Abstract

One of the major challenges in the rapidly advancing field of nanophotonics is creating high-aspect-ratio nanostructures over large-area with consistent precision. Traditional techniques like photolithography and etching fall short, being limited to fabricating structures with a typical feature size of 100 nm and a maximum aspect ratio of 30:1. To break through these barriers, herein we introduce a strategy, called wet-chemical etching assisted aberration-enhanced single-pulsed femtosecond laser-supplemented nanolithography (WEALTH), for manufacturing large-area deep holey nanostructures. This strategy enables fabrication of nanostructures with diameters as small as 25 nm (exceeding 1/30 of Abbe’s diffraction limit), aspect ratios greater than 104:1, and large-area holey lattices spanning 10 mm2 with potential scalability up to several cm2. We have successfully harnessed this technique to develop cutting-edge applications, including immunoassay biosensing chips, large-area nanophotonic crystals, nanophotonic crystal microcavities, and chiral nanophotonic devices. Moreover, it is adaptable to a wide range of materials, including crystals, glasses, and silicon-based semiconductors. Our approach offers high flexibility in customizing large-area holey nanophotonic structures, paving the way for breakthrough advancements in 3D integrated optics.

Similar content being viewed by others

Introduction

High-aspect-ratio (AR, the ratio of depth to width) and large-area repeatable nanostructures have the potential to revolutionize the emerging field of nanophotonics1,2,3,4,5,6, particularly in the development of cm2-scale achromatic metalens1,7. As is known, the performance of achromatic and broadband nanophotonic devices is governed by phase dispersion, given by the equation \(\frac{\partial \varnothing (\omega,{H})}{\partial \omega }=H(\frac{1}{c}{n}_{{eff}}+\frac{\omega }{c}\frac{\partial {n}_{{eff}}}{\partial \omega })\), where ω is the angular frequency of incident light, H denotes the AR, and c is the speed of light. This equation denotes that the performance of nanophotonic devices scales linearly with AR7. Over the past decades, traditional photolithography and etching techniques have driven the rapid development of nanophotonics1,3,5,6,7,8. However, no existing technique can fabricate nanostructures that combine both high-AR and large-area repeatability, with the highest reported AR being only 30:11,7. This limitation has restricted the expansion of applications beyond large-area, achromatic, and broadband nanophotonic devices, where ARs greater than 30:1 are essential. This includes fields such as specific immunoassay, single-molecule DNA/RNA sequencing, cell screening, and biomimetic ion transport9,10. Consequently, the development of high-AR nanostructures has been highly anticipated for so long.

Laser lithography has ushered in a new era in the fabrication of micro-/nano-structures in across various materials, including glasses11,12,13,14, crystals15,16,17,18, silicon-based semiconductors19,20,21, and polymers22,23,24. Among these, one of the most notable attempts to create high-AR nanoholes by ultrafast laser direct-writing involves the use of Bessel beam25 and laser filamentation26 in crystals and glasses. However, the formation of deep nanoholes mainly relies on micro-explosions27,28, which generate porous structures with significant inhomogeneity on inner walls of nanoholes29,30,31,32. Moreover, stress accumulation and laser beam side lobe effects are prominent33,34, affecting the limited spacing between adjacent nanoholes. As a result, the fabrication of densely packed, high-duty-cycle, and large-area holey nanostructure lattices remains unachievable. On the other hand, the longitudinal depth of the processed volume is limited by the energy distribution within the focal region. Consequently, the AR of the resulting holey nanostructure is difficult to exceed 100035,36. In addition, small energy fluctuations within multiple pulses can be rapidly amplified by optical nonlinearities and scattering, ultimately leading to structural inhomogeneity along the longitudinal dimension. Although these techniques can rapidly customize holey nanostructures with depth as high as 100 μm, it is generally believed that the minimum size of the nanostructures in hard-brittle materials is limited to 100 nm25, and the duty cycle to less than 30%26, making it impossible to fabricate large-area lattices. These limitations hinder the development of high-performance nanophotonic devices using existing laser direct lithography techniques.

In this work, we propose and experimentally demonstrate a technique for manufacturing large-area, high-AR holey nanostructures, called wet-chemical etching-assisted aberration-enhanced single-pulsed laser nanolithography (WEALTH). Unlike nanocavitation effects in conventional femtosecond laser irradiation followed by the chemical etching (FLICE) method37 (see Supplementary data 1), the WEALTH method operates within a new processing window, where laser irradiation does not directly induce nanocavitation within the material but instead causes structural modification. This technique combines aberration-enhanced single-pulsed femtosecond (AESPF) laser modification with wet-chemical etching to enable volumetric processing at any position within crystals. Our approach breaks through the minimum size limit imposed by typically existing system fluctuations while enabling several key advancements simultaneously: it achieves the smallest feature size (~25 nm), highest AR (>104:1), densely packed features (pitch of <450 nm), high duty-cycles (>70%), and large-area (10 mm2, with scalability up to several cm2) holey nanostructural lattices and nanophotonic devices. Notably, the circularity of the deep nanoholes produced by this technique is unaffected by laser polarization. This versatility allows for the design and fabrication of both traditional holey nanophotonic elements and cutting-edge devices that combine high-AR and densely-packed large-area features.

Results and discussion

Superiority and versatility of the WEALTH technique

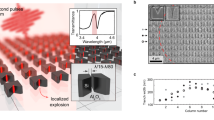

We leverage the spherical aberration enhancement effect to redistribute the light field energy, stretching the Rayleigh length of the focus beyond 100 µm (Supplementary Fig. #1), and facilitating the creation of high AR structures (Fig. 1a). When the AESPF laser pulse interacts with the crystal lattices, it triggers photoionization and avalanche ionization, producing high-density free carriers (>4 × 10²⁸ m⁻³, as estimated numerically) concentrated in a confined region less than 200 nm in diameter (Fig. 2, Supplementary Fig. #1, details in Supplementary Note 1). Consequently, this allows for precise control over the amorphization of the material within the confined nano-region, with minimal impact on the surrounding areas (Figs. 1a and 2), making it possible to fabricate densely packed, large-area holey nanostructural lattices. Additionally, the use of wet-chemical etching provides high selectivity for the amorphous nano-regions (Fig. 1a), resulting in smaller nanohole diameters, more uniform lateral and longitudinal dimensions, and smoother inner surfaces of the holey nanostructures, compared to conventional laser processing methods due to micro-explosion25,27,28.

a Schematic illustration. The single crystals were firstly modified by the AESPF laser and then etched by a wet-chemical etching solution, forming high aspect-ratio (AR) nanoholes. The curved arrow indicates the next step of wet-chemical etching. The blue arrows indicate the flow direction of the etching solution. b Lattice of Nanoholes fabricated in yttrium aluminum garnet (YAG). c Cross-sectional optical microscope of through nanoholes in (b). Inset, Longitudinal cross-section image of a nanohole after material removal by focus ion beam (FIB) milling. d Control of nanohole diameter over single pulse with energy of 3.8–11 μJ/pulse in YAG. The curved arrow indicates the evolution of the nanohole diameter with increasing single pulse energy. Inset, scanning electron microscopy (SEM) image of a nanohole in YAG fabricated under a single pulse energy of 5 μJ/pulse. e Histogram of nanohole size distribution at single pulse energy of 5 μJ/pulse after a series of repeated experiments, showing a diameter of 25 nm for most nanoholes. f Summary on features of nanoholes achieved by the WEALTH technique, compared to those in Sapphire29,35,78, fused silica26,79,80,81, Corning 7980-5F25,31,46,82,83,84,85,86, and borosilicate glasses36,87,88 by Bessel beam laser processing. Scale bars, 1 μm [b, inset in (c)], 20 μm (c), 2 μm (d), and 50 nm [inset in (d)].

a Schematic illustration of temporal and spatial phase transformations in the volume of ionized monocrystal affected by the AESPF laser. Horizontal and vertical axis denotes time and distance from the center of the nano-sized amorphization region, respectively. t1, multi-photon absorption and ionization. t2, twist lattice caused by repulsive interatomic forces. t3, shock-wave emission. b Spherical aberration corrected scanning transmission electron microscopy (STEM) image of YAG after modification by a single-pulsed laser with an energy of ~5.1 μJ/pulse, pulse duration of 226 fs, repetition rate of 10 kHz, and 50x objective of NA = 0.55. The regions marked with i-v correspond to the materials labeled with Amorphous, Amorphous → Twist monocrystal, Twist monocrystal, Twist monocrystal → Monocrystal, and Monocrystal, respectively. c Bright-field STEM (BF-STEM) images of the corresponding regions marked in (b). Insets, selected area electron diffraction (SAED) patterns. d, e Inverse Fast Fourier Transform (IFFT) fringes of the region marked in (c)-ii (d) and (c)-iv (e). A yellow elliptical ring marks the dislocation between the twist monocrystal and the pristine YAG single crystal. f Schematic evolution of local atomic structure. Region within white ring, disordered atomic structure (amorphous phase). The region between the white and yellow rings is twisted, and the atomic structure is twisted (twist monocrystal). Scale bars, 200 nm (b), 2 nm [i, iii, v in (c)], and 5 nm [ii, iv in (c)].

Development of high-performance volumetric nanophotonic devices in dielectric crystals requires the control of several factors, including reproducibility over large areas (mm2 and beyond), feature size, AR, uniformity in longitudinal dimension, close-packing spacing, and duty cycle of the nanohole structures. We demonstrate that all the above features can be effectively controlled by using our AESPF laser modification (Supplementary Figs. #1 and #2, see “Methods”) in combination with wet-chemical etching (Supplementary Figs. #3 and #6, see Supplementary Notes 2 and 3).

We conducted the creation of high-AR nanohole lattices in two representative crystals, namely, c-cut yttrium aluminum garnet (YAG) (optically isotropic) and z-cut Sapphire (optically anisotropic). High-AR nanohole lattices with 2 μm in-plane spacing are created with high lateral and longitudinal homogeneity over an area of 2 × 5 mm2 in both YAG (Fig. 1b) and Sapphire (Supplementary Fig. #5a). Remarkably, we achieved a homogeneous circular nanohole of ~100 nm in YAG (single pulse, 5.3 μJ/pulse, Fig. 1b, see Supplementary Note 4). Interestingly, the dimension and circularity of nanoholes are independent of the crystalline axis, and a homogeneous circular nanohole of ~80 nm can be obtained in Sapphire (single pulse, 7.5 μJ/pulse, Supplementary Figs. #5a and #11). This is primarily because a 4-mm-thick c-cut YAG plate in this work was used to enhance spherical aberration, which can minimize the splitting effect between the ordinary (O) and extraordinary (E) light. As a result, the O-light and E-light beams effectively overlap into a single beam. Similar uniform nanostructures can be achieved in anisotropic crystals by the WEALTH technique, including LiNbO3 crystal (Supplementary Fig. #16), ferroelectric PMN-PT crystals (Supplementary Fig. #17a), and silicon-based semiconductor SiC crystals (Supplementary Fig. #17b). Notably, this level of control has not been previously achieved in either optically isotropic or anisotropic crystals by conventional laser direct-writing techniques16,29,38,39,40. Theoretically, our technique can be generalized for drilling nanoholes in arbitrary crystals and can be extended to materials like glasses13,26 and silicon-based semiconductors19,20,21. The minimum size of the nanohole depends solely on the single pulse energy and laser wavelength. The circularity, defined as the ratio of the short axis to the long axis of a nanohole is as high as 95% (see Supplementary Note 4). Notably, both the size and circularity are independent of factors such as polarization, pulse duration, repetition rate of the fs laser (Supplementary Figs. #10–#14), and the wet-chemical etching time (Supplementary Fig. #8).

The evolution of nanohole size in YAG (Fig. 1d) and Sapphire (Supplementary Fig. #5c) was studied when manipulated by a single pulse. Nanoholes with diameters below 400 nm can be precisely created using AESPF laser modification (see Supplementary Note 4). Remarkably, we were able to achieve nanoholes with diameters of 24 nm in YAG (Fig. 1d, inset) and 22 nm in Sapphire (Supplementary Fig. #5c, inset). To confirm the repeatability of drilling such small nanoholes with our method, we conducted 100 reproducibility tests under identical conditions. As shown in Fig. 1e, most of the nanhole diameter is 25 nm, significantly beyond the Abbe’s diffraction limit (1/30, Supplementary Table #3). To the best of our knowledge, this represents the smallest deep nanohole achieved to date. Theoretically, it is possible to achieve nanoholes with diameters of just a few nanometers13,41, regardless of laser instability and drift. For comparison, we also explored the effects of multi-pulse laser modification. The results show that single-pulse laser modification produces smaller nanohole diameters (see Supplementary Note 4) with higher homogeneity in longitudinal direction than multi-pulse laser modification (Supplementary Fig. #9), which is prone to motion stage shaking, laser instability, and pulse offset.

We then investigated the maximum depth of nanoholes that can be achieved with our technique. In our experiments, the total length of the AESPF laser-modified structures in YAG and Sapphire during a single exposure was ~320 and ~250 μm (Supplementary Fig. #6, see Supplementary Note 3), respectively. After wet-chemical etching, these nanoholes exhibit an AR greater than 104. Theoretically, the AR can further be increased by enhancing the spherical aberration effect to achieve a longer stretched focus. Besides, our technique supports vertical splicing of nanoholes by continuously scanning multiple layers along the laser propagation direction. Therefore, the total length of the final nanohole can theoretically be extended infinitely, via coherent stitching of multiple layers to the next one, regardless of hardware limitations, such as the motion stage and the working distance of the objective lens. Notably, uniformity through nanoholes (Fig. 1c, Supplementary Figs. #5b, #6, and #7) can be achieved by polishing both front and rear surfaces, enabling the customization of holey nanophotonic devices with nanohole depths of any desired length.

Another crucial factor to consider is the uniformity of nanoholes along their longitudinal dimension, as this directly influences the scattering optical loss and, in turn, the optical quality of a nanophotonic device. The optical microscope images (Fig. 1c, Supplementary Figs. #5b, #8, and #9) provide evidence that the nanoholes are quite uniform in the longitudinal direction, even if the nanoholes have a depth of up to hundreds of μm. As shown in the inset of Fig. 1c, the scanning electron microscopy (SEM) image demonstrates a 15-μm-long longitudinal cross-section with an average diameter of 94 nm (Supplementary Fig. #18). To further validate that the nanohole size remains consistent along the depth direction, we used SEM to characterize and statistically analyze the nanohole diameters of a sample on top and bottom surfaces, showing an identical diameter of nanoholes (Supplementary Fig. #19). All the above indicate that the nanoholes remain uniform along the longitudinal direction. In our method, deep nanoholes are fabricated through a two-step process, namely, i) AESPF laser modification of the crystals, and ii) wet-chemical etching. During the laser modification, the beam-stretching focus light field is locally confined through spherical aberration enhancement, resulting in a more uniform longitudinal light field distribution. Additionally, the single-pulsed fs laser modification of crystals involves moderate light-matter interaction, which selectively amorphizes the localized crystal regions, leading to a loose chemical structure with short-range disorder. This greatly reduces the likelihood of stress accumulation and micro-explosion, which are common in traditional fs laser processing strategies25,26,27,28,33, thereby minimizing the formation of inhomogeneous nanostructures (e.g., porous media)29,30,31,32. The wet-chemical etching step further contributes to uniformity, with a selectivity of 104 to 106 for the amorphous region compared to pristine crystals16,42,43. The chemical reaction specifically targets the loose and disordered chemical substances confined within the amorphous regions (Supplementary Fig. #3). Importantly, the reaction products are solvated by water, allowing them to be easily removed without leaving any residues, which results in a smooth inner wall of the nanohole.

As discussed above, the single-pulsed fs laser governs the longitudinal stretching of the focused light field and the generation of nano-sized amorphization modification in crystals, whereas the wet-chemical etching precisely controls the chemical reaction between the amorphous phase and the etching solution. This combination yields sub-30 nm holey nanostructures with an AR greater than 104 (in a single exposure), featuring smoother inner walls and a homogeneously longitudinal cross-section (Fig. 1c, inset). Compared to traditional Bessel beam processing approach25,26,29,31,35, our strategy achieves the smallest nanohole diameter of ~25 nm, the highest AR of >104, the minimum close-pack spacing of <450 nm, and the largest duty cycle of >70% (Fig. 1f, Fig. 3a, b, Supplementary Tables #1–#3). This is because there exists a diffraction effect of side-lobes for a Bessel beam, which will affect the shape and size of adjacent areas, making it challenging to achieve a smaller spacing and a higher duty cycle. In contrast, our technique overcomes these drawbacks.

a Deep nanohole arrays of 3 × 3 with 500 nm spacing in YAG. b Histogram of duty cycles at different limit spacing in (a). Inset, pink spheres denote nanholes, where D stands for the diameter of a nanohole, and P illustrates the period between adjacent nanoholes. c Orientation control of nanoholes. Schematic illustration (left) and SEM images of elliptical nanoholes with orientations of 0o, 45o, 90o, and 135o (right). Double arrows indicate the orientation of nanoholes. d Optical microscope images of the nanohole patterns designed as Archimedean-spiral-like structure with nanoholes of 240 nm (left), 260 nm (middle), and 280 nm (right) in diameter, respectively. Insets, local SEM images. e Phase retardance distribution images of the nanohole structures corresponding to (d). Scale bars, 500 nm [a, c], 10 µm [d, e], and 1000 nm [insets in d].

Photo-physical model and microstructure evolution mechanism

We delineate a light-matter interaction model, considering both time and spatial domains, to explain how our strategy achieves nanoholes with a diameter as small as ~25 nm. The beam diameter in the focus plane is ~1 µm as calculated in Supplementary Note 1. Due to the well-known nonlinear threshold-effect44, the laser modification area becomes concentrated at the center of the spot. This area is significantly smaller than the overall spot diameter and, in theory, can approach an infinitesimally small size, potentially even close to the quantum limit45. However, in laser volume 3D nanopatterning of bulk glass and crystals, previous studies have typically considered that the extreme size is generally greater than 100 nm13,16,46,47,48. Newly emerged approaches leveraging near-field interactions induced by intense laser fields themselves have, in principle, surpassed this empirical limitation, enabling the engraving of sub-100 nm continuous solid-line structures13,48,49. However, these near-field interaction methods rely heavily on the incubation effect, with seed diameters typically exceeding 100 nm, making it challenging to achieve the discrete distribution of sub-100 nm circularly symmetric holey nanostructures as done by the proposed WEALTH approach. Besides, unlike nanocavitation effects in conventional FLICE method37 (see Supplementary data 1), the WEALTH method operates within a novel processing window, where laser irradiation does not directly induce nanocavitation within the material but instead causes structural modification. The sub-100 nm modified regions are then selectively removed through subsequent wet-chemical etching, resulting in regular nanocavities. Notably, understanding the sub-100 nm laser-induced modifications requires examining material structural changes at the atomic scale, an area previously unexplored. Our research addresses this gap, providing insights into atomic-scale transformations at the laser-irradiated interface.

Understanding the interaction between light and matter in the time domain is shown in Fig. 2a. Within tens of femtoseconds (t1), the AESPF laser transfers energy to electrons through multi-photons and avalanche ionization50,51,52. When the density of excited carriers reaches approximately 1028 m–3, the high-density carriers behave as a plasma confined within a sub-30 nm region. In this region, the pristine crystal is fully converted to an amorphous phase, causing the crystal lattice collapse and form a disordered network27,42,53,54,55. This amorphous area becomes significantly more susceptible to etching by wet-chemical solutions, due to a specific chemical reaction between the amorphous phase and etching solutions (Supplementary Fig. #3, see Supplementary Note 2). Over a picosecond timescale (t2), a fraction of the optical energy absorbed by the electrons is transferred to the lattice, inducing lattice oscillations and generating a shock wave51,52. Within a couple of nanoseconds (t3), the shock wave propagates outward, gradually cooling down, and separating from the nano-confined amorphous region, creating a shock-affected region with a radius of ~ 250 nm from the shock front to the cooling boundary27,51,52. Although the lattice in this region becomes twisted, it does not alter its monocrystalline phase nature56. Compared to the amorphous region, the selectivity of etching in the lattice-twisted area is very low, and the etching rate is slow, which can be essentially negligible57. Thus, it can be approximately believed that the wet-chemical etching does not affect this area, allowing precise control over etching within the nano-sized amorphous region, due to high etching selectivity of 104 to 106 and fast etching rate16,42,43, resulting in the smallest nanohole.

To provide direct experimental evidence, we performed high-resolution spherical aberration corrected scanning transmission electron microscopy (STEM) on YAG samples, thinned to ~50 nm using FIB milling. As shown in Fig. 2b, the laser-affected region is approximately 500 nm in diameter when the AESPF laser energy is ~5.1 μJ/pulse, just above the optical breakdown threshold. Interestingly, a two-layered homogeneous region is observed at the center, consisting of region i (~50 nm in diameter) and region iii surrounding it, with a ring-like edge ii displaying an abrupt contrast. This observation aligns well with the model we proposed in Fig. 2a. The bright-field STEM (BF-STEM) image (Fig. 2c-i) in region i (Fig. 2b) reveals a disordered and chaotic amorphous phase, consistent with the nanoscale selected area electron diffraction (SAED) pattern (inset in Fig. 2c-i). Surprisingly, in region iii (Fig. 2b), the BF-STEM image (Fig. 2c-iii) indicates that the material remains in a monocrystalline phase, although the lattice plane orientation differs from the (111) plane of the pristine crystal (Fig. 2c-v). This difference is due to a slight twist in the crystal axis orientation by approximately \({\theta }_{y}\) ~ 0.7o (Supplementary Fig. #20, see Supplementary Note 5). The SAED pattern (point arrays with slight axis offset, inset in Fig. 2c-iii) further confirms the twisted monocrystalline phase in region iii (Fig. 2b), which is clearly distinct from the pristine crystal (centrosymmetric point arrays, Fig. 2c–v). The BF-STEM image (Fig. 2c-ii) provides additional details about the boundary between twisted monocrystalline and amorphous phases (region ii in Fig. 2b), showing an oriented atomic lattice near region iii (Fig. 2b), while a disordered lattice network forms closer to region i (Fig. 2b), consistent with the SAED pattern (a mixture of monocrystalline point arrays and bright amorphous ring, inset in Fig. 2c-ii). Lattice dislocations and distortions (Fig. 2d) are also evident in the inverse Fast Fourier Transform (IFFT) fringe of the yellow-marked area in Fig. 2c-ii. A clear boundary between the twisted monocrystal and pristine crystal is observed in the BF-STEM (Fig. 2c-iv) images, corresponding to the SAED pattern (only monocrystalline point arrays, inset in Fig. 2c-iv). Additionally, the IFFT fringe of the purple-marked region in Fig. 2c-iv confirms the presence of dislocations58 between the twisted monocrystal and pristine crystal regions (Fig. 2e). Notably, the high-density carriers of the AESPF laser induce amorphization only occurring in the center as confined within a sub-30 nm region, without causing nanocracks, even when the laser energy is over twice (~11 μJ/pulse, single pulse, Supplementary Fig. #21) the optical breakdown threshold or when the pulse numbers is doubled (~5.8 μJ/pulse, Supplementary Fig. #22) [see Supplementary Note 6]. Therefore, our technique enables precise control over the fabrication of nanoholes with ultra-small diameters and ultra-long depths.

Based on the above discussion, it can be concluded that the AESPF laser primarily controls local amorphization (disordered lattice) through the nano-confinement of high-density carriers in the center (Fig. 2f, within the white ring). In contrast, the shock wave generated by multi-photon ionization only leads to lattice distortion and dislocation (between the yellow and white ring in Fig. 2f, see Supplementary Movie 1)58. The formation of the amorphous phase, along with lattice dislocation and distortion, can be regarded as plastic deformation55,59,60, which is further confirmed by micro-region photoluminescence and Raman (Supplementary Figs. #23 and #24, see Supplementary Note 7). Thus, the observed phenomenon can be attributed to the structural differences between nano-sized amorphous phases and monocrystalline phases, after AESPF laser modification. The amorphous phase, due to its disordered atomic arrangement and potentially higher surface area, is more susceptible to chemical etching, exhibiting very high etching selectivity of 104 to 106 compared to the unmodified region16,42,43. In contrast, the twisted monocrystalline phase, influenced by the shock wave, only exhibits lattice distortion but without altering its single-crystal nature, making it protected from etching56,57.

Control of nanohole packing density, shape, orientation, and distribution

To achieve volume nanophotonic devices, it is crucial to arrange nanoholes in an arbitrary close-packed structure without causing brittle fractures from excessive stress accumulation. We show that high-AR nanoholes with desired pitch and duty cycle can be obtained in single crystals. In YAG, we achieved deep nanohole lattice with a minimum spacing of 500 nm (Fig. 3a), an average nanohole diameter of ~360 nm, a dielectric wall thickness of ~140 nm between adjacent nanoholes, and a duty cycle >70% (Fig. 3b). Even more impressively, a minimum spacing of ~450 nm was achieved in Sapphire (Supplementary Fig. #25). The AESPF laser modification process is more moderate compared to traditional micro-explosion techniques25,26,27,28, as it only triggers amorphization in the center nano-sized region confined with high-density carriers. The localized amorphization of the material by the AESPF laser modification precisely reduces crosstalk between neighboring nanoholes, enabling the fabrication of super-close proximity nanoholes with high-AR. Additionally, the refractive index change in the lattice-twist area is relatively small, so it offers a robust WEALTH strategy for producing high-density nanohole arrays. The primary limitation on the spacing and density is due to the diffraction limit in laser processing.

To control light propagation in nanophotonic devices, it is essential to manipulate the wavefront, phase, and electromagnetic waves at the level of the nanohole structural unit61, which includes cross-sectional shape, spatial orientation, and distribution. As discussed above, the circularity of the high-AR nanoholes produced by our technique is unaffected by the linearly- and circularly-polarization of the AESPF laser (Supplementary Figs. #10 and #11). This results in the formation of circular nanoholes in both optically isotropic (e.g., c-cut YAG) and anisotropic crystals (e.g., z-cut Sapphire). Although it is not possible to manipulate the nanohole shape and orientation by tailoring the input AESPF laser polarization, this approach enables the precise regulation of these features by beam shaping, without causing birefringence-induced focal splitting in either optically isotropic or anisotropic crystals. We achieved elliptical nanoholes (with an average length of ~450 nm and width of ~150 nm, yielding a 3:1 length-to-width ratio) leveraging a cylindrical lens pair in combination with a 4-mm-thick c-cut YAG plate for enhancing spherical aberration, which were also obtained by loading aberration-enhanced hologram phase combined with cylindrical mirror phase in SLM (Supplementary Fig. #26). Importantly, the elliptical nanoholes can be oriented arbitrarily (e.g., 0o, 45o, 90o, 135o) by rotating the angle of the cylindrical lens pair (Fig. 3c, Supplementary Figs. #1 and #2). Additionally, we demonstrate that oriented two- (Supplementary Fig. #27a) and four-nanohole (Supplementary Fig. #27b) structural units can be achieved in a single exposure by utilizing multi-beam shaping of the AESPF laser (see Supplementary Note 8). This is accomplished by using first-order (1st-order) and second-order (2nd-order) Laguerre-Gaussianian (LG) beams, respectively. Of course, we also achieved the same results by leveraging SLM. The strategy of parallel multi-beam laser lithography of high-AR nanoholes not only improves processing efficiency but also reduces the demands for the accuracy and stability of the mechanical movement platform, which are critical in traditional multi-step pointing and scanning techniques62. More importantly, the ability to create oriented multi-nanohole structural units expands the potential applications for various large-area nanophotonic devices.

To show the capability of controlling phase distribution, we designed the holey nanostructure as an Archimedean spiral (Supplementary Fig. #29a)63, and successfully fabricated three 50-µm-long through nanohole patterns (Fig. 3d), with 240, 260, and 280 nm in diameter and 500, 750, and 1000 nm in spacing, respectively. Figure 3e shows the phase retardance distribution images of the Archimedean-spiral-like holey nanostructures corresponding to Fig. 3d. A maximum retardance of ~7 nm is found, which aligns well with the calculated results (see Supplementary Note 9), confirming that the nanoholes are fully etched. The intensity and phase of the Archimedean-spiral-like holey nanostructures were accurately simulated (Supplementary Figs. #29b and #29c)[see Supplementary Note 10], validating that the phase distribution can be precisely controlled by adjusting nanohole size, spacing, and depth.

The facile control over the nanohole cross-sectional shape, spatial orientation, and distribution opens up vast possibilities for manipulating the phase of nanohole structural units, enabling the construction of arbitrary holey nanophotonic devices.

Specific immunoassay biosensing chips

To showcase the potential of high-AR nanoholes fabricated by the WEALTH technique for a specific immunoassay, we created nanohole arrays with various AR in YAG (Fig. 4a, ii and iii) (Fig. 4a-i, see “Methods”). The nanoholes, with a large surface-to-volume ratio and high-AR, are particularly beneficial for amplifying the photoluminescence (PL) signal of dye-labeled specific antibody4. Indeed, the PL intensity of nanohole arrays with Rodamine B (RhoB)-labeled detection antibody (dAb) was found to be twice than that of unstructured sample (Fig. 4b). Interestingly, the sample with AR = 300:1 exhibited the greatest PL enhancement, suggesting that the structures with depth up to 60 µm are highly effective for specific biodetection. This depth would be challenging to achieve using traditional lithography techniques. However, it is important to note that a higher AR does not result in greater PL enhancement. As shown in Fig. 4b, the PL intensity for AR = 1000:1 or AR = 1500:1 was lower than that for AR = 300:1. This phenomenon is attributed to scattering losses and detection limitation in nanoholes with depth extending to hundreds of µm. Specific and non-specific detection was conducted to assess the biosensing performance. As shown in Fig. 4c, the PL intensity of RhoB-labeled dAb with antigen (Antigen-dAb) is significantly higher than that of dAb within phosphate buffer saline (PBS-dAb) (see “Methods”), indicating effective specific binding. The signal-to-noise ratio, calculated as \(\frac{{I}_{{specific}}-{I}_{{non}-{specific}}}{{I}_{{non}-{specific}}}\), where I denotes PL intensity, reaches a maximum of 3.8 (Fig. 4d), which is comparable to technologies based on photonic crystals64. Additionally, single crystals hold high-temperature stability (>1000 °C), which means that, despite the biological proteins and antibodies being vaporized at such high temperatures, the chips containing nanohole arrays remain unchanged, maintaining their original holey nanostructure and can be further reused for exploiting new biosensing devices. As shown in Fig. 4e, the PL intensity exhibits minimal variation across multiple recycle experiments, even after 6 cycles of specific biodetection and followed by high-temperature (high-T) treatment at 1000 °C. Importantly, the high-T heat-treatment can burn and vaporize all of the organic groups labeled on the inner wall of the nanoholes, restoring the through nanohole array samples to a state in which it was originally fabricated. This demonstrates that the high-AR nanohole array samples made from single crystals can theoretically be reused infinitely in specific biodetection. This not only reduces costs but also minimizes resource waste, offering a significant advantage over conventional biomedical detection materials.

a Schematic illustration of specific immune detection based on through nanohole arrays fabricated by the WEALTH technique. Insets, introduced –NH2 group via bonding (3-Aminopropyl) trimethoxysilane (APTMS) with –OH group on the inner wall of YAG. (ii) SEM image of nanohole arrays. Inset, magnified SEM image of a nanohole. (iii) Cross-section microscope image of the nanohole. b Photoluminescence (PL) spectra of Rodamine B (RhoB) labeled detection antibody (dAb) in the nanohole arrays with various AR during specific detection. c PL spectra of specific dAb with antigen (Antigen-dAb) and non-specific dAb within phosphate buffer saline (PBS-dAb) detection. d Signal-to-noise ratio of PL between specific and non-specific detection in (c). e Reusability of a same nanohole sample for specific immunoassay. “High-T treated chip” means the biosensing chip was heat-treated at 1000 °C, to burn and vaporize of organic groups for next-cycle experiment. f Photograph of a large-area nanophotonic crystal device. g Geometric schematic of the designed large-area nanophotonic crystal. h SEM image of the fabricated large-area nanophotonic crystal device. i Transmittance spectra of large-area holey nanophotonic crystal devices fabricated with energies of 6, 8, and 10 μJ/pulse, respectively. Reference: transmittance spectrum without nanoholes on YAG. Blue and red arrows indicate the photonic band gap. Scale bars, 2 µm (a, ii), 200 nm (a, inset in ii), 50 µm (a, iii), and 1 µm (h).

Large-area holey nanophotonic devices

To evaluate the scalability of subwavelength nanophotonic devices based on high-AR nanoholes, we successfully fabricated large-area nanophotonic crystals with a dimension of 2 5 mm2 in YAG. These structures exhibit distinct structural color due to nanophotonic crystal bandgap (Fig. 4f). The holey nanophotonic crystal was designed with a pitch of 500 nm for both rows and columns, with a deliberate disturbance shift of 50 nm between rows (Fig. 4g), which matches well with the laser-manufactured structures (Fig. 4h). Figure 4i shows the experimental transmittance spectra of the large-area holey nanophotonic crystal fabricated at single pulse energies of 6, 8, and 10 µJ/pulse. These energies primarily control the diameters of the deep nanoholes, resulting in average diameters of ~150, ~200, and ~250 nm, respectively. The spectra reveal two photonic band gaps in the range of 480–550 nm and 900–1100 nm, with a maximum transmittance of ~99% and a modulation depth of as high as 50%, indicating the potential for customization of large-area nanophotonic elements. The experimental results are in good agreement with simulation data (Supplementary Fig. #30). This large-area nanophotonic crystal was fabricated using line scanning at a high speed of 200 mm/s, a process that could theoretically be faster if not limited by the motion platform. The processing rate of our single-pulsed laser nanolithography exceeds that of the existing serial laser writing techniques by more than 100 times13,15,16,17,41,62, which can be much faster if adopting an fs laser with a repetition rate of GHz. Remarkably, our technique allows the creation of the holey nanophotonic crystal with an area of 2 × 5 mm2 within ~100 s, outperforming any existing nanofabrication methods13,15,16,41,62. Most significantly, this large-area holey nanophotonic crystal can be regarded as a perfect photonic crystal due to the substantial depth of the nanoholes, which facilitates the straightforward fabrication of arbitrary through-nanoholes-based nanophotonic devices (Supplementary Fig. #6). This is in stark contrast to traditional nanophotonic crystal devices, which are typically referred to as quasi-photonic crystals, because the nanohole depth is usually less than 1 µm due to limitations of conventional lithography techniques1,4.

In addition to their applications in large-area holey nanophotonic devices, volumetric nanoholes in dielectric crystals offer novel approaches for designing classical linear and nonlinear nanophotonic devices, such as nanophotonic crystal microcavities (Supplementary Fig. #31, see Supplementary Note 11), chiral nanophotonics (Supplementary Fig. #32, see Supplementary Note 12). Interestingly, we achieved chiroptical feature with a CD value of approximately 1% from the Archimedean-spiral-like nanohole structure, which can be further enhanced up to 93% in future works65,66,67. These nanoholes also pave the way for customizing a variety of emerging holey nanophotonic devices, particularly large-area (cm2-scale) achromatic metalens1,7 and dynamically tailorable metasurfaces by filling the nanoholes with liquid-crystals68 and nonlinear materials69. This advancement could herald a new era in nanophotonics. Moreover, high-AR nanoholes have potential applications beyond photonics, including single-molecule DNA/RNA sequencing, cell screening, and biomimetic ion transport9,10. These capabilities highlight the versatility and transformative potential of volumetric nanohole structures in both existing and emerging technologies.

In conclusion, we have developed a wet-chemical etching-assisted single-pulsed femtosecond laser nanolithography technique that enables the fabrication of small-diameter (~25 nm), high-aspect-ratio (>104:1), and large-area (10 mm2, and potentially cm2-scale) holey nanostructures. This method is characterized by its precise control over AESPF laser-induced amorphization within nano-sized regions that are selectively etched by chemicals. Although our work focuses on specific crystals like YAG and Sapphire, there are no fundamental barriers to applying the technique to other materials. The technique is particularly advantageous for creating large-area, achromatic, and broadband tailorable holey nanophotonic devices, with significant implications for nanophotonic and biomedical applications. Additionally, the ability to fabricate deep nanoholes with high precision opens up avenues for designing advanced nanophotonic elements, such as photonic crystal microcavities, chiral nanophotonics, and dispersion elements. Beyond nanophotonics, this technique shows potential in various fields, including 3D integrated optics5, lab-on-fiber systems70, nanodicing71, microelectronics72, and nano-biotechnology2 (see Supplementary Note 13). The scalability, efficiency, and broad material compatibility of this laser nanolithography method position it as a powerful tool for advancing the design and fabrication of next-generation nanophotonic and biomedical devices.

Methods

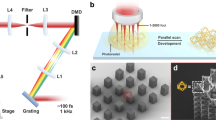

Laser processing system

A home-built femtosecond laser (Pharos, Light Conversion, Lithuania) processing system was used for photo-modification of samples, as shown in Supplementary Fig. #2. The laser processing parameters were selected from a wavelength of 1030 nm or frequency-doubling 515 nm, pulse duration ranging from 214 fs to 10 ps, and pulse repetition rate in the range of 1 Hz to 200 kHz. The laser beam diameter is ~5 mm after propagation over a long distance, which is just enough to fill the full aperture of a focusing 50× objective lens of 0.55 NA (ELWD 50×/0.55 B, Nikon, Japan). The beam stretching, in this work, was controlled by the spherical aberration enhancement effect with a 4-mm-thick YAG plate lying on the single crystals to be processed or with a spatial light modulator (LCOS-SLM, X13138, Hamamatsu, Japan). The hologram phase patterns of SLM can be found in Supplementary Fig. #26. Long and uniform track lengths hundreds of micrometers in YAG, Sapphire, LiNbO3, PMN-PT, and SiC single crystals were generated by this method. The processing laser power was controlled by a combination of a zero-order 1/2 waveplate and a polarizing beam splitter (PBS). The laser linear polarization was manipulated by another zero-order 1/2 waveplate, and a 1/4 waveplate was used to convert linear polarization into circular polarization. The elliptical nanoholes with any orientation were firstly laser-modified by using beam shaping with a cylindrical pair imposed onto the AESPF laser beam or with the SLM-manipulated AESPF laser beam with a corresponding phase pattern. The parallel two-nanohole and four-nanohole with arbitrary orientation were controlled by a combination of first-order (1st-order) and second-order (2nd-order) radial polarizers with a zero-order 1/2 waveplate and a linear polarizer or by the SLM-modulated multiple AESPF laser beams with corresponding phase pattern. The designed nanohole pattern structures of the samples were performed by computer-controlled XYZ linear stages (ABL1000-100 and ANT130V-5, Aerotech, USA). The laser modification process allows for monitoring in real time by integrating a CMOS camera (STC-MCS122BPOE, LUBANG Technology, China) in the laser processing system.

Materials, chemicals and biomolecules

Pure c-cut YAG (< 111 >) single crystals were procured from SHANGHAI BLUEOPTICS TECHNOLOGY LTO (5 × 5 × 0.5 mm3 and 10 × 10 × 4 mm3). Nd3+-doped YAG single crystals (<111 > , 5 × 5 × 0.23 mm3, 1 at% doping) were procured from Chengdu Alfa Metal Material Co., Ltd. Pure z-cut Sapphire (<0001 >) single crystals of 5 × 5 × 0.5 mm3 were procured from CASCRYSTECH Co., Ltd. Pure z-cut LiNbO3 crystals of 5 × 5 × 0.5 mm3 were procured from Jinan Jingzheng Electronics Co., Ltd. Pure ferroelectric PMN-PT crystals of 5 × 5 × 0.5 mm3 were procured from Xi’an Jiaotong University. Silicon-based semiconductor SiC crystals 10 × 5 × 0.5 mm3 were procured from Shanxi SEMISiC Co., Ltd.

Phosphoric acid (ACS, 85 wt. % in H2O) and (3-Aminopropyl) trimethoxysilane (APTMS, 97%, Cl-<13 ppm) were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd. Hydrofluoric acid (40 wt. % in H2O) was purchased from Sinopharm Chemical Reagent Co., Ltd.

N-hydroxysulfosuccinimide (NHS) and 1-Ethyl-3[dimethylaminopropyl] carbodiimid (EDC) were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd. Phosphate buffer saline (PBS) was purchased from Beijing Solarbio Science and Technology Co., Ltd. Buffer MES solutions were purchased from Sigma-Aldrich Co., Ltd. Human native cardiac troponin complex antibody (Ab) was purchased from Shenzhen Yazhengtai Biotechnology Co., Ltd. Capture antibody (cAb) and Rhodamine B (RhoB) labeled detection antibody (dAb) were conducted from Hebei Langfei Biotechnology Co., Ltd.

Wet-chemical etching

After the AESPF laser modification, the single crystals were polished on both front and rear surfaces to expose terminations of the laser-modified structures for the following wet-chemical etching. Phosphoric acid (H3PO4, 44 wt% solution) in deionized water was used for etching of laser-modified YAG crystals, performed in a magnetic stirrer with an intelligent constant temperature magnetic heating mantle (ZNCL-TS, China) at 353 K. Sapphire crystals were etched in hydrofluoric acid (HF, 30 wt% solution) in deionized water at ambient temperature in an ultrasonic bath. Additionally, all the samples were removed, dried, and placed in fresh etching solution after etching for 2 h, repeated 3–5 times, to ensure the size and uniformness of the nanoholes remain consistent along the depth direction. After etching, the samples were consecutively immersed in deionized water, acetone, and ethanol for 5 min with ultrasonic baths, and ultimately dried with nitrogen flow. For both YAG and Sapphire, no dependence on crystalline axis was observed for the high-AR nanohole size within our experimental resolution. The elucidation of the specific chemical reaction of the etching can be found in Supplementary Note 2 and Supplementary Fig. #3, in combination with spherical aberration corrected STEM results (Fig. 2).

Material characterization

The top-down images of the high-AR nanoholes after wet-chemical etching were viewed with a field-emission scanning electron microscopy (SEM, GEMINI300, ZEISS, Germany). The open-source Fiji image processing package73 was employed to digitally analyze the statistical size and shape distributions of all SEM images of the high-AR nanohole lattices. The top-down and cross-section optical microscope images of the high-AR nanoholes during the workflows of laser-modification, polishing, and wet-chemical etching were captured by a CCD camera (SC180, Japan) equipped with an Olympus microscope (BX53MTRF-S, Japan). For characterization of in-volume holey nanostructures, FIB milling (Helios 5 CX, Thermo Fisher Scientific, USA) was used to expose the profile of a homogeneously longitudinal distribution of the high-AR nanoholes. The in-situ features of the laser-modified single crystals were recorded by spherical aberration corrected scanning transmission electron microscopy (STEM, Titan ChemiSTEM, FEI, USA) after FIB thinning the sample down to ~50 nm in thickness. The crystal phase characters of the single crystals with and without the AESPF laser-modification localization were studied by the high-resolution micro-XRD diffractometer (D8 Discover HR-XRD, Bruker, Germany). The laser confocal Raman micro-spectroscopy (InVia, Renishaw, UK) equipped with 405, 532, and 785 nm lasers was utilized to analyze the variation of crystal phase and chemical bonding.

Optical measurement

Optical transmission spectra of the large-area holey nanophotonic crystals and microcavities were captured by employing a UV–vis–NIR microspectrophotometer (508PV, CRAIC, USA). The chiroptical features of the Archimedean-spiral-like holey metasurface were recorded by the UV–vis–NIR microspectrophotometer equipped with a switchable polarizer and a 1/4 waveplate at will. The relative PL spectra were measured by laser confocal Raman micro-spectroscopy (InVia, Renishaw, UK) upon excitation of a 532 nm C.W. laser, which allows for detecting the 2D and 3D PL microscopic images. The phase retardance distribution imaging of the Archimedean-spiral-like nanohole matasurfaces was quantified with a birefringence measurement system (MicroImager, Hinds Instruments, USA) equipped with a 20× optical microscope objective lens (NA = 0.42), operating at 535 nm wavelength.

Specific immunoassay

Surface modification. The samples with various AR through nanohole arrays (see Supplementary Note 3) were fabricated, and treated with O2 plasma for 10 min, and then treated with 5% APTMS in 95% ethanol for 30 min under ambient temperature. The samples were then rinsed in 97% ethanol and deionized water for three times, respectively, to remove excess reagents and then dried with gentle N2 flow.

Antibody labeling. (1) Activation: 40 mg/mL NHS and 40 mg/mL EDC (50 mM MES, pH = 4) were blended in equal volumes, and 20 µL of the mixed NHS-EDC solution was dripped on the surface of each modified sample, and treated with vacuum for 2 min, and then leaved at room temperature for 10 min, and finally washed with amounts of water for 3 times and dried with gentle N2 flow. (2) Capture antibody: 10 µL of cAb solution (50 µg/mL in PBS) was added to the surface of each activated sample, and treated with vacuum for 2 min, followed by incubation at 25 °C for 2 h, and finally washed with amounts of water for 3 times and dried with gentle N2 flow. (3) Blocking: The samples labeled cAb were rinsed in 10 mL of blocking solution (1% bovine serum albumin + 0.005% sodium caseinate), and treated with vacuum for 2 min, and then left at room temperature for 30 min, and finally washed with amounts of water for 3 times and dried with gentle N2 flow.

Specific detection. 10 µL of specific detection solution (blend of 45 µL 0.52 ng/L antigen solution and 5 µL 800 µg/mL RhoB labeled dAb) was added on the surface of each sample labeled cAb above, and treated with vacuum for 2 min, and then leaved at 25 °C for 10 min, and finally washed with amounts of water for 3 times and dried with gentle N2 flow. For control, we only need to change the antigen solution with PBS solution at the same volume, and other procedures keep the same for the background and non-specific detection. All the procedures were conducted in a dark ambient at 25 °C. The fluorescence spectra of the specific and non-specific immune detection were measured by laser confocal Raman micro-spectroscopy (InVia, Renishaw, UK) upon excitation of a 532 nm C.W. laser.

Statistic and error bars

Due to the influence of the location of the motion stage and environmental vibration on the shape and geometric size of the nanoholes, a statistical method is required to give a description of the range of measured quantities. In Figs. 3b, 4e, and Supplementary Figs. #10–#15, the error bars are defined by the standard deviation \({{{\rm{S}}}}=\sqrt{\frac{{\sum }_{i}^{n}{({x}_{i}-\bar{x})}^{2}}{n-1}}\) of the quantity x measured by repeating the experiment n times, where \(\bar{x}=\frac{{\sum }_{i}^{n}{x}_{i}}{n}\) is the mean value. Actually, we set n = 10 for the calculation74.

Theoretical calculations and numerical simulations

Simulation of the 3D light-field intensity distribution (Supplementary Fig. #1c) expected from the AESPF laser modification was performed by diffraction integral, and the nonlinear propagation of laser pulses and ionization of material were calculated by employing the nonlinear Schrödinger equation and electron rate equation using Matlab (Supplementary Fig. #1, see Supplementary Note 1). COMSOL Multiphysics 6.2 and finite-difference time-domain (FDTD) method were utilized for design and modeling of the high-AR nanohole-based large-area nanophotonic crystal devices3, nanophotonic crystal microcavities16, and Archimedean-spiral-like holey metasurfaces63. Simulation of diffraction pattern of the STEM results for the shock-wave affected region was conducted by using Crystalmaker Software75,76,77.

Data availability

All data are available in the main text or the supplementary information. Source data are provided with this paper (reference[Chen, Z., Zhong L., Sun, X., Fu, Y., He, H., Ji, H., Wang, Y., Liu, X., Xu, B., Wu, Z., Zou, C., Ma, Z., Zhang, J., Dong, G., Barillaro, G., Qiu, C.-W., Qiu, J. & Qiu J. All the source data sets for the main text and supplementary information. Figshare https://doi.org/10.6084/m9.figshare.29351579 (2025)]). Source data are provided with this paper.

Code availability

Code for simulation, calculation, and design is available from the corresponding author upon request.

References

Ossiander, M. et al. Extreme ultraviolet metalens by vacuum guiding. Science 380, 59–63 (2023).

Balaur, E. et al. Colorimetric histology using plasmonically active microscope slides. Nature 598, 65–71 (2021).

Duan, X. et al. Valley-addressable monolayer lasing through spin-controlled Berry phase photonic cavities. Science 381, 1429–1432 (2023).

Roques-Carmes, C. et al. A framework for scintillation in nanophotonics. Science 375, eabm9293 (2022).

Ourari, S. et al. Indistinguishable telecom band photons from a single Er ion in the solid state. Nature 620, 977–981 (2023).

Jin, J. et al. Topologically enabled ultrahigh-Q guided resonances robust to out-of-plane scattering. Nature 574, 501–504 (2019).

Lim, S. W. D., Meretska, M. L. & Capasso, F. A High Aspect Ratio Inverse-Designed Holey Metalens. Nano Lett. 21, 8642–8649 (2021).

Gu, L. et al. A biomimetic eye with a hemispherical perovskite nanowire array retina. Nature 581, 278–282 (2020).

Ying, Y. L. et al. Nanopore-based technologies beyond DNA sequencing. Nat. Nanotechnol. 17, 1136–1146 (2022).

Chou, Y. C. et al. Coupled nanopores for single-molecule detection. Nat. Nanotechnol. 19, 1686–1692 (2024).

Huang, X. et al. Reversible 3D laser printing of perovskite quantum dots inside a transparent medium. Nat. Photonics 14, 82–88 (2020).

Sun, K. et al. Three-dimensional direct lithography of stable perovskite nanocrystals in glass. Science 375, 307–310 (2022).

Zhen-Ze Li, H. F. et al. Super-stealth dicing of transparent solids with nanometric precision. Nat. Photonics 18, 799–808 (2024).

Wang, Y. et al. Precise mode control of laser-written waveguides for broadband, low-dispersion 3D integrated optics. Light Sci. Appl. 13, 130 (2024).

Xu, X. et al. Femtosecond laser writing of lithium niobate ferroelectric nanodomains. Nature 609, 496–501 (2022).

Ródenas, A. et al. Three-dimensional femtosecond laser nanolithography of crystals. Nat. Photonics 13, 105–109 (2019).

Wei, D. et al. Experimental demonstration of a three-dimensional lithium niobate nonlinear photonic crystal. Nat. Photonics 12, 596–600 (2018).

Chen, D. et al. 3D Laser Writing of Low-Loss Cross-Section-Variable Type-I Optical Waveguide Passive/Active Integrated Devices in Single Crystals. Adv. Mater. 36, 2404493 (2024).

Asgari Sabet, R., Ishraq, A., Saltik, A., Butun, M. & Tokel, O. Laser nanofabrication inside silicon with spatial beam modulation and anisotropic seeding. Nat. Commun. 15, 5786 (2024).

Day, A. M., Dietz, J. R., Sutula, M., Yeh, M. & Hu, E. L. Laser writing of spin defects in nanophotonic cavities. Nat. Mater. 22, 696–702 (2023).

Tokel, O. et al. In-chip microstructures and photonic devices fabricated by nonlinear laser lithography deep inside silicon. Nat. Photonics 11, 639–645 (2017).

Liu, S.-F. et al. 3D nanoprinting of semiconductor quantum dots by photoexcitation-induced chemical bonding. Science 377, 1112–1116 (2022).

Li, F. et al. 3D printing of inorganic nanomaterials by photochemically bonding colloidal nanocrystals. Science 381, 1468–1474 (2023).

Ni, J. et al. Unidirectional unpolarized luminescence emission via vortex excitation. Nat. Photonics 17, 601–606 (2023).

Bhuyan, M. K. et al. Ultrafast laser nanostructuring in bulk silica, a “slow” microexplosion. Optica 4, 951–958 (2017).

Mahmoud Aghdami, K., Rahnama, A., Ertorer, E. & Herman, P. R. Laser nano-filament explosion for enabling open-grating sensing in optical fibre. Nat. Commun. 12, 6344 (2021).

Vailionis, A. et al. Evidence of superdense aluminium synthesized by ultrafast microexplosion. Nat. Commun. 2, 445 (2011).

Juodkazis, S. et al. Laser-induced microexplosion confined in the bulk of a sapphire crystal: evidence of multimegabar pressures. Phys. Rev. Lett. 96, 166101 (2006).

Rapp, L. et al. High aspect ratio micro-explosions in the bulk of sapphire generated by femtosecond Bessel beams. Sci. Rep. 6, 34286 (2016).

Lu, Y. et al. Nanochannels with a 18-nm feature size and ultrahigh aspect ratio on silica through surface assisting material ejection. Adv. Photon. Nexus 1, 026004 (2022).

Zhang, G. et al. Ultrashort Bessel beam photoinscription of Bragg grating waveguides and their application as temperature sensors. Photon. Res. 7, 806–814 (2019).

Velpula, P. K. et al. Spatio-temporal dynamics in nondiffractive Bessel ultrafast laser nanoscale volume structuring. Laser Photon. Rev. 10, 230–244 (2016).

Bellouard, Y. et al. Stress-state manipulation in fused silica via femtosecond laser irradiation. Optica 3, 1285 (2016).

Götte, N. et al. Temporal Airy pulses for controlled high aspect ratio nanomachining of dielectrics. Optica 3, 389–395 (2016).

Lavin-Varela, S. et al. Formation of nanochannels in sapphire with ultrashort Bessel pulses. Opt. Express 30, 6016–6036 (2022).

del Hoyo, J., Meyer, R., Furfaro, L. & Courvoisier, F. Nanoscale confinement of energy deposition in glass by double ultrafast Bessel pulses. Nanophotonics 10, 1089–1097 (2020).

Wang, Z. et al. High-throughput microchannel fabrication in fused silica by temporally shaped femtosecond laser Bessel-beam-assisted chemical etching. Opt. Lett. 43, 98–101 (2018).

Liu, H., Lin, W. & Hong, M. Hybrid laser precision engineering of transparent hard materials: challenges, solutions and applications. Light Sci. Appl. 10, 162 (2021).

Salter, P. S. & Booth, M. J. Adaptive optics in laser processing. Light Sci. Appl. 8, 110 (2019).

Yan, T. & Ji, L. Ultrafast laser filamentation in transparent solids. Ultrafast Sci. 3, 0023 (2023).

Li, Z., Allegre, O. & Li, L. Realising high aspect ratio 10 nm feature size in laser materials processing in air at 800 nm wavelength in the far-field by creating a high purity longitudinal light field at focus. Light Sci. Appl. 11, 339 (2022).

Juodkazis, S. et al. Control over the crystalline state of sapphire. Adv. Mater. 18, 1361–1364 (2006).

Paz-Buclatin, F. et al. Circularly symmetric nanopores in 3D femtosecond laser nanolithography with burst control and the role of energy dose. Nanophotonics 12, 1511–1525 (2023).

Joglekar, A. P., Liu, H. -h, Meyhofer, E., Mourou, G. & Hunt, A. J. Optics at critical intensity: applications to nanomorphing. PNAS 101, 5856–5861 (2004).

Wang, X. J., Fang, H. H., Li, Z. Z., Wang, D. & Sun, H. B. Laser manufacturing of spatial resolution approaching quantum limit. Light Sci. Appl. 13, 6 (2024).

Zhang, G. et al. Thermal and mechanical limitations to processing resolution in volume non-diffractive ultrafast laser structuring. Appl. Surf. Sci. 570, 151170 (2021).

Stoian, R. & Bonse, J. Ultrafast Laser Nanostructuring: The Pursuit of Extreme Scales. Vol. 239 (Springer Nature, 2023).

Lei, Y. et al. High speed ultrafast laser anisotropic nanostructuring by energy deposition control via near-field enhancement. Optica 8, 1365–1371 (2021).

Li, Z. Z. et al. O-FIB: far-field-induced near-field breakdown for direct nanowriting in an atmospheric environment. Light Sci. Appl. 9, 41 (2020).

Stuart, B. C., Feit, M. D., Rubenchik, A. M., Shore, B. W. & Perry, M. D. Laser-induced damage in dielectrics with nanosecond to subpicosecond pulses. Phys. Rev. Lett. 74, 2248–2251 (1995).

Sundaram, S. K. & Mazur, E. Inducing and probing non-thermal transitions in semiconductors using femtosecond laser pulses. Nat. Mater. 1, 217–224 (2002).

Gattass, R. R. & Eric, M. Femtosecond laser micromachining in transparent materials. Nat. Photonics 2, 219–225 (2008).

Choudhury, D. et al. Three-dimensional microstructuring of yttrium aluminum garnet crystals for laser active optofluidic applications. Appl. Phys. Lett. 103, 041101 (2013).

Okhrimchuk, A. G. et al. Phase transformation under direct laser writing in a YAG single crystal. Opt. Mater. Express 7, 3408–3421 (2017).

Lipateva, T. O. et al. Direct laser writing in YAG single crystal: Evolution from amorphization to nanograting formation and phase transformation. J. Alloy. Compd. 942, 169081 (2023).

Basterfield, J. The chemical polishing of yttrium iron garnet. J. Phys. D. 2, 1159–1161 (1969).

Mazilu, M., Juodkazis, S., Ebisui, T., Matsuo, S. & Misawa, H. Structural characterization of shock-affected sapphire. Appl. Phys. A 86, 197–200 (2007).

Katagiri, K. et al. Transonic dislocation propagation in diamond. Science 382, 69–72 (2023).

Xie, J., Yan, J., Zhu, D. & He, G. Atomic-level insight into the formation of subsurface dislocation layer and its effect on mechanical properties during ultrafast laser micro/nano fabrication. Adv. Funct. Mater. 32, 2108802 (2022).

Fedotov, S. S., Butvina, L. N. & Okhrimchuk, A. G. Plastic deformation as nature of femtosecond laser writing in YAG crystal. Sci. Rep. 10, 19385 (2020).

Huang, L. et al. Sub-wavelength patterned pulse laser lithography for efficient fabrication of large-area metasurfaces. Nat. Commun. 13, 5823 (2022).

Li, J. et al. Nanoscale multi-beam lithography of photonic crystals with ultrafast laser. Light Sci. Appl. 12, 164 (2023).

Jin, Z. et al. Phyllotaxis-inspired nanosieves with multiplexed orbital angular momentum. eLight 1, 5 (2021).

Chi, J. et al. All-printed point-of-care immunosensing biochip for one drop blood diagnostics. Lab Chip 22, 3008–3014 (2022).

Chen, Y. et al. Observation of intrinsic chiral bound states in the continuum. Nature 613, 474–478 (2023).

Zhang, X., Liu, Y., Han, J., Kivshar, Y. & Song, Q. Chiral emission from resonant metasurfaces. Science 377, 1215–1218 (2022).

Shi, T. et al. Planar chiral metasurfaces with maximal and tunable chiroptical response driven by bound states in the continuum. Nat. Commun. 13, 4111 (2022).

Zheng, Z. et al. Digital photoprogramming of liquid-crystal superstructures featuring intrinsic chiral photoswitches. Nat. Photonics 16, 226–234 (2022).

Guo, Q. et al. Ultrathin quantum light source with van der Waals NbOCl2 crystal. Nature 613, 53–59 (2023).

Bai, H. et al. Stretchable distributed fiber-optic sensors. Science 370, 848–852 (2020).

Sugioka, K. & Cheng, Y. Ultrafast lasers—reliable tools for advanced materials processing. Light Sci. Appl. 3, e149–e149 (2014).

Dieny, B. et al. Opportunities and challenges for spintronics in the microelectronics industry. Nat. Electron. 3, 446–459 (2020).

Schindelin, J. et al. Fiji: an open-source platform for biological-image analysis. Nat. Methods 9, 676–682 (2012).

Germans, F. H. Automatic computation of the standard deviation. Nature 163, 25–26 (1949).

Cherniukh, I. et al. Perovskite-type superlattices from lead halide perovskite nanocubes. Nature 593, 535–542 (2021).

Nagaoka, Y. et al. Superstructures generated from truncated tetrahedral quantum dots. Nature 561, 378–382 (2018).

Zhao, L. D. et al. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 508, 373–377 (2014).

Ardaneh, K. et al. A new route to high energy density inside the bulk of transparent materials. Phys. Plasma Phys. https://doi.org/10.48550/arXiv.2109.00803 (2021).

Liu, X., Clady, R., Grojo, D., Utéza, O. & Sanner, N. Engraving depth-controlled nanohole arrays on fused silica by direct short-pulse laser ablation. Adv. Mater. Interfaces 10, 2202189 (2023).

Rahnama, A., Mahlooji, H., Djogo, G., Azhari, F. & Herman, P. R. Filament-arrayed Bragg gratings for azimuthally resolved displacement sensing in single-mode fibers. Opt. Express 30, 4189–4201 (2022).

Rahnama, A., Dadalyan, T., Mahmoud Aghdami, K., Galstian, T. & Herman, P. R. In-fiber switchable polarization filter based on liquid crystal filled hollow-filament Bragg gratings. Adv. Opt. Mater. 9, 2100054 (2021).

Liu, X. et al. Truncated Gaussian-Bessel beams for short-pulse processing of small-aspect-ratio micro-channels in dielectrics. Opt. Express 27, 6996–7008 (2019).

Chen, T. et al. Reconstructing of embedded high-aspect-ratio nano-voids generated by ultrafast laser Bessel beams. Micromachines 11, 671 (2020).

Somayaji, M. et al. Multiscale electronic and thermomechanical dynamics in ultrafast nanoscale laser structuring of bulk fused silica. Sci. Rep. 10, 15152 (2020).

Bhuyan, M. K., Velpula, P. K., Somayaji, M., Colombier, J.-P. & Stoian, R. 3D Nano-fabrication using controlled Bessel-glass interaction in ultra-fast modes. J. Laser Micro Nanoeng. 12, 274–280 (2017).

Bhuyan, M. K. et al. Single-shot high aspect ratio bulk nanostructuring of fused silica using chirp-controlled ultrafast laser Bessel beams. Appl. Phys. Lett. 104, 021107 (2014).

Bhuyan, M. K. et al. High aspect ratio nanochannel machining using single shot femtosecond Bessel beams. Appl. Phys. Lett. 97, 081102 (2010).

Meyer, R. et al. Single-shot ultrafast laser processing of high-aspect-ratio nanochannels using elliptical Bessel beams. Opt. Lett. 42, 4307–4310 (2017).

Acknowledgements

We thank Y. Dai and H. Shi (Shanghai University), T. Mu (Zhejiang Lab), and Y. Xiao, X. Chen and X. Miao (Westlake University) for performing measurements of retardance, FIB milling, micro transmission spectra, and high-resolution micro-XRD, respectively. We are also grateful to X. Zheng and D. Qi of the Analysis Center for Agriculture, Life and Environment Sciences of Zhejiang University for their technical assistance with SEM. This work was financially supported by the National Natural Science Foundation of China [grant Nos. 52432001 (J.Q.), 62475244 (Z.C.), 62105297 (Z.C.), 62375246 (Z.M.), and 12404367 (L.Z.)], Zhejiang Provincial Natural Science Foundation [grant Nos. LZ23F050002 (Z.C.), and LQ22F050022 (L.Z.), Yunnan Provincial Xingdian Talent Support Program—Young Talent Project (Z.C.), and Open Fund of the State Key Laboratory of Luminescent Materials and Devices of South China University of Technology (Z.C.).

Author information

Authors and Affiliations

Contributions

Z.C. and L.Z. conceived the idea. J.Q. organized, coordinated, and supervised the project. Z.C. performed the main experiments and collected the data. Y.F. conducted the fabrication of holey nanostructured nanophotonic devices. Z.C. and H.J. completed the experiments of a specific immunoassay. Z.W. and C.Z. performed the measurements of spherical aberration-corrected STEM. H.H. conducted the characterization of chiral nanophotonics. L.Z., H.H., X.S., and Y.W. performed the theoretical simulations and calculations. Z.C., L.Z., and J.Q. interpreted the results and proposed the mechanism. Z.C. wrote the manuscript. Z.M., J.Z., X.L., B.X., G.D., G.B., C.Q., J.Q., and J.Q. discussed and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chen, Z., Zhong, L., Sun, X. et al. 25 nm-Feature, 104-aspect-ratio, 10 mm2-area single-pulsed laser nanolithography. Nat Commun 16, 7434 (2025). https://doi.org/10.1038/s41467-025-62426-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-62426-1