Abstract

Antiferroelectric ceramics, driven by electric-field-induced antiferroelectric-ferroelectric phase transitions, hold exceptional potential for high capacitance density capacitors. However, conventional antiferroelectric ceramics are capable of releasing only 70-80% of the energy during the charging-discharging cycles, limiting their practical applications. Herein, we propose a novel approach using heterogeneous dipolar structures in PbHfO3-based AFE ceramics to achieve remarkable energy density. By compositionally inducing structural order-disorder transitions, heterogeneous dipolar structures with complex interactions are created, within which dipoles can rapidly flip under the applied electric field, thereby substantially reducing the hysteresis losses. Combined with significantly improved breakdown strength, the optimized antiferroelectric ceramics exhibits a large recoverable energy density approximately 20.04 J cm−3 and a high efficiency of around 90.5%, setting a new benchmark for antiferroelectric ceramics. This work, focusing on the atomic scale, clarifies the structure-property relationship and provides valuable insights for developing next-generation high-performance antiferroelectric materials.

Similar content being viewed by others

Introduction

With the development of the new energy and electronic information industries, the demand for energy storage electronic devices has escalated significantly. This necessitates the development of energy storage units that are not only compact but also possess higher energy efficiency and lower losses. Among numerous energy storage devices, ceramic dielectric capacitors stand out due to their characteristics, such as rapid charge and discharge, extremely high-power density, and energy density, finding wide applications in high-voltage transmission engineering, electric vehicles, microelectronic circuits, and other fields1,2,3,4,5,6. However, the energy density of ceramic capacitors remains relatively low, and further improvements in recoverable energy density (Wrec) are needed to achieve miniaturization of devices and enhance their integrity7,8,9,10.

To date, researchers have employed various strategies to enhance the energy storage density of bulk ceramics, such as defect design, structural engineering, and assisted sintering techniques11,12,13,14. The core principle lies in transforming long-range ordered macrodomain structures into short-range disordered nanodomains through ionic doping or strain/interface modulation15,16,17. In this regard, relaxor ferroelectric (RFE) ceramics, known for their highly reversible polarization due to nanoscale domain structures, have emerged as a focal point in energy storage research18,19,20. For instance, incorporating (Zn2/3Ta1/3)O3 into the K0.5Na0.5NbO3 system induces polar nanoregions (PNRs), resulting in slim polarization–electric (P–E) field loops and achieving a high Wrec of 6.7 J cm−3 and a high energy storage efficiency (η) of 92%21. Similarly, in (BaNaBi)0.205(SrCa)0.1925Ti0.92Nb0.08O3 ceramics, the highly dynamic PNRs and local polymorphic distortion configurations enable a Wrec of 7.3 J cm−3 and a high η of 94.2% at 340 kV cm−122. Despite the extensive exploration of nanoscale structural design in RFEs, few studies have reported achieving both ultrahigh Wrec and η values (Wrec > 15 J cm−3, η > 90%) at room temperature.

In contrast, Pb-based antiferroelectric (AFE) materials offer energy storage advantages that are difficult to achieve with lead-free RFE ceramics, primarily due to the field-induced antiferroelectric–ferroelectric (AFE–FE) phase transition and nearly zero residual polarization (Pr)23,24,25,26. Similar to RFE materials with PNRs, when the local symmetry of AFE ceramics is broken, the weak atomic interactions between the high-dynamic heterogeneous dipolar structures (HDSs) reduce the energy hysteresis between polarization and depolarization27,28,29,30. At the same time, the arrangement of dipoles within the material becomes more random and complex, causing the polarization response to no longer be a simple two-state switching, but to exhibit broader time and temperature dependence31. This typically means that extremely high external electric fields are required to effectively drive the AFE to FE phase transition, manifesting characteristics such as small hysteresis and delayed saturation polarization24. Therefore, exploring nanoscale structural heterogeneity to optimize the domain structure, electric field-induced polarization response, and phase transition characteristics of AFE materials is crucial for enhancing their energy storage performance.

In this work, we report a highly disordered (Pb0.94−xCdxLa0.04)(Hf0.7Sn0.3)O3 (x = 0.00, 0.01, 0.02, 0.03, 0.04, denoted as Cd0–Cd4) (PCLHS) AFE ceramics. We selected pure PbHfO3 (PH) and Cd0 and Cd3 as comparisons due to their distinct differences in electric hysteresis width, phase switching field (EAF/EFA), and electric domain configurations. By introducing La3+, Sn2+, and Cd2+ ions with varying valence states and ionic radii into the PH lattice, the aim is to disrupt the local periodicity and translational symmetry of dipoles, gradually inducing disorder in the AFE domain structure. We define the resulting structures as HDSs. The formation of HDSs leads to several effects favorable for energy storage, such as promoting the formation of locally diverse polarization configurations, enhancing the speed of electric field polarization response, reducing thermal losses during high-field use, and significantly delaying polarization saturation. Benefiting from these effects, the Cd3 sample achieved a large Wrec of 20.04 J cm−3 and a high η of ~90.5%. This study demonstrates the potential of the HDSs structure in the development of novel AFE materials with exceptional comprehensive performance.

Results and discussion

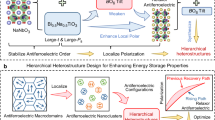

Theoretical demonstration of HDSs in AFE

Phase-field simulations are employed to investigate the dipole distributions and P–E loop characteristics of PH, Cd0, and Cd3 samples. For the conventional long-range ordered AFE system of PH ceramic, the AFE–FE transition is induced under an applied electric field, resulting in a characteristic double P–E loop (Fig. 1a). Such ceramics exhibit large AFE domains with relatively uniform polarization orientations, which switch slowly under the external electric field, contributing to substantial hysteresis losses. As the concentration of doped elements increases, defects induced by atomic size, mass, and electronegativity mismatches cause local compositional inhomogeneity, disrupting the long-range AFE ordering. This leads to a progressive reduction in domain size and an increasingly disordered polarization orientation (Fig. 1b). Especially, in Cd3 ceramics featuring highly dynamic hybrid dynamic structures (HDSs), AFE nanodomains exhibit rapid reversion to their initial state upon electric field removal, substantially suppressing hysteresis loss (Fig. 1c). In addition, from an electrostatic perspective, the disordered modulation structures disrupt long-range AFE ordering, generating polarization discontinuities that trigger bound charge redistribution and local electric field rearrangement, which in turn delays the polarization saturation. In summary, the HDSs structure not only substantially improves the EAF/EFA characteristics of the AFE system but also effectively minimizes hysteresis loss, demonstrating exceptional potential for designing ceramic materials with superior energy storage performance.

Local structure and disorder analysis of HDSs

Figures 2a and S1 display the room-temperature X-ray diffraction (XRD) patterns of the ceramics. All samples exhibit a pure perovskite structure without any observable secondary phases. The difference in ionic radii leads to lattice contraction, thus each diffraction peak shifts to a higher angle. Raman spectroscopy and X-ray photoelectron spectroscopy (XPS) illustrated the effect of doping on the local chemical structure of the ceramics, and XRD refinement results confirm the Pbam space group structure (Figs. 2b and S2–S4, and Table S1). In particular, superlattice reflections associated with the antiparallel displacement of Pb2+ ions (marked with blue symbols) are observed in both XRD patterns (Fig. 2c) and the selected-area electron diffraction (SAED) patterns (Fig. 2d), suggesting typical orthorhombic AFE phase features. Combined with the SAED plot in the [001] direction, the modulating wave is along the [\(1\bar{1}0\)] direction, with average modulation period (N) of 4, 4, and 4.5, respectively. The N can be derived from the ratio of the spacing between the main diffraction points to the spacing between the main and satellite diffraction points, reflecting the interaction between neighboring dipoles32. The dark field (DF) images of the PH, Cd0, and Cd3 samples are shown in Fig. 2e. In the PH samples, the domain boundaries exhibit a highly regular, typical 180° antiparallel structure. Meanwhile, in the Cd0 sample, some mildly disordered domain structures appear in addition to the 180° antiparallel domains. In contrast, the Cd3 sample shows highly disordered HDSs with diffuse contrast. The increased structural disorder reflects an enhancement in microstructural heterogeneity, which is anticipated to lead to more complex and diverse electrical behavior33,34.

As demonstrated in the phase-field simulation, the AFE disorder in HDSs serves as the structural foundation for achieving high energy storage performance. To verify this, the high-angle annular dark field (HAADF) imaging at the atomic scale is utilized to investigate the cation displacement-driven dipole ordering configurations in the PH, Cd0, and Cd3 samples, respectively. Figure S5 illustrates the positions of the atomic columns. The displacement vectors are calculated based on the center displacement of A-site cations relative to their nearest four B-site cations (Fig. S6)35,36. As is well known, the antiferroelectricity of PH arises from the difference in the direction of sublattice polarization, i.e., the “+ + − −” occupancy pattern of Pb2+ ions along the (110) direction37. N is the wavelength of the four layers of the pseudo-cubic (110)C-plane38. In Fig. 3a, the displacement vectors display remarkable regularity in both their angular and magnitude distributions, indicating a highly ordered dipole configuration within the material. This ordered structure typically exhibits the characteristic double “S”-shaped P–E curve. In contrast, the dipole arrangement in Cd0 deviates from the standard 180°antiparallel displacement, displaying localized displacement deflections (Fig. 3b). This region exhibits increased randomness in the dipole arrangement and slight localized chemical disorder, indicating a decrease in the orderliness of the structure, as evidenced by variations in displacement angles and vectors. In the Cd3 sample (Fig. 3c), the displacement sequence of Pb2+ ions can be roughly divided into two categories: displacement vectors with three blue and two yellow layers in the upper right (3-2 sequences), and displacement vectors with two blue and two yellow layers in the lower left (2-2 sequences). The N lies between 4 and 5 pseudo-cubic (110) planes, consisting of a mixture of N = 4 and N = 5 stripes. In the SAED pattern, N is 4.5 due to the averaging effect of N39. Although the displacement vectors of Pb2+ ions in adjacent stripes are essentially antiparallel, their distribution is highly disordered in both magnitude and direction, exhibiting nanoscale local heterogeneity. Compared to uniformly ordered AFE domains, HDSs are considered highly dynamic and extremely sensitive to external stimuli, which can result in slimmer P–E loops.

Dielectric properties and thermotropic phase transitions

Figures 4a and S7 show the dielectric constant (εr)-temperature response characteristics of the ceramics over the temperature range of −100 °C to 400 °C. Three dielectric anomaly peaks (T0, T1, and T2) are observed across a broad temperature range, corresponding to the AFEI-AFEII, AFEII-multicell cubic (MCC), and MCC-Paraelectric (PEC) phase transitions, respectively. As the doping concentration increases, the high-temperature phase region gradually broadens and shifts toward room temperature, indicating typical diffusive phase transition characteristics (Figs. 4b and S8). As mentioned earlier, HDSs exhibit significant temperature dependence. Consequently, changes in composition inevitably lead to alterations in the domain structure. To further investigate the microstructural evolution under temperature variation, XRD is employed to conduct a detailed analysis of the phase transition process in the Cd3 sample over the temperature range of 25 °C–400 °C (Figs. 4c and S9). As the temperature increases, all diffraction peaks gradually shift to lower angles due to cell expansion during the heating process23,40. The primary diffraction peak (200) demonstrates a splitting state between 25 and 140 °C, indicating that the matrix possesses orthorhombic spatial symmetry. When the temperature exceeds 180 °C, the diffraction peak (200) transforms into a single, nearly symmetric peak, signaling a phase transition from AFEII to MCC, which aligns with the results obtained from the dielectric temperature spectrum.

a Temperature-dependent εr curves of ceramics. b Phase transition points of each phase of ceramics under temperature change. c Variable temperature XRD images of Cd3 samples. d TEM images and SAED images of the Cd3 samples at different temperatures. e Free energy profiles of HDSs as a function of temperature. f Dielectric performance response of HDSs as a function of temperature.

The in situ SAED technique is used to observe the dynamic evolution of the domain structure in the Cd3 sample, as shown in Figs. 4d and S10. At room temperature, distinct domain boundaries, 1/2(110) superlattice reflections associated with the tilt of the oxygen octahedron, and 1/4(110) superlattice reflections characteristic of the AFE are clearly observed (marked with white, yellow, and blue arrows). As the temperature rises, the disorder within the domain structure intensifies, accompanied by a rise in the N value. Influenced by the high-temperature diffusive phase transition, the material still retains some AFE characteristics during the AFEII-MCC phase transition, manifested by the gradual fading of the domain morphology. Notably, the disappearance of the 1/4(110) superlattice reflection at 165 °C signifies the complete transformation of the matrix into the pseudo-cubic MCC phase region. Above 350 °C, the large-scale degradation of the domain structure, along with the passivation disappearance of 1/2(110) superlattice reflection, indicates a substantial enhancement in long-range order, marking the final transition of the matrix into the PEC phase region. Analysis reveals that local structural heterogeneity in the AFE phase region primarily arises from the heterogeneous energy generated by polarization and strain discontinuities at nanoscale interfaces. This heterogeneous energy competes with the intrinsic Landau energy of the system and is also significantly influenced by thermal energy. As the temperature rises, the Landau potential well gradually becomes shallower (Fig. 4e). When the reduction in heterogeneous energy compensates for the increase in Landau energy required for the transition to HDSs, the disorder within the domain morphology intensifies accordingly41. During this process, the weakly interacting dipoles in the HDSs become increasingly prone to reorientation under an applied electric field, thereby significantly enhancing the dielectric response of the material (Fig. 4f)41,42,43.

Energy storage performance

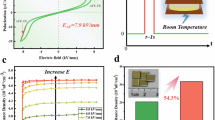

The P–E loop of the ceramics is shown in Figs. 5a and S11. Although the maximum polarization (Pmax) of the PH sample is relatively high (>40 µC cm−2), the improvement in energy storage performance is limited by the earlier polarization saturation and substantial hysteresis loss44. As the doping content increases, the tolerance factor of the ceramics decreases (Fig. S12) and the EAF gradually increases from 170 kV cm−1 for PH to 556 kV cm−1 for Cd345,46. Figures 5b and S13 demonstrate the energy storage performance curves of the ceramics at different electric field strengths. In contrast to the rapid polarization saturation observed in PH samples beyond the critical electric field, Cd3 samples possessing HDSs exhibit significant nanoscale structural heterogeneity due to the local random field generated by the cation order-disorder nature, which effectively delays the polarization saturation47. Meanwhile, the highly dynamic dipole can be rapidly reversed after unloading the electric field, resulting in an almost hysteresis-free polarization response and negligible Pr48,49,50. The improvement in breakdown strength (Eb) can be ascribed to the pivotal role of Cd2+ as a sintering additive in tailoring the microstructure of the synthesized samples, promoting greater homogeneity and fine-grain morphology (Fig. S14)51,52. Especially for Cd3 (Eb ~920 kV cm−1, β ~15.91) (Figs. 5c and S15). The high Eb preserves the integrity of the polarization process, with a Pmax of 44 μC cm−2 (Fig. 5d). Coupled with the significantly suppressed hysteresis width (ΔE), the energy storage performance of Cd3 ceramic is highly competitive, with a Wrec of ~20.04 J cm−3 and η of 90.5% (Figs. 5e and S16). Compared with lead-free and lead-based ceramics, Cd3 exhibits clear advantages (Fig. 5f, g, and Tables S2 and S3), highlighting its potential for applications in energy storage capacitors.

a P–E hysteresis loops of ceramics. b Wrec and η values under variation with electric field of ceramics. c Weibull distribution and fitting lines of Eb of ceramics. d P–E hysteresis loops and Pmax of Cd3 under variation with electric field. e Variation of energy storage properties of PH, Cd0, Cd3 samples. f Comparison of the Wrec and η of Cd3 with other Pb-based AFE ceramics. g Wrec of Cd3 compared to other ceramics with η > 90%. h Wdis of Cd3 samples under variation with electric field.

In practical applications, ensuring reliable and stable performance is a fundamental requirement for dielectric capacitors. The Cd3 ceramics exhibited excellent cycling stability over 104 cycles, with a Wrec of ~7.54 ± 0.13 J cm−3 and an ƞ of about 90.3 ± 1.55% (Fig. S17a). No sign of changes in both Wrec (~7.68 ± 0.22 J cm−3) and η (~90.2 ± 1.1%) across the frequency range of 1–200 Hz (Fig. S17b). Changing the temperature from 20 °C to 110 °C, the rate of change of Wrec is less than 13.5% (Fig. S17c). Additionally, in terms of charging and discharging performance. The Cd3 ceramic achieves high current (Imax), current density (CD = Imax/S), and power density (PD = (EImax/2S)) of 20.83 A, 663.48 A cm−2, and 238.82 MW cm−3, respectively (Fig. S18). The superior discharged energy density is 13.54 J cm−3, along with an ultra-fast discharge rate (t0.9 ≈ 88 ns) (Fig. 5h), demonstrating excellent charge-discharge performance and positioning it as a promising candidate for pulsed-power applications.

In summary, a high-performance PH ceramic is prepared by constructing room-temperature HDSs structures, with its antiferroelectricity originating from various modulation ensembles associated with Pb2+ displacements. Unlike the completely symmetric antiparallel dipole arrangement seen in traditional AFE ceramics, the microscopic Pb2+ ion displacements exhibit an antiparallel yet imbalanced state. This ceramic demonstrates a highly heterogeneous structure on the microscopic level while macroscopically displaying slender P–E loop characteristics. Combined Phase-field simulations and HAADF-STEM analyses reveal that local compositional inhomogeneity induces structural disorder, further promoting the formation of random nanodomains, which significantly reduces polarization loss. Furthermore, the ceramic samples prepared by this method exhibit high quality and excellent insulation levels. As a result, the Cd3 ceramics achieved a Wrec of 20.04 J cm−3 and a η of 90.5%, representing the best performance reported for PH-based ceramics to date. The room-temperature HDSs structures construction strategy proposed in this study provides new insights for developing the next generation of high-energy-storage capacitor materials.

Methods

Ceramics synthesis

Lead-based PbHfO3 and (Pb0.94−XCdXLa0.04)(Hf0.7Sn0.3)O3 (x = 0.00, 0.01, 0.02, 0.03, 0.04) AFE ceramics, referred to as (PH and Cd0–Cd4), were prepared by the conventional solid-state sintering method. The Pb3O4 (95%), CdO (99%), La2O3 (99%), HfO2 (99.99%), and SnO2 (99.5%) powders were weighed according to the stoichiometric ratios. An excess of 2 mol% of Pb3O4 powder was added to compensate for the lead loss in the high-temperature environment. The weighed powders were ball-milled in ethanol for 24 h to make a homogeneous mixture and then calcined at 850 °C for 3 h. The calcined product was ground into powder, mixed with polyvinyl alcohol (PVA) binder, and pressed into 10 mm diameter discs. The discs were heated at 500 °C for 10 h to remove the PVA and finally sintered at 1250 °C–1350 °C for 3 h using a double crucible.

Phase-field simulations

In phase-field models, the phase transition from antiferroelectric to ferroelectric has been established, with the corresponding model parameters summarized in Table S4. The phase-field simulations were carried out in two dimensions with cell sizes 256×256 with periodic boundary conditions, where the length scale l0 is 2 nm.

The total free energy of the whole system can be described as follow53,54,55:

where V is the volume of the system.

The Landau free energy flan can be expressed in terms of P as:

where αij is the Landau coefficient.

The gradient free energy fgrad representing the energy from polarization inhomogeneity is described as:

where G1 is a negative coefficient representing the stability of antiferroelectric phase, G2 is a positive coefficient representing the stability of ferroelectric phase.

The elastic energy felas can be written as

where Cijkl, εij, ε0kl are the elastic stiffness tensor, the total strain, and the electrostrictive stress-free strain, i.e., ε0kl = QijklPkPl.

The electrostatic energy felec can be expressed as:

where fdipole, fdepol, and fappl are the dipole-dipole interaction energy from polarization, the depolarization energy, and the energy from applied electric field, respectively. Ei, Ei, depol, and Ei, appl represent the inhomogeneous electric field caused by dipole-dipole interactions, the mean depolarization field arising from the surface charges, and the applied electric field expressed as a sine function along the [100] direction. And Ei,localelec is the random distribution electric field.

The temporal evolution of the polarization of antiferroelectric system can be calculated by solving the time-dependent Ginzburg–Landau equation:

where M is the kinetic coefficient related to the domain mobility, t is time, Pi(x, t) is the polarization and F is the total free energy of the whole system.

X-ray diffraction

The ceramic phase structure was analyzed by XRD (PANalytical Empyrean) with a slow scanning speed (0.6° min−1, 20°–70°, 30 °C–400 °C).

High-resolution synchrotron XRD was performed with an incident X-ray energy of 75.051 keV (λ = 0.16520 Å) at beamline ID31 of the European Synchrotron Radiation Facility (ESRF).

Raman spectroscopy

Raman spectroscopy (Renishaw inVia) was used to study the effect of doping on the local chemical structure.

X-ray photoelectron spectroscopy

XPS (Thermo Scientific K-Alpha, USA) was used to study the changes in the energy states of the samples. The spot size was 400 μm, the operating voltage was 12 kV, and the filament current was 6 mA; the narrow-spectrum scanning fluence energy was 50 eV in 0.1 eV steps.

Transmission electron microscopy

The temperature-dependent domain evolution and the corresponding SAED mapping were performed on a JEOL JEM-2100F microscope. Atomic-scale HAADF imaging was performed on Cs-corrected JEOL JEM-ARM300F and Hitachi HF5000 microscopes.

Field emission scanning electron microscope

The surface morphology of the samples was observed using a scanning electron microscope (SEM, Regulus 8230).

Electric properties characterization

The sintered samples were polished to ~30–50 µm, and gold electrodes were sputtered on both sides of the samples with a diameter of 2 mm. Room temperature polarized electric field hysteresis loops were measured using an FE tester (TF Analyzer 2000) under a monopole field at a frequency of 100 Hz. Fatigue, frequency, and temperature stability tests were performed over the ranges of 1–10,000 cycles, 1–200 Hz, and 20 °C–110 °C, respectively. Temperature-dependent dielectric characteristics (−100 °C to 400 °C, 1–1000 kHz) were measured using an LCR meter (TH2838A). Charge/discharge characteristics were evaluated using an RLC (SDS5032X) resistive inductive load circuit with an applied resistance of 150 Ω.

Data availability

All data supporting this study and its findings are available within the article and its Supplementary Information. Any data deemed relevant are available from the corresponding author upon request.

References

Pan, Z. et al. Interfacial coupling effect in organic/inorganic nanocomposites with high energy density. Adv. Mater. 30, 1705662 (2018).

Cheng, Y. et al. Multilayer nanocomposites with ultralow loadings of nanofillers exhibiting superb capacitive energy storage performance. Energy Environ. Sci. 16, 5881–5890 (2023).

Li, W. et al. Generative learning facilitated discovery of high-entropy ceramic dielectrics for capacitive energy storage. Nat. Commun. 15, 4940 (2024).

Chu, B. et al. A dielectric polymer with high electric energy density and fast discharge speed. Science 313, 334–336 (2006).

Pan, H. et al. Ultrahigh energy storage in superparaelectric relaxor ferroelectrics. Science 374, 100–104 (2021).

Pan, Z. et al. Aluminum macrocycles induced superior high-temperature capacitive energy storage for polymer-based dielectrics via constructing charge trap rings. Energy Environ. Sci. 18, 4405–4415 (2025).

Zhao, P. et al. High-performance relaxor ferroelectric materials for energy storage applications. Adv. Energy Mater. 9, 1803048 (2019).

Wang, G. et al. Electroceramics for high-energy density capacitors: current status and future perspectives. Chem. Rev. 121, 6124–6172 (2021).

Luo, H. et al. Outstanding energy-storage density together with efficiency of above 90% via local structure design. J. Am. Chem. Soc. 146, 460–467 (2023).

Zhou, Z. et al. Ultrahigh capacitive energy storage of BiFeO3-based ceramics through multi-oriented nanodomain construction. Nat. Commun. 16, 2075 (2025).

Yan, F. et al. Significantly enhanced energy storage density and efficiency of BNT-based perovskite ceramics via A-site defect engineering. Energy Storage Mater. 30, 392–400 (2020).

Che, Z. et al. Phase structure and defect engineering in (Bi0.5Na0.5)TiO3-based relaxor antiferroelectrics toward excellent energy storage performance. Nano Energy 100, 107484 (2022).

Xiong, X. et al. Ultrahigh energy-storage in dual-phase relaxor ferroelectric ceramics. Adv. Mater. 36, 2410088 (2024).

Wang, S. et al. Embedding plate-like pyrochlore in perovskite phase to enhance energy storage performance of BNT-based ceramic capacitors. Adv. Energy Mater. 15, 2403926 (2024).

Duan, J. et al. High-entropy tungsten bronze ceramics for large capacitive energy storage with near-zero losses. Adv. Funct. Mater. 34, 2409446 (2024).

Dong, X. et al. Realizing enhanced energy storage and hardness performances in 0.90NaNbO3−0.10Bi(Zn0.5Sn0.5)O3 ceramics. J. Adv. Ceram. 11, 729–741 (2022).

Lv, Z. et al. NaNbO3-based multilayer ceramic capacitors with ultrahigh energy storage performance. Adv. Energy Mater. 14, 2304291 (2024).

Kang, R. et al. Superior energy storage capacity of a Bi0.5Na0.5TiO3-based dielectric capacitor under moderate electric field by constructing multiscale polymorphic domains. Nano Energy 112, 108477 (2023).

Long, C. et al. Excellent energy storage properties with ultrahigh Wrec in lead-free relaxor ferroelectrics of ternary Bi0.5Na0.5TiO3-SrTiO3-Bi0.5Li0.5TiO3 via multiple synergistic optimization. Energy Storage Mater. 65, 103055 (2024).

Zhao, R. et al. High recoverable energy storage density and efficiency achieved in doped NaNbO3 ceramics via composition design strategy for pulsed power capacitor. Chem. Eng. J. 495, 153421 (2024).

Li, D. et al. Improved energy storage properties achieved in (K, Na)NbO3‑based relaxor ferroelectric ceramics via a combinatorial optimization strategy. Adv. Funct. Mater. 32, 2111776 (2022).

Ning, Y. et al. Novel high-entropy relaxors with ultrahigh energy-storage efficiency and density. Chem. Eng. J. 476, 146673 (2023).

Ge, G. et al. Synergistic optimization of antiferroelectric ceramics with superior energy storage properties via phase structure engineering. Energy Storage Mater. 35, 114–121 (2021).

Ge, G. et al. Tunable domain switching features of incommensurate antiferroelectric ceramics realizing excellent energy storage properties. Adv. Mater. 34, 2201333 (2022).

Ge, P. et al. Energy storage density and charge-discharge properties of PbHf1−xSnxO3 antiferroelectric ceramics. Chem. Eng. J. 429, 132540 (2022).

Wang, H. et al. Ultrahigh energy-storage density in antiferroelectric ceramics with field-induced multiphase transitions. Adv. Funct. Mater. 29, 1807321 (2019).

Borkar, H. et al. Room temperature lead-free relaxor-antiferroelectric electroceramics for energy storage applications. RSC Adv. 4, 22840–22847 (2014).

Liu, L. et al. Large strain response based on relaxor-antiferroelectric coherence in Bi0.5Na0.5TiO3-SrTiO3-(K0.5Na0.5)NbO3 solid solutions. J. Appl. Phys. 116, 184104 (2014).

Ma, C. et al. In situ transmission electron microscopy study on the phase transitions in lead-free (1-x)(Bi1/2Na1/2)TiO3-xBaTiO3 ceramics. J. Am. Ceram. Soc. 94, 4040–4044 (2011).

Jo, H. R. et al. A high energy density relaxor antiferroelectric pulsed capacitor dielectric. J. Appl. Phys. 119, 024104 (2016).

Li, Z. et al. Discovery of electric devil’s staircase in perovskite antiferroelectric. Sci. Adv. 8, eabl9088 (2022).

Li, Y. et al. Achieving high energy storage performance in PbHfO3-based antiferroelectric ceramics by Sr element doping. J. Alloy. Compd. 994, 174651 (2024).

Ma, T. et al. Uncompensated polarization in incommensurate modulations of perovskite antiferroelectrics. Phys. Rev. Lett. 123, 217602 (2019).

Fu, Z. et al. Unveiling the ferrielectric nature of PbZrO3-based antiferroelectric materials. Nat. Commun. 11, 3809 (2020).

Wang, W. et al. Advancing energy storage properties in barium titanate-based relaxor ferroelectric ceramics through a stagewise optimization strategy. Chem. Eng. J. 488, 151043 (2024).

Shi, W. et al. Moderate fields, maximum potential: achieving high records with temperature-stable energy storage in lead-free BNT-based ceramics. Nano Micro Lett. 16, 91 (2024).

Madigout, V. et al. Crystallographic structure of lead hafnate (PbHfO3) from neutron powder diffraction and electron microscopy. Philos. Mag. A 79, 847–858 (1999).

Wan, H. et al. High strain and energy-storage density across a wide temperature range in fine PbHfO3 ceramics. Acta Mater. 267, 119715 (2024).

He, H. et al. Electric-field-induced transformation of incommensurate modulations in antiferroelectric Pb0.99Nb0.02[(Zr1−xSnx)1−yTiy]0.98O3. Phys. Rev. B 72, 024102 (2005).

Yang, J. et al. One doping strategy to simultaneously lower the sintering temperature and increase the energy storage properties. Chem. Eng. J. 434, 134660 (2022).

Wu, T. et al. Nanosized multistate configurations of relaxor-like antiferroelectric revealed by atomic-scale in situ electron microscopy. Adv. Mater. 37, 2503339 (2025).

Li, F. et al. The origin of ultrahigh piezoelectricity in relaxor-ferroelectric solid solution crystals. Nat. Commun. 7, 13807 (2016).

Li, F. et al. Local structural heterogeneity and electromechanical responses of ferroelectrics: learning from relaxor ferroelectrics. Adv. Funct. Mater. 28, 1801504 (2018).

Wei, J. et al. Excellent energy storage and charge-discharge performances in PbHfO3 antiferroelectric ceramics. J. Eur. Ceram. Soc. 39, 624–630 (2019).

Hu, J. et al. Enhanced energy storage capabilities in PbHfO3-based antiferroelectric ceramics through delayed phase switching and induced multiphase transitions. Inorg. Chem. Front. 11, 4187–4196 (2024).

Hu, J. et al. Superb energy density of PbHfO3-based antiferroelectric ceramics via regulating the antiferroelectric-ferroelectric transition energy barrier. J. Mater. Chem. A 12, 32836–32844 (2024).

Zhao, J. et al. Delayed polarization saturation induced superior energy storage capability of BiFeO3-based ceramics Via introduction of non-isovalent ions. Small 19, 2206840 (2023).

Fu, J. et al. A highly polarizable concentrated dipole glass for ultrahigh energy storage. Nat. Commun. 15, 7338 (2024).

Duan, J. et al. High-entropy superparaelectrics with locally diverse ferroic distortion for high-capacitive energy storage. Nat. Commun. 15, 6754 (2024).

Hu, J. et al. Achieving exceptional energy storage performance in PbHfO3 antiferroelectric ceramics through defect engineering design. Mater. Horiz. 12, 3368–3377 (2025).

Liu, X. et al. Ultra-high energy-storage density and fast discharge speed of (Pb0.98−xLa0.02Srx)(Zr0.9Sn0.1)0.995O3 antiferroelectric ceramics prepared via the tape-casting method. J. Mater. Chem. A 7, 11858–11866 (2019).

Li, Y. et al. Improving energy storage properties of PbHfO3-based antiferroelectric ceramics with lower phase transition fields. Inorg. Chem. Front. 11, 196–206 (2024).

Yang, B. et al. Enhanced energy storage in antiferroelectrics via antipolar frustration. Nature 637, 1104–1110 (2025).

Wang, Z. et al. Ultra-high energy storage in lead-free NaNbO3-based relaxor ceramics with directional slush-like polar structures design. Nat. Commun. 16, 2892 (2025).

Li, Y. et al. A phenomenological thermodynamic potential for BaTiO3 single crystals. J. Appl. Phys. 98, 064101 (2005).

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant No. 52472126, 52402152, 5247021173, and 52302136), Funded by China Postdoctoral Science Foundation, China (Grant No. 2023M742631), Postdoctoral Fellowship Program of CPSF, China (Grant No. GZC20231931), Natural Science Foundation of Zhejiang Province (Grant No. LY24E010002), Fundamental Research Funds for the Provincial Universities of Zhejiang (Grant No. SJLY2025004), Natural Science Foundation of Ningbo City (Grant No. 2023J377, 2024J003, and 2024J197).

Author information

Authors and Affiliations

Contributions

J. Hu, G. Ge, and Z. Pan conceived the experiments. J. Hu, P. Wang, and J. Liu synthesized the samples and measured macroscopic properties. L. He and P. Wang performed the calculation. T. Hu, Z. Fu, and F. Xu performed the TEM experiments. J. Hu, G. Ge, W. Li, T. Zeng, J. Zhai, and Z. Pan analyzed the data, wrote, and edited the manuscript. All authors contributed to the discussion and manuscript preparation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Shibnath Samanta, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hu, J., Wang, P., He, L. et al. Local heterogeneous dipolar structures drive gigantic capacitive energy storage in antiferroelectric ceramics. Nat Commun 16, 5535 (2025). https://doi.org/10.1038/s41467-025-60685-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-60685-6