Abstract

Enhancing the durability of electrodes under high-power conditions is crucial for advancing high-power secondary batteries. Despite numerous optimization strategies proposed to mitigate electrode structural degradation, the performance of common electrodes inevitably deteriorates under high currents over extended cycling life. In this study, we report a capacity refreshing strategy for a porous organic framework electrode operating under high power conditions. By intermittently applying low currents, deactivated ions trapped within the framework can be effectively released, thus refreshing the electrode’s capacity. Importantly, this capacity refreshing can be periodically repeated. The framework electrode thus achieves an extended cycle life of over 60,000 cycles at 20 C (6 A/g) with a specific power of 28 kW/kg (based on active material). This strategy represents an alternative concept for designing organic electrodes that combine high power and long cycle life.

Similar content being viewed by others

Introduction

Electrode materials for high-power energy storage need to be operated under high current densities while maintaining a long lifespan. However, traditional electrode materials often suffer structural fatigue and deterioration as a result of extended and rapid ion storage1,2. In contrast to rigid inorganic electrode materials, organic electrode materials typically possess more flexible molecular skeletons and open internal porousness3,4,5. Some organic electrodes have even operated at high currents, up to 50 A, showcasing potential for high-power applications6. Nevertheless, their capacity also gradually declines, primarily resulting from degradation at both the electrode structure and electrode material levels. The degradation of electrode materials involves organic molecular collapse and ion trapping within the molecular skeleton, thereby impeding the efficient cycling of ion carriers. The key to designing high-power and long-cycle organic materials thus lies in maintaining skeleton stability and re-activating trapped ions. However, the re-activating strategies for liberating ions from organic hosts remain poorly studied, both experimentally as well as theoretically.

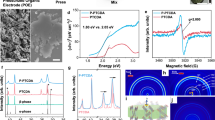

We recently found that the porous organic framework with a cationic skeleton (Fig. 1a) can operate at a high rate of up to 20 C (6 A/g, 1 C corresponds to 0.3 A/g) with a refreshable capacity. Specifically, after 10,000 cycles of discharging at 20 C, the discharge capacity decreases from the initial 153 mAh/g to 110 mAh/g (Fig. 1b). However, after only 10 cycles of refreshing at a low rate of 0.5 C, the capacity is restored to 148 mAh/g upon returning to 20 C operation, which is very close to the initial capacity (Fig. 1b and Supplementary Fig. 1a). Remarkably, this refreshing process can be repeated, enabling the framework to operate for up to 60,000 cycles at 20 C, surpassing the lifespan of most well-known organic electrodes under high-rate cycling (Supplementary Table 1)7,8. This capacity refreshing has not been previously observed in organic electrode materials. Three questions now arise. First, which sites in the organic framework are reversibly refreshed? Second, what is the mechanism behind this refresh? Third, does this refresh mechanism occur universally across diverse organic electrodes? This article addresses the questions based on direct experimental observations of the capacity refresh in the organic framework electrode. It elucidates the details of capacity refresh dynamics and highlights the role of the porous ionic framework in re-activating trapped ions. The capacity refresh mechanism enriches the design principles for organic electrodes, offering the potential to significantly prolong the cycling life of electrodes under high-current operation.

a Schematic diagram illustrating the organic framework model. b Long cycling performance of AP-FW at 20 C assisted by repeated refreshing at 0.5 C every 10,000 cycles. Inset: the refreshing process after 10,000 cycles. At around 30 k cycles, the Li metal electrode was replaced because its capacity had significantly decreased starting from approximately 26k cycles due to prolonged high-current cycling (Supplementary Fig. 2 and Supplementary Note 1). Source data is provided as a Source Data file.

Results and discussion

What sites were refreshed?

Porous ordered organic framework electrodes typically exhibit outstanding power performance9,10. The selected framework model consists of a cationic skeleton containing triazine and bipyridine segments (denoted as AP-FW, Fig. 1a, Supplementary Figs. 3, 4, and Supplementary Note 2), forming a π-π stacked layered structure. The relatively low crystallinity is due to both the built-in counter anions within the framework and the loose stacking caused by electrostatic repulsion between the ionic skeleton layers, which hinders the formation of well-defined crystals11,12. AP-FW exhibits a specific surface area of 76 cm2/g and a pore size distribution ranging from 10 Å to 20 Å (Supplementary Fig. 5 and Supplementary Note 3). The electrochemical processes of AP-FW have been explored in our prior work13, revealing two ion storage sites: the triazine and bipyridine segments, dedicated to storing cations (Li+) and anions (PF6−), respectively:

where ideally the reduced triazine provides coordinating sites for Li+ storage (Eq. 1) during the initial discharge, while the bipyridine segment (referred as V2+) is reduced to an intermediate radical cation (V•+) and further to neutral form (V0) during continuous discharge, releasing two PF6− (Eq. 2), as illustrated in Fig. 2a14.

a Schematic of the electrochemical process involving triazine and pyridine segments of AP-FW. b Corresponding charge/discharge curves of AP-FW during the 1st refreshing. The framework electrode undergoes 10,000 cycles under 20 C (blue curves) followed by refreshing under 0.5 C (red curves). c Ex situ FTIR and d in situ Raman spectra of AP-FWs undergo refreshing (0.5 C, after 20 C operating for 10,000 cycles), revealing the refreshed triazine and bipyridine segments after refreshing. The symbols △ (charged stated) and * (discharged stated) represent the different cycling stages of AP-FW as descript in Fig. 2b. The measurements were conducted around 25 °C. e Side and top views of the two staggered tribranched triazine segments within the AP-FW. Anions are omitted for clarity. Carbon atoms are marked in orange balls, and nitrogen atoms in blue balls. Source data are provided as a Source Data file.

To identify the sources of capacity refreshing shown in Fig. 2b (see all the curves in Supplementary Fig. 1b), the evolution of the triazine segments was analyzed by Fourier transform infrared spectroscopy (FTIR). The original AP-FW exhibits distinct FTIR signals of triazine at around 1605 and 1504 cm−1 (Fig. 2c)15,16,17. After 10,000 cycles under 20 C, the triazine signal significantly weakens, suggesting that some Li+ was trapped near the triazine. However, after only one refreshing cycle, the triazine signal significantly recovers (Fig. 2c). This is consistent with the charge capacity increased from 110 to 215 mAh/g (shown in Fig. 2b), suggesting that the trapped Li+ is effectively removed. The refreshed framework after 20k cycling retained IR spectra similar to those observed after 10k cycling, indicating the framework stability over long cycles (Supplementary Fig. 6 and Supplementary Note 4). On the other hand, the in situ Raman was employed to investigate the V2+ evolution during refreshing. Typically, the Raman signals of V2+ and V0 are weak, whereas only V•+ shows strong signals due to resonance scattering of the radical cation excited by the lase18,19. A strong V•+ Raman signal at around 1647 cm−1 was observed from the original AP-FW (Fig. 2d), which is attributed to the partial chemical reduction of V2+ to V•+ during synthesis. The V•+ signal only slightly decreases after long cycling at 20 C. However, it significantly weakens upon refreshing (Fig. 2d), suggesting a more complete reduction from V•+ to V0 during refreshing and consequently an increased anion capacity. This is consistent with the further refreshed discharge capacity to 267 mAh/g (shown in Fig. 2b). Similar phenomenon was also confirmed by in situ UV analysis (Supplementary Fig. 7 and Supplementary Note 5).

Typically, porous framework structures may provide internal spaces favorable for ion trapping, a phenomenon commonly known as spatial confinement in framework-based porous materials20. To shed more light on this, we conducted framework simulations focusing specifically on the active segments. Contrary to intuition, the triazine segments in adjacent framework layers, consisting of a central triazine and three branch phenyl rings (highlighted in pink region in Fig. 1a), do not exhibit strictly parallel stacking. Instead, the tribranched triazine segments have their branches rotated approximately 60° out of register (highlight the staggered tribranched segments in red and blue), pairing to form staggered structures with a large spacing of 21 Å (Fig. 2e). This staggered arrangement could provide substantial geometric space for accommodating diverse working ions. More importantly, as we discuss later, the cationic framework itself also influences ion distribution within the framework through electrostatic interactions, a phenomenon referred as “secondary confinement” in this study.

In addition to contributions from the electrode material itself, we also investigate whether the electrode structure contributes to capacity refreshing. Electron microscopy analysis indicates no significant changes in the overall electrode structure before and after refreshing (Supplementary Fig. 8). Furthermore, X-ray diffraction (XRD) analysis showed no noticeable change in the crystalline state of AP-FW before and after refreshing (Supplementary Fig. 9 and Supplementary Note 6). These findings suggest that neither the electrode configuration nor the crystal structure of AP-FW undergoes regeneration or optimization during the refreshing process, ruling out their contributions to capacity refreshing. The refreshed capacity should primarily come from the reactivated Li+ and PF6− trapped within the framework.

Why can it be refreshed?

As the simulated density contours of ions shown in Fig. 3a, the native TFSI- in original AP-FW reside near the cationic framework and form an annular layer (Fig. 3a and Supplementary Data 1). While interestingly, upon Li+ entry into the framework (corresponding to the discharging process), they tend to interact with the TFSI−, ultimately forming ion pairs relatively concentrated in the framework channels (Fig. 3b, Supplementary Fig. 10, and Supplementary Data 2). This ion aggregation was clearly observed from in situ Raman measurements of AP-FW during discharging or charging at 20 C. Distinctive Raman signals of aggregated TFSI− at approximately 754 cm−1, attributed to the multiple Li+-TFSI− pair aggregation, were clearly identified (Fig. 3c, d). In contrast, under a low rate of 0.2 C, the TFSI− predominantly exists in a relatively free state (at approximately 741 cm−1), and no obvious aggregation was detected (Supplementary Fig. 11 and Supplementary Note 7). Similar ion-specific adsorption within ionic organic frameworks has been observed in the field such as membrane separation21,22. We refer to it as “ionic framework-induced secondary confinement” to distinguish it from the inherent space confinement imposed by the skeleton itself.

a Simulated density contours of original TFSI− in the cationic framework. b Simulated density contours of the incoming Li+ in the cationic framework. In situ Raman spectra of AP-FW collected at 25 °C during (c) discharging and d charging process after 1k cycles under 20 C. Note that the TFSI− anion was employed in both Raman and simulation experiments owing to its sensitivity to ion aggregation states within the 730–770 cm−1 of the Raman spectra, aiming to distinguish the ion states accurately. It has been confirmed that AP-FW containing TFSI− demonstrates comparable charge-discharge behavior to those with PF6−. e Corresponding radial distribution function of Li-(S)TFSI in the framework. Bottom: Schematic diagrams illustrating three states of ion aggregation. Crystallographic Information Files are contained in Supplementary Data 1 and 2. Source data is provided as a Source Data file.

To elucidate the role of “ionic framework-induced secondary confinement” in the refreshing process, we designed a neutral framework by replacing the bipyridine segments with the electrochemically inert biphenyl segments as a control electrode (Supplementary Fig. 12a and Supplementary Note 8). Under the same test conditions, the neutral framework did not exhibit any noticeable capacity refreshing, despite its crystal structure, BET, and chemical structure being similar to AP-FW (Fig. 5a, Supplementary Fig. 12b–f and Supplementary Note 8). These findings underscore the essential role of secondary confinement in the cationic AP-FW.

The secondary confinement primarily arises from two key factors. On the one hand, the native large anions carried by the cationic framework spatially increase the probability of ion interaction. On the other hand, and more importantly, the cationic framework itself tends to trap the ions as ion pairs within the framework. The radial distribution function (RDF) between Li+ and TFSI- within the framework shows three peaks at 2.6, 4.5, and 6.4 Å, respectively (Fig. 3e), corresponding to three types of Li+-TFSI- interactions: contact ion pairs (CIPs, where cations and anions have direct strong interaction with little or no solvent molecules intervening), solvent-shared ion pairs with relatively loose contact (SIPs, where the solvated shells of cations and anions partially overlap), and free ions (FIPs, each with complete solvated shells)23. It means there are only a few free ions within the framework; instead, Li+ and TFSI- mostly exist as SIPs. The preference for more SIPs over FIPs or CIPs within the framework may be attributed to the slightly decreased coordination number of Li+, which reduces from 3.8 to 2.2 when Li+ needs to be partially desolvated to enter the confined frameworks. The slight decrease in the coordination number of Li+ leads to a higher tendency for forming the loosely bonded Li+-TFSI− SIPs within the framework compared to its fully solvated state in common dilute solutions (which favors FIPs) or completely desolvated state (which favors tight CIPs)24. Note that the theoretical calculations above assume an ordered framework, although the actual framework’s crystallinity is lower. These simulations primarily aim to offer a qualitative understanding.

The loosely aggregated SIPs contribute to the refreshing process within the framework. When working at high currents, substantial ions diffuse rapidly into the framework and become dynamically trapped as SIPs due to the secondary confinement over cycles. This explains why the Raman peak attributed to Li+−TFSI− pair aggregation significantly intensifies during the intermediate stages of charging and discharging at 20 C (Fig. 3c, d). These ion pairs not only compress the space for subsequent incoming ions but also result in unfavored localized polarization, leading to a gradual decay in capacity (Fig. 4a). Conversely, when operating at low current following high-current cycling, the diminished ion influx and the consequent gradual weakening of localized polarization allows more average diffusion time for SIPs dissociation or migration (Fig. 4a). This process facilitates the release of trapped ions and thus refreshes the framework.

a Schematic diagram illustrating the aggregation state of ions in the AP-FW channel during discharge under different current densities. b Relationship between the critical refreshing current factor (IRe) and the increase of refreshed capacity. The different working and refreshing currents for AP-FW are indicated by symbol and color, respectively. c Solid-state NMR 7Li spectra of AP-FW before and after refreshing. d Impedance spectroscopy of AP-FW during a refreshing process. Source data are provided as a Source Data file.

Therefore, logically, the key experimental parameter for refreshing is the current density required to break the SIPs. We define the ratio of the working current (used for high power cycling) to the refreshing current (used for refreshing) as the critical refreshing current factor (IRe=Iwork/Irefresh). Besides, we define the effective refreshing as occurring only when the capacity increase exceeds 5%, aiming to exclude the capacitance contribution from carbon additives and other factors within the electrode. The AP-FW electrodes were cycled under various working currents of 0.5, 1, 5, 10, and 20 C, and then refreshed under various refreshing currents of 0.1, 0.5, 1, 5, and 10 C, respectively. The Irefresh is set to be lower than the Iwork, with an IRe range from 2 to 200 (Supplementary Table 2). Figure 4b shows the relationship between IRe and the refreshed capacities. Whenever IRe exceeds 2, there is a minimum 5% increase in capacity. Furthermore, beyond IRe > 5, the efficiency of capacity refreshing significantly improves (see more details in Supplementary Fig. 13). Interestingly, not only the capacity but also the ion kinetics were partially recovered upon refreshing. For the refreshed AP-FW, a slightly sharper 7Li signal was observed in the 7Li solid-state NMR (Fig. 4c), indicating more mobile 7Li species resulting from the refreshing. Correspondingly, the overall impedance of the AP-FW, after one refreshing cycle, decreased from 308 to 148 Ω (Fig. 4d).

Material requirements for refreshing

Next, we addressed the third question posed in the introduction, which focuses on identifying the specific requirements for refreshing organic electrodes. Clearly, for AP-FW, the cationic and porous framework are two main structural features. As discussed above, the control neutral framework has clearly demonstrated the significant role of the cationic framework in refreshing (Fig. 5a, Supplementary Fig. 14 and Supplementary Note 9). On the other hand, to investigate the influence of porous structure, another control experiment was processed by in situ polymerization of vinylene carbonate monomer within AP-FW, with the aim of effectively “filling” the channels (Supplementary Fig. 15, referred as fAP-FW). This polymerized vinylene carbonate itself, with high Li+ conductivity up to ~10−4 S/cm, theoretically would not hinder the Li+ diffusion25. As a result, fAP-FW also exhibited little capacity refreshing (Fig. 5a, Supplementary Fig. 15, and Supplementary Note 10), indicating that the nanopore is also an essential factor. We also verified that almost no capacity refreshing occurs in neutral organics (Supplementary Figs. 16, 17, and Supplementary Note 11). In short, an ionized porous framework is a prerequisite for the capacity refreshing in such organic electrodes.

a Comparison of capacity changes among AP-FW and the two control frameworks (neutral framework AB -FW and filled framework fAP-FW) cycled under identical test conditions. Both demonstrated minimal capacity for refreshing (blue and brown curves). The constant current dis/charging conditions of working/refreshing for AP-FW is 20 C(6 A/g)/0.5 C, for fAP-FW are 1 C(0.3 A/g)/0.1 C, and for AB-FW are 2 C(0.3 A/g)/0.2 C in the potential range of 1.5 – 4.5 V. b Performance comparison of refreshed AP-FW with common organic electrodes. See references in SI. c Dis/charging curves of AP-FW under constant current charging to 4.5 V at 20 C and constant voltage charging to 0.5 C at 4.5 V (150 mA/g) for refreshing. Inset: corresponding cycle performance. d Performance of pouch cell cycling at approximately 12 C and refreshing at 0.5 C. Inset: image of pouch cell. Source data are provided as a Source Data file.

Despite the limited attention received by ionic organic framework-based electrodes, they have actually shown advantages in electrode capacity and rate performance compared to common neutral organics. The high capacity primarily stems from the higher utilization of active sites in these frameworks26,27. Additionally, if anions (generally with low charge density) are involved in storage, the frameworks often exhibit much faster kinetics than conventional single-cation electrodes, as widely reported in anion batteries28. Beyond these advantages, our study reveals a unique capacity refreshing in such electrodes, a strategy that can be applied to different working ions (Supplementary Fig. 18 and Supplementary Note 12) and working rates (Supplementary Fig. 19), endowing them with an exceptionally prolonged cycling life at high rates (Fig. 5b). This sheds new light on the potential of these organic electrodes.

Finally, the refreshing efficiency and the refreshing strategy on pouch cells were preliminarily investigated to explore the potential application. Refreshing efficiency is closely related to refreshing modes. In addition to the constant-current refreshing mode, the constant-voltage refreshing mode was explored to compare their refreshing efficiency in capacity (Fig. 5c, see method). Although constant voltage refreshing also enables certain capacity recovery, it requires approximately 20 h for a single refreshing process, equivalent to 5 cycles in the constant current refreshing mode at 0.5 C. Furthermore, the constant-voltage refreshing mode is accompanied by a significant decrease in coulombic efficiency to around 40% (inset in Fig. 5c), mainly attributed to electrolyte overconsumption and degradation of the interface layer under prolonged high-voltage treatment. Consequently, the constant-voltage refreshing mode is not suitable for practical refreshing. To explore the potential application of constant-current refreshing mode, a pouch cell with approximately 30 mAh capacity was fabricated to further evaluate this strategy (Fig. 5d). After undergoing over 100 cycles at 12 C, the pouch cell was refreshed under 0.5 C. Similar to that observed in coin cells, the pouch capacity increased significantly and continued stable cycling. It confirms the reliability of the refreshing process and may pave the way for further development.

In summary, we report a reversible capacity refreshing in ionic organic framework electrodes. Under high-rate cycling, the working ions may be trapped as ion pairs within the frameworks due to the localized effects from both the spatial and secondary confinement from the porous cationic skeleton. We demonstrate that the refreshing is a kinetically controlled process, where the ion pairs can be dissociated under a low current. Thanks to this repeatable refreshing process, the AP-FW electrode achieves a long 60,000 cycles at a high rate of 20 C (6 A/g), while providing 554 Wh/kg specific power and 28 kW/kg specific energy (based on active material). This work showcases the potential of porous ionic organic electrodes for high-power, long-cycle applications, also providing insights for designing future organic electrodes.

Methods

Materials and chemicals

4-aminobenzonitrile (98%), trifluoromethanesulfonic acid (98%), 4,4’-bipyridine (98%), 2,4-Dinitrochlorobenzene (90%) were purchased from Alfa-Aesar. [1,1’:4’,1”:4”,1”’quarter-phenyl]-4,4”’-dicarbonitrile (4PCN, 95%) was purchased from Shanghai Tengqian Biotechnology Co., Ltd. Carboxyl MWCNTs (95%) were purchased from XFNANO. AIBN and all other solvents (analytical grade) were purchased from Aladdin. Vinylene carbonate (VC, battery grade), all the Li salts and electrolytes (battery grade) were purchased from DuoDuo Reagents company. PVDF (average molecular weight 1,000,000), Conductive Additive (Super P), and Al foil were obtained from Shenzhen KejingStar Technology. All chemicals and reagents (except the AIBN was recrystallized) were commercially available and used without further purification.

Synthesis of AP-FW

1,1’-bis(2,4-dinitrophenyl)-[4,4’-bipyridine]-1,1’-diium dichloride (BDB) and 1,3,5-tris-(4-aminophenyl)triazine (TAPT) were synthesized according to previous reports29,30. The synthesis of AP-FW was conducted according to our previous report with some modifications13. Typically, MWCNTs (500 mg) and TAPT (354 mg, 1 mmol) were dissolved in a mixture of EtOH and H2O (100 mL, V/V = 4/1) under sonication for 30 min. Then, BDB (561 mg, 1 mmol) was added with stirring, and the solution was heated at 80 °C for 12 h. The precipitate was washed thoroughly with THF, water, acetone, and diethyl ether before being Soxhlet extracted with methanol. Subsequently, the product was dried under vacuum at 120 °C for 12 h. The final product was collected and named AP-FW.

Synthesis of AB-FW

The synthesis of AB-FW was synthesized referring to the previous report31. Typically, MWCNTs (356 mg) and [1,1’:4’,1”:4”,1”’quarter-phenyl]-4,4”’-dicarbonitrile (4PCN, 356 mg, 1 mmol) were dissolved with 30 mL CHCl3 under sonication for 30 min. Trifluoromethanesulfonic acid (712 μL, 8 mmol) and CHCl3 (10 mL) were subsequently added with stirring under an ice bath and a protective nitrogen atmosphere. The mixture of MWCNTs and 4PCN was added slowly and stirred for 30 min. The reaction was then conducted at room temperature for 48 h before being poured onto an aqueous ammonia solution (30%) to neutralize the trifluoromethanesulfonic acid. The precipitate was washed with water, dichloromethane, ethanol, and methanol. The final product was dried at 120 °C for 12 h under a vacuum, named as AB-FW.

Synthesis of fAP-FW

The synthesis of fAP-FW was conducted by in situ polymerization of vinylene carbonate (VC) within the pores of AP-FW25. Typically, 1.52 g LiPF6 (99.9%, battery grade) was dissolved in 10 mL VC (99.9%, battery grade) to form a homogeneous and transparent solution, then the solution was added in 10 mg AIBN in a glove box with an Ar atmosphere. The resulting solution was dropped onto the AP-FW electrodes (φ = 12 mm) and immediately subjected to a vacuum to facilitate deep penetration of the electrolyte into the framework. After standing in a vacuum for 20 min, the electrodes were kept at 60 °C for 12 h and 80 °C for 6 h to complete the polymerization of VC. The resulting electrode was named as fAP-FW, and used as the working electrode without further treatment.

Electrochemical testing

To prepare working electrodes for cycling tests, the mixture of active material/Super P/PVDF was stirred in a sealed glass vial for 5 h, using N-Methyl-2-pyrrolidone (NMP) as the solvent with a ratio of 7/2/1. The obtained slurry was cast onto Al foil with a doctor blade and dried at 80 °C under vacuum overnight. The typical mass loading was ~1.0 mg/cm2. The stainless steel CR2032 coin cells were assembled by using Li metal (300 μm) as the negative electrode, polypropylene film as the separator (Celgard 2500, with a porosity 55% and a thickness of 25 μm, cut into circular pieces with a diameter of 19 mm before use) and 40 μL solution of 1 M LiPF6 in EC/DMC/EMC (V/V/V = 1/1/1) as the electrolyte.

The Coulombic Efficiency (CE) metric employed in this study was operationally defined as the ratio of discharge specific capacity of the preceding cycle to the charge specific capacity of the subsequent cycle. This CE definition specifically highlights the significant disparity between the discharge specific capacity during the working process and the charge specific capacity during the refreshing process. The C-rate of AP-FW was determined by the theoretical specific capacity calculation (Supplementary Note 13). The detailed calculation and comparison of specific energy, specific power and critical refreshing current (IRe) is discussed in Supplementary Note 14 and 15.

To prepare the pouch cell, the organic electrode was obtained following the aforementioned method and cut into a 6 × 10 cm sheet with a mass loading of ~1.8 mg/cm2. Li foil (300 μm) was used as the negative electrode. 1 M LiPF6 EC/DMC/EMC electrolyte (the same volume/active material mass ratio as coin cells) was injected before vacuum sealing. Galvanostatic cycling was carried out using the NEWARE battery test system (NEWARE Technology Ltd., Shenzhen, china). Constant potential AC impedance tests (1 MHz to 0.1 Hz, amplitude 5 mV) were carried out using the Autolab PGSTAT 302 N system, and recorded with a 1 min standing processing upon the required cycling reached.

For in situ Raman characterization, the electrode was prepared using PTFE as the binder and rolled onto Al mesh, with the ratio of active material/Super P/PVDF as 7/2/1. 1 M LiTFSI in EC/DMC/EMC was used as the electrolyte. For ex-situ FTIR characterization, the ratio of active material/Super P/PVDF was set as 7/2/1. The samples for ex-situ FTIR were washed carefully with DMC and dried under vacuum at 80 °C after the coin cells were disassembled. The specific capacity was calculated based on the mass of porous organic polymer as active material in the electrode.

All the batteries for electrochemical testing were assembled in an Ar-filled glove box (water and oxygen level is controlled <1 ppm), and tested immediately. All electrochemical tests are performed at 25 °C (±5 °C) with no strict environmental control.

Different refreshing operation

The constant-current refreshing mode was conducted by charging/discharging between 1.5–4.5 V under a constant current as needed. The constant voltage refreshing mode was conducted by initially charging to 4.5 V at a constant current, followed by charging with a constant voltage at 4.5 V until reaching a cutoff current of 30 mA/g.

Material characterization

The Fourier transform infrared (FT-IR) spectra were acquired using a Perkin Elmer Spectrum One system. Raman spectra were recorded using a Jobin Yvon LabRam HR 800 confocal micro-Raman system. The solid-state NMR 13C and 7Li spectra were recorded on a Bruker Avance 500 spectrometer at a magnetic field strength of 11.7 T, at Larmor frequencies of 73.6 and 194.4 MHz for 13C and 7Li, respectively. X-ray diffraction (XRD) patterns were recorded at room temperature on a Rigaku X-ray diffractometer with Cu Kα1 radiation (l = 1.5406 Å) at 40 kV and 40 mA, respectively. Nitrogen sorption isotherms were acquired using a Micromeritics 3Flex surface analyzer (model 3500) at liquid nitrogen temperature (77 K), with the Brunauer-Emmett-Teller (BET) theory applied for specific surface area determination. Scanning electron microscopy (SEM) images were recorded using a field-emission scanning electron microscopy (FE-SEM, FEI Verios 460 L, USA). TEM images were recorded using a Tecnai G2 F20 S-TWIN at 200 kV.

Theoretical calculation

The molecular dynamics simulations were conducted using GROMACS (version 2021.3)32,33,34,35. Initial molecular configurations were refined through Gaussian 16 calculations, while the COF framework underwent further optimization via CP2K36. Atomic interactions for Li-TFSI systems were defined using the Optimized Potentials for Liquid Simulations all-atom (OPLS-AA) force field37. RESP2 charges derived from Multiwfn calculations were incorporated into the simulation parameters38. Following energy minimization, systems were equilibrated in the NPT ensemble for 10 ns using the Berendsen temperature and pressure coupling algorithm. Subsequently, production simulations were executed in the NVT ensemble at 300 K with a 1 fs integration time step. After 50 ns of simulation time, radial distribution functions (RDFs) and two-dimensional density maps (2D densmap) were evaluated using GROMACS analysis modules.

Data availability

The data generated in this study are provided in the Supplementary Information/Source Data file. Source data are provided with this paper.

References

Palacín, M. R. & de Guibert, A. Why do batteries fail?. Science 351, 1253292 (2016).

Palacín, M. R. Understanding ageing in Li-ion batteries: a chemical issue. Chem. Soc. Rev. 47, 4924–4933 (2018).

Haldar, S., Schneemann, A. & Kaskel, S. Covalent organic frameworks as model materials for fundamental and mechanistic understanding of organic battery design principles. J. Am. Chem. Soc. 145, 13494–13513 (2023).

Lu, Y. & Chen, J. Prospects of organic electrode materials for practical lithium batteries. Nat. Rev. Chem. 4, 127–142 (2020).

Cheng, Z. et al. Self-activation enables cationic and anionic co-storage in organic frameworks. Adv. Energy Mater. 12, 2101930 (2021).

Gao, H. et al. Integrated covalent organic framework/carbon nanotube composite as Li-Ion positive electrode with ultra-high rate performance. Adv. Energy Mater. 11, 2101880 (2021).

Yan, L. et al. Solid-state proton battery operated at ultralow temperature. ACS Energy Lett. 5, 685–691 (2020).

Xu, J. et al. Challenges and perspectives of covalent organic frameworks for advanced alkali-metal ion batteries. Sci. China Chem. 64, 1267–1282 (2021).

Zheng, S. et al. Orthoquinone–based covalent organic frameworks with ordered channel structures for ultra high performance aqueous zinc–organic batteries. Angew. Chem. Int. Ed. 61, e202117511 (2022).

Xie, L. et al. Localized ligands assist ultrafast multivalent-cation intercalation pseudocapacitance. Angew. Chem. Int. Ed. 62, e202300372 (2023).

Mi, Z. et al. Stable radical cation-containing covalent organic frameworks exhibiting remarkable structure-enhanced photothermal conversion. J. Am. Chem. Soc. 141, 14433–14442 (2019).

Das, G. et al. Viologen-Based Conjugated Covalent Organic Networks via Zincke Reaction. J. Am. Chem. Soc. 139, 9558–9565 (2017).

Sun, W. et al. Ion Co-storage in porous organic frameworks through on-site coulomb interactions for high energy and power density batteries. Angew. Chem. Int. Ed. 62, e202300158 (2023).

Tal, S., Blumer-Ganon, B., Kapon, M. & Eichen, Y. Reversible and persistent electrical bistability in single crystals of a self-assembled pi-conjugated tetraaryl system: a submicrometer scale electrical characterization. J. Am. Chem. Soc. 127, 9848–9854 (2005).

Wang, Z. et al. Redox of dual-radical intermediates in a methylene-linked covalent Triazine framework for high-performance lithium-ion batteries. ACS Appl. Mater. Interfaces 13, 514–521 (2021).

Miao, Z. et al. A novel strategy for the construction of covalent organic frameworks from nonporous covalent organic polymers. Angew. Chem. Int. Ed. 58, 4906–4910 (2019).

Yang, Z. et al. Fabrication of ionic covalent triazine framework-linked membranes via a facile sol–gel approach. Chem. Mater. 33, 3386–3393 (2021).

Wen, B.-Y. et al. In-situ monitoring of redox processes of viologen at Au(hkl) single-crystal electrodes using electrochemical shell-isolated nanoparticle-enhanced Raman spectroscopy. Electrochem. Commun. 72, 131–134 (2016).

Ma, T., Liu, L., Wang, J., Lu, Y. & Chen, J. Charge storage mechanism and structural evolution of viologen crystals as the cathode of lithium batteries. Angew. Chem. Int. Ed. 59, 11533–11539 (2020).

Shen, J., Liu, G., Han, Y. & Jin, W. Artificial channels for confined mass transport at the sub-nanometre scale. Nat. Rev. Mater. 6, 294–312 (2021).

Lu, J. & Wang, H. Emerging porous framework material-based nanofluidic membranes toward ultimate ion separation. Matter 4, 2810–2830 (2021).

Xie, L. et al. Surface charge modification on 2D nanofluidic membrane for regulating ion transport. Adv. Funct. Mater. 33, 2208959 (2023).

Marcus, Y. & Hefter, G. Ion Pairing. Chem. Rev. 106, 4585–4621 (2006).

van der Vegt, N. F. A. et al. Water-mediated ion pairing: occurrence and relevance. Chem. Rev. 116, 7626–7641 (2016).

Chai, J. et al. In situ generation of poly (Vinylene carbonate) based solid electrolyte with interfacial stability for LiCoO2 lithium batteries. Adv. Sci. 4, 1600377 (2017).

Zhao, G. et al. Dual-active-center of polyimide and triazine modified atomic-layer covalent organic frameworks for high-performance Li storage. Adv. Funct. Mater. 31, 2101019 (2021).

Shi, R. et al. Nitrogen-rich covalent organic frameworks with multiple carbonyls for high-performance sodium batteries. Nat. Commun. 11, 178 (2020).

Liu, Q. et al. Rechargeable anion-shuttle batteries for low-cost energy storage. Chem 7, 1993–2021 (2021).

Li, Z. et al. Three-dimensional covalent organic framework with ceq Topology. J. Am. Chem. Soc. 143, 92–96 (2021).

Gomes, R., Bhanja, P. & Bhaumik, A. A triazine-based covalent organic polymer for efficient CO2 adsorption. Chem. Commun. 51, 10050–10053 (2015).

Meier, C. B. et al. Structure-property relationships for covalent triazine-based frameworks: The effect of spacer length on photocatalytic hydrogen evolution from water. Polymer 126, 283–290 (2017).

Van Der Spoel, D. et al. GROMACS: fast, flexible, and free. J. Comput. Chem. 26, 1701–1718 (2005).

Páll, S., Abraham, M. J., Kutzner, C., Hess, B. & Lindahl, E. In Solving Software Challenges for Exascale: International Conference on Exascale Applications and Software, EASC 2014, Stockholm, Sweden, April 2-3, 2014, Revised Selected Papers 2. 3-27 (Springer).

Abraham, M. J. et al. GROMACS: High performance molecular simulations through multi-level parallelism from laptops to supercomputers. SoftwareX 1, 19–25 (2015).

Berendsen, H. J. C., van der Spoel, D. & van Drunen, R. GROMACS: A message-passing parallel molecular dynamics implementation. Comput. Phys. Commun. 91, 43–56 (1995).

Kühne, T. D. et al. CP2K: An electronic structure and molecular dynamics software package-Quickstep: Efficient and accurate electronic structure calculations. J. Chem. Phys. 152, 194103 (2020).

Jorgensen, W. L., Maxwell, D. S. & Tirado-Rives, J. Development and testing of the OPLS all-atom force field on conformational energetics and properties of organic liquids. J. Am. Chem. Soc. 118, 11225–11236 (1996).

Lu, T. & Chen, F. Multiwfn: A multifunctional wavefunction analyzer. J. Comput. Chem. 33, 580–592 (2012).

Acknowledgements

The authors acknowledge the support from the Key R&D Program of Xiamen (No. 3502Z20231059, H.W.C.), Natural Science Foundation of Fujian Province (No. 2023T3024 and No. 2023J02021, H.W.C.), National Natural Science Foundation of China (No. 22372063, H.W.C.; No. 22302072, H.B.K; No. 52367023, H.Z.), Natural Science Foundation of Xiamen (No. 3502Z20227029, H.B.K), Natural Science Foundation of Ningxia (No.2023AAC05026, H.Z.), Industrial Pilot (Key) Project of Fujian Province (No. 2022H0015, Z.L.Q). We acknowledge the support from the Instrumental Analysis Center of Huaqiao University. H.W.C. acknowledges the support from the Open Research Fund of the Academy of Advanced Carbon Conversion Technology, Huaqiao University.

Author information

Authors and Affiliations

Contributions

H.W.C. proposed the concept and supervised the work; W.L.S. conducted the material preparations and electrochemical characterizations; L.F. conducted the simulations; W.L.S., Y.L.H., J.R.Z., E.L.T. and T.P.H conducted the spectral characterizations; H.Z. conducted the gas adsorption-desorption experiments; D.R.L., C.J.H., Z.L.Q. and H.B.K. helped to analyze the data; H.W.C. and W.L.S. wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Yunhai Zhu, Manuel Souto and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, W., He, Y., Fang, L. et al. Refresh organic electrodes for high-power and long-cycle applications. Nat Commun 16, 5075 (2025). https://doi.org/10.1038/s41467-025-60355-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-60355-7