Abstract

Nature has a delicate system for catalysis due to optimization through evolution, which often displays unparalleled efficiency and selectivity. “Learning from nature” is a popular and effective approach in designing alternative reactions and catalysts when traditional strategies fail. Here, we demonstrate that it can be highly rewarding to consider nature’s repertoire of catalysis during the effort to facilitate the challenging heterolytic C–O bond cleavage of methanol (MeOH). Inspired by MeOH metabolism by methyltransferase complex in certain methanogenic microorganisms that contain a Brønsted acid cluster flanked by a Zinc moiety, we successfully identify the combination of an easily available Brønsted acid and Zn(OTf)2 as a highly efficient and practical binary catalyst for cooperative MeOH activation. This strategy enables the direct application of MeOH in various important methylation reactions, including some of those carried out in large scale in industry with significantly increased selectivity under relatively less demanding conditions. Mechanistic studies and density functional theory (DFT) calculations suggest a synergy between the Brønsted acid and Zn(OTf)2, suggestive of that found in methanol-activating MtaBC complex in Methanosarcina barkeri.

Similar content being viewed by others

Introduction

Alkylation is one of the most important organic transformations that has drawn long-lasting attention from both industry and academia1,2, among which the structural modification via methylation bears high significance in medicinal chemistry due to the well-known “magic methyl effect”3,4. Alcohols are ideal alkylating agents due to the low cost, reduced toxicity, as well as ease with which they are handled. Tremendous efforts have been dedicated to the development of methodologies that utilize alcohols without pre-activation in alkylation reactions5,6,7,8,9,10,11,12. However, most established protocols suffered from inherent limitations that make them unsuitable for S-alkylations and Friedel-Crafts alkyations13,14. It is even more challenging for the direct application of MeOH as a methylation agent, mainly due to the increased C–O bond energy compared to its higher homologs15. As a result, activation of MeOH as a methyl source usually occurs via C–H cleavage (Fig. 1a); for example, the MacMillan group16 and the Li group17 reported a spin-center shift strategy via photocatalysis for the methylation of various N-containing heteroarenes (equation 1). Another method, based on hydrogen-borrowing strategy, requires the dehydrogenation of MeOH to form formaldehyde in-situ, which then undergoes condensation with various nucleophiles, followed by hydrogenation (equation 2)18,19,20,21. Catalytic heterolytic cleavage of the C–O bond in MeOH has been relatively difficult22, and for a very long time, this was only possible in some high-value-added industrial processes under heterogeneous catalysis at elevated temperature and pressure (Fig. 1b) 23,24,25,26,27,28. Only recently, this process was realized under relatively less demanding conditions by two research groups for Friedel-Crafts methylations: The Moran group used super Brønsted acid (TfOH) in HFIP to activate aliphatic alcohols, in which methanol was shown to react with mesitylene in 55% yield (Fig. 1c, equation 4)29, while the Oestreich group used a super Lewis acid to activate methanol as a superelectrophile to react with non-electron-rich arenes (equation 5)30.

a Activation of MeOH via C–H cleavage. b Methylation with MeOH via C–O cleavage in industry. c Catalytic C–O cleavage of methanol under milder conditions. d Biological methanol C–O activation for thiol methylation. e Bio-inspired methanol C–O activation by a tunable sulfonic acid and a zinc cocatalyst.

In nature, certain methanogenic and acetogenic microorganisms are able to cleave the C–O bond of methanol heterolytically31. The methanol metabolism is catalyzed by the methanol:coenzyme M methyl transferase MtaABC (equation 6). As shown in Fig. 1d, MtaABC contains a subunit MtaB that activates methanol with an acidic cluster flanked by a zinc moiety. This cooperation weakens the C–O bond of methanol so that its methyl group could be transferred to the subunit MtaC as a methylated corrinoid protein, which then transfers methyl group to the group of coenzyme M (HS-CoM) with the assistance by subunit MtaA32. The fact that MtaB cunningly exploits the oxygenophilic nature of Zn2+ for C–O bond activation in MeOH inspires us to combine an easily tunable Brønsted acid with an Lewis acid co-catalyst that contains Zn2+ ion for the similar task.

Here, we show that this bioinspired approach leads to the discovery of the combination of 2,5-dichlorobenzenesulfonic acid and Zn(OTf)2 as a highly efficient binary catalyst for cooperative methanol activation in S-methylation, Friedel-Crafts type arene methylation, as well as selective mono-O-methylation of benzenediols (Fig. 1e). Furthermore, MeOH was activated via heterolytic C–O bond cleavage rather than C–H bond cleavage, therefore, inexpensive and less toxic CD3OD could be used directly as an effective d3-methylating agent.

Results

Reaction optimization

To begin with, in order to achieve catalytic C–O bond cleavage of methanol under less demanding conditions for practical considerations, we speculated that a benzenesulfonic acid derivative instead of TfOH29 could provide the opportunity for structure modification so as to optimize its interactions with both substrate (methanol) and solvent by systematically studying substituent effects on the benzene ring. Additionally, most derivatives of benzenesulfonic acids are crystalline, easier to work with, and have improved functional group tolerance due to significantly reduced acidity and oxidation capability. As a result, it will be of significance if this industrially and academically important transformation could be realized with such a benzenesulfonic acid derivative, if it exists or can be easily prepared.

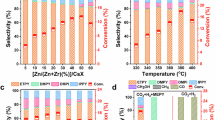

To our delight, after initial screening, we were able to identify a few such derivatives that catalyze the C–O bond cleavage of methanol for thiophenol S-methylation with promising yields when HFIP was used as the solvent (Table 1, entries 1–4). However, further variations of the benzene ring turned out to be fruitless. In light of nature’s unique machinery for methanol activation that exploits the acidity of an acid cluster and the oxygenophilic feature of a Zn2+32, we became aware that insisting on pursuing a highly engineered benzenesulfonic acid derivative might be less productive. Therefore, further effort was focused on combining these promising acids with a zinc cocatalyst, and this strategy led to the identification of the combination of 2,5-dichlorobenzenesulfonic acid (Cat. 1) and Zn(OTf)2 as a highly potent binary catalyst for cooperative MeOH activation, delivering the S-methylation product 2a in almost quantitative yield (entry 5). p-toluenesulfonic acid (Cat. 2) and p-chlorobenzenesulfonic acid (Cat. 3) only showed minimal improvement with Zn(OTf)2 (entries 6–7). Surprisingly, more acidic p-nitrobenzenesulfonic acid (Cat. 4) was completely inactive with Zn(OTf)2 (entry 8), suggesting that an optimal cooperation between Brønsted acid and Zn(OTf)2 was crucial. Other triflates (entries 9–12) were inferior to Zn(OTf)2. Screening of other Zn2+ sources showed the importance of the conjugated anions, ZnSO4 was slightly less effective (entry 13), and Zn(OAc)2 was completely inactive (entry 14). Solvent screening showed that HFIP is not compulsory, although halogenated solvents such as DCE are poor solvents (entry 15), hydrocarbons such as hexane are suitable solvents, albeit more equivalents of MeOH were necessary to achieve the same level of efficiency (entry 16). Zn(OTf)2 was comparable to Cat. 1 when used alone (entry 17), suggesting that it was not simply an additive effect. Finally, reducing the reaction time (entry 18) or catalyst loading by half (entry 19), or slightly decreasing the reaction temperature to 140 °C (entry 20) only has a small negative effect, but further reduction in these parameters turned out to be inappropriate (see Supplementary Information).

Synthetic scope

Two reaction conditions were identified for MeOH activation after optimization, in HFIP (2.0 equiv. of MeOH) and Hexane (5.0 equiv. of MeOH), respectively. Next, we explored the substrate scope of this MeOH activation strategy. Generally, methylated products of thiophenols with chlorine (2a–2c), fluorine (2d–2f), bromine (2g–2i), or multiple halogen substituents (2j–2l) at various positions could be obtained in almost perfect conversion, slightly lower yields reported in Fig. 2 were majorly due to the volatile nature of these products. Additionally, thiophenol derivatives substituted with electron-donating groups (2m–2n), alkyl groups (2o–2q), and electron-withdrawing groups (2r–2s) could all be methylated to give the corresponding products in good to excellent yields. Napthalene-1-thiol (2t) and aliphatic thiol (2u) are also viable substrates. However, heterocyclic thiol (2v) usually gives reduced yield, probably due to its instability under the reaction condition or its basicity, which influences the activity of the catalyst. Other than S-methylation, O-methylation could also be carried out to give the corresponding anisole derivatives (2w–2x) in synthetically useful yields. Exclusive S-methylation was observed when both a hydroxy group and a mercapto group were present (2y–2aa), which is remarkable considering the interesting biological profile of these compounds in nature as well as the redundancy of the traditional protocols for their preparation33. Heavier chalcogen analog benzeneselenol was methylated under the standard condition to give the selenoether (2bb) in excellent yield. Considering the importance of incorporating deuterium atoms in medicinal chemistry34,35,36 as well as the recent efforts in developing d3-methylating agents37,38,39, we speculated that inexpensive CD3OD could be directly used as an effective agent for heteroatom d3-methylating. As shown in Fig. 2, in all of these examples, d3-methylation was equally efficient compared to methylation. It is worth mentioning that in most of these cases, both HFIP and hexane are suitable solvents, while only the results for HFIP were shown, except for highly electron-rich substrates such as 2m, 2n, 2w, 2y, 2z, and 2aa, for which hexane was shown to be a better solvent while HFIP gave reduced yields or led to substrate degradation (see the supplementary information for more details). When HFIP was used as the solvent, cheaper CD3OD could be used as a d3-methylation agent without any unnecessary arene C–H deuteration40,41,42, due to a proton dilution effect. However, when hexane was a necessary solvent for highly electron-rich substrates (2m, 2n, 2w, 2y, 2z, and 2aa), a switch to CD3OH was necessary to avoid the unnecessary arene C–H deuterations.

Unless mentioned otherwise, reactions were performed with 1 (1.0 equiv.), MeOH or CD3OD (2.0 equiv.), HFIP (0.4 M), Cat.1 (10 mol%), Zn(OTf)2 (10 mol%) at 150 °C for 24 ha. Isolated yieldb. Yields were determined by analyzing 1H NMR of the reaction mixture with an internal standardc. Hexane was used as the solventd. CD3OH (5.0 equiv.) was usede. Yields were determined by analyzing GC of the reaction mixture with an internal standard. (Note: HFIP was used for S-methylation because more equivalents of CD3OD were necessary when hexane was used as the solvent).

Encouraged by this initial excess, we then tested the possibility of direct application of methanol in Friedel-Crafts type methylation reactions, which were known to be notoriously difficult29,30. Fortunately, alkylated benzenes reacted under the standard condition to give the methylation products (2cc–2ff) in excellent yields. However, 1,4-disubstituted benzenes are poor substrates, and reduced yields were obtained (2gg–2hh), even for highly electron-rich 1,4-dimethoxybenzene (2hh). More electron-rich 1,3,5-trimethoxybenzene (2ii) and indole derivative (2jj) could also be methylated in good yields. For the substrates shown in Fig. 2, a highly selective monomethylation product was obtained, while for other substrates, mixtures of regioisomers and/or multiply methylated products were observed (see the supplementary information). Finally, this bio-inspired methanol activation strategy is not limited to methanol activation. Other aliphatic alcohols, including primary alcohols (2kk–2nn), secondary alcohol (2oo), and cyclic secondary alcohols (2pp–2qq), could all be activated under the standard condition to serve as efficient alkylating agents. Diols such as glycol and 1,4-butanediol could also be used as bisalkylation agents and the corresponding products (2rr–2ss) could be obtained in good isolated yields, and this is important because these products are useful intermediates to highly useful bis-sulfoxide ligands43,44, which usually need several preparation steps with toxic alkylation reagents.

Selective monomethylation of benzenediols

An interesting observation (Fig. 3, inset) showed that benzene-1,4-diol (3a) could be monomethylated to give 4a as the only product when hexane was used as the solvent. This high selectivity was surprising considering that 5.0 equivalents of MeOH were used. What was more intriguing was that when p-methoxyphenol (4a) was submitted to the standard condition, the dimethylation product 4a′ could not be produced in any noticeable amount. On the other hand, when dimethylated substrate 4a′ was submitted to the standard reaction condition, demethylation to give the monomethylation product 4a was observed (see the supplementary information). This suggested that the monomethylation product was thermodynamically more stable under this protocol. Similar results were obtained for resorcinol and catechol, and the corresponding monomethylation products (4b and 4c) were obtained exclusively in high yields (spot to spot reaction, the lower 80s isolation yields were primarily due to the volatile nature of the product). This result is highly inspiring since monomethylation of benzenediols is a well-known biological process45,46. In industry, a vaporized mixture of catechol (3c) and methanol was passed through heterogeneous catalysts at high temperature and pressure to generate a mixture of mono-O-methylation, di-O-methylation, as well as Friedel-Crafts methylation products, after which separation of the mixture give the industrially significant monomethylation product guaiol (4c)47,48,49, although fine-tuning of the catalysts and reaction condition could improve the selectivity to certain extent50,51. In research laboratories, only limited examples of mono-methylation were reported that apply highly toxic methylation reagents (directly applied or generated in situ) and are highly substrate-dependent52,53. These initial results encouraged us to apply this bioinspired strategy for methanol activation as an operationally facile and generally applicable protocol for monomethylation of benzenediols under relatively milder reaction conditions. Delightfully, other than the three benzenediols, substrates derived from naphthalene and indane could be monomethylated as well (4d–4e).

Unless mentioned otherwise, reactions were performed with 3 (1.0 equiv.), MeOH (5.0 equiv.), hexane (0.4 M), Cat. 1 (10 mol%), Zn(OTf)2 (10 mol%) at 150 °C for 24 ha. Isolated yieldb. 2.0 equiv. of MeOH was usedc. Yields were determined by analyzing 1H NMR of the reaction mixture with an internal standard. (Note: for benzenediol monomethylation, hexane was better than HFIP as the solvent).

As shown in Fig. 3, we next focused on the monomethylation of various derivatives of resorcinol and catechol, considering their significance in industry, material science, and medicinal chemistry54,55. Resorcinol derivatives with alkyl groups (4f–4i), and halogens (4j–4l) at the 5-position could all be monomethylated to give the corresponding products in good to excellent yields, except for 4j, for which the conversion of starting material is low. An ester group at the 5-position also led to incomplete conversion of the starting material and the monomethylation product was obtained with a 50% isolated yield. Phenyl group (4n), substituted phenyl groups (4o–4q), and naphthyl group (4r) at the 5-position are all well tolerated. Substituents at the 2-position also reduced the yield of monomethylation products (4s–4t), probably due to increased steric hindrance that resulted in incomplete conversion of starting materials. Resorcinol derivatives with substituents at the 4-position have two different hydroxy groups, and monomethylation is slightly preferred to occur at the less hindered site (4u). Increasing the steric hindrance of the substituent did not lead to improved selectivity (4v). Catechol derivatives with an alkyl group (4w), halogens (4x–4y) at the 3-position, and the monomethylation occurred at the less hindered site with moderate selectivity. However, catechol derivatives with substituents at the 3-position led to reduced selectivity (4z–4bb), even a bulky t-butyl group has only a marginal effect (4bb). Interestingly, a fluoro group slightly increased the selectivity to 2.4:1 (4cc), and an ester group reversed the selectivity (4dd), probably due to the fact that this electron-withdrawing group makes the hydroxy group at its para position less nucleophilic.

Synthetic applications

The synthetic potential of this methodology has been verified by carrying out a few gram-scale reactions for substrates 2g, 2h and 4l, and chemical yields comparable to those of the small-scale reactions were achieved (see Supplementary Information). Many of these thiophenol methylation or benzenediol monomethylation products are industrially significant compounds and serve as important synthetic intermediates in material science and pharmaceutical chemistry. For example, sulfone intermediate 6 could be obtained from methylation product 2h, Suzuki coupling of 6 with borane intermediate 7, followed by N-deprotection and N-alkylation delivered dopaminergic D2 antagonists pridopidine (8, Fig. 4a)56. Coupling of 2h or its regioisomer 2g with an easily available lactam intermediate 9 followed by thioether oxidation produced two HIV inhibitor analogs 10 and 11, respectively (Fig. 4b)57. The S-methylation products of thiophenols have rich chemistry (Fig. 4c), for example, 2g could be converted to a thiocyanate 1258, oxidized to inimosulfone 1359, the halogen substituents on the aryl group could also be elaborated via copper catalyzed coupling reactions to provide 14 and 1560,61, without any interference from the thioether moiety. Thiophenol methylation products are produced in large quantities due to their sizable applications in industry, and are therefore commercially available at reasonable price. However, some important alkylation products used in a small scale for material research or drug discovery are highly expensive (Fig. 4d). With the alcohol activation strategy developed herein, these alkylation products (2y′, 2z′, 2aa′) could now be obtained in one single operation from inexpensive starting material with high efficiency and selectivity. Finally, stilbenoids are naturally potent antioxidants produced by some plants in trace amounts as defense compounds, the interesting therapeutic effects of these compounds have drawn increased synthetic efforts toward facile preparations of their derivatives, many such derivatives have partially methylated benzenediol moiety, and this phenomenon is related to its biological properties62,63. As shown in Fig. 4e, Heck-type coupling of mono-methylation product 4l obtained by using our methodology with styrene (16) or styrene derivatives (18–19) followed by deprotection of protected phenols (if necessary) led to the facile preparations of pinosylvin-4-monomethyl ether (17), thunalbene (20), and pinostilbene (21), respectively.

Mechanistic investigations

We then carried out a series of control experiments to possibly to shed light on mechanism underlying this bioinspired methanol activation. Firstly, to test the possibility of hydrolysis of Zn(OTf)2 at high temperature with the presence of adventitious H2O that led to the formation of TfOH, we submitted mesitylene (1cc) to various amounts of Zn(OTf)2 with the presence of the small amount of H2O, no trace amount of Friedel-Craft product could be detected, ruling out the possible formation of TfOH as the actual catalyst, which was reported earlier to be capable of promoting this transformation to certain extend (Fig. 5a)29. Using methyl triflate (16) or methyl sulfonate ester (17) instead of MeOH did not led to the formation of any methylation product, which ruled out the possible formation of methyl sulfonate ester as the real methylation agent (Fig. 5b). Evaluation of the reaction kinetics showed that when the loadings of MeOH are low, the reaction displayed complicated dependence on MeOH: no methylation product could be detected with 0.2 equivalent or less MeOH, methylation product started to emerge with 0.3 equivalent or more MeOH, and the reaction displayed first order dependence on MeOH when the loadings of MeOH is high. This suggested that several MeOH molecules might need to coordinate with Zn2+ to trigger the reaction and the first order dependence on MeOH at higher loadings might be due to coordination saturation with excess MeOH. On the other hand, the reaction showed monotonous first order dependence on three other reagents involved (namely Cat. 1, Zn(OTf)2 and 1o), no matter whether HFIP or hexane was used as the solvent (Fig. 5c, see the Supplementary Information for more details). The Hammett plot [log(kX/kH) versus σ] displayed a linear relationship with a ρ value of −0.2742 (R2 = 0.992), which suggests that the reaction proceeds through a single mechanism with only partial positive charge developed in the transition state, indicative of a mechanism similar to that of SN2 substitution (Fig. 5d)64,65.

DFT calculations

DFT calculations were conducted for the C–O bond activation66,67,68,69 with two representative substrates 1o and 1y to provide further mechanistic insights into this bioinspired methanol activation. The calculations showed that both 2,5-dichlorobenzenesulfonic acid and methanol could be ligated to Zn(OTf)2, and the most stable one (labeled as Int0) is the zinc complex with three methanol ligands, two OTf ligands, and one dichlorobenzenesulfonic acid ligand, this result agreed with the previous kinetic studies with MeOH in which the methylation product only started to emerge with 0.3 equivalent of MeOH, which is three times of the equivalency of Zn(OTf)2. For the methylation of 1o, an SN2 transition state TS1 is located. It has a barrier of 28.2 kcal/mol (Fig. 6a). In TS1, one of the methanol substrates dissociates from the zinc ion, and a proton is transferred from dichlorobenzenesulfonic acid to the hydroxyl group of the methanol, which is coupled with the nucleophilic attack of the thiol group of 1o on the methanol carbon center and the cleavage of the C–O bond. The critical C–S and C–O bond distances are 2.35 Å and 2.03 Å, respectively. This methylation reaction was calculated to be exergonic by 11.3 kcal/mol. In this mechanism, the zinc ion functions as a Lewis acid to activate the dichlorobenzenesulfonic acid, which acts as a Brønsted acid to protonate the leaving hydroxyl group. In addition, one of the OTf anions serves as the Brønsted base to abstract a proton from the thiol group of 1o. Other mechanistic scenarios have also been considered, including the coordination of the hydroxyl or thiol groups to the zinc ions in the transition states. However, their barriers are much higher (see Supplementary Information Fig. 27). Our results may also imply that in methanol: coenzyme M methyl transferase MtaABC24, the methanol substrate does not need to be coordinated to the zinc ion during the C–O bond cleavage, which deserves further studies.

The suggested mechanism was then used to rationalize the chemoselectivity observed for the methylation of 1y. As shown in Fig. 6b, the barrier for O-methylation (TS2b) is 3.7 kcal/mol higher than that for S-methylation (TS2). In addition, the O-methylation of 1 y was calculated to be slightly exergonic by 2.5 kcal/mol, while it is exergonic by 12.5 kcal/mol for the S-methylation. Therefore, S-methylation is thermodynamically and kinetically more favorable. For the methylation of benzenediols, the calculations showed that the first methylation is exergonic by 4.1 kcal/mol, while the second methylation becomes endergonic by 8.3 kcal/mol (see supplementary information Fig. 30). Two benzenediol molecules and two methanol molecules (3a + MeOH)2 could form an eight-membered ring hydrogen bonding network, which could maintain after the first methylation reaction (see product (4a + MeOH)2). However, this hydrogen bonding network is disrupted after the second methylation reaction, as in the product (4a′ + MeOH)2 the ester can only act as a hydrogen bonding acceptor, and the two hydrogen atoms of each water molecule have to form two hydrogen bonds with 4a′.

Discussion

In conclusion, we have shown a bioinspired reaction optimization that lead to discovery of a highly efficient and practical binary catalyst that combines an easily available benzenesulfonic acid (Cat. 1) and Zn(OTf)2 for heterolytic C–O bond cleavage of MeOH. This method allows direct application of methanol in various methylation processes, including thiol S-methylation, arene C–H methylation, as well as selective monomethylation of benzenediols, many of which are highly important industrial processes that previously require much more demanding reaction conditions. Mechanistic experiments, as well as DFT calculations suggest a synergy between Cat. 1 and Zn(OTf)2, which shows high level of resemblance to that found in the methanol-activating MtaABC complex in Methanosarcina barkeri. We anticipate that this methodology will inspire further efforts in advancing catalysis for industrially and academically relevant methylation reactions, and it will facilitate biological research that requires methylated or d3-methylated ethers and thiol ethers. From a broader perspective, we envisage that this work will provide valuable insights for developing C–O bond activation strategies for the direct application of aliphatic alcohols in various important alkylation reactions.

Methods

General procedure for the heterolytic C–O Bond cleavage of MeOH catalyzed by Cat.1 and Zn(OTf)2 to prepare 2 and 4

General procedure A: To 10 mL Schlenk tube was charged with Cat.1 (10 mol%), Zn(OTf)2 (10 mol%), 1 or 3 (1.0 equiv.) and an oven-dried stirring bar. The Schlenck tube was subjected to three cycles of pressurization–depressurization using dry argon. After that, under the protection of an argon atmosphere, HFIP (0.4 M) and MeOH (2.0 equiv.) were added and the reaction mixture was stirred at 150 °C for 24 h. The reaction was then quenched by adding K2CO3 (20 mol%), filtration, and then washing the solid with DCM, the combined organic phase was concentrated under reduced pressure, and the residue was purified using flash column chromatography on silica gel to give the products.

General procedure B

In a nitrogen-filled glove box, a 10 mL Schlenk tube was charged with Cat.1 (10 mol%), Zn(OTf)2 (10 mol%), 1 or 3 (1.0 equiv.), Hexane (0.4 M), MeOH (5.0 equiv.), and an oven-dried stirring bar. The tube was sealed and removed from the glove box. After degassing, the reaction mixture was stirred at 150 °C for 24 h. The reaction was then quenched by adding K2CO3 (20 mol%), filtration, and then washing the solid with DCM. The combined organic phase was concentrated under reduced pressure, and the residue was purified using flash column chromatography on silica gel to give the products.

Data availability

The data that support the findings of this study are available in the article and the Supplementary Information section. Details about materials and methods, experimental procedures, characterization data, mechanistic studies, DFT calculations, and NMR spectra are available in the Supplementary Information. Cartesian coordinates of all the optimized structures are provided in Supplementary Data 1. Data supporting the findings of this manuscript are also available from the corresponding author upon request.

References

Dong, Z., Ren, Z., Thompson, S. J., Xu, Y. & Dong, G. Transition-metal-catalyzed C−H alkylation using alkenes. Chem. Rev. 117, 9333–9403 (2019).

Poulsen, T. B. & Jørgensen, K. A. Catalytic asymmetric Friedel-Crafts alkylation reactions-copper showed the way. Chem. Rev. 108, 2903–2915 (2008).

Schönherr, H. & Cernak, T. Profound methyl effects in drug discovery and a call for new C−H methylation reactions. Angew. Chem. Int. Ed. 52, 12256–12267 (2013).

Barreiro, E. J., Kümmerle, A. E. & Fraga, C. A. The methylation effect in medicinal chemistry. Chem. Rev. 111, 5215–5246 (2011).

Obora, Y. Recent advances in α-alkylation reactions using alcohols with hydrogen borrowing methodologies. ACS Catal. 4, 3972–3981 (2014).

Dobereiner, G. E. & Crabtree, R. H. Dehydrogenation as a substrate-activating strategy in homogeneous transition-metal catalysis. Chem. Rev. 110, 681–703 (2010).

Dryzhakov, M., Richmond, E. & Moran, J. Recent advances in direct catalytic dehydrative substitution of alcohols. Synthesis 48, 935–959 (2016).

Rueping, M. & Nachtsheim, B. J. A review of new developments in the Friedel–Crafts alkylation—from green chemistry to asymmetric catalysis. Beilstein J. Org. Chem. 6, No 6 (2010).

Estopiñá-Durán, S. & Taylor, J. E. Brønsted acid-catalysed dehydrative substitution reactions of alcohols. Chem. Eur. J. 27, 106–120 (2021).

Wu, F. et al. A green route to benzyl phenyl sulfide from thioanisole and benzyl alcohol over dual functional ionic liquids. Chem. Asian J. 18, e202201078 (2023).

Ke, Z. et al. Ionic-liquid hydrogen-bonding promoted alcohols amination over cobalt catalyst via dihydrogen autotransfer mechanism. ChemSusChem. 16, e202300513 (2023).

Hoof, M. V., Mayer, R. J., Moran, J. & Lebœuf, D. Triflic acid-catalyzed dehydrative amination of 2-arylethanols with weak N-nucleophiles in hexafluoroisopropanol. Angew. Chem. Int. Ed. 64, e202417089 (2025).

Chelucci, G. Ruthenium and osmium complexes in C−C bond-forming reactions by borrowing hydrogen catalysis. Coord. Chem. Rev. 331, 1–36 (2017).

Saidi, O. et al. Borrowing hydrogen in water and ionic liquids: Iridium-catalyzed alkylation of amines with alcohols. Org. Process Res. Dev. 14, 1046–1049 (2010).

Blanksby, S. J. & Ellison, G. B. Bond dissociation energies of organic molecules. Acc. Chem. Res. 36, 255–263 (2003).

Jin, J. & MacMillan, D. W. C. Alcohols as alkylating agents in heteroarene C–H functionalization. Nature 525, 87–90 (2015).

Liu, W., Yang, X., Zhou, Z.-Z. & Li, C.-J. Simple and clean photo-induced methylation of heteroarenes with MeOH. Chem. 2, 688–702 (2017).

Corma, A., Navas, J. & Sabater, M. J. Advances in one-pot synthesis through borrowing hydrogen catalysis. Chem. Rev. 118, 1410–1459 (2018).

Chan, L. K. M., Poole, D. L., Shen, D., Healy, M. P. & Donohoe, T. J. Rhodium-catalyzed ketone methylation using methanol under mild conditions: formation of α-branched products. Angew. Chem. Int. Ed. 53, 761–765 (2014).

Natte, K., Neumann, H., Beller, M. & Jagadeesh, R. V. Transition-metal-catalyzed utilization of methanol as a C1 source in organic synthesis. Angew. Chem. Int. Ed. 56, 6384–6394 (2017).

Iuchi, Y., Obora, Y. & Ishii, Y. Ir-catalyzedα-alkylation of acetates with primary alcohols and diols. J. Am. Chem. Soc. 132, 2536–2537 (2010).

Han, F., Yang, L., Li, Z. & Xia, C. Sulfonic acid-functionalized ionic liquids as metal-free, efficient and reusable catalysts for direct amination of alcohols. Adv. Synth. Catal. 354, 1052–1060 (2012).

Dong, P. et al. Progress of methylation of C6−8∼arene with methanol: mechanism, catalysts, kinetic/thermodynamics and perspectives. Processes 10, 881 (2022).

Alharbi, W., Kozhevnikova, E. F. & Kozhevnikov, I. V. Dehydration of methanol to dimethyl ether over heteropoly acid catalysts: the relationship between reaction rate and catalyst acid strength. ACS Catal. 5, 7186–7193 (2015).

Chakinala, N. & Chakinala, A. G. Process design srategies to produce p-Xylene via toluene methylation: a review. Ind. Eng. Chem. Res. 60, 5331–5351 (2021).

Huang, X. et al. Catalyst design strategies towards highly shape-selective HZSM-5 for para-xylene through toluene alkylation. Green. Energy Environ. 5, 385–393 (2020).

Zhou, J., Liu, Z., Wang, Y., Kong, D. & Xie, Z. Shape selective catalysis in methylation of toluene: Development, challenges and perspectives. Front. Chem. Sci. Eng. 12, 103–112 (2018).

Perego, C. & Ingallina, P. Recent advances in the industrial alkylation of aromatics: new catalysts and new processes. Catal. Today 73, 3–22 (2002).

Zhang, S. et al. Unlocking the Friedel-Crafts arylation of primary aliphatic alcohols and epoxides driven by hexafluoroisopropanol. Chem 7, 3425–3441 (2021).

He, T., Klare, H. F. T. & Oestreich, M. Catalytically generated Meerwein’s salt-type oxonium ions for Friedel-Crafts C(sp2)−H methylation with methanol. J. Am. Chem. Soc. 145, 3795–3801 (2023).

Sauer, K. & Thauer, R. K. Methanol: coenzyme M methyl transferase from Methanosarcina barkeri. Eur. J. Biochem. 249, 280–285 (1997).

Hagemeier, C. H., Krer, M., Thauer, R. K., Warkentin, E. & Ermler, U. Insight into the mechanism of biological methanol activation based on the crystal structure of the methanol-cobalamin methyltransferase complex. Proc. Natl. Acad. Sci. USA 103, 18917–18922 (2006).

Bohman, B., Phillips, R. D., Flematti, G. R., Barrow, R. A. & Peakall, R. The spider orchid Caladenia crebra produces sulfurous pheromone mimics to attract its male wasp pollinator. Angew. Chem. Int. Ed. 56, 8455–8458 (2017).

Kopf, S., Bourriquen, F., Li, W., Neumann, H., Junge, K. & Beller, M. Recent developments for the deuterium and tritium labeling of organic molecules. Chem. Rev. 122, 6634–6718 (2022).

Pirali, T., Serafini, M., Cargnin, S. & Genazzani, A. A. Applications of deuterium in medicinal chemistry. J. Med. Chem. 62, 5276–5297 (2019).

Atzrodt, J., Derdau, V., Fey, T. & Zimmermann, J. The renaissance of H/D exchange. Angew. Chem. Int. Ed. 46, 7744–7765 (2007).

Sun, Q. & Soulé, J.-F. Broadening of horizons in the synthesis of CD3-labeled molecules. Chem. Soc. Rev. 50, 10806–10835 (2021).

Steverlynck, J., Sitdikov, R. & Rueping, M. The deuterated “Magic Methyl” group: a guide to site-selective trideuteromethyl incorporation and labeling by using CD3 reagents. Chem. Eur. J. 27, 11751–11772 (2021).

Wang, M. Y., Zhao, Y. F., Zhao, Y. & Shi, Z. Z. Bioinspired design of a robust d3-methylating agent. Sci. Adv. 6, No. eaba0946 (2020).

Prakash, G., Paul, N., Oliver, G. A., Werz, D. B. & Maiti, D. C−H deuteration of organic compounds and potential drug candidates. Chem. Soc. Rev. 51, 3123–3163 (2022).

Munz, D. et al. Proton or metal? The H/D exchange of arenes in acidic solvents. ACS Catal. 5, 769–775 (2015).

He, T., Klare, H. F. T. & Oestreich, M. Perdeuteration of deactivated aryl halides by H/D exchange under superelectrophile catalysis. J. Am. Chem. Soc. 144, 4734–4738 (2022).

Sipos, G., Drinkel, E. E. & Dorta, R. The emergence of sulfoxides as efficient ligands in transition metal catalysis. Chem. Soc. Rev. 44, 3834–3860 (2015).

Evans, D. R., Huang, M., Seganish, W. M., Fettinger, J. C. & Williams, T. L. Facile access to enantiomerically pure bis(sulfoxide) chelates of late transition metals. Inorg. Chem. Commun. 6, 462–465 (2003).

Koirala, N., Thuan, N. H., Ghimire, G. P., Thang, D. V. & Sohng, J. K. Methylation of flavonoids: Chemical structures, bioactivities, progress and perspectives for biotechnological production. Enzym. Microb. Technol. 86, 103–116 (2016).

Wang, X. et al. Rational reprogramming of O-methylation regioselectivity for combinatorial biosynthetic tailoring of benzenediol lactone scaffolds. J. Am. Chem. Soc. 141, 4355–4364 (2019).

Olah, G. A. Friedel–Crafts and Related Reactions Vol. 3 (Wiley–Interscience, 1964).

Durgakumari, V., Narayanan, S. & Guczi, L. Alkylation of phenol with methanol over AlPO and SAPO molecular sieves. Catal. Lett. 5, 377–384 (1990).

Fu, Z. et al. Vapor-phase highly selective O-methylation of catechol with methanol over ZnCl2 modified γ-Al2O3 catalysts. J. Mol. Catal. A Chem. 232, 69–75 (2005).

Cejka, J. & Wichterlova, B. Acid-catalyzed synthesis of mono- and dialkyl benzenes over zeolites: active sites, zeolite topology, and reaction mechanisms. Catal. Rev. 44, 375–421 (2002).

Kirumakki, S. R., Nagaraju, N., Chary, K. V. R. & Narayanan, S. A facile O–alkylation of 2–naphthol over zeolites Hβ, HY, and HZSM5 using dimethyl carbonate and methanol. J. Catal. 221, 549–559 (2004).

Stoochnoff, B. A. & Benoiton, N. L. The methylation of some phenols and alcohols with sodium hydride/methyl iodide in tetrahydrofuran at room temperature. Tetrahedron Lett. 14, 21–24 (1973).

Cao, Y. Q. & Pei, B. G. Etherification of phenols catalyzed by solid–liquid phase transfer catalyst PEG-400 without solvent. Synth. Commun. 30, 1759–1766 (2000).

Lindgren, A. E. G., Öberg, C. T., Hillgren, J. M. & Elofsson, M. Total synthesis of the resveratrol oligomers (±)-ampelopsin B and (±)-ϵ-viniferin. Eur. J. Org. Chem. 2016, 426–429 (2016).

Guo, R., Witherspoon, B. P. & Brown, M. K. Evolution of a strategy for the enantioselective synthesis of (−)-cajanusine. J. Am. Chem. Soc. 142, 5002–5006 (2020).

Campbell, P. S., Jamieson, C., Simpson, I. & Watson, A. J. B. Practical synthesis of pharmaceutically relevant molecules enriched in sp3 character. Chem. Commun. 54, 46–49 (2018).

Wu, B. et al. Pyrrolidones with anti-HIV activity. WO2004037784A2.

Chen, Y. et al. Fluorium-initiated dealkylative cyanation of thioethers to thiocyanates. J. Org. Chem. 84, 9044–9050 (2019).

Su, W., Xu, P., Petzold, R., Yan, J. & Ritter, T. Ligand-to-copper charge-transfer-enabled C−H sulfoximination of arenes. Org. Lett. 25, 1025–1029 (2023).

Zhang, Y., Yang, X., Yao, Q. & Ma, D. CuI/DMPAO-catalyzed N-arylation of acyclic secondary amines. Org. Lett. 14, 3056–3059 (2012).

Xia, S., Gan, L., Wang, K., Li, Z. & Ma, D. Copper-catalyzed hydroxylation of (Hetero)aryl halides under mild conditions. J. Am. Chem. Soc. 138, 13493–13496 (2016).

Cárdenas, J., Morales-Serna, J., Zúñiga-Martínez, A., Salmón, M. & Gaviño, R. Heck arylation of styrenes promoted by an air-stable phosphinito complex with palladium(II); synthesis of resveratrol. Synthesis 44, 446–452 (2012).

Liu, Y., Ni, D. & Brown, M. K. Boronic ester enabled [2 + 2]-cycloadditions by temporary coordination: synthesis of artochamin J and piperarborenine B. J. Am. Chem. Soc. 144, 18790–18796 (2022).

Nakagawa, Y. & Mizuno, N. Mechanism of [γ-H2SiV2W10O40]4−-catalyzed epoxidation of alkenes with hydrogen peroxide. Inorg. Chem. 46, 1727–1736 (2007).

Kamata, K., Hirano, T., Ishimoto, R. & Mizuno, N. Sulfoxidation with hydrogen peroxide catalyzed by [SeO4{WO(O2)2}2]2−. Dalton Trans. 39, 5509–5508 (2010).

Xu, L., Chung, L. W. & Wu, Y.-D. Mechanism of Ni-NHC-catalyzed hydrogenolysis of aryl ethers: roles of the excess base. ACS Catal. 6, 483–493 (2016).

Schwarzer, M. C. et al. Combined theoretical and experimental studies of nickel-catalyzed cross-coupling of methoxyarenes with arylboronic esters via C–O bond cleavage. J. Am. Chem. Soc. 139, 10347–10358 (2017).

Zhang, S.-Q. et al. Mechanism and origins of ligand-controlled stereoselectivity of Ni-catalyzed Suzuki–Miyaura coupling with benzylic esters: a computational study. J. Am. Chem. Soc. 139, 12994–13005 (2017).

Xu, X. & Lin, Z. Understanding the reaction mechanism of nickel-catalyzed enantioselective arylative activation of the aromatic C–O bond. Organometallics 42, 114–122 (2023).

Acknowledgements

Financial support for this work is provided by the National Science Foundation of China (NSFC, 21801084 and 22171095). We are grateful to the Analytic and Testing Centre of HUST for data characterization.

Author information

Authors and Affiliations

Contributions

H.Q. and X.Y.W. conceived the project. H.Q., X.Y., and Z.Y. designed and performed the synthetic experiments. W.Y., and L.R.-Z. carried out DFT calculations. H.Q., X.Y., W.Y., L.R.-Z., and X.Y.W. analyzed the data. H.Q., L.R.-Z., and X.Y.W. wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

A patent application (CN119039096A, China) has been filed, dealing with the application of aliphatic alcohols for alkylation reactions by the catalysis described in this article, wherein H.Q., X.Y., and X.Y.W. were listed as inventors. The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Lung Wa Chung and Yong Wang for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Huang, Q., Xiang, Y., Wu, Y. et al. Methylations with methanol via bioinspired catalytic C–O bond cleavage. Nat Commun 16, 5896 (2025). https://doi.org/10.1038/s41467-025-61200-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-61200-7