Abstract

Photocatalysis has greatly advanced in organic synthesis but still confronts challenges, including light attenuation in reaction media and excessive solvent utilization. These issues lead to inefficiencies, particularly in heterogeneous cloudy mixtures and in scaling-up applications. Integrating photocatalysis with mechanochemistry offers a nascent but promising solution to these challenges. Herein, we present a scalable photo-mechanochemical platform that combines visible-light photocatalysis with Resonant Acoustic Mixing (RAM), enabling efficient cross-coupling reactions under solvent-minimised conditions. This approach demonstrates broad substrate tolerance, accommodating a variety of aryl (hetero) halides and N-, O-, P-, S-nucleophiles. The protocol supports scaling up to 300 mmol, representing a 1500-fold increase, while maintaining exceptionally low catalyst loading and achieving up to 9800 turnover numbers (TON). The generality of this platform is further validated by its applicability to other synthetic transformations.

Similar content being viewed by others

Introduction

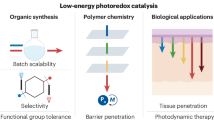

Developing environmentally friendly, efficient, and economically viable strategies has long been a priority in both academic and industrial chemistry. Photocatalysis1,2,3,4, particularly visible-light-driven processes, aligns well with these goals by facilitating a broad range of chemical transformations under mild conditions5,6,7. It has significantly enriched the synthetic toolbox with diverse mechanisms such as single electron transfer (SET), energy transfer (EnT), hydrogen atom transfer (HAT), and halogen atom transfer (XAT), among others8,9,10,11,12,13. However, the application of visible light in photocatalysis is constrained by its limited penetration depth and the extensive solvent volumes required for dilution, complicating scalability14,15,16,17,18. Conventional scaling strategies, such as enlarging reactor size, have proven less effective, especially for turbid suspensions where light attenuation reduces reaction efficiency18,19,20. While flow chemistry offers an engineering solution to the problem of light attenuation in large-scale reactions, issues such as the handling of insoluble reagents and high solvent consumption due to highly dilute reactions still persist (Fig. 1a)15,16,17,18. Since solvents constitute about 85% of the total chemical mass in the pharmaceutical industry21, solvent-minimised photocatalysis offers great potential for advancing green and sustainable processes (Fig. 1b)20.

Mechanochemical synthesis, on the other hand, has emerged as a useful tool across materials science, as well as polymer, inorganic, and organic chemistry22,23,24,25,26,27,28. Mechanochemistry can reduce or eliminate solvent use, shorten reaction times, and facilitate the exploration of novel synthetic pathways29,30,31,32,33,34,35,36,37. In 2019, its potential for environmental and methodological improvements led IUPAC to name it among the top ten emerging technologies that will change our world38. The integration of photocatalysis and mechanochemistry builds on these strengths, offering synergistic potential to expand the synthetic landscape. Despite its promise, the emerging field of photo-mechanochemistry remains underexplored, largely due to the challenges of integrating light sources into mechanochemical systems. Early studies by MacGillivray et al.39,40,41,42, König et al.43,44, Hernández45, and Štrukil et al.46 demonstrated the feasibility of photo-mechanochemical reactions, while more recent advances by Rappe and Braunschweig et al.47, Zysman-Colman et al.48, and Borchardt et al. 49 further expanded this field by integrating blue and UV light into ball milling setups. Wu and Wang et al. also demonstrated the use of mechanoluminescent materials as internal photon sources50. Although these findings are encouraging, these methods remain limited by experimental complexity, deficiencies in reaction efficiency and scalability, and reaction versatility51,52. Addressing these barriers requires a versatile and scalable platform to propel photo-mechanochemistry beyond its early stages.

Among various mechanochemical tools, Resonant Acoustic Mixing (RAM) emerges as a promising candidate for photo-mechanochemical applications. Recently introduced into organic synthesis53,54,55,56,57,58,59,60,61, RAM offers two key advantages. First, it eliminates the need for milling media, such as balls or screws, reducing contamination risk and simplifying reactor design. This allows the use of glass reactors, typically impractical or not feasible in ball milling due to the risk of breakage. Second, RAM’s powerful mixing capabilities are particularly suited to solvent-minimised photocatalytic processes, where solid reactants often form paste-like mixtures rather than homogeneous solutions. Such conditions pose challenges to traditional photochemical methods due to non-uniform reactant distribution, uneven irradiation, and light scattering, which reduces light penetration and hinders efficient photon absorption20. We envisioned that by leveraging RAM, photo-mechanochemical processes could overcome these issues by enhancing reactant mixing and increasing reactant exposure frequency.

Herein, we present a new photo-mechanochemical platform that combines visible-light photocatalysis with RAM to enable an efficient, general, and scalable method for metallaphotoredox catalysis under solvent-minimised conditions. As a proof of concept, we select the photoredox dual-catalysed C–X (X = N, O, P, S) bond cross-coupling reactions, which are known for their industrial relevance (Fig. 1c)62,63,64,65,66,67,68,69,70,71,72. We also explore five additional types of photoinduced reactions, further showcasing the versatility of this platform. This strategy features operational simplicity, broad substrate tolerance, reduced reaction times, and scalability with exceptionally low catalyst loading. By addressing key limitations in both photocatalysis and mechanochemistry, this approach broadens the accessible chemical space and opens new opportunities in synthetic chemistry.

Results and discussion

Evaluation of the reaction conditions

Photo-mechanochemical experiments were conducted utilising a commercial Resodyn LabRAM II instrument with a capacity of 1 kg. The Resonant Acoustic Mixer (RAM) employs a non-contact, forced-vibration method that uses a robust acoustic field to facilitate effective particle collisions at low frequencies, commonly around 60 Hz54. The energy delivered during the RAM procedure is controllable through variations in the oscillation amplitude of the sample container, which adjusts its acceleration from 0 to 100 g (gravity, g = 9.81 m·s−2). To facilitate light exposure, a modular lamp holder was designed to accommodate four lamps and two cooling fans. The holder is engineered for easy installation and removal. Additionally, a custom-designed 3D-printed sample holder, made from ABS polymer, was tailored to fit 4 mL glass vials. This design enhances the throughput of photo-mechanochemical reactions, enabling up to 12 reactions to be conducted simultaneously while maintaining excellent reproducibility (Fig. 2 and Supplementary Fig. 1).

Our optimisation studies began with conditions previously established by König and co-workers for nickel photoredox catalysis67. The results are summarised in Table 1. In the photo-mechanochemical setup, 4-bromobenzonitrile (1a) and aniline (2a) were used as representative starting materials in a 4 mL glass vial. The reaction mixture comprised 4CzIPN (0.1 mol%), NiBr₂·glyme (5 mol%), DABCO (2.0 equiv.), and Et₃N (0.25 equiv.) in DMA (0.4 mL) and was irradiated with 90 W Aqua Blue LEDs at 90 g for 90 min. Under these conditions, a 90% yield of compound 3 was achieved, as determined by GC-FID using dodecane as the internal standard (entry 1). This positive outcome led us to further explore the reaction’s parameters. Remarkably, omitting the solvent led to only a marginal decrease in yield, though it resulted in the formation of a sticky, heterogeneous, and cloudy mixture (entry 2). The application of grinding agents commonly used in ball milling, such as sea sand and silica gel, resulted in a decrease in yield for 3 to 82% and 43%, respectively (entry 3 and 4). Control experiments showed that light, a photocatalyst, and nickel salt are all essential to the reaction (entries 5–7). In the absence of DABCO or Et3N, or both, the reaction proved to be ineffective (entries 8–10). To our delight, the concurrent use of 1 equiv. each of DABCO and Et3N achieved a quantitative yield and reduced the reaction time to 30 min (entry 11). Replacing NiBr2·glyme with alternative nickel catalysts did not alter the outcome (entries 12–15). Moreover, the optimal conditions can be applied to 4-chlorobenzonitrile (1b) with an extended reaction time of 90 min (entry 16). Crucially, the approach demonstrated scalability, smoothly transitioning from a 0.2 mmol scale directly to 2 mmol and 5 mmol scales within a 4 mL glass vial without necessitating any modifications (entries 17 and 18). Such scalability highlights the protocol’s potential for wider application in synthetic chemistry. When the argon atmosphere was replaced by air, no reaction was observed (entry 19).

Scope of substrates

Encouraged by the initial findings, the scope of the substrates was examined (Fig. 3). We first investigated different aryl halides 1 in reactions with aniline (2a). A wide range of aryl bromides bearing electron-withdrawing and electron-donating groups were well tolerated, giving the corresponding products in moderate to good yields. Several functional groups at the para position such as cyano, ester, ketone, sulfone, trifluoromethyl, alkyl, and phenyl were all compatible. Boronic esters and chloro functionalities, providing the possibility for further late-stage modifications, also reacted well, affording 9 and 10 in 75% and 74% yields, respectively. The presence of ortho-cyano groups introduced steric hindrances, mildly affecting yield (16, 50%). Furthermore, di-substituted variants and bicyclic aryl bromides containing dioxole and ketone functionalities, as well as polyaromatic bromides, also demonstrated good reactivity in this transformation (18–24). Notably, the photo-mechanochemical method accommodated a variety of heterocyclic substrates with pharmaceutical relevance, including structures bearing indole, pyridine, quinoline, dibenzofuran, dibenzothiophene, and carbazole motifs (25–34). A set of biologically active moiety and drug molecules, including adamantanecarboxylic acid (35), pregnenolone (36), fenofibrate (37), and indomethacin (38), were also successfully applied, further demonstrating the generality of this methodology.

Reactions conditions: aryl halides (0.5 mmol, 1.0 equiv.), nucleophiles (2.0 − 6.0 equiv.), 4CzIPN (0.1 – 0.5 mol%), and nickel catalyst (5 mol%) in a 4 mL glass vial under irradiation of 90 W Aqua Blue LEDs. Yields after column chromatography. aUsing 40 W 440 nm Blue LEDs. bWith 4-chlorobenzonitrile (1b). cThe compound was isolated as its respective oxide. dAdding 200 μL of DMA.

Next, the substrate scope with respect to nucleophiles was explored. 4-Bromobenzonitrile (1a) reacted smoothly with a wide array of N-, O-, P-, and S-containing nucleophiles. Various anilines regardless of their electronic nature were well tolerated, giving the corresponding products in good to excellent yields (39–43). Solid state 2-naphthylamine also reacted well, affording 44 in 90% yield. Furthermore, both primary and secondary alkyl-amine nucleophiles displayed high tolerance, affording the corresponding products in moderate to good yields (45–55). At this stage, the project had made significant progress by developing an effective solvent-minimised photo-mechanochemical protocol for aryl amination. However, its performance declined with low-reactivity substrates such as weak nucleophiles (e.g., S,S-dimethyl sulfoximine, benzamide, p-toluenesulfonamide) and an electron-rich aryl bromide (4-methoxyphenyl bromide). Under high-intensity, broad-spectrum irradiation (90 W Aqua Blue LEDs), the organic photocatalyst 4CzIPN might decompose, further reducing efficiency. In contrast, using 40 W 440 nm blue LEDs as the light source overcame these challenges, achieving excellent yields in all aforementioned cases (15, 56–58, for further information, see Supplementary Table 2). With respect to other heteroatom coupling partners, we adopted the conditions reported by König and co-workers67, simply omitting the solvent without additional adjustments. Under the irradiation of 40 W 440 nm Blue LEDs, effective coupling was achieved for primary alcohols (59–62), secondary alcohols (63, 64), and diphenylphosphine (65). Additionally, aliphatic thiol and thiophenol also reacted effectively, although the addition of 200 μL of DMA (η = 0.87-1.10 μL/mg) was required to inhibit their dimerisation (66–68). It is worth noting that all the reaction mixtures were viscous, with some forming heterogeneous phases due to solid content, yet the glass vials remained intact in all cases.

Reducing catalyst loading

Motivated by the high efficiency of the current protocol and aiming to further evaluate the performance of the photo-mechanochemical platform, we hypothesised that low catalyst loadings could still achieve comparable reactivity. To test this hypothesis, a series of experiments were conducted to explore the impact of reducing catalyst loading, as illustrated in Fig. 4a. Aniline (2a) and pyrrolidine (2c) were selected as nucleophiles for these studies, with reactions performed on a 0.5 mmol scale and a reaction time of 30 min. Initial experiments, conducted with a fixed nickel catalyst loading of 5 mol%, revealed that photocatalyst loadings below 0.01 mol% led to reduced reaction efficiency for both nucleophiles. Subsequent investigations with the photocatalyst fixed at 0.01 mol% highlighted a critical dependency on nickel catalyst loading, particularly for aniline (2a). Reducing the nickel loading to 1 mol% significantly compromised the yield. Considering that the RAM generates additional heat with larger amounts of reactants, this thermal characteristic was factored into further experiments conducted on a 2 mmol scale with aniline (2a). The results showed that nickel loadings of 0.1 mol% and 0.01 mol% produced yields of 78% and 45%, respectively, suggesting a potential benefit from the slight temperature increase. For pyrrolidine (2c), the system tolerated nickel catalyst loading as low as 1 mol%, but further reduction or scaling up to a 2 mmol scale did not significantly improve performance.

a Investigations of reducing catalysts loading. Reactions were performed on 0.5 mmol scale in a 4 mL glass vial for 30 min. The yields were determined by GC-FID with dodecane as the internal standard. a2 mmol scale. b Scale-up experiments of product 4 with images showing the reaction mixture before and after completion. c Scale-up experiments of product 70 with images showing the reaction mixture before and after completion. d Other scale-up experiments with 0.01% 4CzIPN as a photo catalyst.

Scale-up experiments

Scalable synthesis is a fundamental requirement for applications in industrial catalysis. Building on these promising results, we expanded our experiments to larger scales to demonstrate the platform’s synthetic utility. Remarkably, for aniline (2a), product 4 was obtained in a 93% yield within 20 min using only 0.01 mol% of both photocatalyst and nickel catalyst on a 10 mmol scale, representing a 50-fold increase in reaction volume (10 mmol vs 0.2 mmol). This success was readily reproduced at 100 mmol and 300 mmol scales (500- and 1500-fold scale-ups), achieving 95% and 98% yields, respectively, with extended reaction times, as illustrated in Fig. 4b. Notably, the corresponding catalyst turnover number (TON) reached 9800. To the best of our knowledge, such high efficiency for nickel-catalysed cross-coupling reactions has not been previously reported. Similarly, for pyrrolidine (2c), a 92% yield of product 70 was achieved at a 10 mmol scale within 20 min using 0.01 mol% photocatalyst and 1 mol% nickel catalyst. Reducing the nickel loading to 0.5 mol% and prolonging the reaction time to 40 min maintained the yield. However, further reduction in NiBr₂·glyme loading led to incomplete conversion. Scaling up to 100 mmol (200-fold increase compared to the 0.5 mmol reaction scale), product 70 was obtained in a 91% yield after 2 h, with a corresponding turnover number (TON) of 91 for the nickel catalyst, as shown in Fig. 4c. In experiments at 100 mmol and 300 mmol scales, a normal 400 mL glass vial was used, and operations were paused for 5 min after every 20–30 min to prevent overheating. During these reactions, solid products and salts gradually precipitated, turning the mixture into a semi-solid, viscous state. The desired products were easily isolated through a brief water wash and slurry purification. This photo-mechanochemical approach avoids the need for solvents and eliminates more wasteful work-up procedures. In contrast, conventional solution-based photoredox catalysis typically requires large amounts of solvents (DMA, DMF, or DMSO) to ensure complete dissolution and homogeneous reaction conditions. The equipment used in this study is a small research instrument, with the combined mass of the glass vial and reactants at the 300 mmol scale approximately 500 g, well below its capacity limit of 1 kg. Even with the current setup, theoretical throughput rates of 569 g day−1 for product 4 and 200 g day−1 for product 70 could be achieved. Future designs aim to incorporate more effective heat management strategies and larger vials to enhance reaction efficiency further. As shown in Fig. 4d, the approach also proved effective for aryl bromides with electron-donating or neutral groups, and drug molecules containing aryl chloride, all reacting successfully with just 0.01 mol% photocatalyst. When butan-1-amine was used as a nucleophile, it led to a 43% yield of product 71 using 0.01 mol% photocatalyst and 1 mol% nickel catalyst. These results are particularly noteworthy because scaling in photochemical synthesis usually requires substantial re-optimisation of reaction parameters54,73. Additionally, the degradation of organic dyes and nickel64,68, which is commonly encountered in metallaphotoredox catalysis, often necessitates higher catalyst loadings to maintain reaction efficiency. Overall, the photo-mechanochemical platform holds promise as a powerful tool for rapid, large-scale synthesis of high-value chemical products in the pharmaceutical and chemical industries.

Comparison between photo-mechanochemical and solution-based approaches

To further demonstrate the efficiency of the newly devised photo-mechanochemical platform, a direct comparison was made with a traditional solution-based photocatalytic approach (Fig. 5a). The study focused on four different amines: aniline, an aromatic amine; 4-chloroaniline, a solid aromatic amine; pyrrolidine, a secondary amine; and butan-1-amine, a primary amine. Each amine was reacted with methyl 4-bromobenzoate (1 d) at a 10 mmol scale with low catalyst loading. In the photo-mechanochemical system, the reaction temperature stabilised at approximately 50–55 °C upon completion, while solution-based reactions were conducted at 55 °C in 0.5 M DMA for 48 h to ensure comparable conditions. The photo-mechanochemical method consistently delivered higher results across all tested amines, with reaction times significantly shorter (20 or 90 min vs. 48 h). Moreover, the superiority of this approach was highlighted by assessing green metrics such as the E factor, mass intensity, and molar efficiency (Fig. 5b, for details, see section 7 of the Supplementary Information). These results illustrate the platform’s potential to outperform traditional solution-based methods in both efficiency and sustainability. The platform’s versatility was validated through five additional photoinduced reactions, including: (i) Dual Ni/photoredox decarboxylative C(sp2)–C(sp3) cross-coupling reaction74, (ii) Ullmann-type C−N cross coupling75, (iii) intermolecular [2 + 2] dimerisation76, (iv) Arbuzov-type α-C(sp3)–H phosphonylation of aliphatic amine77, and (v) decarboxylative alkylation via electron donor–acceptor (EDA) complex78. All reactions demonstrated shortened reaction times and comparable yields under solvent-minimised conditions (Fig. 5c–g).

a Methyl 4-bromobenzoate (1d, 10 mmol) was reacted separately with four different amines. The yields were determined by GC-FID with dodecane as the internal standard. PM (purple): photo-mechanochemical approach. SOL (blue): solution-based photocatalytic approach. PC: photo catalyst. b Calculation of green metrics. c–g Other reaction types, results comparing the two methods shown below the equations.

In conclusion, we have developed a novel photo-mechanochemical platform that enables efficient dual-catalysed cross-coupling reactions under solvent-minimised conditions. This approach demonstrates multiple advantages, including operational simplicity, broad substrate tolerance, shortened reaction times, low catalyst loading, and compatibility with paste-like mixtures. The platform’s scalability and synthetic utility have been validated across reaction scales ranging from 0.2 to 300 mmol. Compared to traditional solution-based methods, this photo-mechanochemical strategy offers superior efficiency and environmental benefits. We anticipate that this platform will inspire further advancements in industrially viable, solvent-minimised photocatalytic processes, particularly in applications where conventional photochemistry is limited. Additionally, the high customizability of RAM opens possibilities for its integration into continuous production workflows, potentially expanding its industrial relevance.

Methods

Representative procedures

All reactants, catalysts and additives were loaded into a glass vial. The vial was then sealed and subjected to the photo-mechanochemical platform. After irradiation and mixing, the crude product was analysed by GC-MS and then purified by flash column chromatography using hexane/EtOAc as eluent. For scale-up experiments, if the starting materials achieved full conversion, the reaction mixture was washed with water and the collected solid was mixed with a small amount of ethyl acetate (EtOAc) to form a slurry. Hexane was then added to precipitate the product which was filtered and dried under reduced pressure.

Data availability

The authors declare that the data supporting the findings of this study are available within the article and its Supplementary Information Files (including experimental details, NMR data and NMR spectra). Data supporting the findings of this manuscript are also available from the corresponding author upon request.

References

Marzo, L., Pagire, S. K., Reiser, O. & König, B. Visible‐light photocatalysis: does it make a difference in organic synthesis? Angew. Chem. Int. Ed. 57, 10034–10072 (2018).

Yu, X.-Y., Chen, J.-R. & Xiao, W.-J. Visible light-driven radical-mediated C–C bond cleavage/functionalization in organic synthesis. Chem. Rev. 121, 506–561 (2020).

Candish, L. et al. Photocatalysis in the life science industry. Chem. Rev. 122, 2907–2980 (2021).

Rolka, A. B. & König, B. Bifunctional organic photocatalysts for enantioselective visible-light-mediated photocatalysis. Nat. Synth. 2, 913–925 (2023).

Matsui, J. K., Lang, S. B., Heitz, D. R. & Molander, G. A. Photoredox-mediated routes to radicals: the value of catalytic radical generation in synthetic methods development. ACS Catal. 7, 2563–2575 (2017).

Milligan, J. A., Phelan, J. P., Badir, S. O. & Molander, G. A. Alkyl carbon–carbon bond formation by Nickel/Photoredox cross‐coupling. Angew. Chem. Int. Ed. 58, 6152–6163 (2019).

Pitre, S. P. & Overman, L. E. Strategic use of visible-light photoredox catalysis in natural product synthesis. Chem. Rev. 122, 1717–1751 (2022).

Prier, C. K., Rankic, D. A. & MacMillan, D. W. Visible light photoredox catalysis with transition metal complexes: applications in organic synthesis. Chem. Rev. 113, 5322–5363 (2013).

Strieth-Kalthoff, F., James, M. J., Teders, M., Pitzer, L. & Glorius, F. Energy transfer catalysis mediated by visible light: principles, applications, directions. Chem. Soc. Rev. 47, 7190–7202 (2018).

Zhou, Q. Q., Zou, Y. Q., Lu, L. Q. & Xiao, W. J. Visible‐light‐induced organic photochemical reactions through energy‐transfer pathways. Angew. Chem. Int. Ed. 58, 1586–1604 (2019).

Zhang, J. & Rueping, M. Metallaphotoredox catalysis for sp3 C–H functionalizations through hydrogen atom transfer (HAT). Chem. Soc. Rev. 52, 4099–4120 (2023).

Zhang, J. & Rueping, M. Metallaphotoredox catalysis for sp3 C–H functionalizations through single-electron transfer. Nat. Catal. 7, 963–976 (2024).

Juliá, F., Constantin, T. & Leonori, D. Applications of halogen-atom transfer (XAT) for the generation of carbon radicals in synthetic photochemistry and photocatalysis. Chem. Rev. 122, 2292–2352 (2021).

Noël, T. & Zysman-Colman, E. The promise and pitfalls of photocatalysis for organic synthesis. Chem Catal 2, 468–476 (2022).

Cambie, D., Bottecchia, C., Straathof, N. J., Hessel, V. & Noel, T. Applications of continuous-flow photochemistry in organic synthesis, material science, and water treatment. Chem. Rev. 116, 10276–10341 (2016).

Harper, K. C., Moschetta, E. G., Bordawekar, S. V. & Wittenberger, S. J. A laser driven flow chemistry platform for scaling photochemical reactions with visible light. ACS Cent. Sci. 5, 109–115 (2019).

Donnelly, K. & Baumann, M. Scalability of photochemical reactions in continuous flow mode. J. Flow Chem. 11, 223–241 (2021).

Buglioni, L., Raymenants, F., Slattery, A., Zondag, S. D. & Noël, T. Technological innovations in photochemistry for organic synthesis: flow chemistry, high-throughput experimentation, scale-up, and photoelectrochemistry. Chem. Rev. 122, 2752–2906 (2022).

König, B. Photocatalysis in organic synthesis–past, present, and future. Eur. J. Org. Chem. 2017, 1979–1981 (2017).

Obst, M. & König, B. Organic synthesis without conventional solvents. Eur. J. Org. Chem. 2018, 4213–4232 (2018).

Sheldon, R. A. Green solvents for sustainable organic synthesis: state of the art. Green Chem. 7, 267–278 (2005).

James, S. L. et al. Mechanochemistry: opportunities for new and cleaner synthesis. Chem. Soc. Rev. 41, 413–447 (2012).

Do, J.-L. & Friščić, T. Mechanochemistry: a force of synthesis. ACS Cent. Sci. 3, 13–19 (2017).

Bolm, C. & Hernández, J. G. Mechanochemistry of gaseous reactants. Angew. Chem. Int. Ed. 58, 3285–3299 (2019).

Friščić, T., Mottillo, C. & Titi, H. M. Mechanochemistry for synthesis. Angew. Chem. Int. Ed. 132, 1030–1041 (2020).

Porcheddu, A., Colacino, E., De Luca, L. & Delogu, F. Metal-mediated and metal-catalyzed reactions under mechanochemical conditions. ACS Catal. 10, 8344–8394 (2020).

Jones, A. C., Leitch, J. A., Raby-Buck, S. E. & Browne, D. L. Mechanochemical techniques for the activation and use of zero-valent metals in synthesis. Nat. Synth. 1, 763–775 (2022).

Krusenbaum, A., Grätz, S., Tigineh, G. T., Borchardt, L. & Kim, J. G. The mechanochemical synthesis of polymers. Chem. Soc. Rev. 51, 2873–2905 (2022).

Cao, Q., Crawford, D. E., Shi, C. & James, S. L. Greener dye synthesis: continuous, solvent-free synthesis of commodity perylene diimides by twin-screw extrusion. Angew. Chem. Int. Ed. 59, 4478–4483 (2020).

Kubota, K., Pang, Y., Miura, A. & Ito, H. Redox reactions of small organic molecules using ball milling and piezoelectric materials. Science 366, 1500–1504 (2019).

Seo, T., Toyoshima, N., Kubota, K. & Ito, H. Tackling solubility issues in organic synthesis: solid-state cross-coupling of insoluble aryl halides. J. Am. Chem. Soc. 143, 6165–6175 (2021).

Kong, D. & Bolm, C. Stainless steel-initiated thiosulfonylations of unactivated alkenes under solvent-free conditions in a mixer mill. Green Chem. 24, 6476–6480 (2022).

Hu, C., van Bonn, P., Demco, D. E., Bolm, C. & Pich, A. Mechanochemical synthesis of stimuli responsive microgels. Angew. Chem. Int. Ed. 62, e202305783 (2023).

Patel, C. et al. Fluorochemicals from fluorspar via a phosphate-enabled mechanochemical process that bypasses HF. Science 381, 302–306 (2023).

Zholdassov, Y. S. et al. Acceleration of diels-alder reactions by mechanical distortion. Science 380, 1053–1058 (2023).

Shi, P. et al. Iron‐catalyzed intramolecular arene C (sp2)− H Amidations under mechanochemical conditions. Angew. Chem. Int. Ed. 61, e202204874 (2022).

Ardila‐Fierro, K. J. & Hernández, J. G. Intermediates in mechanochemical reactions. Angew. Chem. Int. Ed. 63, e202317638 (2024).

Gomollón-Bel, F. Ten chemical innovations that will change our world: IUPAC identifies emerging technologies in chemistry with potential to make our planet more sustainable. Chem. Int. 41, 12–17 (2019).

Stojaković, J., Farris, B. S. & MacGillivray, L. R. Vortex grinding for mechanochemistry: application for automated supramolecular catalysis and preparation of a metal–organic framework. Chem. Commun. 48, 7958–7960 (2012).

Stojaković, J., Farris, B. S. & MacGillivray, L. R. Liquid-assisted vortex grinding supports the single-step solid-state construction of a [2.2] paracyclophane. Faraday Discuss. 170, 35–40 (2014).

Sokolov, A. N., Bučar, D. K., Baltrusaitis, J., Gu, S. X. & MacGillivray, L. R. Supramolecular catalysis in the organic solid state through dry grinding. Angew. Chem. Int. Ed. 122, 4369–4373 (2010).

Elacqua, E., Kummer, K. A., Groeneman, R. H., Reinheimer, E. W. & MacGillivray, L. R. Post-application of dry vortex grinding improves the yield of a [2+ 2] photodimerization: Addressing static disorder in a cocrystal. J. Photochem. Photobiol. A 331, 42–47 (2016).

Obst, M. & König, B. Solvent-free, visible-light photocatalytic alcohol oxidations applying an organic photocatalyst. Beilstein J. Org. Chem. 12, 2358–2363 (2016).

Obst, M., Shaikh, R. & König, B. Solvent-free coupling of aryl halides with pyrroles applying visible-light photocatalysis. React. Chem. Eng. 2, 472–478 (2017).

Hernández, J. G. Mechanochemical borylation of aryldiazonium salts; merging light and ball milling. Beilstein J. Org. Chem. 13, 1463–1469 (2017).

Štrukil, V. & Sajko, I. Mechanochemically-assisted solid-state photocatalysis (MASSPC). Chem. Commun. 53, 9101–9104 (2017).

Biswas, S. et al. Photomechanochemical control over stereoselectivity in the [2+2] photodimerization of acenaphthylene. Faraday Discuss. 241, 266–277 (2023).

Millward, F. & Zysman‐Colman, E. Mechanophotocatalysis: a generalizable approach to solvent‐minimized photocatalytic reactions for organic synthesis. Angew. Chem. Int. Ed. 63, e202316169 (2024).

Baier, D. M., Spula, C., Fanenstich, S., Grätz, S. & Borchardt, L. The regioselective solid‐state photo‐mechanochemical synthesis of nanographenes with UV light. Angew. Chem. Int. Ed. 62, e202218719 (2023).

Xin, X. et al. Mechano-photoexcitation for organic synthesis using mechanoluminescent materials as photon sources. Nat. Synth. 4, 177–187 (2024).

Reynes, J. F., Isoni, V. & Garcia, F. Tinkering with mechanochemical tools for scale up. Angew. Chem. Int. Ed. 135, e202300819 (2023).

Martinez, V., Stolar, T., Karadeniz, B., Brekalo, I. & Užarević, K. Advancing mechanochemical synthesis by combining milling with different energy sources. Nat. Rev. Chem. 7, 51–65 (2023).

Titi, H. M., Do, J.-L., Howarth, A. J., Nagapudi, K. & Friščić, T. Simple, scalable mechanosynthesis of metal–organic frameworks using liquid-assisted resonant acoustic mixing (LA-RAM). Chem. Sci. 11, 7578–7584 (2020).

Gonnet, L. et al. Metal‐catalyzed organic reactions by resonant acoustic mixing. Angew. Chem. Int. Ed. 134, e202115030 (2022).

Effaty, F. et al. Resonant acoustic mixing (RAM) for efficient mechanoredox catalysis without grinding or impact media. Chem. Commun. 59, 1010–1013 (2023).

Wohlgemuth, M. et al. Milling medium‐free suzuki coupling by direct mechanocatalysis: from mixer mills to resonant acoustic mixers. Chem. Eur. J. 29, e202301714 (2023).

Lennox, C. B. et al. Direct mechanocatalysis by resonant acoustic mixing (RAM). Chem. Sci. 14, 7475–7481 (2023).

Gonnet, L. et al. The “η-sweet-spot”(ηmax) in liquid-assisted mechanochemistry: polymorph control and the role of a liquid additive as either a catalyst or an inhibitor in resonant acoustic mixing (RAM). Faraday Discuss. 241, 128–149 (2023).

Nanni, A., Kong, D., Zhu, C. & Rueping, M. Nickel-catalyzed cross-coupling aminations via high-throughput mechanochemistry enabled by resonant acoustic mixing. Green Chem. 26, 8341–8347 (2024).

Makarov, A. S. & Rueping, M. Scalable depolymerizing transesterification and amidation of (poly) lactic acid (PLA) enabled by resonant acoustic mixing (RAM). Green Chem. 27, 716–721 (2025).

Dey, A., Kancherla, R., Pal, K., Kloszewski, N. & Rueping, M. Rapid and scalable ruthenium catalyzed meta-C–H alkylation enabled by resonant acoustic mixing. Commun. Chem. 7, 295 (2024).

Corcoran, E. B. et al. Aryl amination using ligand-free Ni (II) salts and photoredox catalysis. Science 353, 279–283 (2016).

Till, N. A., Tian, L., Dong, Z., Scholes, G. D. & MacMillan, D. W. Mechanistic analysis of metallaphotoredox C–N coupling: photocatalysis initiates and perpetuates Ni (I)/Ni (III) coupling activity. J. Am. Chem. Soc. 142, 15830–15841 (2020).

Gisbertz, S., Reischauer, S. & Pieber, B. Overcoming limitations in dual photoredox/nickel-catalysed C–N cross-couplings due to catalyst deactivation. Nat. Catal. 3, 611–620 (2020).

Goldschmid, S. L. et al. Overcoming photochemical limitations in metallaphotoredox catalysis: red-light-driven C–N cross-coupling. J. Am. Chem. Soc. 144, 22409–22415 (2022).

Seo, T., Kubota, K. & Ito, H. Dual nickel(II)/mechanoredox catalysis: mechanical-force-driven aryl-amination reactions using ball milling and piezoelectric materials. Angew. Chem. Int. Ed. 62, e202311531 (2023).

Ghosh, I. et al. General cross-coupling reactions with adaptive dynamic homogeneous catalysis. Nature 619, 87–93 (2023).

Nikitin, M. et al. C(sp2)–S cross-coupling reactions with nickel, visible light, and mesoporous graphitic carbon nitride. Green Chem. 26, 5845–5851 (2024).

Muralirajan, K. et al. Ba/Ti MOF: a versatile heterogeneous photoredox catalyst for visible‐light metallaphotocatalysis. Adv. Mater. 37, 2405646 (2025).

Kancherla, R. et al. Photoexcitation of distinct divalent palladium complexes in cross‐coupling amination under air. Angew. Chem. Int. Ed. 136, e202314508 (2024).

Karpova, L. et al. Excited-state nickel-catalyzed amination of aryl bromides: synthesis of diphenylamines and primary anilines. Org. Lett. 26, 1657–1661 (2024).

Zhu, C., Kale, A. P., Yue, H. & Rueping, M. Redox-neutral cross-coupling amination with weak N-nucleophiles: arylation of anilines, sulfonamides, sulfoximines, carbamates, and imines via nickelaelectrocatalysis. JACS Au. 1, 1057–1065 (2021).

Slattery, A. et al. Automated self-optimization, intensification, and scale-up of photocatalysis in flow. Science 383, eadj1817 (2024).

Zuo, Z. et al. Merging photoredox with nickel catalysis: coupling of α-carboxyl sp3-carbons with aryl halides. Science 345, 437–440 (2014).

Yoo, W.-J., Tsukamoto, T. & Kobayashi, S. Visible light-mediated Ullmann-type C–N coupling reactions of carbazole derivatives and aryl iodides. Org. Lett. 17, 3640–3642 (2015).

Lei, T. et al. General and efficient intermolecular [2+2] photodimerization of chalcones and cinnamic acid derivatives in solution through visible‐light catalysis. Angew. Chem. Int. Ed. 56, 15407–15410 (2017).

Lei, Z., Zhang, W. & Wu, J. Photocatalytic hydrogen atom transfer-induced arbuzov-type α-C (sp3)–H phosphonylation of aliphatic amines. ACS Catal. 13, 16105–16113 (2023).

Fu, M.-C., Shang, R., Zhao, B., Wang, B. & Fu, Y. Photocatalytic decarboxylative alkylations mediated by triphenylphosphine and sodium iodide. Science 363, 1429–1434 (2019).

Acknowledgements

This work was financially supported by the King Abdullah University of Science and Technology (KAUST), Saudi Arabia, Office of Sponsored Research (URF/1/4405). We thank Dr. Bo Li and Mr. Amir I. Gizatullin (both KAUST) for providing starting materials. Helpful discussions with Prof. Chen Zhu (Eastern Institute for Advanced Study, Eastern Institute of Technology) and Prof. José G. Hernández (Universidad de Antioquia) are gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

D.K. and L.Y. designed and performed the experiments. D.K. and A.N. designed the photo-mechanochemical platform and prepared the images in Fig. 1a–c using Adobe Illustrator. D.K. wrote the manuscript with feedback from all authors. M.R. conceived the project and prepared the final draft of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Zepeng Yang, and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kong, D., Yi, L., Nanni, A. et al. A scalable photo-mechanochemical platform for sustainable photoredox catalysis by resonant acoustic mixing. Nat Commun 16, 3983 (2025). https://doi.org/10.1038/s41467-025-59358-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-59358-1