Abstract

The integration of microbial nitrogen (N2) fixation with photochemical processes using inorganic light-absorbing nanomaterials is a burgeoning field in sustainable energy production. Here, we explore the synergistic combination of inorganic semiconductor nanowires (NWs) with whole-cell microorganisms to create an inorganic-bacterial biohybrid system. Specifically, we employ Cu2O@TiO2 NWs with a core/shell structure to harness sunlight and generate photoexcited electrons. Azotobacter vinelandii, serving as a biocatalyst, adsorbs onto these NWs and facilitates the reception of photoexcited electrons, thereby enhancing the efficiency of the photoelectrochemical N2 fixation reaction (PEC-NRR). The biohybrid system achieves an impressive ammonia (NH3) yield of (1.49 ± 0.05) × 10-9 mol s-1 cm-2 (5.36 ± 0.18 μmol h-1 cm-2). The enhancement in NH3 synthesis within the Cu2O@TiO2 NWs/A. vinelandii biohybrid is attributed to the increased concentrations of nicotinamide adenine dinucleotide-hydrogen (NADH) and adenosine 5’-triphosphate (ATP), as well as the overexpression of N2-fixing genes like nifH and nifD within the nitrogenase enzyme complex. This study underscores the potential of inorganic-bacterial biohybrid systems in solar-chemical conversion, paving the way for more diverse and functional approaches to harnessing solar energy for sustainable chemical production.

Similar content being viewed by others

Introduction

Ammonia (NH3) is a critical compound in fuel production, agriculture, industry, and everyday life1,2,3. However, converting atmospheric nitrogen (N2) to NH3 is challenging due to the stability of the N ≡ N triple bond4,5. The Haber-Bosch process dominates industrial NH3 synthesis6, but requires harsh conditions, high temperatures, pressures, and catalysts, leading to significant energy use and CO2 emissions7,8. Nanotechnology offers a sustainable alternative by harnessing solar energy for N2 reduction, yet converting photoexcited electrons into chemical bonds with high specificity remains a challenge. Biological catalysts, such as enzymes or living bacteria, can perform chemical conversions but often lack the efficiency needed for industrial-scale production9. Thus, combining the light-harvesting capabilities of semiconductors with the catalytic power of microorganisms presents a promising solution.

The development of inorganic semiconductor-bacterial biohybrid systems enables highly specific and cost-effective solar-to-chemical energy conversion10,11,12. Diazotrophic microorganisms fix N2 through nitrogenase, which was the primary source of nitrogen in organisms before the Haber-Bosch process13,14. Nitrogenase, composed of iron (Fe) protein and ferromolybdenum (MoFe) protein, catalyzes N2 reduction to NH3 using metal hydride intermediates rather than H215,16,17,18. King et al. replaced the Fe protein with CdS nanocrystals to photosensitize the MoFe protein, achieving light-driven N2 reduction to NH3 without ATP4. This CdS:MoFe protein bio-hybridization provides a photochemical model for light-driven N2 reduction. Subsequent studies have shown the potential of mixed microbial communities for bioelectro-synthesis of NH319,20,21. Minteer et al. demonstrated bioelectrocatalytic N2 reduction to NH3 using methyl viologen as an electron mediator, creating an enzymatic fuel cell that produces NH3 from H2 and N2 while generating electricity22. They also showed that nitrogenase can be protected from oxygen damage and maintain activity by regulating the potential of the [2Fe-2S] cluster23. However, immobilizing nitrogenase on electrodes is not straightforward. Liu et al. integrated living cells with electrodes for N2 fixation24. Daniel Nocera and Pamela Silver’s group demonstrated the synthesis of NH3 from N2 and H2O under ambient conditions using a biohybrid system with H2-oxidizing bacterium Xanthobacter autotrophicus, powered by solar energy25. This system combines the high light-harvesting efficiency of semiconductors with the catalytic performance of whole-cell microorganisms, offering new insights into ecological N2 fixation.

In semiconductor-microbial hybrid systems, the choice of nanostructures is crucial. Yang et al. have shown that semiconductor nanowires offer advantages in light absorption and catalytic activity26. Their high surface area, efficient charge separation, light absorption, and mass transport make them ideal for N2 reduction.

Here, we report a Cu2O@TiO2 nanowires (Cu2O@TiO2 NWs) core/shell structure as a photocathode to capture sunlight and generate photogenerated electrons. Living A. vinelandii is adsorbed onto the nanowires to receive these electrons and catalyze the reduction of N2 to NH3. Under optimal conditions, the system achieves an NH3 yield of (1.49 ± 0.05) × 10-9 mol s-1 cm-2 (5.36 ± 0.18 μmol h-1 cm-2) at −0.3 V versus reversible hydrogen electrode (RHE), surpassing pristine inorganic catalysts by an order of magnitude. The self-replicating and self-healing properties of whole cells ensure long-term photochemical stability and catalytic reproducibility in the hybrid system.

Results

Biohybrid formation with A. vinelandii

The fabrication of the Cu2O@TiO2 NWs/A. vinelandii biohybrid system is depicted in Fig. 1. Cu2O was chosen as the base material for the photoelectrochemical (PEC) platform due to its two key advantages: (1) a narrow direct band gap of ~2.0 eV27, which ensures efficient absorption of visible light, and (2) a suitable conduction band position at −0.7 eV versus RHE, which provides the thermodynamic feasibility for N2 reduction using photogenerated electrons. However, the photo-corrosion of Cu2O at the electrolyte interface under illumination poses a challenge to its practical use, necessitating an effective protective strategy28. To address this, various protective measures have been employed, such as atomic layer deposition (ALD)29, ion doping30, and in-situ generated protective layers31. The TiO2 modification was performed using ALD, allowing precise control over the thickness and composition at the angstrom level. This meticulous method not only prevents photo-corrosion of Cu2O and enhances the electrode’s stability but also maintains the surface’s catalytic activity for N2 reduction. Furthermore, TiO2-modified electrodes facilitate bacterial adhesion. This improved adsorption increases the likelihood of boosting NH3 production, thereby enhancing the system’s overall efficiency and performance.

The detailed experimental procedures are outlined in the Methods. Initially, a Cu foam (CF) was anodized in an alkaline solution to form Cu(OH)2 NWs, which were subsequently converted into Cu2O NWs through annealing in a N2 atmosphere. A TiO2 layer was then deposited onto the Cu2O NWs using ALD method to create the Cu2O@TiO2 NWs structure. The crystal structure of the Cu2O@TiO2 NWs/CF was analyzed using X-ray diffraction (XRD), and the absence of a distinct TiO2 peak indicated that the outer TiO2 layer was amorphous (Supplementary Fig. 1). We have conducted electron paramagnetic resonance (EPR) measurements on the Cu2O@TiO2 to investigate the presence and nature of defects. The strong EPR signal with a g-value of 2.003 (Supplementary Fig. 2) is indeed a characteristic feature of oxygen vacancies in TiO232. The micro-morphologies of the core/shell Cu2O@TiO2 NWs were examined via scanning electron microscopy (SEM), as shown in Supplementary Fig. 3, which clearly revealed the nanowire morphology. Transmission electron microscopy (TEM) images further confirmed the varying thicknesses of the core/shell structure (Supplementary Fig. 4). A high-resolution TEM (HRTEM) image displayed clear lattice fringes with a spacing of 0.217 nm, corresponding to the (200) crystal plane of Cu2O. No crystalline lattice was observed in the outer TiO2 layer (Supplementary Fig. 5), further confirming its amorphous nature. Additionally, the optical absorption properties of both Cu2O NWs and Cu2O@TiO2 NWs were measured (Supplementary Fig. 6), demonstrating that the addition of the TiO2 protective layer significantly improved light absorption capabilities. The defect of oxygen vacancies in TiO2 can introduce additional electronic states within the bandgap, which can act as traps for photogenerated electrons and holes. These mid-gap states create an intermediate bandgap that allows for the absorption of photons with longer wavelengths, extending into the NIR region33. The existence of defects in TiO2 was also confirmed from X-ray photoelectron spectroscopy (XPS) measurements (Supplementary Fig. 7)34.

PEC N2 fixation on biohybrid

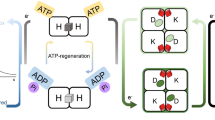

The nitrogen reduction reaction (NRR) performance of the Cu2O@TiO2 NWs/A. vinelandii biohybrid system was evaluated in a H-type PEC cell under purified N2 atmosphere, utilizing a three-electrode configuration with the biohybrid as the working electrode, a graphite rod counter electrode, and an Ag/AgCl reference electrode (Fig. 2a). The extracellular electron uptake pathways mediated by photoelectrode-derived carriers. The extracellular electron uptake pathways in the Cu2O@TiO2 NWs/A. vinelandii biohybrid system are facilitated by photoelectrode-derived charge carriers. This process operates via a broad redox cascade, where photogenerated electrons from the Cu2O@TiO2 NWs photoelectrode are shuttled to A. vinelandii through redox-active mediators or enzymatic pathways, potentially involving—but not limited to—membrane-associated enzyme complexes such as Rnf and Fix35,36. This electron transport process not only drives the enzymatic reduction of N2 to NH3 but also generates a measurable photocurrent, which serves as a direct indicator of interfacial charge transfer efficiency.

a Schematic illustration of Cu2O@TiO2 NWs/A. vinelandii biohybrid for N2 reduction in PEC model and corresponding extracellular electron uptake mechanism; (b) SEM image of A. vinelandii on Cu2O@TiO2 NWs electrode, the SEM image is representative of results obtained from at least three independent experiments with similar outcomes; (c) photocurrent response of biohybrid system with/without N2; (d) fluorescence spectra of A. vinelandii before and after PEC reactions (A. vinelandii in biohybrid was stained by DiOC2(3) green membrane potential dyeing probe in advance, λexc = 482 nm); (e) the corresponding NADH/NAD+ ratio before and after the PEC reaction (−0.3 V vs RHE for 2 h) (n = 5, statistical analysis was performed using a two-tailed student’s t-test (*P < 0.05, **P < 0.01, and ***P < 0.001)), the inset presents variation of molecular structures under illumination of light between NAD+ and NADH; (f) relative ATP levels (before/after PEC reaction) in Cu2O@TiO2 NWs/A. vinelandii biohybrid (−0.3 V vs RHE for 2 h) (n = 5, statistical analysis was performed using a two-tailed student’s t test (*P < 0.05, **P < 0.01, and ***P < 0.001)); (g) relative transcription of nifH and nifD in A. vinelandii and biohybrid in PC and PEC models, n = 3 biological replicates, with data presented as mean. Source data are provided as a Source Data file.

After the initial culture period (Supplementary Table 1), A. vinelandii was enriched on the surface of the Cu2O@TiO2 NWs electrode. As shown in Fig. 2b (with raw image in Supplementary Fig. 8), A. vinelandii formed a stable abiotic-biotic semiconductor-bacterium biohybrid system on the electrode’s surface. While the adhesion of A. vinelandii to TiO2-modified electrodes is evident from SEM imaging, the molecular basis of this interaction remains unclear. Gram-negative bacteria, including A. vinelandii, possess an outer membrane rich in lipopolysaccharides (LPS), with phospholipids primarily localized to the inner membrane37. Further studies are required to elucidate whether LPS, extracellular polymeric substances, or other surface components mediate cell-electrode association. These enzyme complexes then transfer electrons, reducing nicotinamide adenine dinucleotide (NAD+) to NADH and oxidizing flavodoxin/ferredoxin (Fld/Fdred) from the reduced state to the oxidized state38.

The PEC response of A. vinelandii is shown in Fig. 2c. The Cu2O@TiO2 NWs electrode exhibited a rapid photo-response, and the adsorption of living A. vinelandii on the electrode surface led to a noticeable increase in photocurrent, indicating A. vinelandii’s intrinsic photo-responsiveness due to light-induced electron transfer from excited NADH to oxidized NAD+39. After purging with N2, the photocurrent response further increased, confirming the photo-induced N2 reduction.

To further verify the successful transmembrane electron transport, we conducted fluorescence spectroscopy experiments using DiOC2(3) staining. DiOC2(3) is a membrane-potential-responsive fluorescent probe that binds to bacterial membranes and emits green fluorescence40. When the membrane potential changes due to external stimuli, the dye molecules undergo self-polymerization, causing the fluorescence to redshift. As shown in Fig. 2d, in untreated A. vinelandii, the fluorescence emission wavelength after DiOC2(3) staining was 501 nm. However, following the PEC-N2 reaction, the fluorescence emission of the bacteria exhibited a pronounced redshift to 528 nm. This result indicates that electrons were successfully transferred from the electrode through the bacterial membrane into the cell for nitrogen fixation. These findings provide direct evidence of transmembrane electron transport.

By injecting photoelectrons into A. vinelandii, NAD+ was converted to its reduced form, NADH (inset in Fig. 2e). NAD+ and NADH are essential cofactors in redox metabolism and signalling in all cellular life forms41, playing central roles in metabolic pathways such as glycolysis, tricarboxylic acid (TCA) cycle, and oxidative phosphorylation (OXPHOS)42, ultimately leading to ATP production, the energy currency of cells43. The NADH/NAD+ ratio in A. vinelandii was measured before and after the reaction (Fig. 2e), and an increase in this ratio post-reaction demonstrated that the photoelectrons generated by the electrode promoted the conversion of NAD+ to NADH, facilitating NH3 generation. Additionally, the concentration of ATP, an intracellular energy source, is crucial for efficient N2 reduction. The relative ATP levels in the biohybrid before and after the reaction are shown in Fig. 2f (Supplementary Fig. 9). A 1.2-fold increase in ATP levels indicated that extracellular electron uptake was beneficial for ATP synthesis, providing additional energy for the reduction of N2 to NH3. Furthermore, to gain insights into the role of electrons in nitrogenase, the relative expression levels of relevant genes in the Cu2O@TiO2 NWs/A. vinelandii biohybrid were investigated. Nitrogenase consists of Fe and MoFe proteins44, with the Fe protein, encoded by nifH, involved in electron transport, and the MoFe protein, encoded by nifD, catalysing the conversion of N2 to NH345. The relative transcription levels of nifH and nifD were quantified using real-time quantitative polymerase chain reaction (qPCR). As depicted in Fig. 2f (also see Supplementary Table 2 and 3), under illumination of the biohybrid system, specifically in the photocatalytic (PC) mode (Supplementary Fig. 10a), the expression of nifH and nifD was downregulated. This can be attributed to the fact that when Cu2O@TiO2 is exposed to light, it generates photoinduced electrons and holes on its surface. The photogenerated holes can oxidize water to produce oxygen (Supplementary Fig. 11). The resulting increase in oxygen concentration leads to the downregulation of nifH and nifD expression46,47. However, in the PEC mode (Supplementary Fig. 10b), the applied bias drives photogenerated holes to the counter electrode, where water is oxidized to O2, preventing localized O2 accumulation near the bacteria. (Supplementary Fig. 11). Instead, the enhanced electron supply further stimulates the NRR, leading to increased gene expression.

PEC-bacterial biohybrid performances

The linear sweep voltammetry (LSV) curves for the Cu2O@TiO2 NWs/A. vinelandii biohybrid system were measured in both dark conditions and under simulated solar light illumination in N2- and Ar-saturated electrolyte solution (Fig. 3a) to evaluate the NRR performance. Upon illumination, the biohybrid system showed a notable increase in photo-responsive current in both atmospheres, with a pronounced enhancement in N2 conditions, indicating significant catalytic activity for NRR. To optimize the PEC N2 fixation system, the influence of TiO2 layer thickness on electron transfer was examined (Supplementary Fig. 12). Cu2O without a TiO2 protective layer showed rapid photocurrent decay under light. A thinner TiO2 layer may improve electron migration and transfer efficiency to N2-fixing bacteria, promoting the N2 fixation reaction. Conversely, a thicker layer could hinder electron transfer and reduce efficiency. Precise control over TiO2 layer thickness is beneficial for enhancing electron transfer and improving NRR efficiency.

a LSV curves of Cu2O@TiO2 NWs/A. vinelandii in Ar- and N2-saturated electrolyte in dark and under irradiation of simulated solar light; (b) UV-vis absorption spectra of the electrolytes stained with indophenol indicator after NRR with different potentials; 1H NMR spectra of synthetic NH3 with (c) 14N2 and (d) 15N2 as seed gases for PEC-NRR on biohybrid at −0.3 V vs RHE for 2 h; (e) comparison of calculated NH3 yield rate by UV−vis and NMR methods for PEC-NRR on biohybrid at −0.3 V vs RHE for 2 h (n = 5, statistical analysis was performed using a two-tailed student’s t test (*P < 0.05, **P < 0.01, and ***P < 0.001)); (f) NH3 yield rates and FEs of biohybrid system for PEC-NRR on biohybrid at different potentials, n = 5, statistical analysis was performed using a two-tailed student’s t test (*P < 0.05, **P < 0.01, and ***P < 0.001)), error bars represent the standard error of the mean based on five independent measurements (n = 5); (g) comparison of NH3 yield of biohybrid system, A. vinelandii, Cu2O@TiO2, and Cu2O under PEC-NRR condition at −0.3 V vs RHE (n = 5, statistical analysis was performed using a two-tailed student’s t test (*P < 0.05, **P < 0.01, and ***P < 0.001)); (h) NH3 yields of biohybrid system in N2-saturated solution at –0.3 V, Ar-saturated solution at –0.3 V, and N2-saturated solution at open circuit potential under irradiation of simulated solar light (n = 5, statistical analysis was performed using a two-tailed student’s t test (*P < 0.05, **P < 0.01, and ***P < 0.001)); (i) NH3 yield rate on biohybrid system under different reaction conditions of PEC, EC, PC, and none (n = 5, statistical analysis was performed using a two-tailed student’s t test (*P < 0.05, **P < 0.01, and ***P < 0.001)); (j) recycling test for biohybrid system with PEC-NRR model at –0.3 V for 6 times (n = 5); (k) comparison of N2 conversion to NH3 with different catalysts. Source data are provided as a Source Data file.

For reliably detection and quantification of NH3 from N2 reduction, we have employed spectrophotometric and nuclear magnetic resonance (NMR) methods, and have also utilized isotope measurements with cycling of 15N2 gas as N source. For spectrophotometric measurements, NH3 was measured using the indophenol blue method (Supplementary Fig. 13)48, while hydrazine was determined using the Watt and Chrisp method (Supplementary Fig. 14)49. Spectrophotometric methods were used to detect the PEC-NRR on the biohybrid at different voltages. Within the range of –0.2 V to –0.5 V, the NH3 yield at –0.3 V is higher than others (Fig. 3b), with an NH3 production of 3.6 μg/mL. The 1H nuclear magnetic resonance (NMR) spectra were acquired to confirm the presence of NH4+ ions. The triple signal of 14NH4+ (Fig. 3c) and the doublet signal of 15NH4+ (Fig. 3d) were clearly detected when 14N2 and 15N2 were used as the gas supplies, respectively. This confirms the formation of NH3 from N2 reduction on biohybrid.

The NH3 yield rate after PEC-NRR on biohybrid were determined using both spectrophotometric and NMR methods, with 14N2 (Supplementary Fig. 15) and 15N2 (Supplementary Fig. 16) as the gas sources. The results obtained from both methods are presented in Fig. 3e. The consistency in NH3 yield rates determined by both methods, along with the identical results obtained from using either 14N2 or 15N2 gas, underscores the high reliability and accuracy of the quantitative measurements of NH3. This cross-verification ensures the validity of the findings and the robustness of the PEC-NRR process on biohybrid.

The average NH3 yields and corresponding Faraday efficiencies (FEs) are depicted in Fig. 3f. The maximum NH3 yield of (1.49 ± 0.05) × 10–9 mol s–1 cm–2 (5.36 ± 0.18 μmol h-1 cm-2) was obtained at –0.3 V. At –0.2 V, insufficient electron driving force was observed, while more negative potentials led to competition with the hydrogen evolution reaction (HER) on the electrode surface (Supplementary Fig. 17, Supplementary Fig. 18, and Supplementary Fig. 19)50,51,52. Compared with the Cu2O@TiO2 NWs, the Cu2O@TiO2 NWs/A. vinelandii biohybrid generates less hydrogen gas under the same PEC conditions (Supplementary Fig. 20 and Supplementary Fig. 21). Beyond –0.3 V, NH3 yield and FEs decreased due to increased HER FEs, which competed for active sites on the photoelectrode. The maximum FE reached 72.6 ± 5.1% at –0.2 V. All FEs at different potentials have been summarized in Supplementary Table 4. Under 1 sun illumination, the biohybrid system’s light conversion efficiency was calculated to be 0.43% at −0.3 V. (Supplementary Table 5). Chronoamperometry curves at various potentials demonstrated the good stability of the Cu2O@TiO2 NWs/A. vinelandii biohybrid under N2-saturated electrolytes (Supplementary Fig. 22).

A comparison of NH3 production activity on Cu2O NWs, Cu2O@TiO2 NWs, A. vinelandii, and the Cu2O@TiO2 NWs/A. vinelandii biohybrid system is summarized in Fig. 3g. Trace NH3 was detected on pristine Cu2O NWs under illumination, likely due to minor N2 reduction on Cu2O. However, severe photo-corrosion of Cu2O resulted in minimal NH3 production. After TiO2 ALD, NRR activity on Cu2O@TiO2 NWs slightly increased but remained low. Bare A. vinelandii could reduce N2 to NH3 through natural metabolism. The Cu2O@TiO2 NWs/A. vinelandii biohybrid system showed the high NH3 production activity, attributed to rapid photoelectron transfer between the electrode and bacteria. The Cu2O@TiO2 NWs generated photogenerated electron/hole pairs under light, and an external voltage accelerated their separation. These photogenerated electrons promoted NAD+ to NADH conversion, producing more ATP and providing electrons to nitrogenase for NRR, enhancing N2 fixation efficiency. The synergistic effect of the inorganic semiconductor electrode and microbial N2-fixing bacteria significantly improved the NH3 production rate.

In a biohybrid system, NH3 production rates and yields may be limited by factors such as semiconductor catalytic activity, material stability, and biocompatibility. Addressing these factors through optimization and innovation can greatly enhance hybrid system performance. Controlled experiments were conducted at –0.3 V in an Ar-saturated solution and at open circuit conditions in an N2-saturated solution, as shown in Fig. 3h. Compared to the results at –0.3 V in the N2-saturated solution, no NH3 was detected in either of these control experiments. A trace amount of NH3, possibly originating from ambient air, was also ruled out. This further confirmed that the detected NH3 was produced by the PEC-NRR in the biohybrid system.

The biohybrid system’s NH3 production test was conducted under different models, including PEC, electrocatalytic (EC), PC, and none (Fig. 3i). The biohybrid system showed low NRR catalytic activity without external conditions. EC and PC models enhanced NRR performance, while the Cu2O@TiO2 NWs/A. vinelandii biohybrid system achieved the high NH3 production rate under PEC conditions. No by-product N2H4 was detected in the final electrolytes at any potential (Supplementary Fig. 23), even when bacteria were broken down (Supplementary Fig. 24), indicating good NRR selectivity. Long-term stability testing at –0.3 V in N2-saturated electrolyte showed no significant photocurrent density decay over 24 h (Supplementary Fig. 25), with the ALD TiO2 layer remaining uniformly intact (Supplementary Fig. 26). XPS of the biohybrid system was almost unchanged after long-term NRR (Supplementary Fig. 27). The NH3 yield remained consistent across 6 cycles of tests (Fig. 3j), indicating good reproducibility. These results demonstrated the biohybrid system’s long-term stability and reproducibility. Finally, a comparison of N2-to-NH3 conversion activity on different catalysts and hybrid systems (Supplementary Table 6 and 7) is summarized in Fig. 3k. The Cu2O@TiO2 NWs/A. vinelandii biohybrid system achieved high conversion activity of (1.49 ± 0.05) × 10–9 mol s–1 cm–2 (5.36 ± 0.18 μmol h-1 cm-2), significantly outperforming reported inorganic catalysts. The exceptional performance of the Cu2O@TiO2 NWs/A. vinelandii biohybrid system indicates that the inorganic-biological hybrid strategy holds great promise for efficient NH3 generation.

Biocompatibility and viability of A. vinelandii

Viability and biocompatibility are crucial for catalyst systems that incorporate living microorganisms. In the Cu2O@TiO2 NWs/A. vinelandii biohybrid system, the viability and biocompatibility of A. vinelandii on Cu2O@TiO2 NWs were assessed before and after prolonged NH3 synthesis reactions using confocal laser scanning microscopy (CLSM) analysis. The bacteria were stained with the N01/PI fluorescent probe53. The BBcellPrebe™ N01 probe can penetrate the cell membrane of live bacteria, emitting bright green fluorescence upon excitation, while PI, which cannot enter live bacteria, stains only dead bacteria and exhibits red fluorescence upon excitation.

The CLSM images of A. vinelandii on Cu2O@TiO2 NWs before and after the NRR are shown in Fig. 4a, b, respectively. The predominant bright green and weak red fluorescence in Fig. 4a indicate high bacterial activity of A. vinelandii on Cu2O@TiO2 NWs prior to the reaction. After the long-term NH3 synthesis reaction, a slight increase in the red fluorescent signal was observed (Fig. 4b2), indicating some cell death, but the green fluorescent intensity remained strong (Fig. 4b1), suggesting that a significant number of A. vinelandii cells remained viable. This could imply that the bacteria are able to withstand the conditions of the experiment, although it does not directly indicate self-repair or growth mechanisms. To further investigate the number of live and dead bacteria, flow cytometry measurements were performed. 99.6% of a sample of a hundred thousand A. vinelandii were analyzed for apoptosis (Supplementary Fig. 28a). As shown in Fig. 4c, flow cytometry detected very few dead A. vinelandii. After PEC NRR, another sample of a hundred thousand A. vinelandii was collected for testing (Supplementary Fig. 28b). Compared to the pre-reaction A. vinelandii, a slight increase of 102.2% in survival rate was recorded (Fig. 4d). The number of bacteria was also determined by colony-forming units (CFU) assays (Fig. 4e), and the count remained essentially unchanged or even slightly increased after PEC NRR measurements (initial count: (2.3 ± 0.15) × 105 cells mL-1). These results confirm the excellent biocompatibility of the Cu2O@TiO2 NWs.

Fluorescence staining images of A. vinelandii in biohybrid dyed with (a1, b1) BBcellPrebe™ N01 (green), (a2, b2) PI (red), and (a3, b3) merging patterns before and after long-term NH3 synthesis reaction respectively, the scale bars are 25 μm, the fluorescence images are representative of results obtained from at least three independent experiments with similar outcomes; flow cytometry with gated events of A. vinelandii (c) before and (d) after long-term reaction; (e) the number of A. vinelandii before and after NRR, the insets are CFU images of A. vinelandii (n = 5). Source data are provided as a Source Data file.

Discussion

In summary, we have developed a Cu2O@TiO2 NWs/A. vinelandii biohybrid system that enables efficient PEC-NRR under ambient conditions. The system capitalizes on the excellent biocompatibility and specific binding affinity of the Cu2O@TiO2 NWs, allowing A. vinelandii to adhere to the electrode surface and form a robust inorganic-biological hybrid. The photogenerated electrons from the Cu2O@TiO2 NWs facilitate the conversion of NAD+ to NADH, leading to increased ATP production and supplying additional electrons for the NRR, which in turn results in enhanced NH3 production activity. This synergistic approach, which combines the light-harvesting capabilities of inorganic semiconductors with the high catalytic efficiency of microorganisms, paves the way for directing photoinduced reactions in an ideal and selective manner. The Cu2O@TiO2 NWs/A. vinelandii biohybrid system serves as a promising platform for sustainable NH3 synthesis through PEC-NRR, offering a significant step forward in the development of environmentally friendly and energy-efficient technologies for NH3 production.

Methods

Materials

All reagents are of analytical grade and used as received without any further purification. Copper foam (1 mm thickness) was supplied by Tianjin An Nuohe New Energy Technology Co., LTD. (China). Sodium hydroxide (NaOH), ammonium chloride (NH4Cl), hydrazine hydrate (N2H4·H2O), sodium hypochlorite (NaClO), sodium salicylate (C7H5O3Na), sodium sulfate (Na2SO4), hydrochloric acid (HCl), ethanol (CH3CH2OH), Para-(dimethylamino) benzaldehyde (C9H11NO) and sodium nitroferricyanide (III) dihydrate (Na2Fe(CN)5NO·2H2O) were bought from Macklin Inc., Shanghai, China. A. vinelandii was obtained from Shanghai Qincheng Biological Technology Co., Ltd, China. All aqueous solutions were prepared using deionized (DI) water with a resistivity of 18.2 MΩ·cm.

Preparation of Cu2O@TiO2 nanowires

The CF was anodized in an alkaline solution (3 M NaOH) for 30 min at 45 mA·cm−2 to form Cu(OH)2 NWs/CF, following which the color of the CF changed from reddish brown to sky blue. The as-anodized nanowire was annealed in a tube furnace at 550 °C for 2 h under N2 atmosphere, to convert Cu(OH)2 NWs/CF to Cu2O NWs/CF, following which the color of the Cu2O NWs changed to brick red. Finally, TiO2 was modified by atomic layer deposition (ALD) to prepare Cu2O@TiO2 NWs with core-shell structure.

Bacterial cultivation

A. vinelandii was cultured in a modified Bushnell-Haas (BH) medium containing (per liter): 0.2 g KH2PO4, 0.8 g K2HPO4, 0.1 g CaSO4·2H2O, 20 g Mannitol, 0.1 g FeCl3, 0.1 g Na2MoO4·2H2O, 0.2 g MgSO4·7H2O, 0.5 g Yeast extract, 15 g Agar. Cultures were maintained at 30 °C with shaking at 180 rpm (aerobic pre-culture phase). Lyophilized powder activation involves using a sterile pipette to draw up 0.3 mL of culture fluid or sterile water and adding it dropwise into the lyophilized vial. Gently shake until fully dissolved. Draw up the entire bacterial suspension and inoculate onto the culture medium, then culture at 30 °C for 2 days. After activation, the bacterial strain needs to be sub-cultured two more times for optimal vitality.

Preparation of Cu2O@TiO2 NWs/A. vinelandii biohybrid system

The A. vinelandii was inoculated in 50 mL culture solution, and was aerobically cultured in an incubator at 30 °C for 3 days. The bacteria in the culture samples were collected by centrifugation at 5590 x g for 10 min, and then re-dispersed in 50 mL 0.1 M Na2SO4 electrolyte containing Cu2O@TiO2 NWs electrode to construct the Cu2O@TiO2 NWs/A. vinelandii biohybrid system. The reactor was purged with N2 for 30 min prior to the reaction. The reactor was designed to be micro-aerobic, minimizing oxygen ingress to 0.5-1.0% while allowing for metabolic gas exchange.

Characterizations

The morphologies of electrodes were characterized by scanning electron microscopy (SEM, Hitachi S4800) and transmission electron microscopy (TEM, JEOL JEM 2100). The crystalline structure of the electrodes was analyzed by X-ray diffraction (XRD) (Bruker D8 Discover diffractometer, using Cu Kα radiation (1.540598 Å)). The UV-vis adsorption spectra were recorded on a spectrophotometer (Lengguang Teach, UV 759S). Confocal laser scanning microscopy (CLSM) images were obtained by a confocal laser scanning microscope (TCS SP8 MP SMD, LEICA, German). The light source was derived from a Xenon lamp (PLS-SXE300, Perfect Light, Beijing) with a filter (AM 1.5 G, Perfect Light, Beijing).

Pre-treatment of the Cu2O@TiO2 NWs/A. vinelandii for SEM characterization

A. vinelandii underwent centrifugation at 5590 x g for 10 min, followed by re-dispersion in a 50 mL 0.1 Na2SO4 electrolyte and a subsequent 2 h incubation period. In the process of sample preparation, the electrode designated for A. vinelandii adsorption underwent fixation in 4% glutaraldehyde at 4 °C overnight. Post-fixation, the samples underwent a triple rinse with deionized water at room temperature. Subsequently, a stepwise dehydration process was executed, involving sequential exposure to 50%, 70%, 90%, and 100% ethanol, each stage lasting 5–10 min. The resulting dried samples are now ready for SEM characterization.

PEC-NRR on Cu2O@TiO2 NWs/A. vinelandii

Before NRR measures, the Nafion proton exchange film was pretreated by heating in 5% H2O2 solution, 0.5 M H2SO4 and ultrapure water at 80 °C for 1.5 h, respectively. PEC measurements were performed with a CHI 660E electrochemical analyzer (CH Instruments, Inc., Shanghai) in a standard three-electrode system using biohybrid system as the working electrode, graphite rod as the counter electrode, and saturated Ag/AgCl electrode as the reference electrode. The saturated Ag/AgCl electrode was calibrated against RHE using the following equation:

All experiments were carried out at room temperature. The high-purity N2 (99.999%) gas used in our experiments was purified through a multi-step process to eliminate trace NOx and other contaminants. The N2 gas was passed through a series of alkaline traps (1 M NaOH) and 5% w/v KMnO4 to remove acidic impurities such as NOx and CO2. Then, the N2 gas was passed through a concentrated sulfuric acid to remove moisture and other impurities. The residual moisture and volatile organic compounds were adsorbed by molecular sieves (5 Å). This protocol ensures that the N2 gas used in our experiments is free from contaminants that could interfere with NH3 production. For N2 reduction experiments, the 0.1 M Na2SO4 electrolyte was purged with N2 for 30 min before the measurement. PEC test was conducted in N2-saturated 0.1 M Na2SO4 solution in a two-compartment cell, which was separated by Nafion 211 membrane. NH3 yields from biohybrid were corrected by subtracting the baseline NH3 production from A. vinelandii alone. Isotopic labeling 15N2 was as well as used as nitrogen source for PEC-NRR. For the intracellular metabolic assays (NADH/NAD+, ATP, and gene expression), the biohybrid system was operated at −0.3 V vs. RHE under simulated solar illumination (AM 1.5 G, 100 mW cm-2) in N2-saturated 0.1 M Na2SO4 electrolyte. Chronoamperometry was performed for 2 h prior to sample collection; However, for Faradaic efficiency (FE) calculations, both the charge (Q) and NH3 concentration were normalized to a per-hour basis.

NAD+/NADH assay kit measurements

NAD+/NADH assay kit (Beyotime Biotechnology) with WST-8 was used to determine the concentration of NADH and NAD+ in A. vinelandii following the standard manual of the assay kit.

Measurement of ATP content

ATP levels were quantified using a luminescent ATP Detection Assay Kit (ab113849). A. vinelandii cells were harvested before- or post-reaction by centrifugation (10,000 × g, 10 min) and resuspended in 1 × PBS. Cells were lysed by adding 200 μL of ATP assay lysis buffer (provided in the kit) and vortexing for 30 s. The lysate was incubated on ice for 10 min to ensure complete cell disruption. The lysate was centrifuged (12,000 × g, 5 min, 4 °C) to remove cellular debris. The supernatant (200 μL) was transferred to a 96-well plate. ATP detection solution (100 μL, containing luciferase and D-luciferin) was added to each well. Luminescence was measured immediately using a microplate reader (BioTek Synergy H1). Bacterial ATP levels were quantified using a chemiluminescence assay. The luminescence intensity corresponding to ATP was normalized to the bacterial dry weight (μg) to calculate ATP content per unit biomass. For baseline determination, ATP% values were derived from five independent measurements of untreated bacterial cultures, and the mean value was established as the reference (100%). Bacterial cells subjected to the biohybrid PEC system were analyzed using the same protocol. The ATP% of treated cells was then expressed relative to the untreated control baseline.

Nitrogenase gene expression test

The specific primers of three key genes (nifH and nifD) encoding nitrogenase were designed and synthesized. The housekeeping gene 16 s rDNA served as internal control. The total RNA of A. vinelandii was extracted using the Trizol reagent. The integrity and concentration of the total RNA was confirmed by denatured agarose gel electrophoresis and ultraviolet absorption assay. The cDNA was gained by reverse transcription using Maxima Reverse Transcriptase (200 U). Subsequently, the samples were measured by quantitative reverse transcription polymerase chain reaction in triplicate. The expression level of the nif genes was calculated on the basis of the 2-DDCT method and normalized according to the internal control.

Determination of NH3

The produced NH3 was detected with indophenol blue by ultraviolet spectroscopy. In detail, extract 4 mL of the reacted solution from the cathode chamber, centrifuge at 10,000 revolutions per minute for 10 min to remove the N2-fixing bacteria. The supernatant was reacted with 50 µL oxidizing solution containing NaClO (0.05 M) and NaOH (0.75 M), 500 µL coloring solution containing 0.4 M C7H5O3Na and 0.32 M NaOH, and 50 µL catalyst solution (1 wt% Na2[Fe(CN)5NO]) at room temperature for 1 h. Subsequently, the UV-visible absorption spectrum is measured to calculate the concentration of NH3 at =660 nm. The concentration-absorbance curve was calibrated using standard NH3 solution with a serious of concentrations. The fitting curve (y = 0.45x + 0.026, R2 = 0.999) shows good linear relation of absorbance value with NH3 concentration.

Determination of N2H4

The amount of N2H4 present in the electrolyte was determined by the method of Watt and Chrisp. The mixture of C9H11NO (5.99 g), HCl (30 mL), and C2H5OH (300 mL) was used as a color reagent. In detail, 5 mL electrolyte was removed from the electrochemical reaction vessel, and added into 5 mL above prepared color reagent and stirring 10 min at room temperature. Moreover, the absorbance of the resulting solution was measured at a wavelength of 455 nm. The concentration absorbance curves were calibrated using standard N2H4 solution with a series of concentrations. The fitting curve (y = 2.3x + 0.032, R2 = 0.999) shows good linear relation of absorbance value with N2H4 concentration.

Calculations of NH3 formation rate and FE

NH3 formation rate was calculated using the following equation:

FE was calculated according to following equation:

where [NH3] is the measured NH3 concentration; V is the volume of the cathodic reaction electrolyte; t is the potential applied time; A is the geometric area of the cathode (1 cm × 1 cm); F is the Faraday constant; and Q is the quantity of applied electricity.

Calculation of solar-to-ammonia efficiency

The solar-to-ammonia energy conversion efficiency (η) is calculated using the following equation:

where ΔGNH3 is the Gibbs free energy required to produce ammonia. The value is 383 kJ/mol per mole of NH3 produced (based on the reaction N2 + 3H2 → 2NH3). rNH3 is the ammonia production rate per unit area (in mol s-1 cm-2). Plight is the light power density (in W cm-2). In this work, as the ammonia can also be generated in electrocatalytic model (EC model), for accurately calculate the solar-to-ammonia efficiency, the ammonia production rate was determined by subtracting the baseline EC contribution from the PEC activity.

Staining analysis of bacteria

The bacteria before and after reactions were resuspended in 100 μL BBcellProbe™ N01 Dye solution A and PI Dye solution B. After incubating at room temperature for 15 min, the bacteria were washed with 0.85% NaCl solution once and then suspended again. Finally, add 20 μL bacterial to the confocal surface dish and the samples were imaged with CLSM under the excited laser of 488 nm, the emission wavelength of 525 nm and 617 nm respectively.

Flow cytometry

Flow cytometric measurements of A. vinelandii were performed with BD FACSMelody, and the data analysis of the cytometric files was automatically performed by FlowJo software.

A. vinelandii viability

During the long-term test, the viability of A. vinelandii was determined by colony-forming units (CFU) assays. At fixed time intervals, aliquots of 500 μL reaction solution was collected by a sealing syringe. One hundred μL of the collected sample was serially diluted with saline. One hundred μL of the original and diluted sample were spread on sterilized nutrient agar plates, then incubated at 37 °C for 16 h. Finally, the survival number of cells (in CFU) was quantified by counting the visible colonies and the survival rate was calculated.

Statistics

Statistical analysis was performed using GraphPad Prism 8.0.2 software using a two-tailed t test analysis of variance hypothesis. Significant differences are marked as *P < 0.05, **P < 0.01, and ***P < 0.001. All data are presented as mean ± SD. The number of biologically independent samples for each panel was three unless otherwise stated in the figure legends.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

Data supporting the findings of this work are available within the paper and its Supplementary Information files. A reporting summary for this Article is available as a Supplementary Information file. Source data are provided with this paper.

References

Han, S. H. et al. Ultralow overpotential nitrate reduction to ammonia via a three-step relay mechanism. Nat. Catal. 6, 402–414 (2023).

Zhou, F. et al. Electro-synthesis of ammonia from nitrogen at ambient temperature and pressure in ionic liquids. Energy Environ. Sci. 10, 2516–2520 (2017).

Wang, H. et al. Ambient electrosynthesis of ammonia: electrode porosity and composition engineering. Angew. Chem. Int. Ed. 57, 12360–12364 (2018).

Brown, K. A. et al. Light-driven dinitrogen reduction catalyzed by a CdS nitrogenase MoFe protein biohybrid. Science 352, 448–450 (2016).

Ghorai, U. K. et al. Scalable production of cobalt phthalocyanine nanotubes: efficient and robust hollow electrocatalyst for ammonia synthesis at room temperature. ACS Nano 15, 5230–5239 (2021).

Wang, Y. & Meyer, T. J. A route to renewable energy triggered by the Haber-Bosch process. Chem 5, 496–497 (2019).

Chen, Y. et al. Highly productive electrosynthesis of ammonia by admolecule-targeting single Ag sites. ACS Nano 14, 6938–6946 (2020).

Service, R. F. New recipe produces ammonia from air, water, and sunlight. Science 345, 610–610 (2014).

Hawkins, A. S. et al. Biological conversion of carbon dioxide and hydrogen into liquid fuels and industrial chemicals. Curr. Opin. Biotech. 24, 376–384 (2013).

Sakimoto, K., Wong, A. & Yang, P. Self-photosensitization of nonphotosynthetic bacteria for solar-to-chemical production. Science 351, 74–77 (2016).

Tapia, C. et al. In situ determination of photobioproduction of H2 by In2S3-[NiFeSe] hydrogenase from desulfovibrio vulgaris hildenborough using only visible light. Acs Catal 6, 5691–5698 (2016).

Wilker, M. B. et al. Electron transfer kinetics in CdS nanorod-[FeFe]-hydrogenase complexes and implications for photochemical H2 generation. J. Am. Chem. Soc. 136, 4316–4324 (2014).

Gaby, J. C. & Buckley, D. H. A global census of nitrogenase diversity. Environ. Microbiol. 13, 1790–1799 (2011).

Wang, H. et al. Carbon dots enhance the nitrogen fixation activity of azotobacter chroococcum. ACS Appl. Mater. Interfaces 10, 16308–16314 (2018).

Hoffman, B. M., Lukoyanov, D., Yang, Z. Y., Dean, D. R. L. & Seefeldt, C. Mechanism of nitrogen fixation by nitrogenase: the next stage. Chem. Rev. 114, 4041–4062 (2014).

Hageman, R. V. & Burris, R. H. Nitrogenase-and-nitrogenase-reductase-associate-and-dissociate-with-each-catalytic-cycle. Proc. Natl. Acad. Sci. USA 75, 2699–2702 (1978).

Liu, H. M. et al. Homogeneous, heterogeneous, and biological catalysts for electrochemical N2 reduction toward NH3 under ambient conditions. Acs Catal 9, 5245–5267 (2019).

Burgess, B. K. & Lowe, D. J. Mechanism of molybdenum nitrogenase. Chem. Rev. 96, 2983–3012 (1996).

Dong, F., Lee, Y. S., Gaffney, E. M., Liou, W. & Minteer, S. D. Engineering cyanobacterium with transmembrane electron transfer ability for bioelectrochemical nitrogen fixation. ACS Catal. 11, 13169–13179 (2021).

Rago, L. et al. Bioelectrochemical nitrogen fixation (e-BNF): Electro-stimulation of enriched biofilm communities drives autotrophic nitrogen and carbon fixation. Bioelectrochemistry 125, 105–115 (2019).

Ortiz-Medina, J. F., Grunden, A. M., Hyman, M. R. & Call, D. F. Nitrogen gas fixation and conversion to ammonium using microbial electrolysis cells. ACS Sustainable Chem. Eng. 7, 3511–3519 (2019).

Milton, R. D. et al. Bioelectrochemical haber–bosch process: an ammonia‐producing H2/N2 Fuel. Cell. Angew. Chem. Int. Ed. 56, 2680–2683 (2017).

Milton, R. D. et al. The in vivo potential-regulated protective protein of nitrogenase in azotobacter vinelandii supports aerobic bioelectrochemical dinitrogen reduction in vitro. J. Am. Chem. Soc. 139, 9044–9052 (2017).

Lu, S., Guan, X. & Liu, C. Electricity-powered artificial root nodule. Nat. Commun. 11, 1–10 (2020).

Liu, C., Sakimoto, K. K., Colón, B. C., Silver, P. A. & Nocera, D. G. Ambient nitrogen reduction cycle using a hybrid inorganic–biological system. Proc. Natl. Acad. Sci. USA. 114, 6450–6455 (2017).

Andrei, V., Roh, I. & Yang, P. Nanowire photochemical diodes for artificial photosynthesis. Sci. Adv. 9, eade9044 (2023).

Li, Z., Xin, Y. & Zhang, Z. New photocathodic analysis platform with quasi-core/shell-structured TiO2@Cu2O for sensitive detection of H2O2 release from living cells. Anal. Chem. 87, 10491–10497 (2015).

Liu, G. et al. Investigation and mitigation of degradation mechanisms in Cu2O photoelectrodes for CO2 reduction to ethylene. Nature Energy 6, 1124–1132 (2021).

Paracchino, A., Laporte, V., Sivula, K., Grätzel, M. & Thimsen, E. Highly active oxide photocathode for photoelectrochemical water reduction. Nat. Mater. 10, 456–461 (2011).

Zhang, M. et al. Acceptor‐doping accelerated charge separation in Cu2O photocathode for photoelectrochemical water splitting: theoretical and experimental studies. Angew. Chem. Int. Ed. 59, 18463–18467 (2020).

Zhou, X. et al. Hydrogen-substituted graphdiyne encapsulated cuprous oxide photocathode for efficient and stable photoelectrochemical water reduction. Nat. Commun. 13, 5770 (2022).

Carter, E., Carley, A. F. & Murphy, D. M. Evidence for O2- radical stabilization at surface oxygen vacancies on polycrystalline TiO2. J. Phys. Chem. C 111, 10630–10638 (2007).

Yang, Y. et al. An unusual strong visible-light absorption band in red anatase TiO2 photocatalyst induced by atomic hydrogen-occupied oxygen vacancies. Adv. Mater. 30, 1704479 (2018).

Zhang, Z., Hedhili, M. N., Zhu, H. & Wang, P. Electrochemical reduction induced self-doping of Ti3+ for efficient water splitting performance on TiO2 based photoelectrodes. Phys. Chem. Chem. Phys. 15, 15637–15644 (2013).

Chen, Z. et al. A broad light-harvesting conjugated oligoelectrolyte enables photocatalytic nitrogen fixation in a bacterial biohybrid. Angew. Chem. Int. Ed. 62, e202307101 (2023).

Alleman, A. B. & Peters, J. W. Mechanisms for generating low potential electrons across the metabolic diversity of nitrogen-fixing bacteria. Appl. Environ. Microbiol. 89, e00378–23 (2023).

Wilson, A. & Ruiz, N. Transport of lipopolysaccharides and phospholipids to the outer membrane. Curr. Opin. Microbiol. 60, 51–57 (2021).

Alleman, A. B., Costas, A. G., Mus, F. & Peters, J. W. Rnf and fix have specific roles during aerobic nitrogen fixation in azotobacter vinelandii. Appl. Environ. Microbiol. 88, e01049–01022 (2022).

Shanmugam, M., Quareshy, M., Cameron, A. D., Bugg, T. D. H. & Chen, Y. Light‐activated electron transfer and catalytic mechanism of carnitine oxidation by rieske‐type oxygenase from human microbiota. Angew. Chem. Int. Ed. 60, 4529–4534 (2020).

Khater, M., Khater, S. S., Gholap, H., Patil, R. & Kulkarni, G. Comparative studies on measurement of membrane potential of bacterial cells treated with ZnO nanoparticles by Spectrofluorometry, fluorescence microscopy and flowcytometry. J. Microbiol. Methods 173, 105920 (2020).

Petriti, B., Williams, P. A., Lascaratos, G., Chau, K.-Y. & Garway-Heath, D. F. Neuroprotection in glaucoma: NAD+/NADH redox state as a potential biomarker and therapeutic target. Cells 10, 1402 (2021).

Lautrup, S., Sinclair, D. A., Mattson, M. P. & Fang, E. F. NAD+ in brain aging and neurodegenerative disorders. Cell Metab 30, 630–655 (2019).

Parpura, V. et al. Glutamate and ATP at the interface between signaling and metabolism in astroglia: examples from pathology. Neurochem. Res. 42, 19–34 (2016).

Burgess, B. A. The iron-Molybdenum cofactor of nitrogenase. Chem. Rev. 90, 1377–1406 (1990).

Fani, R., Gallo, R. & Liò, P. Molecular evolution of nitrogen fixation: the evolutionary history of the nifD, nifK, nifE, and nifN Genes. J. Mol. Evol. 51, 1–11 (2000).

Ryu, M. H. et al. Control of nitrogen fixation in bacteria that associate with cereals. Nat. Microbio. 5, 314–330 (2020).

Gregor, J. et al. Bacterial regulatory networks include direct contact of response regulator proteins: interaction of RegA and NtrX in Rhodobacter capsulatus. Microb. Physiol. 13, 126–139 (2007).

Zhu, D., Zhang, L., Ruther, R. E. & Hamers, R. J. Photo-illuminated diamond as a solid-state source of solvated electrons in water for nitrogen reduction. Nat. Mater. 12, 836–841 (2013).

Watt, G. W. & Chrisp, J. D. Spectrophotometric method for determination of hydrazine. pdf. Anal. Chem. 24, 2006–2008 (1952).

Lv, C. D. et al. An amorphous noble-metal-free electrocatalyst that enables nitrogen fixation under ambient conditions. Angew. Chem. Int. Ed. 57, 6073–6076 (2018).

Qiu, W. et al. High-performance artificial nitrogen fixation at ambient conditions using a metal-free electrocatalyst. Nat. Commun. 9, 3485 (2018).

Ren, X. et al. High-performance N2-to-NH3 conversion electrocatalyzed by Mo2C nanorod. ACS Cent. Sci. 5, 116–121 (2019).

Li, P. et al. Metal-organic frameworks with photocatalytic bactericidal activity for integrated air cleaning. Nat. Commun. 10, 2177 (2019).

Acknowledgements

This research was supported by National Natural Science Foundation of China (No. 22474041), Shanghai Sailing Program (22YF1417800), the Special Project for Clinical Research in the Health Industry of the Shanghai Municipal Health Commission (20224Y0368), “Chen Guang” project supported by Shanghai Municipal Education Commission and Shanghai Education Development Foundation (No. 23CGA80), Shanghai Key Laboratory of Molecular Imaging (18DZ2260400), and Scientific Research Foundation of SUMHS (SSF-23-18-001, AM-SCP-23-18-01).

Author information

Authors and Affiliations

Contributions

X.Z., D.W., W.Z. and Z.Z. designed the experiments. X.Z., D.W., Y.J. and T.F. carried out the experiments. X.Z. and D.W. conducted the characterizations. All authors wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhou, X., Wu, D., Zhang, Y. et al. Inorganic-bacterial biohybrids for efficient solar-driven nitrogen fixation. Nat Commun 16, 5690 (2025). https://doi.org/10.1038/s41467-025-60937-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-60937-5