2024).

Zhao, W. et al. Functional integration of hierarchical core–shell architectures via vertically arrayed ultrathin CuSe nanosheets decorated on hollow CuS microcages targeting highly effective sodium-ion storage. J. Mater. Chem. A 9, 27615–27628 (2021).

Ali, Z. et al. Cobalt selenide decorated carbon spheres for excellent cycling performance of sodium ion batteries. Energy Storage Mater. 13, 19–28 (2018).

Shan, H. et al. Controllable heterojunctions with a semicoherent phase boundary boosting the potassium storage of CoSe2/FeSe2. Adv. Mater. 33, 2102471 (2021).

Dong, W. et al. Superwettable high-voltage LiCoO2 for low-temperature lithium ion batteries. ACS Energy Letters 8, 881–888 (2023).

Lv, Z. et al. Quasi‐topological intercalation mechanism of Bi0.67NbS2 enabling 100 C fast‐charging for sodium‐ion batteries. Adv. Energy Mater. 13, 2300790 (2023).

Huang, S. et al. Promoting highly reversible sodium storage of Iron sulfide hollow polyhedrons via cobalt incorporation and graphene wrapping. Adv. Energy Mater. 9, 1901584 (2019).

Yang, C. et al. V5S8-graphite hybrid nanosheets as a high rate-capacity and stable anode material for sodium-ion batteries. Energy Environ. Sci. 10, 107–113 (2017).

Fu, R. et al. In situ atomic-scale deciphering of multiple dynamic phase transformations and reversible sodium storage in ternary metal sulfide anode. ACS Nano 17, 12483–12498 (2023).

Cao, L. et al. Heterointerface engineering of hierarchical Bi2S3/MoS2 with self‐generated rich phase boundaries for superior sodium storage performance. Adv. Funct. Mater. 30, 1910732 (2020).

Wu, J. et al. Rod-shaped Cu1.81Te as a novel cathode material for aluminum-ion batteries. Dalton Trans 49, 729–736 (2020).

Pei, X. et al. Single-crystal Copper sulfide anode with fast ion diffusion for high-rate sodium-ion batteries. ACS Appl. Energy Mater. 6, 8132–8140 (2023).

Li, T. et al. Deciphering the performance enhancement, cell failure mechanism, and amelioration strategy of sodium storage in metal chalcogenides‐based andes. Adv. Mater. 34, 2314271 (2024).

Yang, S. H., Park, S. K. & Kang, Y. C. Mof-derived CoSe2@N-doped carbon matrix confined in hollow mesoporous carbon nanospheres as high-performance anodes for potassium-ion batteries. Nanomicro Lett. 13, 9 (2020).

Zou, Z. et al. High-performance alkali metal ion storage in Bi2Se3 enabled by suppression of polyselenide shuttling through intrinsic Sb-substitution engineering. ACS Nano 17, 13769–13783 (2023).

Mcdowell, M. T., Lee, S. W., Nix, W. D. & Cui, Y. 25th anniversary article: Understanding the lithiation of Silicon and other alloying anodes for lithium-ion batteries. Adv. Mater. 25, 4966–4985 (2013).

Li, A.-M., Zavalij, P. Y., Omenya, F., Li, X., & Wang, C. Salt-in-presalt electrolyte solutions for high-potential non-aqueous sodium metal batteries. Nat. Nanotechnol. 20, 388–396 (2025).

Li, A.-M. et al. Asymmetric electrolyte design for high-energy lithium-ion batteries with micro-sized alloying anodes. Nat. Energy 9, 1551–1560 (2024).

Xiao, X., Xu, Z., Lin, F. & Lee, W. K. TXM-Sandbox: An open-source software for Transmission X-ray Microscopy data analysis. J. Synchrotron Radiat. 29, 266–275 (2022).

Momma, K. & Izumi, F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 44, 1272–1276 (2011).

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 22472062 and 22372063), Natural Science Foundation of Fujian Province (2019J05091, 2023T3024) and Key R&D Program of Xiamen (3502Z20231059). Argonne National Laboratory is operated for DOE Office of Science by UChicago Argonne, LLC, under contract number DE-AC02-06CH11357. K.A. and G.X. thank the support from Clean Vehicles, US-China Clean Energy Research Centre (CERC-CVC2). This research used beamline 18-ID of the National Synchrotron Light Source II, a US DOE Office of Science user facility operated for the DOE Office of Science by Brookhaven National Laboratory under contract No. DE-SC0012704.

Author information

Authors and Affiliations

Contributions

F.F., M.D.Y. and G.L.X. conceived the idea and designed the experiments; S.F.Z. prepared electrode materials, conducted the electrochemical measurements and the DFT calculations. W.H.Z. and X.H.X. performed and analysis TXM data, X.G.F. performed and analysis in situ XRD data. J.T.L., Q.W.Z., W.H.Y., H.W.C., J.Y.Z. and S.G.S. helped with data analysis. S.F.Z., W.H.Z. and G.L.X. wrote and revised the manuscript; F.F., H.W.C., G.L.X. and K.A. managed the project; all authors contributed to discussions and paper revisions.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Zhihua Xiao and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, S., Zuo, W., Fu, X. et al. High-entropy sulfoselenide as negative electrodes with fast kinetics and high stability for sodium-ion batteries. Nat Commun 16, 4052 (2025). https://doi.org/10.1038/s41467-025-59078-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-59078-6