Abstract

Thick-panel origami structures are able to deploy into expansive configurations, making them suitable for industrial applications such as deployable stadium domes, water-tight roof tiling, sun shields, furniture, antennas, solar arrays, space telescopes, etc. Existing methods often introduce structural complexities or fail to ensure seamless surfaces, limiting their practicality. Here our process involves modifying valley-crease panels and extending adjacent panels to eliminate grooves, thus achieving a seamless surface. The paper presents the geometric conditions for ensuring motion compatibility and analyzes the kinematics of the modified structures. Additionally, an approach for minimizing the number of top panels is proposed to simplify fabrication and enhance lightweight design. Prototypes of these designs are 3D-printed to validate the concepts. The methods and results offer valuable insights for developing deployable structures with customizable shapes and enhanced functionality.

Similar content being viewed by others

Introduction

Origami is an ancient art. Rigid origami is a specialized branch of origami where the paper’s facets remain rigid, neither bending nor stretching during the folding process. The transformation of shape occurs exclusively along the creases. This type of origami offers significant potential for applications across various fields, including space exploration1,2, metamaterial3,4,5,6,7,8, robots9,10,11, rotors12, and deployable structures13,14. In addition to flat paper folding, origami tubes are another important research field15,16. These structures have applications in areas such as shelters17, energy absorption structures18,19,20, robot arms21,22, self-locking deployable tubular structures23, etc. As a result, they have garnered considerable interest from researchers across diverse disciplines.

By modeling creases as rotational joints and paper facets as rigid links, origami patterns can be understood as mechanisms capable of structural transformation during folding or deployment24. This perspective allows mechanism theory to be applied to analyze existing origami patterns25 or to design innovative ones. Conversely, origami also serves as an inspiration for developing mechanisms26.

Applying origami to specific practical scenarios can be highly complex and challenging, particularly when thick materials are required to ensure motion accuracy and structural robustness. The accumulation of material thickness during folding causes structure interference, making folding or deployment difficult27,28. To overcome these obstacles, various thickness-accommodation strategies have been developed, including the use of compliant joints29,30,31, offsetting panels or joints32,33,34, splitting creases35,36,37,38,39, etc. These techniques aim to mitigate panel interference and expand the feasibility of origami-inspired designs in engineering applications.

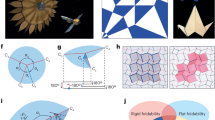

Many applications, such as deployable roofs, deployable kitchen furniture, and convertible cars also require seamless (gap-free) surfaces after deployment to ensure that water and food do not penetrate or accumulate in the crevasses formed by joints. For antennas, any microscopic imperfections, including gaps, protrusions, or depressions on the antenna’s reflective surface will critically degrade high-frequency signal processing fidelity and substantially compromise satellite operational performance. However, conventional thick-panel origami often results in uneven surfaces, as illustrated in Fig. 1a. The top surface is not seamless due to the presence of grooves, with the yellow sections interrupted by joints between the panels, which are visible as white areas.

a Conventional thick-panel origami with an uneven surface interrupted by joints between the panels. b The origami structure with seamless surface based on the structure in (a). c Tessellation of the origami structure in (b) with higher fold-to-deploy efficiency. d Curved-trajectory origami structure with a seamless surface.

To overcome this limitation, researchers have proposed various modifications. One method constructs structures with uniformly thick panels, but this approach requires hinges on both sides, which disrupts surface continuity40. Another method uses virtual hinges, replacing the front-facing hinges with virtual counterparts and shifting all physical hinges to the back. This achieves a seamless front surface but increases the number of physical hinges and reduces structure stability41,42. Subsequent studies added supporting frames to these structures inspired by the Miura-ori origami tubes. However, cylindrical joints were used to resolve kinematics compatibility issues, which significantly increased structural complexity and made the direct design of deployable structures based on origami tubes more challenging43.

This paper presents an approach to constructing deployable structures inspired by origami tubes. By applying mechanism theory, the study reduces overconstraints and simplifies the structure rather than adding complexity. Through comprehensive kinematic analysis, this research develops a systematic method for modifying conventional origami tubes by adjusting so-called valley-crease (concave folding) panels and extending adjacent panels. This modification eliminates surface grooves entirely, achieving a seamless planar top layer. The technique proposed in this paper is specifically designed for certain kinematically compatible patterns. However, it offers significant adjustability and is well-suited for a wide range of applications.

Around so-called mountain creases (convex folding), panels can either remain unmodified or be altered to reduce the number of panels. The paper derives geometric conditions to ensure motion compatibility and provides a detailed kinematic analysis of the modified structures. In particular, curved-trajectory origami, which refers to origami tubes deploying along a curved trajectory, is analyzed alongside linear-trajectory origami structures. The study also examines their symmetrical tessellation patterns, enhancing fold-to-deploy efficiency and expanding their practical applications, as shown in Fig. 1b–d.

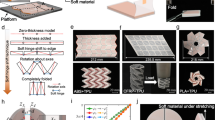

The fundamental concept is illustrated in Fig. 2. The original origami tube in Fig. 2a(i) consists of a flat top layer and an intermediate-folding bottom layer for support. To develop thick-panel structures, a quasi-flat-folded tube in Fig. 2a(ii) is first achieved by converting paper facets into thick panels and creases into rotational joints. However, the resulting thick-panel structure in Fig. 2a(iii) retains grooves that hinder applications due to the lack of a seamless top surface37. To address this, the unsmooth green panel and its relevant joints are removed, while nearby panels are extended, forming a seamless top surface in Fig. 2b. This method allows for versatile shapes, such as the seamless quadrangle top surface in Fig. 2c, and can be further applied to curved-trajectory origami structures in Fig. 2d.

a Transformation of an origami tube into a thick-panel structure. i Original origami tube in the fully deployed state with a flat top layer and intermediate-folding bottom layer. ii Quasi-flat-folded tube as an intermediate step. iii Thick-panel structure with rotational joints and motion-compatible grooves, though lacking a seamless top surface. b Refined thick-panel structure with a seamless top surface, achieved by removing the uneven green panel and extending neighboring panels. c Seamless thick-panel structure adapted into a quadrangular top surface. d Application of the seamless design approach to a curved-trajectory origami structure, showcasing its adaptability to complex geometries.

Here, we show a method for transforming origami tubes into thick-panel structures while ensuring motion compatibility. By eliminating structural grooves, origami structures with seamless surfaces can be achieved, broadening the applicability of origami-based engineering structures.

Results

Thick-panel origami tube

A methodology for constructing deployable thick-panel origami tubes was proposed in ref. 37. An example in Fig. 3a consists of three layers and four sections, with the vertices of each section labeled by Ai, Bi, Ci, or Di, \(i{{{\rm{\in }}}}\)[1,2,3,4]. For simplicity, the max value of i is assumed to be 4, though it can be any even number for alternative tube designs. This methodology establishes three key geometric conditions for the tube: (1) each section must be a planar symmetric polygon; (2) the creases between two sections must be parallel to one another; (3) two adjacent creases around a section must lie in a plane perpendicular to that section, for instance, the planes AiBiCi are perpendicular to section-Bi.

a A general zero-thickness origami tube with rigid foldability. Facets containing Ai, Bi, Ci, and Di (i = 1,2,4) belong to the top layer, and facets containing Ai, Bi, Ci, and Di (i = 2,3,4) belong to the bottom layer. The top layer can fully deploy into a flat state, enabling further structural modifications. b Alternative Miura-ori tube and its rigid-foldable thick-panel origami tube derived from (a). The facets are replaced with thick panels, and the creases are converted into rotational joints. To avoid structural interference near valley creases (e.g., C1C2 and D1D2), material from adjacent panels of valley creases is removed. c Tessellation of the basic unit from (b). The top surface is not seamless due to the presence of grooves, which are evident in Section A around the joints M and N. d 3D-printed model of thick-panel origami. The yellow surfaces form a seamless layer, while the white areas consist of bevel structures and rotational joints. The blue panels form the back frames and belong to the bottom layer. The physical model is presented in the attached video, S1.

The origami tube shown in Fig. 3b represents a special case of the structure in Fig. 3a. The geometrical conditions for Fig. 3b are:

This cube has two layers, the top layer containing Ai, Bi, Ci, Di (i = 1,2,4) and the bottom layer containing Ai, Bi, Ci, and Di (i = 2,3,4). To allow the top layer to deploy into a flat state, it is assumed A1 A2 < A2 A3. A deployable thick-panel origami tube is constructed by replacing the facet with thick panels and the creases with rotational joints. However, some modifications are necessary to prevent structural interference, especially around valley creases. For example, along valley creases C1C2 and D1D2, material from their adjacent panels is removed, such as the green panel C1C2D2D1, which has a cuneiform section shape.

Figure 3c illustrates a tessellation of the basic unit in Fig. 3b. The top surface of this tessellated structure is not seamless and features some grooves, which are particularly visible in Section A. A 3D-printed model of this design is shown in Fig. 3d. In this physical model, the yellow surface is seamless, and the white area among it contains the bevel structures and joints. Thus, the whole top surface of this structure is not seamless because of these grooves and joints. This characteristic may limit some applications of thick-panel origami.

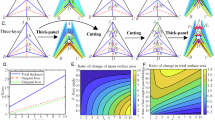

Geometrical conditions for seamless origami

To achieve a seamless top surface, our focus is on modifying the top layer while keeping the bottom layer unchanged. To eliminate the need for material removal around valley creases, these valley creases are removed entirely, and their adjacent panels are extended to fill the resulting gaps. The process of modifying the top layer is illustrated in Fig. 4a. The green panels containing valley creases are removed, while green panels with mountain creases are retained. The yellow and blue panels are then extended to occupy the spaces previously taken by the removed green panels. Despite these modifications, the motions of the yellow and green facets in their three states in Fig. 4a remain unchanged. A detailed kinematic analysis of this process can be found in Supplementary Note 1.

a Modification of the top layer pattern, removing green panels with valley creases from the top layer and the extension of adjacent yellow and blue panels to fill the space. Green panels with mountain creases remain intact. b The corresponding modifications for thick panels. The yellow panel is extended, represented by a transparent block, while the blue panel is adjusted to fit. Material from the bottom layer is selectively removed to prevent motion interference. c A modified unit with a seamless top surface and its folding process. Virtual joints M and N guide the consistent rotation of the yellow and blue panels, ensuring symmetric motion about the perpendicular bisector of line MN. d A detailed view of motion interference between the yellow and blue panels. The coordinate system X1NY1 is fixed to the blue panel as the base, and the coordinate system X2MY2 to the yellow panel as the moving platform. Points P and Q coincide at the flat state, while the motion path of P in X1NY1 is represented as a solid gray line. e The effect of panel extension length, i.e., t/d, on the panel design. For t/d = 0.5, the angularity of the tangent line remains zero, so the design parameter must also be zero, which is incompatible with thick-panel structures. Thus, asymmetrical extensions of the yellow and blue panels are essential. f The relationship between panel thickness h/d and the angularity of the tangent line. Decreasing h/d increases, with approaching as h/d nears zero.

The corresponding modifications to thick panels based on Fig. 4a are shown in Fig. 4b. The yellow panel is extended with the added portion represented by a transparent block. The blue panel is adjusted to match the yellow panel and fill the remaining space. As the yellow panel becomes larger, some material from the panels in the bottom layer may be removed to avoid motion interference. However, from a mechanism perspective, the rotational axes of the joints determine the motion of the linkages. Altering the physical shapes of the panels while maintaining the positions of the rotational joints does not affect the folding motion of the overall structure. Additionally, more material can be removed to achieve a lightweight design. A detailed discussion of the design method is provided in Supplementary Note 5.

A single unit with a flat surface and its folding process is shown in Fig. 4c. The structure is seamless only in the fully deployed state, which is the working state. Comparing Fig. 3c with Fig. 4c, M and N represent the positions of virtual joints. The yellow panel rotates around M, while the blue panel rotates around N. The motions of these two panels are symmetrical to the perpendicular bisector of the line MN, i.e., the angle θ between the yellow panel and the line MN is equal to the angle between the blue panel and the line MN.

The motion interference may occur in the adjacent area between the yellow and blue panels. A detailed view of this part is shown in Fig. 4d. In this figure, P is the top-right point of the yellow panel, and Q is the left-top point of the blue panel. At the flat state, P and Q coincide. The coordinate system X1NY1 is fixed to the blue panel, while the coordinate system X2MY2 is fixed to the yellow panel. These panels have four design parameters: h, t, d, and α. The thickness of the panel is h, the length of MN is d, and the length of PM projecting into axis X2 is t. The wedge angle of the blue panel is α. The section design of the panel in Fig. 4d is the simplest example for illustrating the method and proposing the geometrical conditions. More examples are presented in Supplementary Note 3, with animations included in the supplementary video, S2. Supplementary Code 1 provides the MATLAB codes that offer further details of the algorithm.

By treating the coordinate system X1NY1 as the base and the coordinate system X2MY2 as the moving platform, the mechanism theory can be used to analyze the motion of the yellow panel relative to the blue panel. The motion path of P in X1NY1 can be obtained and presented by a gray solid line in Fig. 4d(ii), with Q as the starting point of this path. The angle between the tangent line of the motion path at Q and the axis X1 is γ. The geometric condition for avoiding motion interference is given as

The analysis of getting γ is in Supplementary Note 2, and the equation is

Assuming d is constant, the effect of h and t can be analyzed. When the projection of P lies at the midpoint of MN, i.e., the yellow and blue panels are symmetric from the top view with t/d = 0.5. γ is always zero regardless of the panel thickness, as shown in Fig. 4e. This condition makes α>0 impossible for thick-panel structures. Therefore, the extended portions of the yellow and blue panels should not be symmetrical. For one panel with a given thickness, increasing t helps increase γ, so as to α.

The relationship between h and γ is shown in Fig. 4f. For one given thick panel, decreasing h helps increase γ. If the panel thickness approaches zero, γ can be π/2. Therefore, the design parameter α can be adjusted by selecting appropriate values of h and t.

Modification of seamless origami and its tessellation

The model shown in Fig. 4c already features a seamless top surface. Building on this structure, additional shapes can be created. One example is presented in Fig. 5a. The positions of the joints determine the motion of the linkages, so they must remain unchanged. However, the shapes of the panels in the top layer can be modified to suit specific applications. In Fig. 5a, the transparent blocks represent the extended portions of the original panels. After this modification, an alternative structure is obtained. Compared to the model in Fig. 4c, the top surface of the updated structure is more uniform, making it better suited for various applications.

a A modified structure is derived from the model in Fig. 4c. Transparent blocks represent the extended parts of the original panels. While the joint positions remain unchanged to preserve motion, the panel shapes are adjusted, resulting in a more regular and application-ready top surface. The key parameters of this structure is h = 3.5, d = 20.5, and t = 20.5. More details can be seen in the 3D drawings in the Supplementary Files. b The tessellation of the unit in (a). c A 3D-printed physical model of the modified structure in (b). The yellow top layer forms a seamless, groove-free surface in the fully deployed state. Blue panels in the bottom layer provide structural stiffness and serve as the supporting frame. d Symmetric tessellation for fold-deploy efficiency. A tessellation pattern incorporates two modified patterns from Fig. 4a. A gray rectangle highlights one unit. The symmetric arrangement increases the fold-deploy ratio, optimizing the structure for practical applications. e A 3D-printed physical model of the tessellated structure. The blue bottom panels act as a supporting back frame, while the modified top surface provides a seamless, deployable platform. The physical models are presented in the attached video, S1.

A physical model of the modified structure is shown in Fig. 5c. In its fully deployed state, the yellow area represents the top surface, which is free of grooves. The panels in the bottom layer serve as a supporting frame to enhance the structural stiffness. These panels are 3D-printed using blue material.

Through symmetric tessellation, the fold-to-deploy ratio of the structure can be further improved. The pattern in Fig. 5d consists of two patterns derived from Fig. 4a, with one highlighted in a gray rectangle. The modification process follows the same approach as before. First, the green panels with valley creases are removed, and their adjacent panels are extended under Eqs. 1 and 2. The panels in the bottom layer continue to act as a supporting frame. A physical 3D-printed model of this tessellated structure is shown in Fig. 5e. A detailed discussion about this tessellation is presented in Supplementary Note 7.

Closed-loop deployed seamless origami

In addition to linear-trajectory origami structures, curved-trajectory origami structures can also be developed. Instead of using the typical Miura-ori pattern, a curved-trajectory pattern can be created by symmetrizing the basic unit, as shown in Fig. 6a. For simplicity, we assume that all units are identical, with A1A2 = A2A3 and B1B2 = B2B3. We also assume that \({\alpha }_{1} < \pi /2,{\beta }_{1} < \pi /2,{\beta }_{1} > {\alpha }_{1}\) to specify the curve bending direction. Half of the folding unit is denoted in the figure. Point O is the intersection point of lines A1A3 and B1B3. In the folding state, plane A1A2A3 is perpendicular to plane A1B1O, and so is plane B1B2B3 because of the symmetry of this pattern. ρ is the folding angle which is the dihedral angle between planes A1B1O and A1A2B2B1. The dihedral angle between the planes A1A2A3 and B1B2B3 is \({\delta }\) which is obtained in Supplementary Note 4.

a A curved-trajectory origami pattern based on symmetric basic units. Each unit is assumed to be identical and has two design parameters for the basic unit, and. The geometric relationships between folding angles and dihedral angles are defined to create a curved-trajectory structure. b Folding process and intersection analysis of closed-loop deployed origami patterns. The blue solid curve represents a pattern with intersections due to violating the geometric condition, rendering the design immobile. In contrast, the green dashed line satisfies the condition, enabling seamless folding and mobility. c Modified curved-trajectory pattern for thick panels. The pattern design satisfying Eq. 5 is suitable for constructing thick-panel curved-trajectory origami structures. Additional facets are added to adapt the structure, preparing it for thick-panel conversion. d A thick-panel structure derived from the modified curved-trajectory pattern. Grooves are visible in the top view, arising from the folding mechanism of the thick panels. e An alternative deployable structure based on the mechanism in (d). The seamless top surface is achieved by applying methods used for straight origami structures in Figs. 4 and 5. The physical models are presented in the attached video, S1.

The number of units is n. So the overall angels of the whole structure is

If we use this pattern to design a closed-loop deployed structure, the max value of \(\delta\) is \({{\delta }}_{\max }={{\beta }}_{1}-{\alpha }_{1}\) which is obtained at the flat-deployed state. Otherwise, ξ exceeds 2π and this means some intersections happen during folding. To avoid this, \({\delta }\) should decrease during the folding process and its derivative \({\delta }^{{\prime} }\le 0\) as analyzed in Supplementary Note 4. So, the geometrical condition is

Some examples are presented in Fig. 6b. When \({\alpha }_{1}\) and \({\beta }_{1}\) do not satisfy Eq. 5, like the blue solid curve line and its corresponding origami patterns, the intersections happen from the state (i) to (iii). Based on these design parameters, the rigid origami pattern or its corresponding thick-panel structure is immobile. The green dash line and its corresponding origami pattern satisfy Eq. 5, and there is no intersection during the folding process. So, these patterns are available for designing thick-panel structures.

There is a pattern design satisfying Eq. 5 in Fig. 6c, and it can be used for the top layer of a curved-trajectory origami structure. According to the design process in Fig. 2, this pattern should be modified by adding some facets first. The modified pattern is also shown in Fig. 6c. Then, one thick-panel structure based on this modified pattern and its folding process is shown in Fig. 6d. From the top view of the structure, some grooves can be seen. In order to get a seamless top surface, the approach for the straight origami structure in Fig. 4 is also suitable for this curved-trajectory structure. Following the steps in Fig. 4a, b and Fig. 5a, b gives the around flat surface structure in Fig. 6e.

Two factors influence the size of the central hole in the structure depicted in Fig. 6e: the width of the green panel and the thickness of the panels. Reducing these two parameters helps minimize the hole size. In theory, if both parameters approach zero, the hole size can also be reduced to zero. So, this central hole in the thick origami structure can not be filled. Attempting to do so would result in all 18 panels coming into contact with one another, leading to significant intersection issues. To address this challenge, the spatial relationships between each panel and the remaining 17 panels must be carefully analyzed. These intricate spatial interactions greatly complicate the structural design process.

Minimizing top panels

The core concept of this paper is to remove the panels containing valley creases. In the earlier process, only the necessary and minimum number of panels were removed. However, in some instances, reducing the number of top panels further can simplify fabrication. Based on the analysis in Supplementary Note 1, all green panels can be removed without altering the motion of the remaining panels. The detailed kinematic analysis is also provided in Supplementary Note 1. While fewer connections between panels may reduce the overall stiffness of the structure, this section introduces a methodology for minimizing the number of top panels, allowing designers to balance panel reduction with structural stiffness based on specific application requirements.

Figure 7a illustrates the modification process, which is similar to Fig. 4a. The key difference is that all green panels are removed in Fig. 7a. The remaining panels are extended along both the left and right sides to fill the spaces previously occupied by the green panels. The corresponding thick-panel design is shown in Fig. 7b. For the valley crease areas, the design parameters must satisfy Eq. 1, while for the mountain crease areas, the extension length of the panels is arbitrary. A detailed explanation is provided in Supplementary Note 6. The modifications to the blue and yellow panels, as well as the process of transforming the basic unit into a seamless top surface structure, are also demonstrated in Fig. 7b.

a The modification process of panel reduction in the top layer of the origami structure. All green facets in the top layer are removed. The remaining yellow and blue panels are extended along both left and right sides to fill the gaps, simplifying the structure while maintaining its folding motion. b Thick-panel design for the facet-reduced origami structure. The yellow and blue panels are modified for the reduced origami structure design, and transparent blocks represent extension parts. Design parameters are adjusted to satisfy geometric conditions in Eq. 1 and Supplementary Note 6. The resulting structure achieves a seamless top surface. c A structure with fewer top panels. The modified structure has only 12 top panels, compared to 18 in the original design in Fig. 5c. This reduced-panel structure retains similar folding motion and appearance but decreases fabrication complexity. d Adjustable top surface design. The top panels can take on various shapes, such as an ellipse or other complex geometries, while maintaining the rotational axes of the joints for a consistent folding process. The physical models are presented in the attached video, S1.

The resulting structure, with fewer top panels, is shown in Fig. 7c. Compared to the structure in Fig. 5c, the appearance and folding motion remain essentially unchanged. However, the structure in Fig. 7c has 12 top panels, whereas the structure in Fig. 5c contains 18 panels.

Building on the structure in Fig. 7b, the design of the panels can be customized into any shape, but the rotational axes of the joints remain unchanged. This adjustability allows the top surface to take on various shapes, such as an ellipse or other complex geometries. An example of such a design is presented in Fig. 7d.

Discussion

This paper presents a comprehensive approach to designing and optimizing thick-panel origami structures with seamless top surfaces, addressing challenges in deployable systems for advanced engineering applications. Starting from a general origami tube design, the study focuses on modifying valley-crease panels and extending adjacent panels to eliminate surface grooves, thus achieving a seamless and functional top layer. Geometric conditions are derived to ensure motion compatibility, and detailed kinematic analyses are performed to validate the modifications.

The research explores both linear-trajectory and curved-trajectory origami structures, demonstrating how tessellation can enhance the fold-deploy ratio. Additionally, a methodology for reducing the number of top panels is introduced, simplifying fabrication, enabling lightweight designs, and providing adjustability for creating customizable shapes such as ellipses or other complex geometries. The rotational joints can also be replaced by compliant hinges to reduce the structure’s weight.

The methodology in this paper is not limited to flat top surfaces, and it offers greater adjustability. The variable thickness of the top-layer panels would allow for the creation of free-form curved surfaces. Additionally, utilizing an intermediate folding state provides another approach to generating non-flat top surfaces. A detailed discussion about this is presented in Supplementary Note 8.

Prototypes of the proposed designs are 3D-printed to verify their feasibility and effectiveness. The study not only advances the understanding of thick-panel origami mechanisms but also provides practical solutions for creating deployable structures with seamless surfaces, making them suitable for a wide range of industrial applications.

While structural integrity is not the primary focus of this paper, it remains a compelling and highly practical topic for future research. For example, the prototypes in Fig. 5c and Fig. 7c exhibit a high degree of similarity, with the key distinction being the number of panels in the top layer. Both structures follow the same deployment process and maintain identical dimensions in their fully folded and fully deployed states. Investigating their structural performance and load-bearing capacity can provide valuable insights for real-world engineering applications.

Methods

All prototypes in this study were fabricated using FDM (Fused Deposition Modeling) 3D printers with PLA filaments. The outer surfaces are covered with colorful films to emphasize the seamless surfaces. Rotational joints were printed integrally with the panels, and 2 mm diameter steel pins were inserted into pre-printed holes to securely connect the components. All 3D drawings are provided in STEP format in Supplementary Data 1.

Any commercial 3D printer, including FDM, SLS (Selective Laser Sintering), SLA (Stereolithography Apparatus), etc., can be used to replicate the prototypes presented in this study by printing the provided STEP files. We chose FDM technology primarily due to its low cost and wide accessibility.

Most of the components were printed using the Bambu X1C printer. For the larger parts shown in Figs. 5e and 6e, which exceeded the build volume of the Bambu printer, we used the Raise3D Pro3 printer. All PLA filaments used in this work were sourced from the same manufacturer, 3D AURA. There are no special material requirements. However, it is recommended to use filaments suggested by the printer manufacturer for optimal print quality. More detailed information regarding the design and fabrication processes of these prototypes is provided in Supplementary Note 5.

Data availability

The data that support the findings of this study are available in the main text or the Supplementary Files.

Code availability

The codes that support the findings of this study are available from the corresponding author upon reasonable request.

References

Georgakopoulos, S. V. et al. Origami antennas. IEEE Open J. Antennas Propag. 2, 1020–1043 (2021).

Miura, K. Method of packaging and deployment of large membranes in space. Inst. Space Astronaut. Sci. Rep. 618, 1–9 (1985).

Schenk, M. & Guest, S. D. Geometry of Miura-folded metamaterials. Proc. Natl. Acad. Sci. USA 110, 3276–3281 (2013).

Jamalimehr, A., Mirzajanzadeh, M., Akbarzadeh, A. & Pasini, D. Rigidly flat-foldable class of lockable origami-inspired metamaterials with topological stiff states. Nat. Commun. 13, 1–14 (2022).

Feng, H., Ma, J., Chen, Y. & You, Z. Twist of tubular mechanical metamaterials based on waterbomb origami. Sci. Rep. 8, 1–13 (2018).

Silverberg, J. L. et al. Using origami design principles to fold reprogrammable mechanical metamaterials. Science 345, 647–650 (2014).

Gao, Y., Kang, X., & Li, B. Programable mechanical metamaterials with tunable Poisson’s ratio and morphable stiffness. Compos. B Eng. 292, 112089 (2024).

Chirikjian, G. S. Group-theoretic analysis of symmetry-preserving deployable structures and metamaterials. Philos. Trans. A 382, 20230352 (2024).

Faber, J. A., Arrieta, A. F. & Studart, A. R. Bioinspired spring origami. Science 359, 1386–1391 (2018).

Lee, D. Y., Kim, J. K., Sohn, C. Y., Heo, J. M. & Cho, K. J. High–load capacity origami transformable wheel. Sci. Robot. 6, eabe0201 (2021).

Felton, S., Tolley, M., Demaine, E., Rus, D. & Wood, R. A method for building self-folding machines. Science 345, 644–646 (2014).

Moses, M. S., Ackerman, M. K. & Chirikjian, G. S. Origami rotors: Imparting continuous rotation to a moving platform using compliant flexure hinges. International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, American Society of Mechanical Engineers V06BT07A037 (ASME, 2013).

Chen, Y., Yan, J. & Feng, J. Geometric and kinematic analyses and novel characteristics of origami-inspired structures. Symmetry 11, 1101 (2019).

Jia, G., Li, B. & Dai, J. S. Oriblock: The origami-blocks based on hinged dissection. Mech. Mach. Theory 203, 105826 (2024).

Liu, S., Lv, W., Chen, Y. & Lu, G. Deployable prismatic structures with rigid origami patterns. J. Mech. Robot. 8, 031002 (2016).

Yasuda, H., Yein, T., Tachi, T., Miura, K. & Taya, M. Folding behaviour of Tachi–Miura polyhedron bellows. Proc. R. Soc. A Math. Phys. Eng. Sci. 469, 20130351 (2013).

Melancon, D., Gorissen, B., García-Mora, C. J., Hoberman, C. & Bertoldi, K. Multistable inflatable origami structures at the metre scale. Nature 592, 545–550 (2021).

Huang, K., Ye, H., Yu, Z., & Zhou, X. Energy absorption properties of composite sandwich tubes with pre-folded cores. Compos Struct. 294, 115737 (2022).

Li, Y. & You, Z. Origami concave tubes for energy absorption. Int. J. Solids Struct. 169, 21–40 (2019).

Filipov, E. T., Tachi, T. & Paulino, G. H. Origami tubes assembled into stiff, yet reconfigurable structures and metamaterials. Proc. Natl. Acad. Sci. USA 112, 12321–12326 (2015).

Kim, S. J., Lee, D. Y., Jung, G. P. & Cho, K. J. An origami-inspired, self-locking robotic arm that can be folded flat. Sci. Robot. 3, eaar2915 (2018).

Salerno, M., Zhang, K., Menciassi, A. & Dai, J. S. A novel 4-DOF origami grasper with an SMA-actuation system for minimally invasive surgery. IEEE Trans. Robot. 32, 484–498 (2016).

Lee, T.-U. et al. Self-locking and stiffening deployable tubular structures. Proc. Natl. Acad. Sci. USA 121, e2409062121 (2024).

Dai, J. S. & Jones, J. Rees Mobility in metamorphic mechanisms of foldable/erectable kinds. J. Mech. Des. 121, 375–382 (1999).

Zhang, H., Feng, H., Huang, J.-L. & Paik, J. Generalized modeling of origami folding joints. Extrem. Mech. Lett. 45, 101213 (2021).

Zhang, X., Kang, X. & Li, B. Origami-inspired design of a single-degree-of-freedom continuous variable bending mechanism based on constraint linkage groups. Mech. Mach. Theory 179, 105106 (2023).

Tachi, T. Rigid-foldable thick origami. Origami 5, 253–264 (2011).

Hoberman, C. Folding structures made of thick hinged sheets. US Patent (2010).

Lin, Z., Ai, L., Feng, H., He, W. & Li, Y. Multistable compliant linkages with multiple kinematic paths separated by energy barriers, Extreme Mech. Lett. 70, 102175 (2024).

Yellowhorse, A., Lang, R. J., Tolman, K. & Howell, L. L. Creating linkage permutations to prevent self-intersection and enable deployable networks of thick-origami. Sci. Rep. 8, 12936 (2018).

Bolanos, D. et al. Considering thickness-accommodation, nesting, grounding and deployment in design of Miura-ori based space arrays. Mech. Mach. Theory 174, 104904 (2022).

Edmondson, B. J., Lang, R. J., Magleby, S. P. & Howell, L. L. An offset panel technique for thick rigidily foldable origami. International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, American Society of Mechanical Engineers V05BT08A054 (ASME, 2014).

Chen, Y., Peng, R. & You, Z. Origami of thick panels. Science 349, 396–400 (2015).

Chen, Y., Feng, H., Ma, J., Peng, R. & You, Z. Symmetric waterbomb origami. Proc. R. Soc. A Math. Phys. Eng. Sci. 472, 20150846 (2016).

Hull, T. C. & Tachi, T. Double-line rigid origami, arXiv preprint arXiv:1709.03210, (2017).

Tolman, K. A., Lang, R. J., Magleby, S. P. & Howell, L. L. Split-vertex technique for thickness-accommodation in origami-based mechanisms. International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, American Society of Mechanical Engineers V05BT08A054 (ASME, 2017).

Peng, R. & Chirikjian, G. S. A methodology for thick-panel origami pattern design. Mech. Mach. Theory 189, 105423 (2023).

Ku, J. S. & Demaine, E. D. Folding flat crease patterns with thick materials. J. Mech. Robot. 8, 031003 (2016).

Tolman, K. A. Developing Hybrid Thickness-accommodation Techniques for New Origami-inspired Engineered Systems. Brigham Young University (2017).

Zhu, Y. & Filipov, E. T. Large-scale modular and uniformly thick origami-inspired adaptable and load-carrying structures. Nat. Commun. 15, 2353 (2024).

Zhang, Y., Li, M., Chen, Y., Peng, R. & Zhang, X. Thick-panel origami-based parabolic cylindrical antenna. Mech. Mach. Theory 182, 105233 (2023).

Peng, R. & Chirikjian, G. S. Morphable thick-panel origami. Mech. Mach. Theory 192, 105528 (2024).

Zhao, C. et al. Deployable structure based on double-layer Miura-ori pattern. Mech. Res. Commun. 131, 104152 (2023).

Acknowledgements

This work was supported by NUS Startup Grants A-0009059–02–00 and A-0009059–03–00, and SMI Grant A-8000081–02–00.

Author information

Authors and Affiliations

Contributions

R.P. and G.S.C. designed the research. R.P. and G.S.C. wrote and reviewed the original draft. R.P. fabricated the prototypes. G.S.C. supervised and edited the final version.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Tian Chen, and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Peng, R., Chirikjian, G.S. Thick-panel origami structures forming seamless surfaces. Nat Commun 16, 3881 (2025). https://doi.org/10.1038/s41467-025-59141-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-59141-2