Abstract

Photoelectrochemical production of ammonia usually suffers from a low solar-to-ammonia efficiency and a high overpotential, which influences the bias-free operation of sustainable photoelectrochemistry. Herein, we realize solar-driven ammonia production from waste nitrate by constructing copper-osmium catalysts deposited on the Sb2(S,Se)3 semiconductor, enabling optimized photo-carrier transport pathways and a beneficial co-adsorption configuration of *NO3-H2O moieties. The photocathode reaches a photocurrent density of 5.6 mA cm−2 at 0 VRHE with a low onset potential of 0.86 VRHE and a Faradaic efficiency of 96.98% at 0.6 VRHE under AM 1.5 G illumination. We further employ glycerol oxidation reaction on ruthenium doped bismuth oxide catalyst decorated on titanium oxide photoanode, requiring an onset potential of 0.3 VRHE to enable bias-free operation. The unbiased photoelectrochemical system shows Faradaic efficiencies of over 97% for ammonia products and above 77% for glycerol oxidation product under AM 1.5 G illumination. The large-sized photoelectrodes maintain a stability for 24 h without noticeable degradation. Our works indicate that unassisted and stable PEC ammonia production is feasible with in situ glycerol valorization using the photoanode and photocathode.

Similar content being viewed by others

Introduction

Ammonia (NH3) is the second most produced chemical globally, a key precursor for fertilizers and fine chemicals1,2. The sustainable solar energy renders it an option for renewable energy applications3,4. Photoelectrochemical nitrate reduction reaction (PEC NO3RR) for NH3 production is one of the promising manners performed at ambient temperature and pressure without emitting carbon dioxide5,6,7,8. However, it suffers from low solar-to-ammonia efficiency, poor selectivity, and high onset potentials since the conversion of nitrate to ammonia involves an eight-electron transfer process. Such performance is mainly attributed to poor utilization of solar flux and slow charge transport in the photoelectrodes. Furthermore, hydrogen evolution reaction becomes competitive compared to PEC NO3RR9,10. Also, the nitrite (NO2-) as an incomplete reduction product of nitrate poses a threat to the selectivity and yield of NH311,12. To address these, Fan et al. employed a ZnIn2S4/TiO2 photocathode to convert nitrate to ammonia, exhibiting a photocurrent density of 3 mA cm−2 at −0.1 VRHE13. On the other hand, to advance the bias-free operation with the photoanode side for PEC system, semiconductor’s onset potential must be low enough, which is a criterion for the bias-free PEC cell since applying bias increases production cost and energy consumption14,15,16. Amal et al. reported a Cu2ZnSnS4 photocathode loaded with the defective TiOx cocatalyst and CdS buffer layer for PEC NO3RR, showing an ammonia yield of 8.21 µmol h−1 cm−2 at −0.2 VRHE and a Faradaic efficiency of 89.1% at 0.1 VRHE with a positive onset potential of 0.38 VRHE17. Moreover, our group reported CuSn alloy catalyst decorated on the Sb2S3 photocathode with the deposition of a titanium oxide layer, exhibiting an onset potential of 0.62 VRHE5. Although the low onset potential has been obtained, the current density at low potentials is not ideal, and the performance of the PEC unbiased system greatly depends on the current density at low bias potential. Therefore, developing a suitable photoelectrode and cocatalyst becomes a primary challenge in enhancing solar conversion efficiency and improving photogenerated charge utilization efficiency for potential applications.

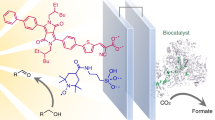

As we know, NH3 production coupled with water oxidation requires an additional bias owing to high thermodynamic potential for water oxidation (1.23 V). To replace the traditional water oxidation reaction to produce oxygen with low economic value, glycerol oxidation reaction (GOR) has been developed to convert low-cost feedstock to high-value-added chemicals with thermodynamic equilibrium potential18,19,20. Coupling a favorable anode oxidation reaction to obtain value-added products with NH3 production at the photocathode might offer sustainable applications1. More recently, Si/Cu-NSTL/Co(OH)2 photocathode with a Schottky barrier contact was reported to enable optimizing photogenerated carrier transport pathways and a beneficial co-adsorption configuration of *NO3-H2O moieties21. The photocathode for PEC NO3RR was then coupled with a Cu/Pt-Si photoanode for GOR to produce formate without any applied additional bias, lowering the potential requirement in comparison to that of water splitting. Jang et al. applied a triple-cation lead halide perovskite photocathode with integrated electrocatalyst to achieve high solar-to-ammonia productivity and coupled electrochemical glycerol oxidation (glyceric acid as a major value-added product) for bias-free NH3 production1. Dihydroxyacetone (DHA) is driven by substantial market demand and a high market value ($150/kg), establishing it as the most desirable product within GOR22,23,24. It originates from secondary hydroxyl oxidation, yielding a three-carbon (C3) product within a carbon chain. The pursuit of maintaining a balanced carbon chain to produce DHA selectively is thus appealing for energy conversion. Designing a suitable photoelectrode with a low onset potential applied in PEC couplings while obtaining high value-added products remains challenging.

Herein, we developed a high-performance PEC cell using a low-cost Sb2(S,Se)3 photocathode with the deposition of copper-osmium electrocatalyst (CuOs/CdS/SSS) for selective PEC NO3RR towards efficient ammonia products. The resultant photocathode reaches a photocurrent density of 5.6 mA cm−2 at 0 VRHE with a low onset potential of 0.86 VRHE, and especially, it exhibits much higher performance in the low overpotential compared to the traditional photoelectrodes reported. In addition, we employed ruthenium doped bismuth oxide decorated on titanium oxide photoanode for glycerol oxidation reaction, requiring a low onset potential of 0.3 VRHE to enable bias-free operation. The selective CuOs and Ru-Bi2O3 cocatalysts provide improved stability and selectivity with low onset potentials in acid electrolytes. The CuOs/CdS/SSS photocathode coupled with a GOR photoanode show Faradaic efficiencies of over 90% for NH3 production and above 77% for GOR under AM 1.5 G illumination without applying any potential. Furthermore, the large-sized photoelectrodes maintain a stability for 24 h without noticeable degradation, representing one of the notable performances among bias-free PEC cells for high value-added products reported so far. This work motivates development for producing value-added products from low-value/waste compounds.

Results

Characterization of CuOs/CdS/SSS photocathode

The CuOs/TiO2/CdS/Sb2(S,Se)3 photocathode was fabricated via a two-step hydrothermal approach, as illustrated in Fig. 1a. Briefly, an Sb2S3 seed layer was firstly prepared on a fluorine-doped tin oxide substrate using a hydrothermal method. Afterwards, Sb2(S,Se)3 absorber layer was formed in a second hydrothermal process in a selenourea precursor. The film formed a gradient doping of Se enriched at the bottom during the reaction. A CdS layer as a transfer layer was deposited on the top surface of Sb2(S,Se)3, following by the deposition of an amorphous TiO2 protective layer (noted as CdS/SSS). Finally, the copper-osmium-based cocatalyst was decorated on the CdS/SSS, and the sample is denoted as CuOs/CdS/SSS. For comparison, the Cu cocatalyst deposited on the CdS/SSS photocathode was synthesized (labeled as Cu/CdS/SSS). The morphology structures of the relevant photocathodes were observed by scanning electron microscopy (SEM). The pristine SSS and CdS/SSS show a dense grain with a size of ~500 ± 100 nm (Supplementary Figs. S1 and S2). The CuOs catalyst exhibits a nanoparticle structure on the surface of CuOs/CdS/SSS (Supplementary Fig. S3), similar to that of Cu/CdS/SSS (Supplementary Fig. S4). The layered structure of the electrode is clearly shown in Fig. 1b and Supplementary Fig. S5. Transmission electron microscopy (TEM) image exhibit the thicknesses of 700–800 nm for the light-absorbing layer with a Se-rich layer of ~300 nm. The interface between CuOs, TiO2, CdS, and Sb2(S,Se)3 can be evidently observed (Fig. 1c). The lattice spacing for the CuOs catalyst is measured to be 0.182 nm corresponding to the (200) plane of Cu (Fig. 1d and Supplementary Fig. S6), and Sb2(S,Se)3 presents the lattice spacing of 0.302 nm assigned to the (211) plane of Sb2S3 (Fig. 1e and Supplementary Fig. S7).

a Schematic illustration of the synthesis of CuOs/CdS/SSS. b, c Cross-sectional TEM images of CuOs/CdS/SSS. d, e HRTEM images of d CuOs catalysts and (e) Sb2(S,Se)3. f EDX mapping images of CuOs/CdS/SSS. g Cu 2p, h Cu LMM, and i Os 4 f XPS spectra of CuOs. Source data are provided as a Source Data file.

All the photocathodes exhibit the crystal structure of Sb2S3 (JCPDS No. 73-0393) in the X-ray diffraction (XRD) patterns (Supplementary Fig. S8)5. In the X-ray photoelectron spectroscopy (XPS), the peak at 932.1 eV in the Cu 2p spectra and the peaks at 564.4 eV and 566.1 eV in the Cu LMM spectra represent the metallic states of Cu on both Cu/CdS/SSS and CuOs/CdS/SSS, the presence of Cu+ and Cu2+ can be associated to oxidation caused by exposure to air (Fig. 1g, h and Supplementary Fig. S9a, b). The Os 4 f spectrum shows an oxidation state at 52.6 and 56.6 eV, which suggests surface oxidation of the photoelectrodes due to air exposure (Fig. 1i and Supplementary Fig. S9c). Energy dispersive X-ray spectroscopy (EDX) elemental mappings obtained from the cross-sections of CuOs/CdS/SSS exhibit that Cu and Os elements are distributed on the surface of the semiconductor, and Se is detected at the bottom of the film with a thickness of around 300 nm (Fig. 1f and Supplementary Figs. S10-S12). The band gaps of the pristine TiO2, CdS, and Sb2(S,Se)3 based on the absorption edges of the UV-vis spectra are 3.2, 2.55, and 1.75 eV, respectively (Supplementary Fig. S13). Ultraviolet photoelectron spectroscopy determines the energy band structure of the photoelectrodes (Supplementary Fig. S14). The layered heterostructure of TiO2, CdS, and Sb2(S,Se)3 result in a series of step like conduction band shifts (Supplementary Fig. S15), effectively suppressing interface charge carrier recombination and promoting charge transfer.

PEC NO3RR performance

We measured the PEC NO3RR performance of the photocathodes in an H-cell in 5 mM H2SO4 and 0.1 M KNO3 (pH=2) under AM 1.5 G illumination without iR correction. As shown in Fig. 2a, no evident photocurrent density for the photocathodes can be observed under dark conditions. Under one sun illumination, the pristine SSS shows a low photocurrent density of −1.57 mA cm−2 at 0 VRHE. CdS/SSS and CuOs/CdS/SSS display enhanced photocurrent densities under tested potential range, −3.37 mA cm−2 and −5.6 mA cm−2 obtained at 0 VRHE, respectively. Cu/CdS/SSS exhibits a similar photocurrent density with the CuOs/CdS/SSS at the potential range from 0.4 to 0.8 VRHE. Importantly, the onset potentials of Cu/CdS/SSS and CuOs/CdS/SSS are considerably shifted to the positive values of 0.84 VRHE and 0.86 VRHE, respectively, which are lower than those of SSS (0.42 VRHE) and CdS/SSS (0.63 VRHE) (Supplementary Fig. S16). This proves that the decoration of Cu or CuOs cocatalyst facilitates the nitrate conversion. The linear sweep voltammetry (LSV) curves of all photocathodes in the absence of NO3− show the lower photoresponses (Supplementary Fig. S17) in comparison to the photocathodes in the presence of NO3−, which denotes the positive PEC NO3RR activity of the photocathodes. Note that CuOs/CdS/SSS reaches a photocurrent density of −0.26 mA cm−2 at 0.1 VRHE compared to the Cu/CdS/SSS (−0.17 mA cm−2) in the electrolyte without the addition of NO3−. The increase in hydrogen evolution reaction (HER) activity of CuOs/CdS/SSS could be correlated with the ability of Os cocatalyst to adsorb hydrogen protons.

a J-V curves in 0.1 M KNO3 and 10 mM H2SO4. b NH4+ FEs, c yields, and d selectivities. The error bar represents the standard deviation of values calculated from three independent samples. e NH4+ FEs and yields of CuOs/CdS/SSS in various NO3− concentrations at 0.6 VRHE. f Calibration curves for 15NH4+ detection using 1H NMR. Inset upper left: comparison of the ammonia yields and FEs over CuOs/CdS/SSS quantified by the UV−Vis spectra and 1H NMR. Inset bottom right: 1H NMR spectra before and after 15NO3RR reaction. g I-t plots and related FEs on CuOs/CdS/SSS. h FEs and yields during cycle stability measurement on CuOs/CdS/SSS. Each 30 min was taken as one cycle, and fresh electrolyte was replaced in each cycle. i Charge transfer rate constants, j charge recombination rate constants, and k electrochemical impedance spectroscopy for the samples. Z’ and Z” represent as the real and imaginary parts of the Nyquist function, respectively. Source data are provided as a Source Data file.

Faradaic efficiencies (FEs) and ammonia yields were evaluated through an indophenol blue approach (Supplementary Fig. S18)17. As displayed in Fig. 2b, CdS/SSS exhibits an ammonia FE of 35.6% at 0.1 VRHE, and FE decreases as the potential shifts to the positive direction, indicating that its slow charge carrier dynamics impedes the conversion of NO3- to NH4+. Although CuOs/CdS/SSS and Cu/CdS/SSS display a similar photoresponse (Fig. 2a), there is a noticeable difference in ammonia FE. Cu/CdS/SSS has an FE of 70.4% at 0.1 VRHE, accompanied by a decrease with potential. In contrast, CuOs/CdS/SSS depicts an averaged ammonia FE of ~90% over the potential range from 0.1 to 0.8 VRHE, reaching a maximum value of 96.98% at 0.6 VRHE. The partial photocurrent density of CuOs/CdS/SSS for NH4+ synthesis (JNH3) is −4.28 mA cm−2 at 0.1 VRHE (Supplementary Fig. S19), almost consistent with the LSV curve (Fig. 2a). This high FE on CuOs/CdS/SSS can be attributed to distinct PEC NO3RR behaviors between Cu/CdS/SSS and Os/CdS/SSS, in which Os/CdS/SSS has shown enhanced FEs with increasing the applied potential owing to facile PEC NO3RR kinetics on the Os sites (Supplementary Figs. S20 and S21). In Fig. 2c, CuOs/CdS/SSS displays the highest NH4+ yield among these photocathodes, reaching 19.87 μmol h−1 cm−2 at 0.1 VRHE, which is higher than the Cu/CdS/SSS (15.10 μmol h−1 cm−2) and CdS/SSS (2.25 μmol h−1 cm−2). CuOs/CdS/SSS exhibits a maximum NH4+ selectivity of ~98% (Fig. 2d), notably higher than Cu/CdS/SSS (55.8%) and CdS/SSS (38.9%). These results suggest the improved PEC NO3RR kinetics on the sulfide-based photocathodes by the deposition of CuOs catalyst. In addition, NH4+ yield and FEs are also influenced by the concentration of nitrate sources. CuOs/CdS/SSS shows that ammonia yield raises from 1.18 to 5.67 μmol h−1 cm−2 with an average FE over 96% as the NO3- concentration increases from 10 to 200 mM (Fig. 2e). This indicates that the photoelectrode could maintain high selectivity of active hydrogen in NO3RR process over a wide range of nitrate concentration, enabling efficient intermediate hydrogeneration25.

We also compared the electrocatalytic properties of the Cu and CuOs catalysts (Supplementary Fig. S22). Cu and CuOs catalysts exhibit comparable current densities in the LSV curves. Cu shows a FE of 37.5% at 0.2 VRHE and its FE gradually increases to 72.4% at −0.2 VRHE, while CuOs maintains an average FE of ~90% in the potential range from −0.2 to 0.2 VRHE. Ammonia selectivity has demonstrated that CuOs achieves high selectivity at more negative potentials, reaching a selectivity of 95% with a yield of 2.1 mmol h−1 cm−2 at −0.2 VRHE. Cu catalyst displays inferior ammonia selectivity compared to CuOs, consistent with the results on the CuOs/CdS/SSS for PEC NO3RR. The electrocatalytic NO3RR is operated continuously for 24 h at 140 mA cm−2 without obvious performance degradation, indicating a stable property of the catalyst toward NO3RR.

NO2- as the main by-product seriously influences the hydrogenation process of NH4+ reduction, and we thus examined the PEC NO2- performances for the corresponding photocathodes (Supplementary Fig. S23). Except for CdS/SSS, Cu/CdS/SSS produces a large amount of NO2− at the measured potentials. To confirm the origin of NH4+ and the accuracy of the ammonia yield, we analyzed the N source in NH4+ by nuclear magnetic resonance (NMR) spectroscopy using isotopically labeled N15O3− (Fig. 2f and Supplementary Fig. S24). No characteristic peaks of N15H4+ are detected in the fresh electrolyte before NO3RR measurement (bottom right as illustration in inset of Fig. 2f). After the reaction, the typical 1H NMR double peaks corresponding to the N15H4+ are observed in the electrolyte, suggesting that the detected N15H4+ is derived from N15O3- reduction rather than from environmental N contamination. The yield and FE of NH4+ determined by 1H NMR are consistent with the colorimetric method, which verifies the reliability of the experimental results (upper left as illustration in inset of Fig. 2f). The catalytic activity and product yield of CuOs/CdS/SSS were further investigated during a long-term operation. The photocathode exhibits stable photocurrent densities at 0.6 and 0.4 VRHE for 6 h, and its FEs remain an average value of 93% and an accumulated yield of 78.8 μmol cm−2 during 12 h (Fig. 2g and Supplementary Fig. S25). Furthermore, the sample maintains stable ammonia yields and FEs in 20-cycle testing (Fig. 2h), suggesting the stable property of the photocathode toward PEC NO3RR.

We employed intensity-modulated photocurrent spectroscopy (IMPS) to determine the photocathode’s charge transfer rate and charge recombination rate. The rate constant of the maximum phase shift at the apex of the semicircle in the third quadrant represents charge transfer rate (Ktran) and charge recombination rate (Krec) (Supplementary Fig. S26). The semicircles in the second and three quadrants of IMPS plots reflect the competition between interfacial charge carrier transfer and recombination, and the relation of charge carrier and relaxation in the photoelectrodes26. The charge transfer efficiency [ktrans/(ktrans+krec)] is obtained by calculating the steady-state and instantaneous photocurrent densities. In the potential range of 0.6 to 0 VRHE, the surface recombination of Cu/CdS/SSS and CuOs/CdS/SSS are completely suppressed (Supplementary Fig. S27). Also, in conjunction with the frequency at the maximum imaginary value in the IMPS plot, we analysed the rate constants (ktrans+krec) for charge transfer (ktrans) and recombination (krec). The trend of ktrans is CuOs/CdS/SSS ≈ Cu/CdS/SSS > CdS/SSS (Fig. 2i, j), consistent with the above PEC activities, indicating that the photocarriers can be rapidly transferred from semiconductor to the surface reactions for CuOs/CdS/SSS or Cu/CdS/SSS. The surface co-catalyst promotes the release of photogenerated charge to the reactants by lowering the potential barrier of NO3RR. Moreover, CuOs/CdS/SSS has shown the highest electrochemical active surface area (Supplementary Fig. S28) and the lowest resistance (Fig. 2k) among these photocathodes.

PEC GOR performance of Ru-Bi2O3/TiO2 photoanode

Recently, the PEC oxidation of glycerol (GOR) to dihydroxyacetone (DHA) has received increasing attention. TiO2 exhibits inherent advantages, including stability in acidic media and a favorable onset potential, making it particularly suitable for integration with the present photocathode. Although the wide bandgap and the limited light absorption capacity of TiO2 limit its theoretical photocurrent density, we synthesized the TiO2 photoanode with the decoration of Ru doped Bi2O3 cocatalyst (noted as Ru-Bi2O3/TiO2) since Bi2O3 can enhance the visible light absorption of TiO219. XRD pattern confirms the crystalline structure of anatase TiO2 (JCPDS No.21-1276) (Supplementary Fig. S29). SEM and TEM images exhibit a one-dimensional nanorod structure of TiO2 (Fig. 3a and Supplementary Fig. S30). The nanoparticles with a size of 40-50 nm are covered on the top surface of sample (Fig. 3b, c), with a d-spacing of 0.316 nm corresponding to the (201) plane of Bi2O3 (Fig. 3d and Supplementary Fig. S31). The Bi and Ru elements are also reflected by the Bi 4 f and Ru 3 d XPS peaks (Supplementary Fig. S32). TEM elemental mappings exhibit Bi and Ru species decorated on the TiO2 nanorod (Fig. 3e).

a, b SEM images of (a) TiO2 and (b) Ru-Bi2O3/TiO2. c, d TEM and HRTEM images of Ru-Bi2O3/TiO2. e EDS mappings of Ru-Bi2O3/TiO2. Inset shows the related TEM image. f J-V curves of TiO2 and Ru-Bi2O3/TiO2 in 0.5 M Na2SO4 with or without 0.1 M glycerol (pH = 2) under AM 1.5 G illumination. g FEs of TiO2 and Ru-Bi2O3/TiO2 at 0.6 VRHE. h DHA selectivities and yields over TiO2 and Ru-Bi2O3/TiO2 at various potentials. i FEs of Ru-Bi2O3/TiO2 at various potentials. The error bar represents the standard deviation of values calculated from three independent samples. j I-t curve and FEs over Ru-Bi2O3/TiO2 at 1.2 VRHE for 20 h under AM 1.5 G illumination. Source data are provided as a Source Data file.

We next compared the LSV curves of TiO2 and Ru-Bi2O3/TiO2 for PEC GOR in 0.5 M Na2SO4 (pH=2, adjusted by H2SO4) with or without 0.1 M aqueous glycerol solution under AM 1.5 G illumination. Both TiO2 and Ru-Bi2O3/TiO2 exhibit higher photoresponses in the presence of glycerol than those in the absence of glycerol (Fig. 3f), suggesting a lower reaction energy barrier for glycerol oxidation than water oxidation. Ru-Bi2O3/TiO2 exhibits an enhanced GOR performance compared to the pristine TiO2, with a photocurrent density of 2.81 mA cm−2 at 1.2 VRHE. Ru-Bi2O3 can serve as an efficient photosensitizer to enlarge the optical absorption to the visible light region19. Fig. 3g and Supplementary Fig. S33 show the FEs over TiO2 and Ru-Bi2O3/TiO2 within 1 h quantitatively analyzed by high-performance liquid chromatography. TiO2 produces a large amount of formic acid (FA) with a FE of 23.1% and a selectivity of 41.3% at 0.6 VRHE (Supplementary Fig. S34). After the Ru-Bi2O3 deposition, the FE of FA product decreases, while C3 products, including DHA and glyceraldehyde (GLD) increase, especially for the considerable increment of DHA with a FE of 42.9% and a selectivity of 59.2% at 0.6 VRHE. For the total C3 products, including DHA, glyceric acid (GLA), and GLD, Ru-Bi2O3/TiO2 has yielded a higher total FE of 62.9% than TiO2 (26.2%) at 0.6 VRHE (Supplementary Fig. S35). Figure 3h depicts the DHA yields and selectivities for the Ru-Bi2O3/TiO2 under a wide potential window of 0.4 ~ 1.2 VRHE. The increase in potential leads to a decrease in DHA selectivity, while the DHA yield gradually increases owing to the increase in photocurrent density, reaching a maximum value of 18.84 μmol cm−2 h−1 at 0.8 VRHE. We also evaluated the FEs and yields of products for the Ru-Bi2O3/TiO2 at various potentials (Fig. 3i and Supplementary Fig. S36). As the potential increases, the FE of C1 product (FA) increases, while the FEs of C3 products (DHA, GLA, GLD) decrease. In addition, the overall FEs for GOR gradually decrease with increasing the potential, from 81.13% (0.4 VRHE) to 70.25% (1.2 VRHE) (Supplementary Fig. S37). The photocurrent density of Ru-Bi2O3/TiO2 remains unchanged at 1.2 VRHE over 20 h, accompanying with the relative stable FE values (Fig. 3j). It is generally considered that a high DHA selectivity would be difficult to obtain under glycerol conversion owing to over-oxidation of DHA via C-C bond cleavage27,28. In this work, the Ru-Bi2O3/TiO2 photoanode can offer high selectivity of DHA.

Unassisted NH3 production with simultaneous glycerol oxidation

Since the intersection of working curves on both photocathode and photoanode in a three-electrode system displays the ability to realize unbiassed operation, 1.65 mA cm−2 obtained at 0.51 VRHE (Fig. 4a), we integrated CuOs/CdS/SSS photocathode with Ru-Bi2O3/TiO2 photoanode to realize unassisted NH3 and C3 production. The system consisted of two photoelectrodes connected by a copper wire in a two-compartment reactor, as depicted in Fig. 4b. The unassisted PEC system on the CuOs/CdS/SSS ‖ Ru-Bi2O3/TiO2 shows the stability with the photoresponse of ~1.4 mA cm−2 for 10 h under AM 1.5 G illumination (Fig. 4c). The total FEs of GOR remain above 77%, and the FEs of PEC NO3RR show an average value exceeding 90% during 10 h testing (Fig. 4d). The yields of NH3 and C3 (DHA, GLD, and GLA) products increase with time, and the accumulated yields of NH3 and C3 reach 55.12 μmol cm−2 and 132.52 μmol cm−2 after 10 h (Fig. 4e), respectively. We also prepared the photoelectrodes with a large-size of 6 cm2. The coupling system exhibits a high current of ~6.55 mA with a stable operation of over 25 h (Supplementary Fig. 38). This provides a potential application of unbiased PEC synthesis for directly converting solar energy into high-value-added chemicals.

a LSV curves for CuOs/CdS/SSS as the photocathode for NO3RR and Ru-Bi2O3/TiO2 as the photoanode for GOR under AM 1.5 G illumination. b Schematic of a PEC cell for unbiased production of NH3 and DHA. c Unbiased stability for the CuOs/CdS/SSS ‖ Ru-Bi2O3/TiO2 device. d FEs of products in unbiased system under cyclic testing. e Yields of DHA, GLD, GLA, and NH3 products over time. f Economic values of the unbiassed system under optimal conditions. Source data are provided as a Source Data file.

Moreover, we evaluated the economic viability of the PEC device in the unbiased system based on the market price of the products (Fig. 4f and Supplementary Tables S1–S2). The unbiassed system produces 112.08 mmol of DHA per hour under light illumination per square meter, and achieves 60.7 mmol of conversion from nitrate to NH3. The product revenues are $151 × 10−2, and the raw materials have increased in value by nearly 624.5 times their original value. The system drives the overall reaction only by solar without other energy consumption, producing high-value-added chemicals. We also performed a preliminary economic analysis to quantify the economic and the competitive edge analysis. Benefits of using this technology in a modeled 50 m2 each of anode and cathode. The methodology used is an ideal analysis and does not take into account the cost of associated operating, sales, and equipment depreciation. When only considering the values of the produced chemicals in their average price (Supplementary Table S1) and the operating costs, the proposed process shows a potential to be profitable up to about $117,000 per year for this modeled plant (Supplementary Table S2). The largest revenue and cost come from the produced DHA, catalyst preparation, and product separation, respectively. The annual consumption of glycerol and the annual production of DHA are about 2.45 ton and 1.47 ton, respectively.

Mechanistic analysis

The on-line differential electrochemical mass spectrometry (DEMS) and in situ Fourier transform infrared spectroscopy (FTIR) were conducted to explore the underlying reaction mechanism and detect the intermediate species generated on the photocathodes during PEC NO3RR under light illumination. Figure 5a display the mass-to-charge ratio (m/z) signals on the CuOs/CdS/SSS recorded as a function of time while performing 5 tests at intervals (each test involves a i-t scan at 0.6 VRHE). It can be seen that m/z signals at 46, 30, 31, 33, and 17 are observed, corresponding to the NO2, NO, NOH, NH2OH, and NH3, respectively11. Based on in situ FTIR measurements in Fig. 5b and c, the peak at ~1095 cm–1 can be associated to the NO3- reactant in the electrolyte. At 0.8 VRHE, close to the onset potential of LSV curve, the peak of *NO2 appears at ~1241 cm–129,30,31, representing the formation of nitrite on the Cu/CdS/SSS from nitrate reduction. This peak intensity increases with increasing the applied potential to a more negative range. The peak related to *NH appears at 1432 cm−1, and the characteristic *NOH peak appears at 1365 cm−129,30,31. With the potential moving from 0.8 VRHE to 0.3 VRHE, the small peak at 1125 cm–1 can be observed, ascribing to -N-O- stretching vibration of hydroxylamine (NH2OH), which is a key intermediate for NH3 formation. Note that these hydrogenation intermediates appear at more positive potentials on CuOs/CdS/SSS compared to the Cu/CdS/SSS, confirming the rapid hydrogenation kinetics of CuOs catalysts for nitrogen-oxygen intermediates. Besides, a series of weak peak related to the *NO signal is shown at ~1589 cm−1 on Cu/CdS/SSS, while these are not be observed on CuOs/CdS/SSS. Instead, the peak at 1645 cm−1 attributed to *H2O can be observed on CuOs/CdS/SSS, which comes from the oscillation of the H-O bond during the *H2O dissociation process12, implying an effective detachment of *H from H2O and facilitating the NH3 production through transferring to nitrogen-oxygen intermediates.

a DEMS measurements of PEC NO3RR over CuOs/CdS/SSS under light illumination. b, c ATR-FTIR spectra for b Cu/CdS/SSS and c CuOs/CdS/SSS under light illumination. d DMPO-involved EPR spectra of Cu/CdS/SSS, Os/CdS/SSS, and CuOs/CdS/SSS without NO3− under light illumination. e DMPO-involved EPR spectra of CuOs/CdS/SSS without or with NO3− under light illumination (each line is collected after 10 min PEC reaction at 0 VRHE). f In-situ Raman spectroscopy of NO3RR on Cu and CuOs electrocatalysts. g FTIR spectra of isopropanol adsorbed on TiO2 and Ru-Bi2O3/TiO2. Inset shows the related model. h In-situ FTIR spectra of the dynamic oxidation process of isopropanol on Ru-Bi2O3/TiO2 under light illumination for 60 min. Source data are provided as a Source Data file.

We also examined in-situ Raman spectra of the Cu or CuOs electrocatalysts toward NO3RR. As shown in Fig. 5f, all the catalysts exhibit two Raman bands within the potential range of 0.4 to −0.1 VRHE. Namely, the vibration mode of aqueous NO3– centers at 1049 cm–1, and the peak contributed by NO3– adsorption (*NO3–) centers at 1357 cm−18. These indicate the strong adsorption ability of NO3– on the surfaces of Cu and CuOs for the comparable NO3RR activity of Cu-based catalysts. As the potential decreases, the Raman band at 1204 cm–1 associated to the NO2 adsorption (*NO2) appears at 0.3 VRHE, indicating that *NO2 intermediates are directly introduced into ammonia production at this potential. This peak gradually decreases with decreasing the potential, and then disappears at −0.1 VRHE for CuOs. In addition, the Raman band at 1140 cm−1 associated to the ν2(NH3) appears simultaneously at 0.3 VRHE with the *NO2 signal on the CuOs catalyst, where the ν2(NH3) peak appears at 0.1 VRHE on the Cu catalyst. This indicates that adding Os can initiate the reaction process of the Cu catalyst from NO2 to NH3 at a lower potential. To assess the amount of H radical (*H) produced or consumed during PEC NO3RR, electron paramagnetic resonance (EPR) analysis was implemented using 5,5-dimethyl-1-pyrroline N-oxide (DMPO) as the radical trapping reagent32,33. In the absence of nitrate (Fig. 5d), Os/CdS/SSS and CuOs/CdS/SSS exhibit similar but stronger DMPO-*H signals than Cu/CdS/SSS (nine characteristic peak intensity ratios of 1:1:2:1:2:1:2:1:1), denoting that *H preferentially adsorbs onto Os or CuOs sites compared to Cu sites. In the presence of nitrate (Fig. 5e), the DMPO-*H signal is barely detectable on CuOs/CdS/SSS. This evidences that the generated *H at the CuOs/CdS/SSS surface is rapidly consumed in the hydrogenation of surface-active nitrogen-containing intermediates, producing enhanced ammonia yields and FEs.

Moreover, Fourier transform infrared (FTIR) spectroscopy was implemented to investigate the role of Ru-Bi2O3 on TiO2 for PEC GOR (Fig. 5g). Isopropanol and n-propanol were used to distinguish the adsorption of middle and terminal hydroxyls on the catalyst surface during glycerol oxidation. The bands at 2979 and 2885 cm−1 correspond to the methyl symmetric (ν (CH3)) and asymmetric (ν (CH2)) stretching modes, respectively. The adsorption of isopropanol on TiO2 or Ru-Bi2O3/TiO2 leads to a wavenumber shift to the negative shift in the C-O stretching mode (ν (C-O)) from 1164 to 1162 or 1158 cm−1. This implies the bond breaking owing to the adsorption of the hydroxyl group of isopropanol to the surface on TiO2 or Ru-Bi2O3/TiO2, especially that Ru-Bi2O3 is more conductive to the adsorption of hydroxyl groups of glycerol17. On the contrary, for n-propanol adsorption (Supplementary Fig. S39a), the characteristic ν(C–O) band shifts to a lower wavenumber on TiO2, greater than that on Ru-Bi2O3/TiO2, suggesting that Ru-Bi2O3/TiO2 has weaker adsorption for n-propanol. TiO2 prefers to adsorb the terminal hydroxyl position, while Ru-Bi2O3/TiO2 tends to adsorb the intermediate hydroxyl group, providing an extremely favourable prerequisite for the generation of intermediate ketone groups in dihydroxyacetone. Moreover, by simulating and analyzing the adsorption of ketone-based products on the electrode using acetone (Supplementary Fig. S39b), Ru-Bi2O3/TiO2 has a weakened tendency to adsorb acetone compared to TiO2, which means that DHA is more easily desorbed on Ru-Bi2O3/TiO2 rather than further oxidization. The adsorption process of isopropanol on Ru-Bi2O3/TiO2 was further examined by in situ FTIR under illumination. As shown in Fig. 5h, the intensities of two signals at 1731 and 1347 cm–1 gradually increase over Ru-Bi2O3/TiO2 after adsorbing isopropanol, which corresponds to the formation of the carbonyl group (C═O) and carboxyl group (O═C–O)18. The appearance of the C═O bond originals from the formation of acetone by isopropanol oxidation, and the O═C–O bond is due to the C–C cleavage of isopropanol. Among them, the weak O═C-O bond signal indicates that C-C cleavage is inhibited, demonstrating high selectivity of C3 products on Ru-Bi2O3/TiO2. In contrast, the high intensity of C═O band implies high selectivity of Ru-Bi2O3/TiO2 towards ketone species.

DFT calculations

Combining DEMS analysis and in-situ characterization, we proposed a reaction pathway for NO3RR and calculated the Gibbs free energy of each intermediate. The process involves sequential deoxygenation steps (*NO3 → *NO2 → *NO), followed by hydrogenation (*NO → *NOH → *NH2OH → *NH3) and final NH3 desorption. The free energy profiles of all intermediates on Cu/CdS/SSS, Os/CdS/SSS, and CuOs/CdS/SSS were systematically evaluated in Fig. 6a. Notably, although Os incorporation has minimal impact on deoxygenation, it lowers the thermodynamic barrier for hydrogenation. Specifically, on Cu-modified surfaces, *NO hydrogenation to NOH proceeds via a proton-coupled electron transfer mechanism (*NO + H2O + e− → *NOH + OH-) due to the negligible *H coverage on Cu, requiring an energy input of 0.32 eV. In contrast, for CuOs/CdS/SSS, the reaction follows an alternative pathway where *H adsorbed on Os sites directly participates in NOH formation (*NO + *H → *NOH) through in situ hydrogen transfer, bypassing electron transfer and releasing 0.27 eV. This highlights the critical role of Os in facilitating energetically favorable hydrogenation11. Therefore, we calculated HER energy barrier of the Cu, Os, and CuOs deposited electrodes (Fig. 6b). When Os was induced, the activation energy barrier of the catalyst for hydrogen can be improved, confirming the high surface *H density caused by additional Os. We further investigated the optimal active site and the promoting effect of Os using electronic structure calculations. Analyzing the pdos and d-band center, Os incorporation adjusts the d-band center from −2.57 to −2.41 (Fig. 6c). This optimizes the ability to capture reaction intermediates and facilitate bond formation, therefore improving catalytic activity34. Charge density analysis shows that the charge transfers of Cu/CdS/SSS, Os/CdS/SSS, and CuOs/CdS/SSS to NO3− are 1.12, 0.83, and 1.05 e−, respectively (Fig. 6d), indicating that the adsorption of nitrate on Cu is much stronger than that of Os35. In short, Cu atoms as the main adsorption and active center are responsible for initiating the reduction reaction and most of the main activity, while the modification of Os mainly contributes to the provision of *H protons, thereby promoting the selectivity of NH3.

a, b Free energy diagrams (FED) for a NO3RR and b HER from active sites over Cu/CdS/SSS, Os/CdS/SSS, and CuOs/CdS/SSS. Inset of a shows the modeling of the adsorption of the relevant intermediates on the catalysts. c Corresponding partial density of states (pDOS). d The stick model and the calculation of differential charge density. Source data are provided as a Source Data file. The corresponding atomic coordinates are contained in Supplementary Data 1.

Discussion

In summary, we developed a high-performance PEC cell using Sb2(S,Se)3 photocathode with the deposition of copper-osmium electrocatalyst for selective PEC NO3RR towards efficient ammonia products. The photocathode reaches a photocurrent density of 5.6 mA cm−2 at 0 VRHE with a low onset potential of 0.86 VRHE, and especially, it exhibits much higher performance in the low overpotential compared to the traditional photoelectrodes reported. Besides, we employed Ru-Bi2O3 decorated on the TiO2 photoanode for glycerol oxidation reaction, requiring a low onset potential of 0.3 VRHE to enable bias-free operation. The selective CuOs and Ru-Bi2O3 cocatalysts provide improved stability and selectivity with low onset potentials in acid electrolytes. The CuOs/CdS/SSS photocathode coupled with Ru-Bi2O3/TiO2 photoanode show a FE over 90% for NH3 and a FE above 77% towards GOR under AM 1.5 G illumination without applying any potential. Furthermore, the large-sized photoelectrodes maintain a stability for 24 h without noticeable degradation. This work motivates development for producing value-added products from low value/waste compounds.

Methods

Material preparation

Preparation of CuOs/CdS/SSS, Cu/CdS/SSS, and Os/CdS/SSS photocathodes

1.33 g of potassium antimonyl tartrate (Innochem, AR) and 1.98 g of sodium thiosulfate pentahydrate (Innochem, 99%) were dissolved in 100 mL deionized (DI) water. Subsequently, 20 mL solution was transferred to a 30 mL reactor. The fluorine-doped tin oxide (FTO) substrate (1 × 2 cm) was immersed in precursor and reacted at 135 °C for 1 h to form a seed layer on the substrate. Next, 1.33 g of potassium antimony tartrate, 1.98 g of sodium thiosulfate pentahydrate, and 0.061 g of selenourea (Alfa, 99%) were dissolved in 100 mL DI water at 75 °C for second hydrothermal approach at 135 °C for 4 h. The film was heated at 350 °C for 20 min under a nitrogen atmosphere to form the Sb2(S,Se)3 photocathode. 0.114 g of thiourea (Aladdin, 99%), 0.063 g of cadmium sulfate hydrate (Innochem, 99 + %), and 6 mL of ammonia solution (25%) were added to 20 mL DI water. The prepared Sb2(S,Se)3 was soaked in above precursor at 65 °C to deposit the CdS layer, followed by annealing at 200 °C for 1 h to form CdS/Sb2(S,Se)3. TiO2 passivation layer was then deposited on the CdS/Sb2(S,Se)3 through an atomic layer deposition (ALD) at 120 °C using tetrakis(dimethylamino) titanium and H2O. A total of 600 ALD cycles were performed, following by annealing at 200 °C for 1 h in Ar, and the above prepared sample was noted as CdS/SSS. For the cocatalyst decoration, CuO powder was reacted completely with NaBH4 (Innochem, GR), collected by centrifugation and vacuum dried, and subjected to 3 h of grinding to obtain Cu powder. The Cu powder was soaked in an aqueous solution containing 1 mM OsCl3 (Thermo scientific, 99.99%) and 1 M HCl to undergo displacement reaction, and the obtained CuOs powder was loaded onto the CdS/SSS surface by dispersing it in a mixed solution of ethanol and isopropanol, followed by annealing at 250 °C in Ar to obtain CuOs/CdS/SSS. All catalysts were loaded at 200 μg/cm2.

For the Cu/CdS/SSS photocathode, its preparation is similar to the CuOs/CdS/SSS, only removing 1 mM OsCl and 1 M HCl. Besides, 14.83 mg OsCl3 was ultrasonically dispersed in 1 mL DI water, followed by mixing with 5 mL of 10 mM NaBH4 aqueous solution to obtained Os powder. Os powder was loaded onto the surface of CdS/SSS, followed by annealing at 250 °C in Ar to obtain Os/CdS/SSS.

Preparation of TiO2 and Ru-Bi2O3/TiO2 photoanodes

A clean FTO was placed in a mixed solution of 1 mL tetrabutyl titanate (Aladdin, 99%), 30 mL DI water, and 30 mL HCl (Sinopharm, 36 ~ 38 wt.%). TiO2 photoanode was obtained through a hydrothermal approach at 150 °C for 12 h, followed by air annealing at 450 °C for 1 h. Ru-Bi2O3 cocatalyst was electrodeposited on the surface of TiO2 at −0.7 VAgCl, followed by air annealing at 450 °C for 1 h to obtain Ru-Bi2O3/TiO2. The deposition solution was 0.2 mM bismuth nitrate pentahydrate (Innochem, 99%) and 2 μM ruthenium chloride (Innochem, 99.5%), and the solvent is a mixture of water and ethylene glycol in a volume ratio of 1:2.

Photoelectrochemical measurements

The PEC NO3RR measurements were carried out in a standard three-electrode configuration connected to the 760E electrochemical workstation in a H-cell. The Ag/AgCl and platinum foil were used as reference electrode and counter electrode, respectively. 0.1 M KNO3 was used as the electrolyte and the pH was adjusted to 2 by sulfuric acid, which was stored at room temperature. All photoelectrodes were encapsulated through a light shielding mask and the exposed area of the photoelectrodes was controlled to be 1 × 1 cm2. Before testing, Ar was used to blow the electrolyte for 20 min to eliminate the influence of water-soluble oxygen and CO2. Before each independent test, the optical power was calibrated to align with the standard AM 1.5 G illumination (100 mW cm−2). LSV scans were performed at 10 mV/S without iR compensation. All potentials were converted to the reversible hydrogen electrode (RHE) reference scale by the equation E (V vs. RHE) = E (V vs. Ag/AgCl) + 0.0591 × pH + 0.197. During PEC NO3RR, the working electrode was measured by i-t curves for 1 h at various applied potentials under AM 1.5 G illumination. Electrochemical impedance spectroscopy measurements were conducted in the frequency range of 100 kHz to 0.1 Hz at 0 V (vs. RHE) under one sun illumination. PEC glycerol oxidation reactions were conducted inside a sealed H-type cell over a 1 h duration in 0.1 M glycerol + 0.5 M Na2SO4 with the pH 2 by adding 0.5 M H2SO4. A Nafion membrane was used to separate the anode and cathode chambers. For the cycling experiment, each 30 min were taken as a cycle, and fresh electrolyte was replaced in each cycle. All the measurements were performed on independent three samples under controlled conditions (exposure area: 1 cm²).

DFT calculation

All first-principles calculations were conducted within the density functional theory (DFT) framework using Vienna Ab-initio Simulation Package (VASP)36,37. The Perde–Burke–Ernzerhof (PBE) form of the generalized gradient approximation (GGA) was utilized to describe exchange-correlation interactions38. To accurately characterize the localized d-electron behavior of Ti atoms, the DFT + U method was applied, with the on-site Coulomb interaction parameter (U) set to 4 eV39. A plane-wave basis set with a kinetic energy cutoff of 500 eV was employed. Structural optimizations were considered converged when the maximum force on each atom was below 5 × 10−3 eV/Å, and electronic self-consistent field (SCF) iterations were deemed converged when the total energy change between steps was less than 10-5 eV40. Dispersion interactions were incorporated via the Grimme DFT-D3 method as a post-DFT correction. A vacuum layer exceeding 15 Å was introduced along the surface normal to eliminate spurious interactions between periodic images. Thermodynamic properties, such as the Gibbs free energy change (ΔG) for each elementary step, were evaluated using computational hydrogen electrode (CHE) model. Specifically, ΔG was calculated via the relation ΔG = ΔE + ΔZPE - TΔS, where ΔE is the reaction energy from DFT calculations, ΔZPE represents the zero-point energy variation, and ΔS is the entropy difference between products and reactants at 298.15 K41.

In the modeling work, the Cu (001), Os (001), and TiO2 (001) basal planes were selected as the basic structural units to construct Cu/TiO2 and Os/TiO2 heterostructures, respectively. The CuOs/TiO2 heterojunction was developed by introducing Os through doping. According to the characteristics of different materials, differentiated supercell models were adopted: a 4 × 4 supercell for the Cu system, a 5 × 5 supercell for the Os system, and a 3 × 3 supercell for the TiO2, balancing computational accuracy and cost. Additionally, during the structure construction, three atomic layers were selected for each system, and a 15 Å vacuum layer was set. This vacuum layer design can effectively eliminate the mutual interference of adjacent images under periodic boundary conditions, ensuring the accuracy and reliability of the calculation results.

Product analysis

Ammonia was measued using an indophenol-blue method to determine NH4+ concentration. The 1 mL catholyte was collected, and then mixed with the following solution, 800 µL 1 M NaOH contained 5 wt% salicylic acid, 5 wt% sodium citrate, 200 µL 0.05 M NaClO, and 60 μL of 1 wt% sodium nitroferricyanide solution. The UV-Vis absorption spectra of the resultant solutions were performed at wavelength from 550 to 800 nm. The absorbance peak near 653 nm allowed the concentration of NH4+ to be calculated from the calibration of a standard solution containing an NH4+ concentration. 2 g p-aminoben zenesulfonamide was added to a solution composed of 25 mL DI water and 5 mL phosphoric acid, and then 0.1 g N-(1-naphthyl)-ethylened iamine dihydrochloride was added. The soution was diluted to 50 mL. We added 1 mL of cathode chamber liquid to 4 mL of DI water and 0.2 mL of color developer for 20 min, measured absorbance at 540 nm, and obtained standard curves through KNO2 electrolyte with various concentrations.

PEC glycerol oxidation was carried out within a sealed H-type cell for a duration of 1 h. 1 mL of the solution was withdrawn, subjecting to analysis using high-performance liquid chromatography (HPLC). The column was operated at 50 °C and eluted with 5 mM aqueous H2SO4. The eluent was delivered at a flow rate of 0.5 mL min−1.

The Faradaic efficiency can be obtained from the following formula:

Where e is the number of electrons (or holes) required to generate one product molecule, V is the volume of the electrolyte, C is the concentration of the product, N is Avogadro’s constant, Q is the quantity of electric charge, and n is the number of product molecules produce. The number of electrons required to generate an NH3 molecule is 8, while the number of holes required to generate DHA, GLA, GLD, GA, and FA are 2, 4, 2, 10/3, and 8/3, respectively.

The selectively is calculated using the following equations:

where nNH3 is the amount of NH3 produced, nNO3- is the amount of NO3- consumed, nDHA, nGLA, nGLD, nGA and nFA are the amount of DHA, GLA, GLD, GA, and FA produced, respectively.

The production rate is calculated using the following equation:

where V is the volume of reaction solution, t is the reaction time, A is the area of photoelectrode, and C is the concentration of product.

TEA Analysis

The Techno-Economic Analysis (TEA) was based on indoor PEC experimental data, simulated using a bias-free dual electrode system. The methodology used was an ideal analysis and does not take into account the cost of associated operating, sales, and equipment depreciation, when only considering the values of the produced chemicals in their average prices and the operating costs. The capital cost was calculated as the sum of the equipment purchase costs and corresponding installation costs. The operational cost was composed of electrode and energy costs, and product separation costs incurred during the operation of the facility. The values of all of the costs, as well as the sales prices of chemicals, were obtained from the benchmark study and market search (Supplementary Table 1)42,43. The economic performance was measured by the annual net income and payback period. A complete summary of facility operations, and equipment purchase cost for the TEA model could be found in Supplementary Tables 2-3.

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request. Source data are provided in this paper. Source data are provided with this paper.

References

Tayyebi, A. et al. Bias-free solar NH3 production by perovskite-based photocathode coupled to valorization of glycerol. Nat. Catal. 7, 510–521 (2024).

Chen, F.-Y. et al. Efficient conversion of low-concentration nitrate sources into ammonia on a Ru-dispersed Cu nanowire electrocatalyst. Nat. Nano. 17, 759–767 (2022).

Qi, Y. et al. Efficient overall water splitting of a suspended photocatalyst boosted by metal-support interaction. Joule 8, 193–203 (2024).

Qi, Y. et al. Unraveling of cocatalysts photodeposited selectively on facets of BiVO4 to boost solar water splitting. Nat. Commun. 13, 484 (2022).

Ren, S. et al. Enhanced charge-carrier dynamics and efficient photoelectrochemical nitrate-to-ammonia conversion on antimony sulfide-based photocathodes. Angew. Chem. Int. Ed. 63, e202409693 (2024).

Ren, S., Gao, R.-T., Nguyen, N. T. & Wang, L. Enhanced charge carrier dynamics on Sb2Se3 photocathodes for efficient photoelectrochemical nitrate reduction to ammonia. Angew. Chem. Int. Ed. 136, e202317414 (2024).

Ding, J. et al. Efficiently unbiased solar-to-ammonia conversion by photoelectrochemical Cu/C/Si-TiO2 tandems. Appl. Catal. B 345, 123735 (2024).

Gao, W. et al. Alloying of Cu with Ru enabling the relay catalysis for reduction of nitrate to ammonia. Adv. Mater. 35, 2202952 (2023).

Han, S. et al. Ultralow overpotential nitrate reduction to ammonia via a three-step relay mechanism. Nat. Catal. 6, 402–414 (2023).

Gao, R.-T. et al. Photoelectrochemical production of disinfectants from seawater. Nat. Sustain. 8, 672–681 (2025).

Liu, H. et al. Efficient electrochemical nitrate reduction to ammonia with copper-supported rhodium cluster and single-atom catalysts. Angew. Chem. Int. Ed. 61, e202202556 (2022).

Fang, J.-Y. et al. Ampere-level current density ammonia electrochemical synthesis using CuCo nanosheets simulating nitrite reductase bifunctional nature. Nat. Commun. 13, 7899 (2022).

Wang, F. et al. Frustrated Lewis pairs boosting photoelectrochemical nitrate reduction over ZnIn2S4/BiVO4 heterostructure. Chem. Eng. J. 450, 138260 (2022).

Kang, F. et al. Photoelectrochemical ethylene glycol oxidization coupled with hydrogen generation using metal oxide photoelectrodes. Angew. Chem. Int. Ed. 64, e202417648 (2024).

Jung, G. et al. Monolithically integrated BiVO4/Si tandem devices enabling unbiased photoelectrochemical water splitting. Adv. Energy Mater. 13, 2301235 (2023).

Wang, L., Guo, F., Ren, S., Gao, R.-T. & Wu, L. Unbiased photoelectrochemical H2O2 coupled to H2 production via dual Sb2S3-based photoelectrodes with ultralow onset potential. Angew. Chem. Int. Ed. 63, e202411305 (2024).

Zhou, S. et al. Engineering a kesterite-based photocathode for photoelectrochemical ammonia synthesis from NOx reduction. Adv. Mater. 34, 2201670 (2022).

Lu, Y. et al. Solar-driven highly selective conversion of glycerol to dihydroxyacetone using surface atom engineered BiVO4 photoanodes. Nat. Commun. 15, 5475 (2024).

Luo, L. et al. Selective photoelectrocatalytic glycerol oxidation to dihydroxyacetone via enhanced middle hydroxyl adsorption over a Bi2O3-incorporated catalyst. J. Am. Chem. Soc. 144, 7720–7730 (2022).

Kim, S., Oh, D. & Jang, J.-W. Unassisted photoelectrochemical H2O2 production with in situ glycerol valorization using α-Fe2O3. Nano Lett. 24, 5146–5153 (2024).

Han, C. et al. Nanostructured hybrid catalysts empower the artificial leaf for solar-driven ammonia production from nitrate. Energy Environ. Sci. 17, 5653–5665 (2024).

Xiao, Y. et al. Selective photoelectrochemical oxidation of glycerol to glyceric acid on (002) facets exposed WO3 nanosheets. Angew. Chem. Int. Ed. 136, e202319685 (2024).

Wang, L. et al. Modulating surface oxygen valence states via interfacial potential in BiVO4/CoOx/Au photoanode for enhanced selective photoelectrochemical oxidation of glycerol to dihydroxyacetone. Adv. Funct. Mater. 34, 2409349 (2024).

Lin, C. et al. Photo-electrochemical glycerol conversion over a mie scattering effect enhanced porous BiVO4 photoanode. Adv. Mater. 35, 2209955 (2023).

Carvalho, O. Q. et al. Role of electronic structure on nitrate reduction to ammonium: a periodic journey. J. Am. Chem. Soc. 144, 14809–14818 (2022).

Yu, F. et al. Fabrication and kinetic study of a ferrihydrite-modified BiVO4 photoanode. ACS Catal. 7, 1868–1874 (2017).

Liu, S.-S., Sun, K.-Q. & Xu, B.-Q. Specific selectivity of Au-catalyzed oxidation of glycerol and other C3-polyols in water without the presence of a base. ACS Catal. 4, 2226–2230 (2014).

Tateno, H. et al. Photoelectrochemical oxidation of glycerol to dihydroxyacetone over an acid-resistant Ta:BiVO4 photoanode. ACS Sustain. Chem. Eng. 10, 7586–7594 (2022).

Duca, M. et al. Selective catalytic reduction at quasi-perfect Pt(100) domains: a universal low-temperature pathway from nitrite to N2. J. Am. Chem. Soc. 133, 10928–10939 (2011).

Hu, Q. et al. Ammonia electrosynthesis from nitrate using a ruthenium–copper cocatalyst system: a full concentration range study. J. Am. Chem. Soc. 146, 668–676 (2024).

Pérez-Gallent, E., Figueiredo, M. C., Katsounaros, I. M. & Koper, T. M. Electrocatalytic reduction of nitrate on copper single crystals in acidic and alkaline solutions. Electrochim. Acta 227, 77–84 (2017).

Li, X., Shen, P., Li, X., Ma, D. & Chu, K. Sub-nm RuOx clusters on Pd metallene for synergistically enhanced nitrate electroreduction to ammonia. ACS Nano 17, 1081–1090 (2023).

Chen, K. et al. Single-atom Bi alloyed Pd metallene for nitrate electroreduction to ammonia. Adv. Funct. Mater. 33, 2209890 (2023).

Li, Y. et al. Mo−Ni-based heterojunction with fine-customized d-band centers for hydrogen production coupled with benzylamine electrooxidation in low alkaline medium. Angew. Chem. Int. Ed. 62, e202306640 (2023).

Lin, H. et al. Bi1-CuCo2O4 hollow carbon nanofibers boosts NH3 production from electrocatalytic nitrate reduction. Adv. Funct. Mater. 34, 2409696 (2024).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comp. Mater. Sci. 6, 15–50 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Perdew, J. P., Ernzerhof, M. & Burke, K. Rationale for mixing exact exchange with density functional approximations. J. Chem. Phys. 105, 9982–9985 (1996).

Grimme, S. Semiempirical GGA-type density functional constructed with a long-range dispersion correction. J. Comput. Chem. 27, 1787–1799 (2006).

Hasnat, M. A. et al. N. Dissimilar catalytic trails of nitrate reduction on Cu-modified Pt surface immobilized on H+ conducting solid polymer. J. Mol. Catal. A-Chem. 383, 243–248 (2014).

Tu, Q. et al. Electrocatalysis for chemical and fuel production: investigating climate change mitigation potential and economic feasibility. Environ. Sci. Technol. 55, 3240–3249 (2021).

Page, J. R., Manfredi, Z., Bliznakov, S. & Valla, J. A. Recent progress in electrochemical upgrading of bio-oil model compounds and bio-oils to renewable fuels and platform chemicals. Materials 16, 394 (2023).

Acknowledgements

The work was supported by the National Science and Technology Major Project (2022YFA1205200), the National Natural Science Foundations of China (22269016, 22479083, 22405138), the Group Project of Developing Inner Mongolia through Talents from the Talents Work Leading Group under the CPC Inner Mongolia Autonomous Regional Committee (2025TYL03), the Natural Science Foundations of Inner Mongolia Autonomous Regional (2024QN02012), and program for Young Talents of Science and Technology in Universities of Inner Mongolia Autonomous Region (Grant NJYT25001). N.T. Nguyen acknowledges NSERC and FRQNT for the financial support.

Author information

Authors and Affiliations

Contributions

L.M.W., L.W. and R.-T.G. proposed and supervised the project. X.G. performed the materials synthesis and PEC measurements. S.R., N.T.N. and H.C. assisted the data analysis. X.G. and R.-T.G. wrote the manuscript. L.M.W., L.W. and R.-T.G. revised the manuscript. All authors contributed to discussion and manuscript review.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no completing interests.

Peer review

Peer review information

Nature Communications thanks Sixto Gimenez, Ahmad Tayyebi and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Guo, X., Gao, RT., Ren, S. et al. Direct ammonia and dihydroxyacetone production in an unbiased photoelectrochemical cell. Nat Commun 16, 6220 (2025). https://doi.org/10.1038/s41467-025-61080-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-61080-x

This article is cited by

-

Photo-deposition of dual Ni(OH)2 and NixP cocatalysts on ZnIn2S4/ZnS for efficient photocatalytic hydrogen production

Communications Chemistry (2026)

-

Robust high-yield dry mill syntheses of nanocrystalline Sb2(S,Se)3 solid solution exhibiting tunable band gap and electrocatalytic properties

Journal of Materials Science (2026)

-

Hybrid island-and-sea approach for corrosion protection of Si photocathode in neutral-pH water splitting

Scientific Reports (2025)