Abstract

Present main-stream medical ultrasonic nebulizers contain Pb(Zr,Ti)O3-based piezoceramics, which could expose the patients to toxic lead when the acidic liquid medicine, compounded with ultrasonic vibration, corrodes the piezoceramics. Enormous amount of lead ions up to 150 ppm can be extracted when lead-containing piezoceramics were exposed to typical acidic liquid medicines. Thus, a series of nebulization in a course of treatment could easily raise a child’s blood lead level well above the blood lead reference value of 0.035 ppm, causing adverse and likely irreversible health effects. Herein, we introduce the lead-free medical ultrasonic nebulizers based on high-performance (K,Na)NbO3-based lead-free piezoceramics. It’s designed for facile and safe at-home treatment, offering a healthy, safe, and lead-free solution for patients. It also marks the first commercialization of (K,Na)NbO3-based lead-free piezoceramics as a replacement for Pb(Zr,Ti)O3, helping expedite the lead-removing process of piezoelectric materials in general, in line with sustainable development goals worldwide.

Similar content being viewed by others

Introduction

Respiratory epidemics and pandemics have triggered the urgent and critical need for medical ultrasonic nebulizers, which can deliver microdroplets of liquid medicine to the respiratory system and thus produce a therapeutic effect. Medical ultrasonic nebulizers have also emerged as an effective treatment device for a wide range of respiratory diseases, such as chronic obstructive pulmonary disease, asthma, acute respiratory infection, etc, which affect over one billion patients worldwide1,2. With its piezoelectric effect, piezoelectric components are indispensable for the nebulizers to disperse the liquid medicine into micro-droplets of micrometer-size, as schematically illustrated in Fig. 1a, b. At present, all the commercial medical ultrasonic nebulizers rely on lead-based piezoelectric materials (e.g., lead zirconate titanate, PZT), because of their high electrical performance3,4,5. Usually, the PZT piezoelectric components are covered with an isolating membrane to prevent direct contact between PZT ceramics and liquid medicine. Despite that, the mechanical failure of the isolating membrane could potentially render the extraction of toxic lead as a result of the corrosion by the liquid medicine (mostly acidic), which can be further augmented by the ultrasonic vibration. Lead intoxication through the respiratory system could result in grievous side effects, particularly on children, such as brain and nerve damage, decreased mental ability and learning difficulties, speech problems, to name a few (see Fig. 1c)6. Consequently, there remains an urgent challenge for developing lead-free piezoelectric materials and nebulizers that are both biocompatible and high-performance to ensure one’s health security during long-term treatments.

The last two decades have witnessed the enthusiastic research of lead-free piezoelectrics, represented by (K,Na)NbO3 (KNN)7,8,9,10,11,12,13, BaTiO3 (BT)14,15,16, and (Bi,Na)TiO3 (BNT)17,18,19 systems. Among them, KNN is considered one of the most promising candidates to substitute for its lead-containing counterparts, especially in resonant applications, e.g., ultrasonic nebulizers, ultrasonic motors, and therapeutic & surgical ultrasound, owing to their high Curie temperature and competent piezoelectricity20. Piezoelectric ceramics’ most important parameters for the application to ultrasonic nebulizers are the piezoelectric coefficient d33 and the mechanical coupling factors kp. High electromechanical properties are the key to improving the nebulizer performance, yet KNN remains inferior to its lead-containing counterpart in its electromechanical properties. Moreover, the detailed biocompatibility of KNN lead-free piezoelectric material has yet to be verified, albeit its discovery since over half a century ago.

Apparently, a personal, wearable nebulizer can be ideal for patients with chronic respiratory diseases. Combined with a built-in or separate respirator21, patients could benefit from the easy accessibility and instant treatment in a personalized, hands-free setup, rather than having to go to the clinic or to hold a handheld device during the treatment. For the moment, wearable ultrasonic nebulizers are still not commercially available, thus impeding their practical and widespread application.

Herein, we introduce a wearable lead-free medical ultrasonic nebulizer, designed for facile and personalized at-home therapy for respiratory diseases. The lead-free medical ultrasonic nebulizer features a high nebulization rate of 0.25 ml/min and superfine droplets with an average size of 3.42 μm, comparable to those of the PZT lead-based nebulizers. The superior performance of this lead-free medical ultrasonic nebulizer is mainly ascribed to the exceptional electrical properties of the KNN-based piezoceramics through multiscale structure engineering. And the KNN lead-free piezoceramics were found to be highly biocompatible, in sharp contrast to the case of PZT samples, where an enormous amount of lead ions was extracted when exposed to typical acidic liquid medicines.

Results

Structure-property relationship

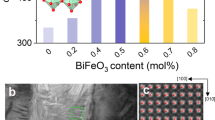

The electromechanical properties of the KNN-based lead-free piezoceramics were evaluated and compared with those of commercial PZT ceramics applied for medical ultrasonic nebulizers. The key parameters of piezoelectric coefficient d33 and electromechanical coupling factor kp for KNN reached 420 ± 10 pC/N and 0.48 ± 0.03, respectively, comparable to those of PZT (490 ± 6 pC/N and 0.52 ± 0.02). Figure 2a, b presents the typical polarization hysteresis and bipolar strain curves for KNN and PZT ceramics measured at an electric field of 3 kV/mm, demonstrating their decent ferroelectricity and piezoelectricity. Two abnormal peaks were observed in the temperature dependence of permittivity of KNN, which correspond to the rhombohedral-tetragonal phase transition TR-T near ambient temperature and Curie temperature TC (215 °C), respectively, resembling that of PZT, but with a slightly higher TC (see Fig. S1).

Polarization hysteresis and bipolar strain curves for a KNN and b PZT ceramics. c SEM image, d out-of-plane amplitude, and e phase image for KNN samples. The high-angle annular dark-field (HAADF) image for KNN viewed along [100]pc zone axis. f, g Polar vector mapping and h distribution mapping of polar vector angles that are off the [110] direction for KNN samples. i SEM image, j out-of-plane amplitude, and k phase image for PZT samples.

To discern the origin of KNN’s superior piezoelectric performance, we systematically characterized its multiscale structures, including macroscopic phase structure, microscale grain size, nanoscale domain, and atomic polarization. The X-ray diffraction profiles reveal that both KNN and PZT show a typical perovskite structure (Fig. S2). To determine the phase structure, Rietveld refinement was conducted by the Maud software, indicating the coexistence of tetragonal and rhombohedral phases in KNN (Fig. S3), consistent with the above analysis of temperature-dependent permittivity22. The coexistence of tetragonal and rhombohedral phases contributes to the high piezoelectricity because of the facile polarization rotation enabled by the decreased energy barrier and polarization anisotropy at the phase boundary.

Figure 2c, i shows the representative SEM images for KNN and PZT samples, which have a very dense microstructure. Quadrate grains are observed in KNN samples with the presence of abnormal grain growth (grain size falls in the range from 1 to 12 μm), while PZT has polygonal grains with a uniform size (2–4 μm). The domain morphology was unveiled by the piezoresponse force microscope (PFM). The corresponding out-of-plane amplitude and phase images are shown in Fig. 2d, e, j, k. Strip-like nanodomains dominate in KNN lead-free ceramics, while irregular nanodomains with predominantly wavy character are observed in PZT samples with large internal stresses23. Previous research has established that domain size is proportional to the square root of domain wall energy. The total piezoelectric effect is generally composed of two components: intrinsic and extrinsic contributions. The intrinsic contribution is linked to the linear piezoelectric effect resulting from lattice displacement, whereas the extrinsic contribution is associated with the movement of domain walls. Nanodomains with lower domain wall energy can readily respond to external stimuli, such as electric field or mechanical force, thereby further enhancing the piezoelectric effect24.

To unveil the local structure of KNN, aberration-corrected STEM was utilized to map atomic arrangement along the [100]pc zone axis (Fig. 2f ). In the HAADF image, the brighter dots represent the B-site atoms, i.e., Nb, due to the larger atomic number, whereas dimmer spots represent A-site Na/K atoms. The polar vectors of the KNN, derived from the relative displacements of Nb cation to the center of their surrounding A-site cations, are quantitatively analyzed (Fig. 2g)25. Some areas are characterized by the polar vectors oriented close to [011]pc direction, while others are aligned along [001]pc direction, indicating the coexistence of rhombohedral and tetragonal symmetries. The angular distribution of polar vectors is shown in Fig. 2h, where the angular deviations between the polar vector directions and [110]pc direction are depicted. Compared with the tetragonal area, the polar vector configuration in the rhombohedral area seems more intricate, with a lower average angle of ~4.5°. The coexistence of rhombohedral and tetragonal symmetries features multiplexity of polarization angles. In this case, high piezoelectric performances can be expected due to the strong response to external mechanical or electrical stimuli arising from the multiplex low-angle polar vectors.

For practical applications, not only high piezoelectricity but also good stability of electromechanical properties against electric cycling are essential to guarantee the functional operation of piezoelectric components. It was found that KNN samples also show excellent bipolar fatigue resistance (Fig. S4), which is potentially attributed to the reduced lattice distortion and coexistence of rhombohedral and tetragonal phases, as elaborated by the refined XRD analyses above.

Stability and biocompatibility of piezoceramics

Given that the commonly prescribed liquid medicines for the treatment of respiratory system diseases are acidic, the stability of the piezoceramics against the synergistic effect of erosion by the acidic liquids and ultrasonic vibrations should be considered, in case of the failure of the isolating membrane over the piezoceramics. To this end, we evaluated the stability and dissolution of heavy metal ions from both PZT and KNN piezoceramics in representative liquid medicines that treat respiratory diseases. In this test, we chose acidic medicines budesonide (abbreviated as Bu), terbutaline sulfate (Te), and salbutamol sulfate (Sa), and acetic acid (Ac) and normal saline (Ns) were chosen for comparison. The pH values for these liquids are summarized in Table S1. And to mimic the working conditions of nebulizers, the samples immersed in the liquids were subjected to ultrasound.

It is noted that sub-micron particles were exfoliated from both the KNN and PZT samples under the synergistic effect of erosion by the acidic liquids and ultrasonic vibrations, as identified by the elemental mapping using an energy dispersive spectrometer and the evolution of surface morphology (Figs. 3a, b and S5–7). These solid sub-micron particles can be delivered into the respiratory system along with the nebulized droplets, adding further burden to the respiratory system. In addition, an enormous amount of lead ions were dissolved, particularly in the strongly acidic Bu, Te, and Ac (Figs. 3c, d, and S8a), and the corresponding concentration reaches up to 150 ppm, 60 ppm, and 120 ppm, respectively, after 5 days of treatment with the application of ultrasound. It was estimated that a series of nebulizations in a course of treatment could easily raise a child’s blood lead level well above the blood lead reference value suggested by the U.S. Centers for Disease Control and Prevention (see Methods)26, causing adverse and likely irreversible health effects for the child.

TEM images and corresponding elemental mapping of nanoparticles exfoliated from the a KNN and b PZT samples under the synergistic effect of erosion by the acidic liquids and ultrasonic vibrations. Concentration of lead ions dissolved in acidic c budesonide and d terbutaline sulfate liquid medicines after 5 days of treatment with application of ultrasound. SEM images of L929 cells cultured on the surfaces of e KNN and f PZT ceramics. g Optical density (OD) values and h cell viability of L929 cells on the surfaces of KNN and PZT ceramics after 1, 3, and 5 days of incubation. Error bars represent the standard deviation based on 10 repeated measurements (n = 3). *P < 0.05, **P < 0.01.

In sharp contrast, the concentration of dissolved heavy metal ions (bismuth and barium) is much lower (<1 ppm) for the case of KNN lead-free piezoceramics. In addition to that, the phase structure, ferroelectric and piezoelectric properties, and temperature dependence of dielectric properties for samples were barely affected after the erosion by the drug under the influence of the ultrasonic vibration, as shown in Figs. S9–12.

The biosafety and biocompatibility of KNN piezoceramics were assessed and compared with those of the PZT ceramics. L929 cells were cultured on KNN and PZT ceramics, and the cells’ proliferation and viability were evaluated by SEM and cholecystokinin octapeptide (CCK-8) analyses. SEM images taken on days 1, 3, and 5 reveal distinct cell densities on both substrates (Fig. 3e, f). The number of cells has increased on both surfaces over time, with significantly higher densities observed on KNN on days 3 and 5, compared to PZT, suggesting enhanced cell proliferation on the KNN surface (Fig. 3e). In cell viability studies, the CCK-8 assay results (Fig. 3g, h) demonstrated that lower optical density (OD) values indicate increased cytotoxicity for the PZT group. In this study, using cover glass as the control group, the OD values for the control group were consistently higher than PZT group, and were comparable to KNN on day 5. Among all groups, PZT exhibited the lowest viable cell counts throughout the test period, particularly on days 3 and 5. In contrast, the KNN group showed significantly higher OD values and cell viability over time, indicating superior biocompatibility (Fig. 3g,h). These findings suggest that the KNN sample exhibits a combination of competent piezoresponse and good biocompatibility.

Design and performance of lead-free nebulizers

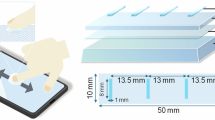

Based on the high-performance KNN lead-free piezoceramics with good biocompatibility, lead-free nebulizers were rationally designed and demonstrated. Firstly, the vibration modes of piezoelectric components composed of KNN piezoceramic ring and metal sheet with microsized mesh in the central location were simulated using finite element analysis (Fig. S13). Figure 4a presents the vibration modes at three typical resonant frequencies (122 kHz, 131 kHz, 142 kHz). The frequency dependence of vibration amplitude for the central point reveals two peaks at 121 kHz and 140 kHz (Fig. S14), suggesting the presence of ideal vibration modes, despite the slight shift in frequency. The absence of a peak at 131 kHz and the severe deformation of the piezoceramic rings significantly shorten the lifetime of the devices. The influence of all relevant parameters on the vibration modes is optimized, including the inner diameter and the thickness of KNN piezoceramic rings, the type and height of the boss, the thickness of the metal sheet, and the number of micropores on the mesh. The piezoelectric components with an inner diameter of 7.5-7.6 mm show the best overall performance (Fig. S15, Table S2). Thus, the inner diameter of 7.5 mm was chosen for the following simulations. It should be noted that the vibration amplitude of the piezoceramic ring increases dramatically with increasing inner diameter at the resonant frequency of 131 kHz (Table S2), which could lower the lifetime of piezoelectric components. Therefore, the working mode at the resonant frequency of 131 kHz should be avoided. It was found that the vibration magnitude of mode 1 at resonant frequency 122 kHz (Fig. S16) reaches its optimum when the thickness of the piezoceramic rings is 0.6 mm, while the values for other two modes are averaged. Therefore, piezoceramic rings with a thickness of 0.6 mm are optimal. The boss on the metal sheet serves to transform the planar stretching vibration of the piezoceramic rings along the radial direction into axial vibration of the central location of the metal sheets and can also further amplify the vibration. Two types of bosses, namely flat-bottom and arc-shaped, were considered. The larger vibration amplitude and smaller stress (beneficial for improving the life time of the devices) of modes 1 and 3 suggest that the arc-shaped boss is more suitable for practical implementation (Fig. S17 and Table S3). An optimal height of 0.3 mm for the boss was chosen as the resonant frequency of the lowest order mode is closest to the practical resonant frequency of piezoceramic rings. The central area of piezoelectric components could produce the largest displacement and velocity in response to the applied driving voltage at the same frequency. And the vibration amplitude and velocity of the central point for modes 1 and 3 reach a plateau (Fig. S18 and Table S4). To get a balanced vibration amplitude and stress, a thickness of 0.045 mm is preferred for the metal sheet (Fig. S19 and Table S5). And the introduction of micropores into the metal sheets leads to increased resonant frequency and consistent vibration magnitude (Fig. S20 and Table S6). Figure 4b is a simulation contour plot showing the periodic variation of micropore volume in one cycle for piezoelectric components with 2000 micropores. The points with zero amplitude on the nebulizer plate during the vibration cycle are referred to as nodes, while the points with maximum amplitude are called antinodes. It is observed that when the metal substrate is positioned at the neutral plane, the micropore volumes remain consistent. However, when the metal substrate deviates from this position, the micropore volumes exhibit periodic changes.

a Vibration modes of piezoelectric components at typical resonant frequencies by using finite element simulation. b Simulation contour plot of the periodic variation of micropore volume in one cycle for piezoelectric components with 2000 micropores at different positions. c SEM image of the micromesh. d Photo of scalable lead-free piezoelectric components. e Exploded view and f photo of wearable lead-free nebulizer. Comparison of g average size distribution of liquid droplets and h nebulization rate for the lead-free nebulizers and lead-containing counterparts. Deionized water was used for these tests.

Micromesh metal sheets were fabricated via laser drilling, followed by electrolytic polishing to remove the slags around the pores. Figure 4c shows the representative SEM image of the micromesh. The conical pores have an average size of 40 μm and a conical angle of 18°. Then, the micromesh metal sheets were bonded with poled piezoceramic rings using adhesive, followed by printing an isolating membrane and welding wire. Figure 4d demonstrates the KNN-based lead-free piezoelectric components by mass production.

Finally, wearable lead-free nebulizers were designed and assembled, as shown in Fig. 4e, f. The key performance of the lead-free nebulizers was further evaluated and compared with that of commercial PZT counterparts. The average size distribution D50 of liquid droplets produced by the lead-free nebulizers is 3.42 μm (Fig. 4g), close to the value of commercial PZT nebulizers (3.30 μm). This feature enables these fine droplets can be effectively delivered into the bronchial tube to produce therapeutic effects. And the average size distribution of droplets is barely influenced by the liquid medium (Fig. S21). And the lead-free nebulizers have the merits of a high nebulization rate of 0.25 ml/min and a low residual liquid volume (<0.1 ml), as shown in Fig. 4h and Fig. S22. All these features demonstrate that the comprehensive performance of lead-free nebulizers is comparable to that of PZT counterparts. The lead-free nebulizers in working state were demonstrated in Supplementary Movie 1. And the lead-free nebulizers have been issued a product registration certificate (Fig. S23) and successfully commercialized.

In summary, we introduce a wearable lead-free medical ultrasonic nebulizer, which is suitable for facile and personalized at-home therapy for respiratory diseases. The performance of the lead-free medical ultrasonic nebulizers is comparable to that of commercial PZT lead-based counterparts, thanks to the exceptional electrical properties of the KNN-based lead-free piezoceramics through multiscale structure engineering. A comprehensive comparison and assessment of the risk of heavy metal poisoning for patients using lead-containing and lead-free medical nebulizers is conducted, demonstrating the safety and reliability of lead-free medical nebulizers. We offer a healthy, safe, and lead-free solution for patients. Continuing the decades-long fundamental research on lead-free piezoelectric materials, an application is introduced in the field of healthcare where its lead-free feature is most valued. This study will expedite the lead-removing process of piezoelectric materials, which is in line with the Sustainable Development Goals worldwide.

Methods

Characterization of structures and electrical properties of piezoceramics

The KNN-based lead-free piezoceramics and lead-containing PZT were acquired from Tongxiang Tsingfeng Technology Ltd. The nominal composition for the KNN and PZT is 0.92(Na0.5K0.5)NbO3-0.02(Bi0.5Li0.5)TiO3-0.06BaZrO3 + 2 wt% MnO2 and Pb0.94Sr0.04Ba0.02(Zr0.525Ti0.475)O3 + 0.1wt%Fe2O3 + 0.25wt%Bi2O3 + 0.05 wt%MnCO3, respectively. Both materials were prepared by a conventional solid-state reaction approach as described elsewhere22. The phase structure of the samples was determined using an X-ray diffractometer (XRD, Bruker D8 Advanced). The surface morphology of thermally etched KNN samples was observed by scanning electron microscope (SEM, Zeiss LEO15305). Domain morphologies of samples at the nanoscale were studied using a PFM (Oxford Instruments Jupiter XR). High-resolution scanning transmission electron microscopy–high-angle annular dark-field (STEM–HAADF) images were obtained using a JEOL ARM 200 STEM equipped with a cold field-emission gun and a spherical-aberration corrector operated at 200 kV. Ceramic disks with a diameter of 10 mm and a thickness of 1 mm were used for the measurement of electromechanical properties. The dielectric constant and dielectric loss of the samples were measured by a dielectric temperature spectrometer (TZDM-RT-1000) at temperatures of 25 °C to 500 °C and a frequency of 100 Hz~1 MHz. The samples were polarized by applying a DC voltage of 4 kV for 30 min in silicone oil at 160 °C (ET2673D). It should be noted that the electric field will not be removed until the temperature is lowered to room temperature after the poling treatment at 160 °C. The polarized samples were aged for 24 h before the measurement of the piezoelectric constants using a piezo-d33 meter (ZJ-3AN). The polarization hysteresis loop and bipolar strain curves were recorded using a ferroelectric analyzer (aixACCT, TF2000).

Dissolution of heavy metal ions in liquid medicines

KNN and PZT piezoceramic pellets were immersed in representative commercial liquid medicines, i.e., budesonide and terbutaline sulfate. For each medicine, six samples were prepared, namely, samples for immersion of 1 day, 3 days, and 5 days, each with (“vibrated”) and without (“immersed”) ultrasonic vibration. Ultrasonic vibrations are applied for 7 h each day to avoid overheating problems.

Once all samples were collected, the concentrations of dissolved heavy metal ions in the liquid drugs were probed using an inductively coupled plasma mass spectrometer (ICP-MS, NexION 2000G). And the morphologies of nanoparticles exfoliated from the bulk ceramics and the surface of ceramic samples were observed with a scanning electron microscope (SEM, Zeiss LEO15305) equipped with an energy dispersive spectrometer.

In order to obtain the lead ion dissolution information during a single typical nebulization treatment of 20 minutes, we interpolated the 1-, 3-, and 5-day data plus a data point that represents zero concentration at zero time. We also assume that the overall rate of dissolution \({{{{\rm{r}}}}}_{{{{\rm{tot}}}}}\) is the sum of the rate of dissolution from immersion alone \({{{{\rm{r}}}}}_{{{{\rm{imm}}}}}\), and the rate of dissolution from vibration alone \({{{{\rm{r}}}}}_{{{{\rm{vib}}}}}\), i.e., \({{{{\rm{r}}}}}_{{{{\rm{tot}}}}}={{{{\rm{r}}}}}_{{{{\rm{imm}}}}}+{{{{\rm{r}}}}}_{{{{\rm{vib}}}}}\). We need \({r}_{{tot}}\) to interpolate, but the data we obtained for the “vibrated” samples were in fact \({r}_{{imm}}+\frac{7}{24}{r}_{{vib}}\), since vibration was limited for 7 h each day. The difference in concentrations between “immersed” and “vibrated” samples is then \(\frac{7}{24}{r}_{{vib}}\), thus \({r}_{{tot}}\) could be calculated and used for interpolation later. We also found that the choice of method of interpolation does not significantly affect the final results.

Our results show that the interpolated Pb ions’ concentrations are 2.01 ppm in terbutaline sulfate and 1.72 ppm in budesonide, respectively, for a period of 20 minutes, typical of a nebulization treatment. Suppose 5 ml of terbutaline sulfate is delivered into a 16 kg, 4-year-old child’s lung. In the extreme case, his or her blood lead level could rise 0.01 ppm in one nebulization therapy. This is a non-negligible amount compared to the blood lead reference value (BLRV) of 0.035 ppm, suggested by the US centers for disease control and prevention26, as a series of nebulization therapies in a course of treatment could easily raise a child’s blood lead level much above the BLRV of 0.035 ppm, causing adverse and likely irreversible health effects.

Evaluation of the biocompatibility of the piezoceramics

Cell culture

L929 cells (obtained from the Cell Culture Center, Peking Union Medical College, China) were grown in Dulbecco’s Modified Eagle Medium (Gibco) supplemented with 10% fetal bovine serum (Gibco, Australia) and 1% streptomycin/penicillin antibiotics (Gibco). Cells were maintained in a 5% CO2 incubator at 37 °C and high humidity until 80% confluency before use.

Cell viability assays

The CCK-8 assay (Dojindo, Mashikimachi, Japan) was performed following the manufacturer’s instructions. Briefly, cells were seeded at a density of 1 × 10⁴ cells/well on cover glass, PZT, and KNN substrates in 24-well plates. Cells were treated with serial extracts, with media exchanged every two days. On days 1, 3, and 5, 500 μL of culture medium containing 50 μL of CCK-8 was added and incubated with the cells for 1 hour. Cell viability was measured using a microplate reader at a wavelength of 450 nm (Bio-Rad, Hercules, USA).

SEM imaging

After culturing L929 fibroblasts on cover glass, PZT, and KNN for 1, 3, and 5 days, cells were washed and fixed with 2.5% glutaraldehyde in PBS for 1 hour at room temperature. Samples were washed with PBS three times and dehydrated using a graded ethanol series (30%, 50%, 70%, 85%, 95%, and 100%), with each step lasting 15 minutes. After air drying for at least 24 h, the samples were sputter-coated with gold. SEM imaging was performed using a Hitachi SU8010 instrument (Hitachi, Japan) at ×400 magnification and 5.0 kV. Five images were collected per substrate (n = 5).

Design and evaluation of nebulizers

To design high-performance nebulizers, the piezoelectric nebulizer component was first simulated using the finite element method. The vibration analysis on the piezoelectric nebulizer component was conducted using ANSYS finite element analysis software. Modal analysis can provide the vibration mode and corresponding resonance frequency of the piezoelectric nebulizer component during operation, while harmonic response analysis can predict the amplitude of the piezoelectric nebulizer component during operation.

The size distribution of liquid droplets produced by the nebulizers was determined using a laser particle size analyzer (Fritsch, Analysette 22 NeXT). The nebulization rate was obtained by measuring the weight loss of the apparatus after operation for a certain duration. And the minimum residual liquid volume was also monitored after operation. The lifetime of the nebulizers was defined as the total time of continuous operation before the nebulization rate drops below 90%.

Data availability

More relevant data sets generated during and/or analyzed during the current study are available from the first authors and corresponding authors on reasonable request. Source data are provided with this paper.

References

World Health Organization. Chronic respiratory diseases. www.who.int/gard/publications/chronic_respiratory_diseases.pdf (2024).

World Health Organization. Global Alliance against Chronic Respiratory Disease. https://www.who.int/groups/global-alliance-against-chronic-respiratory-diseases-(gard) (2024).

Yang, S. et al. Textured ferroelectric ceramics with high electromechanical coupling factors over a broad temperature range. Nat. Commun. 12, 1414 (2021).

Qi, H. et al. Giant dynamic electromechanical response via field driven pseudo-ergodicity in nonergodic relaxors. Nat. Commun. 14, 2414 (2023).

Arzenšek, M. et al. Origins of the large piezoelectric response of samarium-doped lead magnesium niobate–lead titanate ceramics. Sci. Adv. 10, eadp0895 (2024).

Lanphear, B., Navas-Acien, A. & Bellinger, D. C. Lead poisoning. N. Engl. J. Med. 391, 1621–1631 (2024).

Zhu, L.-F. et al. Ultrahigh piezoelectric performances of (K,Na)NbO3 based ceramics enabled by structural flexibility and grain orientation. Nat. Commun. 16, 901 (2025).

Xu, Z. et al. High electrostrain in a lead-free piezoceramic from a chemopiezoelectric effect. Nat. Mater. 24, 565–573 (2025).

Das Adhikary, G. et al. Longitudinal strain enhancement and bending deformations in piezoceramics. Nature 637, 333–338 (2025).

Zou, J. et al. Enhancing piezoelectric coefficient and thermal stability in lead-free piezoceramics: insights at the atomic-scale. Nat. Commun. 15, 8591 (2024).

Wang, Q. et al. Lead-free dual-frequency ultrasound implants for wireless, biphasic deep brain stimulation. Nat. Commun. 15, 4017 (2024).

Tan, P. et al. Deciphering the atomistic mechanism underlying highly tunable piezoelectric properties in perovskite ferroelectrics via transition metal doping. Nat. Commun. 15, 10619 (2024).

Wang, J., Wang, B., Zhang, H., Zhang, S. & Guo, Y. Ultrahigh electro-bending deformation in lead-free piezoelectric ceramics via defect concentration gradient design. Adv. Mater. 36, e2404682 (2024).

Wu, B. et al. Origin of ultrahigh-performance barium titanate-based piezoelectrics: Stannum-induced intrinsic and extrinsic contributions. Nat. Commun. 15, 7700 (2024).

Zhao, C. et al. Precipitation hardening in ferroelectric ceramics. Adv. Mater. 33, 2002421 (2021).

Liu, W. & Ren, X. Large piezoelectric effect in Pb-free ceramics. Phys. Rev. Lett. 103, 257602 (2009).

Luo, H. et al. Achieving giant electrostrain of above 1% in (Bi,Na)TiO3-based lead-free piezoelectrics via introducing oxygen-defect composition. Sci. Adv. 9, eade7873 (2023).

Zhang, J. et al. Semiconductor/relaxor 0-3 type composites without thermal depolarization in Bi0.5Na0.5TiO3-based lead-free piezoceramics. Nat. Commun. 6, 6615 (2015).

Khansur, N. H. et al. Enhanced electromechanical response and thermal stability of BNT-BT through aerosol deposition of base metal electrodes. Adv. Mater. Interfaces 8, 2100309 (2021).

Liu, H. et al. K, Na)NbO3-based lead-free piezoceramics: one more step to boost applications. Natl. Sci. Rev. 9, 101 (2022).

Heng, W. et al. A smart mask for exhaled breath condensate harvesting and analysis. Science 385, 954–961 (2024).

Zhang, M.-H. et al. Origin of high electromechanical properties in (K,Na)NbO3-based lead-free piezoelectrics modified with BaZrO3. Phys. Rev. Mater. 4, 064407 (2020).

Schönau, K. A. et al. Nanodomain structure of Pb[Zr1−xTix]O3 at its morphotropic phase boundary: investigations from local to average structure. Phys. Rev. B 75, 184117 (2007).

Bassiri-Gharb, N. et al. Domain wall contributions to the properties of piezoelectric thin films. J. Electroceram. 19, 49–67 (2007).

Tao, H. et al. Ultrahigh performance in lead-free piezoceramics utilizing a relaxor slush polar state with multiphase coexistence. J. Am. Chem. Soc. 141, 13987–13994 (2019).

Childhood lead poisoning prevention: guidelines and recommendations. Centers for Disease Control and Prevention https://www.cdc.gov/lead-prevention/php/guidelines/ (2024).

Acknowledgements

This work is supported by the National Natural Science Foundation of China under grants Nos. 12474213 (W.G.), 52032005 (K.W.), 52325204 (K.W.), 82225012 (Y.W.), U22A20254 (F.-Z.Y.), Key R&D Program of Zhejiang under grant No. 2022C01229 (K.W.), and the Program for Jiaxing Leading Innovative and Entrepreneurial Teams (W.G.).

Author information

Authors and Affiliations

Contributions

F.-Z.Y. and W.G. conceived the idea of this work. W.Y.F. performed the structural and electrical properties measurements. Y.F.Z. evaluated the biocompatibility of the piezoceramics under the guidance of B.H. Z.M.F. performed the life cycle assessment. B.J.C., Z.S.D., and C.F.W. prepared and characterized the lead-free nebulizers. F.-Z.Y., W.G., and K.W. provided financial and technical support for this work. J.J., Z.Y.L., H.H.G., Y.W., N.X.L., and X.M. helped to revise the paper. All authors discussed the results and contributed to the paper.

Corresponding authors

Ethics declarations

Competing interests

W.G. and C.F.W. have a financial interest in Tongxiang Tsingfeng Technology Co. Ltd. The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Limin Guo, Le Dai Vuong, and Abdullah Riaz for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yao, FZ., Fan, W., Zhang, Y. et al. Eliminating lead-exposure in nebulization therapy by lead-free piezoelectric. Nat Commun 16, 7101 (2025). https://doi.org/10.1038/s41467-025-61993-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-61993-7