Abstract

Birch reduction is a well-known process for transforming aromatic compounds. The reduction of aromatic rings using alkali metals produces anionic species that react with protons or electrophiles. Generally, this reaction is accompanied by significant limitations in the available nucleophiles, since in most cases only alkyl halides and silyl chlorides are available. In particular, the arylation of unfunctionalized polycyclic aromatic hydrocarbons (PAHs), so-called Birch reductive arylation, has not yet been investigated. Herein, we report a Birch reductive arylation by mechanochemical anionic activation using a lithium(0) wire, followed by addition of various fluoroarenes. Specifically, not only Birch reductive arylation products but also formal C–H arylation products can be obtained from unfunctionalized PAHs, achieving one-pot annulative π-extension to give nanographenes. This process is a unique reaction that is rarely achieved in solution, and shows the interesting reactivity of lithium metal and fluoroarenes in the solid state.

Similar content being viewed by others

Introduction

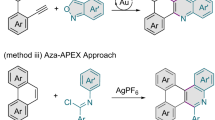

The transformation of readily available aromatic compounds is considered one of the main methods of organic synthesis. In particular, connecting aromatics and extending π-systems have been extensively performed for synthesizing polyarylenes and polycyclic aromatic hydrocarbons (PAH) with intriguing properties1,2. Except for cross-coupling reactions using halogenated and metalated arenes, Birch reductive functionalization is a classical representative transforming method for preparing arene-derived compounds via dearomative functionalization3. In the Birch reductive alkylation, the reduction of the aromatic ring using alkali metals initially produces anionic species4,5,6,7, which are further reacted with electrophiles such as alkyl halides (Fig. 1a). This protocol is widely used in natural product synthesis and other fields but has almost only been applied to small aromatics such as benzenes and biphenyls8,9,10. As recent examples, reductive alkylation biphenyls and PAHs with fluoroalkanes was reported by Albert and Miguel in 200711. Birch reductive silylation of anthracene with chlorotrimethylsilane was also reported by Kanno in 201312. Furthermore, in 2021, Yorimitsu and co-workers reported the reductive borylation of anthracene using highly reactive sodium dispersion and methoxyboronic acid pinacol ester (MeOBpin)13. They also developed the multi-methylation of corannulene in a similar reaction system14. The generated anionic arene species are unstable under air and thus require immediate trapping with electrophiles such as co-existing proton (Birch reduction) or post-adding alkyl halides (Birch reductive alkylation)15,16,17,18. However, no example of trapping the anionic arene species with aryl halides, i.e., ‘Birch reductive arylation’ have been reported so far, whereas inter-/intramolecular dearomative hydroarylations of arenes are achieved by radical and photocatalytic reactions19. One of simple potential pathways to afford Birch arylation products from simple aromatics would be nucleophilic aromatic substitution (SNAr) of fluoroarenes with reduced arene nucleophiles. However, even SNAr using inert fluoroarenes and carbon nucleophiles is expected to pose considerable challenges, and had not been achieved until the recent demonstration by Shigeno et al. using organic superbases20. Such untapped “Birch reductive arylation” is challenging but has been regarded as an important missing piece in fundamental organic chemistry and polyaromatics synthesis.

We recently developed Li(0)-mediated mechanochemical cyclodehydrogenation using a ball-milling machine for the efficient and rapid synthesis of PAHs (Fig. 1b)21. Although bulk Li commonly exhibits low reactivity in the solution state, the mechanochemical direct grinding with pieces of lithium(0) wire and 1,1’-binaphthyl results in the efficient formation of aromatic anion followed by cyclization and dehydrogenation, realizing the efficient and rapid synthesis of rylene-type nanographenes. Mechanochemical Birch reduction using K+(LiHMDS)·e– (HMDS: 1,1,1,3,3,3-hexamethyldisilazide), Li(0) and Mg/Ca22 were also reported by Lu23, Kubota/Ito22 and Aav/Kananovich24 groups. The process developed by Kubota/Ito was realized via the mechanochemical grinding of aromatic compounds using a lithium(0) wire and an ethylene diamine additive afforded hydrogenated arenes such as 1,4-cyclohexadienes and 9,10-dihydroanthracene23. A key feature in both reactions is the efficient and rapid generation of aromatic anion species using less reactive bulk lithium even under air at ambient temperature, without the use of a solvent or ammonia via “mechanochemical anionic activation,” which has been hardly achieved in the solution state25,26. This type of mechanochemical reaction shows great potential for achieving efficient and practically known reactions and unknown challenging transformations specific to solid-state, thus significantly contributing to the further development of organic synthesis25,27,28,29,30,31,32,33,34,35,36,37,38.

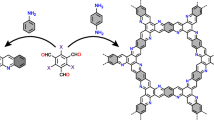

Herein, we report the C–C bond-forming SNAr type Birch reductive arylation via the mechanochemical anionic activation of unfunctionalized PAHs using lithium(0) and fluoroarenes. By directly mixing pieces of easy-to-handle lithium(0) wire, PAHs, and stoichiometric amine additives using a ball-milling machine, the formation of aromatic anions, followed by the stepwise addition of fluoroarenes, enabled SNAr-type reactions to afford arylated and hydroarylated PAHs. Depending on the reaction conditions and substrates, diverse unprecedented arylation processes have been achieved to produce mono-, di-, tetra-arylated PAHs and dihydro PAHs. Furthermore, the synthesis of large PAHs using commercially available unfunctionalized aromatic compounds has been conducted via sequentially mechanochemical SNAr reaction and mechanochemical cyclodehydrogenation19. Although related cross-coupling reactions using fluoroarenes and aryl metals via transition metal catalysis39 and the Birch reductive alkylation of arenes with alkyl halides have been reported, C–C bond forming reaction using unfunctionalized (less reactive) aromatic hydrocarbons with fluoroarenes is highly challenging and have not been achieved yet. Regardless of the reaction type and mechanism, the direct use of easily available unfunctionalized aromatics is highly desirable in organic synthesis. Such a long-awaited process is achieved via mechanochemical anionic activation.

Results and discussion

Modification of reaction conditions

We began our investigation with the Birch reductive arylation of anthracene 1a (Table 1). Following previous work on mechanochemical Birch reduction, ethylenediamine was selected as the additive for stabilizing anion species22. By investigating the reaction conditions, we observed the unprecedented Birch reductive arylation of 1a with fluorobenzene (PhF), yielding 9-phenyl-9,10-dihydroanthracene (2a), which can also be obtained by Birch reduction of 9-phenylanthracene40. The protocol is as follows: (1) 1.0 mmol of 1a (1 eq.), a piece of lithium wire (4.0 eq.), ethylenediamine (0.35 mL, 5.2 eq.) were weighed in air and added to a 5.0 mL stainless-steel jar along with two 7 mm stainless-steel balls, which were closed in air and then subjected to ball-milling at a rate of 30 Hz for 5 min (ball-milling-I); (2) after opening the jar, fluorobenzene (PhF, 1.4 eq.) was rapidly added to the dark black reaction mixture in air, and additional ball-milling was performed for 60 min at room temperature (20–25 °C) (ball-milling-II). Then, lithium and the anionic species were quenched by water, yielding the arylated product 2a in 76% NMR yield and 73% isolated yield (Table 1, entry 1). Based on the high magnetic field-shifted peaks in 1H NMR, we showed that the dark black mixture after treatment with lithium(0) and ethylenediamine corresponded to the anthracene dianion (see Supplementary Information (SI) for details, Supplementary Fig. S1). In the controlled experiments, neither an addition and mixing of PhF for 5 min in the second step nor shortening ball-milling time (60 → 5 min) significantly reduced the yield (entries 2 and 3). A reduction in the amount of lithium(0) to 2 eq. and the use of sodium(0) pieces rather than lithium(0) reduced the yields of 2a to 48% and 17% yields, respectively (entries 4 and 5). The use of other electrophiles such as chlorobenzene, bromobenzene, and benzenesulfonates in place of fluorobenzene did not afford the desired products (entries 6–8). Furthermore, the reactions using N,N’-dimethylethylenediamine or N,N,N’,N’-tetramethylethylenediamine (TMEDA) significantly decreased the yields to 0% and 11% (entries 9 and 10). Although the Birch reduction to form anthracene dianion may proceed under both reaction conditions, the following arylation did not proceed. Finally, when 6 eq. of THF was added rather than ethylenediamine, the desired arylation reaction proceeded to afford 2a in 75% NMR yield and 70% isolated yield (entry 11). Interestingly, regardless of the presence or absence of a proton source in the ball-milling-I step (e.g., entries 1 and 11), the use of lithium(0), ethylenediamine or THF, and PhF as nucleophiles was essential for this unprecedented arylation reaction. Finally, a gram-scale synthesis was performed using a large stainless-steel jar (10 mL or 50 mL volume), two or three 10-mm-diameter stainless-steel balls with 0.45 g (2.5 mmol) or 6.0 mmol (1.1 g) of 1a, giving 2a in a satisfactory yield of 43 or 41% (0.28 or 0.63 g) (entry 12 and 13). The yield in the 6.0 mmol scale (1.1 g) reaction of 2a with THF was comparable to the yield achieved using EDA (entry 14). In these large-scale reactions, significant amount of 1a remained unreacted, and side-products such as 1b, aromatized product 2a’, 9,10-diarylanthracene (5a’), and other over-reduced anthracenes were observed in 1H NMR and GC-MS analysis. As differences in the reaction profile in the different scale reaction are often observed in mechanochemical reactions, further investigation is needed on the reaction scale, size of vessel/balls, number of balls, vibration frequency, and amount of additive. To determine whether this reaction was influenced by trace metal contaminants, such as Ni and Cr, from the stainless-steel jar and balls, we also conducted the reaction using a ZrO2 jar and ZrO2 balls (entry 15). Compared to the comparable reaction conducted in the stainless-steel setup (entry 13), no significant difference in yield was observed (yield of 2a: 42%).

Control experiments

Control experiments were conducted to verify the synthesis benefits of the solid-state ball-milling reaction over the solution-state reaction. When the solution-state reaction was performed using 1a (1.0 mmol, 1.0 eq.) and Li (4.0 eq.) in THF (5.0 mL, 62 eq.) in a Schlenk tube under an argon atmosphere at 70 °C for 60 min followed by the addition of PhF, almost anthracene and lithium metal remained unreacted, and 2a was not detected at all (Fig. 2a). However, the use of ethylenediamine (5.0 mL, 75 eq.) as a solvent, at room temperature and the same reaction time as entry 1 in Table 1, afforded a trace amount of 2a. Moreover, the reaction time for the anionic activation step was extended to 60 min in ethylenediamine at 70 °C, and 2a was obtained in 14% isolated yield. Under these solution-state conditions, unreacted lithium wire was observed before quenching the reaction. The solution-state, concentrated reactions were carried out using a minimal amount of THF (0.35 mL, 6.0 eq.) or ethylenediamine (0.35 mL, 5.2 eq.) in a Schlenk tube with a magnetic stirring bar under an argon atmosphere (Fig. 2b). While the reaction with THF at 70 °C and ethylene diamine at room temperature afforded trace amount of 2a, the reaction with ethylene diamine at elevated temperature (70 °C) resulted in the formation of 2a in 23% yield. These results indicate that the Birch arylation is also promoted by the concentration effects in the conventional Schlenk tube solution-state reaction, but the reaction efficiency of these solution-state reactions was even lower than that in the ball-milling reaction in terms of yield, temperature, and reaction time. Furthermore, we conducted the first step of anionic activation by ball-milling, followed by the second step of arylation in the solution state (Fig. 2c). However, only a trace amount of 2a was obtained under both conditions. In these reactions, the Birch reduction product (9,10-dihydroanthracene) was the main product. These results showed that the newly discovered arylation reaction proceeded not only in the solid state but also in the solution state. However, the present solid/slurry-state mechanochemical reaction was advantageous in terms of handleability in air, high reactivity at room temperature, yield, and reduced use of solvents.

a Comparison with the solution-state reactions. b High-concentrated reactions in the solution-state. c Stepwise in-solution and in-solid state reaction. d Deuteration experiment in the reaction with ethylenediamine by quenching D2O. e Deuteration experiment in the reaction with THF by quenching D2O. f Reaction from dihydroanthracene 1b. g Side reaction from fluorobenzene. h Cyclization of 1-(3-buten-1-yl)−2-fluorobenzene suggesting generation of anion radical. i Control reaction of anthracene with 1-(3-buten-1-yl)−2-fluorobenzene. j Plausible pathways of Birch reductive arylation.

Further, we conducted control experiments to elucidate the arylation reaction mechanism. In deuteration experiments involving the addition of D2O rather than H2O in the quenching step of the reaction with ethylenediamine additives, deuterated products were not observed (Fig. 2d). This indicated that protonation occurred by ethylenediamine before the addition of H2O/D2O. However, D2O-quenching in the reaction with THF as an additive resulted in the formation of deuterated products 2a-D as a mixture in 60% yield with 22%, and 40/50% deuteration of three benzylic hydrogen atoms, which were confirmed by 1H NMR analysis (Fig. 2e). This fact indicated that most benzylic anion species remained intact before the addition of D2O. Using 9,10-dihydroanthracene (1b) as the starting material with Li(0) and ethylene diamine provided the arylated product 2a in a low yield of 21% along with 74% recovery of 1b, proving that the deprotonation of 1b by an in-situ-generated strong base such as amide ion is an alternative minor pathway affording 2a (Fig. 2f). In addition, the ball-milling process with lithium and fluorobenzene followed by the addition of anthracene (1a) afforded biphenyl (3) in 19%, 1b in 24%, and recovery of unreacted 1a in 62% (Fig. 2g), suggesting the competitive formation of anion radial or phenyl anion species from Li(0) and fluorobenzene41. The reaction with simultaneous mixing all reagents resulted in a lower yield of 2a along with considerable formation of by-products such as 3, 1b and other Birch reduction products (see Supplementary Fig. 5). To further investigate the active species, the ball-milling process was performed with lithium(0) and 1-(3-buten-1-yl)−2-fluorobenzene without anthracene, resulting in the formation of 1-methylindane (4) as the main product in 22% isolated yield (Fig. 2h). These results indicate the generation of the arenium radical anion by one-electron reduction, and the aryl radical species after elimination of fluoro ion followed by radical cyclization in a 5-exo-trig manner, to afford 442,43,44,45. Finally, the Birch reductive arylation of anthracene with 1-(3-buten-1-yl)−2-fluorobenzene was performed, and we obtained 1b and the arylated product 2b in 44% and 13% yield, respectively (Fig. 2i). However, the formation of a trace amount of 4 was observed by GC-MS analysis. The radical cyclization of 1-(3-buten-1-yl)−2-fluorobenzene is considered to be much faster than the other intermolecular reactions, which suggests that the formation of arenium radical anion/aryl radical via one-electron reduction of fluoroarene by anthracene dianion or remaining Li(0) is a minor pathway in the present Birch reductive arylation. Overall, these observations and the results presented in Table 1, highlight two possible pathways (Fig. 2j): One is a 2e– reduction by 2.0 eq. of Li(0), followed by SNAr with fluorobenzene and protonation by ethylenediamine or post-added H2O (path A). Another minor pathway is initiated by Li(0)-promoted Birch reduction with ethylenediamine as the proton source, along with the formation of lithium amide (R–NLi). Following the reformation of the benzyl anion in equilibrium with R-NLi, SNAr reaction with fluorobenzene can afford 2a (path B). The use of lithium(0) in the present mechanochemical reaction is rationalized by the following: (1) the highest reduction potential of Li (–3.04 V)46 in the metals, (2) effective formation of reactive fine dispersion and rapid reduction by mechanochemical grinding47,48, (3) enthalpically favorable formation of LiF (a high lattice energy (ΔH0)49 of LiF (1041 kJ/mol) than those of NaF (858 kJ/mol) and KF (799 kJ/mol), and thus lowering both the relative Gibbs energy of formation and the activation energy in SNAr step. Although these assumptions are unclear at this stage, they provide a new aspect of the mechanochemical (solid-state) reaction that cannot easily be achieved using typical solution-state reactions. Further theoretical and experimental investigations of the reaction mechanism are required to understand this reaction.

Substrate scope with various fluoroarenes

We explored the substrate scope using various fluoroarenes with a highly efficient and easy-to-handle mechanochemical arylation (Fig. 3). All the experiments were performed on a 1.0 mmol scale of anthracene (1a) unless otherwise stated. The reactions with 1,2- and 1,4-difluorobenzenes afforded corresponding fluorophenyldihydroanthracenes 2c and 2 d in 42% and 41% yields, respectively (Fig. 3). However, the reaction with 1,3-difluorobenzene yielded 9-(3-phenyl)anthracene (2e’), which is considered to form through spontaneous oxidization of 9-(3-fluorophenyl)-9,10-dihydroanthracene (2e) by air during a purification process. The use of 4-fluorobenzonitrile afforded cyanophenyldihydroanthracene 2 f in 26%. In contrast, other fluoroarenes bearing electron-withdrawing groups such as 4-ethoxycarbonyl, 4-nitro, 4-trifluoromethyl groups, and hexafluorobenzene were proved to be ineffective in this reaction (see SI for details). Fluoroarenes with electron-donating groups, such as methoxy, methyl-, and dimethyl groups, were also applicable to this reaction. When using 3- and 4-fluoroanisoles, methoxy groups were tolerated to some extent and the 9-arylanthracenes 2 g’ and 2 h’ (via oxidation) were obtained in 31% and 32% yields, respectively. The reactions of 1-fluoro-3-methylbenzene and 1-fluoro-3,5-dimethylbenzene proceeded well, affording the corresponding arylated dihydroanthracenes 2i and 2j in 69% and 50% yields, respectively. The use of 2-fluoropyridine afforded 9-(2-pyridyl)-9,10-dihydroanthracene (2k) in 64% yield, whereas the reaction using 3-fluoropyridine resulted in the formation of 9-(3-pyridyl)anthracene (2 l’) in a 41% yield. When using 1-fluoronaphthalene or 9-fluoroanthracenes, 9-(naphthalen-1-yl)anthracene (2 m’) and 9,9’-bianthryl (2n’) were obtained in 48% and 27% yields, respectively. In another demonstration, the diarylation of anthracene was performed using 2.5 eq. of fluoroarenes. The reactions with fluorobenzene, 1,4-difluorobenzene, and 1-fluoronaphthalene afforded the corresponding diarylated anthracenes 5a’, 5b’ and 5c’ in 57%, 50%, and 43% yield, respectively. Fluoroarenes with electron-withdrawing groups such as 2-fluoropyridine or 1,3,5-trifluorobeznene were converted to 9,10-diaryl-9,10-dihydroanthracenes syn-5d and a separable mixture of syn-5e and anti-5e in 43%, 19%, and 22% yields, respectively. Single crystals of syn-5e and anti-5e were obtained by recrystallization from hexane (for syn-5e) and CHCl3/MeOH (anti-5e), respectively, and their structures were elucidated by X-ray diffraction analysis. The reaction with 2-fluoropyridine afforded only syn-5d, probably because of the Li chelation effect between pyridine and the benzyl anion in the monoarylated intermediate (see SI for details); thus, syn-face-selective second arylation would preferentially occur. This result contrasts with the use of 1,3,5-trifluorobeznene with almost no stereoselectivity for syn-5e and anti-5e because of the absence of the chelation effect.

a Isolated yield. b Reactions are conducted in a 50-mL stainless-steel jar using two 10-mm stainless-steel balls. The reaction time and temperature of ball-milling-II are 180 min and heated 70 °C (heat-gun preset temperature). c The reaction time of ball-milling-II is 6 h. d The reaction time of ball-milling-II is 8 h. e The reaction time of ball-milling-II is 120 min. f 1.6 equivalent of 9-fluoroanthracene is used.

Substrate scope with various PAHs and applied for nanographene synthesis

Following the established mechanochemical arylations of anthracene, we investigated the arylation of other PAHs for the synthesis of largely π-extended structures and nanographenes (Fig. 4). Based on the results that aryldihydroanthracenes 2/5 and arylanthracenes 2’/5’ were obtained depending on the types of electronically different fluoroarenes, we conducted standard mono-arylation reactions using various PAHs (step-A) followed by oxidation of arylated dihydro-PAHs 7 to fully aromatized aryl PAHs 7’ (step-A) if the reaction gave mixtures of 7 and 7’. Interestingly, the use of TMEDA as an additive was also effective in the arylation of other PAHs. First, the oxidation of dihydroanthracene 2a with 2,3-dichloro-5,6-dicyano-1,4-benzoquinone (DDQ) was examined to afford 9-arylanthracene (2a’) in a good isolated yield (94%). The application of mono-arylation (step-A) to fluoranthene (6a) yielded complex mixtures, including dihydroarylated product 7a, arylated 3-phenylfluoranthene (7a’), and other Birch reduction side-products, in the crude mixture. Therefore, oxidation (step-B) with o-chloranil was conducted to obtain 7a’ in 20% yield. The reaction of pyrene (6b) and benzo[a]pyrene (6c) afforded the corresponding spontaneously oxidized arylated-PAH 7b’ and 7c’ as single products without step-B. The arylation reaction with benzo[a]anthracene (6 d) afforded 7-phenyl-7,12-dihydrotetraphene (7 d), whose structure was elucidated by X-ray crystallographic analysis, in a 42% yield. 7 d could be converted to 7-phenyltetraphene (7 d’) using DDQ in 54% isolated yield. The use of benzo[f]tetraphene(6e), tetracene(6 f), and pentacene(6 g) provided arylated dihydro-PAHs 7e–7 g, and 7g-py were obtained in 27% to 56% yields.

a Indicated yields are isolated ones. b Step-B is conducted with o-chloranil (2.0 eq.) in benzene (10 mL). c step-B is conducted with 2,3-dichloro-5,6-dicyano-p-benzoquinone (DDQ) (4 eq.) after the ball-milling-II. d The reaction is conducted in a 5.0-mL stainless-steel jar using two 7-mm stainless-steel balls at a 1.0-mmol scale. e The reaction time of ball-milling-II is 6 h. f The reactions are conducted on a 0.12 mmol scale. g The reactions are conducted on a 0.15 mmol scale, and 2-fluoropyridine is used rather than fluorobenzene. Anthracene (1a), fluoranthene (6a), pyrene (6b), benzo[a]pyrene (6c), benzo[f]tetraphene(6e), tetracene(6f), and pentacene (6g) were used as starting materials.

Inspired by these regioselective arylations of PAHs, we performed natural bond orbital (NBO) analysis using density functional theory calculations to understand high regioselectivities. As shown in Fig. 2j, we hypothesized that this reaction mainly proceeds via the dianion species of PAHs and that each reactive site can be formed by disproportional HOMO coefficients and NBO charges50,51 in each peripheral carbon atom of the PAH dianions (Fig. 5). Notably, the carbon atoms with the maximum absolute value of the HOMO coefficient and the largest negative value of the NBO charge are identical to each arylated position in the case of dianions of 1a, 6a, 6b, and 6d–6 g. In the case of the dianions of 6c, the experimental reaction positions did not match the positions with the largest positive or negative values. However, arylations occurred at the carbon atoms where the negative charges tended to be localized. The analysis of the electrostatic potential52 of the same dianionic PAHs also supported this regioselectivity (see SI for details).

Red-colored values represent the positive or negative largest values of the HOMO coefficient and negative largest NBO charge. Red-colored circles represent the experimental arylation positions. The bond lengths (Å) are shown inside structures. All values were calculated at B3LYP/6-31 + G(d,p) level of theory.

Multi-fold arylation of acenes

Next, we attempted multi-fold arylation at the C9 and C10 positions of anthracene. When using 8.2 eq. of lithium(0), TMEDA, and an excess amount of 2-fluoropyridine, 9,9,10,10-tetra(pyridin−2-yl)-9,10-dihydroanthracene (8) was obtained in 27% isolated yield (Fig. 6a). This multi-fold arylation can be also applied to pentacene, affording 6,6,13,13-tetra(pyridin-2-yl)-6,13-dihydropentacene (9) in a 24% isolated yield (Fig. 5b). At this stage, we confirmed that only 2-fluoropyridine was effective for the four-fold arylation of acenes, whereas reactions with excess amounts of other fluoroarenes resulted in the formation of diarylated products as major products, along with small quantities of four-fold arylation products. One reason for this is the increased acidity of pyridylated intermediates. For example, when the reaction of 1a with Li and TMEDA was conducted, anthracene dianion A was formed in the first step (Fig. 5c), followed by diarylation to afford 5 d, as shown in Fig. 3. Compound 5 d was considered to possess more acidic benzylic hydrogen atoms (blue-colored protons) than simple hydrocarbon compounds such as 2a. This implied that further deprotonation occurred easily in the presence of co-existing strong anions, such as dianion A and monoanion B. Finally, repeating the SNAr reaction with 2-fluoropyridine affords the multi-fold arylation product 9. Single crystals of 8 and 9 were also obtained by recrystallization from CHCl3/hexane (for 8) and MeOH/Et2O (for 9), respectively, and X-ray diffraction analyses revealed that the original flat acene structures were retained even after the central carbon atoms changed to sp3 carbons.

Annulative π-extension by the sequence of mechanochemical arylation and cyclodehydrogenation

Finally, to apply current mechanochemical arylation for nanographene synthesis, we attempted fissure-region53,54 annulative π-extension2,54,55,56,57,58,59,60,61 (fissure-APEX) reaction by combining previously developed lithium(0)-mediated mechanochemical cyclodehydrogenation21. Grinding fluoranthene (6a) with lithium(0) wire and 1-fluoronaphthalene afforded 3-(1-naphthalenyl)fluoranthene (10) in an 18% yield (Fig. 7a). 10 was converted to a perylene derivative 11 using the mechanochemical cyclodehydrogenation method that we previously reported21. The one-pot C–H arylation and cyclodehydrogenation was attempted with pyrene (6b) and afforded 12 as an orange solid in a 6% yield (Fig. 7b). While the yield was not unsatisfactory, this reaction represents the first example of one-pot fissure-region APEX. Further investigations on the conditions of fissure-region APEX reaction are ongoing in our laboratory.

In this study, we developed an arylation reaction of unfunctionalized PAHs by mechanochemical anionic activation with lithium(0) followed by adding various fluoroarenes. To the best of our knowledge, this is the first example of a Birch reductive arylation of polyaromatic compounds and a rare example of carbon–carbon bond formation reaction between carboanions and fluoroarenes via SNAr. Unlike previous solution-based Birch reductive functionalizations, the discovered method allows a rapid, in-air and at-room temperature reaction with least amount of liquid additives. Using this method, various arylated polyaromatic compounds including mono-, di-, tetraarylated ones could be rapidly synthesized from unfunctionalized PAHs. One of highlighting applications is the demonstration of fissure-region APEX reaction by mechanochemical Birch reductive arylation and cyclodehydrogenation providing nanographenes. Our methodology is useful not only as a formal direct arylation method for unfuctionalized aromatics, but also a complementary arylation method for conventional cross-coupling reaction. Further investigations into the reaction mechanism are ongoing in our laboratory.

Methods

General procedure A for a 1.0 mmol scale reaction at room temperature (20–25 °C)

The synthesis of 9-phenyl-9,10-dihydroanthracene (2a) is described as a representative example of the general procedure A for 1.0-mmol scale reaction. To a 5.0-mL stainless-steel jar containing two 7-mm-diameter stainless-steel balls was added anthracene (1a) (177.7 mg, 1.0 mmol, 1.0 eq.). Pieces of Li (27.4 mg, 4.0 mmol, 4.0 eq.) cut from Li wire (3.2 mm in diameter, 99.9% purity) were washed with hexane for removing mineral oil, weighed on an electronic balance, and added into the jar under air. Then, ethylenediamine (0.35 mL, 5.2 mmol, 5.2 eq.) was added to the jar by a syringe under air. The jar was capped with a stainless-steel cap equipped with a handmade O-shaped packing made of 1 mm width polyethylene sheet, and the jar was sealed tightly with a wrench and a vise. The reaction jar and a same-weight blank jar (or a same-weight reaction jar) were fixed in a mixer mill (Retsch MM400 or MM500 Vario), and shaken at 30 Hz (1800 rpm) at room temperature (20–25 °C) for 5 min (ball-milling-I). The reaction jar was opened under air, and fluorobenzene (136.6 mg, 1.4 mmol, 1.4 eq.) was added by a glass syringe in one portion in ca. 2–3 s. Then, the jar was sealed tightly again, and shaken in a same manner at 30 Hz (1800 rpm) at room temperature (20–25 °C) for 60 min (ball-milling-II). Notably, the entire experimental manipulations including opening the jar, adding PhF, and closing the jar take 2–3 min in air, and no noticeable air-oxidation of anionic species was observed. After shaking, the reaction jar was opened, and the reaction was quenched by adding water. Then, the organic phase was extracted three times with chloroform (10 mL × 3). The combined organic layers were dried over Na2SO4, filtered, and concentrated under reduced pressure to obtain a crude product which was further purified by silica gel column chromatography (eluent: hexane), affording 2a as a white solid (186.6 mg, 0.73 mmol, 73% yield).

General procedure B for a 1.0-mmol scale reaction at 25 °C

The synthesis of 9,10-diphenylanthracene (5a’) is described as a representative example of the general procedure B for 1.0-mmol scale reaction. To a 5.0-mL stainless-steel jar containing two 7-mm-diameter stainless-steel balls was added anthracene (1a) (178.2 mg, 1.0 mmol, 1.0 eq). Pieces of Li (28.1 mg, 4.0 mmol, 4.0 eq.) cut from Li wire (3.2 mm in diameter, 99.9% purity) was washed with hexane for removing mineral oil, weighed on an electronic balance, and added into the jar under air. Then, ethylenediamine (0.35 mL, 5.2 mmol, 5.2 eq.) was added to the jar by a syringe under air. The jar was capped with a stainless-steel cap equipped with a handmade O-shaped packing made of 1 mm width polyethylene sheet, and the jar was sealed tightly with a wrench and a vise. The reaction jar and a same-weight blank jar (or a same-weight reaction jar) were fixed in a mixer mill (Retsch MM400 or MM500 Vario), and shaken at 30 Hz (1800 rpm) at room temperature (20–25 °C) for 5 min (ball-milling-I). The reaction jar was opened under air, and fluorobenzene (241.2 mg, 2.5 mmol, 2.5 eq.) was added by a glass syringe in one portion in ca. 2–3 s. Then, the jar was sealed tightly again, and shaken in a same manner at 30 Hz (1800 rpm) at room temperature (20–25 °C) for 120 min (ball-milling-II). Notably, the entire experimental manipulations including opening the jar, adding PhF, and closing the jar take 2–3 min in air, and no noticeable air-oxidation of anionic species was observed. After shaking, the reaction jar was opened, and the reaction was quenched by adding water. Then, the organic phase was extracted three times with chloroform (10 mL × 3). The combined organic layers were dried over Na2SO4, filtered, and concentrated under reduced pressure to obtain a crude product which was further purified by silica gel column chromatography (eluent: hexane/CHCl3 = 100:0 → 90:10), afforded 5a’ as a white yellow solid (186.7 mg, 0.57 mmol, 57% yield).

Data availability

CCDC numbers of anti-5e (2374003), syn-5e (2374004), 8 (2374002), and 9 (2379941) contain the supplementary crystallographic data for this paper. These data can be obtained free of charge via www.ccdc.cam.ac.uk/data_request/cif, or by emailing data_request@ccdc.cam.ac.uk, or by contacting The Cambridge Crystallographic Data Centre, 12 Union Road, Cambridge CB2 1EZ, UK; fax: +44 1223 336033. All other data supporting the findings of this manuscript are also available in the Supplementary Information, Supplementary Datasets, or from the corresponding author upon request.

References

Segawa, Y., Ito, H. & Itami, K. Structurally uniform and atomically precise carbon nanostructures. Nat. Rev. Mater. 1, 1–14 (2016).

Ito, H., Ozaki, K. & Itami, K. Annulative π-extension (APEX): rapid access to fused arenes, heteroarenes and nanographenes. Angew. Chem. Int. Ed. 56, 11144–11164 (2017).

Roche, S. P. & Porco, J. A. Jr Dearomatization strategies in the synthesis of complex natural products. Angew. Chem. Int. Ed. 50, 4068–4093 (2011).

Birch, J. A. Reduction by dissolving metals. Part I. J. Chem. Soc. 1944, 430–436 (1944).

Rabideau, P. W. & Marcinow, Z. The Birch reduction of aromatic compounds. Org. React. 42, 1–334 (2004).

Zimmerman, H. E. A mechanistic analysis of the Birch reduction. Acc. Chem. Res. 45, 164–170 (2012).

Benkeser, R. A., Robinson, R. E. & Landesman, H. The true identity of the solvated free radical “triphenylsilicyl ethylammine.” the multiple addition of lithium to an aromatic system in ethylamine. J. Am. Chem. Soc. 74, 5699–5701 (1952).

Lebeuf, R. et al. Birch reductive alkylation of Biaryls: scope and limitations. J. Org. Chem. 74, 6469–6478 (2009).

Hook, J. M. & Mander, L. N. Recent developments in the Birch reduction of aromatic compounds: applications to the synthesis of natural products. Nat. Prod. Rep. 3, 35–85 (1986).

Perez, H., Melero, C., Guijarro, A. & Yus, M. The reaction of biphenyl radical anion and dianion with alkyl fluorides. From ET to SN2 reaction pathways and synthetic applications. Tetrahedron 65, 10769–10783 (2009).

Melero, C., Herrera, R. P., Guijarro, A. & Yus, M. New modes of reactivity in the threshold of the reduction potential in solution. Alkylation of lithium PAH (polycyclic aromatic hydrocarbon) dianions by primary fluoroalkanes: a reaction pathway complementing the classical Birch reductive alkylation. Chem. Eur. J. 13, 10096–10107 (2007).

Kanno, K. I., Maemura, Y., Kobayashi, N. & Kyushin, S. Synthesis of silyl-substituted anthracene derivatives via Birch-type silylation. Chem. Lett. 42, 112–114 (2013).

Fukazawa, M., Takahashi, F. & Yorimitsu, H. Sodium-promoted borylation of polycyclic aromatic hydrocarbons. Org. Lett. 23, 4613–4617 (2021).

Miwa, K. et al. Multiply exo-methylated corannulenes. Chem. Eur. J. 29, e202301557 (2023).

Rodenburg, L., De Block, R., Bieze, T. W. N., Cornelisse, J. & Lugtenburg, J. Reactivity of pyrene dianion and some of its 2-substituted derivatives. Recl. Trav. Chim. Pays-Bas. 107, 9–14 (1988).

Van loo, M. E., Lugtenburg, J. & Cornelisse, J. Reactivity of the acenaphthylene dianion towards electrophiles. Polycycl. Aromat. Comp. 14, 109–118 (1999).

Harvey, R. G., Lindow, D. F. & Rabideau, P. W. Metal-ammonia reduction—XIV: fluoranthene: correlation of primary product structure with HMO theoretical prediction. Tetrahedron 28, 2909–2911 (1972).

Lindow, D. F., Cortez, C. N. & Harvey, R. G. Metal-ammonia reduction. XIII. Regiospecificity of reduction and reductive methylation in the terphenyl series. J. Am. Chem. Soc. 94, 5406–5420 (1972).

Liu, D. H. & Ma, J. Recent advances in dearomative partial reduction of benzenoid arenes. Angew. Chem. Int. Ed. 63, e202402819 (2024).

Shigeno, M. et al. Catalytic concerted SNAr reactions of fluoroarenes by an organic superbase. J. Am. Chem. Soc. 146, 32452–32462 (2024).

Fujishiro, K. et al. Lithium-mediated mechanochemical cyclodehydrogenation. J. Am. Chem. Soc. 145, 8163–8175 (2023).

Gao, Y., Kubota, K. & Ito, H. Mechanochemical approach for air-tolerant and extremely fast lithium-based Birch reductions in minutes. Angew. Chem. Int. Ed. 135, e202217723 (2023).

Davison, N. et al. A room-temperature-stable electride and its reactivity: Reductive benzene/pyridine couplings and solvent-free Birch reductions. Chem 9, 576–591 (2023).

Nallaparaju, J. V. et al. Mechanochemical birch reduction with low reactive alkaline earth metals. Angew. Chem. Int. Ed. 63, e202319449 (2024).

Wang, G. W. Mechanochemical organic synthesis. Chem. Soc. Rev. 42, 7668–7700 (2013).

Kubota, K. & Ito, H. Mechanochemical cross-coupling reactions. Trends Chem. 2, 1066–1081 (2020).

James, S. L. et al. Mechanochemistry: opportunities for new and cleaner synthesis. Chem. Soc. Rev. 41, 413–447 (2012).

Do, J.-L. & Friščić, T. Mechanochemistry: a force of synthesis. ACS Cent. Sci. 3, 13–19 (2017).

Hernández, J. G. & Bolm, C. Altering product selectivity by mechanochemistry. J. Org. Chem. 82, 4007–4019 (2017).

Howard, J. L., Cao, Q. & Browne, D. L. Mechanochemistry as an emerging tool for molecular synthesis: what can it offer. Chem. Sci. 9, 3080–3094 (2018).

Andersen, J. & Mack, J. Mechanochemistry and organic synthesis: from mystical to practical. Green. Chem. 20, 1435–1443 (2018).

Tan, D. & Friščić, T. Mechanochemistry for organic chemists: an update. Eur. J. Org. Chem. 1, 18–33 (2018).

Tan, D. & García, F. Main group mechanochemistry: from curiosity to established protocols. Chem. Soc. Rev. 48, 2274–2292 (2019).

Bolm, C. & Hernández, J. G. Mechanochemistry of gaseous reactants. Angew. Chem. Int. Ed. 58, 3285–3299 (2019).

Friščić, T., Mottillo, C. & Titi, H. M. Mechanochemistry for synthesis. Angew. Chem. Int. Ed. 59, 1030–1041 (2020).

Cuccu, F. et al. Mechanochemistry: new tools to navigate the uncharted territory of “impossible” reactions. ChemSusChem 15, e202200362 (2022).

Williams, M. T. J., Morrill, L. C. & Browne, D. L. Mechanochemical organocatalysis: do high enantioselectivities contradict what we might expect?. ChemSusChem 15, e202102157 (2022).

Hwang, S., Grätz, S. & Borchardt, L. A guide to direct mechanocatalysis. Chem. Commun. 58, 1661–1671 (2022).

Eisenstein, O., Milani, J. & Perutz, R. N. Selectivity of C–H activation and competition between C–H and C–F bond activation at fluorocarbons. Chem. Rev. 117, 8710–8753 (2017).

Chatterjee, A. & König, B. Birch-type photoreduction of arenes and heteroarenes by sensitized electron transfer. Angew. Chem. Int. Ed. 58, 14289–14294 (2019).

Kondo, K., Kubota, K. & Ito, H. Mechanochemical activation of metallic lithium for the generation and application of organolithium compounds in air. Nat. Synth. https://doi.org/10.1038/s44160-025-00753-3 (2025).

Röckl, J. L., Robertson, E. L. & Lundberg, H. Electrosynthetic C–F bond cleavage. Org. Biomol. Chem. 20, 6707–6720 (2020).

Kariv-Miller, E. & Vajtner, Z. Electroreductive dehalogenation of fluorobenzenes. J. Org. Chem. 50, 1394–1399 (1985).

Kariv-Miller, E. & Andruzzi, R. Dimethylpyrrolidinium, a catalyst for organic electroreductions. J. Electroanal. Chem. Interf. Electrochem. 187, 175–186 (1985).

Loffredo, D. M., Swartz, J. E. & Kariv-Miller, E. Reductive cyclization of o-(3-butenyl)fluorobenzene at mercury and lead cathodes. J. Org. Chem. 54, 5953–5957 (1989).

Atkins, P. W., Overton, T. L., Rourke, J. P., Weller, M. T. & Armstrong, F. M. Shriver and Atkins’ Inorganic Chemistry, Fifth Edition, (Oxford University Press, 2010).

Kubota, K., Fukuzawa, Y., Kondo, K., Gao, Y. & Ito, H. Highly efficient and air-tolerant calcium-based Birch reduction using mechanochemistry. Chem. Lett. 53, upae060 (2024).

Kondo, K., Kubota, K. & Ito, H. Mechanochemistry enabling highly efficient Birch reduction using sodium lumps and D-(+)-glucose. Chem. Sci. 15, 4452–4457 (2024).

Housecroft, C. E. & Sharpe, A. G. Inorganic Chemistry 5th edition, Pearson (2018).

Weinhold, F. & Landis, C. R. Natural bond orbitals and extensions of localized bonding concepts. Chem. Educ. Res. Pract. 2, 91–104 (2001).

Glendening, E. D., Landis, C. R. & Weinhold, F. NBO 6.0: natural bond orbital analysis program. J. Comput. Chem. 34, 1429–1437 (2013).

Singh, U. C. & Kollman, P. A. An approach to computing electrostatic charges for molecules. J. Comput. Chem. 5, 129–145 (1984).

Dias, J. R. Perimeter topology of benzenoid polycyclic hydrocarbons. J. Chem. Inf. Model. 45, 562–571 (2005).

Ozaki, K., Kawasumi, K., Shibata, M., Ito, H. & Itami, K. One-shot K-region-selective annulative π-extension for nanographene synthesis and functionalization. Nat. Commun. 6, 6251–6258 (2015).

Matsuoka, W., Ito, H. & Itami, K. Rapid access to nanographenes and fused heteroaromatics by palladium-catalyzed annulative π-extension reaction of unfunctionalized aromatics with diiodobiaryls. Angew. Chem. Int. Ed. 56, 12224–12228 (2017).

Matsuoka, W., Ito, H., Sarlah, D. & Itami, K. Diversity-oriented synthesis of nanographenes enabled by dearomative annulative π-extension. Nat. Commun. 12, 3940–3948 (2021).

Matsuoka, W., Kawahara, K. P., Ito, H., Sarlah, D. & Itami, K. π-extended rubrenes via dearomative annulative π-extension reaction. J. Am. Chem. Soc. 145, 658–666 (2023).

Kawahara, K. P., Matsuoka, W., Ito, H. & Itami, K. Synthesis of nitrogen-containing polyaromatics by aza-annulative π-extension of unfunctionalized aromatics. Angew. Chem. Int. Ed. 132, 6445–6450 (2020).

Kawahara, K. P., Ito, H. & Itami, K. Rapid access to polycyclic thiopyrylium compounds from unfunctionalized aromatics by thia-APEX reaction. Chem. Commun. 157, 1157–1160 (2023).

Bhattacharyya, A., Sk, M. R., Sen, S., Kundu, S. & Maji, M. S. Annulative π-Extension by Cp*Co(III)-Catalyzed Ketone-Directed peri-Annulation: An Approach to Access Fused Arenes. Org. Lett. 25, 8622–8627 (2023).

Sk, M. R., Bhattacharyya, A., Saha, S., Brahma, A. & Maji, M. S. Annulative π-Extension by Rhodium(III)-Catalyzed Ketone-Directed C−H Activation: Rapid Access to Pyrenes and Related Polycyclic Aromatic Hydrocarbons (PAHs). Angew. Chem. Int. Ed. 62, e202305258 (2023).

Acknowledgements

This study was supported by the Sumitomo Foundation (2300884 to H.I.), Foundation of Public Interest of Tatematsu (22B025 to H.I.), Kondo Memorial Foundation (2022-03 to H.I.), NAGAI Foundation of Science & Technology (to H.I.), JSPS KAKENHI (JP25K01764 and JP25H01408 to H.I.), and JST-CREST (JPMJCR19R1 to A.Y.). Y.T. thanks the Interdisciplinary Frontier Next-Generation Researcher Program of the Tokai Higher Education and Research System for the fellowships. This work is partially supported by Nagoya University Research Fund. We thank Dr. Keigo E Yamada (Nagoya Univ.) and Mr. Takato Mori (Nagoya Univ.) for helping the X-ray diffraction analysis. The computations were performed at the Research Center for Computational Science, Okazaki, Japan (Project Nos. 23-IMS-C061 and 24-IMS-C059).

Author information

Authors and Affiliations

Contributions

H.I. conceived the concept and directed the project. Y.T. conducted experiments, analyses, and calculations. H.I. and A.Y. acquired the funding. Y.T. and H.I. prepared the manuscript with feedback from A.Y. and K.I. All authors approved the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Modhu Maji and the other anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Toyama, Y., Yagi, A., Itami, K. et al. Birch reductive arylation by mechanochemical anionic activation of polycyclic aromatic compounds. Nat Commun 16, 5044 (2025). https://doi.org/10.1038/s41467-025-60318-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-60318-y