Abstract

Artificial stimulus-responsive membranes, particularly those responsive to different solvents, have important applications in complex and graded separation systems. Inspired by natural lipid membrane that alters mass transport behavior in response to interactions with various solvents, we report that incorporating porous graphene (PG) into graphene oxide (GO) membrane enables smart and switchable molecular sieving reversibly responsive to solvent types. The membrane shows high permeance for water and methanol, 45.52 and 13.56 L m−2 h−1 bar−1, respectively, and its molecular weight cut-off (MWCO) at ~319 g mol−1 in water, similar to pristine GO membrane, reversibly switches to 960 g mol−1 in methanol which is not observed in either pristine GO or graphene membrane. We accounted this switching to the change of transport pathways. In water, the GO-GO nanochannel is dominant, providing similar molecular sieving to pristine GO. In methanol, the GO-PG nanochannel becomes favorable because a strong solvent adsorption on the nanochannel surface, coupled with a weak solvent network under nanoconfinement, promotes a significant interlayer expansion, reducing the transport resistance and enabling larger, switched MWCO. This switchable sieving behavior is further demonstrated for efficient graded separation of ternary solution of solutes with various molecular weights.

Similar content being viewed by others

Introduction

Controlled molecular and ionic transport in response to stimuli is prevalent in the natural world, and plays a crucial role in regulating complicated functions of biological systems including the human body1,2,3,4. In nature, most of the controllable transport behaviors are ultimately dictated by a cell membrane that undergoes structural change to external stimulus5. Inspired by these natural membranes, artificial stimuli-responsive membranes have been developed, and show responses to small changes in environmental conditions, including pH, pressure, temperature, ionic strength, electric fields, and light irradiation6,7,8,9, leading to significant advances in the development of smart membranes and their separation technologies.

Not only do some cell membranes show responsive mass transport in an aqueous environment, but they also respond to changes in solvent types. For example, lipid membrane, a self-assembled bilayer structure of phospholipid molecules10, shows higher ionic and molecular permeation when water is replaced by ethanol, such solvent−dependent mass transport behavior is attributed to that, compared to water, ethanol causes structural expansion of the bilayer due to strong hydrogen-bond-mediated interactions between ethanol and phospholipid molecules5,11,12. Realization of similar solvent-responsive molecular transport in an artificial membrane enables sophisticated membrane separation, for example, graded separation for the ternary or even more complex compositions in various solvent systems, which previously can only be achieved by energy-intensive and time-consuming distillation or chromatography processes13,14,15. Recently, the polymeric membrane that undergoes pore size change in different solvents has been reported to have a switchable molecular sieving property and promise advanced and practically usable separation technologies16. However, the known instability of many polymeric membranes in organic solvents may limit their stable use in “smart” solvent-responsive separation17.

Inspired by the lipid membrane that, other than relying on a well-defined pore size change, its smart molecular transport is dictated by a difference in the interaction of its molecular chain with different solvents, our interests lie in two-dimensional materials, especially graphene-based materials, which are stable in organic solvents.18. Specifically, graphene and its derivatives, graphene oxide (GO), show distinct interactions with water and organic solvents. For example, water is pinned at the oxidized region of GO, but moves frictionlessly on the graphene surface19. This suggests that the integration of different graphene derivatives into one membrane may lead to solvent-dependent molecular sieving behavior. However, despite there are intensive studies on GO/graphene composite membranes, their focus is on improving membrane selectivity by controlling interlayer spacing or achieving high permeance by generating extra transport pathways20,21,22,23,24. In addition, although graphene-based membranes have been widely used for stimuli-responsive separation25, but such responsivity is generally induced by magnetic, electrical, thermal stimulus, pH and light irradiation, with little attention to solvent-responsive separation. One previous study shows nanoporous graphene membrane has switchable molecular sieving when subjected to permeating organic solvents, but such membranes assembled by the thick graphene nanosheets (~6 nm) only, may suffer from possible assembly defects. Furthermore, its similar structure in different solvents indicates the switchable sieving does not rely on the interaction between the membrane and the solvent type26.

Here, we report the smart, solvent-dependent molecular sieving in a membrane assembled by porous graphene (PG) and GO nanosheets. Incorporating PG in the GO membrane leads to a reversible switch of the molecular transport and sieving properties when it is used in different solvents (for example, water and methanol). The membrane has a water and methanol permeance of 45.52 L m−2 h−1 bar−1 and 13.56 L m−2 h−1 bar−1 respectively, and it allows larger molecules (molecular weight (MW) > 319 g mol−1) that are rejected in water, to pass the membrane in methanol. We further demonstrate graded molecular separation using a single membrane based on the solute size and the interaction between the membrane and the solvents.

Results

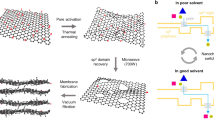

Our study starts with preparing GO and PG, which are used for the membrane assembly (Fig. 1a). The GO nanosheets were prepared by a modified Hummers’ method27. The PG nanosheets were prepared following our previous report28. Briefly, the nickel salt etches carbon atoms and generates pores on the GO nanosheets during their thermal reduction, the average pore size is ~70 nm, the largest size we can achieve (Fig. S1) Then, the GO/PG membrane is made by mixing the aqueous dispersion of GO and PG in N-methylpyrrolidone (NMP) and then filtrating the stable colloidal mixture through a nylon support membrane by vacuum filtration (See Methods, Figs. S2, S3 and S4). The optimal mixing ratio of GO/PG was determined by monitoring the resulted membrane’s rejection to a probe molecule violet blue (VB, ~506 g mol−1), and we found when the PG content is ≤40 wt%, the water permeance increases with the PG content and maintains a ~100% rejection to VB molecules, but such rejection decreases rapidly when the PG content is >40 wt% (Figs. S5 and S6). This suggests that a GO/PG composite membrane with 40 wt% has the highest permeance without sacrificing membrane selectivity (Supplementary sections 1–3), we therefore, use GO/PG membrane with 40 wt% PG content for in-depth study.

a Schematic of the fabrication process for the GO/PG membranes. The right panel is the SEM image of the surface of a GO/PG membrane. Scale bar, 5 µm. The inset is the image of a GO/PG membrane deposited on a nylon substrate. b Permeance of organic solvents through GO/PG membrane as a function of their inverse viscosity. Dotted lines are best linear fits. The physical properties of each organic solvent are listed in Table S1. c MWCO curves of GO/PG membranes in water (black) and methanol (red) containing 10 ppm dye. The MWCO was determined by interpolating from the plot of rejection versus the MW of the dyes obtained from the pressurized nanofiltration experiments. Insets: the diffusion tests for VB molecules diffusing through a GO/PG membrane before (upper) and after (lower) 72 h in water (left) and methanol (right). MWCO curve for (d) pristine GO and (e) pristine PG membrane in water (red) and methanol (black) containing 10 ppm dye solutes. All error bars are standard deviations from at least three different measurements of the independent membrane.

The introduction of PG to the GO membrane increases the permeance of the membrane. The pristine GO membrane has a water permeance of 3.08 L m−2 h−1 bar−1, the introduction of non-porous graphene in the GO membrane results in a water permeance increased to ~6.89 L m−2 h−1 bar−1 (Fig. S7). In stark contrast, the GO/PG membrane shows a water permeance of ~45.52 L m−2 h−1 bar−1 (the average pore size of PG is 70 nm, with a pore density of ~9.8 × 109/cm2) (Fig. S1). We also tried PG with an average pore size of ~30 nm, which has a pore density of ~6.2 × 109/cm2 and found the water permeance of the resulting GO/PG membrane decreases to 23.8 L m−2 h−1 bar−1 (Fig. S7). We note an increase in the pore size and/or pore density could further increase the membrane permeance but is challenging to achieve experimentally28. Such an increase in permeance by intercalation of porous materials in the GO membrane is not surprising and is generally explained by shortening and increasing number of the molecular pathways29.

Not only for water, but the GO/PG membrane also shows methanol permeance of 13.56 L m−2 h−1 bar−1, significantly higher than the pristine GO membrane (~0.21 L m−2 h−1 bar−1) (Fig. S8). Given that methanol has a higher inverse viscosity (1/η) than water, but shows lower permeance through the GO/PG membrane, inconsistent with the classical mechanism that the solvent viscosity governs membrane permeability, indicating the two solvent molecules may diffuse through different pathways. To validate this, we further measured the permeance of ethanol, butanol, pentanol, acetonitrile, and acetone through the membrane and plotted their permeance versus 1/η, found a good linearity (R2 = 0.97) for the organic solvents, but with water as the exception (Fig. 1b). In addition, we found a similar linear relationship between the permeance and solvent solubility parameters of the corresponding solvent (Fig. S9), again, with water as an exception, indicating that the diffusion pathways of organic solvents and water in the membrane are indeed different.

The change of the molecular pathway in different solvents indicates the solvent type may change the molecular sieving properties of the GO/PG membrane. To testify this, we have measured the rejection of membrane to the dye molecules with different MWs (94−1470 g mol−1) and charges dissolved in water and methanol, respectively, and compared this molecular sieving property with pristine GO and PG membranes. The MW cut-off (MWCO) of the GO/PG membrane is at ~319 g mol−1 when water is used as a solvent, but this MWCO shifts to ~960 g mol−1 in methanol (Fig. 1c, Figs. S10 and S11). That is, the GO/PG membrane shows a solvent-dependent molecular sieving behavior. This also sets a distinct difference between GO/PG membranes with the pristine GO and PG membranes. Specifically, the GO membrane shows a similar MWCO at ~319 g mol−1 regardless of using water or methanol as the solvent (Fig. 1d), suggesting an absence of solvent-dependent molecular sieving, which is also consistent with our previous report18. For the PG membrane, we did not observe effective molecular sieving either in both water or methanol (Fig. 1e and Fig. S12). In addition, such a change in the molecular sieving of the GO/PG membrane was also observed in a diffusion experiment. In water, the membrane allows no permeation of VB for 72 h but shows an instant permeation of VB in methanol (Fig. 1c inset and Fig. S13). The mass balance analysis shows that less than 5% of the dyes are adsorbed by the membrane during the filtration test, and we also examined the dye rejection in relation to its charge but found no clear correlation (Table S2), indicating the size extrusion is the dominant molecular sieving mechanism (Fig. S14).

The observed shift of molecular sieving in the GO/PG membrane is reversible. Using aqueous and methanol solutions of VB as an example, we show the solvent permeance through the membrane and, more importantly, its rejection to VB switched instantaneously in response to an alternating change of the solvent (water/methanol) (Fig. 2a, b). Specifically, the permeance decreased from ~40 L m−2 h−1 bar−1 for water to ~10 L m−2 h−1 bar−1 for methanol and recovered to the original permeance for aqueous nanofiltration of VB solution. Note that the permeance of dye solutions is slightly lower than that of pure solvents, this is not unusual and is possibly due to the membrane fouling by the dye molecules30. For the sieving property, the membrane’s rejection to VB is ~100% when water is used as the solvent but decreases to <15% in methanol, and again recovers to 100% when the solvent switches to water.

a Reversible solvent permeance through the GO/PG membrane and b rejection of VB measured upon switching the feedstock solvent between water and methanol. c Rejection of VB (left inset: rejection of MLB and BB) in a mixed solvent of water and methanol (v/v) for the GO/PG membrane. Insets are photographs of their corresponding permeates (right inset). All error bars are standard deviations from at least three different measurements of the independent membrane.

In another experiment, we conducted a permeation test of the VB molecule using a mixture of water and methanol with different volume percentages (vol%). As shown in Fig. 2c, the membrane retains a rejection >90% when the vol% of methanol is lower than 30%, further increasing the vol% of the methanol leads to a gradual decrease in rejection. We note that similar phenomena are seen for different probing molecules, including negatively charged dye (bright blue, BB, ~792 g mol−1) and small MW dye (methylene blue, MLB, ~319 g mol−1), supporting tunable molecular sieving of the membrane in response to the solvent compositions (Fig. 2c inset).

While the MWCO of the membrane reversibly shifts in response to the change of solvent, it maintains a long-term stability with respect to its permeance and molecular sieving property. Specifically, it demonstrates consistent nanofiltration performance, including dye rejection and permeance, for 150 h in both water and organic solvents (Fig. S15). Additionally, it withstands high pressure (~10 bar) with a linear flux-pressure relationship and remains structurally intact after soaking in water and methanol for over 30 days (Figs. S16, S17 and S18). In addition, the GO/PG membrane exhibits high permeance and rejection, compared to the previously reported GO-based membranes (Table S3). These results highlight its potential for stable and responsive molecular sieving applications.

The switchable molecular sieving allows the graded separation using the same membrane by only altering the choice of solvents. To demonstrate this, a ternary aqueous mixture of phenol (transparent, ~94 g mol−1), VB (blue, ~506 g mol−1), and reactive red 195 (RR 195, red, ~1136 g mol−1) was filtered through a GO/PG membrane (Fig. 3a). For the first round of filtration, because the membrane has a MWCO at ~319 g mol−1 in water, it allows only the smallest phenol molecules to pass through the membrane, while the larger molecules, VB and RR 195, were rejected at the feed solution. This is confirmed by the colorless appearance of the permeate and the absence of the characteristic peaks for VB and RR 195 from the UV-Vis analysis of the permeate (Fig. 3b). Next, we followed the previous reports16,26, used water to flush residual phenol in the retentate and repeated the process until the phenol concentration in the permeate was <1% (determined by the UV-Vis spectroscopy). When the vol% of the aqueous retentate is <10%, the methanol was added to the retentate (for comparison, we kept the filtrate volume similar to the one used in the first round of nanofiltration), in this case, because the membrane has a MWCO of ~960 g mol−1 in methanol, VB can permeate through the membrane and be collected in the permeate side, leaving RR 195 in the retentate. Finally, excess methanol was added to the retentate, and a second round of filtration was employed to remove the residual VB from the feed solution and leave only RR 195 to be collected in the retentate (Fig. 3c). The entire process allows the graded molecular separation of three molecules using one membrane.

a Scheme showing ternary molecular separation of three dyes (phenol, VB, and RR 195) using one single GO/PG membrane in a two-step nanofiltration process. In step 1, only the smallest phenol molecules can permeate the membrane. In step 2, VB can permeate through the membrane, leaving RR 195 in the retentate. Note: The P and RR refer to phenol and RR 195, respectively. b, c UV-visible absorption spectra of (b) the feed mixture containing three molecules in water and its permeate, (c) feed solution after water nanofiltration (in 90 vol% of methanol), its permeate and retentate after the second step nanofiltration. The photographs show the mixture feedstock, the permeate collected in the first and second steps, and the retentate collected in the second step.

We next investigated why GO/PG has a switchable molecular sieving in different solvents. First, we considered the GO/PG membrane comprises three types of nanochannels, they are nanochannels made by stacking two GO nanosheets (denoted as GO–GO), two PG nanosheets (denoted as PG-PG), and, one GO and one PG nanosheet (denoted as GO–PG). Because the GO membrane has unchanged molecular sieving in both water and methanol (Fig. 1d), and the PG membrane has no molecular sieving in either water or methanol (Fig. 1e), it is reasonable to presume the observed switched molecular sieving of the GO/PG membrane involves the transport channel switching between the GO–GO and the GO–PG nanochannel. Specifically, in water, the GO/PG membrane has the same molecular sieving as that of the pristine GO membrane, suggesting each pathway for water in the GO/PG membrane should contain at least one GO–GO nanochannel dictating the molecular sieving of the GO/PG membrane, thus similar molecular sieving as the pristine GO membrane is observed. While in methanol, because of the change of MWCO, the molecular transport should not diffuse through any GO–GO nanochannel, but become dictated by the GO–PG nanochannel. Changing the PG content in the GO/PG membrane further confirms that the nanochannel switch governs smart molecular sieving (Fig. S19). At a low PG content of 5 wt%, the membrane exhibits no solvent-dependent molecular sieving, behaving similarly to a pristine GO membrane. This suggests that, with limited PG, each molecular pathway includes at least one GO–GO nanochannel, resulting in the same molecular sieving in both methanol and water. Increasing the PG content to 20 wt%, the membrane displays the same solvent-dependent molecular sieving switch as the studied GO/PG membrane (40 wt% PG), indicating that the GO–PG nanochannel becomes the dominant pathway for organic solvent diffusion. However, at a high PG content of 70 wt%, the membrane’s MWCO in water increases to ~1017 g mol−1, likely due to misalignment-induced defects caused by weak interlayer locking due to a lack of sufficient functional groups on PG.

To understand this further, we performed the XRD measurements for the GO/PG and pristine GO membranes when they were soaked in water and methanol respectively (Fig. 4a). The GO/PG membrane shows two diffraction peaks corresponding to the PG-PG stacking and GO–GO stacking, for PG-PG nanochannel, its peak shows little change in water and methanol, similar to the pristine PG membrane (Fig. S20). However, for the GO–GO stacking, it is similar to the pristine GO membrane, but exhibits less swelling (smaller interlayer distance, d), this is in good agreement with previous reports that the intercalation of graphene inhibits the swelling of GO membrane31,32. On the other hand, compared with the pristine GO membrane, a smaller d (~1.1 nm) of GO–GO nanochannel, but a larger MWCO in methanol observed in the GO/PG membrane suggests that the GO–GO nanochannel indeed is not accounted for the switched MWCO in methanol. It is then important to study the change of the GO–PG nanochannel in methanol. Unfortunately, the GO-PG nanochannel does not show a diffraction peak (Fig. S20), this is not surprising and seen in previous hybrid GO/graphene membranes22,23,32, and should stem from a random distribution of GO–PG nanochannel in the membrane, hence lacking periodicity which can be probed by XRD.

a XRD patterns of dry and wet (in methanol and water) GO membrane and GO/PG membrane. The diffraction peaks reflect the GO–GO nanochannel. b, c Free energy profiles of the swelling of the GO–PG nanochannel in water (b) and methanol (c). Inset: The d of GO–PG nanochannel swelled in methanol. The snapshots present the swollen GO–PG nanochannel from independent equilibrium MD simulations.

We therefore, performed molecular dynamics (MD) simulation and more experiments to study this further. For clarity, we used graphene nanosheets in the simulation to replace the PG nanosheet used in the experiment. A GO–PG nanochannel was constructed and filled with water and methanol respectively. After adequate equilibrium, defined by the smallest free energy for the solvent entering the nanochannel, the widths of the GO–PG nanochannel in the solvents are obtained, these widths show good agreement with additional MD simulation on the width of GO–PG nanochannel measured by free swelling in various solvents (Fig. 4b, c and Supplementary Section 10). The simulation results show that compared to the water-filled nanochannel, the methanol-filled one has a much stronger swelling (\({d}_{\mathrm{methanol}}^{\mathrm{GO}-\mathrm{PG}}\) = ~1.9 nm, \({d}_{\mathrm{water}}^{\mathrm{GO}-\mathrm{PG}}\) = ~0.9 nm) (Fig. 4b, c inset). Given that \({d}_{\mathrm{methanol}}^{{\mathrm{GO}}-{\mathrm{GO}}}\) (~1.1 nm, Fig. 4a) is much smaller than \({d}_{\mathrm{methanol}}^{\mathrm{GO}-\mathrm{PG}}\), we believe it is this larger \({d}_{\mathrm{methanol}}^{\mathrm{GO}-\mathrm{PG}}\) that reduces the transport resistance thus making the methanol transport nanochannel switched from GO–GO to GO–PG nanochannel, furthermore, a larger \({d}_{\mathrm{methanol}}^{\mathrm{GO}-\mathrm{PG}}\) obtained from simulation also qualitatively explains the shifts of MWCO to larger probing molecules.

Detailed MD simulation provides further insights into why \({d}_{\mathrm{methanol}}^{\mathrm{GO}-\mathrm{PG}}\) is larger than \({d}_{\mathrm{water}}^{\mathrm{GO}-\mathrm{PG}}\). To perform the simulation, we considered two types of interactions, solvent–channel interaction and solvent–solvent interaction. For the solvent-channel interaction, unsurprisingly, methanol has strong interactions with both GO and PG surfaces, showing a spatial orientation where its hydroxyl group tilts towards the GO surface due to their strong hydrogen bonding interactions33, and its methyl groups tilt towards the PG surface owing to dipole-π interactions34 (Fig. S22a). For water, it has no interaction with the PG surface35, only preferably adsorbs on the GO side because of the hydrogen bond, in good agreement with the inhibited water swelling in the GO/PG membrane (Fig. 5a). This suggests methanol is more favorable than water to enter the GO–PG nanochannel because of a stronger methanol-channel interaction.

a Schematic illustration of GO–PG nanochannel swelling in various solvents. (i) Strong solvent-channel interaction and weak solvent-solvent interaction, lead to strong swelling of GO–PG nanochannel; (ii) Strong solvent-channel interaction and strong solvent-solvent interaction, lead to medium swelling; (iii) Weak solvent-channel interaction and strong solvent-solvent interaction, lead to weak swelling. b Average numbers of hydrogen bonds between confined solvent molecules. c Average numbers of apolar association bonds between confined alcohol molecules. d Comparison of MWCO of GO/PG membranes in different solvents. Inset: The MWCO of GO/PG membrane in butanol and pentanol.

The solvent-solvent interaction is rather interesting, as it is generally weak in the bulk phase due to its liquid nature, but becomes significant because the molecules are squeezed by the nano-confinement, and such interaction could be further enhanced by the solvent-channel interaction, which pins the molecules at the channel surface. The quantitative analysis shows that, in contrast to the bulk phase, the hydrogen bond number between the confined neighboring methanol molecules increases from 1.89 to 2.06, and that of confined water molecules increases from 3.41 to 3.76 (Fig. 5b), while, the apolar association bond number between the methyl group of neighboring methanol increases from 3 to 3.31 (Figs. 5c and S22b). Because the apolar association bonding energy was found one order of magnitude lower than that of the hydrogen bond36, and the methanol molecules form significantly fewer hydrogen bonds, methanol-methanol interaction is much weaker than water-water interaction, this loose solvent network allows more methanol molecules to intercalate in the nanochannel.

Collectively, compared with water confined in the GO–PG nanochannel, stronger solvent adsorption (methanol-channel interaction) and a weaker solvent network (methanol-methanol interaction) will attract a larger number of methanol molecules to reside in the GO–PG nanochannel, explaining its higher d (Fig. 5a). To further validate this, we considered long alcohol molecules would have similar adsorption behavior in GO–PG nanochannel, but have a stronger solvent network than methanol because a longer methyl chain provides more sites for apolar association interaction (Figs. 5a and S22c, d), causing a changing dGO-PG. We have simulated the structure change of the GO–PG nanochannel filled with butanol and pentanol, respectively. Indeed, our simulation result shows that, for the solvent-solvent interaction, butanol and pentanol have similar hydrogen bond numbers as the methanol (Fig. 5b), but its apolar association bond number increases with the length of the methyl chain (9 for butanol and 11 for pentanol) (Fig. 5c). That is, comparing to methanol, butanol and pentanol have stronger solvent-solvent interactions, as a result, GO–PG nanochannels intercalated with pentanol and butanol show the intermediate d, following the order \({d}_{\mathrm{methanol}}^{\mathrm{GO}-\mathrm{PG}}\) > \({d}_{\mathrm{butanol}}^{\mathrm{GO}-\mathrm{PG}}\) > \({d}_{\mathrm{pentanol}}^{\mathrm{GO}-\mathrm{PG}}\)> \({d}_{\mathrm{water}}^{\mathrm{GO}-\mathrm{PG}}\). To further testify the simulation results, we performed further experiments to investigate whether the MWCO would switch when the butanol and pentanol are used as the solvents and found that the MWCO of GO/PG membrane switches to 792 g mol−1 in butanol, and 452 g mol−1 in pentanol, in good agreement with the simulation results (Fig. 5d and inset). Bring together, experimentally, the molecular sieving switching in methanol is not observed in either pristine GO or PG membranes. This suggests that the molecular sieving in response to solvent type stems from the newly formed GO–PG nanochannel, absent in both GO and PG membranes. Furthermore, unlike other organic solvents, water’s permeance doesn’t follow the expected linear trend with 1/viscosity, indicating distinct pathways for water and organic solvents in the membrane. Our simulation results further reveal that in the GO/PG membrane, the GO–PG nanochannel becomes favorable for methanol due to strong interactions between its hydroxyl group and the GO surface, and its methyl groups with the PG surface. These interactions pin methanol to the channel walls, coupled with a weak solvent-solvent interaction inside the channel, causing a larger expansion in the GO–PG nanochannel, which lowers transport resistance for preferred organic solvent permeation and increasing the MWCO.

In summary, despite the GO-based membranes have been extensively studied for their potential in molecular separation processes. In our study, we incorporate the PG in the GO membrane, surprisingly, the resulting GO/PG membrane has a high solvent permeance without sacrificing its molecular sieving in water, more importantly, the membrane shows a switchable molecular sieving in response to the solvent type. We demonstrate such a reversible switch for the separation of the ternary solution using the same membrane by only changing the choice of the solvent type, providing an energy-efficient route for active, multi-component molecular separation. Furthermore, other than dedicating pore structure design to the development of a smart and responsive membrane, our results show that control of the membrane-solvent interaction could alter the mass transport pathway and its molecular sieving of the membrane, providing a new route for the design of smart, solvent-switchable membrane and its separation technologies.

Methods

Materials

Reaction red 120 (RR 120, 1469.98 g mol−1), direct red 80 (DR 80, 1373.07 g mol−1), reactive red 195 (RR, 1136.31 g mol−1), rose bengal (RB, 1017.64 g mol−1), evans blue (EB, 960.81 g mol−1), bright blue (BB, 792.85 g mol−1), victoria blue (VB, 506.08 g mol−1), sunset yellow (SY, 452.36 g mol−1), crystal violet (CV, 407.99 g mol−1), methylene blue (MLB, 319.86 g mol−1), chrysoidine G (CSG, 248.72 g mol−1), 4-nitrophenol (NP, 139.11 g mol−1), phenol (94.11 g mol−1), methanol, ethanol, n-butanol, n-pentanol, acetonitrile and acetone were purchased from Macklin Biotech Co., Ltd.

Preparation of composite membrane

GO nanosheets were prepared by a modified Hummers method27. First, 4 g of graphite was added to 192 mL H2SO4 with an ice-cold bath and magnetic stirring. A 24 g of KMnO4 was then slowly added while keeping the bath temperature under 5 °C. After homogeneous mixing to form a dark-green-color suspension, the temperature was increased to 35 °C and kept for 2.5 h, and then further to 55 °C for 1.5 h. Then 160 mL of water was slowly added to the dispersion in an ice bath. Subsequently, 20 mL of H2O2 was added to the mixture. The obtained yellow graphite oxide suspension was centrifuged and dialyzed in water. Finally, graphite oxide was sonicated to obtain GO dispersion.

PGs with a different pore size of 30 nm and 70 nm were prepared by etching GO with Ni (NO3)2 and Ni (CH3COO)2 in a heat treatment process28. Briefly, 50 mg of nickel salt (for an average pore size of 30 and 70 nm, Ni (NO3)2 and Ni (CH3COO)2 were used respectively) was added to a 100 mL GO solution. The mixture was sonicated for 30 min and stirred for 12 h. The final solution was freeze-dried to obtain the GO-Ni salt mixture. The mixture powder was heated to 800 °C for 2 h in N2, this process thermally reduces GO and generates pores on the graphene plane. The obtained PG with Ni particles was immersed in dilute HCl (0.1 mol L−1) and stirred for 2 days to remove Ni particles. Then, the resulting samples were collected by filtration, and washed with water and ethanol. Finally, freeze-dried for membrane assembly. The non-porous graphene was prepared following identical conditions but without adding the nickel salt.

For the preparation of the GO/PG membrane, various volumes of aqueous GO dispersion (0.1 mg mL−1) were added into the PG dispersion (0.1 mg mL−1) in NMP (agglomeration is observed for a GO/PG dispersion with a PG content ≥ 80 wt% after 12 h, while, for PG content < 80 wt%, the dispersion remains stable (Fig. S3)), diluted with water to have a fixed liquid volume of 50 mL then stirred for 10 min, and ultrasonicated for 30 min. The mixture was directly filtrated through a nylon support membrane (Jin Teng, pore size ~200 nm) using vacuum filtration. The total mass loading of GO and PG loaded on each membrane was kept at 0.016 mg cm−2 (thickness of pure GO was ~90 nm). The GO/PG membranes with different PG contents were prepared by changing the volume of GO and PG dispersion but with the same mass loading. For example, for a GO/PG composite membrane with a PG content of 40 wt%, 1.2 mL of GO dispersion and 0.8 mL of PG dispersion are mixed.

Material characterization

The surface morphology of the nanofiltration membrane is characterized using a scanning electron microscope (SEM, Sirion 200FEI). X-ray diffraction (XRD) patterns are collected on a Bruker D8 Advance X-ray diffractometer using a Cu Kα source (λ = 0.154056 nm). The dye concentration in feed, permeate and retentate solutions was determined by a UV-vis spectrophotometer (SHIMADZU UV-2600i).

Evaluation of the membrane separation performance

The water permeance and dye rejection of the membranes were measured on a pressure dead-end filtration device (Sterlitech, HP4750X) with an effective area of 2.9 cm2 and a pressure difference of 2–10 bar provided by the compressed N2 at room temperature. Various solvents and dye solutions (dye concentration is 10 ppm) were filtrated through the membrane, and the rejection of different dyes and the corresponding permeance to the solution were recorded. The water permeance J (L m−2 h −1 bar−1) and rejection R (%) were calculated according to Eqs. (1) and (2), respectively:

where V (L) is the volume of permeated solvent, A (m2) is the effective membrane area, Δt (h) is the permeate time, P (bar) is the applied pressure, the Cp and Cf is the dye concentration in permeate and feed solutions, respectively. The solution concentration was calculated based on UV–vis spectroscopy. For long-term stability, the feed solution was 10 ppm VB aqueous solution. The permeance and dye rejection were monitored every 6 h. All the reported permeance and rejection results are the average values obtained by measuring at least three membranes.

Molecular dynamics simulation

The L−K model was applied to construct the GO nanosheets with the C/O ratio of 6:1, of which the hydroxyl and epoxy groups were randomly distributed on the surface and the carboxyl groups were set at the edges37,38. The GO–PG nanochannel was constructed by the GO and graphene nanosheets. As shown in Fig. S21, the GO–PG nanochannel with an area of 2.5 nm × 2.5 nm and an interlayer distance of 1.0 nm was placed in the center of the simulation system, which was respectively filled with the desired solvent molecules (such as water, methanol, butanol, and pentanol) in a dimension of 6 nm × 5 nm × 6 nm.

The MD simulations were performed using the NAMD software (version 2.14)39. The GO and graphene sheets were parameterized according to the previous reports40,41. Water molecules were described by the extended simple point charge (SPC/E) model42. The alcohol molecules were parameterized based on the previous study43. The CHARMM 27 force field was adopted to format all the intra- and inter-molecular interactions44. During the simulation run, the face-to-face nanosheets of the GO–PG nanochannel were only permitted to move along the vertical direction to avoid their offset sliding45. Three-dimensional periodic boundary conditions were adopted to alleviate the edge effect. For precisely describing the swelling of the GO–PG nanochannels, the cut-off distance for the Lennard-Jones potential function was set according to the solvent type. In detail, the cut-off distances of 14, 22, 18, and 18 Å were set for the solvents of water, methanol, n-pentanol, and n-butanol, respectively. Particle Mesh Ewald (PME) method was employed to treat the full electrostatic interaction46. The Langevin dynamics and the Langevin piston Nosé-Hoover methods were adopted to maintain the system temperature and pressure, respectively. For each common swelling simulation, a total MD run for 100 ns was carried out under the isothermal-isobaric (NpT) ensemble at 298 K and 0.1 MPa with a sampling interval of 1000 timesteps, during which the timestep was set to 2 fs.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The data supporting the findings in this study are available within the paper and its Supplementary Information. Source data are provided in this paper. Source data are provided with this paper.

References

Yin, J., Kuang, Z., Mahankali, U. & Beck, T. L. Ion transit pathways and gating in ClC chloride channels. Proteins 57, 414–421 (2004).

Perozo, E., Cortes, D. M., Sompornpisut, P., Klode, A. & Martinac, B. Open channel structure of MscL and the gating mechanism of mechanosensitive channels. Nature 418, 942–948 (2002).

Eisenberg, B. Ionic channels in biological membranes: natural nanotubes. Acc. Chem. Res. 31, 117–123 (1998).

Gouaux, E. & MacKinnon, R. Principles of selective ion transport in channels and pumps. Science 310, 1461–1465 (2005).

Gurtovenko, A. A. & Anwar, J. Interaction of ethanol with biological membranes: the formation of non-bilayer structures within the membrane interior and their significance. J. Phys. Chem. B 113, 1983–1992 (2009).

Zhao, C., Nie, S., Tang, M. & Sun, S. Polymeric pH-sensitive membranes–a review. Prog. Polym. Sci. 36, 1499–1520 (2011).

Liu, Z., Wang, W., Xie, R. & Chu, L. Stimuli-responsive smart gating membranes. Chem. Soc. Rev. 45, 460–475 (2016).

Zhou, K.-G. et al. Electrically controlled water permeation through graphene oxide membranes. Nature 559, 236–240 (2018).

Liu, J. et al. Bioinspired graphene membrane with temperature tunable channels for water gating and molecular separation. Nat. Commun. 8, 2011 (2017).

Duché, G. & Sanderson, J. M. The chemical reactivity of membrane lipids. Chem. Rev. 124, 3284–3330 (2024).

Williams, T. I., Combs, J. C., Lynn, B. C. & Strobel, H. J. Proteomic profile changes in membranes of ethanol-tolerant clostridium thermocellum. Appl. Microbiol. Biot. 74, 422–432 (2007).

Frallicciardi, J., Melcr, J., Siginou, P., Marrink, S. J. & Poolman, B. Membrane thickness, lipid phase and sterol type are determining factors in the permeability of membranes to small solutes. Nat. Commun. 13, 1605 (2022).

Bouzouita, D. et al. Co-processing bio-liquids with vacuum gasoil through hydrocracking. Appl. Catal. B-Environ. 304, 120911 (2022).

Olujic, Z., Fakhri, F., de Rijke, A., de Graauw, J. & Jansens, P. J. Internal heat integration—the key to an energy-conserving distillation column. J. Chem. Technol. Biotechnol. 78, 241–248 (2003).

Lee, U., Kim, J., Seok Chae, I. & Han, C. Techno-economic feasibility study of membrane based propane/propylene separation process. Chem. Eng. Process 119, 62–72 (2017).

He, A. et al. A smart and responsive crystalline porous organic cage membrane with switchable pore apertures for graded molecular sieving. Nat. Mater. 21, 463–470 (2022).

Shi, G. M. et al. Recent progress of organic solvent nanofiltration membranes. Prog. Polym. Sci. 123, 101470 (2021).

Yang, Q. et al. Ultrathin graphene-based membrane with precise molecular sieving and ultrafast solvent permeation. Nat. Mater. 16, 1198–1202 (2017).

Nair, R. R., Wu, H. A., Jayaram, P. N., Grigorieva, I. V. & Geim, A. K. Unimpeded permeation of water through helium-leak–tight graphene-based membranes. Science 335, 442–444 (2012).

Han, Y., Jiang, Y. & Gao, C. High-flux graphene oxide nanofiltration membrane intercalated by carbon nanotubes. ACS Appl. Mater. Interfaces 7, 8147–8155 (2015).

Jiang, W.-L. et al. Carbon nanotubes intercalated rGO electro-fenton membrane for coenhanced permeability, rejection and catalytic oxidation of organic micropollutants. J. Membr. Sci. 623, 119069 (2021).

Morelos-Gomez, A. et al. Effective NaCl and dye rejection of hybrid graphene oxide/graphene layered membranes. Nat. Nanotechnol. 12, 1083–1088 (2017).

Liang, J. et al. Macroscopic heterostructure membrane of graphene oxide/porous graphene/graphene oxide for selective separation of deuterium water from natural water. Adv. Mater. 34, 2206524 (2022).

Cho, K. M. et al. Ultrafast-selective nanofiltration of an hybrid membrane comprising laminated reduced graphene oxide/graphene oxide nanoribbons. ACS Appl. Mater. Interfaces 11, 27004–27010 (2019).

Yu, X. et al. Graphene-based smart materials. Nat. Rev. Mater. 2, 17046 (2017).

Kang, J. et al. Microwave-assisted design of nanoporous graphene membrane for ultrafast and switchable organic solvent nanofiltration. Nat. Commun. 14, 901 (2023).

Zhao, J., Pei, S., Ren, W., Gao, L. & Cheng, H.-M. Efficient preparation of large-area graphene oxide sheets for transparent conductive films. ACS Nano 4, 5245–5252 (2010).

He, X. et al. Facile and controllable synthesis N-doping porous graphene for high-performance supercapacitor. J. Electroanal. Chem. 871, 114311 (2020).

Huang, H. et al. Ultrafast viscous water flow through nanostrand-channelled graphene oxide membranes. Nat. Commun. 4, 2979 (2013).

Han, Y., Xu, Z. & Gao, C. Ultrathin graphene nanofiltration membrane for water purification. Adv. Funct. Mater. 23, 3693–3700 (2013).

Akbari, A. et al. Highly ordered and dense thermally conductive graphitic films from a graphene oxide/reduced graphene oxide mixture. Matter 2, 1198–1206 (2020).

Goh, K. et al. All-carbon nanoarchitectures as high-performance separation membranes with superior stability. Adv. Funct. Mater. 25, 7348–7359 (2015).

Zheng, S., Tu, Q., Wang, M., Urban, J. J. & Mi, B. Correlating interlayer spacing and separation capability of graphene oxide membranes in organic solvents. ACS Nano 14, 6013–6023 (2020).

Georgakilas, V. et al. Functionalization of graphene: covalent and non-covalent approaches, derivatives and applications. Chem. Rev. 112, 6156–6214 (2012).

Leenaerts, O., Partoens, B. & Peeters, F. M. Water on graphene: hydrophobicity and dipole moment using density functional theory. Phys. Rev. B 79, 235440 (2009).

Ghosh, M. K., Uddin, N. & Choi, C. H. Hydrophobic and hydrophilic associations of a methanol pair in aqueous solution. J. Phys. Chem. B 116, 14254–14260 (2012).

He, H., Riedl, T., Lerf, A. & Klinowski, J. Solid-state NMR studies of the structure of graphite oxide. J. Phys. Chem. 100, 19954–19958 (1996).

Lerf, A., He, H., Forster, M. & Klinowski, J. Structure of graphite oxide revisited. J. Phys. Chem. B 102, 4477–4482 (1998).

Phillips, J. C. et al. Scalable molecular dynamics on CPU and GPU architectures with NAMD. J. Chem. Phys. 153, 044130 (2020).

Williams, C. D., Carbone, P. & Siperstein, F. R. In silico design and characterization of graphene oxide membranes with variable water content and flake oxygen content. ACS Nano 13, 2995–3004 (2019).

Williams, C. D., Carbone, P. & Siperstein, F. R. Computational characterisation of dried and hydrated graphene oxide membranes. Nanoscale 10, 1946–1956 (2018).

Jorgensen, W. L., Chandrasekhar, J., Madura, J. D., Impey, R. W. & Klein, M. L. Comparison of simple potential functions for simulating liquid water. J. Chem. Phys. 79, 926–935 (1983).

Azamat, J., Ghasemi, F., Jahanbin Sardroodi, J. & Jahanshahi, D. Molecular dynamics simulation of separation of water/methanol and water/ethanol mixture using boron nitride nanotubes. J. Mol. Liq. 331, 115774 (2021).

MacKerell, A. D., Banavali, N. & Foloppe, N. Development and current status of the charmm force field for nucleic acids. Biopolymers 56, 257–265 (2001).

Tong, W., Cui, D., Xu, Z. & Yang, X. Molecular simulation on thermodynamic swelling behavior of bilayer graphene oxide in solvents. J. Phys. Chem. C. 125, 24692–24701 (2021).

Wang, H., Gao, X. & Fang, J. Multiple staggered mesh Ewald: boosting the accuracy of the smooth particle mesh Ewald method. J. Chem. Theory Comput. 12, 5596–5608 (2016).

Acknowledgments

This research is supported primarily by the National Natural Science Foundation of China (52472298 to Y.S., 52476179 to N.Z.), the National Key Research and Development Program (2021YFC2901300 to N.Z.), Science Fund for Creative Research Groups of the National Natural Science Foundation of China (22021005 to N.Z.), Peacock Team project (KQTD20210811090112002 to Y.S.), Scientific Research Start-up Funds of Tsinghua SIGS (QD2021026C to Y.S.), Natural Science Foundation of Guangdong Province, China (2024A1515012424 to Y.S., 2025A1515012306 to Y.S.) and Shenzhen Geim Graphene Center.

Author information

Authors and Affiliations

Contributions

Y.S., J.P.Z. and N.Z. conceived the idea and supervised the project. Y.X.L. prepared the sample, performed the membrane experiments, and analyzed the results with the help of X.Y.G., J.Z. and J.D.Z. performed simulation with the supervision of N.Z. All authors analyzed the data, Y.S., Y.X.L., J.P.Z. and N.Z. wrote the manuscript with input from all authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Chao Gao and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, Y., Zhao, J., Zhang, J. et al. Smart and solvent-switchable graphene-based membrane for graded molecular sieving. Nat Commun 16, 5363 (2025). https://doi.org/10.1038/s41467-025-60680-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-60680-x