Abstract

The development of sustainable artificial nitrogen recycling technologies enables ammonia extraction from ambient sources, facilitating zero-carbon Water-Energy-Food (WEF) Nexus integration. While electrochemical reduction of oxidized nitrogen offers promise for ammonia synthesis, purifying low-concentration products remains a challenge, limiting practical applications and undermining the Haber-Bosch process’s viability. Here, we introduce a photothermal-electrocatalysis interface (PTEI) based on a Janus hybrid nanoarchitecture electrode, demonstrating synergistic enhancement in ammonia yield and evaporation performance. The photothermal-electrocatalysis interface-integrated system continuously produces and purifies ~2 M pure ammonia solution at up to 13.7 mg cm−2 h−1 from plasma-ionized air and achieves 80% total nitrogen recovery with 0.36 M ammonia from simulated industrial wastewater. This approach enables efficient extraction of concentrated ammonia for direct fuel cell use, offering techno-economic benefits and significantly reducing global warming impacts via life cycle assessment. Our findings highlight the PTEI system’s innovative potential in addressing WEF Nexus challenges, paving the way for sustainable waste-to-resource/fuel transitions.

Similar content being viewed by others

Introduction

The production of green ammonia has the potential to significantly contribute to the transition towards a zero-emission future by decarbonizing its primary applications in both fertilizer production and as a fuel source. Currently, the global annual output of ammonia is ~183 million tonnes, primarily produced through the Haber–Bosch process, which requires elevated temperatures (450−650 °C) and high pressures (>100 atm)1,2,3,4,5. This process relies heavily on fossil fuels as the principal hydrogen source, resulting in significant CO2 emissions of around 0.5 gigatonnes, accounting for 1−2% of worldwide greenhouse gas emissions6,7. These emissions, coupled with the impact of ammonia production on the global nitrogen cycle, have been identified as potential contributors to the decline of global biodiversity and the deterioration of air quality8. According to records from the early 21st century, anthropogenic activities fix approximately 213 teragrams (Tg) of nitrogen annually, surpassing natural nitrogen fixation, which amounts to about 203 Tg per year (Supplementary Fig. 1a)9,10. Despite these environmental concerns, the global demand for ammonia continues to rise annually with the growing population, presenting considerable challenges related to its uneven distribution (Supplementary Fig. 1b)11. In various regions worldwide, intensive agricultural activities have led to substantial waste emissions, particularly from fertilizer use. These emissions have detrimental environmental effects, including soil acidification, ecosystem degradation, and increased atmospheric pollutants12. Conversely, certain developing areas face ongoing challenges related to insufficient access to agricultural fertilizers and inadequate soil fertility, primarily due to cost and affordability issues. Therefore, there is an urgent need for research aimed at developing highly efficient ammonia production technologies that can decentralize the Haber–Bosch process13,14,15.

The reliance on the Haber–Bosch process for ammonia production, despite its established industrial foundation, presents significant challenges. This method, characterized by high energy consumption and substantial greenhouse gas emissions, underscores the urgent need for sustainable alternatives. Emerging technologies such as direct electrochemical nitrogen reduction (eNRR) and lithium-mediated electrochemical nitrogen reduction (LiNRR) offer promising avenues for reducing environmental impact16,17,18. However, eNRR faces challenges related to catalyst efficiency and selectivity, while LiNRR involves complex operational requirements, cost considerations in non-aqueous systems, and inherent energy efficiency issues13. In contrast, electrochemical reduction of nitrate to ammonia presents unique advantages. This method utilizes nitrate as a feedstock, which is readily accessible from wastewater, groundwater, and through plasma ionizing air to form nitrogen oxides (NOx) capable of dissolving in water19,20,21,22,23. This approach offers milder reaction conditions and greater selectivity, potentially enabling decentralized production facilities and reducing the environmental footprint associated with ammonia production (Supplementary Fig. 2 and Supplementary Table 1). Additionally, nitrate reduction holds significance for the current global nitrogen cycle24,25. By converting nitrate to ammonia and purifying it, this process can potentially reduce nitrogen pollution and enhance the utilization of nitrogen resources, thus supporting the sustainable advancement of the WEF Nexus26,27,28. Despite these advantages, a significant challenge remains due to the limited concentration of nitrate, resulting in very low concentrations of ammonia formed through electroreduction, necessitating substantial energy input for purification (Supplementary Fig. 3). Current common solutions focus on using stripping methods or direct contact membrane distillation (DCMD), where dilute acid absorbs the electrochemically reduced ammonia, followed by high-temperature evaporation to obtain ammonium salts2,20,26. However, these methods necessitate the introduction of additional anions, which require considerable thermal energy input for the recovery of ammonium salts. The resulting products, containing anions such as Cl⁻ and SO₄²⁻, have been shown to poison platinum-based noble metals, thereby limiting the potential applications of ammonia fuel cells29. This concern is particularly relevant as a significant quantity of ammonia is expected to be utilized for energy in the future, with aqueous or liquid ammonia being highly favored6. Addressing this challenge is crucial to realizing the full potential of electrochemical nitrate reduction as a viable alternative to conventional ammonia production methods.

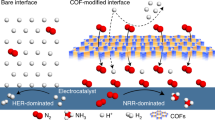

In this study, we present a sustainable strategy for the continuous production and purification of ammonia via a photothermal-electrocatalysis interface (PTEI), facilitating the harvesting of fuel-cell-grade ammonia from both wastewater and air (Fig. 1 and Supplementary Note 1). Inspired by advanced solar vapor generation systems30,31,32, we constructed the PTEI using a Janus hybrid nanoarchitecture electrode that integrates a hydrophobic photothermal gel (HPG) membrane with a nickel single-atom modified cuprous oxide catalyst layer (NiCu-SA). The NiCu-SA electrocatalytically converts nitrogen oxides, while the HPG porous membrane absorbs light to heat the interface and enable in situ ammonia evaporation. The incorporation of nickel single-atom sites into the copper oxide matrix significantly enhanced the nitrate reduction-to-ammonia (NO3RR) efficiency of NiCu-SA at low overpotentials. This improvement stems from two synergistic mechanisms: (i) asymmetric adsorption of *NOx intermediates on Ni-Cu dual sites, which lowers the energy barrier for hydrogenation pathways, and (ii) the strong water dissociation capability of atomic Ni sites, which provides active hydrogen (*H) to drive intermediate conversion into NH320,33,34. Additionally, by fine-tuning the wettability of the HPG membrane, we achieved a remarkable 80% ammonia recovery efficiency alongside a more than three-fold increase in evaporation rate. Implementing the PTEI in a continuous flow photoelectrochemical reactor enabled the sustainable harvesting of ammonia from simulated wastewater or plasma-activated air, yielding an impressive NH3 concentration of ~2 M with anion-free, suitable for driving direct ammonia fuel cells (DAFCs)35. These findings underscore the potential for scalable and practical applications of this approach within the sustainable WEF Nexus, particularly through the utilization of renewable energy, thereby addressing nitrate pollution and contributing to the reduction of greenhouse gas emissions.

Results

Construction and characterization of PTEI

The construction of the Janus structure for PTEI is illustrated in Fig. 2a. This structure is formed by integrating the hydrophobic photothermal gel (HPG) and NiCu-SA layers. The top HPG layer is designed for the ammonia evaporation process, while the underlying NiCu-SA layer is responsible for nitrate reduction reaction. The top layer is formed using a gel structure, cross-linked with glutaraldehyde while polyvinyl alcohol (PVA) serves as the polymer framework blended with polypyrrole (PPy) as solar absorbers. The surfactant properties of PVA enable the dispersion of PPy in aqueous solutions, leading to the formation of a multi-level pore structure after gelation. In addition, controlling the wettability has been demonstrated as an effective approach in solar-driven evaporation. To regulate the overall wettability, the gel is immersed in an octadecyltrichlorosilane (OTS) solution at room temperature for a certain period of time. The bottom layer consists of copper oxide nanowires modified with nickel single-atomic sites. Briefly, copper hydroxide nanowires as precursors were grown on the surface of copper mesh using a typical chemical oxidation method. Subsequently, the precursors were impregnated with a low concentration of nickel ions, followed by annealing and electrochemical reduction processes. This process resulted in the formation of a nickel single-atom anchored copper oxide nanowire electrode. Finally, the two layers were adhered together through PVA.

a Schematic of the hybrid nanoarchitecture floating on water for interfacial nitrate-to-ammonia electrocatalysis and heating-driven evaporation. b, c SEM images of NiCu-SA; d Atomic-scale HAADF-STEM images of NiCu-SA, along with integrated pixel intensities. e FT-EXAFS spectra of Ni K-edge for Ni(OH)2, Ni foil, NiO, and NiCu-SA. f, g SEM images of the HPG. h N2 sorption isotherms and pore size distributions of HPG. i Contact angle testing of gels treated with OTS solutions of different concentrations, as well as the Si/O ratio on the surface. OG1, OG2, OG3, and OG4 refer to gels treated with OTS solutions at different dilution factors (1, 10, 100, 1000 times), while PG denotes an untreated pure gel. The vertical axis in blue represents the Si/O ratio on the gel’s surface. The ratio of Si and O contents was determined through X-ray photoelectron spectroscopy (XPS) analysis of Si 2p and O 1 s spectra.

The surface morphology of NiCu-SA was first examined using scanning electron microscopy (SEM) (Fig. 2b, 2c). The copper mesh is composed of copper wires with a diameter of ~50 μm, where the densely packed arrays of nanowires are grown. To further characterize the atomic structure of the catalyst, high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) images were obtained. The results reveal a lattice spacing of ~0.3 nm between Cu atoms, which corresponds to the (0 1 1) crystal plane of Cu2O as shown in Fig. 2d. The results of auger electron spectrometry (AES) and energy-dispersive X-ray spectroscopy (EDS) mappings also support the composition of copper nanowires mainly consisting of Cu2O (Supplementary Figs. 4 and 5). In principle, the brightness of the atomic columns in the HAADF-STEM image is proportional to the square of the atomic number, allowing differentiation between Ni and Cu atoms based on Z-contrast between adjacent atomic columns. The intensity profile similarly corroborates the anchoring of nickel monomers on the surface36,37. This supports the presence of single-atom nickel species in the structure depicted in Fig. 2d. The Fourier-transformed extended X-ray absorption fine structure (FT-EXAFS) analysis of the nickel (Ni) K-edge in NiCu-SA (Fig. 2e) reveals a Ni bond length of 1.44 Å. This value is shorter than both the Ni-O bond length observed in NiO, Ni(OH)2 and the Ni-Ni bond length in bulk nickel foil. Additionally, the relatively low intensity of the Ni scattering peak in NiCu-SA suggests a low coordination number for nickel, suggesting that nickel species are atomically anchored on the Cu2O surface (Supplementary Fig. 6). Further analysis of the O 1 s XPS spectra reveals that the oxygen vacancy concentration in NiCu-SA is significantly higher than that in Cu2O (Supplementary Fig. 7), providing direct evidence for the successful incorporation of high-valent Ni2+ into the Cu2O lattice.

SEM images provide further evidence of the three-dimensional hierarchical pore structure of the gel membrane (Fig. 2f, g and Supplementary Fig. 8). The result reveals the presence of large pores ranging from tens to hundreds of micrometers. Additionally, there is a uniform distribution of mesoporous structures, on the orders of tens of nanometers, along the gel walls. This characteristic multilevel structure is attributed to the dispersion of PPy assisted by PVA, acting as a surfactant in the solution. Consequently, PVA-PPy clusters form with interstitial gaps after gelation. To gain more insight into the multilevel porous structure of the HPG, the Brunauer-Emmett-Teller (BET) analysis was employed, as displayed in Fig. 2h. The N2 adsorption isotherm exhibits a Type II isotherm, suggesting the predominance of macropore structures within the material. Further analysis of the pore size distribution (Supplementary Fig. 9) indicates that the most prevalent pore size in the material is ~1.4 nm. Moreover, the wettability of the original PVA gel material (PG) was controlled by immersing it into OTS solutions with different dilution ratios (0, 10, 100, 1000 times), denoted as OG1, OG2, OG3, and OG4, respectively. XPS was performed to examine the coverage of OTS modified on the material surface after the OTS treatment (Supplementary Fig. 10). Figure 2i indicates a significant increase in coverage of OTS as the solution concentration increases, with OG1 exhibiting slightly higher coverage than OG2. Contact angle measurements were employed to investigate the wettability of the sample group. The water contact angle on the PG to OG2 surface increases noticeably with higher OTS content, while OG1 shows a slightly lower contact angle compared with OG2. This trend aligns with previous studies38, highlighting the influence of surface microstructures on material wettability. Based on these findings, it can be concluded that a 10-fold dilution of the OTS solution offers an appropriate treatment concentration.

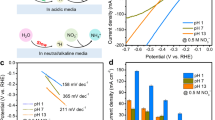

Electrocatalytic performance for nitrate to ammonia conversion

Under neutral conditions, we conducted an evaluation of the catalytic performance for nitrate reduction with varying concentrations (Fig. 3a and Supplementary Fig. 11), which are close to the nitrate concentration in common agricultural and industrial wastewaters7. Specifically, at low overpotentials, the NO2− is primarily produced, consistent with previous reports on copper-based materials. At potentials ranging from −0.2 V to −0.6 V, NiCu-SA exhibits significantly higher faradaic efficiency (F.E.) for ammonia production, indicating that the introduction of isolated nickel species promotes the conversion of nitrate to ammonia at low overpotentials. Additionally, NiCu-SA demonstrates robust ammonia production performance across a wide concentration range in Supplementary Fig. 12 (50–5000 ppm NO3−-N). Supplementary Fig. 13 exhibits the catalytic stability of NiCu-SA. The durability assessments demonstrate that NiCu-SA proceeds electrochemical NO3RR with an F.E. beyond 90% over ten consecutive catalytic cycles, supporting its commendable stability in nitrate electrolysis. It was hypothesized that during the illumination process, the photo-induced heat could be transferred from the upper HPG to NiCu-SA, inducing alteration in temperature possibly affecting ammonia production. Therefore, we investigated the performance of nitrate electroreduction at various temperatures under a given potential of −0.5 V (Fig. 3b). The results reveal that temperature had minimal influence on the F.E. of ammonia at this potential but significantly enhanced the yield rate (Y.R.) of ammonia as the temperature increased. Notably, in our previous studies, temperature elevation at low overpotentials was found to enhance the F.E. of NO3RR, which was attributed to differences in solution pH and operating potential33. To ensure the accuracy of the measurements, 1H nuclear magnetic resonance (NMR) spectroscopy was employed to qualitatively confirm that all ammonia originated from the electrochemical reduction of nitrate in the solution (Supplementary Fig. 14), while ion chromatography (IC) was used to quantitatively validate the accuracy of the indophenol-blue method (Supplementary Fig. 15 and Supplementary Table 2). Further characterization of the post-tested NiCu-SA reveals that the Ni 2p XPS spectra remain nearly identical before and after testing, indicating no significant changes in the chemical environment of Ni species. Additionally, the nanowire array morphology of the catalyst remains intact without observable collapse or agglomeration, as confirmed by SEM analysis (Supplementary Figs. 16 and 17).

a Faradaic efficiency of ammonia and nitrite products on NiCu-SA and Cu2O in PTEI under neutral conditions with a NO3--N concentration of 200 ppm. b Faradaic efficiency and yield rate of ammonia for NiCu-SA at −0.5 V under different temperatures. c The calculated Gibbs free energy diagram of the reaction pathway for the nitrate reduction to ammonia on NiCu-SA and Cu2O surface. d Snapshots of the differential charge density of nitrite ions on NiCu-SA and Cu2O, along with N-O Crystal Orbital Hamilton Population (COHP).

To provide a deeper understanding of the enhanced performance of NiCu-SA, density functional theory (DFT) calculations were performed. The models of Cu2O (1 1 0) with and without a single-atomic Ni site modification were built (Supplementary Figs. 18 and 19). In general, the nitrate reduction pathway involves nitrate adsorption, hydrogenation and deoxygenation of *NOx intermediates, and ends up with ammonia desorption. Figure 3c shows the impact of Ni single-atom modification on NO3RR and hydrogen evolution reaction (HER), taking into account the conditions of pH = 12. In particular, the nitrate adsorption free energy on NiCu-SA is ~0.15 eV lower relative to Cu2O, indicating a thermodynamically favorable process. Besides, the positive free energy change of the *NO to *NHOH step is assumed to be the potential-determining step (PDS), of which Cu2O is higher than the NiCu-SA (1.06 eV to 1.01 eV). Furthermore, the energy analysis of the HER pathway demonstrates the prohibition nature of water splitting over pure Cu2O. In contrast, NiCu-SA exhibited notable thermodynamic advantages in water adsorption and dissociation, which could enable NiCu-SA surface with abundant active hydrogen atoms for the hydrogenation of *NOx39. To further investigate the origin of NiCu-SA’s superior ability to activate *NOx intermediates, we examined the adsorption of NO2− on the NiCu-SA surface (Fig. 3d). NO2− is one of the most common side reaction products in copper-based catalysts during NO3RR, making the catalytic ability of the reaction substrate towards adsorbed NO2- crucial. The differential charge density simulations were performed to denote that the introduction of single-atomic Ni site results in the asymmetric NO2- adsorption on the copper site. Regarding the Cu2O model, a total charge transfer of 0.257 e− has been calculated during the bonding process between the substrate and *NO2 with each copper atom contributing 0.106 e− and 0.109 e−, respectively. By contrast, a total charge transfer of 0.243 e− is observed in the NiCu-SA model, where the copper and nickel atoms contribute 0.102 e− and 0.131 e−, respectively. Furthermore, Crystal Orbital Hamilton Population (COHP) analysis of *NO2 in N-O orbitals shows that the antibonding orbitals of N-O in NiCu-SA shift to lower energies with the -ICOHP value of 1.46 eV in comparison to the Cu2O, providing supportive evidence of favorable N-O activation by the synergistic interaction between isolated nickel atoms and Cu2O surface. The negative shift of the Fermi energy level in NiCu-SA after NO3− adsorption compared to Cu₂O further supports this conclusion (Supplementary Fig. 20).

Photothermal evaporation performance for ammonia recovery

The solar-thermal evaporation of ammonia with the HPG was then investigated. In the solar-driven water evaporation process, controlling the wettability of the gel membrane is crucial. The surface wettability plays a key role in how water molecules bond with the surface. To improve ammonia-water separation performance, we utilized a soaking treatment method with a range of OTS solution concentrations to regulate the gel’s wettability. Figure 4a demonstrates the temperature fluctuations of the floating gels caused by solar radiation. The gels OG1, OG2, and OG3, which are highly hydrophobic, present a rapid increase in surface temperature, exceeding 40 °C within 10 seconds, followed by reaching a temperature of about 48 °C after 10 min. In contrast, the hydrophilic PG and OG4 require ~10 min to attain a state of thermal equilibrium. Additionally, the gels with stronger hydrophobicity show a noticeable increase in surface temperatures when exposed to light, as compared to hydrophilic membranes. This can be attributed to the substantial amount of liquid water present in hydrophilic gels, which helps in maintaining a lower temperature by surface evaporation and significant heat absorption. The infrared images reveal the thermal dissipation of PGs into the bulk water, indicating the convection between the PGs and water underneath. In contrast, the heat of OG2 is primarily concentrated on the surface, which is beneficial for the on-site ammonia evaporation. Figure 4b presents the rate of ammonia evaporation over the gels with varied wettability under illumination (1 sun, 100 mW cm−2) in an ammonia solution with the concentration of 200 ppm (NH3-N). Two distinct trends emerge upon observation, delineated within two delineated regimes. In the first regime (white region), there is an initial increase in the plots followed by a decrease in OTS hydrophobic treatment concentration. Notably, OG2 exhibits the highest ammonia evaporation rate of ~1.32 ± 0.14 g h−1 m−2. Regarding the second regime (blue region), PG demonstrates a significant increase in the evaporation rate compared to OG4. To allow more insights, we carried out finite element analysis to simulate the impact of hydrophobicity on the ammonia evaporation performance as shown in Fig. 4b. The modeling (Supplementary Fig. 21 and Supplementary Table 3) involved a gel membrane immobilized at the surface of the ammonia-water solution and examined the relationship between the relative humidity of the gel against the normalized ammonia evaporation rate. The results suggest that the capacity for ammonia evaporation is likely to decrease with diminished hydrophobicity. However, the lowest normalized ammonia evaporation rate is evident at a relative humidity of approximately 0.8 (Fig. 4b and Supplementary Figs. 22–25). Upon further analysis of the model, we have found that when both liquid and gas phases exist within the porous gel (Supplementary Fig. 26), high relative humidity (>0.8) results in the dominance of liquid-phase water, and the rate of ammonia evaporation is determined by the flux of ammonia in the liquid phase. Yet, at the low relative humidity levels (<0.8), the ammonia evaporation rate is predominantly governed by the flux of ammonia in the gas phase. In addition, as the relative humidity increases, the flux of ammonia in the liquid phase decreases significantly, while the gas phase remains confined to a small volume, resulting in substantial tortuosity for ammonia diffusion. Additionally, the hydrophobically modified materials exhibit significantly better mechanical stability compared to the untreated PG (Supplementary Fig. 27). Among them, OG1 demonstrates the highest elastic modulus (185.3 MPa), while OG2 achieves a substantial improvement in ammonia evaporation efficiency and selectivity (Fig. 4b and Supplementary Fig. 28) while retaining acceptable mechanical strength (166.2 MPa). OG2 also demonstrated high thermal stability during prolonged testing (The ammonia evaporation rate remains above 90%), further confirming its robustness under operational conditions (Supplementary Fig. 29).

a Variation of temperature over time under 1 sun illumination for gels with different wettability, along with infrared thermal imaging of PG and OG2. b The ammonia evaporation rates of various modified electrodes as experimentally measured or simulated from finite element modeling. c Molecular dynamics simulations of the evaporation process through pores with hydrophobic and hydrophilic modification. d Temporal evolution of hydrogen bond count at the interface of hydrophilic and hydrophobic models, along with their average values (dashed line), and adsorption energy of ammonia molecules on hydrophilic and hydrophobic chains.

Molecular dynamics simulations were employed to provide a clear understanding of the influence of the wettability of porous gels on ammonia evaporation at the microscopic scale. A solution box was built, containing a total of 14,700 water molecules and 300 ammonia molecules (Fig. 4c). To confine molecular movement, a metallic layer was incorporated beneath the solution box. Additionally, two distinct pore models were constructed above the solution box: a hydrophilic pore model consisting of PVA chains and a hydrophobic pore model composed of alkane chains (Supplementary Figs. 30 and 31). These pore models were designed with a pore width of ~1 nm, as determined from the BET results. In order to avoid the rebounding of water or ammonia molecules into the solution during evaporation, a restraining force was implemented above the pore models. This force was specifically applied to account for the periodic boundary conditions and effectively confine the molecules within the designated simulation region, ensuring their proper containment. As a result, notable differences were observed after a 500 ps evaporation simulation. Specifically, in the hydrophilic model, the water molecules gradually infiltrated the PVA pores, leading to an obvious upward displacement of the liquid surface. Conversely, in the hydrophobic model, the liquid surface exhibited minimal alteration throughout the simulation. Namely, the number of evaporated ammonia molecules (17) in the hydrophobic model was higher than that in the hydrophilic model (11). Considering that hydrogen bonding is the dominant interaction between ammonia and water molecules, we extracted the hydrogen bonding data for ammonia molecules at the interface as demonstrated in Fig. 4d. The results show that, during the 500 ps simulation, the hydrophobic model exhibited a lower average number of hydrogen bonds for ammonia molecules on the liquid surface (1.82) relative to the hydrophilic model (1.97). These findings imply that the hydrophobic system weakens the hydrogen bonding between ammonia and water molecules at the interface, thereby facilitating the detachment of ammonia molecules from the solution. Moreover, the hydrophilic chains exhibit a significantly higher affinity for ammonia adsorption relative to the hydrophobic chains. This implies that the hydrophilic pores may offer greater resistance to ammonia evaporation, potentially hindering the evaporation process.

PTEI for ammonia harvesting from wastewater in a batch reactor

A customized cell for evaporation of ammonia with PTEI was designed and developed (Fig. 5a and Supplementary Figs. 32–34). The cell design is based on an H-type electrolytic cell, which consists of a cathodic chamber and an anodic chamber. Our primary focus is on the recovery of ammonia through photo-induced heat coupled electrosynthesis, which occurs in the cathodic chamber. To enable solar radiation to reach the PTEI, a quartz window is incorporated at the top of the cathodic chamber. Upon applying a potential on NiCu-SA, the NO3RR takes place on NiCu-SA, resulting in the dissociation of water molecules on the surface and the generation of a substantial amount of OH-. The locally high pH value facilitates the presence of NH3 in its molecular form. Furthermore, the photo-induced heat increases the temperature of the gas-liquid interface, accelerating the evaporation of ammonia molecules from the liquid surface.

a Schematic of the batch reactor-based PTEI for ammonia harvesting. b Nitrogen collection efficiency and ammonia recovery rate within the system under 0, 0.5, 1, and 2 sun illumination intensities. c Evaluation of nitrogen collection efficiency and ammonia recovery rate within the lab-prepared nitrate solutions at concentrations of 50, 100, 200 and 500 ppm (NO3−-N), as well as simulated industrial wastewater (IW) and textile wastewater (TW). d Analysis of residual nitrogen content in wastewater with initial nitrate concentrations of 50, 100, 200, 500 ppm, as well as in IW and TW nitrogen-containing effluents after treatment. e A schematic representation of the SECM setup operated in substrate generation-tip collection (SG/TC) mode using a Pt-UME to detect NH3 produced during NO3RR on PTEI. f Current and fitted curves of the tip approaching the substrate. g Snapshots of ammonia production via NO3RR on the substrate and its simulated diffusion coefficient in the air.

To account for variations in solar irradiance across different regions, we examined the ammonia collection capacity of the NiCu-SA under different light intensities (Fig. 5b). The collection efficiency of nitrogen resources was determined by measuring the ammonia content in the acid solution. In the initial electrolyte solution with a nitrate nitrogen concentration of 200 ppm, the nitrogen resource collection efficiency was only about 40% in the absence of light. By contrast, under the light intensity of 0.5 sun, the overall nitrogen resource collection efficiency increased to 64.2%. At higher irradiance levels of 1 and 2 sun, the efficiency achieved values of 74.1% and 80.8%, respectively, while the ammonia collection rates were recorded as 0.073 mg h−1 cm−2 and 0.082 mg h−1 cm−2. In addition, we further investigated the system’s nitrogen resource collection capacity with different nitrate concentration solutions (Fig. 5c). Specifically, at a concentration of 50 ppm, the nitrogen resource collection rate was 50.8%. In conditions of higher concentration, resembling levels found in industrial wastewater, the ammonia capture efficiency surpassed 70%, and the ammonia collection rate reached 0.184 mg h−1 cm−2. Furthermore, we prepared two types of wastewater samples with more complicated contents (Supplementary Table 4) to simulate realistic industrial wastewater (IW) and textile wastewater (TW). In particular, the outcomes for the treatment of IW with concentrations of NO3−-N (~580 ppm), NH3-N (~400 ppm), and Cl− (~460 ppm) demonstrate an exceptional total nitrogen collection efficiency of 78.8% as well as an ammonia recovery rate of 0.43 mg h−1 cm−2. In TW, the nitrate nitrogen content was ~104 ppm, resulting in a nitrogen collection efficiency of 54.5%. This difference can be attributed to the inherently higher concentrations of ammonia in IW, thereby leading to a higher total nitrogen collection efficiency. The residual nitrate species in the liquid phase were analyzed after the treatment (Fig. 5d). The levels of remaining nitrate in the solution exhibit a direct correlation with the initial nitrate concentration. After treatment, the removal efficiency of nitrate ions for all components except TW exceeded 90%. The slightly lower nitrate nitrogen removal efficiency in TW could be attributed to its significantly higher Cl− content compared to nitrate ions. Multi-physics finite element simulations were employed to gain a deeper understanding of the transport behavior of reactive species within the batch reactor (Supplementary Fig. 35 and Supplementary Table 5). The analysis indicated that the pH at the interface rapidly increased to above 11, suggesting that even under neutral conditions, the OH− produced by electroreduction is sufficient to maintain ammonia in its molecular form at the interface (Supplementary Figs. 36 and 37). By analyzing the concentration changes of major nitrogen-containing species in the cell, including ammonia molecules, ammonium ions, and nitrate ions, we observed that during the evaporation process under illumination, the rate of ammonia concentration decrease gradually stabilized over time, indicating that the evaporation rate of ammonia is influenced by its own concentration (Supplementary Figs. 38–42). Additionally, temperature was found to facilitate the evaporation of ammonia at the interface (Supplementary Figs. 43–46).

To obtain direct evidence demonstrating the enhancement of ammonia evaporation by the PTEI, a scanning electrochemical microscopy experiment (SECM) was conducted using the surface generation-tip collection mode (SG/TC)40,41. As shown in Fig. 5e, a negative potential was applied to the NiCu-SA surface to induce NO3RR and produce ammonia. The NiCu-SA integrated with a hydrophobic photothermal gel-coated PTFE membrane (HPG), formed the PTEI. 1 mM ferrocene methanol was used as a reference to calibrate the distance between the tip and the substrate. Three different scenarios were investigated, named I, II, and III. Scenario I included NO3RR, illumination, and purging to promote ammonia evaporation; scenario II included NO3RR and purging; scenario III only involved NO3RR. A positive potential was applied to a 25-micron platinum microelectrode (Pt-UME) to detect ammonia produced on the NiCu-SA. Due to the smaller size of the Pt-UME compared to the substrate below, as the tip gradually approached the substrate, the current on the Pt-UME originated entirely from the oxidation of ammonia produced on the substrate. Numerical simulation of the gradual current change on the tip allowed for the fitting of surface ammonia concentration and its diffusion rate at the photothermal interface. As shown in Fig. 5f, as the tip gradually approached the substrate, the current on the tip in scenario I was significantly lower than in scenarios II and III, indicating that a large amount of ammonia on the substrate was evaporated through the photothermal interface. Fitting results indicated that the ammonia diffusion rate in scenario II without illumination was 5.36 × 10−7 cm2 s−1, while the diffusion rate at the photothermal interface was 1.78 × 10−6 cm2 s−1, demonstrating that the photothermal interface greatly facilitated ammonia evaporation in scenario I, approximately by more than three times. Visualized 2D concentration profiles in Fig. 5g were used to better understand this process, showing that a large amount of ammonia in scenario I evaporated in gaseous form from the photothermal electrocatalytic interface compared to scenarios II and III.

Photothermal Electrocatalytic Interface for Continuous Ammonia Production and Purification

Above, we have demonstrated the application of PTEI in a batch reactor for water purification and denitrification. However, the mismatch between the evaporation rate and production rate of ammonia results in suboptimal ammonia production efficiency. Flow-type reactors, on the other hand, offer advantages in production efficiency and integration, making them more suitable for practical industrial applications. By combining the plasma-mediated nitrogen oxide generation system with the PTEI for NOx reduction reaction (P-PE-NOxRR), we designed a system capable of continuously producing high-purity concentrated aqueous ammonia from air, further extending the potential of PTEI system (Fig. 6a and Supplementary Figs. 47–49). The P-PE-NOxRR maintained stable operation for 30 hours continuously, with the current stabilizing above 200 mA cm−2 h−1 after the initial 30 min, indicating a balance between nitrate generation and consumption at the cathode. After 4 hours, the ammonia collection rate gradually stabilized due to the accumulation of ammonia in the cathode tank, ultimately reaching a balance for the ammonia collection rate reached up to 13.7 mg cm−2 h−1 (Fig. 6b). During the 24-h collection period, P-PE-NOxRR collected about 23 mL of pure ammonia solution with a concentration of 1.96 M (~3.25 wt%), which is comparable to previously reported ammonia concentrations for ammonia fuel cells32. Using industrial simulated wastewater (IW) as nitrate nitrogen source in this system (W-PE-NOxRR), ~25 mL of aqueous ammonia at a concentration of 0.36 M (~0.61 wt%) was collected (Fig. 6c and Supplementary Fig. 50). The ammonia obtained from air and simulated wastewater was mixed with 10 M NaOH at a 9:1 volume ratio for use in an ammonia fuel cell (Fig. 6d). The peak power densities of fuel cells directly driven by the yield ammonia from P-PE-NOxRR and W-PE-NOxRR are 1.77 mW cm−2 and 1.32 mW cm−2, respectively. It should be noted that this is only a proof of concept, and in fact, optimizing the catalyst can greatly enhance the power density of DAFCs35,42.

a Schematic diagram of the photothermal-electrocatalysis interface for a cascade plasma ionization air generator in a flow-type electrolytic cell. b Long-term stability testing of the system at −0.6 V vs. RHE under illumination with the light power density of 200 mW cm−2 in 1 M KOH as supporting electrolytes. c Ammonia concentration extracted from air or simulated wastewater over 24 h. d Use of ammonia extracted from air or simulated wastewater in a direct ammonia fuel cell, with both cathode and anode utilizing Pt/C with a loading of 0.4 mg PGM cm−2.

To comprehensively evaluate the economic viability of our proposed ammonia production strategy, we conducted a rigorous techno-economic analysis (TEA). The total expenditure, including capital expenditure (CAPEX) and operational expenditure (OPEX), was calculated, accounting for costs associated with electrodialysis in W-PE-NOxRR, the plasma unit in P-PE-NOxRR, ammonia synthesis via electrolysis, and ammonia concentration through steam stripping distillation (Supplementary Note 2). Under base case conditions43, which reflect current technological standards, the cost of ammonia concentration and purification in P-NOxRR accounts for more than half of the total expenditure. In contrast, for the PTEI-based pathway, electricity is the primary cost driver, with the ammonia purification cost in P-PE-NOxRR reduced to 7% of the total cost (Fig. 7a and Supplementary Fig. 51). This reduction results in a decrease of 0.88 USD per kg NH3 in total cost. However, the costs of P-PE-NOxRR (2.00 USD per kg NH3) and W-PE-NOxRR (1.71 USD per kg NH3) still do not fall within the economically viable range (< 1.6 USD per kg NH3)44. A univariate sensitivity analysis was conducted to identify key parameters for optimizing system costs (Supplementary Fig. 52 and Supplementary Table 6). The results indicate that electricity price, plasma unit energy efficiency, and electrolyzer energy efficiency are the primary factors influencing the P-PE-NOxRR system, while electrolyzer energy efficiency, electricity price, and distillation feed concentration are the critical factors for W-PE-NOxRR. These findings highlight key areas for future research, including the broader deployment of renewable energy systems and the optimization of catalyst and electrolyzer designs. We further performed an economic assessment using parameters optimized within reasonable limits (Supplementary Table 7), indicating that the costs of P-PE-NOxRR and W-PE-NOxRR could fall within the range of ammonia market prices, suggesting their potential profitability.

a Evaluation of the economic viability of ammonia production via PTEI. This assessment considers two technological scenarios: the base case and the optimistic case (Supplementary Table 7). The light blue shaded area represents the market price of anhydrous ammonia over the past three years44. b The Global Warming Potential (GWP) of Ammonia Production via the Haber–Bosch process and electrochemical treatment of nitrate wastewater. The scenarios include: Approach I: the current Haber-Bosch process, II: P-NOxRR (The plasma system combines with NOxRR but without PTEI), III: P-PE-NOxRR, IV: W-NOxRR (NOxRR for wastewater treatment but without PTEI), and V: W-PE-NOxRR. The GHG emissions are indicated by black numbers when ammonia is stored, and by green numbers when it is used as green fuel for power generation.

To further evaluate the potential environmental impact of this strategy, we conducted a life cycle assessment (LCA), comparing the global greenhouse gas (GHG) emissions between traditional methods and the innovative electrochemical-photothermal coupled approach proposed in this study (Fig. 7b). The power sources considered include the U.S. grid and wind energy (Supplementary Note 3). The functional unit is 1 kilogram of anhydrous ammonia. In the traditional Haber-Bosch process, the extensive use of fossil fuels, both as feedstock and for thermal energy, results in GHG emissions of up to 2.49 kg CO2 per kg of ammonia produced. For P-NOxRR and W-NOxRR, carbon emissions from thermal energy account for over 50% of the total carbon footprint (Supplementary Fig. 53). In contrast, utilizing PTEI combined with NOxRR, P-PE- NOxRR, and W-PE-NOxRR demonstrates exceptional decarbonization potential. Notably, when considering the use of ammonia as a green fuel for power generation, P-PE- NOxRR and W-PE-NOxRR can reduce GHG emissions to -0.12 kg CO2 per kg of ammonia and −0.27 kg CO2 per kg of ammonia, respectively. This is attributed to the electrochemical-photothermal coupling, which facilitates the direct production of high-concentration ammonia solutions, significantly reducing the energy required for subsequent distillation. Additionally, due to its electrification and suitability for distributed production, this approach aligns well with the use of renewable energy sources. It is important to note that W-PE-NOxRR is applicable for wastewater with nitrate-nitrogen concentrations around 100 ppm. When using lower concentration water sources such as groundwater for electrodialysis, energy consumption increases sharply. This may limit its applicability specifically in ammonia production45,46. The P-PE-NOxRR system, on the other hand, offers the potential for continuous ammonia production directly from air47. These results position the proposed PTEI as one of the best strategies for ammonia synthesis and purification (Supplementary Table 8).

Discussion

In this study, we developed a Janus hybrid nanostructured PTEI system that harnesses solar energy to reduce energy consumption and purify low-concentration ammonia from the NOxRR process, enabling continuous electrified production from environmental sources like air and wastewater. The integration of nickel single atoms within the cuprous oxide substrate markedly enhances ammonia yield by facilitating the generation of active hydrogen and the dissociation of NOxRR intermediates, attaining a F.E. of over 90% with the Y.R. exceeding 2.8 mg cm⁻² h⁻¹ in a 200 ppm NO3--N solution. By optimizing the hydrophobicity of the interface, we ensured stable and continuous ammonia production and purification within the integrated PTEI system. SECM demonstrated a 3.3-fold increase in the ammonia evaporation rate under photothermal conditions. When utilizing air as a nitrogen source, the PTEI system reached an ammonia extraction rate of up to 13.7 mg cm−2 h−1 and produced aqueous ammonia at a concentration of ~2 M. Furthermore, treatment of simulated industrial wastewater resulted in an ammonia solution concentration of 0.36 M and a total nitrogen recovery rate surpassing 80% LCA assessments demonstrate that the P-PE-NOxRR system exhibits superior decarbonization capabilities. Additionally, TEA model results highlight the potential of photothermal-electrocatalysis interface to decarbonize chemical production, especially as low-cost renewable electricity becomes more widely accessible. This synergistic innovation in materials and device design has facilitated the development of a multifunctional platform for water treatment, chemical synthesis, and separation purification, offering a sustainable strategy for advancing the WEF Nexus. Moreover, this approach shows prospects for extension to other low-boiling point product reactions, such as CO2 reduction reaction (CO2RR) and nitrogen reduction reaction (NRR).

Methods

Chemicals

All aqueous solutions were prepared using ultrapure water. Copper mesh (300 mesh) was purchased from Ares Metal Technology Co., Ltd. Sodium nitroferricyanide (C5FeN6Na2O, 99.0%), was purchased from Macklin. Nickel chloride hexahydrate (NiCl2·6H2O, 98%), ammonium sulfate ((NH4)2SO4, ≥99.0%), ammonium persulfate ((NH4)2S2O8, 99.9%), sodium sulfate (Na2SO4, 99.9%), sodium nitrite (NaNO2, 99.0%), polyvinyl alcohol 1799 (PVA, 90.5%), pyrrole, hydrochloric acid (HCl, 36.0%), glutaraldehyde (50.0%), hexane (97.0%) sodium hypochlorite solution (NaClO, 5.5% Cl) potassium nitrate (KNO3, 99.9%), potassium hydroxide (KOH, 90%), sodium hydroxide (NaOH, 98% metals basis), were all came from KESHI. Octadecyltrichlorosilane (OTS, 97.0%) and N-(1-naphthyl) ethylenediamine dihydrochloride were purchased from Adamas.

Synthesis of NiCu-SA

A standard synthetic procedure initiated with the treatment of a 300-mesh Cu mesh (~0.022 g cm-2) using ~20 mL 0.5 M H2SO4 followed by ethanol rinsing. Subsequently, the growth of Cu(OH)2 nanowires on the Cu mesh occurred by immersion in a solution comprising 4.0 mL 10.0 M NaOH, 2.0 mL 1.0 M (NH4)2S2O8, and 9.0 mL deionized water for 20 min. The resulting Cu(OH)2 nanowires underwent washing with deionized water and drying at 60 °C for 1.0 h, then were immersed in a 20.0 mM NiCl2 solution for 12.0 h, facilitating an ion exchange process. Post ion exchange, the Ni-doped Cu(OH)2 nanowires were dried at 80 °C for 1.0 h, succeeded by thermal treatment in an air atmosphere at 200 °C, yielding Ni-doped CuO. Finally, the electrochemical reduction of Ni-doped CuO using chronoamperometry at −0.50 V vs. RHE for 2.0 h in electrolyte led to the preparation of NiCu-SA. Additionally, Cu2O were synthesized via identical thermal treatment and electrochemical reduction applied to Cu(OH)2 nanowires, excluding the Ni ion exchange stage.

Preparation of PTEI

Using a typical method to synthesize HPG, 1 mL of pyrrole was added to 10 mL of water and sonicated for 15 min to form Solution A. Subsequently, 3.304 g of ammonium persulfate was sonicated in 10 mL of water to prepare Solution B. Solutions A and B were added to 50 mL of 1.2 M HCl and stirred for ten minutes. The pyrrole rapidly polymerized to form polypyrrole (PPy), which was then washed, filtered, and sonicated in water to form Solution C (1 wt%). 0.8 g of PVA was dissolved in 10 mL of water by heating and stirring (PVA: H2O = 0.8:10). To this solution, 0.5 mL of 1.2 M HCl, 1.25 mL of glutaraldehyde, and 3 mL of Solution C were added. After thorough mixing, the mixture was quickly poured into a mold and allowed to crosslink and solidify for two hours. The resulting material was then carefully cut into 1 × 1 cm² or 3 × 3 cm² squares, followed by freeze-drying. Subsequently, a hydrophobic treatment was applied. 20 μL of water was added to 2 mL of OTS, sonicated for 10 seconds, and left to stand for 2 h. The solution was then diluted 1, 10, 100, and 1000 times with n-hexane. The freeze-dried material was immersed in the diluted solutions for 20 min, washed with n-hexane, and dried. According to the dilution factor, they were named OG1, OG2, OG3, and OG4 in ascending order. The untreated freeze-dried PVA gel was named as PG, with PG0.6, PG0.8, PG1.0, and PG1.2 representing PVA: H2O mass ratios of 0.6:10, 0.8:10, 1.0:10, and 1.2:10, respectively. For the PPY1, PPY2, and PPY3, PPy concentrations of approximately 0.5 wt%, 1 wt%, and 1.5 wt% were employed, respectively. HPG was then bonded with NiCu-SA using PVA solution to form a Janus structure.

HPG was employed in a flow cell by preparing a photothermal coating on a commercial porous PTFE membrane. The PPy solution was centrifuged, dried, and ground into powder, then mixed with XC-72R in a 1:3 mass ratio. A 10 mg portion of the prepared powder was ultrasonically dispersed in 1 mL of isopropanol solution and sprayed onto a PTFE membrane (50% porosity, 150 μm), with a loading of ~0.4 mg cm−2. Subsequently, a diluted OTS solution was uniformly sprayed onto the photothermal coating. HPG and NiCu-SA were directly clamped together by the electrode plates.

Characterization

Aberration-corrected high-angle annular dark-field STEM images were obtained using JEOL NEOARM (Japan). The ultraviolet-visible absorbance spectra were collected on a UNICO UV-4800 spectrophotometer (China). Scanning electron microscopy (SEM) photos were measured by a ZEISS GeminiSEM 300 scanning electron microscope (Germany). X-ray absorption fine structure analysis (XAFS) was carried out at the Shanghai Synchrotron Radiation Facility (China). The corresponding extended X-ray absorption fine structure (EXAFS) were processed by using the IFEFFIT program package. Brunauer-Emmett-Teller (BET) was tested on Quantachrome EVO (USA). X-ray Photoelectron Spectroscopy (XPS) were performed in Thermo Scientific K-Alpha (USA). Contact angle testing was carried out on Zhongcheng JC2000D1 (China). INSTRON 5982 (USA) was employed to test the compressive mechanical properties of the materials. 1H NMR spectra were recorded on a Bruker 600 MHz spectrometer (Germany).

Determination of NH3

To assess the NH3 generated in electrolytes following chronoamperometric tests, the indophenol-blue technique was utilized in the experiment14. A mixture of collected electrolytes (1.0 mL) and 1.0 M NaOH solution containing 5.0 wt% sodium citrate and 5.0 wt% salicylic acids, 0.5 mL of 0.05 M NaClO, and 0.1 mL of 1.0 wt% C5FeN6Na2O was prepared. After 2.0 h, Ultraviolet-visible spectroscopy (UV-Vis) absorption testing in the 500–800 nm wavelength range was performed on this mixture. The absorption peak at approximately 650 nm was attributed to the generated NH3. To determine the NH3 concentration, a calibration curve was generated using standard solutions of ammonia sulfate with various concentrations prepared. The absorbance of a control sample without ammonia sulfate was subtracted from all other sample readings to account for background noise.

The NH3 yield rate (Y.R.(NH3), mgNH3 h-1 cm-2) in the NO3RR process was calculated using the following formula, where A represents the electrode area, t is the reaction time, and V is the solution volume:

Here, V denotes the solution volume, t represents the electrolysis time, and A stands for the electrode reaction area.

The F.E. of NH3 (F.E.(NH3)) was the percentage of the charge consumed for NH3 generation in the total charge passed through the electrode according to the equation below:

In the equation, n represents the number of transferred electrons, where n is 6 for nitrite and 8 for nitrate. CNH3-N represents the measured NH3-N concentration (μg mL−1, ppm), V represents the volume of the electrolyte (30 mL), t represents the electrolysis time (0.5 h), A represents the geometric area of the electrode (0.5 cm2), F represents the faraday constant (96500 C mol-1), and Q represents the total charge passed through the electrode, which is calculated as the integral of the I-t curve.

For the measurement of ammonia concentration using ion chromatography (IC), the ammonia concentration was determined using a Thermo Fisher ICS-5000+ ion chromatography system equipped with an eluent generator (isocratic elution with 30 mM KOH/methanesulfonic acid as the mobile phase) and anion/cation suppressors. The pump flow rate was set at 1 mL/min, and the suppressor regenerant flow rate was 0.45 mL/min. Quantification was performed via an external single-point calibration method with quadratic fitting. Sample preparation included dilution of the liquid sample, followed by high-speed shaking (800 rpm, 1 h), ultrasonic dispersion (1 h), filtration through a 0.2 μm syringe filter, and injection into the system (25 μL per injection). All steps adhered to standard operating protocols.

Determination of NO2 −

To measure the nitrite concentration in electrolytes following chronoamperometric curve tests, we utilized the Griess method. The Griess colorimetric reagent was prepared by dissolving N-(1-naphthyl) ethylenediamine dihydrochloride (0.04 g), sulfanilamide (0.8 g), and 85% H3PO4 (2.0 mL) in 10 mL deionized water. The electrolyte after electrolysis (50 μL) was first neutralized with hydrochloric acid (1.0 M, 50 μL) and the resulting solution was diluted to 2.0 mL with deionized water. Next, Griess colorimetric reagent (40 μL) was added to the diluted solution, which was incubated for 10 min to promote the formation of chromophores. UV-Vis absorption curves of the above mixture were conducted from 400 to 650 nm, and the absorption intensity at around 540 nm was employed to calculate the concentration of nitrite. A calibration curve was established by analyzing standard NaNO2 samples with known concentrations and corresponding absorbance values.

The F.E. of NO2− (F.E.(NO2−)) was determined as the percentage of the charge for producing NO2- in the total charge (Q) recorded by the chronoamperometric curve according to the equation below:

n is the number of electron transfers (2), V represents the solution volume, F is the Faraday constant, Q denotes the total electric charge consumed during electrolysis, where CNO2- is the measured NO2− concentration.

Determination of NO3 −

After the chronoamperometric curve tests, a 50 μL aliquot of the electrolyte was withdrawn from the cathodic compartment and diluted to 2 mL. It was then mixed with 40 μL of 1 M HCl and 40 μL of sulfamic acid solution (0.8 wt%). The solution was allowed to stand for 15 min. The UV-Vis absorption spectrum of the mixed solution was collected in the range of 200–300 nm. The absorption intensities at approximately 220 and 275 nm were recorded to determine the concentration of nitrate. The final absorbance value of nitrate was calculated using the equation:

Photothermal driven ammonia evaporation test

The experimental study on the evaporation properties of ammonia was conducted in the laboratory using a solar simulator (PLS-SXE300C), which generated a simulated solar radiation flux of 100 mW cm−2 (equivalent to 1 solar radiation intensity). The solar radiation flux was accurately measured using a light power meter (PL-MW2000). Since the solar radiation flux varies across the light spot, and to ensure accurate power input, HPG pieces with a surface area of 1 cm2 were cut and transferred to float on the surface of dilute ammonia solution (NH3-N 200 ppm) contained in a glass cuvette placed within the light spot. The solar radiation flux within the light spot was maintained at 1 solar intensity. All evaporation rates were measured after a 10-min stabilization period at 1 solar intensity. The remaining ammonia in the solution was quantitatively determined using UV-Vis absorption tests.

Electrochemical measurements

The investigation of nitrate reduction reaction activities was carried out using a sealed H-type electrochemical cell, with a Nafion 115 membrane separating the compartments. Electrochemical data were recorded using an Autolab PGSTAT204 workstation. Prior to all experiments, the Nafion membrane was treated with a 5.0 wt% aqueous solution of H2O2 at 80 °C for 1.0 hour, followed by rinsing with deionized (DI) water at 80 °C for an additional hour. The working electrode consisted of Cu2O nanowires, with an active area of 0.5 cm2, carefully sealed around the edges with hot melt adhesive. A saturated calomel electrode (SCE) was used as the reference electrode, respectively. The electrolytes (0.5 M K2SO4 and KNO3 with 200 ppm NO3--N) were degassed using ultrapure argon flow to remove O2 and N2 prior to the electrochemical measurements. Chronoamperometry tests were performed at specific potentials for 30.0 min to evaluate the yield rate and F.E. of NH3. The cell temperature was controlled using a water-bath heater equipped with a thermocouple detector. No data were excluded from the analyses and the experiments were not randomized.

For the batch reactor used in photothermal-electrochemical ammonia production testing, a custom device with a bipolar membrane was employed. PTEI floated on the water surface, and electrolysis was conducted under Xenon lamp illumination for 24 h, with the electrolysis itself lasting 6 h. Argon gas at a flow rate of 80 sccm was used to purge the evaporated ammonia into a 0.5 M sulfuric acid solution for collection. Post-illumination, the concentrations of ammonia and nitrate were measured.

For the flow reactor used in photothermal-electrochemical ammonia production testing, a custom flow-type electrochemical cell was utilized. The electrolyte used was 1 M KOH, which absorbs NOx generated from ionized air. The cathode compartment had a thickness of 4 mm, and a bipolar membrane was used as the separator. HPG and NiCu-SA (2 × 2 cm2) were directly clamped together by the electrode plates. Argon gas at a flow rate of 400 sccm swept over the HPG surface. During a 30-hour stability test, an acid trap was used to collect the evaporated ammonia from the PTEI, confirming the obtained ammonia concentration. A liquid nitrogen cold trap replaced the acid trap to test the concentration of the obtained aqueous ammonia, with the collection time being 24 h. For P-PE-NOxRR, a plasma system was employed to generate nitrogen oxides. This system included a high-voltage power supply (HB-C06, Foshan Hongba Electronics Co., Ltd., China) and a voltage regulator (TDGC2−0.5KVA, Zhejiang Chengqiang Electric Co., Ltd., China), applying 60 W of power to tips, with an air flow rate of 100 sccm. For the W-PE-NOxRR system, a 1000 mL industrial simulated wastewater was used as the cathode tank.

To calibrate the measured potentials at different temperatures to the RHE, the Nernst equation was employed:

where R represents the gas constant (8.314 J mol-1·K-1), T represents the cell temperature (K), F is the faraday constant (96500 C mol-1), and \({{{{\rm{E}}}}}_{{{{\rm{SCE}}}}}^{\varphi }\) is the conversion value between the SCE and RHE.

SECM for ammonia evaporation testing

Ammonia evaporation experiments were electrochemically measured using a MinTech super-resolution electrochemical microscopy system (MT-SRECM200). The MT-SRECM200 system includes a piezoelectric displacement platform for precise x, y, z positioning, a mechanical three-dimensional displacement platform for large-scale movement, and a video microscopy system with optic cold light for sample and SECM probe visualization. All equipment was installed inside a Faraday cage and placed on a pneumatic damping anti-vibration platform, with device control and data acquisition managed by SPRM v1.0 software48,49. A custom-made PTFE interlayer electrolytic cell was used. For test groups I and II, NiCu-SA and HPG were closely assembled as the substrate, with Ag/AgCl as the reference electrode and a 25 μm Pt ultramicroelectrode used to detect ammonia produced by the substrate. Group I was illuminated with a xenon lamp light source from below and subjected to gas purging, while Group II was not illuminated but had gas purging. Group III was neither illuminated nor subjected to gas purging.

Direct ammonia fuel cell testing

A custom-designed electrolytic cell was utilized for ammonia fuel cell testing. Both the cathode and anode catalysts consisted of 20 wt% Pt/C powder, while PAP polymers based on the terphenyl group were employed as hydroxide exchange membranes (HEMs) and ionomers (Purchased from Versogen). The mass ratio of catalyst to ionomer was 9:1 for both the cathode and anode. The ink for electrode spraying was prepared by dispersing the catalyst and ionomer in an isopropanol solvent, followed by 15 min of ultrasonic treatment. The ink was then uniformly sprayed onto 1 cm² electrodes, with a catalyst loading of 0.4 mgPt cm⁻². The anolyte was a mixture of 18 mL of ammonia solution obtained from air or simulated wastewater and 2 mL of 10 M KOH, with a liquid flow rate of 10 sccm. The catholyte was 1 M KOH, with an oxygen flow rate of 60 sccm.

Data availability

The data supporting the plots within this paper and other study findings are available from the corresponding author upon request. Source data are provided with this paper.

References

Luo, Y. et al. Selective electrochemical synthesis of urea from nitrate and CO2 via relay catalysis on hybrid catalysts. Nat. Catal. 6, 939–948 (2023).

Chen, F. Y. et al. Efficient conversion of low-concentration nitrate sources into ammonia on a Ru-dispersed Cu nanowire electrocatalyst. Nat. Nanotechnol. 17, 759–767 (2022).

Wang, L. et al. Greening ammonia toward the solar ammonia refinery. Joule 2, 1055–1074 (2018).

Goodwin, C. M. et al. Operando probing of the surface chemistry during the Haber-Bosch process. Nature 625, 282–286 (2024).

Xu, Z. et al. Continuous ammonia electrosynthesis using physically interlocked bipolar membrane at 1000 mA cm-2. Nat. Commun. 14, 1619 (2023).

Gül, T. et al. Ammonia Technology Roadmap: Towards More Sustainable Nitrogen Fertiliser Production (IEA, Paris, 2021). https://www.iea.org/reports/ammonia-technology-roadmap.

van Langevelde, P. H., Katsounaros, I. & Koper, M. T. M. Electrocatalytic nitrate reduction for sustainable ammonia production. Joule 5, 290–294 (2021).

Galloway, J. N. et al. Transformation of the nitrogen cycle: recent trends, questions, and potential solutions. Science 320, 889–892 (2008).

Stein, L. Y. & Klotz, M. G. The nitrogen cycle. Curr. Biol. 26, R94–R98 (2016).

Fowler, D. et al. The global nitrogen cycle in the twenty-first century. Philos. Trans. R. Soc. Lond. B Biol. Sci. 368, 20130164 (2013).

Stevens, C. J. Nitrogen in the environment. Science 363, 578–580 (2019).

Erisman, J., Bleeker, A., Galloway, J. & Sutton, M. Reduced nitrogen in ecology and the environment. Environ. Pollut. 150, 140–149 (2007).

John, J., MacFarlane, D. R. & Simonov, A. N. The why and how of NOx electroreduction to ammonia. Nat. Catal. 6, 1125–1130 (2023).

De Maigret, J., Macchi, E. G. & Blanco, H. Global hydrogen trade to meet the 1.5 °C climate goal: Part II – Technology review of hydrogen carriers (International Renewable Energy Agency (IRENA), Abu Dhabi, 2022). https://www.irena.org/Publications/2022/Apr/Global-hydrogen-trade-Part-II.

Rosa, L. & Gabrielli, P. Energy and food security implications of transitioning synthetic nitrogen fertilizers to net-zero emissions. Environ. Res. Lett.18, 014008 (2022).

Chang, W., Jain, A., Rezaie, F. & Manthiram, K. Lithium-mediated nitrogen reduction to ammonia via the catalytic solid-electrolyte interphase. Nat. Catal. 7, 231–241 (2024).

Garrido-Barros, P., Derosa, J., Chalkley, M. J. & Peters, J. C. Tandem electrocatalytic N2 fixation via proton-coupled electron transfer. Nature 609, 71–76 (2022).

Li, P., Jin, Z., Fang, Z. & Yu, G. A Surface-strained and geometry-tailored nanoreactor that promotes ammonia electrosynthesis. Angew. Chem. Int. Ed. 59, 22610–22616 (2020).

Miller, D. M. et al. Engineering a molecular electrocatalytic system for energy-efficient ammonia production from wastewater nitrate. Energy Environ. Sci. 17, 5691–5705 (2024).

Liu, W. et al. Efficient ammonia synthesis from the air using tandem non-thermal plasma and electrocatalysis at ambient conditions. Nat. Commun. 15, 3524 (2024).

Kong, X. et al. Synthesis of hydroxylamine from air and water via a plasma-electrochemical cascade pathway. Nat. Sustain. 7, 652–660 (2024).

Liu, Y. et al. Pyridine-N-rich Cu single-atom catalyst boosts nitrate electroreduction to ammonia. Appl. Catal. B: Environ. 340, 123228 (2024).

Wang, X. et al. Efficient photoelectrocatalytic synthesis of ammonia by superionic conductor with mixed ion/electron conduction. Adv. Mater. 37, 2500446 (2025).

Kuypers, M. M. M., Marchant, H. K. & Kartal, B. The microbial nitrogen-cycling network. Nat. Rev. Microbiol. 16, 263–276 (2018).

Tang, S. et al. General synthesis of high-entropy single-atom nanocages for electrosynthesis of ammonia from nitrate. Nat. Commun. 15, 6932 (2024).

Zhou, B. et al. Renewable energy driven electroreduction nitrate to ammonia and in-situ ammonia recovery via a flow-through coupled device. Water Res 242, 120256 (2023).

Xu, H., Ma, Y., Chen, J., Zhang, W. X. & Yang, J. Electrocatalytic reduction of nitrate - a step towards a sustainable nitrogen cycle. Chem. Soc. Rev. 51, 2710–2758 (2022).

Li, P. et al. Pulsed nitrate-to-ammonia electroreduction facilitated by tandem catalysis of nitrite intermediates. J. Am. Chem. Soc. 145, 6471–6479 (2023).

Holst-Olesen, K., Reda, M., Hansen, H. A., Vegge, T. & Arenz, M. Enhanced oxygen reduction activity by selective anion adsorption on non-precious-metal catalysts. ACS Catal. 8, 7104–7112 (2018).

Guo, Y. et al. Tailoring surface wetting states for ultrafast solar-driven water evaporation. Energy Environ. Sci. 13, 2087–2095 (2020).

Zhao, F. et al. Highly efficient solar vapour generation via hierarchically nanostructured gels. Nat. Nanotechnol. 13, 489–495 (2018).

Zhao, F., Guo, Y., Zhou, X., Shi, W. & Yu, G. Materials for solar-powered water evaporation. Nat. Rev. Mater. 5, 388–401 (2020).

Liu, K. et al. Thermally enhanced relay electrocatalysis of nitrate-to-ammonia reduction over single-atom-alloy oxides. J. Am. Chem. Soc. 146, 7779–7790 (2024).

Wang, Y. et al. Enhanced nitrate-to-ammonia activity on copper–nickel alloys via tuning of intermediate adsorption. J. Am. Chem. Soc. 142, 5702–5708 (2020).

Zhao, Y. et al. An efficient direct ammonia fuel cell for affordable carbon-neutral transportation. Joule 3, 2472–2484 (2019).

Zhang, X. et al. Platinum-copper single atom alloy catalysts with high performance towards glycerol hydrogenolysis. Nat. Commun. 10, 5812 (2019).

Xiang, J. et al. Inter-site distance effect in electrocatalysis. Angew. Chem. Int. Ed., 64, e202500644 (2025).

Zhang, L., Zhou, A. G., Sun, B. R., Chen, K. S. & Yu, H. Z. Functional and versatile superhydrophobic coatings via stoichiometric silanization. Nat. Commun. 12, 982 (2021).

Li, H. et al. Modulating the surface concentration and lifetime of active hydrogen in cu-based layered double hydroxides for electrocatalytic nitrate reduction to ammonia. ACS Catal. 14, 12042–12050 (2024).

Jin, Z. High-spatiotemporal-resolution electrochemical measurements of electrocatalytic reactivity. Anal. Chem. 95, 6477–6489 (2023).

Xu, J., Gao, H., Wang, F. & Zhou, M. Nanoscale electrochemical approaches to probing single atom electrocatalysts. Curr. Opin. Electrochem. 39, 101299 (2023).

Li, Y. et al. High-performance ammonia oxidation catalysts for anion-exchange membrane direct ammonia fuel cells. Energy Environ. Sci. 14, 1449–1460 (2021).

Wang, Y. et al. Ammonia electrosynthesis from nitrate using a stable amorphous/crystalline dual-phase Cu catalyst. Nat. Commun. 16, 897 (2025).

Nick Paulson, G. S., Carl Z. Where Might Nitrogen Fertilizer Prices Be Headed? Farmdoc Daily https://farmdocdaily.illinois.edu/2024/06/where-might-nitrogen-fertilizer-prices-be-headed.html (2023).

Chen, F.-Y. et al. Electrochemical nitrate reduction to ammonia with cation shuttling in a solid electrolyte reactor. Nat. Catal. 7, 1032–1043 (2024).

Chen, Y. et al. Sustainable waste-nitrogen upcycling enabled by low-concentration nitrate electrodialysis and high-performance ammonia electrosynthesis. EES Catal. 1, 504–515 (2023).

Yi, M. et al. Electrocatalysis for sustainable nitrogen management: materials innovation for sensing, removal and upcycling technologies. Sci. China Chem. 68, 1–21 (2024).

Gao, H., Xu, J., Zhang, X. & Zhou, M. Benchmarking the intrinsic activity of transition metal oxides for the oxygen evolution reaction with advanced nanoelectrodes. Angew. Chem. Int. Ed. 63, e202404663 (2024).

Pan, Y. et al. Accelerating the discovery of oxygen reduction electrocatalysts: high-throughput screening of element combinations in pt-based high-entropy alloys. Angew. Chem. Int. Ed., 63, e202407116 (2024).

Acknowledgements

Z.J. and P.L. thank funding support from the National Key Research and Development Project(2022YFA1505300), National Natural Science Foundation of China (22476141, 22304021, and 52202372). G.Y. acknowledges the financial support from the Welch Foundation Award F-1861 and Norman Hackerman Award in Chemical Research.

Author information

Authors and Affiliations

Contributions

Z.J., P.L., M.Z. and G.Y. conceived the idea and supervised the project. P.W. performed the experiments, measurements and simulations, and wrote the draft of the paper. K.L. assisted in the measurements. L.Z. validated the result of the eco-economic analysis. Z.J. edited the paper. P.L., Z.P. and M.X. proofed the writing. All authors discussed and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, P., Li, P., Pan, Z. et al. Photothermal-electrocatalysis interface for fuel-cell grade ammonia harvesting from the environment. Nat Commun 16, 5581 (2025). https://doi.org/10.1038/s41467-025-60636-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-60636-1

This article is cited by

-

Steering the catalyst structure and intermediates adsorption configuration during pulsed nitrate electroreduction

Nature Communications (2025)