Abstract

Brittle fracture and facile crack initiation present significant challenges for the toughening and processing of cementitious composites. In this work, the continuous and large-scale fabrication of cement-based fiber is enabled by cellulose-assisted wet spinning strategy, during which cement grains are in-situ implanted into porous cellulose matrix. The subsequent hydration process induces the in-situ formation of a hard continuous network which interconnects with the flexible porous cellulose skeleton, leading an interpenetrating dual-network architecture formed within the resulting cellulose-supported cement-based (CSC) fibers. This architecture provides simultaneous mechanical strength and toughness. Moreover, the resulting CSC fibers exhibit hydration-enabled manufacturability and can be woven into fabrics. The CSC fiber fabric demonstrates high toughness and impact resistance, lightweight properties, low thermal conductivity, and great water-resistance, holding significant potential for applications in thermal insulation, seismic high-rise buildings, and durable construction materials.

Similar content being viewed by others

Introduction

Concrete comprised by mixing cement with water, sand, gravel, and other reinforcing agents, is by far the most common building material and the second consumed material only after water in the world1,2,3. Unfortunately, concrete is not sustainable and the concrete industry brings serious environmental impact due to the substantial amounts of CO2 emission. Besides, concrete suffers from low toughness under tension and inferior capability to resist plastically deform4,5,6. With the sustainable economy development and the growing population, there are increasing requirements in new constructing materials with tiny environmental footprint and high mechanical performance. Cement is the indispensable binder component in concrete construction. The hydration reaction drives the cement setting into diverse hydration products which determine the mechanics of concrete7. Especially, calcium-silicate-hydrate (C-S-H) as one of primary hydration products, commonly presents in the form of cohesive gel capable of functioning as a reinforcing adhesive, thereby playing a siginificant role on the ultimate mechanical performance8. Different types of cements have been fabricated with nanomaterials additives, including metal oxide nanoparticles, nanofibers or nanocarbon, in this way to promote the hydration reaction and manipulate the hydration products of cement9,10,11. Great progress has been achieved on improving the mechanical performance of cement-based composites with great resistance to deformation and fracture, together with new functionalities such as self-healing12,13, thermal energy storage14,15, and electrical conducting16,17. Nonetheless, most of the cement/nanomaterial composites are commonly casted into monolithic materials at a macro scale11,18,19, which still have poor impact resistance. Additionally, for cement-based construction, cement grains are usually mixed with water and additives to prepare mortar, which are ready to use when they are hardened. That implies the poor processability of cement-based composites.

Recently, Brewin and Crawford constructed concrete canvas materials (also called concrete cloth)20, i.e., three-dimensional (3D) spacer fabric-reinforced cement-based composite, by filling cement composite powder into the porous surface of 3D spacer fabric and then applying a layer of sealant on the lower surface of the fabric after compaction. The spacer fabric is soft and flexible enough, enabling concrete canvas to be flexibly tailored and deformed to fit various working planes like a soft cloth before hardening21,22. Furthermore, concrete canvas can be made into coils for convenient storage and transport. These advantages bring beneficial effects for concrete canvas when they are applied in the protection of emergency tents and shelters, emergency repair and construction of airport pavement, and other emergency engineering projects, outperforming conventional cement-based materials23,24. However, the planar structure with a certain thickness still restrict the practical applications of concrete canvas in the daily life, especially where the special-shaped cementitious materials are required. Compared with concrete canvas, the elementary cement-based fiber can be woven into various fabrics due to its high flexibility. This flexibility of cement-based fiber also enables great convenience during practical applications. Designing flexible cement-based composite fiber materials (cement-based fibers) and further weaving them into fabrics via conventional textile process would spring up the emergence of new cementitious materials which combine the features of both cement and textile materials, holding enormous potential in the field of strong and tough building materials for constructing engineering projects. However, the development of cement-based fibers faces great difficulty in fiber forming due to the nature rigidness and non-adhesiveness of anhydrous cement grains. Despite the hydration promotes the formability of cement grains, the hardening effect hampers the further processing.

In this work, we demonstrate the continuous and large-scale fabrication of cement-based fibers via cellulose-assisted wet spinning strategy. The cellulose-assisted wet spinning strategy allows the in-situ implantation of hard cement phase into soft cellulose matrix with good interfacial bonding, that results in an interpenetrating dual-network architecture for the obtained cellulose-supported cement-based (CSC) fibers. Within the bi-phase composite, the roles of renewable and sustainable cellulose have been demonstrated, including providing continuous skeleton acting as nucleation sites for hydration products grown, facilitating the hydration degree, contributing the fiber forming, and promoting gains in mechanical performance. More intriguingly, CSC fibers have great editability and molding capabilities, which can be woven and shaped into cement-based fabrics via a simple hydration setting process. As-woven cement-based fabrics combine the features of high mechanical properties, low density, low thermal conductivity, and feasibility of large-scale fabrication, outperforming the conventional cement-based composite materials.

Results

We proposed a cellulose-assisted wet spinning strategy to develop cement-based fiber materials (Fig. 1a). To achieve this, firstly, wood cellulose was dissolved in LiCl/DMAc solvent to prepare cellulose solution (Supplementary Fig. S1a), and then cement grains (Supplementary Fig. S1e–g) are added into the solution. The adding content of cement grains was adjusted, with cellulose/cement mass ratio from 1:0 to 1: 50 (Table S1). The obtained cellulose-cement composite suspensions present good stability without obvious precipitation of cement grains after standing for 12 h at room temperature (Supplementary Fig. S1b–d). That is attributed to the cellulose functioning as the dispersant and stabilizer for cement grains25,26. Moreover, with incorporation of cement grains into cellulose solution, the obtained composite suspensions show high fluidity, as indicated by the viscosity measurement, as evidenced by viscosity measurements (Supplementary Fig. S2). Even with the loading content of cement grains as high as 50 wt.% respect to cellulose matrix, the corresponding composite suspension shows a low viscosity of 11.7 Pa.s, implying a high fluidity. Besides, cellulose-cement composite suspensions show shear thinning feature, that brings benefits for them to be used as spinning solution for wet spinning (rate of 10 cm/s, anhydrous ethanol coagulation bath) (Fig. 1b). During spinning process, cellulose is regenerated to form gel fiber to support structural stability and integrity. Meanwhile, the cement grains are in situ embedded within the cellulose gel matrix with tight interfacial bonding27, which prevents the cement grains falling off from the gel fiber. Such synergistic effect ensures the continuous and large-scale fabrication of cellulose-cement composite gel fibers (Fig. 1b, Supplementary Movie 1). In this way, we obtain a series of composite gel fibers from different composite suspensions, which are marked as CSCx, where x is the mass multiple of cement respect to cellulose in the corresponding composite suspension (Supplementary Table S1). Thereafter, those cellulose-cement composite gel fibers were washed with ethanol for several times to remove the residual solvents followed by drying at room temperature. Finally, as-dried CSC fibers were immersed in water for hydration to obtain hardened cement-based fibers.

a Fabrication and hydration process of the cellulose-supported cement fiber. Stage I refers to the initial dried state, Stage II refers to the fiber at early stage of hydration, and Stage III refers to the hardened cement-based fiber after sufficient hydration. b Schematic diagram of the wet spinning process and the photograph of cellulose-cement gel fibers. c Large-sized fabric woven by CSC fibers. d Illustration showing the potential application of cellulose-supported cement fibers for construction.

It should be noted that the entire wetting spinning process of composite gel fiber is conducted under an anhydrous environment to avoid the hydration of cement. Therefore, as-spun composite gel fibers are flexible to be woven into fabrics via conventional textile process (Fig. 1c, Supplementary Movie 2), showing a good manufacturing capability. Subsequently, the hydration process makes as-woven fabrics hardening and molding, that generates cement-based fabrics which hold promising potential toward the building constructions where the customized cement materials are required (Fig. 1d).

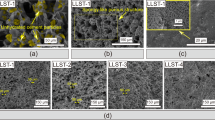

After gel fiber fabrication, the influence of cement loading amount on the morphology of cellulose-cement composite fibers was investigated before hydration. For neat cellulose fiber regenerated in anhydrous ethanol, it has a compact structure (Fig. 2a) differing from the traditional porous network of cellulose gel fiber regenerated in water28. This might be due to the flux-in rate of ethanol molecule toward fiber internal lower than the flux-out rate of the solvent (LiCl/DMAc) from the fiber. Such difference in solvent exchange rate causes the fiber collapsed29. Introducing cement grains into cellulose matrix has no effect on the fiber formation during wetting spinning. As we can see, all the cellulose-cement composite suspensions used as spinning solution enables the continuous fabrication of composite fibers with good structural integrity, except that the diameter of fiber becomes larger with increasing the cement loading (Fig. 2b–d). As observed at higher magnification, the presence of cement grains makes the cellulose matrix changed from compact to porous, accompanied with the density of 1.51 g/cm3 for compact cellulose fiber decreased to 1.36 g/cm3 for the porous composite fiber. In turn, as-formed porous cellulose skeleton supports the uniform distribution of cement grains within it, that prevents the aggregation of cement grains with themselves (Fig. 2b–d). Especially, for CSC10 fiber, the cement grains are well embedded in the continuous porous network of cellulose (Fig. 2c). However, excessive cement adding as high as 5000 wt.% respect to cellulose causes the porous network damaged (Fig. 2d).

SEM images of the cross section of a neat cellulose fiber, b CSC1, c CSC10, d CSC50 and their corresponding enlarged view. SEM images of CSC10 after hydration for e 1d, f 3d, g 7d, and h 28d and their corresponding enlarged view. Scale bar: (a–d, top panel) 200 μm, (a–d, bottom panel) 10 μm, (e–h, top panel) 100 μm, and (e–h, bottom panel) 10 μm.

We further investigated the hydration process of CSC fibers by monitoring the microstructure evolution of CSC10 fiber with different curing time. At the early stage of hydration for 1d, most of cement grains are involved in hydration reaction that generates two major hydration products with needle- and honeycomb-like morphology (Fig. 2e), which are corresponding to ettringite (AFt) and C-S-H gel respectively as confirmed by EDS mapping analysis (Supplementary Fig. S3). After curing for 3d, increased hydration products are generated and intermixed within the fiber matrix (Fig. 2f). Besides, benefiting from fiber surface providing nucleation sites, needle-like hydration products form along the fiber surface (Supplementary Fig. S4a). As the hydration extended for 7d, the hydration products within the fiber matrix become formless (Fig. 2g), and the hydration products on fiber surface become dense and aggregated (Supplementary Fig. S4b). The hydration products within the matrix fill the pores to form an intimately interweaved architecture, indicative of a high degree of hydration occurred at this stage30. With the hydration prolonged to 28d, no obvious microstructure change was observed within the fiber except that the hydration products on the fiber surface become more evident compared with that of 7d (Fig. 2h), suggesting that the hydration reaction continuously proceeds during this period.

To further investigate the hydration degree of CSC fibers with different curing time, thermogravimetric (TG) and derivative thermogravimetric (DTG) measurements were conducted according to previous works27,31. Initially, CSC fibers before hydration have two major weight loss at around 250–350 °C and 600–650 °C (Supplementary Fig. S5), which are assigned to the decomposition of cellulose and gypsum and the decarbonation of lime filler31, respectively. After hydration with different curing time, the hydrated CSC fibers present weight loss at 50–150 °C, 300–400 °C, 400–550 °C, and 650–750 °C (Supplementary Fig. S5), which are related to the dehydration of hydration products, decomposition of C-S-H or Aft, dehydroxylation of the calcium hydroxide, and the decarbonation of CaCO3, respectively32. Note that the mass-loss rate around 300–400 °C reaches the highest value of 1.47%/min from 1d to 7d, and then gradually decreases to 1.14%/min after 14d, and as low as 1.07%/min after 28d (Fig. 3a). That indicates many hydration products of C-H-S or AFt developed within 7d of hydration coinciding with SEM observation. Further, XRD analysis (Fig. 3b) reveals that the characteristic peaks located at 32.8°, 41.5°, 56.9°, and 60.3°, which assigned to the Alite (A, tricalcium silicate, C3S) and Belite (B, dicalcium silicate, C2S) corresponding to the un-hydrated cement, show great decrease in their intensity after hydration for 7d, with reduction of 37%, 39%, 27%, and 53%, respectively. With the hydration proceeded up to 28d, no obvious change was observed for the main hydration products with only a slight decrease in the intensity of characteristic peaks (C3S and C2S). All the results above suggest a high degree of hydration occurred within 7d, reaching 61.7% as calculated according to Bhatty33, and the hydration rate slow down progressively with the hydration prolonged to 28d.

a DTG curves and b XRD patterns of hydrated CSC fibers with different curing time from 1 to 28 d. c–f SEM images showing cellulose skeleton acting as nucleation sites for hydration products. Yellow arrows indicate the cellulose skeleton. Scale bar: 2 μm. g Schematic diagram of the Ca-O connections and H bonds between cement and cellulose during the hydration process. h Schematic diagram of the cellulose network promoting the hydration process of cement. The green coloring indicates the cellulose network and the dashed arrows indicates the water diffusion from cellulose network to cement phase. Source data are provided as a Source Data file.

As is well known, during curing, the hydration product commonly forms a shell around the unhydrated cement particles, that slows down the diffusion of water molecules to its interior, hence limiting the hydration rate34. Compared with that, we suggest the presence of cellulose skeleton bring benefits on accelerating the hydration for CSC fibers. Specifically, with monitoring the structure evolution of CSC fiber during hydration via SEM observation, it clearly shows that more and more hydration productions are formed on cellulose skeleton with hydration time prolonged (as yellow arrows indicated in Fig. 3c–f). That is attributed to cellulose skeleton with good hydrophilicity act as nucleation sites for hydration products, leading a faster hydration process35. Importantly, the cellulose network supports the uniform distribution of cement grains within it (Fig. 2c), providing a short-circuit diffusion effect for cement grains34. That is, the cellulose skeleton works as a transport channel to enable water transfer into the un-hydrated grains (Fig. 3g, h), thereby facilitating a larger portion of cement reacting with water compared with the cement grains without cellulose skeleton.

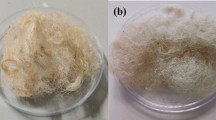

Due to the cellulose skeleton acting as nucleation sites for hydration products, the hydrated productions are well connected to the cellulose skeleton without obvious cracks and separations (Fig. 3f), that greatly supports the structural integrity of the obtained CSC fibers. To further investigate the composite architecture, the CSC fibers after hydration for 7 d were subjected to burning and acid hydrolysis treatments, respectively (Fig. 4a). Considering that the hydration products are very easy to decompose in hydrochloric acid (Supplementary Fig. S6) while cellulose is acid-resistance36, based on this, the hydrated cement phase can be removed from composite fibers while the cellulose network is remained after acid hydrolysis treatment. Indeed, as we can see, the hydrated CSC fibers with relative low cement loading (CSC0.5-10) can well retain the fiber shape like the neat cellulose after HCl treatment (Fig. 4b, Supplementary Fig. S7). SEM image shows that the continuous cellulose skeleton is well kept in the retaining fiber (Fig. 4c), which is robust to support the fiber shape under acid condition. However, with high loading content of cement grains, the corresponding CSC fibers (CSC20-50) collapse after acid treatment (Fig. 4b, Supplementary Fig. S7). That might be due to that the excessive loading of cement breaks the continuity of cellulose network, which is not strong enough to support the fiber structural integrity. In addition, due to that cellulose and hardened cement show different stability to thermal treatment (Supplementary Fig. S8), we can remove the cellulose matrix from the composite fiber via burning treatment. For neat cellulose fiber, it is ignited extremely quickly and engulfed in flames, leaving char residue powder after complete burning (Fig. 4d, left). Incorporating cement into cellulose matrix greatly improves the fire-resistant capability for the composite fiber (Supplementary Fig. S9). In particular, when the loading amount of cement over 1000 wt.% relative to cellulose, the corresponding CSC fibers (CSC10-50) well retain the fiber shape after complete burning (Fig. 4d). SEM image further reveals that the remaining fiber shows an interconnected structure composed by hardened cement phase (Fig. 4e). According to the above observations, only for CSC10 fiber after hydration, the self-supported hard skeleton combined with continuous cellulose skeleton is obtained. As further confirmed by 3D X-ray tomography, within hydrated CSC10 fiber, cellulose and hydrated cement capable to generate isotropic 3D interconnected structures by themselves (Fig. 4f). The two phases are connected and supported with each other to form an interpenetrating dual-network architecture for the hardened cement-based fibers.

a Schematic diagram of CSC fibers subjected to acid and burning treatments. b Photographs of the acid treatment for CSC fibers and c SEM images of CSC10 after acid treatment. d Photographs of the burning treatment for CSC fibers and e SEM images of the CSC10 after burning treatment. f Micro-CT visualization of CSC fibers showing continuous cellulose phase, interconnected cement phase and air phase in their architectures.

We note that CSC fibers experience different stages in their mechanical behavior upon hydration process. Specifically, as shown in Supplementary Fig. S10, the dried composite fiber is rigid with a high Young’s modulus of 54.2 MPa at initial state (stage I). Once immersing in water, the wet fibers become soft and flexible at a very early stage of hydration (within 1 d), showing obvious decline in strength and Young’s modulus and increase in elongation (stage II). As prolonging the immersing time, the fiber becomes stiff with the highest Young’s modulus of 90.8 MPa due to the hardening effect after sufficient hydration (stage III). Based on the changes in mechanical properties, CSC fibers are enabled with good editability capability, which are further evaluated by knotting test (Fig. 5a, b). The minimum radius (r) of the knotted ring before fiber broken was measured to evaluate the editability37, and the smaller r, the better editability. As shown in Fig. 5e and Supplementary Fig. S11, the loading amount of cement affects the editability capability of CSC fibers. With a low cement loading below 1000 wt.%, CSC fibers show good editability comparable to that of neat cellulose fiber during hydration process, with the minimum r close to zero. When the cement loading reaching 1000 wt.%, the editability capability starts to decrease. As the cement loading as high as 5000 wt.%, the corresponding CSC fibers become very stiff and are prone to break when knotting, presenting a very poor editability capability. The hardened cement network combined with the damaged cellulose network accounts for the poor editability for CSC fibers with high cement loading.

Schematic of a knotting experiment and the b photographs of the cement fibers with different cement content under different states. Schematic of c hanging experiment and the d photographs of the cement fibers under different states. Comparison of e the radius and f the angle of the cement fibers with different cement content under different states. Error bars represent standard deviations, and the number of replicates, n = 6. g Improvement of the solutions over iterations. The former numbers in parentheses represent the cellulose content within the cement-based fibers, and the latter numbers in parentheses refers to the content of cement respect to the cellulose matrix. Various fabrics weaved using the CSC10 fibers including h cement fiber/viscose yarn mixed woven fabric, i cement fiber/cotton yarn fabric with plain weave, j twill weave, and k satin weave. l Weavable and hydraulic performance of the pure cement fiber fabrics. The blue arrow indicates softening of the fabric upon brief water exposure, while the red arrow denotes hardening under prolonged immersion. Application of the pure cement fibers fabric for m pen holder and n cement fiber/cotton yarn fabric for fracture fixation. Source data are provided as a Source Data file.

The molding capability of CSC fibers is another key factor in term of their practical applications, which is evaluated via the handing test (Fig. 5c, d). The angle (α) between the fiber and the horizontal line refers to molding capability38, and the smaller α, the better molding capability. As shown in Fig. 5f and Supplementary Fig. S12, CSC fibers with low cement loading below 1000 wt.% present α close to 90° even after sufficient hydration, indicating that the composite fiber are too soft to self-support and reflecting a poor molding capability. This might be attributed to that the hardening effect from the hydration of low-content cement grains is not enough to support the fiber self-standing. When increasing cement content to 1000 wt.%, the hardened network start to form within the hydrated CSC fiber that allows the modeling capability. As further increase in the cement loading to 5000 wt.%, the modeling capability is the highest as indicated by the smallest α value.

The editability and molding are highly associated to the weavability of CSC fibers. Based on this, optimization algorithm (Supplementary Fig. S13) was applied to optimal the cellulose/cement component for CSC fibers, in terms of manufacturability, formability, and comprehensive mechanical performance for the final cement-based fabrics. In the optimization stage, the maximum number of iterations Nmax is defined as 15 and the optimal cost Joptimal of jumping out of the loop is 5 to ensure efficiency. Considering that both editability and molding are equally important, the objective weight value \({\omega }_{i=1,\ldots,4}\) are defined as (0.5, 0.5, 0.5, 0.5), and the target value \({O}_{i=1,\ldots,4}\) that needs to be optimized is taken as (60, 40, 1.5, 3) to balance the editability and molding properties. Figure 5g shows the improvement of the cost value over iteration times. The optimization algorithm realizes the rapid reduction of the cost function. The condition for jumping out of the loop is satisfied when the number of iterations reaches 12. When the mass ratio of cellulose and cement is ca 1: 10, which corresponds to CSC10 fiber, the final angle and radius are 61.85, 40.50, 1.59, 3.01, which meets the requirement for the fabric weaving.

Indeed, CSC10 fibers with both editability and molding capabilities demonstrate great manufacturability, which can be woven into diverse fabric materials via a facile hydrtion setting method. Specifically, the dried CSC10 fibers are immersed in water for softening. Then, the wetted fibers are woven followed by hardening to obtain cement-based fabrics. As a result, the wetted fibers, either with themselves or other fibers like cotton or viscose yarns, can be woven into diverse fabrics with different structures including plain weave, twill weave, and stain weave, via conventional processing process (Fig. 5h–k, Supplementary Movie 2). Moreover, the obtianed fabrics also present three different stages in their mechanical performance during hydration process (Fig. 5l), in consistence with that of CSC fibers. That allows as-woven fabrics to be further shaped into 3D complex constructions (Fig. 5m, n), which is elusive for the traditional cement-based composite materials.

Finally, we evaluated the potential of the as-woven cement-based fabrics for practical application in terms of mechanical property, thermal conductivity, and water-resistance. Firstly, a typical three-point bending test commonly used for cementitious materials39, was conducted to investigate the flexural strength of as-prepared cement-based fabrics. As shown in Fig. 6a, CSC10-woven fabric (CSC fabric) after 7-d hydration has a greatly improved flexural strength with extended elongation, compared with cellulose-supported cement-based plate (CSC gel) and pristine cement (CM) plate. Accordingly, CSC fabric enables a high toughness reaching ca. 600 kJ m-3. Such mechanical performance combined the light-weight feature (with a low density of 1.2 g/cm3), intensifies the merits on the specific toughness of as-woven cement-based fabrics as comparison to various kinds of cement-based composite materials (Fig. 6c)40,41,42,43,44,45, fibreglass mesh, or AR glass textiles-reinforced foamcretes which have the light-weight feature similar to that of cement-based fabric46,47 (Supplementary Fig. S14). Besides, CSC10 fabric also demonstrates greatly enhanced impact resistance (Fig. 6b) in contrast to the pristine cement plate which is brittle and prone to crack due to the stress concentration within the plate structure (Supplementary Fig. S15). Based on above, we claim that the high toughness and impact resistance for as-woven farics are attributed to benefits from the interpenetrating dual-network architecture of elementary fibers and the braided structure of fabric, which contribute to dissipate loading energy and prevent crack propagation, hence achieving a good fracture resistance. Indeed, as confirmed by Numerical simulation analysis (Fig. 6d, e), as-woven fabric shows a great capability to absorb energy and a plastically deform without fracturing. Beyond the impressive mechanical performance, cement-based fabrics also show a low thermal conductivity coefficient comparable to that of commonly-used aerated concrete, while the latter suffers poor mechanical strength48. Besides, the resulting cement-based fabrics demonstrate low hygroscopicity and great water-resistance capability (Supplementary Fig. S16), they can well maintain the structural stability for a long time in water environment (Supplementary Fig. S17). Overall, the proposed cement-based fabrics demonstrate a promising potential to be use in practice due to their multiple superiorities (Fig. 6f).

a Flexural stress-strain curves and b impact resistance of the cement plate, CSC gel and CSC fabric. c Toughness comparisons between the as-woven cement fabrics and other cement-based composite materials40,41,42,43,44,45. Numerical simulation of stress state under impact of d CSC gel and e CSC fabric. f Comparing multi functions of as-woven fabrics to those of cement plate and CSC gel. Source data are provided as a Source Data file.

Discussion

In summary, we report a facile method to fabricate cellulose-support cement fibers on a large scale via wet spinning, during which the cement is in situ implanted into cellulose matrix. As-obtained fibers after hydration that generates cement-based fibers with an interpenetrating dual-network composite architecture composed by interconnected hardened structure and continuous cellulose network with tight interfacial bonding. The resulting hydrated composite fibers show high toughness and impact resistance outperforming most of cement-based composites. More importantly, the cement-based fibers present great processing and manufacturing capability via a simple hydration setting method, which can be woven into diverse cement-based fabric constructions with complex 3D configurations. Furthermore, those cement-based fabrics combine excellent performances including good toughness, high strength, lightweight, thermal insulation, water-resistance, and the feasibility of large-size fabrication, holding great promising in many potential applications, including construction engineering, art work, water conservancy engineering, civil engineering, decoration engineering.

Methods

Materials

The cellulose (Mη = 10.0 × 104), wood pulps with α-cellulose more than 97%, obtained from Jinhuan Co., Ltd. (Hubei, China). N, N-Dimethylacetamide (DMAc, chemical reagent), and absolute ethanol (EtOH, analytical grade) were purchased from Sinopharm Chemical Reagent Co. (Shanghai, China). Anhydrous aluminum chloride powders (LiCl, analytical grade) were provided by Macklin Biochemical Technology Co. (Shanghai, China). Ordinary Portland cement with a strength grade of 42.5 was obtained from Huaxin cement plant, Hubei province, PR China.

Cellulose solution preparation

Cellulose solution was prepared according to previously reported methods49. In brief, the raw wood slurry was activated with DMAc at 162 °C and then dried. The activated wood slurry was dissolved in a 9 wt.% LiCl/DMAc solution with mechanical stirring at 112 °C to obtain a transparent cellulose solution.

Cellulose-supported cementitious fiber fabrication

Cement grains were added into cellulose solution under continuous stirring to obtain uniform cement-cellulose composite dispersion. The cellulose/cement mass ratio in the solution was tuned, from 1:0 to 1:50 w/w% (Supplementary Table S1). Those cellulose-cement composite suspensions were used as spinning solution directly for wetting spinning, which were drawn into a syringe and slowly extruded into an absolute ethanol bath. In this way, a series of cement-cellulose composite gel fibers were generated, which were marked as CSCx fibers, where x is the mass multiple of cement respect to cellulose in the corresponding composite suspension (Supplementary Table S1). The obtained composite gel fibers were washed with ethanol for several times followed by drying at room temperature to obtain cellulose-supported cement-based (CSC) fibers. Finally, the dried fibers were immersed in water for hydration with different curing time to obtain hardened CSC fibers. Additionally, the water-to-cement (w/c) ratio of CSC fibers upon hydration process with different curing time was monitored, as shown in Supplementary Fig. S18. It can be seen that the value of w/c ratio increases greatly at very early stage of hydration and levels off at ca. 0.3 with the hydration proceeded continuously.

Characterization

SEM images of CSC fibers were obtained using a Phenom Pure instrument (Fu Na, China). The wet-spun fibers were soaked in tertiary butanol for 3 h at −10 °C, freeze-dried for 48 hours, and then embrittled in liquid nitrogen to prepared the SEM samples.

Energy dispersive X-ray spectroscopy (EDS) was carried out via field-emission scanning electron microscopy (FE-SEM) (JSM-6701F, JEOL), equipped with an EDS system (INCA Energy, Oxford Instruments Analytical Ltd.).

X-ray diffraction (XRD) of the cement fibers was examined with a Rigaku Miniflex600 diffractometer operated at 40 kV and 40 mA in reflection mode with Cu Kα radiation (λ = 0.154 nm) over the 2θ range from 4° to 80°.

Thermal gravimetric analysis (TGA) was performed on TA Instruments SDT Q500 thermogravimetric analyzer (New Castle, DE, USA) under nitrogen atmosphere (40 mL/min) from 30 to 800 °C at a heating rate of 10 °C/min.

The Micro-CT (skysCan2211, Bruker, Germany) was used to characterize the hardened fibers, with a scanning voltage of 40 kV, a current of 50 μA, and a resolution of 1.3 μm.

Mechanical testing was performed on the fibers using a universal tensile tester (YG004, Laizhou Electronic Instrument Co., Ltd. China). Two ends of the fiber sample were wrapped with filter paper to prevent the fiber sliding during stretching. Then, the samples were stretched at room temperature at a rate of 5 mm/min with a firmware separation distance of 10 mm (Supplementary Movie 3). The distance of the fixture movement is accurately recorded by the tester for strain calculation. Young’s modulus was defined as the ratio of stress to strain during elastic loading50. The same test conditions were used for further testing on water-wetted and hardened staple fibers.

Three-point bending tests were conducted on the cement plate, CSC gel and CSC fabric using the Instron 5943 testing machine. The loading speed of crosshead was 2 mm/min. The sample size was 80 mm × 13 mm × 2 mm and the support span were 64 mm.

The low-velocity impact tests on the cellulose-cement composites were performed on an Instron Ceast 9350 drop-weight machine, in which a load cell and LVPT was used to measure the impact force and displacement respectively. Total mass of the drop weight was 10 kg, and the initial kinetic energy was changed by different dropping heights to achieve different initial impact velocities. In this study, the initial impact velocities (i.e., 2.5 m/s) were pre-established.

The hydration degree of CSC fiber has been assessed according to Bhatty33.

where α is the hydration degree expressed in percentage. Ldh, Ldx, and Ldc are weight losses on TGA and DTA plots during dehydration of the C-S-H gel, dehydroxylation of the calcium hydroxide, and decarbonation of the carbonates, respectively.

To anticipate the impact resistance of cellulose-cement composite materials, a multiscale model was established for finite element analysis (using ABAQUS). At microscopic scale, yarns were considered transversely isotropic. Mechanical parameters for both fibers and cement were derived from fundamental experimental tests. Employing a Representative Volume Element (RVE), mechanical performance parameters of yarn were calculated, subject to periodic boundary conditions. At macroscopic scale, yarns were systematically assembled into fiber-reinforced cementitious composites. An incremental damage model was applied to simulate the damage behavior observed in impact tests on composite materials. Fabric mesh type used in the test was C3D8R, with a total of 12,576 elements. The cement plate type adopted was C3D8R, comprising a total of 7220 elements.

The muti-objective parameters optimization algorithm design was listed as follows. The cellulose concentration (CCL) and the weight ratio of cement/cellulose (RCC) have a significant impact on the rigidity and flexibility of the cement fibers. Therefore, a multi-objective optimization model was used to evaluate the relationship between CCL/RCC and the stiffness/flexibility of cement fibers. The CCL before and after adding water was defined to be \(c{c}_{1}\) and \(c{c}_{2}\), respectively. Define RCC before and after entering the water as \(r{c}_{1}\) and \(r{c}_{2}\), respectively. The vertical angle and fiber knot radius which before and after entering water are chosen as the optimization objective. The optimize object parameter are devoted as \({\alpha }_{1}\), \({\alpha }_{2}\), \({r}_{1}\) and \({r}_{2}\). Therefore, the optimal CCL and RCC can be transformed as the follow discrete model:

where, \({s}_{i=1,\ldots,4}\) are chosen section for the CCL/RCC in this paper. Inspired by the foraging of bee colonies, this section designs a discrete artificial bee colony optimization algorithm to obtain the optimal CCL and RCC. The design of the method aims to reduce the number of experiments and improve efficiency. The algorithm process is shown in Supplementary Fig. S13.

Data availability

The data supporting the findings of this study are available within the article and its Supplementary Information as well as Source Data. Source data are provided with this paper.

References

Wahedy, M. N., Sharbatdar, M. K. & Rezaifar, O. Mechanical, environmental, and economic assessment of sustainable cement mortar using Afghan natural pozzolan as a partial replacement for cement. Constr. Build. Mater. 386, 131574 (2023).

Gu, Y. et al. Characterization of solidification for disposal of hazardous waste landfill leachate. Environ. Sci. Pollut. Res. 27, 4227–4235 (2020).

Kamau, J., Ahmed, A., Hirst, P. & Kangwa, J. Suitability of corncob ash as a supplementary cementitious material. Int. J. Mater. Sci. Eng. 4, 215–228 (2016).

Manzano, H. et al. Do cement nanotubes exist?. Adv. Mater. 24, 3239–3245 (2012).

Mehta, P. K. & Monteiro, P. J. M. Concrete: microstructure, properties, and materials, 4th ed. (McGraw-Hill, 2014).

Liu, X. et al. High Energy Absorption Nacre-Like Calcium Silicate Hydrate (C-S-H) composite toward elastic cementitious materials. Adv. Funct. Mater. 34, 2307437 (2024).

Ioannidou, K. et al. Mesoscale texture of cement hydrates. Proc. Natl Acad. Sci. 113, 2029–2034 (2016).

Allen, A. J., Thomas, J. J. & Jennings, H. M. Composition and density of nanoscale calcium–silicate–hydrate in cement. Nat. Mater. 6, 311–316 (2007).

Banthia, N. & Sappakittipakorn, M. Toughness enhancement in steel fiber reinforced concrete through fiber hybridization. Cem. Concr. Res. 37, 1366–1372 (2007).

Wang, R., Wang, P.-M. & Li, X.-G. Physical and mechanical properties of styrene–butadiene rubber emulsion modified cement mortars. Cem. Concr. Res. 35, 900–906 (2005).

Krystek, M. et al. High-performance graphene-based cementitious composites. Adv. Sci. 6, 1801195 (2019).

Dinarvand, P. & Rashno, A. Review of the potential application of bacteria in self-healing and the improving properties of concrete/mortar. J. Sustain. Cem. Based Mater. 11, 250–271 (2022).

Aytekin, B., Mardani, A. & Yazıcı, Ş State-of-art review of bacteria-based self-healing concrete: biomineralization process, crack healing, and mechanical properties. Constr. Build. Mater. 378, 131198 (2023).

Wang, S. et al. Thermal energy storage in concrete: review, testing, and simulation of thermal properties at relevant ranges of elevated temperature. Cem. Concr. Res. 166, 107096 (2023).

Singh, A. K., Rathore, P. K. S., Sharma, R., Gupta, N. K. & Kumar, R. Experimental evaluation of composite concrete incorporated with thermal energy storage material for improved thermal behavior of buildings. Energy 263, 125701 (2023).

Lu, D. et al. Growing nanocrystalline graphene on aggregates for conductive and strong smart cement composites. ACS Nano 17, 3587–3597 (2023).

Caruso, L., Buhagiar, V. M. & Borg, S. P. The Double C block project: thermal performance of an innovative concrete masonry unit with embedded insulation. Sustainability 15, 5262 (2023).

Dimov, D. et al. Ultrahigh performance nanoengineered graphene–concrete composites for multifunctional applications. Adv. Funct. Mater. 28, 1705183 (2018).

Xu, X. et al. Colonial sandcastle-inspired low-carbon building materials. Matter 6, 3864–3876 (2023).

Li, H. et al. Application design of concrete canvas (CC) in soil reinforced structure. Geotext. Geomembr. 44, 557–567 (2016).

Han, F. et al. Improvement of mechanical properties of concrete canvas by anhydrite-modified calcium sulfoaluminate cement. J. Compos. Mater. 50, 1937–1950 (2016).

Ma, X., Chen, C., Dong, Z. & Ma, P. Mechanical performance of concrete canvas reinforced with insert-bar structures under quasi-static and impact loading. Constr. Build. Mater. 409, 133915 (2023).

Liu, S. et al. Review on the design and application of concrete canvas reinforced with spacer fabric. J. Eng. Fibers Fabr. 18, 15589250231152591 (2023).

Friese, D., Scheurer, M., Hahn, L., Gries, T. & Cherif, C. Textile reinforcement structures for concrete construction applications––a review. J. Compos. Mater. 56, 4041–4064 (2022).

Akinyemi, B. A. & Adesina, A. Utilization of polymer chemical admixtures for surface treatment and modification of cellulose fibres in cement-based composites: a review. Cellulose 28, 1241–1266 (2021).

Taheri, H. et al. Microfibrillated cellulose as a new approach to develop lightweight cementitious composites: Rheological, Mechanical, and microstructure perspectives. Constr. Build. Mater. 342, 128008 (2022).

Oh, J.-A. et al. Durable cement/cellulose nanofiber composites prepared by a facile approach. Cem. Concr. Compos. 125, 104321 (2022).

Chen, J. et al. Combined effects of raw materials and solvent systems on the preparation and properties of regenerated cellulose fibers. Carbohydr. Polym. 128, 147–153 (2015).

Hong, Y.-K., Chung, K.-H. & Lee, W.-S. Structure of regenerated cellulose fibers from DMAc/LiCl solution. Text. Res. J. 68, 65–69 (1998).

Franus, W., Panek, R. & Wdowin, M. SEM investigation of microstructures in hydration products of portland cement. In: 2nd International Multidisciplinary Microscopy and Microanalysis Congress: Proceedings of InterM (Springer, 2015).

Bogas, J. A., Real, S., Carriço, A., Abrantes, J. & Guedes, M. Hydration and phase development of recycled cement. Cem. Concr. Compos. 127, 104405 (2022).

Wu, J., Ding, Q., Yang, W., Wang, L. & Wang, H. Influence of submicron fibrillated cellulose fibers from cotton on hydration and microstructure of portland cement paste. Molecules 26, 5831 (2021).

Bhatty, J. I. Hydration versus strength in a portland cement developed from domestic mineral wastes — a comparative study. Thermochim. Acta 106, 93–103 (1986).

Cao, Y., Zavaterri, P., Youngblood, J., Moon, R. & Weiss, J. The influence of cellulose nanocrystal additions on the performance of cement paste. Cem. Concr. Compos. 56, 73–83 (2015).

Hoyos, C. G., Zuluaga, R., Gañán, P., Pique, T. M. & Vazquez, A. Cellulose nanofibrils extracted from fique fibers as bio-based cement additive. J. Clean. Prod. 235, 1540–1548 (2019).

Peng, J. et al. Cellulose film with air barrier and moisture-conducting character fabricated by NMMO. J. Mater. Sci. 56, 18313–18326 (2021).

Cruz-Silva, R. et al. Super-stretchable graphene oxide macroscopic fibers with outstanding knotability fabricated by dry film scrolling. ACS Nano 8, 5959–5967 (2014).

Zhu, K., Hu, J. & Zhang, L. Editable and bidirectional shape memory chitin hydrogels based on physical/chemical crosslinking. Cellulose 26, 9085–9094 (2019).

Hou, D., Lu, Z., Li, X., Ma, H. & Li, Z. Reactive molecular dynamics and experimental study of graphene-cement composites: structure, dynamics and reinforcement mechanisms. Carbon 115, 188–208 (2017).

Jacquart, S. et al. Mechanical properties of self-setting composites: influence of the carboxymethylcellulose content and hydration state. J. Mater. Sci. 51, 4296–4305 (2016).

Sun, G., Liang, R., Zhang, J., Li, Z. & Weng, L.-T. Mechanism of cement paste reinforced by ultra-high molecular weight polyethylene powder and thermotropic liquid crystalline copolyester fiber with enhanced mechanical properties. Cem. Concr. Compos. 78, 57–62 (2017).

Lu, H. -f, Zhang, K., Yi, J. -l & Wei, A. -c Study on mechanical properties of polycaprolactone modified cement-based material. Int. J. Concr. Struct. Mater. 16, 24 (2022).

Aocharoen, Y. & Chotickai, P. Compressive mechanical properties of cement mortar containing recycled high-density polyethylene aggregates: Stress–strain relationship. Case Stud. Constr. Mater. 15, e00752 (2021).

Parveen, S., Rana, S., Fangueiro, R. & Paiva, M. C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 73, 215–227 (2015).

Shu, Y. & Zhang, J. Effect of basalt fiber content and length on the strength and crack development of polyvinyl alcohol/basalt hybrid fiber-reinforced cement soil. Polymers 15, 2146 (2023).

Mat Serudin, A. et al. The utilization of a fiberglass mesh–reinforced foamcrete jacketing system to enhance mechanical properties. Materials 15, 5825 (2022).

Ahmad, M. H. & Awang, H. Effect of steel and alkaline-resistance glass fibre on mechanical and durability properties of lightweight foamed concrete. Adv. Mater. Res. 626, 404–410 (2013).

Narayanan, N. & Ramamurthy, K. Structure and properties of aerated concrete: a review. Cem. Concr. Compos. 22, 321–329 (2000).

Tanpichai, S., Boonmahitthisud, A., Soykeabkaew, N. & Ongthip, L. Review of the recent developments in all-cellulose nanocomposites: properties and applications. Carbohydr. Polym. 286, 119192 (2022).

Lord, J. D. & Morrell, R. M. Elastic modulus measurement—obtaining reliable data from the tensile test. Metrologia 47, S41 (2010).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (22005226, K.K.Z.; 52373086, X.F.Z.; 52203124, J.F.W.), Center for Carbon Neutral Chemistry, Institute of Chemistry, Chinese Academy of Sciences (No. CCNC-202402, J.M.Z.), the Basic and Advanced Research Project from Wuhan Science and Technology Bureau (2022013988065201, K.K.Z.). We would like to thank Dr. Shuai Nie from Aalborg University for his help in cement hydration product analysis. We thank the Analytical and Testing Center of Wuhan Textile University for SEM-EDS test and analysis.

Author information

Authors and Affiliations

Contributions

K.K.Z., Y.T.L. and J.J.Y. prepared the samples and materials characterizations. L.Q.J. designed the parameters optimization algorithm. K.K.Z., Y.T.L., D.P.S. and L.J.X. built and draw the network model. All authors contributed to the analysis of the experimental results and modeling. K.K.Z., X.F.Z., J.F.W., J.M.Z. and J.Z. wrote the manuscript. K.K.Z. and W.L.X. conceived the idea. K.K.Z, J.F.W., J.M.Z., and X.F.Z. supervised this project. H.Y conducted the EDS test. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Yan Zhuge, Liwen Yan and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhu, K., Liang, Y., Yuan, J. et al. Flexible cement fibers with high toughness and water-activated setting behavior for construction. Nat Commun 16, 6529 (2025). https://doi.org/10.1038/s41467-025-61855-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-61855-2