Abstract

Electrolytically generated gas bubbles can significantly hamper the overall electrolysis efficiency. Therefore it is crucial to understand their dynamics in order to optimise water electrolyzer systems. Herein, we elucidate a distinct transport mechanism whereby electrolyte droplets are sprayed into H2 bubbles. These droplets arise from the fragmentation of the Worthington jet, which is engendered by the coalescence with microbubbles. The robustness of this phenomenon is corroborated under both normal and microgravity conditions. Reminiscent of bursting bubbles on a liquid-gas interface, electrolyte spraying results in a flow inside the bubble. This flow couples, in an intriguing way, with the thermocapillary convection at the bubble’s surface, clearly underlining the high interfacial mobility. In the case of electrode-attached bubbles, the sprayed droplets form electrolyte puddles affecting the dynamics near the three-phase contact line and favoring bubble detachment from the electrode. The results of this work unravel important insights into the physico-chemical aspects of electrolytic gas bubbles, integral for optimizing gas-evolving electrochemical systems.

Similar content being viewed by others

Introduction

The growth of gas bubbles abounds in nature and has various engineering applications1 and is reflected in natural phenomena. Some of them, featuring rapid dynamics, are sonochemistry2 and sonoluminescence3, cavitation4, the evolution of CO2 bubbles in sparkling drinks5, and the bursting bubbles at the oceans surface6,7. The latter contributes significantly to atmospheric aerosol generation8 via two different mechanisms: the disintegration of a thin liquid film between the bubble and gas interface at the onset of bursting9,10,11, and by an inertia-driven liquid jet–referred to as Worthington jet fragmenting into multiple droplets12,13, where the mechanism is either end-pinching14,15,16,17 or Rayleigh–Plateau instability8,18. Beyond aerosol generation19, these jets are responsible for contaminant dispersion20,21. Additionally, they result in surface erosion and deformation through the impact of droplets on solid22 and liquid surfaces23, respectively.

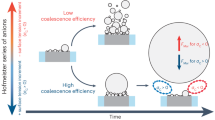

A related problem also occurs in electrolysis, where the coalescence of hydrogen or oxygen bubbles can be approximated to bursting events at a liquid-gas interface. This is a particularly interesting problem of high practical relevance due to the prominent role of hydrogen produced via water electrolysis as an energy carrier, fuel, and feedstock for chemical and steel industries24. Alkaline water electrolysis is still the most mature technology, albeit suffering from inadequate efficiency when operated at high current densities. A considerable part of the losses can be attributed to the formation of H2 and O2 bubbles, present at the electrodes and in the bulk. These bubbles mask the active area of the electrodes, reduce the number of nucleation sites, and raise ohmic cell resistance25,26. Thus, enhanced removal of gas bubbles, inherently requiring a better understanding of their growth and departure, will promote continuous catalytic activity27 and benefit further optimization of the system’s energy efficiency28.

The dynamics of electrolytic bubbles have been extensively studied in the last few decades25,29 to uncover the growth laws controlled by either the diffusion of dissolved hydrogen30,31 or direct injection of the gas at the bubble foot32; mass transfer and associated limitations31,33; interactions between neighboring bubbles27,34; the impact of the electrolyte composition35, also in the presence of surfactants36; the force balance governing the bubble departure34,37 and finally the impact of bubbles on the cell overpotentials25,30. Only recently, the soluto- and thermocapillary Marangoni35,38,39,40 force and an electric32,37 force caused by charge adsorption, which had not been considered before, have been uncovered and quantified. Furthermore, it has been discovered that H2 bubbles on microelectrodes do not necessarily adhere to the surface. Instead, they might reside atop a “carpet" of microbubbles and grow via intensive coalescence with this bed of tiny precursors32. However, the full implications of such rapid coalescence events in water electrolysis remain elusive–an area ripe for further inquiry. Several lingering questions are yet to be addressed: What are the main features of the coalescence in the confined geometry, set by H2 bubble, carpet and electrode, and how do they interact with the Marangoni flow at the bubble surface? Under what conditions does electrolytic bubble coalescence lead to droplet and spray formation? Does this affect the contact line and potentially the detachment of the electrode-attached bubble?

In the present work, we address these open questions by combining experiments on the coalescence-driven dynamics of H2 bubbles, focusing on the interior of the bubbles under both terrestrial and microgravity environments, alongside tailored direct numerical simulations.

Results

Electrolyte spraying

The main phenomenon under study, spray formation inside a H2 bubble during water electrolysis, is presented in Fig. 1. This observation was made under microgravity conditions provided by parabolic flights of an Airbus A31041. The snapshot at t = 0 shown in Fig. 1a documents the time instant when the bubble sits at the electrode surface, blocking most of its active area, hindering the reaction and hydrogen production rates. Figure 1b, c zooms into the central and lower segments of the bubble, respectively, at various time points leading up to its departure. Soon after t = 0, the bubble begins a lateral shift to the right driven by residual gravitational forces releasing the electrode and enabling the formation of a dense carpet of microbubbles. As a result, the primary bubble continuously coalescences with these microbubbles emerging on a time scale of \({{{\mathcal{O}}}}\)(μs). The successive images document an emerging flow consisting of electrolyte droplets, which is initiated soon after the onset of coalescence events and ascends from the base of the bubble toward its apex. These droplets become noticeable at t = 0.16 s, with their population density peaking at t = 1.08 s and declining by t = 2.92 s. The gradual widening of the gap between electrode and bubble interface over time has two different effects: (i) It enhances the electrochemical reaction (by increasing the electric current, see Supplementary Fig. 1), thereby elevating H2 production and bubble–carpet coalescence rates, and (ii) it leads to the generation of larger pre-coalescence bubbles, in turn decreasing the frequency of the coalescence events and, subsequently, droplet injections into the main bubble. The competition between these two effects establishes an optimal carpet thickness at which the coalescence rate has its maximum. Beyond this distance, the droplet population significantly reduces, as evidenced at t = 2.92 s. The droplet radii remain approximately constant at 1.8 ± 0.8 μm during most of the coalescence phase, increasing to about 3.1 ± 1.3 μm only just before bubble departure, when the gap between bubble interface and the electrode is at its maximum.

A series of shadowgraphs documenting the stream of electrolyte microdroplets inside a H2 bubble (Rb = 902 μm at the departure) during the late phase of its evolution in a micro-g environment. At t = 0 in (a) the bubble sits at the electrode. The successive images in (b) and (c), zooming into central and lower segments of the bubble, shown by red and blue rectangles in (a), demonstrate the emerging flow of electrolyte microdroplets, initiated soon after the onset of lateral motion to the right followed by the intensive coalescence events. The H2 bubble is produced during water electrolysis at 100 μm Pt microelectrode at −4 V (vs. Pt wire) in 0.5 mol L−1 H2SO4. The image recording was performed with a frame rate of 50 Hz. For further details, we refer to Supplementary Movie 1.

Impact of Marangoni convection on internal flow structure

In the following, we demonstrate how the phenomenon manifests itself under normal gravity conditions. Figure 2 illustrates (a) the electric current I at − 3 and − 7 V, and shadowgraphs along bubble evolution at −3 V in 0.1 mol L−1 H2SO4. In detail, a single primary bubble forms via coalescence shortly after nucleation at t/T = 0 from many nano- and micrometer bubbles32. It continues to grow through rapid \({{{\mathcal{O}}}}\)(μs) coalescence with the carpet of microbubbles beneath. The evolution ends with the bubble departure at t/T = 1 when buoyancy overcomes downward forces37. T is the bubble lifetime. I(t) reflects variations in ohmic resistance due to bubble size and position relative to the electrode, peaking between the departure and nucleation of the next bubble.

The dynamics of H2 bubble presented in terms of (a) electric current at −3 (top) and −7 V (bottom), supplemented with shadowgraphs throughout its evolution at −3 V. The rightmost image zooms into the middle part of the bubble at t/T = 0.8, shown by the red rectangle. b, c Snapshots highlighting the streaklines of the droplets over Δ t = 25 ms. d, e The streamlines of the averaged drop velocity field. Before velocity calculations, optical distortions (aberration) caused by the curvature of the bubble are analytically corrected (see Methods and Supplementary Note 2). The measurements in (b–d) and (c–e) performed in 0.1 mol L−1 H2SO4 at −3 and −7 V vs. Ag/AgCl, respectively. For further details, we refer to Supplementary Movies 2 to 4. Source data are provided as a Source Data file.

In analogy to Fig. 1, numerous electrolyte droplets are injected during the coalescence events, as seen in the last image of Fig. 2a, which focuses on the central segment of the bubble at t/T = 0.8. The snapshots in (b,c) highlight the streaklines of the droplets over Δt = 25 ms, emerging at the bubble-carpet interface and moving towards the bubble apex with the velocities plotted in (d,e).

The flow in Fig. 2b–e develops continuously throughout the bubble evolution, along with and in response to the growing carpet thickness32,35 and hence elevated current, reaching velocities of up to 14 mm s−1 at t/T = 1.0. High-speed recordings at 600 and 720 kHz (Supplementary Note 3 and Supplementary Fig. 4) reveal that some droplets are injected at velocities up to 15.8 m s−1, i.e. three orders of magnitude higher. These rare events, resulting in larger droplets, occur around the bubble’s departure when the carpet thickness is at its maximum, approximately between δ = 16 μm and δ = 43 μm (see Fig. 2a), but are not observed during the earlier stages of the bubble’s evolution when δ < 16 μm.

At a substantially larger electric current (see Fig. 2a), the flow is altered by the presence of a vortical structure, see a transition from a fireworks-like shape (b,d) at −3 V to a vortex-like shape at −7 V (c,e). Meanwhile, the flow at the base of the injection remains similar. At lower potential, the flow expands away from the injection source, while at higher potential, the droplets are carried away from the injection area and ascend along the bubble-electrolyte interface. In the latter, some droplets enclosing the vortex are carried back toward the electrode. In both cases, the velocity gradually decays with distance. Indeed, the velocity of injected droplets is expected to decay exponentially over time due to viscous drag: \({v}_{{{{\rm{d}}}}}(t)={v}_{0}\cdot \exp \left(-t/{\tau }_{{{{\rm{d}}}}}\right)\) (Supplementary Fig. 5). Here, \({\tau }_{{{{\rm{d}}}}}=\frac{{m}_{{{{\rm{d}}}}}}{6\cdot \uppi \cdot {\upmu }_{{{{\rm{H2}}}}}\cdot {R}_{{{{\rm{d}}}}}}\) and Rd is the radius of the droplet, md is the mass of the droplet, v0 is the initial velocity and μH2 is the dynamic viscosity of H2. For example, a droplet with Rd = 1 μm (implies τd ≈ 25 μs) and initial velocity v0 = 5 m s−1 slows to 10−2 m s−1 in just 160 μs by traveling 124 μm. At − 7 V, droplets near the z-symmetry line (see Fig. 2e) are dragged into the downward flow stream, enclosing the vortex.

The flow transition observed between −3 and −7 V is due to Marangoni convection around an electrogenerated gas bubble existing at its outer interface. This convection originates from a gradient of surface tension caused by thermo- and/or solutocapillary effects35,38,39, creating a shear stress imbalance that moves the liquid-gas interface. The resulting flow is directed alongside the electrolyte-gas interface from small to large values of surface tension, i.e., from the bottom to the top of the bubble. These effects are localized at the foot of the bubble and are consistent with the position of the vortex ring in Fig. 2e. Thermal Marangoni forces are driven by Joule heating from locally high current density (j) at the wetted part of the electrode and scale (via Ohm’s law) with j2, while solutal Marangoni forces arise from electrolyte depletion at the electrode and depend linearly on j. At higher potentials, as in the present study, the Marangoni convection is mainly driven by thermal effects35, with temperature rising up to 14 K39. The velocity magnitude scales with the electric current38 and may reach about 10 mm s−1 at −2.2 mA and 47 mm s−1 at −4.8 mA in 0.5 mol L−1 H2SO442. This concludes that the pronounced variance in flow structure between −3 and −7 V originates from the substantial difference in electric current magnitude and, consequently, the Marangoni convection. Thus, reminiscent of evaporating droplets43 or rising bubbles44, Fig. 2 demonstrates that Marangoni convection at the electrolyte-gas interface drives internal flow in electrogenerated gas bubbles, directing and accelerating injected microdroplets. This also indicates that the gas-electrolyte interface is mobile, though the mechanism behind preferential ion adsorption and its effects remain unclear.

Electrolyte puddles at the bubble-electrode interface

Another intriguing outcome of the spraying, shown in Fig. 3, is the formation of electrolyte fractions within an electrode-attached and growing H2 bubble, specifically at the contact area with the electrode surface34,36. Figure 3a, b, d documents the views from below a transparent planar electrode (20 nm of Pt). The snapshots in Fig. 3b zoom in on the contact patch (area marked by the red rectangle in Fig. 3a), which is seen to feature sessile electrolyte droplets inside the gas phase, that expands throughout the bubble evolution34. The bubble grows mainly due to diffusion of the dissolved gas but also via coalescence with the neighboring bubbles. Here, the smaller bubbles nucleate below the equator of the primary bubble and quickly detach, see a plume of out-of-focus small bubbles in Fig. 3a, likely due to the altered morphology/wettability of a tiny cavity they nucleated at. Consequently, upon reaching the gas-liquid interface of the larger bubble, coalescence occurs between the two, see schematic in Fig. 3c.

a–d Backside views from underneath the electrode of the growing H2 bubble attached to the transparent planar Pt electrode. b Zooms into the bubble-electrode contact area shown by the red rectangle in (a), demonstrating the development of electrolyte puddles throughout the bubble evolution. c, d Schematic and shadowgraphs illustrating the injection of microdroplets upon coalescence events followed by their sedimentation at the contact area. The measurements were carried out at a current density of −50 A m−2 in 0.1 mol L−1 HClO4. The image recording in (a, b) and (d) was performed at frame rates of 60 Hz and 3000 Hz, respectively. For further details, we refer to Supplementary Movies 5 and 6.

Figure 3d details the injection of at least two microdroplets, marked by red and blue arrows, following the coalescence event between the primary and smaller bubble (black arrow at t = 0). The first droplet (red arrow) moves with a much faster velocity, likely shooting through the gas-electrolyte interface on the opposite side. In contrast, the second droplet, about r = 4 μm (blue arrow), slows down quickly due to Stokes’s drag (Supplementary Note 4 and Supplementary Fig. 5) and falls, presumably at terminal velocity, to the contact patch at t = 86.67 ms, merging with another droplet. In detail, it moves with an average velocity of about \({\overline{v}}_{{{{\rm{d}}}}}=0.26\) m s−1 within the first 1.33 ms and about \({\overline{v}}_{{{{\rm{d}}}}}=6\) mm s−1 between 1.33 ms and 86.67 ms, assuming the traveled distance Sd equals the bubble radius Rb = 509 μm. The latter correlates well with the terminal velocity of the droplet vt = 4.1 mm s−1 in the Stokes regime (Supplementary Note 4). The process repeats during numerous coalescence events, resulting in the gradual formation of electrolyte puddles, as shown in Fig. 3b. These puddles grow in size throughout the bubble evolution, as more electrolyte droplets are injected, wetting larger areas of the electrode. Once any of the puddles reaches the gas-electrolyte interface, it rapidly merges with the electrolyte bulk, thereby moving the contact line and effectively reducing the bubble-electrode contact area (see frames at 47.783 s and 64.650 s).

This process thus plays a key role for the bubble detachment. The detachment size of an electrode-attached bubble is primarily governed by the surface tension force Fs, which depends on the length of the contact line (Lc). Comparing the snapshots at 47.783 s and 64.650 s, the length of the contact line can either increase or decrease after the puddle merges into the electrolyte bulk. A sudden reduction in Lc, provided there is sufficient buoyancy, causes an earlier detachment from the electrode surface, as illustrated in the snapshot at 64.667 s. The scarcity of electrolyte puddles in (d) is attributed to the reduced number of nucleation sites and their lower activity near the primary bubble, resulting in a lower frequency of coalescence events and fewer injected droplets.

Worthington jet: electrolyte injection

Figure 4a shows a sequence of shadowgraphs detailing the mechanism of droplet injection characterized by the formation of an internal jet that entrains a volume of electrolyte, known in the fluid mechanics and physical oceanography communities as the Worthington jet12. The process is demonstrated by two coalescing H2 bubbles with sizes Rb = 400 μm and Rs = 205 μm, respectively. The results are corroborated by direct numerical simulations (DNS) shown in Fig. 4b. In detail, when a smaller bubble touches a larger one, the liquid film that separates the bubbles gradually drains, forming a neck connecting the two (t = 33.3 μs)45. Growth of this neck follows a Taylor–Culick-type mechanism45,46,47 exciting capillary waves that propagate along the bubble interface48,49, see t = 66.7 μs –183.3 μs. Viscous forces damp the motion of these capillary waves, except for the strongest ones, which have the highest curvature. These waves concentrate at the bottom and induce a region of high curvature13,50,51, see t = 191.7 μs–208.3 μs. This inertial flow focusing creates an upward jet (t = 216.7 μs–241.7 μs)13,49,52 propagating inside of the merging H2 bubbles. Consequently, this process is controlled by the dimensionless viscosity of the electrolyte given by the Ohnesorge number (Oh)

where μel represents the dynamic viscosity, ρel the density of the electrolyte, γ the surface tension, and Rs the initial radius of the smaller bubble. Eventually, the jet breaks into two droplets due to the end-pinching mechanism13,51, for Oh < Oh*. Here, Oh* ≈ 0.035 is the critical Ohnesorge number for the transition from drops ejection to no-drops ejection13,51 for bursting of a jet at a free liquid-gas interface. The jet fragmentation results from the competition between the pressure-driven flow from the cylindrical jet toward the tip of the jet, and the capillary retraction of the jet tip. As a result of the latter, the tip is converted into a bulbous end, followed by a localized necking near the bulbous end, creating a blob. This blob at the jet tip detaches to form one droplet at a time. This pinching-off mechanism is consistent with the framework established previously for filament breakup14,15,16,17. Beyond the critical Ohnesorge number, viscous dissipation starts to dominate, ceasing the end-pinching of drops. We stress that in this regime, the jet could still break-up following the Rayleigh–Plateau mechanism8,18. On further increasing the Ohnesorge number (Oh > 0.1), the Worthington jet does not form, and there are no droplets13,51.

Coalescence of two H2 bubbles of unequal size, shown by snapshots from (a) an experiment and (b) a numerical simulation. In the experiment, both bubbles were produced during electrolysis in 0.5 mol L−1 H2SO4. While the bigger bubble is pinned to a blunt needle, the smaller bubble rises from the electrode until the coalescence begins at t0 = 0. The coalescence process is accompanied by the injection of two droplets after their consecutive separation from the jet. The first snapshot in (a) (not to scale) demonstrates the configuration, marking the region of interest with a red rectangle. The image recording was performed at 120 kHz. For further details, we refer to Supplementary Movie 7.

The DNS results in Fig. 4b accurately reproduce key features and timescales of the phenomenon, such as neck formation, capillary wave propagation, formation, and breakup of the jet. In the experiments, the first droplet with a radius of rd = 13 μm is observed at t = 250.0 μs and ejects with a velocity of approximately \({\overline{v}}_{{{{\rm{d}}}}}=7.2\,{{{\rm{m}}}}\,{{{{\rm{s}}}}}^{-1}\). In close qualitative and quantitative agreement, the simulation demonstrates the first droplet (radius rd = 15 μm) pinching off at t = 260 μs with \({\overline{v}}_{{{{\rm{d}}}}}=4.3\,{{{\rm{m}}}}\,{{{{\rm{s}}}}}^{-1}\). Minor quantitative discrepancies arise from several factors. Experimental estimates of droplet size and velocity may be compromised due to the bubble curvature, which could be analytically corrected for a spherical shape. However, the significant deformations during the coalescence process complicate precise measurements. We stress that the breakup process is a finite-time singularity53—so whether or not the jet breaks into droplets can be precisely reproduced in the simulations18—however, the time to break up and the velocity of the ejected drop are sensitive to the discrete nature of simulation method, experimental noise, and the measurement technique45. Additionally, the jet velocity, which determines the droplet post-ejection velocity, varies over time13,48; small variations in sampling time can thus explain discrepancies. Factors such as an inaccurate gas-liquid viscosity ratio and the sensitivity of velocity to the Ohnesorge number and size ratio also contribute to the differences between experimental and simulation results51. Given these error sources, the observed discrepancies are reasonable. Further details on the comparison between the experiments and simulations are provided in Supplementary Note 5.

It is important to note that the injection demonstrated at Oh = 0.008 in Fig. 4 represents a relatively isolated but conventional case13,51, with the smaller bubble being located far from the electrode. In contrast, the bursting events in Figs. 1 and 2 taking place in a highly confined configuration near the Pt electrode feature high coalescence rates and involve smaller bubbles (up to about Rs = δ/2 = 8 μm). Despite the higher Ohnesorge number (Oh = 0.042), injections still occur, exceeding the critical Oh* found for an unconfined isolated bubble. This observation suggests that a nearby wall and high coalescence rates can significantly influence the injection mechanism. In agreement with this, Lee et al. (2011)54 identified a higher critical value Oh* = 0.052, specifically for smaller bubbles (with Bond number \(\,{{\mbox{Bo}}}=\frac{{\rho }_{{{{\rm{el}}}}}g{R}_{{\mbox{s}}\,}^{2}}{\gamma } \, < \, 1{0}^{-3}\)) bursting near a solid boundary. g is the gravitational acceleration.

Lee et al. (2011)54 also studied a bubble with a relatively small Rs = 26.5 μm adjacent to a Pt substrate using ultrafast X-ray imaging, finding daughter aerosol droplets (2 μm to 4 μm radii) with velocities around 0.3 m s−1 (Supplementary Movie 5 in Lee et al.54). Consequently, we can classify the bursting events in order of increasing droplet speed: (i) carpet bubbles (Rs = 8 μm) bursting near a solid wall with a velocity of vd ~ 10−2 m s−1, (ii) a bubble with Rs = 26.5 μm bursting near the solid wall, resulting in a droplet velocity of vd ~ 10−1 m s−1, and (iii) the bubble with Rs = 205 μm bursting away from the wall (as detailed in Fig. 4), which results in a droplet velocity in the range of vd ~ 100 m s−1 to 101 m s−1. Further deceleration likely comes from viscous drag within the surrounding H2 gas, as described by the Oseen approximation to the Stokes flow. Finally, a high coalescence rate, as seen in Figs. 1 and 2, could disrupt the symmetry of coalescence, affecting the propagation of capillary waves in each event and potentially significantly reducing the velocity of the ejected droplets to vd ~ 10−2 m s−1. Therefore, the small initial size of the bursting bubble (i.e., large Oh), proximity to a wall, higher viscosity of the gas bubbles, and potentially high coalescence rates can substantially reduce the injection velocity.

Discussion

Our findings demonstrate a distinct transport mechanism of electrolyte droplets inside the gas phase during water electrolysis. As discussed above, the coalescence of a primary bubble with the bubbles-satellites causes the electrolyte spraying via the fragmentation of the Worthington jet. This indicates that the H2 bubble is not only composed of hydrogen gas and vapor but includes electrolyte fractions given the coalescence with nearby bubbles. We emphasize again that the microdroplets formed in the bubble through this process play an important role for the bubble detachment, once they merge with the surrounding electrolyte at the contact line. The results we report will be integral for further studying the limits of jet formation and rupture associated with Oh* in confined geometries near a solid boundary. Additionally, our findings will be valuable for validating and tailoring numerical and theoretical models. In particular, the droplet radii, injection speeds, and trajectories in various configurations, see the bubble-carpet system in Figs. 1 and 2, the surface-attached bubble system in Fig. 3 and the model experiment in Fig. 4, can serve as validation benchmarks. We highlight that the injected droplets serve as a non-invasive tool, making the internal flows associated with Marangoni convection at the electrolyte-gas interface visible and quantifiable. This gives access to the important surface mobility of electrogenerated bubbles, which is determined by preferential ion adsorption—a phenomenon that remains poorly understood. This will allow to assess the role of physicochemistry in the hydrodynamic phenomena related to bubbles. The knowledge could further be transferred to the other side of the electrochemical reaction—the formation of O2 bubbles. The results of this work unravel important insights into the physicochemical aspects of electrochemically generated H2 gas bubbles and have broad relevance, e.g. to acid mist formation in electrowinning processes55; the generation of sea spray aerosols6, which play a role in airborne disease and pollutant transmission21; bursting CO2 bubbles in sparkling drinks5; and to the impact of droplets on liquid23 surfaces. In particular, the findings are essential for the water electrolysis field, where a deeper understanding of bubble evolution mechanisms is essential for optimizing gas-evolving electrochemical systems.

Methods

The hydrogen gas bubbles were produced using both micro- and planar electrodes during water electrolysis. Part of the results (see Fig. 1) were obtained in a microgravity environment achieved during the 34th DLR Parabolic Flight Campaign in September 2019 (see Bashkatov et al.41).

Materials

All chemicals were used without further purification process. The electrolytes were prepared from 1 mol L−1 H2SO4 (Carl Roth GmbH & Co) and 1 mol L−1 HClO4 (Carl Roth GmbH & Co), and Milli-Q water (≥18.2 MΩ cm).

Microelectrode system

Single hydrogen gas bubbles growing on the carpet of microbubbles were produced using a three-electrode electrochemical cell filled with sulfuric acid of either 0.1 mol L−1 or 0.5 mol L−1 concentration, see Fig. 5a. The cell used here closely resembles that used in earlier studies27,56,57. It comprises a cathode (Pt microelectrode, 99.99%, ⌀100 μm, ALS Co., Ltd) inserted horizontally facing upward in the base of a transparent cuboid glass cuvette (Hellma) with dimensions of 10 × 10 × 40 mm3, anode (⌀0.5 mm Pt wire, 99.99%, ALS Co., Ltd) and the Ag/AgCl reference electrode (BASi, Inc.) both inserted from the top. The experiments in a microgravity environment were done using a pseudo-reference electrode (identical to the anode)41. The electrochemical cell was fixed inside an outer housing featuring two optically accessible observation windows. Before the measurements, the microelectrode surface underwent mechanical polishing with sandpaper (2000 grit), sonication, and rinsing with ultrapure water (≥18.2 MΩ cm). For microgravity experiments, it was polished by diamond (1 μm) and alumina (0.05 μm) suspensions (ALS Co., Ltd) instead. The cell was connected to an electrochemical workstation (CHI 660E, Autolab or Biologic VSP-300) and operated at a constant potential of either −3, −4, or −7 V.

Schematics (not to scale) of (a) an electrochemical cell and a shadowgraphy system; (b) an H2 bubble residing atop a carpet of microbubbles, generated between its bottom and the electrode surface, as shown by the red rectangle in (a). An inset zooms into the bottom of the bubble, marked by a black rectangle, where an intensive bubble-carpet coalescence takes place. The red lines represent the distribution of the current density (j), and the black streamlines on the right represent the Marangoni convection with velocity v. The panels (a) and (b) are adapted from Ref. 32; (c) PTV optics used to measure the velocity of injected droplets inside the H2 bubble. The cyan lines indicate the laser rays' path. For details, see text.

The experiments using a blunt needle in Fig. 4 were performed as follows: A larger H2 bubble (≈400 μm radius) was generated upfront at the microelectrode and detached upon potential interruption. As it ascended, it adhered to a blunt needle positioned above the microelectrode, with surface tension keeping the bubble attached. A second, smaller bubble (≈205 μm radius) was produced in the same manner, with the smaller size achieved by applying a shorter pulse of potential. As the smaller bubble rose, it contacted the larger bubble, initiating the coalescence process. The time t0 marks the moment just before coalescence begins.

Planar electrode system

The electrode-attached hydrogen gas bubbles were produced at the surface of a ⌀50 mm disc-like planar electrode (cathode) inserted horizontally facing upward in the base of the cylindrical PTFE (polytetrafluoroethylene) compartment with an inner ⌀ of 40 mm and a height of 50 mm filled with 0.1 mol L−1 HClO4. The cathode was fabricated by sputtering a 20 nm thin film of platinum onto a glass slide, with a 3 nm tantalum layer applied for improved adhesion. The thin layer of platinum ensured the transparency of the cathode and allowed visualization from the bottom of the cell. The cell was completed by a platinized titanium mesh (anode) and the Ag/AgCl reference electrode (BASi, Inc.), both inserted from the top. The system was controlled by the electrochemical workstation (Biologic VSP-300) maintaining a constant current density of −50 A m−2. The relatively low current density and smooth surface of the cathode allowed only a limited number of active nucleation sites, making the study of the contact line and electrolyte puddles dynamics possible. For details, we refer to Demirkır et al.34.

Shadowgraphy system

The visualization of the bubble dynamics is performed using a conventional shadowgraphy system, shown schematically for a microelectrode system in Fig. 5a. It consists of a high-speed camera connected to the microscope and LED illumination. The shadowgraphs in Figs. 1 and 2a were recorded using an IDT camera (NX4-S1 and Os7-S3) with spatial resolutions of 678 and 1391 pixels mm−1, respectively. In Figs. 3 and 4a, a Photron camera (FASTCAM NOVA S16) was used, with spatial resolutions of 530 and 496 pixels mm−1, respectively. To achieve the bottom view (planar electrode system), the optical path of a horizontally installed camera is redirected vertically through the transparent cathode using a 45∘ mirror mounted below the electrode34. The LED light illuminates perpendicularly to the electrode from the top of the cell. The vertical adjustments of the focal plane are achieved using a high-precision motorized stage.

Particle tracking velocimetry (PTV)

The evolution of H2 bubbles at microelectrodes is featured by the intensive coalescence with the carpet of microbubbles sandwiched between the bubble bottom and electrode (Fig. 5b) on a time scale of μs. Owing to these coalescence events, multiple electrolyte droplets are injected into the bubble. The velocity measurement of these electrolyte droplets is performed using a particle tracking velocimetry (PTV) system, schematically shown in Fig. 5c.

The setup employs a light sheet optical configuration comprising a laser (OBIS 488LX, 150 mW, Coherent Inc.) that was spatially enlarged using a telescope (L1 & L2). To minimize reflection at the bubble surface, a λ/2-waveplate is employed to rotate the polarization. Subsequently, the beam is vertically expanded using a cylindrical lens (L3) before being focused inside the bubble by another lens (L4) with a focal length f = 19 mm. For imaging purposes, a microscope objective (PLN 10× , Olympus) is positioned such that the bubble resides within the working distance. Finally, the bubble is imaged onto the camera (EoSens 3CXP, Mikrotron) using a lens (L5) with a focal length f = 160 mm. To resolve the contours of the bubble, the system additionally possesses a background LED illumination. A series of images from Fig. 2b, c is collected at 1 kHz, having a spatial resolution of 1140 pixels mm−1. Before velocity calculations, optical distortions (aberration) caused by the curvature of the bubble are analytically corrected (see next subsection). The resulting series of images were processed by the software DaViS 10, which employs a PTV algorithm to track each particle (droplet) over 25 ms at t/T = 0.6, 0.8 and 1.0. Due to the limited number of droplets, the resulting tracks were collected over several bubbles. Subsequently, the tracks were converted into a vector field using a binning function that interpolates local tracks on a specified fine grid. Finally, the vector fields are used to plot the streamlines of the averaged drop velocity field shown in Fig. 2.

Analytical aberration correction

Aberrations (optical distortions) caused by light refraction at the curved gas-liquid interface of the bubble lead to a significant systematic measurement deviation58,59. As the bubbles are of sub-millimeter size, the correction using an optical element is challenging. However, for object-space telecentric lenses, like the microscope objective used for the measurements here, the aberrations can be corrected analytically, which has already been done for the flows inside the droplets60,61. In the present study, the entrance pupil of the system is at infinity, resulting in chief rays parallel to the optical axis in the object space. When back-propagating the rays through the optical system, the intersection of the back-propagated ray and the light sheet (positioned in the middle of the bubble), can be calculated with and without the bubble in the system.

Supplementary Fig. 2a documents a schematic of the chief rays passing through the bubble surface. The solid lines mark the real path of the light scattered at the injected electrolyte droplets, whereas the dashed lines indicate the path recorded by the camera. Supplementary Fig. 2b demonstrates a single ray passing through the bubble-electrolyte interface with the relevant geometry used in further calculations of the corrected position for each detected droplet. Since the bubble is assumed to be axisymmetric, the position of the droplet is defined by the radial distance from the bubble center in the plane of the laser sheet. The measured and real (corrected) positions of the injected droplet are therefore defined as rmeas and rcorr. The corrected position for each of the detected droplets can be calculated as rcorr = rmeas + Δr using

where n is the refractive index of the electrolyte and Rb is the radius of the bubble. The results of the analytical aberration correction and further details can be found in Supplementary Note 2 and Supplementary Fig. 3.

Numerical method

In this work, the direct numerical simulation, using open source language Basilisk C, is employed to simulate the coalescence of two bubbles. A two-fluid model, combined with a Navier Stokes solver, is employed. The interface of the liquid and gas is tracked with the Volume of Fluid (VoF) method. The liquid phase is water with a density and dynamic viscosity of 1000 kg m−3 and 0.00105 Pa s, respectively. The gas phase is air, with a density and dynamic viscosity of 1.41 kg m−3 and 1.86 ⋅ 10−5 Pa s. The surface tension on the interface of liquid and gas is 0.072 N m−1. The initial radius of bubble 1 is Rb = 400 μm and bubble 2 is Rs = 200 μm. Figure 6 demonstrates a sketch of the simulation model.

Spatial discretization is performed using a quad-tree method in a 2D axisymmetric calculation domain of 1.5 ⋅ 10−3 m × 1.5 ⋅ 10−3 m. The adaptative Mesh Refinement algorithm was used to increase the calculation accuracy and reduce the hardware requirement. The maximum refinement level and the minimum level are 9 and 5, respectively. The calculation time step size is set to 1 ⋅ 10−8 s. We emphasize that while present simulations assume axisymmetric bubbles as previous simulation work has done13, real bursting events may demonstrate slight asymmetry, leading to the deviations in the jet/droplet bursting velocity and droplet radius.

Data availability

The data that support the findings of this study are available from RODARE62 and from the corresponding authors upon request. Source data are provided with this paper.

Code availability

Codes used in this study are available from Zenodo63 and from the corresponding author upon request.

References

Lohse, D. Bubble puzzles: from fundamentals to applications. Phys. Rev. Fluids 3, 110504 (2018).

Suslick, K. S. Sonochemistry. Science 247, 1439–1445 (1990).

Brenner, M. P., Hilgenfeldt, S. & Lohse, D. Single-bubble sonoluminescence. Rev. Mod. Phys. 74, 425 (2002).

Obreschkow, D. et al. Cavitation bubble dynamics inside liquid drops in microgravity. Phys. Rev. Lett. 97, 094502 (2006).

Liger-Belair, G., Polidori, G. & Jeandet, P. Recent advances in the science of champagne bubbles. Chem. Soc. Rev. 37, 2490–2511 (2008).

Villermaux, E., Wang, X. & Deike, L. Bubbles spray aerosols: certitudes and mysteries. PNAS Nexus 1, pgac261 (2022).

Deike, L. Mass transfer at the ocean–atmosphere interface: the role of wave breaking, droplets, and bubbles. Annu. Rev. Fluid Mech. 54, 191–224 (2022).

Blanco-Rodríguez, F. J. & Gordillo, J. M. On the sea spray aerosol originated from bubble bursting jets. J. Fluid Mech. 886, R2 (2020).

Lhuissier, H. & Villermaux, E. Bursting bubble aerosols. J. Fluid Mech. 696, 5–44 (2012).

Rage, G. et al. Bubbles determine the amount of alcohol in Mezcal. Sci. Rep. 10, 11014 (2020).

Jiang, X., Rotily, L., Villermaux, E. & Wang, X. Abyss aerosols: Drop production from underwater bubble collisions. Phys. Rev. Lett. 133, 024001 (2024).

Worthington, A. M. XXVIII. On the forms assumed by drops of liquids falling vertically on a horizontal plate. Proc. R. Soc. London 25, 261–272 (1877).

Sanjay, V., Lohse, D. & Jalaal, M. Bursting bubble in a viscoplastic medium. J. Fluid Mech. 922, A2 (2021).

Stone, H. A. & Leal, L. G. The influence of initial deformation on drop breakup in subcritical time-dependent flows at low Reynolds numbers. J. Fluid Mech. 206, 223–263 (1989).

Keller, J. B., King, A. & Ting, L. Blob formation. Phys. Fluids 7, 226–228 (1995).

Castrejón-Pita, A. A., Castrejón-Pita, J. & Hutchings, I. Breakup of liquid filaments. Phys. Rev. Lett. 108, 074506 (2012).

Anthony, C. R., Kamat, P. M., Harris, M. T. & Basaran, O. A. Dynamics of contracting filaments. Phys. Rev. Fluids 4, 093601 (2019).

Dixit, A., Oratis, A., Zinelis, K., Lohse, D. & Sanjay, V. Viscoelastic Worthington jets and droplets produced by bursting bubbles. J Fluid Mech. 1010, A2 (2025).

Joung, Y. S. & Buie, C. R. Aerosol generation by raindrop impact on soil. Nat. Commun. 6, 6083 (2015).

Dubitsky, L., McRae, O. & Bird, J. C. Enrichment of scavenged particles in jet drops determined by bubble size and particle position. Phys. Rev. Lett. 130, 054001 (2023).

Yang, Z., Ji, B., Ault, J. T. & Feng, J. Enhanced singular jet formation in oil-coated bubble bursting. Nat. Phys. 19, 884–890 (2023).

Zhang, B. et al. Impact forces of water drops falling on superhydrophobic surfaces. Phys. Rev. Lett. 129, 104501 (2022).

Michon, G.-J., Josserand, C. & Séon, T. Jet dynamics post drop impact on a deep pool. Phys. Rev. Fluids 2, 023601 (2017).

Staffell, I. et al. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 12, 463–491 (2019).

Angulo, A., van der Linde, P., Gardeniers, H., Modestino, M. & Rivas, D. F. Influence of bubbles on the energy conversion efficiency of electrochemical reactors. Joule 4, 555–579 (2020).

Hodges, A. et al. A high-performance capillary-fed electrolysis cell promises more cost-competitive renewable hydrogen. Nat. Commun. 13, 1304 (2022).

Bashkatov, A. et al. Performance enhancement of electrocatalytic hydrogen evolution through coalescence-induced bubble dynamics. J. Am. Chem. Soc. 146, 10177–10186 (2024).

Shih, A. J. et al. Water electrolysis. Nat. Rev. Methods Primers 2, 84 (2022).

Zhao, X., Ren, H. & Luo, L. Gas bubbles in electrochemical gas evolution reactions. Langmuir 35, 5392–5408 (2019).

Raman, A. et al. Potential response of single successive constant-current-driven electrolytic hydrogen bubbles spatially separated from the electrode. Electrochim. Acta 425, 140691 (2022).

Sepahi, F., Verzicco, R., Lohse, D. & Krug, D. Mass transport at gas-evolving electrodes. J. Fluid Mech. 983, A19 (2024).

Bashkatov, A., Hossain, S. S., Yang, X., Mutschke, G. & Eckert, K. Oscillating hydrogen bubbles at Pt microelectrodes. Phys. Rev. Lett. 123, 214503 (2019).

Haverkort, J. A general mass transfer equation for gas-evolving electrodes. Int. J. Hydrogen Energy 74, 283–296 (2024).

Demirkır, Ç., Wood, J. A., Lohse, D. & Krug, D. Life beyond fritz: On the detachment of electrolytic bubbles. Langmuir 40, 20474–20484 (2024).

Park, S. et al. Solutal Marangoni effect determines bubble dynamics during electrocatalytic hydrogen evolution. Nat. Chem. 15, 1532–1540 (2023).

Fernandez, D., Maurer, P., Martine, M., Coey, J. & Möbius, M. E. Bubble formation at a gas-evolving microelectrode. Langmuir 30, 13065–13074 (2014).

Hossain, S. S., Bashkatov, A., Yang, X., Mutschke, G. & Eckert, K. Force balance of hydrogen bubbles growing and oscillating on a microelectrode. Phys. Rev. E 106, 035105 (2022).

Yang, X., Baczyzmalski, D., Cierpka, C., Mutschke, G. & Eckert, K. Marangoni convection at electrogenerated hydrogen bubbles. Phys. Chem. Chem. Phys. 20, 11542–11548 (2018).

Massing, J. et al. Thermocapillary convection during hydrogen evolution at microelectrodes. Electrochim. Acta 297, 929–940 (2019).

Meulenbroek, A., Vreman, A. & Deen, N. Competing Marangoni effects form a stagnant cap on the interface of a hydrogen bubble attached to a microelectrode. Electrochim. Acta 385, 138298 (2021).

Bashkatov, A. et al. Dynamics of single hydrogen bubbles at Pt microelectrodes in microgravity. Phys. Chem. Chem. Phys. 23, 11818–11830 (2021).

Babich, A., Bashkatov, A., Yang, X., Mutschke, G. & Eckert, K. In-situ measurements of temperature field and Marangoni convection at hydrogen bubbles using schlieren and PTV techniques. Int. J. Heat Mass Transfer 215, 124466 (2023).

Lohse, D. & Zhang, X. Physicochemical hydrodynamics of droplets out of equilibrium. Nat. Rev. Phys. 2, 426–443 (2020).

Young, N., Goldstein, J. S. & Block, M. The motion of bubbles in a vertical temperature gradient. J. Fluid Mech. 6, 350–356 (1959).

Eggers, J., Sprittles, J. E., & Snoeijer, J. H. Coalescence dynamics. Annu. Rev. Fluid Mech. 57, 61–87 (2024).

Taylor, G. I. The dynamics of thin sheets of fluid. III. Disintegration of fluid sheets. Proc R Soc Lond A Math Phys Sci 253, 313–321 (1959).

Culick, F. E. Comments on a ruptured soap film. J. Appl. Phys 31, 1128–1129 (1960).

Deike, L. et al. Dynamics of jets produced by bursting bubbles. Phys. Rev. Fluids 3, 013603 (2018).

Gordillo, J. & Rodríguez-Rodríguez, J. Capillary waves control the ejection of bubble bursting jets. J. Fluid Mech. 867, 556–571 (2019).

Duchemin, L., Popinet, S., Josserand, C. & Zaleski, S. Jet formation in bubbles bursting at a free surface. Phys. Fluids 14, 3000–3008 (2002).

Walls, P. L., Henaux, L. & Bird, J. C. Jet drops from bursting bubbles: how gravity and viscosity couple to inhibit droplet production. Phys. Rev. E 92, 021002 (2015).

Gordillo, J. M. & Blanco-Rodríguez, F. J. Theory of the jets ejected after the inertial collapse of cavities with applications to bubble bursting jets. Phys. Rev. Fluids 8, 073606 (2023).

Zeff, B. W., Kleber, B., Fineberg, J. & Lathrop, D. P. Singularity dynamics in curvature collapse and jet eruption on a fluid surface. Nature 403, 401–404 (2000).

Lee, J. S. et al. Size limits the formation of liquid jets during bubble bursting. Nat. Commun. 2, 367 (2011).

Ma, Z. et al. Others characteristics and threats of particulate matter from zinc electrolysis manufacturing facilities. J. Cleaner Prod. 259, 120874 (2020).

Yang, X., Karnbach, F., Uhlemann, M., Odenbach, S. & Eckert, K. Dynamics of single hydrogen bubbles at a platinum microelectrode. Langmuir 31, 8184–8193 (2015).

Bashkatov, A. et al. On the growth regimes of hydrogen bubbles at microelectrodes. Phys. Chem. Chem. Phys. 24, 26738–26752 (2022).

Bilsing, C., Nützenadel, E., Burgmann, S., Czarske, J. & Büttner, L. Adaptive-optical 3D microscopy for microfluidic multiphase flows. Light: Adv. Manuf. 5, 385–399 (2024).

Gao, Z. et al. Distortion correction for particle image velocimetry using multiple-input deep convolutional neural network and Hartmann-Shack sensing. Opt. Express 29, 18669–18687 (2021).

Kang, K. H., Lee, S. J., Lee, C. M. & Kang, I. S. Quantitative visualization of flow inside an evaporating droplet using the ray tracing method. Meas. Sci. Technol. 15, 1104 (2004).

Minor, G., Oshkai, P. & Djilali, N. Optical distortion correction for liquid droplet visualization using the ray tracing method: further considerations. Meas. Sci. Technol. 18, L23 (2007).

Bashkatov, A. et al. Data publication: electrolyte spraying within H2 bubbles during water electrolysis. RODARE https://doi.org/10.14278/rodare.3617 (2025).

Bashkatov, A. et al. CoBub: DNS code for “electrolyte spraying within H2 bubbles during water electrolysis”. Zenodo https://doi.org/10.5281/zenodo.15165281 (2025).

Acknowledgements

K.E., X.Y., and G.M. received funding from the German Space Agency (DLR), with funds provided by the Federal Ministry of Economics and Technology (BMWi) due to an enactment of the German Bundestag under Grant No. DLR 50WM2352 (project MADAGAS III), H2Giga (BMBF, 03HY123E), and from the Hydrogen Lab of the School of Engineering of TU Dresden. D.L. and D.K. acknowledge funding from the Advanced Research Center Chemical Building Blocks Consortium (ARC CBBC), under the project of New Chemistry for a Sustainable Future (project number 2021.038.C.UT.14). J.C. and L.B. acknowledge financial support from the German Research Foundation (DFG, project number 459505672). We thank Ayush K. Dixit for the discussions.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

A. Bashkatov and K.E. conceived the project. A. Bashkatov, F.B., Ç.D., A. Babich, X.Y., D.L., D.K., L.B., and K.E. designed the experiments. A. Bashkatov, F.B., Ç.D., and X.Y. carried out the experiments. W.D. and V.S. carried out numerical simulations. A. Bashkatov, Ç.D., W.D., V.S., A. Babich, G.M., J.C., D.L., D.K., and K.E. carried out bubble dynamics analysis. All authors read and commented on the manuscript. All authors approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Gérard Liger-Belair and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bashkatov, A., Bürkle, F., Demirkır, Ç. et al. Electrolyte droplet spraying in H2 bubbles during water electrolysis under normal and microgravity conditions. Nat Commun 16, 4580 (2025). https://doi.org/10.1038/s41467-025-59762-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-59762-7

This article is cited by

-

Particulate matter generated from electrolysis processes: a review of pollution, formation, and control technologies

ENGINEERING Environment (2026)

-

An entropy-information model for evaluating hydrogen bubble dynamics in electrolysis process using an innovative pixel frequency analysis

Heat and Mass Transfer (2025)