Abstract

Carbon dioxide (CO2) conversion to liquid fuels has attracted great attention due to the current environmental concerns and energy crisis. However, the selective conversion of CO2 to target liquids is formidably challenging due to the chemical inertness of CO2. We theoretically and experimentally confirm that the bending of Pd−Pd bond can breaks the asymmetric potential well and facilitate CO2 adsorption. We have successfully synthesized a new class of Pd nanoneedles via a “close edges and open corners” process, with a magic angle of 60o between the main trunk and branch, and realized the selective CO2 hydrogenation to formic acid (HCOOH) at room temperature in water. Impressively, a HCOOH productivity of ~250 mmol g−1 in 100 h while maintaining HCOOH selectivity over 99%. This work bridges nanostructure design and catalytic application, which may open a new avenue for selective CO2 conversion in an elegant manner.

Similar content being viewed by others

Introduction

The conversion of CO2 has raised great attention due to the overuse of fossil energy and the resultant environmental concerns and energy crisis. Among the technologies for CO2 conversion, the catalytic CO2 reduction to liquid chemicals has attracted great interest of researchers1,2,3,4. Nevertheless, the selective conversion of CO2 to target liquids is formidably challenging due to the high energy of C=O bond energy (806 kJ/mol), which is severely limited by the poor activity of catalyst and the low selectivity of desired product. A common strategy for CO2 activation for activating C=O bond is raising the temperature, which is however environmentally unfriendly due to high energy consumption5,6,7,8. In particular, the hydrogenation of CO2 to produce formic acid (HCOOH) represents an atomically efficient reaction, since HCOOH has been widely used in hydrogen storage, agriculture, aesthetics, bio-medicine, chemical industry9,10. In general, HCOOH can be produced via CO2 hydrogenation in alkaline to formate salt or neutral conditions to for HCOOH. The introduction of base thermodynamically favors the CO2 hydrogenation to form formate salt, which increases the cost and brings environmental issues. Consequently, it is highly desired to develop active and selective catalysts for CO2 conversion to liquid products in a sustainable manner without additives.

CO2 hydrogenation is regarded as a feasible strategy for reducing CO2 to liquid products. As a noble element, Pd has been widely used for CO2 hydrogenation due to its unique affinity to H2. However, the weak adsorption ability of Pd towards CO2 limits its application for CO2 hydrogenation to multi-carbon products. Under the circumstances, CO2 hydrogenation over Pd is generally operated under specific conditions (alcohols or alkaline solution) to overcome the mass transfer11,12,13,14,15,16,17,18. In principle, to realize the selective CO2 activation on Pd, one needs to carefully regulate the electronic properties of Pd atoms to modulate the adsorption abilities of CO2 and corresponding intermediates. Recent studies show that the catalytic performance is strongly related to the coordination environment of active center19,20,21,22,23. Empirically, the catalytic performance is strongly related to the local coordination structure of metal center, and those metal centers with low coordination and distortion are generally more active than regular ones24,25,26. Despite great efforts that have been devoted to the modification of catalyst, it is still lack of efficient manners for precisely modulating the coordination structure of metallic center.

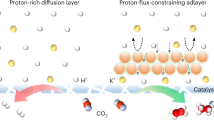

In this work, with the assistance of theoretical simulations, we demonstrate that the malformation of Pd−Pd bond may endow CO2 activation. Compared to the regular Pd nanostructures, the bending of Pd−Pd bond breaks the asymmetric potential well, which can facilitate CO2 adsorption on Pd atoms. Moreover, the prediction has been validated by synthesizing Pd needles with high curvature (e.g., Pd HC-Nds), where the Pd HC-Nds can serve as highly active and selective catalyst for CO2 hydrogenation to formic acid (HCOOH) with a high selectivity over 99% at room temperature and ambient pressure in water without any other additives. Impressively, the efficient performance of Pd HC-Nds for CO2 hydrogenation to HCOOH has been evaluated by continuously bubbling CO2 and H2 into water, with a HCOOH productivity of ~250 mmol g−1 in 100 h while maintaining HCOOH selectivity over 99%.

Results

Density functional theory (DFT) simulations

We first evaluated the CO2 adsorption and activation on curved Pd structures with different curvatures via DFT calculations, while bulk Pd (111) surface was selected as the reference (Supplementary Fig. 1). As the key factors for CO2 adsorption and activation, the coordination environment and electronic properties of Pd nanostructures with different curvatures were evaluated by DFT calculations (Supplementary Figs. 2−5). Moreover, the simulation of electron localization function (ELF) shows that the variation of curvature leads to the reduction of structural symmetry (Supplementary Fig. 6 and Supplementary Movies 1−3). Impressively, with a high curvature of 14 Å, the significant increase of electron dispersion leads to the appearance of localized charge uneven regions on the surface, implying that more unsaturated Pd atoms are exposed on the surface. Analysis on Bader charge further confirms that the charge distribution varies strongly on Pd nanostructures with different curvatures (Supplementary Fig. 7). Based on the differences in electronic structure, edge sites, and surface sites can be identified for CO2 adsorption and activation (Supplementary Fig. 8). Figure 1a shows the relationship between adsorption strength and the generalized coordination number (GCN). Notably, as the curvature increases (i.e., with the reduction of the curvature radius), GCN decreases, indicating the formation of low-coordinated Pd active sites. Furthermore, simulation results demonstrate a significant linear correlation between CO2 adsorption strength and GCN (Fig. 1a). This correlation suggests that low-coordinated Pd sites induced by higher curvature significantly enhance CO2 adsorption. To further study the CO2 adsorption, the radial distribution functions (RDF) were simulated for Pd nanostructures with different curvatures and Pd (111) facets. As shown in Fig. 1b, an intense peak appears at 2.2 Å for Pd-14 Å (the highest curvature), indicating that CO2 can be strongly adsorbed on the surface of Pd-14 Å. Besides, snapshots from molecular dynamics (MD) simulations further verifies the strong CO2 adsorption on Pd-14 Å, as evidenced by the close interaction of CO2 with Pd-14 Å surface (Fig. 1d). The integrated crystal orbital Hamilton population (ICOHP) analysis results (Supplementary Fig. 9) indicate that the bonding interaction of CO2 on the Pd-14 Å surface is significantly enhanced. This enhancement is attributed to stronger hybridization effects, which promote electron transfer from Pd to the CO2 molecule. Additionally, the PDOS of the Pd-4d orbital was calculated to investigate CO2 adsorption on Pd nanostructures with different curvatures (Fig. 1a, c and Supplementary Fig. 10). Further analysis shows that the d-band center (εd) is strongly related to the GCN, that is, the decrease of GCN results in the approach of d-band center to the Fermi level, which means that the low-coordinated Pd site on Pd-14 Å favors the CO2 adsorption (Fig. 1c), being consistent with MD and ICOHP results. Take Pd-14 Å as the example, the εd positions of different active sites on the surface show similar electronic characteristics and are much closer to the Fermi level than those of Pd-23 Å and Pd-slab (Supplementary Fig. 10), further confirming the positive correlation between curvature and CO2 adsorption strength (Fig. 1a). Consequently, theoretical simulations show that, compared to Pd (111) surface with organized arrangement and symmetric electron distribution, Pd nanostructures with high curvatures bring the strong lattice strain and low-coordinated Pd sites, which breaks the symmetric electron distribution, as a result of the strengthened CO2 adsorption (Fig. 1e).

a The relationship between CO2 adsorption energy and the nearest neighbor coordination number for Pd-14 Å, Pd-23 Å clusters, and Pd-slab; The color map indicates the position of the d-band center. In the figure, circles, quadrilaterals, and pentagrams represent Pd-14 Å, Pd-23 Å clusters, and Pd-slab, respectively; dashed shapes represent edge active sites, and hollow shapes represent surface active sites. b Ab initio molecular dynamics (AIMD) simulations of CO2 adsorption on Pd surfaces with varying curvatures. c The partial density of states (PDOS) of the 4 d orbitals for the curvature structures of Pd-14 Å, Pd-23 Å, and Pd-slab. d AIMD snapshots after 10 ps showing the distribution of CO2 on Pd surfaces. e Schematic of bending strain affecting structure symmetry and curvature.

Synthesis and structural characterizations of Pd HC-Nds

Given by the above theoretical prediction, we intend to prepare Pd nanostructures with high curvatures. Inspired by the unique structure of snowflakes, we assume that snowflake-shaped nanostructures are ideal candidates to mimic the model for theoretical calculations. Herein, we synthesized Pd nanoneedles (Pd Nds) with curvature by adding palladium chloride (PdCl2), 2-methylimidazole (2-MIM), and polyvinyl pyrrolidone (PVP) into N,N-dimethylformamide (DMF) solvent (see Methods for details). High-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) image reveals that three-dimensional (3D) Pd nanostructure assembled with ultrathin nanoneedles is produced (Fig. 2a). Moreover, the stacking structure of Pd Nds has been further revealed by the 3D tomographic reconstruction based on TEM images at the consecutive tilt angles from 0° to 90° (Fig. 2b−d). Besides, the low-magnification atomic force microscopy (AFM) image further reveals the multilevel structure of Pd Nds (Fig. 2e). Analysis on the high-magnification AFM suggests that the mean thickness of branch is ~1.7 nm (Fig. 2f, g). Besides, the ultrathin nature of Pd Nds was further validated by the blue color of colloidal Pd Nds solution (Supplementary Fig. 11). To further reveal the structure of Pd Nds, HAADF-STEM image with high magnification was collected, in which the twisted morphology of Pd Nds was clearly observed (Fig. 2h, i). The EDS elemental mappings display a homogeneous distribution of Pd elemental signals across the entire surface of the Pd Nds structure (Supplementary Fig. 12). Furthermore, HRTEM images at the tips of Pd Nds were collected to demonstrate the unique morphology and structure (Supplementary Fig. 13). Note that the intersection angle between the branches and trunk is 60° (Fig. 2j). Inspired by the unique structure, Pd Nds consist of abundant branches with curvature. We then calculated the curvature by measuring the radius (i.e., curvature is the reciprocal of radius) (Fig. 2k and Supplementary Fig. 14)27,28. As a comparison, we changed the synthetic parameters for tuning the curvature of Pd Nds from 1.53 nm−1 to 0.13 nm−1 after adding concentrated hydrochloric acid (HCl, 36 ~ 38 wt.%) into the synthetic system (Supplementary Figs. 14 and 15), which were named as Pd Nds with high curvature (Pd HC-Nds) and low curvature (Pd LC-Nds), respectively. In addition, X-ray absorption near-edge structure (XANES) and extended X-ray absorption fine structure (EXAFS) measurements were employed to study the structures of Pd HC-Nds and Pd LC-Nds. Compared to the K-edge XANES spectra of Pd and PdO, both Pd in Pd LC-Nds and Pd HC-Nds are partially oxidized (Supplementary Fig. 16a). The white line intensity of Pd HC-Nds is slightly higher than that of Pd LC-Nds, which can be attributed to their ultrathin structure and high curvature features, leading to a higher degree of oxidation. Moreover, we determined the position of K-edge with the first derivative of XANES spectra (Supplementary Fig. 16b). Compared to Pd LC-Nds, the energy for the K-edge of Pd HC-Nds positively shifts by 1.1 eV, suggesting that the oxidation state of Pd in Pd HC-Nds is slightly higher than that of Pd LC-Nds. Detailed analysis on EXAFS spectra suggests that coordination number (CN) of Pd−Pd for Pd HC-Nds is 5.34 ± 0.78, which is lower than that of Pd LC-Nds (8.36 ± 0.84) (Supplementary Fig. 17 and Supplementary Table 1), being consistent with the theoretical predictions. Additionally, the negative shift of peaks in the X-ray diffraction (XRD) patterns of Pd-HC Nds and Pd LC-Nds comparing with commercial Pd black (Supplementary Fig. 18), suggesting the stretching of Pd−Pd bond, which is line with EXAFS spectra.

a Low-magnification HAADF-STEM images of Pd HC-Nds. b–d 3D visualization of tomographic reconstruction images of Pd HC-Nds. Low e and high f magnification AFM images of Pd HC-Nds. g The corresponding height profile of Pd HC-Nds. h High-magnification HAADF-STEM and i, j TEM images of Pd HC-Nds. Inset of (i) is a model diagram of a structural unit from Pd HC-Nds. k The relations between average curvature κ, curvature radius R, and CN from the synthesized Pd Nds.

Biomimetic growth process of Pd HC-Nds

The magic intersection angle of 60o inspires us to investigate the growth mechanism for Pd Nds. No products were collected in the absence of CO, suggesting the significance of CO on the formation of ultrathin Pd Nds (Supplementary Fig. 19)29. Moreover, the strong interaction between Pd Nds and CO has been further validated by cyclic voltammetry. A strong CO dissolution peak appears at ~1.04 V vs. RHE on the surfaces of Pd NSs, which is attributed to the CO oxidation on Pd (111) surface (Supplementary Fig. 20)29. For Pd HC-Nds, the peaks become broader and shift to high potential, which suggests that Pd HC-Nds provide more sites for CO adsorption on edge positions in addition to Pd (111) surface. Furthermore, we collected the TEM images of products at different growth times. As shown in Fig. 3a, a branch grew along twisted nanosheets after 5 min. More branches were formed as increasing the growth time to 15 min. Note that the secondary branches, an intersection angle of 60° with the main trunk, were observed after 15 min. Further increase of growth time leads to the formation of main trunks and branches, and hexagram shape was observed after 120 min, being analogous to the snowflake. Based on the above observations, the growth process was schematically illustrated in Fig. 3b. We further studied the influence of reaction parameters on the structure. In the presence of PVP, obvious aggregation was observed, despite the observation of the elongation of nanosheets into branches (Supplementary Fig. 21a−c). Pd nanosheets were obtained when 2-MIM was replaced with 1, 4-dicarboxybenzene (Supplementary Fig. 21d), indicating that 2-MIM played a key role in the synthesis of Pd Nds structures. Consequently, we further investigated the reaction process between 2-MIM and Pd. Initially, we confirmed the oxidation state of the 2-MIM compound through nuclear magnetic resonance (NMR). 1H-NMR was performed on 2-MIM dissolved in DMF, and CDCl3 was used as the deuterated solvent. After dissolving 2-MIM in DMF, the integration ratio of H on NH and CH3 groups was lower than the standard value (1/3), implying that NH underwent deprotonation in DMF (Supplementary Fig. 22a−c). Given that the concentration of 2-MIM in DMF was as low as 0.003 mg/μL in our case, NH in 2-MIM was consumed to be deprotonated into anion. Therefore, the lone pair electrons on N interact with Pd2+ (Supplementary Fig. 22d)30,31. When 2-MIM was replaced with 1, 4-dicarboxybenzene, 1, 4-dicarboxybenzene was unable to interact with Pd2+ due to the absence of N, as a result of the formation of Pd nanosheets (Supplementary Fig. 21d). Besides, the formation of curvature in Pd Nds will inevitably lead to the tension of outer Pd−Pd bonds and compression of inner Pd−Pd bonds (Fig. 3c), which was verified by high-precision TEM images (Supplementary Fig. 23a, b) and corresponding displacement maps (Supplementary Fig. 23c, d)32,33,34. The atomic column positions in the high-precision images were measured with sub-pixel accuracy using two-dimensional Gaussian fitting, which was used to extract information regarding local displacements and strain. The atomic column displacement maps visualize the lattice deformations across Pd Nds, especially at the tip position (Supplementary Fig. 23c, d). Inspired by the above results, we propose a “close edges and open corners” mechanism for the formation of Pd Nds. Specifically, the presence of CO limits the longitudinal growth while enables the lateral growth to form ultrathin nanosheets. Besides, 2-MIM can adsorb and block the edges and lead to preferential growth along the corners of Pd nanosheets (Fig. 3d and Supplementary Fig. 22). Owing to the special feature of Pd (111) surface in Pd fcc unit cell, the secondary branches will growth with the intersection angle of 60° to form the snowflake-like Pd Nds (Fig. 3d).

CO2 hydrogenation to HCOOH

To demonstrate the catalytic performance, Pd HC-Nds, and Pd LC-Nds were directly used as catalysts without any supports for CO2 hydrogenation in a batch stainless-steel reactor embedded with a quartz beaker at room temperature (25 °C). In particular, Pd Nds were dispersed in 15 mL H2O, and the mixture gas of CO2/H2 with a molar ratio of (CO2/H2 = 1/3) was bubbled into solution and pressurize to 3 MPa. Compared to Pd LC-Nds and commercial Pd black, Pd HC-Nds can selectively convert CO2 and H2 to HCOOH with a productivity of 5.1 mmol g−1 h−1 in 2 h at a HCOOH selectivity of ~99.9%, which was confirmed from IC and 1H-NMR analysis (Fig. 4a and Supplementary Fig. 24). Note that the HCOOH selectivity of Pd LC-Nds (~97%) and Pd black (~92.9%) is lower than that of Pd HC-Nds due to the formation of methane, ethane and propane (Fig. 4a and Supplementary Fig. 25). The HCOOH productivity of Pd HC-Nds is ~182 and ~465 times higher than those of Pd LC-Nds and Pd black, respectively (Fig. 4a). No HCOOH was formed in the growth solution of Pd HC-Nds without introducing Pd HC-Nds catalyst, suggesting that HCOOH is indeed generated via CO2 hydrogenation over Pd HC-Nds (Supplementary Fig. 26). Moreover, to demonstrate the potential application of Pd HC-Nds for CO2 hydrogenation, the long-term stability of the catalyst was further evaluated in a gas-flow reactor (Supplementary Fig. 27). Given that Pd HC-Nds without support may suffers from aggregation during long-term test, we loaded Pd HC-Nds on porous sponges (1 × 1 × 0.5 cm) for long-term durability test (inset of Fig. 4b). The productivity of HCOOH gradually increased to ~250 mmol g−1 in 100 h with a nearly linear tendency (Fig. 4b and Supplementary Fig. 28), indicating the enhanced stability of Pd HC-Nds for CO2 hydrogenation to HCOOH. Furthermore, the stability of Pd HC-Nds for CO2 hydrogenation to HCOOH has been validated by the maintained structure (Supplementary Fig. 29a), morphology (Supplementary Fig. 29b) after 100 h, as well as the steady HCOOH productivity in 10 continuous cycles (Supplementary Fig. 30). As a comparison, Pd nanoparticles (NPs) with a size ranging from 3 to 6 nm supported on sponges were synthesized for CO2 hydrogenation in the stainless-steel reactor at 3 MPa (Supplementary Fig. 31a−c). Note that the HCOOH productivity for Pd NPs is only 4.8% of that of Pd HC-Nds (Supplementary Fig. 31d, e), suggesting the structural advantages of high-curvature on CO2 hydrogenation to HCOOH. To further demonstrate the structural advantages of Pd HC-Nds, we synthesized Pd nanosheets without branches for CO2 hydrogenation in a batch reactor (Supplementary Fig. 32a). Despite the similar HCOOH selectivity (~99%), the HCOOH productivity is ~40% lower than that of Pd HC-Nds (Supplementary Fig. 32b, c). Besides, we evaluated the influence of pressure on CO2 hydrogenation over Pd HC-Nds in aqueous solution. The increase of total pressure of CO2/H2 with a fixed ratio of CO2/H2 = 1/3 to 3 MPa (Figs. 4c and 5) MPa (Fig. 4d) strongly favored CO2 hydrogenation to HCOOH. Note the performance of Pd HC-Nds for CO2 hydrogenation to HCOOH in terms of productivity and duration significantly exceeds the reported catalysts (Fig. 4e and Supplementary Table 2). Moreover, we evaluated the performance of CO2 hydrogenation in a continuous glass reactor under ambient conditions (25 °C and 0.1 MPa). ~29 mmol g−1 HCOOH was produced after 130 h at a selectivity of >99%, with a relatively steady formation rate of HCOOH after 60 h (Supplementary Fig. 33), suggesting that Pd HC-Nds can realize the selective CO2 hydrogenation to HCOOH at room temperature (Fig. 4f).

a Catalytic performance towards CO2 hydrogenation to HCOOH in batch reactor. Reaction conditions: VH2O = 15 mL, T = 25 °C, CO2/H2 = 1/3, Ptotal = 3 MPa. b Catalytic performance of Pd HC-Nds loaded on small pieces of sponges (1 × 1 × 0.5 cm) in stainless-steel reactor for 100 h (reaction conditions: VH2O = 150 mL, T = 25 °C, CO2/H2 = 1/3, Ptotal = 3 MPa). Inset of b is the adsorption process of catalyst on sponge, and the real pictures of reaction solution after decompressing. The HCOOH production in a stainless-steel reactor over Pd HC-Nds without sponge (reaction conditions: VH2O = 150 mL, T = 25 °C, CO2/H2 = 1/3, cPtotal = 3 MPa; dPtotal = 5 MPa). e Comparison between Pd HC-Nds and other reported catalysts for CO2 hydrogenation to HCOOH in H2O. f CO2 hydrogenation over Pd HC-Nds in continuous glass reactor for 130 h (reaction conditions: VH2O = 150 mL, T = 25 °C, CO2/H2 = 1/3, Ptotal = 0.1 MPa). Inset is the real pictures of glass reactor.

In-situ DRIFTS spectra of a Pd HC-Nds, b Pd LC-Nds. Reaction pathway diagram for CO2 hydrogenation to HCOOH on the curvature structures, showing changes in reaction free energy, with TS indicating the transition state: c Pd-14 Å, d Pd-23 Å. The inset below shows the molecular structures at each reaction step. The color scheme is as follows: palladium (Pd) atoms are shown in dark teal, oxygen (O) in red, carbon (C) in gray, and hydrogen (H) in white.

Mechanism analysis of CO2 hydrogenation to HCOOH

To visualize the reaction process and intermediates, in-situ diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) was conducted by exposing Pd HC-Nds and LC-Nds to CO2/H2 mixture (CO2/H2 = 1/3, 25 °C, 2 MPa). The observation of *CO2, *COOH, and stretching vibration of C−O (ν(C−O)) demonstrate the production process of HCOOH on Pd HC-Nds surface35,36,37. Besides, the peaks at ~791 and ~900−980 cm−1 in the DRIFTS spectra are corresponding to the deformation vibration peak of CO2− (δ(CO2−)) and the out-of-plane bending vibration of O−H (γ(O−H)), respectively, which gradually weaken with the increased time. While the peak at 800−900 cm−1 corresponds to HCOOH, suggesting the conversion of adsorbed CO2 to HCOOH (Fig. 5a)38,39,40. In contrast, the slight increase of peak of δ(CO2−)/*CO2/*COOH/ν(C−O) and negligible γ(O−H)/HCOOH in the DRIFTS spectra of Pd LC-Nds implies the inferior performance towards CO2 hydrogenation to HCOOH (Fig. 5b), which is in line with the experimental observations. Moreover, DFT calculations were conducted to investigate the pathway for CO2 hydrogenation to HCOOH on Pd-14 Å and Pd-23 Å to mimic Pd HC-Nds and LC-Nds, respectively. Note that Pd HC-Nds give a much lower H2 adsorption energy and H2 dissociation energy than Pd LC-Nds (Supplementary Fig. 34), being a more activated catalyst for CO2 hydrogenation. When Pd-slab was used as a reference, the energy barriers of Pd-slab for *CO2 + *H → *COOH and *CO2 + *H → *HCOO are 0.45 eV and 1.32 eV, respectively, indicating that CO2 hydrogenation on Pd-slab prefers the *COOH intermediate. The energy barrier for the rate-determining step (RDS) of *COOH hydrogenation to *HCOOH on Pd-slab is 1.21 eV (Supplementary Fig. 35). Meanwhile, CO2 hydrogenation on Pd-14 Å and Pd-23 Å also prefer the pathway of *CO2 + *H → *COOH, and the energy barrier for the RDS on Pd-14 Å is 0.70 eV (Fig. 5c). Whereas, for Pd LC-Nds (Pd-23 Å), the RDS for CO2 hydrogenation to HCOOH is *CO2 + *H → *COOH (Fig. 5d). A higher energy barrier (1.02 eV) of Pd-23 Å than that of Pd-14 Å (0.70 eV) suggest that Pd-14 Å tends to promote CO2 hydrogenation to HCOOH, being consistent with experimental observations. The above results demonstrate that the bending of Pd−Pd bond can facilitate both the CO2 adsorption, H2 dissociation, and reduce the energy barrier for CO2 hydrogenation to HCOOH.

Discussion

In summary, we have successfully realized the selective CO2 hydrogenation to HCOOH by integrating theoretical calculations and experimental observations. Theoretically, compared to the regular Pd nanostructures, the bending of Pd−Pd bond breaks the asymmetric potential well, which can further facilitate CO2 adsorption on Pd atoms. Experimentally, we have successfully synthesized Pd nanoneedles via a “close edges and open corners” process, with a magic angle of 60o between the main trunk and branch. Owing to the unique structure of Pd HC-Nds, we have realized the high-performance CO2 hydrogenation to HCOOH. The selectivity of HCOOH, in both closed and continuous models, reaches 99% at room temperature and ambient pressure in water without any other additives. The productivity reaches ~250 mmol g−1 within 100 h by continuously bubbling CO2 and H2 into water at a HCOOH selectivity of 99%. Besides, the increase of pressure significantly promotes the productivity while keeps the high selectivity of HCOOH over 99%. We believe this work opens a new avenue for selective CO2 conversion in an elegant manner, which will attract immediate interest of researchers in the fields of chemistry, catalysis, energy, and beyond.

Methods

Calculation details

All DFT calculations were performed using the Vienna Ab initio Simulation Package (VASP, 6.3.2)41. The calculations employed the Projector Augmented Wave (PAW) pseudopotentials with the PBE Generalized Gradient Approximation (GGA) exchange-correlation functional42,43. The cutoff energy for the plane-wave basis set was set to 400 eV, with a convergence criterion of 10−5 eV. The ionic relaxation was terminated when the force was <0.03 eV/Å. Both structural relaxations and electronic structure calculations were performed using a Monkhorst-Pack type k-point grid to sample the Brillouin zone, with a k-point density of 0.03 Å−1. To avoid interactions between periodic images, a vacuum layer of at least 30 Å was introduced in the c-axis direction perpendicular to the surface. Due to the unsaturated coordination of the curvature structures, spin polarization was considered in the calculations, as the d-orbitals of the transition metal Pd could induce spin asymmetry, potentially affecting catalytic performance.

To more accurately describe the interaction between the surface and adsorbates, van der Waals (vdW) correction (IVDW) was applied44,45. This correction is crucial for dealing with weak intermolecular interactions, particularly in the simulation of large molecular systems or surface adsorption.

The transition state (TS) search was performed using the Dimer method in the VTST package46. The final force on each atom was <0.03 eV Å−1. The initial guess for the geometry in the transition state search was generated using the Climbing Image Nudged Elastic Band (CI-NEB) method47, followed by convergence to the saddle point using the Dimer method. In the Ab Initio Molecular Dynamics (AIMD) simulations, the system temperature was maintained at 300 K using a Nose-Hoover thermostat under canonical ensemble (NVT) conditions. The molecular dynamics time step was set to 1 fs, with a total simulation time of 10 ps to observe the dynamic behavior of the system. To optimize computational resources, water volume models with a volume of 0.5 nm3 were established for both the curvature and planar models, thereby creating a more concentrated water environment in the simulations to enhance the study of intermolecular interactions.

Calculation of adsorption energy

In our study, the adsorption energy \(\varDelta E\) is calculated according to the following formula:

where \(E\{*{ads}\}\) represents the total energy of the adsorption system, \(E\{*\}\) denotes the energy of the bare catalyst surface, and \(E\{{ads}\}\) corresponds to the energy of the isolated adsorbate.

Calculation of Gibbs free energy change

The change in Gibbs free energy \(\varDelta G\) is calculated according to the following formula:

In this equation, \(\varDelta E\) is the adsorption energy, \(\varDelta E\{{ZPE}\}\) is the zero-point energy correction obtained from vibrational frequency calculations, and \(\varDelta S\) represents the change in entropy, also determined using the vibrational frequency calculation method.

Construction and strain application on Pd (111) surface for curvature analysis

To construct structures with different curvatures48,49,50,51,52,53, the Pd (111) surface was selected as the substrate, and a 6 × 3 × 1 supercell was constructed along the x-direction. The selection of the supercell was based on considerations of structural stability and the balance of computational resources. After construction, a strain ranging from 2% to 30% was applied along the x-direction, discretized into 20, 30 and 40 segments, respectively. The strain step size decreased as the number of segments increased, ensuring computational accuracy across a larger strain range. To further analyze the effect of curvature on the structure under different strain conditions, the corresponding curvature radius was calculated.

Calculation for generalized coordination number (GCN)

To accurately describe the coordination environment of Pd nanostructures under strain, we adopted the strain-sensitive generalized coordination number (GCN) as the primary descriptor. The GCN accounts for the influence of lattice strain on the coordination number and provides a more precise quantification of the coordination environment. The GCN is defined as54,55,56:

Here, S represents the percentage of lattice strain, where compressive strain is treated as a negative value and tensile strain as a positive value. The term cn(j) denotes the coordination number of the nearest neighbor atom j, while cnmax is the maximum coordination number in the bulk phase (e.g., 12 for Pd in a face-centered cubic (fcc) structure). The parameter ni represents the number of nearest neighbors for atom i.

Calculation for the d-band center

In Pd curvature structures, the d-band center (εd) is a key parameter for studying catalytic activity and surface electronic properties. Giving the unique structure of Pd Nds, the coordination environment and electronic properties of atoms undergo significant changes. The d-band center can be calculated using the following equation54,55:

In this equation, \({\varepsilon }_{d}^{{surf}}\) denotes the d-band center of surface atoms in the Pd Nds, while \({\varepsilon }_{d}^{{bulk}}\) represents the d-band center of bulk Pd. ECOH represents the cohesive energy of Pd, θd is the d-band occupancy reflecting the filling of d-band electrons, and the factor (f) connects the entire d-band to the Fermi level. Finally, GCNsurf and GCNbulk represent the GCN of surface and bulk atoms in the Pd Nds, respectively. Due to the reduction in GCNsurf caused by bending strain, the d-band center \({\varepsilon }_{d}^{{surf}}\) of surface atoms typically shifts negatively relative to the d-band center of bulk atoms.

Chemicals

Palladium chloride (PdCl2, ≥99.0%) was obtained from Sigma-Aldrich. 2-methylimidazole (C4H6N2, ≥98.0%) was purchased from Aladdin Biochemical Technology Co., Ltd (Shanghai, China). Polyvinyl pyrrolidone ((C6H9NO)n, PVP, MW = 58,000) was obtained from Energy Chemical Co., Ltd. N, N-Dimethylformamide (C3H7NO, DMF, ≥99.5%) and hydrochloric acid (HCl, 36 ~ 38 wt%) were purchased from Sinopharm Chemical Reagent Co., Ltd (Shanghai, China). High-purity CO (99.999%) was purchased from Fuzhou Xinhang Industrial Gas Co., LTD.

Synthesis of Pd Nds

In a typical preparation of Pd HC-Nds, PdCl2 (4.4 mg), C4H6N2 (30 mg), and PVP (150 mg) were dispersed in DMF (10 mL) and ultrasonicated for 1 h, then the mixture was heated at 65 °C for 2 h in an oil bath under 0.2 MPa CO atmosphere. After cooling to room temperature, the products were collected by centrifugation and washed three times with ethanol, followed by fully washing with ultrapure water. The synthesis of Pd LC-Nds was the same as that of Pd HC-Nds, except that 10 mL DMF was converted into a mixture of DMF and HCl (9 mL + 1 mL).

Characterizations

Transmission electron microscopy (TEM) and high angle annular dark field scanning TEM (HAADF-STEM) and high-resolution TEM (HRTEM) were performed on FEI Tecnai F30 transmission electron microscope with an acceleration voltage of 300 kV. 3D visualization of tomographic reconstruction images was conducted on aberration-corrected JEM-ARM300F microscope operating at 300 kV. Atomic force microscope (AFM) images were recorded on a Bruker dimension icon. The X-ray diffraction (XRD) was tested on an Ultima-IV X-ray diffractometer using Cu Kα radiation. The content of metal was measured by the inductively coupled plasma optical emission spectrometer (ICP-OES) conducted with iCAP 7000 Thermo Fisher ICP-OES (Thermo Fisher Scientific, Waltham, MA USA) in axial mode.

XAS measurements

The Pd K-edge X-ray absorption spectroscopy measurements were performed in transmission mode at the TPS beamline BL-44A of the National Synchrotron Radiation Research Center (NSRRC) in Taiwan. Both the sample and reference spectra (Pd metal foil) were collected simultaneously to ensure accurate energy calibration. The acquired EXAFS data were processed using the ATHENA module within the Demeter software suite, following standard analytical protocols. The Pd EXAFS spectra were k2-weighted, and the k-space data from 3 − 12 Å−1 were transformed into real space using a Hanning window (Δk = 0 Å−1). During the fitting process for the Pd EXAFS data, the analysis focused on the k-space range of 3−12 Å−1 and the R-space range of 1−3.5 Å. To enable a precise comparison of bond lengths, the coordination number (CN), interatomic distance (R), Debye-Waller factor (σ2), and edge-energy shift (ΔE0) were all allowed to vary freely. An amplitude reduction factor (S02) of 0.85 was applied consistently across all measurements.

Catalytic performance of CO2 hydrogenation

The CO2 hydrogenation measurement was performed using a closed stainless-steel reactor embedded with a quartz beaker at room temperature (25 °C). In a typical catalytic run, the Pd Nds colloids that dispersed in pure H2O were placed in the reactor, purged 20 min with the mixture gas of CO2 + H2 (CO2/H2 = 1/3), and then pressurized to 3.0 MPa. The reaction was allowed at room temperature and magnetically stirred during the catalysis. After the reaction was over, the solid catalyst was retrieved from the reaction solution by centrifugation. Quantitative and qualitative analysis of the liquid products was done using 1H NMR on the Bruker Advance III 500 MHz instrument. The gaseous products were analyzed by a gas chromatograph (Agilent) equipped with a methanator and flame ionization detector (FID) and thermal conductivity detector (TCD).

Gas-flowing CO2 hydrogenation

High-pressure CO2 hydrogenation experiments were carried out in stainless steel reactor. Where the reactor was connected with the high-pressure cylinders with pressure regulator to keep the target pressure of CO2/H2 (CO2/H2 = 1/3) once CO2 and H2 were consumed. The outlet end is equipped with a liquid trap for collected the liquid product for further analysis. Ambient pressure continuous CO2 hydrogenation was conducted by introducing a mixture of CO2/H2 (CO2/H2 = 1/3) into the solution with a total flow rate of 15 mL/min.

Long term stability experiment

Here, a commercial sponge with a size of 16 cm × 5 cm × 0.5 cm was used as the substrate. To observe the supporting effect of the sponge on catalytic performance, we cut the sponge into several smaller ones (1 cm × 1 cm × 0.5 cm), and then put the cut sponges into Pd HC-Nds aqueous solution. Conduct adsorption experiments under magnetic stirring until all Pd HC-Nds are adsorbed onto the surface of the sponges and the aqueous solution becomes colorless.

CO2 hydrogenation at atmospheric pressure

We conducted CO2 hydrogenation experiments at atmospheric pressure in a glass reactor. Similarly, immerse the sponge sprayed with Pd HC-Nds in H2O. At the intake end, we connect an atomizing device to increase the contact area between gas and H2O, thereby increasing the amount of gas dissolved in H2O.

In-situ DRIFTS measurement

In-situ diffuse reflectance infrared Fourier transformed spectroscopy (DRIFTS) spectra were recorded on a Nicolet iS-50 spectrometer equipped with liquid nitrogen-cooled MCT detector and KBr Optical beam splitter. For in-situ time-resolved DRIFTS spectra of CO2 hydrogenation experiments, the catalyst was exposed to high-purity N2 (30 mL min−1) at 25 °C for 2 h, and the spectrum was taken as the background. Subsequently, the catalysts were exposed to a mixture of CO2 + H2 (CO2/H2 = 1/3, 40 mL min−1) at 25 °C. The spectra were serially recorded in the presence of the CO2 + H2 mixture for 30 min.

Data availability

All relevant data generated in this study are provided in the Supplementary Information/Source Data file. Source data are provided with this paper.

References

Wu, Y. S., Jiang, Z., Lu, X., Liang, Y. Y. & Wang, H. L. Domino electroreduction of CO2 to methanol on a molecular catalyst. Nature 575, 639–642 (2019).

Yang, H. Z. et al. Potential−driven structural distortion in cobalt phthalocyanine for electrocatalytic CO2/CO reduction towards methanol. Nat. Commun. 15, 7703 (2024).

Khan, B. et al. Unassisted photoelectrochemical CO2-to-liquid fuel splitting over 12% solar conversion efficiency. Nat. Commun. 15, 6990 (2024).

Bhattacharjee, S. et al. Photoelectrochemical CO2-to-fuel conversion with simultaneous plastic reforming. Nat. Synth. 2, 182–192 (2023).

Onishi, N. & Himeda, Y. Toward methanol production by CO2 hydrogenation beyond formic acid formation. Acc. Chem. Res. 57, 2816–2825 (2024).

Li, Y. B. et al. Direct conversion of carbon dioxide into liquid fuels and chemicals by coupling green hydrogen at high temperature. Appl. Catal. B Environ. Energy 324, 122299 (2023).

Zhou, W. et al. Enhanced carbon dioxide conversion at ambient conditions via a pore enrichment effect. Nat. Commun. 11, 4481 (2020).

Wang, Y. et al. Carbon−based electron buffer layer on ZnOx−Fe5C2−Fe3O4 boosts ethanol synthesis from CO2 hydrogenation. Angew. Chem. Int. Ed. 62, e202311786 (2023).

Aresta, M., Dibenedetto, A. & Angelini, A. Catalysis for the valorization of exhaust carbon: from CO2 to chemicals, materials, and fuels. Technol. use CO2. Chem. Rev. 114, 1709–1742 (2014).

Wang, W. H., Himeda, Y., Muckerman, J. T., Manbeck, G. F. & Fujita, E. CO2 hydrogenation to formate and methanol as an alternative to photo- and electrochemical CO2 reduction. Chem. Rev. 115, 12936–12973 (2015).

Yu, K. M. K., Yeung, C. M. Y. & Tsang, S. C. Carbon dioxide fixation into chemicals (methyl formate) at high yields by surface coupling over a Pd/Cu/ZnO nanocatalyst. J. Am. Chem. Soc. 129, 6360–6361 (2007).

Xiao, X. et al. Experimental and in situ DRIFTs studies on confined metallic copper stabilized Pd species for enhanced CO2 reduction to formate. Appl. Catal. B Environ. Energy 309, 121239 (2022).

Kuwahara, Y., FuJie, Y., Mihogi, T. & Yamashita, H. Hollow mesoporous organosilica spheres encapsulating PdAg nanoparticles and poly(ethyleneimine) as reusable catalysts for CO2 hydrogenation to formate. ACS Catal. 10, 6356–6366 (2020).

Mori, K., Hata, H. & Yamashita, H. Interplay of Pd ensemble sites induced by GaOx modification in boosting CO2 hydrogenation to formic acid. Appl. Catal. B Environ. Energy 320, 122022 (2023).

Yang, G. X., Kuwahara, Y., Mori, K., Louis, C. & Yamashita, H. PdAg alloy nanoparticles encapsulated in N−doped microporous hollow carbon spheres for hydrogenation of CO2 to formate. Appl. Catal. B Environ. Energy 283, 119628 (2021).

Yang, G. X. et al. PdAg nanoparticles and aminopolymer confined within mesoporous hollow carbon spheres as an efficient catalyst for hydrogenation of CO2 to formate. J. Mater. Chem. A 8, 4437–4446 (2020).

Masuda, S., Mori, K., Futamura, Y. & Yamashita, H. PdAg nanoparticles supported on functionalized mesoporous carbon: promotional effect of surface amine groups in reversible hydrogen delivery/storage mediated by formic acid/CO2. ACS Catal. 8, 2277–2285 (2018).

Mori, K., Sano, T., Kobayashi, H. & Yamashita, H. Surface engineering of a supported PdAg catalyst for hydrogenation of CO2 to formic acid: elucidating the active Pd atoms in alloy nanoparticles. J. Am. Chem. Soc. 140, 8902–8909 (2018).

Shi, H. N. et al. Boosting solar-driven CO2 conversion to ethanol via single-atom catalyst with defected low-coordination Cu−N2 motif. Angew. Chem. Int. Ed. 63, e202404884 (2024).

Sun, B. et al. Engineering low-coordination atoms on RhPt bimetallene for 12-electron ethanol electrooxidation. Energy Environ. Sci. 17, 2219–2227 (2024).

Yuan, J. C. et al. Engineering interfacial low-coordinated Mg3C2+−O3C2− lewis acid-base pairs on MgO for cycloaddition of CO2 with epoxides. ACS Catal. 14, 11045–11050 (2024).

Zhang, Y. Y. et al. Low-coordinated copper facilitates the *CH2CO affinity at enhanced rectifying interface of Cu/Cu2O for efficient CO2-to-multicarbon alcohols conversion. Nat. Commun. 15, 5172 (2024).

Zhao, P. et al. Construction of low-coordination Cu−C2 single-atoms electrocatalyst facilitating the efficient electrochemical CO2 reduction to methane. Angew. Chem. Int. Ed. 62, e202314121 (2023).

Chattot, R. et al. Surface distortion as a unifying concept and descriptor in oxygen reduction reaction electrocatalysis. Nat. Mater. 17, 827–833 (2018).

Luo, H. et al. Sub−2 nm microstrained high-entropy-alloy nanoparticles boost hydrogen electrocatalysis. Adv. Mater. 36, 2403674 (2024).

Moniri, S. et al. Three-dimensional atomic structure and local chemical order of medium- and high-entropy nanoalloys. Nature 624, 564–569 (2023).

Schiller, F. et al. Catalytic oxidation of carbon monoxide on a curved Pd crystal: spatial variation of active and poisoning phases in stationary conditions. J. Am. Chem. Soc. 140, 16245–16252 (2018).

Lv, H., Sun, L. Z., Wang, Y. Z., Liu, S. H. & Liu, B. Highly curved, quasi-single-crystalline mesoporous metal nanoplates promote C−C bond cleavage in ethanol oxidation electrocatalysis. Adv. Mater. 34, 2203612 (2022).

Huang, X. Q. et al. Freestanding palladium nanosheets with plasmonic and catalytic properties. Nat. Nanotech. 6, 28–32 (2011).

He, T. et al. A practice of reticular chemistry: construction of a robust mesoporous palladium metal-organic framework via metal metathesis. J. Am. Chem. Soc. 143, 9901–9911 (2021).

Oh, K. R. et al. Fabrication of hierarchical, porous, bimetallic, zeolitic imidazolate frameworks with the incorporation of square planar Pd and its catalytic application. ACS Appl. Mater. Interfaces 15, 9296–9306 (2023).

Yang, J. et al. Compressive strain modulation of single iron sites on helical carbon support boosts electrocatalytic oxygen reduction. Angew. Chem. Int. Ed. 60, 22722–22728 (2021).

Su, J. J. et al. Strain enhances the activity of molecular electrocatalysts via carbon nanotube supports. Nat. Catal. 6, 818–828 (2023).

Jiang, Z. W. et al. Curvature-induced strain to realize differential lithiophilicity for selective lithium deposition and stable lithium anode. Energy Storage Mater. 72, 103729 (2024).

Dou, T. et al. Dynamic reconstructuring of CuS/SnO2−S for promoting CO2 electroreduction to formate. J. Energy Chem. 82, 497−–506 (2023).

Ma, F. Y. et al. In situ revealing C−C coupling behavior for CO2 electroreduction on tensile strain Ptδ+−Cuδ+ dual sites. Rare Met 43, 6436–6446 (2024).

Li, J. et al. Self-adaptive dual-metal-site pairs in metal-organic frameworks for selective CO2 photoreduction to CH4. Nat. Catal. 4, 719–729 (2021).

Teklemichael, S. T. & McCluskey, M. D. Compensation of acceptors in ZnO nanocrystals by adsorption of formic acid. J. Phys. Chem. C. 116, 17248–17251 (2012).

Janik, I. & Tripathi, G. N. R. The nature of the CO2− radical anion in water. J. Chem. Phys. 144, 154307 (2016).

Millikan, R. C. & Pitzer, K. S. The infrared spectra of dimeric and crystalline formic acid. J. Am. Chem. Soc. 80, 3515–3521 (1958).

Hafner, J. Ab-initio simulations of materials using VASP: density-functional theory and beyond. J. Comput. Chem. 29, 2044–2078 (2008).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Gajdoš, M., Hummer, K., Kresse, G., Furthmüller, J. & Bechstedt, F. Linear optical properties in the projector-augmented wave methodology. Phys. Rev. B 73, 045112 (2006).

Wang, M. J. et al. Phase engineering of Pd−Te nanoplates via potential energy trapping. eScience 4, 100209 (2024).

Jia, J., Li, B. J., Duan, S. Q., Cui, Z. & Gao, H. T. Monolayer MBenes: prediction of anode materials for high-performance lithium/sodium ion batteries. Nanoscale 11, 20307–20314 (2019).

Henkelman, G. & Jónsson, H. A dimer method for finding saddle points on high dimensional potential surfaces using only first derivatives. J. Chem. Phys. 111, 7010–7022 (1999).

Zarkevich, N. A. & Johnson, D. D. Nudged-elastic band method with two climbing images: finding transition states in complex energy landscapes. J. Chem. Phys. 142, 024106 (2015).

Kou, L. Z., Ma, Y. D., Smith, S. C. & Chen, C. F. Anisotropic ripple deformation in phosphorene. J. Phys. Chem. Lett. 6, 1509–1513 (2015).

Tang, S. H. et al. Curvature effect on graphene-based Co/Ni single-atom catalysts. Appl. Surf. Sci. 615, 156357 (2023).

Wang, B. Q. et al. Nanocurvature-induced field effects enable control over the activity of single-atom electrocatalysts. Nat. Commun. 15, 1719 (2024).

She, F. X. et al. Curvature-dependent electrochemical hydrogen peroxide synthesis performance of oxidized carbon nanotubes. ACS Catal. 14, 10928–10938 (2024).

Cepitis, R., Kongi, N., Rossmeisl, J. & Ivaništšev, V. Surface curvature effect on dual-atom site oxygen electrocatalysis. ACS Energy Lett. 8, 1330–1335 (2023).

Chen, F. P. et al. Ethylene electrosynthesis from low-concentrated acetylene via concave-surface enriched reactant and improved mass transfer. Nat. Commun. 15, 5914 (2024).

Calle-Vallejo, F. The ABC of generalized coordination numbers and their use as a descriptor in electrocatalysis. Adv. Sci. 10, 2207644 (2023).

Calle-Vallejo, F., Martínez, J. I., García-Lastra, J. M., Sautet, P. & Loffreda, D. Fast prediction of adsorption properties for platinum nanocatalysts with generalized coordination numbers. Angew. Chem. Int. Ed. 53, 8316–8319 (2014).

Calle-Vallejo, F., Sautet, P. & Loffreda, D. Understanding adsorption-induced effects on platinum nanoparticles: an energy-decomposition analysis. J. Phys. Chem. Lett. 5, 3120–3124 (2014).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (52472310, 22025108, U21A20327, 22121001 to H.X.Q.), the National Key R&D Program of China (2022YFA1504500 to H.X.Q.), the Fundamental Research Funds for the Central Universities (20720240059, 20720240053 to H.X.Q.), the support from the Gusu Leading Talents Program (ZXL2024347 to X.Y.), the Pioneer Hundred Talents Program of Chinese Academy of Sciences, the Scientific Equipment Development Project of Chinese Academy of Sciences, and Youth Innovation Promotion Association Project of Chinese Academy of Sciences (2020026 to X.Y.). Dr. Wang acknowledges the support from China Postdoctoral Science Foundation (2024M763487 to W.M.J.).

Author information

Authors and Affiliations

Contributions

Y.X. designed and supervised this work. M.W. carried out the synthesis/characterizations/catalytic experiments and wrote the manuscript. Y.X. and X.H. revised the manuscript. J.J. and Y.G. conducted theoretical calculations. C.P. and Y.L. are responsible for the X-ray absorption. J.X. measured the 3D visualization images. J.H. and G.Z. carried out the in-situ DRIFTS spectra characterizations. Y.Q., Y.H., F.X., and L.G. participated in the discussion. All authors contributed to the general discussion. M.W. and J.J. contributed equally to this work.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Jae Sung Lee, Meenakshisundaram Sankar, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, M., Jia, J., Xia, J. et al. CO2 hydrogenation to HCOOH catalyzed by aqueous Pd needle assembly. Nat Commun 16, 6454 (2025). https://doi.org/10.1038/s41467-025-61747-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-61747-5