Abstract

Controlling the reactivity of the propagating chain end in polymerization reactions is crucial for achieving well-defined polymers in both synthetic polymer chemistry and biology. Processive enzymes in nature have evolved substrate-enclosing structures, safeguarding the catalytic center against reentry by the nascent polymer. Here, we present a strategy for processive catalytic polymerization by encapsulating catalysts for ring-opening metathesis polymerization (ROMP) into the sub-surface cages of a metal-organic framework. The sub-surface encapsulation of the catalysts within the framework allowed the nascent polymer to grow out of the framework with minimal impedance and achieve continuous chain growth, while protecting the propagating polymer chain end from the secondary metathesis reaction with the alkenes in the backbone of the nascent polymer. As a result, ultra-high-molecular-weight polymers with low dispersity were generated from the ROMP of low ring strain cycloalkenes such as cis-cyclooctene and cyclopentene. We demonstrate that ultra-high-molecular-weight polymers with degradable backbones and enhanced mechanical and adhesive properties could be readily generated from this approach.

Similar content being viewed by others

Introduction

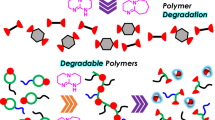

Achieving precise control over molecular weight, dispersity, and polymer microstructures is a central goal both in synthetic polymer chemistry1,2,3 and in biology4. By carefully designing initiating systems, catalysts, or monomer structures, researchers have achieved reactivity regulation of polymer chain ends, thereby controlling molecular weight, topology, tacticity, and regioselectivity across various polymers. These advances have led to tailored physical properties and enhanced material performance. For example, the development of reversible deactivation polymerization techniques such as ATRP or RAFT allowed for precise molecular weight control of radical and cationic polymerization5,6,7. Linear or cyclic topologies of polyesters could be switched from one another by leveraging the different coordinating abilities of the chain end groups through careful selection of the initiating system8. Furthermore, the tacticity of poly(vinyl ether) was elegantly controlled by creating a stereochemical environment at the chain end using chiral phosphoric acid, enabling catalyst-controlled stereoselective polymerization9. Leveraging highly efficient metathesis catalysts, ring-opening metathesis polymerization (ROMP) of cyclic olefins has produced a plethora of functional polymers spanning synthetic elastomers and biomimetic polymers. In particular, high molecular weight polymers produced by ROMP have shown great promise in advanced applications such as biomedical implants10, adhesives11, and tribotechnical materials12. However, to date, only cycloalkenes with high ring strain (e.g., norbornene, cyclobutene, etc.) can be polymerized by ROMP into polymers of high molecular weight and with living characteristics13,14,15. ROMP of cycloalkenes with low or moderate ring strain, despite numerous previous reports16,17,18,19,20,21,22, remains prone to secondary metathesis such as intramolecular and intermolecular chain transfer, leading to polymers with low molecular weight and broad dispersity that hindered their applications (Fig. 1a). Due to the strong motivation to develop sustainable polymers, there is an urgent need for new ROMP techniques that can efficiently synthesize high molecular weight polymers from low ring strain monomers that are either derived from biobased feedstock, consist of degradable moieties, or enable a circular polymerization-depolymerization life cycle23,24,25.

a Cyclic olefins with low ring strain often suffer from inter- or intra-molecular secondary metathesis. R = alkyl groups. b Processive enzymes and macromolecular machines that can produce ultra-high-molecular-weight biopolymers are ubiquitous in nature: DNA polymerase from Thermus aquaticus (left) (PDB: 1QTM), human mitochondrial ribosome (middle) (PDB: 6ZM5), and cellulose synthase from Rhodobacter sphaeroides (right) (PDB: 4HG6). c Catalysts are encapsulated at the sub-surface cages of the MOF crystals. Chain transfer events of the nascent polymers outside of the cages are kinetically inhibited. MOF metal-organic framework; ROMP ring-opening metathesis polymerization.

Enzymes with high catalytic processivity have evolved in nature to synthesize, degrade, and modify biopolymers. Processive enzymes remain bound to their polymeric substrates while performing multiple turnovers at high rates26. A widely conserved structural feature of processive enzymes is substrate enclosure, i.e., polymer substrates/products are threaded through an enclosing motif such that they are restricted from reaccessing the catalytic center (Fig. 1b). Inspired by the substrate enclosure structures of processive enzymes, we envision that catalysts for ROMP (e.g., Ru-based Grubbs catalysts) can be encapsulated into molecularly defined cages to improve catalyst processivity. During polymerization, the cages serve as selective physical barriers that kinetically inhibit intramolecular and intermolecular chain transfer of the nascent polymers that have grown out of the framework and into the solution (Fig. 1c). Such a system would lead to elevated catalyst processivity and the generation of high molecular weight polymers with low dispersity. It is noteworthy that although substrate enclosure has been adopted in polymer chemistry27,28,29,30,31,32, the existing techniques rely on reactions that are already capable of achieving high reactivities in solution (e.g., coordination-insertion polymerization of linear polyethylene, reversible deactivation radical polymerization or ROMP of the monomers with high ring strain). A general method for constructing molecularly confined catalysts to improve the catalytic processivity of ROMP and enable the polymerization of low ring strain cycloalkenes with limited reactivities remains elusive. This molecularly confined catalyst system would also stand in stark contrast to the existing supported (such as polymer-supported and silica-supported) catalysts, which lack molecular confinement and do not reduce secondary metathesis33,34,35,36,37.

Metal-organic frameworks (MOFs), with their tunable cavity dimensions and chemical environment, are ideal candidates as molecularly defined cages for catalyst confinement38,39. Importantly, multiple post-synthetic encapsulation methods have been developed to incorporate complex molecules into MOFs40,41. Among these methods, the aperture-opening encapsulation approach developed by Tsung, Byers, and coworkers could achieve facile encapsulation of organometallic compounds while maintaining their structural integrity and reactivity42,43. In this approach, one linker of a MOF cage dissociates to create an aperture of a MOF cage in polar solvents, which allows a catalyst molecule to diffuse into the cage through the aperture. After encapsulation of the guest molecule, the reassociation of the linker closes the expanded aperture, trapping the catalyst in the cage. Because the encapsulation is driven by ligand dissociation and guest molecule diffusion, only the cages near the surface of a MOF crystal are accessible by the guest molecules, resulting in the distribution of the guest molecules in the cages near the surface (hereafter denoted as the sub-surface cages). When the solvent is switched to non-polar solvents (e.g., dichloromethane), the ligand dissociation is inhibited, and the catalyst is stably encapsulated within the sub-surface cages. Compared to other catalyst encapsulation strategies such as de novo synthesis44 and passive diffusion45, the aperture-opening encapsulation approach achieves stable confinement of the guest molecule into the sub-surface cages of MOF with minimal leaching, while being broadly compatible with a variety of guest molecules (Fig. 1c). Moreover, while the controlled coordination polymerization of linear alkenes using MOF-embeded catalysts has been reported46,47,48,49, these systems require catalysts covalently bonded to MOF metal sites or linkers. The covalent bonding approach is incompatible with the organoruthenium catalysts for ROMP because of their sensitivity to nucleophiles and conditions necessary for MOF synthesis. Critically, compared to bulk encapsulation and reactions that occur entirely within MOF50,51,52,53, encapsulation of ROMP catalysts in the sub-surface cages allowed the unhindered growth of the nascent polymer from the framework into the solution following initiation, thus ensuring continuous chain growth and high processivity.

Results

Catalyst encapsulation and validation

UiO-type MOFs were chosen as the host because of their superior thermal, chemical, and mechanical stabilities, and their versatility for post-synthetic encapsulation of guest molecules54. The encapsulation of the Hoveyda-Grubbs second-generation catalyst (HG2) and the third-generation Grubbs catalyst (G3) into the cages in UiO-66 and UiO-67 using the aperture-opening encapsulation approach was investigated. The octahedral cages in UiO-66 (~10.7 Å) and UiO-67 (~15.6 Å)55 are estimated to be large enough to accommodate HG2 (14.3 Å × 10.7 Å × 6.5 Å) and G3 (14.3 Å × 9.4 Å × 6.5 Å). Meanwhile, the sizes of triangular windows of the octahedral cages in UiO-66 (~5.3 Å) and UiO-67 (~8.1 Å) are smaller than the size of HG2 and G3, such that leaching of the encapsulated catalysts is prevented after the aperture is closed (Figs. 2a and S1). Steric analysis combined with density functional theory (DFT) calculations indicate that, with the appropriate orientation, G3 can fit inside the octahedral cage without major steric clashes or deformation of the MOF structure (Fig. 2a). The closest pairwise atom distances between the guest catalyst and the UiO-67 are either greater than or comparable to the sum of their van der Waals radii (Fig. S2).

a Cavity size of UiO-66 and UiO-67 compared to the size of HG2 and G3 (left). The optimized structure of G3 in the octahedral cage of UiO-67 by DFT shows no apparent deformation of MOF (right). Atom color code: H – white; B – orange; C (MOF) – brown; C (non-MOF) – gray; N – blue; O – red; Cl – green; Zr – lime; Ru – light blue. b A model RCM reaction is used to evaluate the reactivities of MOF-encapsulated catalysts. c The remaining activities are in the presence of tertiary amines (1 equivalent to the Ru loading) of different sizes. HG2 + UiO67 indicates that free HG2 and UiO-67 were added separately into the same reaction as a control. Each experiment was independently repeated three times (n = 3). Error bars represent the standard deviation of the population (σ) calculated from these replicates. Same for data in Fig. 2e. d–f Kinetics of the RCM reactions of a small diene substrate 2 and a large enyne substrate 3 catalyzed by free HG2 (e) and HG2@UiO-67 (f). The kobs refers to the slope of the linear fitting to a first-order kinetic model. Reaction condition in (e): catalyst loading = 1.0 mol%, CD2Cl2 (0.24 M), RT; in (f) catalyst loading = 0.25 mol%, CD2Cl2 (0.18 M), RT. g Chemical structure of HG2-BODIPY and the optimized structure of HG2-BODIPY in the octahedral cage of UiO-67 by DFT shows no apparent deformation of MOF. Atom color code: H – white; B – orange; C (MOF) – brown; C (non-MOF) – gray; N – blue; O – red; F – cyan; Cl – green; Zr – lime; Ru – light blue. Confocal fluorescent microscopy image of HG2-BODIPY@UiO-67 (h, top) and the control sample HG2-BODIPY/UiO-67 (h, bottom), along with the corresponding brightfield images (scale bar = 2 mm).

The aperture-opening encapsulation was performed by first incubating the catalysts and the MOFs in acetonitrile at room temperature for 72 hours for HG2 or 24 hours for G3, before the solvent was switched to dichloromethane to keep the apertures closed. Furthermore, alternating dichloromethane wash and short sonication cycles were repeated six times to remove physically adsorbed catalysts on the exterior of the MOFs. 1H NMR spectroscopy confirmed that HG2 and G3 remained stable under the encapsulation and washing conditions (Fig. S3). Notably, excessive 3-bromopyridine (5 equiv. to G3) was necessary to prevent G3 from decomposition during encapsulation. The crystallinity, morphology, size, and porosity of both UiO-66 and UiO-67 before and after the encapsulation procedure remain largely unchanged, evidenced by powder X-ray diffraction (PXRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and Brunauer-Emmett-Teller (BET) surface area analysis (Figs. S4–7 and Table S1). The ruthenium loading after encapsulation for four different encapsulated catalysts, namely HG2@UiO-66, HG2@UiO-67, G3@UiO-66, and G3@UiO-67, was determined by ICP-OES to be 0.020 ~ 0.10 wt% (Fig. 2b). UiO-67 with larger cages were found to encapsulate ~40% more of both Ru-based catalysts than UiO-66. The catalytic activities of the encapsulated catalysts were evaluated using a ring-closing metathesis (RCM) reaction of diallyl ether (1) (Fig. 2b and Table S2). Under the same catalyst loading, HG2@UiO-67 and G3@UiO-67 showed markedly higher turnover frequency (TOF) in the RCM reaction than HG2@UiO-66 and G3@UiO-66, suggesting the larger cage of UiO-67 enabled better mass transport and provided adequate space for the encapsulated catalyst to interact with the substrate.

To confirm that the catalyst had been encapsulated into the cage rather than physically adsorbed on the exterior of the MOF matrix, we constructed a control catalyst, HG2/UiO-67, by subjecting UiO-67 and HG2 in dichloromethane in which the aperture remains closed. Following the same washing process and loading measurement, the HG2/UiO-67 was found to exhibit 0.0031 wt % of Ru loading, which is two orders of magnitude lower than HG2@UiO-67. Furthermore, no RCM reactivity was observed for HG2/UiO-67 (Table S3). These results suggest that the washing procedure can efficiently remove the physically adsorbed catalyst and that the aperture-opening encapsulation procedure could indeed encapsulate metathesis catalysts into the cage of UiO-type MOFs.

Size-selectivity is a hallmark of MOF-encapsulated catalysts56,57,58. When subjected to tertiary amine inhibitors of different sizes, including trimethylamine (TMA, 4.1 Å), triethylamine (TEA, 6.1 Å), tri-n-butylamine (TBA, 9.1 Å), and tri-n-octylamine (TOA, 14.8 Å) (Fig. S8), HG2@UiO-67 and free HG2 demonstrated distinct properties. While trimethylamine could inhibit both HG2@UiO-67 and HG2 effectively, HG2@UiO-67 became significantly more resistant to tertiary amines with longer alkyl substitutions, exhibiting 2.9- to 6.7-fold higher activity in the model RCM reaction after being exposed to tertiary amines with ethyl substitutions or longer (Fig. 2c and Table S4). It is noteworthy that adding HG2 and UiO-67 separately into a reaction did not exhibit significant resistance to tertiary amine inhibitors. Furthermore, two RCM substrates of different sizes, diallylmalonate (2) and dihexyl 4,4’-((allyl(4-(allyl(hydrosulfonyl)amino)but-2-yn-1-yl)amino)sulfonyl)dibenzoate (3), were subjected to either HG2 or HG2@UiO-67 (Fig. 2d). The observed rate constant of 2 was 1.3-fold higher than that of 3 when the reactions were catalyzed by free HG2 (Fig. 2e and Table S5). In contrast, this ratio increased to 13.3 when the reactions were catalyzed by HG2@UiO-67 (Fig. 2f). Similar to HG2@UiO-67, G3@UiO-67 also exhibited size-selective resistance to trialkylamine inhibitors and size-selective catalytic activity in RCM reactions, showcasing significantly higher resistance and lower reactivity when larger inhibitors and substrates were employed (Figs. S9, 10, Tables S6 and S7). Taken together, these results can all be attributed to the impedance of the diffusion of large molecules by the MOF cage, further confirming the encapsulation of HG2 and G3 inside the MOF cage.

Next, to probe the catalyst distribution in MOFs, we envisioned visualizing a fluorescently labeled catalyst molecule encapsulated within large MOF crystals using confocal fluorescence microscopy. Steric analysis combined with DFT calculations indicates that conjugating a compact BODIPY fluorophore with the ortho-isopropoxybenzylidene ligand of HG2 can still allow it to fit inside the octahedral cage, with the BODIPY moiety protruding through the cage surface to extend slightly into the adjacent tetrahedral cage (Fig. 2g). No major steric clashes or deformation of the MOF structure were found with this orientation of the guest catalyst (Fig. S11). To this end, we prepared HG2-BODIPY consistent with the simulation result following a procedure reported by Toussaint et al.59. After the encapsulation of HG2-BODIPY via the aperture-opening approach, large UiO-67 crystals (~3 μm in diameter) were extensively washed with dichloromethane and methanolic solutions of polyvinylpyrrolidone to remove any surface adsorbed molecules60. As shown in Fig. 2h (top) and Fig. S12, the surface of the MOF crystals exhibited much stronger fluorescence than the center of the crystal, although the exact depth of the fluorescent catalyst cannot be precisely determined due to the resolution limitations of the confocal microscopy. A recent study by Shustova’s group and our group demonstrated that the depth of fluorescent molecules encapsulated within UiO-type MOFs by the aperture opening method could be determined by resonance energy transfer (RET)61. In comparison, the control sample HG2-BODIPY/UiO-67, which was prepared using dichloromethane as the solvent instead of acetonitrile during the incubation with HG2-BODIPY, showed minimal fluorescence signal under the identical imaging condition. These results suggest that the fluorescence observed in HG2-BODIPY@UiO-67 originates from the catalysts encapsulated within the MOF cage rather than from surface adsorption (Fig. 2h, bottom). Similar to HG2@UiO-67, size-selective catalytic activity of HG2-BODIPY@UiO-67 was also observed in RCM reactions when substrates of different sizes were reacted (Fig. S13). Together, these results suggested the catalysts were encapsulated in sub-surface cages in MOFs.

Moreover, X-ray photoelectron spectroscopy (XPS) analysis was performed on G3@UiO-67. Given that XPS probes only a shallow surface depth (5–10 nm) of the material, changes in elemental composition before and after sputtering provide insight into the depth distribution of the catalysts. After sputtering, a notable decrease in the surface atomic percentages of Ru, N, and Br was observed, indicating a reduction in the concentration of Grubbs catalyst near the surface (Fig. S14). In contrast, a slight increase in the signals of Zr and C was detected after sputtering. These trends suggest that the Ru-containing species are predominantly localized within the subsurface layers of the MOF rather than uniformly distributed or embedded deeper within the framework. This conclusion is consistent with fluorescence confocal microscopy results, which also demonstrate sub-surface catalyst distribution.

ROMP of low-ring-strain cycloalkenes by MOF-encapsulated catalysts

We first examined the ROMP of cis-cyclooctene (COE), a model cyclic olefin with low ring strain. It has been well-documented that the ROMP of COE suffers excessive secondary metathesis because of its low ring strain62,63. To investigate if the catalyst processivity in the ROMP of COE could be improved through MOF encapsulation of the catalyst, we performed this reaction using two MOF-encapsulated catalysts, HG2@UiO-67 and G3@UiO-67. While HG2@UiO-67 resulted in a higher molecular weight and a modest reduction in dispersity compared to those resulted from HG2, it did not improve the control over the polymerization as the molecular weight plateaued at low monomer conversion (Figs. S15 and S16 and Table S8). The lack of control could be attributed to the slower rate of initiation of HG2 in ROMP than the rate of propagation, leading to disparate lengths of polymer chains13,64,65. In contrast, the reaction mediated by fast-initiating G3@UiO-67 exhibited some living characteristics including first-order kinetics to the monomer, linear growth of molecular weight of the resulting polyoctenamer versus the conversion, and low dispersity (Đ = 1.13), in addition to producing ultra-high-molecular-weight polyoctenamers up to Mn = 1273 kg/mol (Figs. 3a, b, Fig. S17 and Table S8). The viscosity of the reaction became very high after 23% monomer conversion, likely due to the formation of ultra-high-molecular-weight polymer. Additionally, we observed that the dispersity of the resulting polyoctenamer remained low even during the early stages of polymerization and continued to stay low throughout the entire process, suggesting that G3@UiO-67 maintained high processivity throughout the polymerization (Fig. 3c). We found that the addition of an exogenous ligand 3-bromopyridine was necessary to suppress the fast dissociation of the pyridinyl ligand of G3 and maintain the structural integrity of G3@UiO-67. Meanwhile, free G3 under the same condition and at similar conversion produced a polyoctenamer with much lower molecular weight (Mn = 81 kg/mol) and higher dispersity (Đ = 1.91) (Fig. 3d). The molecular weight of the polyoctenamers increased proportionally with increasing initial monomer:catalyst ratios ([M]0:[I]0) (Fig. S18). Finally, the catalyst-associated polymer chain end remained active after the nearly quantitative monomer conversion was reached. When additional COE was added into the reaction, chain extension successfully produced an extended polyoctenamer product with >10-fold higher molecular weight and lower Ð (Fig. S19 and Table S9). Taken together, these results suggest that ROMP of COE mediated by G3@UiO-67 exhibited certain living characteristics.

a Equation for ROMP of COE. COE = cis-cyclooctene. b The relationship of Mn and Đ with respect to monomer conversion in the ROMP of COE catalyzed by G3@UiO-67. c SEC traces of the polyoctenamers generated during the reaction shown in (b). d SEC traces of the polyoctenamers generated by G3@UiO-67 and G3 at the similar monomer conversion. e ROMP reactions of COE mediated by G3@UiO-67 were performed parallelly. At 120 min, solids in one of the parallel reactions were filtered out, denoted as split. Monomer conversion over time in the supernatant of split (blue) is compared to the other parallel reactions denoted as original (black). f Equation for copolymerization of the COE and DXP. DXP = cis-4,7-dihydro-1,3-dioxepin. g SEC traces of the copolymer of COE and DXP generated using G3 @UiO-67 and G3, and their degradation products. h 1H NMR spectra (CDCl3) of the copolymer of COE and DXP generated using G3@UiO-67 and its degradation product.

The recyclability of heterogeneous catalysts is a distinct advantage. We examined the structural integrity of the MOF using PXRD, and compared the chemical states of the encapsulated organorutheniuim catalyst before and after polymerization by XPS. The PXRD patterns showed no significant changes in peak positions or widths, with only marginal variations in the relative intensities of certain diffraction peaks (e.g., at 2θ = 5.7° and 6.1°) (Fig. S20). XPS analysis revealed minimal shifts in the binding energies of Ru (3p3/2), Br (3d), N (1s), Zr (3d), C (1s), and O (1s) before and after polymerization (Figs. S14 and S21 and Table S10). Together, these results indicate that the MOF crystalline structure remains intact and the chemical state of the Ru-based catalysts was not altered by the polymerization reaction. The MOF-encapsulated catalyst could be recycled by adding cis-stilbene at the end of the reaction, which could cleave the polymer chain from the Ru-chain end and reform the Ru-carbene initiator. After the introduction of the cis-stilbene, the recycled G3@UiO-67 demonstrated a monomer conversion comparable to that of the pristine catalyst, yielding polyoctenamer with similar molecular weight and dispersity. Subsequent recycling cycles resulted in a modest decline in the activity of the catalyst, evident by reduced reaction kinetics. However, the polyoctenamers produced by the recycled catalysts still maintained similar molecular weight and dispersity as the polymers generated by the pristine catalysts (Fig. S22 and Table S11). This result represents a rare example of the recycling of organoruthenium catalysts after ROMP.

We confirmed that the ROMP reaction was mediated by the catalysts encapsulated within the sub-surface cages of MOF, rather than active catalysts leaching into the solution from the MOF or physical absorbed catalyst on the MOF surface. First, we observed that monomer conversion completely halted when the G3@UiO-67 solid was separated from the ROMP reaction, suggesting that no active catalyst was leached into the supernatant (Fig. 3e). Second, we constructed a control catalyst, G3/UiO-67, where G3 was simply physically absorbed to the surface of the UiO-67 MOF. G3/UiO-67 showed one order of magnitude lower Ru loading (0.0031 wt%) than G3@UiO-67 (0.0301 wt%) by ICP-OES and negligible activity for ROMP of COE (Fig. S23).

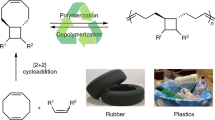

Next, we applied G3@UiO-67 to the copolymerization of COE and cis-4,7-dihydro-1,3-dioxepin (DXP), a comonomer that incorporates degradable motifs in the polymer backbone. Consistent with the result from the homopolymerization, copolymers with ultra-high-molecular-weight and low dispersity (Mn = 757 kg/mol, Đ = 1.19) were generated, compared to the counterpart generated by free G3 at similar conversions (Mn = 58 kg/mol, Đ = 1.57) (Fig. 3f, g and Table S12). Furthermore, the copolymer generated by G3@UiO-67 incorporated 3-fold more DXP (0.74% vs. 0.24%), improving the degradability of the copolymer (Figs. 3h and S24 and Table S13).

Due to the low ceiling temperature of cyclopentene (CPE), polypentenamer can readily undergo depolymerization to generate CPE under ambient conditions in the presence of metathesis catalysts66. In addition, the low ring strain of CPE and the high propensity for secondary metathesis further exacerbate the challenges for ROMP. We reasoned that the MOF cage would serve as a physical barrier for the nascent polypentenamer to reaccess the catalyst and kinetically reduce both the chain transfer reactions and depolymerization during the ROMP of CPE, allowing this reaction to become processive. Indeed, we found that the depolymerization of a purified polypentenamer (Mn = 355 kg/mol, Đ = 1.91) was inhibited when it was incubated with G3@UiO-67 in a dilute solution (0.1 M in THF) at 22 °C over 30 minutes (Fig. 4a and Table S14). No monomer was detected in the additional washing solution of the MOF particles after the depolymerization reaction, confirming that monomers were not adsorbed into MOFs (Table s15). In contrast, free G3 under the same condition led to fast depolymerization evidenced by 1H NMR (Fig. 4b) and size exclusion chromatography (SEC) (Fig. 4c). Doubling the loading of G3@UiO-67 resulted in 3% depolymerization of polypentenamer over the same period of time, suggesting that the depolymerization of polypentenamer mediated by G3@UiO-67 is kinetically inhibited by the cage rather than thermodynamically prohibited. Consistently, the ROMP of CPE mediated by G3@UiO-67 yielded polypentenamer with high molecular weight and low dispersity (Mn = 532 kg/mol, Đ = 1.40) compared to the reaction mediated by free catalyst under the same condition (Mn = 67 kg/mol, Đ = 3.60) (Fig. 4d and Table S16).

Emulsion polymerization mediated by MOF-encapsulated catalysts

During ROMP mediated by the catalysts encapsulated in the sub-surface cages of MOFs, polymerization occurs at the solid-liquid interface, and its rate can be significantly throttled by the rate of diffusion when the viscosity of the solution becomes high. Due to the formation of high molecular weight polymers, the viscosity of the solution at the late stage of the polymerization increased significantly due to the entanglement of long polymer chains, posing a great challenge for the efficient mass transport of both the monomer and the polymer. To address this challenge, we envisioned compartmentalizing catalyst-loaded MOF crystals into microdroplets in emulsion to facilitate efficient mass transport and reduce the viscosity of the polymerization reaction66,67,68. To this end, we first confirmed that the MOF crystals with rhodamine 6 G encapsulated, R6G@UiO-67, could be successfully compartmentalized within the microdroplets in emulsion using confocal fluorescent microscopy (Fig. 5a). As fluorescent indicators of the microdroplets, CdSe/ZnS core-shell type quantum dots (4.8 nm in diameter) were added to the toluene microdroplets69. These quantum dots are significantly larger than the cages of UiO-67, so adsorption into the MOF cage is minimized. All rhodamine 6 G signals were colocalized with the signals from the microdroplets, indicated by the overlapping signals of the rhodamine 6 G and the quantum dots, as well as the microdroplets shown in the brightfield image, suggesting that the MOF particles were successfully compartmentalized into microdroplets. Correspondingly, emulsion ROMP of COE mediated by G3@UiO-67 that was compartmentalized in microdroplets exhibited consistently low viscosity over the course of the reaction and reached 84% monomer conversion within 2 hours. An ultra-high-molecular-weight polyoctenamer with Mn of 1,146 kg/mol and Ð of 1.13 was produced from this reaction (Fig. 5b). Likewise, emulsion ROMP of CPE mediated by the microdroplet-compartmentalized G3@UiO-67 was also significantly faster, reaching 63% monomer conversion within 4 hours and producing an ultra-high-molecular-weight polypentenamer with Mn of 722 kg/mol and Ð of 1.19 (Fig. 5c).

a Confocal fluorescent microscopy images of R6G@UiO-67 compartmentalized in the toluene microdroplets that were stained with CdSe/ZnS core-shell type quantum dots, along with the corresponding brightfield image (scale bar = 5 μm). R6G = Rhodamine 6G. Polyoctenamer (b) and polypentenamer (c) generated by G3@UiO-67 compartmentalized in the microdroplets in emulsion.

Computational simulation of polymerization mediated by MOF-encapsulated catalyst vs. free catalyst in solution

To further probe the reaction kinetics of ROMP mediated by MOF-encapsulated catalysts, we performed DFT calculations of ROMP of cis-cyclooctene mediated by G3@UiO-67 and compared with the same reaction mediated by free G3 in solution (optimized structures available in Supplementary Data 1). For G3 initiation in solution (Figs. S25 and S26), consistent with previous reports70,71, we find the second ligand dissociation step (transformation of 2B to 3B via TS-2B) to be rate-determining. Similarly, for G3@UiO-67, the rate-determining step is also the second ligand dissociation (transformation of 2 to 3 via TS-2, Fig. 6). However, \(\Delta {G}^{{\ddagger} }\) values of both the first and second ligand dissociation steps are higher for G3@UiO-67 than for free G3 in solution (\(\left|\Delta {\Delta G}^{{\ddagger} }\right|\) = 8.4 and 3.7 kcal/mol, respectively) which is likely due to the close steric interaction between dissociating ligands and UiO-67 linker molecules as the ligands exit the octahedral cage. Consequently, the initiation reaction, which is kinetically controlled by the second ligand dissociation, proceeds more slowly in MOF than in solution. In contrast, \(\Delta {G}^{{\ddagger} }\) values for alkene association, cycloaddition and ring-opening steps are nearly identical between G3 in solution and G3@UiO-67 (\(\left|\Delta {\Delta G}^{{\ddagger} }\right|\) = 0.4, 1.7, and 0.8 kcal/mol, respectively).

a Free energy diagram of initiation and metathesis processes inside the MOF cage calculated at the B3LYP level. Computational details are described in the supporting information. Annotations indicate the free energy barriers (\(\Delta {G}^{{\ddagger} }\)) and reaction free energies (\(\Delta G\)) for each elementary step. b Structure of transition states. The catalyst and reacting species are shown in gray, while the surrounding UiO-67 framework is shown in brown. Atom color code: H – white; B – orange; C (MOF) – brown; C (non-MOF) – gray; N – blue; O – red; Cl – green; Zr – lime; Ru – light blue.

For polymerization inside MOF to occur, monomer and polymer must diffuse through the UiO-67 framework. We computed energy profiles for the diffusion of COE monomer and n-octane, representative of a linear polymer generated at the early stage, from the tetrahedral into the octahedral cage of UiO-67 (Fig. S27). The energy barriers (\(\Delta {E}^{{\ddagger} }\)) were found to be 2.5 and 0.1 kcal/mol for the monomer and polymer, respectively. The higher \(\Delta {E}^{{\ddagger} }\) of the cyclic monomer is attributed to its bulkier size and more rigid conformation, which can sterically interact with adjacent MOF linkers as the monomer moves through different cages. Compared to the polymerization in solution, the additional energetic penalty for monomers to diffuse into MOF cages could contribute to the slower polymerization kinetics observed in ROMP mediated by MOF-encapsulated catalysts.

Mechanical and adhesive properties of the polymer generated by MOF-encapsulated catalysts

Molecular weight profoundly impacts the mechanical and adhesive properties of polymers. High molecular weight polymers typically demonstrate higher toughness and stronger adhesion than their low molecular weight counterparts because of increased chain entanglements72,73. We envisioned that the processive ROMP mediated by MOF-encapsulated catalysts could be readily applied to producing ultra-high-molecular-weight polymers with improved mechanical and adhesive performance. To this end, we investigated the synthesis of ultra-high-molecular-weight poly(vinyl acetate-co-ethylene), p(VAE) via ROMP of 3-acetoxy cyclooctene (3AcCOE), followed by hydrogenation to saturate the internal alkenes (Fig. 7a). Zhang et al.74 demonstrated that ROMP of 3AcCOE could produce a regio-regular p(VAE) with an acetoxy group on every 8th carbon on the backbone that is mechanically superior to the polymer produced through the free radical polymerization of ethylene and vinyl acetate75 or the coordination-insertion polymerization of these vinyl monomers76,77,78. Using G3@UiO-67, we synthesized an ultra-high-molecular-weight regio-regular p(VAE) (Mn = 907 kg/mol, Đ = 1.33) via ROMP of 3AcCOE and hydrogenation, which is, to our best knowledge, the highest molecular weight of p(VAE) recorded to date. After hydrogenation, this ultra-high-molecular-weight p(VAE) demonstrated typical thermoplastic behaviors with a strong strain hardening effect, achieving high ultimate stress (52 ± 4 MPa), high strain (750 ± 44%), and an overall toughness (181 ± 24 MJ/m3) comparable to high-density polyethylene (HDPE) and isotactic polypropylene (iPP) (Fig. 7b, c, Table S17 and S18). Notably, these mechanical properties are markedly higher than those (33 ± 2 MPa ultimate stress and 152 ± 10 MJ/m3 toughness) of a lower molecular weight regio-regular p(VAE) synthesized by the free catalyst (Mn = 37 kg/mol, Đ = 2.10). It is noteworthy that the commercial random copolymer of vinyl acetate and ethylene with 50 wt% VAc incorporation, p(VAE50), demonstrated completely different mechanical properties as a ductile elastomer (9 ± 0.3 MPa ultimate stress and 63 ± 3 MJ/m3 toughness).

a Equation for the synthesis of p(VAE) and p(VAVAE). P(VAE) = poly(vinyl acetate-co-ethylene); p(VAVAE) = poly(vinyl acetate-co-vinyl alcohol-co-ethylene). b Ultra-high-molecular-weight p(VAE) generated using G3@UiO-67 and p(VAE) generated using free G3 are compared to high-density polyethylene (HDPE), isotactic polypropylene (iPP) and random p(VAE) with 50 wt% VAc incorporation (p(VAE50)). c Image of p(VAE) (907 kg/mol) sample during tensile testing at the onset of strain-induced crystallization. d Ultra-high-molecular-weight p(VAVAE) shows 6.5-fold higher lap shear strengths than the low-molecular weight p(VAVAE), and over 10-folder higher lap shear strengths than HDPE or iPP. The inset shows the lap shear strengths of each polymer. Each experiment was independently repeated three times (n = 3). Error bars represent the standard deviation of the population (σ) calculated from these replicates.

Finally, the adhesive property of poly(vinyl acetate-co-vinyl alcohol-co-ethylene) (p(VAVAE)), generated by the partial deprotection of the regio-regular p(VAE), was measured by the lap shear test of a single-lap joint of polymer adhesive between two stainless steel slides. The ultra-high-molecular-weight p(VAVAE) (Mn = 990 kg/mol, OH content: 18%) demonstrated 6.5-fold higher lap shear strength than the low molecular weight p(VAVAE) (Mn = 30 kg/mol, OH content: 22%), with apparent lap shear strengths of 1.12 ± 0.23 MPa and 0.17 ± 0.08 MPa, respectively (Fig. 7d and Table S22). This result further supports that the strong chain entanglement of the ultra-high-molecular-weight polymer generated by the MOF-encapsulated catalyst cannot be achieved by the low molecular weight counterpart produced by the free catalyst. Additionally, p(VAVAE)-990 kg/mol also exhibited significantly enhanced adhesion to stainless steel compared to either HDPE (0.057 ± 0.028 MPa) or iPP (0.042 ± 0.026 MPa), surpassing their adhesion strength by more than an order of magnitude (Fig. 7d).

Discussion

In this work, we developed a novel strategy for processive ROMP using MOF-encapsulated catalysts. Ru-based olefin metathesis catalysts were efficiently encapsulated into the sub-surface cages of the MOF crystals via the aperture-opening encapsulation method. The distribution of catalysts in the sub-surface cages was evidenced by visulizing MOF-encapsulated fluorescent catalysts using confocal microscopy. The catalysts demonstrated size-selective resistance to inhibitors and size-selective catalytic activity in a model RCM reaction, suggesting successful encapsulation into MOFs. Homopolymerization of COE and copolymerization of COE and DXP exhibited some living characteristics and high processivity when the MOF-encapsulated catalyst G3@UiO-67 was employed, leading to polymers with ultra-high-molecular-weight and low dispersity. ROMP of CPE mediated by G3@UiO-67 achieved significantly higher molecular weight and lower dispersity than the counterpart mediated by the free catalyst. The ultra-high-molecular-weight polymers generated by the encapsulated catalysts demonstrated enhanced mechanical and adhesive properties compared to the low molecular weight counterparts and commercial polymers.

We observed a stark contrast between the reactions mediated by the MOF-encapsulated catalysts and those that are mediated by the free catalysts. These results confirmed that the sub-surface cages of the MOF crystals could effectively serve as size-selective physical barriers that permit the access of the catalyst by the monomers but reduce the re-entry of the nascent polymers. As a result, intra- and intermolecular chain transfers out of the cages in the ROMP of low ring strain cycloalkenes are significantly reduced. While the polymerization occurs at the solid-liquid interface and the reaction kinetics could be limited by viscosity, compartmentalizing the catalyst-loaded MOF crystals in microdroplets in emulsion was shown to be an effective strategy to expedite the polymerization process and further mitigate the undesired nascent polymer-catalyst interactions.

While we observed that the catalysts are primarily distributed at the sub-surface layer, high-resolution profiling the exact locations of the encapsulated molecular catalysts and their individual activities in ROMP remains challenging. We estimate that the effective Ru-carbene centers highly active in ROMP are likely a fraction of the total populations of MOF-encapsulated Ru-containing guest molecules quantified by ICP-OES. Using a single-addition monomer developed by Xia et al.79, we found the amount of active Ru-carbene in a single-addition ring-opening metathesis reaction was 56 ± 2% with respect to the amount determined by ICP-OES (Fig. S28). Furthermore, ROMP mediated by the MOF-encapsulated catalyst and by the free catalyst produced polymers with identical chain-end groups (Fig. S26), suggesting that the active Ru-carbenes generated by the MOF-encapsulated catalysts are identical to those produced by the free catalyst in solution-phase reactions. However, given that polymers face higher hindrance by the framework than small molecules, the quantity of Ru-carbenes that can actively generate high molecular weight polymers is likely lower than 56% of the total Ru-containing guests. As a result, the observed molecular weights of the polymers generated by the MOF-encapsulated catalysts are consistently higher than the prediction using the apparent [M]0:[I]0 ratios. It should also be noted that, unlike the living ROMP of high ring strain monomers, due to extensive secondary metathesis, the classic ROMP of low ring strain cycloalkenes resulted in polymers with high dispersity and lower-than-expected molecular weight based on [M]0:[I]0 ratios (Figs. 3d and 4d)80. In contrast, the polyoctenamers generated from the ROMP of COE mediated by G3@UiO-67 exhibited significantly increased Mn proportionally to the [M]0:[I]0 ratios and low dispersity (Fig. S18), demonstrating unprecedented living characteristics of the polymerization.

The simplicity and generality make the MOF-encapsulated catalysts reported in this work readily applicable to a wide range of metathesis reactions including challenging ROMP and small molecule olefin metathesis. This work also revealed that molecular confinement is a promising strategy to reduce undesired chain transfer events in the polymerization mediated by other organometallic catalysts.

Methods

Synthesis of UiO-66

To a 20 mL scintillation vial, a solution of 26.6 mg of terephthalic acid in 5.0 mL DMF and a solution of 18.6 mg ZrCl4 and 2.0 mL acetic acid in 3.0 mL DMF were added. The vial was sealed and heated at 100 °C in a preheated oil bath for 24 hours. After the reaction mixture was cooled to room temperature, the supernatant was removed with a glass pipette, and the white crystals at the bottom were agitated by swirling the vail gently, followed by transferring it to a conical tube. The mixture was centrifuged at 3000 rpm (1200 × g) for 10 min. The supernatant was decanted and the fresh DMF was replenished, and the white crystals were dispersed by vortex and sonicating. The mixture was sat for 3 hours before the next round of centrifugation. Three cycles were done with DMF, followed by three cycles of washing with methanol. The crystals were transferred to a vial with a septum top and were dried at 110 °C under vacuum for 12 hours, followed by refilling with N2 and cooling down to room temperature. The UiO-66 was stored under N2 in a glovebox at room temperature.

Synthesis of UiO-67

To a 20 mL scintillation vial, a solution of 19.38 mg of 4, 4’-biphenyldicarboxylic acid and 0.12 mL of triethylamine in 6.38 mL DMF and a solution of 18.64 mg ZrCl4 and 1.24 mL acetic acid in 3.76 mL DMF, and additional 11.5 mL of DMF were added. The vial was sealed and heated at 85 °C in a preheated oil bath for 24 hours. After the reaction mixture was cooled to room temperature, the supernatant was removed with a glass pipette, and the white crystals at the bottom were agitated by swirling the vial gently, followed by transferring to a conical tube. The mixture was centrifuged at 3000 rpm (1200 × g) for 10 min. The supernatant was decanted and the fresh DMF was replenished, and the white crystals were dispersed by vortex and sonicating. The mixture was sat for 3 hours before the next round of centrifugation. Three cycles were done with DMF, followed by three cycles of washing with methanol. The crystals were transferred to a vial with a septum top and were dried at 110 °C under vacuum for 12 hours, followed by refilling with N2 and cooling down to room temperature. The UiO-67 was stored under N2 in a glovebox at room temperature.

Encapsulation of catalysts

HG2@UiO-66 or HG2@UiO-67: To a 20 mL scintillation vial charged with 100 mg UiO-66 or UiO-67 and a PTFE stirring bar, a solution of 10 mg HG2 in 3 mL anhydrous acetonitrile was added in a N2 glovebox. The vial was sealed a screw top and tape, and the mixture was stirred for 72 hours under ambient conditions. The vial was transferred into a N2 glovebox, and the mixture was poured into a conical tube, followed by the addition of 15 mL of anhydrous DCM. The mixture was vortexed and centrifuged at 3000 rpm (1200 × g) for 10 min. The supernatant was decanted and the solid was further washed with anhydrous DCM for another 5 times. The solid was transferred to a vial with a septum cap and dried at room temperature under vacuum (0.1 mbar) for 12 hours, followed by refilling with N2. The encapsulated catalysts were stored under N2 in a glovebox in the freezer. G3@UiO-66 or G3@UiO-67: To a 20 mL scintillation vial charged with 100 mg UiO-66 or UiO-67 and a PTFE stirring bar, a solution of 10 mg G3 and 6 µL 3-bromopyridine in 3 mL anhydrous acetonitrile was added in a N2 glovebox. The vial was sealed a screw top and tape, and the mixture was stirred for 24 hours under ambient conditions. The vial was transferred into a N2 glovebox, and the mixture was poured into a conical tube, followed by the addition of 15 mL 200 ppm of 3-bromopyridine in anhydrous DCM. The mixture was vortexed and centrifuged at 3000 rpm (1200 × g) for 10 min. The supernatant was decanted and the solid was further washed with 3-bromopyridine/DCM solution for another 4 times. The solid was transferred to a vial with a septum cap and dried at room temperature under vacuum (0.1 mbar) for 12 hours, followed by refilling with N2. The encapsulated catalysts were stored under N2 in a glovebox in the freezer.

Model reactions of 1, 2 and 3

The model reaction of 1 catalyzed by different encapsulated catalysts: In a N2 glovebox, the encapsulated catalyst of designated amount (mass of catalyst was calculated based on Ru loading measured by ICP-OES, 0.5 mol%) was weighted out in a 2 mL glass vial with a PTFE stirring bar. 500 µL of dichloromethane was added into the vial and the encapsulated catalyst was thoroughly dispersed by vortex and sonication. The solid was precipitated down by centrifugation at 3000 rpm (1200 × g) for 3 min and the supernatant was removed. In the experiments with HG2@UiO-66 or HG2@UiO-67, a solution of allyl ether (10 µmol, 1 equiv.) in CD2Cl2 (0.1 mL) was added to the vial, followed by dispersing the encapsulated catalyst with vortex and sonication. In the experiments with G3@UiO-66 or G3@UiO-67, a solution of allyl ether (10 µmol, 1 equiv.) and 3,5-dichloropyridine (0.1 µmol, 0.01 equiv.) in CD2Cl2 (0.1 mL) was added instead. For the model reactions in presence of amines, 0.5 mol% of different amines were added prior to the addition of allyl ether solution. The reaction mixture was stirred at room temperature for 1 hour and quenched with one drop of ethyl vinyl ether. The solid was precipitated down and the supernatant was taken out for analysis by 1H NMR. Turnover frequency (TOF) was calculated with the equation 1 below.

The model reaction of 2 or 3 catalyzed by HG2: To a solution of 2 or 3 (24 µmol, 1 equiv.) in CD2Cl2 (0.4 mL) in a NMR tube, a solution of HG2 (0.24 µmol, 1.0 mol%) in CD2Cl2 (0.1 mL) was added under N2 atmosphere. The tube was vortexed, and the reaction was analyzed with an array sampling every 2 min. Averaged conversions and standard deviations were calculated based on 3 replicates of experiments. The model reaction of 2 or 3 catalyzed by HG2@UiO-67: In a N2 glovebox, HG2@UiO-67 of designated amount (mass of catalyst was calculated based on Ru loading measured by ICP-OES, 0.25 mol%) was weighted out in a 2 mL glass vial with a PTFE stirring bar. 500 µL of solvent of reaction was added into the vial and the encapsulated catalyst was thoroughly dispersed by vortex and sonication. The solid was precipitated down by centrifugation at 3000 rpm (1200 × g) for 3 min and the supernatant was removed. A solution of 2 or 3 (17.6 µmol, 1 equiv.) in CD2Cl2 (100 µL) was added to the vial, followed by dispersing the encapsulated catalyst with vortex and sonication. The reaction mixture was stirred at room temperature and quenched with one drop of ethyl vinyl ether at different time points. The solid was precipitated down and the supernatant was taken out for analysis by 1H NMR. The conversion was calculated based on the integrals of protons of reactant and product, with comprehensive details provided in the Supplementary Information.

General procedure for the polymerization by encapsulated catalysts in solution

Comprehensive procedures were provided in the Supplementary Information. Procedure for the polymerization of COE by G3@UiO-67 was stated here as an example. In a N2 glovebox, 25 mg of G3@UiO-67 (mass of catalyst was calculated based on Ru loading measured by ICP-OES, 1 equiv.) was weighed out in a 2 mL glass vial with a PTFE stirring bar. 500 µL of solvent of reaction was added into the vial and the encapsulated catalyst was thoroughly dispersed by vortex and sonication. The solid was precipitated down by centrifugation at 3000 rpm (1200 × g) for 3 min and the supernatant was removed. A solution of 3-bromopyridine (1.73 µmol, 20 equiv.) in CDCl3 (50 µL) was added to the vial, followed by dispersing the encapsulated catalyst with vortex and sonication. COE (15 µL, 115 µmol, 1330 equiv.) was added to the reaction at −10 °C. The reaction mixture was stirred at −10 °C and quenched with one drop of ethyl vinyl ether at different time points. The reaction mixture was diluted with CDCl3 (0.5 mL) and the solid was precipitated down (10,000 rpm or 17888 × g, 5 min). A small portion (20 µL) of supernatant was taken out for analysis by 1H NMR. The rest of the supernatant was concentrated under vacuum to ~0.1 mL and precipitated into 2 mL of MeOH. The precipitation redissolved and precipitated again and the polymer was analyzed by GPC and 1H NMR.

General procedure for the polymerization by encapsulated catalysts in microdroplets

To a 4 mL vial charged with G3@UiO-67 (mass of catalyst was calculated based on Ru loading measured by ICP-OES, 1 equiv.) and a PTFE stirring bar. 500 µL of toluene was added into the vial and the encapsulated catalyst was thoroughly dispersed by vortex and sonication. The solid was precipitated down by centrifugation at 3000 rpm (1200 × g) for 3 min and the supernatant was removed. 50 µL of toluene and 40 µL of hexadecane was added to the solid. The mixture was sonicated for 1 min, followed by the addition of 0.5 mL of sodium dodecyl sulfate aqueous solution (5 mg/mL). The mixture was sonicated for 5 min before the addition of COE (12.5 µL, 2000 equiv.) or CPE (37.5 µL, 4000 equiv.). The reaction mixture was stirred for 2 h for COE or 4 h for CPE at 22 °C. The reaction was quenched by 5 µL drop of ethyl vinyl ether (EVE) in 100 µL CHCl3 and 30 µL of the reaction mixture was taken out and added to a vial containing 500 µL of CDCl3. The vial was shaken violently, and the organic phase was transferred to an NMR tube for conversion determination using EVE as internal standard. The reaction mixture was poured into methanol (15 mL) and the polymer and MOF were precipitated down by centrifugation at 3000 rpm (1200 × g) for 10 min. After the supernatant was decanted, 10 mL of CHCl3 was added to dissolve the polymer. Then the MOF was precipitated down by centrifugation at 3000 rpm (1200 × g) for 10 min. The supernatant was transferred to a 20 mL vial and the solvent was removed under reduced pressure. The resulting polymer was analyzed by GPC and 1H NMR.

Synthesis of poly(vinyl acetate-co-ethylene) (p(VAE))

Ultra-high-molecular-weight polymer (907 kg/mol and 990 kg/mol): In a N2 glovebox, G3@UiO-67 (1.05 g, 1 equiv.) was weighed out in a 20 mL glass vial with a PTFE stirring bar. 3 mL of toluene was added into the vial and the encapsulated catalyst was thoroughly dispersed by vortex and sonication. The solid was precipitated down by centrifugation at 3000 rpm (1200 × g) for 10 min and the supernatant was removed. Toluene (7.5 mL) was added followed by dispersing the encapsulated catalyst with vortex and sonication. 3-acetoxy cyclooctene (3 g, 17.8 mmol, 1333 equiv.) was added at room temperature and the reaction mixture was stirred for 3 hours and quenched by 0.1 mL of ethyl vinyl ether. A small portion (20 µL) of supernatant was taken out for analysis by 1H NMR (conversion = 30%). The reaction mixture was diluted with 400 mL DCM, centrifuged at 12000 rpm (25,759 × g) for 10 min, filtered with 0.45 µm syringe filter, and precipitated into methanol (500*3 mL). The precipitated polymer was dried under vacuum for 12 hours, affording a white solid (yield = 0.66 g, 21%). The condition of hydrogenation of the poly(3-acetoxy cyclooctene) was adopted from literature49, affording while to transparent solid (yield = 0.62 g, 95%). Low molecular weight polymer (37 kg/mol and 30 kg/mol): The procedure was the same as the previous literature49, except that a different amount of cis-4-octene (13.3 mg, 118.1 µmol, 10 equiv.) was used. After hydrogenation, a transparent solid was obtained (yield = 1.35 g, 85%).

Synthesis of poly(vinyl alcohol-co-vinyl acetate-co-ethylene) (p(VAVAE))

Poly(vinyl alcohol-co-vinyl acetate-co-ethylene) was obtained from the corresponding p(VAE) of different molecular weights. To a solution of p(VAE) in THF (50 mM), 25 wt % sodium methoxide methanol solution (0.2 equiv. to the content of acetyl group) was added. The reaction was stirring at room temperature for 1 hour and neutralized with 0.5 M HCl in methanol. The mixture was poured into a methanol solution and the white precipitate was obtained after centrifugation. The resulting polymer was dried, and a small portion was dissolved in deuterated trifluoroacetic acid overnight and integrals of the proton at the α-position of the acetoxyl (5.0 ppm) or the hydroxyl (5.2 ppm) were used to determine the OH content.

Data analysis and plotting

Size exclusion chromatography data were analyzed, and figures were plotted using OriginPro (Version 2024b and 2025b, OriginLab, Northampton, MA, USA).

Data availability

The experimental and characterization data generated in this study are provided in the manuscript or the Supplementary Information and the Supplementary Data files. All data are available from the corresponding author upon request.

References

Bielawski, C. W. & Grubbs, R. H. Living ring-opening metathesis polymerization. Prog. Polym. Sci. 32, 1–29 (2007).

Wu, L. et al. Regulating cationic polymerization: from structural control to life cycle management. Prog. Polym. Sci. 145, 101736 (2023).

Storey, R. F. Chapter 2: Fundamental Aspects of Living Polymerization. In: Fundamentals of Controlled/Living Radical Polymerization pp. 60–77, RSC Publishing, (2013).

Breyer, W. A. & Matthews, B. W. A structural basis for processivity. Protein Sci. 10, 1699–1711 (2001).

Wu, L. et al. Precision native polysaccharides from living polymerization of anhydrosugars. Nat. Chem. 15, 1276–1284 (2023).

Matyjaszewski, K. & Xia, J. Atom transfer radical polymerization. Chem. Rev. 101, 2921–2990 (2001).

Perrier, S. 50th anniversary perspective: RAFT polymerization: a user guide. Macromolecules 50, 7433–7447 (2017).

Zhu, J. B., Watson, E. M., Tang, J. & Chen, E. Y. X. A synthetic polymer system with repeatable chemical recyclability. Science 360, 398–403 (2018).

Teator, A. J. & Leibfarth, F. A. Catalyst-controlled stereoselective cationic polymerization of vinyl ethers. Science 363, 1439–1443 (2019).

Macuvele, D. L. P. et al. Advances in ultra-high molecular weight polyethylene/hydroxyapatite composites for biomedical applications: a brief review. Mater. Sci. Eng. 76, 1248–1262 (2017).

Engelen, S., Droesbeke, M., Aksakal, R. & Du Prez, F. E. Ring-opening metathesis polymerization for the synthesis of terpenoid-based pressure-sensitive adhesives. ACS Macro Lett. 11, 1378–1383 (2022).

Teplov, A. A. et al. Tribological, physicomechanical, and other properties of composites based on ultra-high molecular-weight polyethylene, polytetrafluoroethylene, and ethylene–tetrafluoroethylene copolymer with quasicrystalline filler Al–Cu–Fe. Crystallogr. Rep. 66, 883–896 (2021).

Slugovc, C. The ring opening metathesis polymerisation toolbox. Macromol. Rapid Commun. 25, 1283–1297 (2004).

Miyake, G. M., Weitekamp, R. A., Piunova, V. A. & Grubbs, R. H. Synthesis of isocyanate-based brush block copolymers and their rapid self-assembly to infrared-reflecting photonic crystals. J. Am. Chem. Soc. 134, 14249–14254 (2012).

Yang, J. et al. Bicyclohexene-peri-naphthalenes: scalable synthesis, diverse functionalization, efficient polymerization, and facile mechanoactivation of their polymers. J. Am. Chem. Soc. 142, 14619–14626 (2020).

Bielawski, C. W. & Grubbs, R. H. Highly efficient ring‐opening metathesis polymerization (ROMP) using new ruthenium catalysts containing N‐heterocyclic carbene ligands. Angew. Chem. Int. Ed. 39, 2903–2906 (2000).

Al‐Hashimi, M., Tuba, R., Bazzi, H. S. & Grubbs, R. H. Synthesis of polypentenamer and poly (vinyl alcohol) with a phase‐separable polyisobutylene‐supported second‐generation Hoveyda–Grubbs catalyst. ChemCatChem 8, 228–233 (2016).

Hlil, A. R. et al. Ring opening metathesis polymerization (ROMP) of five‐to eight‐membered cyclic olefins: computational, thermodynamic, and experimental approach. J. Polym. Sci. A Polym. Chem. 55, 3137–3145 (2017).

Herz, K. et al. Functional ROMP‐derived poly(cyclopentene)s. Macromol. Chem. Phys. 214, 1522–1527 (2013).

Xu, G., Wang, D. & Buchmeiser, M. R. Functional polyolefins: poly (ethylene)‐graft‐poly (tert‐butyl acrylate) via atom transfer radical polymerization from a polybrominated alkane. Macromol. Rapid Commun. 33, 75–79 (2012).

Chaimongkolkunasin, S. & Nomura, K. (Arylimido) vanadium (V)-alkylidenes containing chlorinated phenoxy ligands: thermally robust, highly active catalyst in ring-opening metathesis polymerization of cyclic olefins. Organometallics 37, 2064–2074 (2018).

Hejl, A., Scherman, O. A. & Grubbs, R. H. Ring-opening metathesis polymerization of functionalized low-strain monomers with ruthenium-based catalysts. Macromolecules 38, 7214–7218 (2005).

Miller, S. A. Sustainable polymers: opportunities for the next decade. ACS Macro Lett. 2, 550–554 (2013).

Miller, S. A. Sustainable polymers: replacing polymers derived from fossil fuels. Polym. Chem. 5, 3117–3118 (2014).

Sun, H., Liang, Y., Thomspon, M. P. & Gianneschi, N. C. Degradable polymers via olefin metathesis polymerization. Prog. Polym. Sci. 120, 101427 (2021).

Li, Y., Mitaxov, V. & Waksman, G. Structure-based design of Taq DNA polymerases with improved properties of dideoxynucleotide incorporation. Proc. Natl. Acad. Sci. 96, 9491–9496 (1999).

Kageyama, K., Tamazawa, J. & Aida, T. Extrusion polymerization: catalyzed synthesis of crystalline linear polyethylene nanofibers within a mesoporous silica. Science 285, 2113–2115 (1999).

Uemura, T., Yanaia, N. & Kitagawa, S. Polymerization reactions in porous coordination polymers. Chem. Soc. Rev. 38, 1228–1236 (2009).

Kobayashi, Y., Horie, Y., Honjo, K., Uemura, T. & Kitagawa, S. The controlled synthesis of polyglucose in one-dimensional coordination nanochannels. Chem. Commun. 52, 5156–5159 (2016).

Kobayashi, Y. et al. Thermal ring-opening polymerization of an unsymmetrical silicon-bridged [1]ferrocenophane in coordination nanochannels. Chem. Commun. 53, 6945–6948 (2017).

Hwang, J., Lee, H., Antonietti, M. & Schmidt, V. K. J. B. Free radical and RAFT polymerization of vinyl esters in metal–organic-frameworks. Polym. Chem. 8, 6204–6208 (2017).

Yoshida, D. et al. Preparation and activity of ruthenium catalyst based on β-cyclodextrin for ring-opening metathesis polymerization. Tetrahedron Lett. 63, 152712 (2021).

Nguyen, S. T. & Grubbs, R. H. The syntheses and activities of polystyrene-supported olefin metathesis catalysts based on Cl2(PR3)2Ru=CH−CH=CPh2. J. Organomet. Chem. 497, 195–200 (1995).

Al-Hashimi, M., Tuba, R., Bazzi, H. S. & Grubbs, R. H. Synthesis of polypentenamer and poly(vinyl alcohol) with a phase-separable polyisobutylene-supported second-generation Hoveyda–Grubbs catalyst. ChemCatChem 8, 228–233 (2016).

Herrmann, W. A. et al. A molecularly defined, grafted olefin metathesis catalyst from tris(neopentyl)-nitridomolybdenum(VI). Angew. Chem. Int. Ed. 35, 2803–2805 (1996).

Yoon, K. et al. Scalable and continuous access to pure cyclic polymers enabled by ‘quarantined’ heterogeneous catalysts. Nat. Chem. 14, 1242–1248 (2022).

Suriboot, J., Bazzi, H. S. & Bergbreiter, D. E. Supported catalysts useful in ring-closing metathesis, cross metathesis, and ring-opening metathesis polymerization. Polymer 8, 140 (2016).

Bavykina, A. et al. Metal–organic frameworks in heterogeneous catalysis: recent progress, new trends, and future perspectives. Chem. Rev. 120, 8468–8535 (2020).

Liu, J. et al. MOF-enabled confinement and related effects for chemical catalyst presentation and utilization. Chem. Soc. Rev. 51, 1045–1097 (2022).

Kumar, S., Mohan, B., Tao, Z., You, H. & Ren, P. Incorporation of homogeneous organometallic catalysts into metal–organic frameworks for advanced heterogenization: a review. Catal. Sci. Technol. 11, 5734–5771 (2021).

Kalaj, M. & Cohen, S. M. Postsynthetic modification: an enabling technology for the advancement of metal–organic frameworks. ACS Cent. Sci. 6, 1046–1057 (2020).

Morabito, J. V. et al. Molecular encapsulation beyond the aperture size limit through dissociative linker exchange in metal–organic framework crystals. J. Am. Chem. Soc. 136, 12540–12543 (2014).

Li, Z., Rayder, T. M., Luo, L., Byers, J. A. & Tsung, C. Aperture-opening encapsulation of a transition metal catalyst in a metal–organic framework for CO2 Hydrogenation. J. Am. Chem. Soc. 140, 8082–8085 (2018).

Kaye, S. S. & Long, J. R. Matrix isolation chemistry in a porous metal−organic framework: photochemical substitutions of N2 and H2 in Zn4O[(η6-1,4-Benzenedicarboxylate)Cr(CO)3]3. J. Am. Chem. Soc. 130, 806–807 (2008).

Chołuj, A., Zieliński, A., Grela, K. & Chmielewski, M. J. Metathesis@MOF: simple and robust immobilization of olefin metathesis catalysts inside (Al)MIL-101-NH2. ACS Catal 6, 6343–6349 (2016).

Klet, R. C. et al. Single-site organozirconium catalyst embedded in a metal–organic framework. J. Am. Chem. Soc. 137, 15680–15683 (2015).

Ji, P. et al. Transformation of metal–organic framework secondary building units into hexanuclear Zr-alkyl catalysts for ethylene polymerization. J. Am. Chem. Soc. 139, 11325–11328 (2017).

Comito, R. J., Fritzsching, K. J., Sundell, B. J., Schmidt-Rohr, K. & Dincă, M. Single-site heterogeneous catalysts for olefin polymerization enabled by cation exchange in a metal-organic framework. J. Am. Chem. Soc. 138, 10232–10237 (2016).

Dubey, R. J. C. et al. Highly stereoselective heterogeneous diene polymerization by Co-MFU-4 l: a single-site catalyst prepared by cation exchange. J. Am. Chem. Soc. 139, 12664–12669 (2017).

Uemura, T., Kitaura, R., Ohta, Y., Nagaoka, M. & Kitagawa, S. Nanochannel‐promoted polymerization of substituted acetylenes in porous coordination polymers. Angew. Chem. Int. Ed. 45, 4112–4116 (2006).

Uemura, T., Nakanishi, R., Mochizuki, S., Murata, Y. & Kitagawa, S. Radical polymerization of 2, 3-dimethyl-1, 3-butadiene in coordination nanochannels. Chem. Comm. 51, 9892–9895 (2015).

Omrani, A., Deliballi, Z., Kiskan, B., Kaya, K. & Yagci, Y. Kinetic modeling of ring-opening polymerization of benzoxazines using MIL-53-Al as a potent catalyst. Ind. Eng. Chem. Res. 62, 9673–9683 (2023).

Omrani, A., Deliballi, Z., Kaya, K., Kiskan, B. & Akgun, M. Catalytic role of nanoconfinement inside MIL-125 (Ti) on the ring-opening polymerization of simple benzoxazines. ACS Appl. Polym. Mater. 6, 253–264 (2023).

Cavka, J. H. et al. A new zirconium inorganic building brick forming metal organic frameworks with exceptional stability. J. Am. Chem. Soc. 130, 1385013851 (2008).

Chavan, S. et al. H2 storage in isostructural UiO-67 and UiO-66 MOFs. Phys. Chem. Chem. Phys. 14, 1614–1626 (2012).

Zhang, W. et al. A family of metal-organic frameworks exhibiting size-selective catalysis with encapsulated noble-metal nanoparticles. Adv. Mater. 26, 4056–4060 (2014).

Lee, J. et al. Metal–organic framework materials as catalysts. Chem. Soc. Rev. 38, 1450–1459 (2009).

Lo, W. et al. Probing the interface between encapsulated nanoparticles and metal–organic frameworks for catalytic selectivity control. Chem. Mater. 33, 1946–1953 (2021).

Toussaint, S. N., Calkins, R. T., Lee, S. & Michel, B. W. Olefin metathesis-based fluorescent probes for the selective detection of ethylene in live cells. J. Am. Chem. Soc. 140, 13151–13155 (2018).

Lu, G. et al. Imparting functionality to a metal–organic framework material by controlled nanoparticle encapsulation. Nat. Chem. 4, 310–316 (2012).

Thompson, W. J. et al. Catalytically active site mapping realized through energy transfer modeling. Angew. Chem. Int. Ed. 64, e202416695 (2024).

Martinez, H., Ren, N., Matta, M. E. & Hillmyer, M. A. Ring-opening metathesis polymerization of 8-membered cyclic olefins. Polym. Chem. 5, 3507–3532 (2014).

Walker, R., Conrad, R. M. & Grubbs, R. H. The living ROMP of trans-cyclooctene. Macromolecules 42, 599–605 (2009).

Garber, S. B., Kingsbury, J. S., Gray, B. L. & Hoveyda, A. H. Efficient and recyclable monomeric and dendritic ru-based metathesis catalysts. J. Am. Chem. Soc. 122, 8168–8179 (2000).

Michrowska, A. et al. Nitro-substituted Hoveyda−Grubbs ruthenium carbenes: enhancement of catalyst activity through electronic activation. J. Am. Chem. Soc. 126, 9318–9325 (2004).

Tuba, R. & Grubbs, R. H. Ruthenium catalyzed equilibrium ring-opening metathesis polymerization of cyclopentene. Polym. Chem. 4, 3959–3962 (2013).

Lovell, A. P. & Schork, F. J. Fundamentals of emulsion polymerization. Biomacromolecules 21, 4396–4441 (2020).

Claverie, P. J., Viala, S., Maurel, V. & Novat, C. Ring-opening metathesis polymerization in emulsion. Macromolecules 34, 382–388 (2001).

Dabbousi, B. O. et al. (CdSe) ZnS core− shell quantum dots: synthesis and characterization of a size series of highly luminescent nanocrystallites. J. Phys. Chem. B. 101, 9463–9475 (1997).

Trzaskowski, B. & Grela, K. Structural and mechanistic basis of the fast metathesis initiation by a six-coordinated ruthenium catalyst. Organometallics 32, 3625–3630 (2013).

Hyatt, M. G., Walsh, D. J., Lord, R. L., Andino Martinez, J. G. & Guironnet, D. Mechanistic and kinetic studies of the ring opening metathesis polymerization of norbornenyl monomers by a grubbs third generation catalyst. J. Am. Chem. Soc. 141, 17918–17925 (2019).

Kennedy, M. A., Peacock, A. J. & Mandelkern, L. Tensile properties of crystalline polymers: linear polyethylene. Macromolecules 27, 5297–5310 (1994).

Hester, H. G., Abel, B. A. & Coates, G. W. Ultra-high-molecular-weight poly(dioxolane): enhancing the mechanical performance of a chemically recyclable polymer. J. Am. Chem. Soc. 145, 8800–8804 (2023).

Zhang, J., Matta, M. E., Martinez, H. & Hillmyer, M. A. Precision vinyl acetate/ethylene (VAE) copolymers by ROMP of acetoxy-substituted cyclic alkenes. Macromolecules 46, 2535–2543 (2013).

Ittel, S. D., Johnson, L. K. & Brookhart, M. Late-metal catalysts for ethylene homo- and copolymerization. Chem. Rev. 100, 1169–1204 (2000).

Ito, S., Munakata, K., Nakamura, A. & Nozaki, K. Copolymerization of vinyl acetate with ethylene by palladium/alkylphosphine−sulfonate catalysts. J. Am. Chem. Soc. 131, 14606–14607 (2009).

Carrow, B. P. & Nozaki, K. Synthesis of functional polyolefins using cationic bisphosphine monoxide–palladium complexes. J. Am. Chem. Soc. 134, 8802–8805 (2012).

Carrow, B. P. & Nozaki, K. Transition-metal-catalyzed functional polyolefin synthesis: effecting control through chelating ancillary ligand design and mechanistic insights. Macromolecules 47, 2541–2555 (2014).

Su, K. J., Lee, S. Y., Elling, R. B. & Xia, Y. Ring-opening metathesis polymerization of 1,1-disubstituted 1-methylcyclopropenes. Macromolecules 53, 5833–5838 (2020).

Kobayashi, S., Pitet, M. L. & Hillmyer, A. M. Regio- and stereoselective ring-opening metathesis polymerization of 3-substituted cyclooctenes. J. Am. Chem. Soc. 133, 5794–5797 (2011).

Acknowledgements

In memory of our friends and colleagues, Professor Chia-Kuang “Frank” Tsung and Professor Jeffery A. Byers. We thank William J. Thompson, Jiangwei Liu, Jing Jin, Thusitha Jayasundera, Marek Domin, Luke Perreault, and Glenn R. Gaudette for characterization assistance and helpful discussions. We acknowledge the financial support provided by a grant from the National Science Foundation (CHE-2305566 to J.N. and CHE-2304898 to W.H.). The research reported in this publication was supported by the National Science Foundation Major Research Instrumentation (NSF-MRI) Program, under the award number CHE-2117246, and the HEI-S10 Program of the National Institutes of Health, under the award number 1S10OD026910-01A1.

Author information

Authors and Affiliations

Contributions

J.N., Z.Z., W.H., and C.-K.T. designed the experiments. Z.Z., W.-S.L., G.J.G., K.L., W.W., C.F., and A.B. performed experiments. Y.W. and M.G. performed theoretical characterization, supervised by U.M., and J.N. and W.H. supervised the research and secured funding. Z.Z., Y.W., K.L., U.M., W.H., and J.N. wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

A patent application (18/589,967) based on this work has been filed by Boston College. J.N., Z.Z., and W.H. are listed as co-inventors. All other authors claim no competing interests.

Peer review

Peer review information

Nature Communications thanks José-Antonio García-López and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhou, Z., Wang, Y., Lo, WS. et al. Processive ring-opening metathesis polymerization of low ring strain cycloalkenes via molecularly confined catalyst. Nat Commun 16, 8738 (2025). https://doi.org/10.1038/s41467-025-62412-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-62412-7