Abstract

Environmental concerns over heavy metals in spent lithium-ion batteries (LIBs), coupled with the growing scarcity of metal resources, have heightened the need for efficient and cost-effective recycling of metals from spent cathodes. In this study, we propose a laser-induced high-temperature thermal shock strategy that rapidly separates cathode materials from Al foil in just seconds. The instantaneous thermal shock facilitates the reduction of refractory metal oxides and the decomposition of impurity layer, while simultaneously increasing the specific surface area and generating oxygen vacancies. This significantly enhances both the thermodynamics and kinetics of the subsequent leaching process. Leaching tests with 0.1 M HCl show that the efficiencies for Co, Ni, and Mn increase by 147.5%, 125.6%, and 140.0%, respectively, compared to untreated materials. Over 97% of the metals are recovered even using 0.5 M HCl. Here, we propose a laser strategy that is more economically viable and significantly reduces the environmental impact.

Similar content being viewed by others

Introduction

Lithium-ion batteries (LIBs) are widely recognized as a leading technology in electrochemical energy storage and are extensively used in consumer electronics and electric vehicles (EVs)1,2,3,4. Global demand for LIBs is projected to exceed hundreds of gigawatt-hours annually in the next 5 years, with the global EVs stock expected to reach 240 million by 20305,6. As the commercial use of LIBs scales, the number of spent batteries is also expected to rise significantly7,8,9. By 2030, it is estimated that 314 GWh of LIBs will be retired from service10. If not properly managed, these spent batteries pose substantial environmental risks, as they can release harmful organic compounds and heavy metals11,12,13,14. On the other hand, spent LIBs have been described as an “urban mine” because they contain valuable strategic metals in their cathode materials15,16. Consequently, recycling these metal resources is crucial for both sustainable resource management and environmental protection.

Pyrometallurgy and hydrometallurgy are the two primary methods currently employed to recycle spent LIBs17,18,19,20,21. While both have been developed for industrial-scale operations, each technique has notable drawbacks. Pyrometallurgy requires high-temperature processes to melt and calcine spent cathode materials, leading to high energy consumption and releasing toxic gases such as HF, SO2, and H2S22,23. Hydrometallurgy, on the other hand, involves using large quantities of strong acids/alkalis, reducing agents or organic liquid, which results in substantial wastewater pollution24,25,26,27,28. Overall, both metallurgical processes are energy-intensive, environmentally damaging, and time-consuming. Therefore, there is a pressing need to develop a more efficient, environmentally friendly, and faster method for extracting metals from spent cathode materials.

High voltage pulse technology29 has been developed for liquid crystal displays recycling, which improved metal leaching efficiency and was five times less environmentally burdensome than conventional grinding. Notably, recently, advanced pulsed DC flash Joule heating technology has also been explored as a promising method for efficiently recycling spent LIBs. For instance, Zhu et al.30 employed Joule heating in a graphite boat to directly heat spent cathode materials, reaching ~2200 °C within ~20 s. This process enabled the selective leaching of lithium (Li) with water (>90% efficiency) and nickel (Ni), cobalt (Co), and manganese (Mn) with 0.5 M sulfuric acid (>98% efficiency). Chen et al.31 utilized flash Joule heating to regenerate the spent graphite anode and recover the valuable metals. Subsequently, they32 utilized this technique to recover spent cathode materials. The flash Joule heating technique achieved temperatures exceeding 2100 K in seconds, which significantly improves metal leaching kinetics and metal recycling efficiency (≈98% with 1 M hydrochloric acid). However, Joule heating technologies are still limited by their intermittent operation, small-scale processing capacity, and complex pretreatment steps to separate cathode materials from aluminum (Al) foil. Consequently, developing a continuous, cost-effective method for the practical recycling of spent LIBs remains a significant challenge.

In this work, we introduce a laser-induced high-temperature thermal shock strategy for recycling spent LIBs. Unlike traditional methods, this approach directly irradiates the spent LIB cathode sheets with a laser, causing the rapid separation of active materials from the Al foil in just seconds, eliminating the need for pretreatment. The laser’s thermal effect disrupts the stable octahedral structure of the cathode materials, converting high-valence metals into more easily leachable low-valence states. This not only enhances the thermodynamics of metal leaching but also removes impurities and increases the specific surface area of the materials, thereby improving leaching kinetics. The laser-induced rapid heating and cooling also create oxygen vacancies, facilitating enhanced adsorption and charge transfer with hydrochloric acid (HCl) molecules during leaching. With just 0.1 M HCl, the leaching efficiencies for Co, Ni, and Mn increased by 147.5%, 125.6%, and 140.0%, respectively, compared to untreated samples. At 0.5 M HCl, metal leaching efficiency exceeded 97%. Furthermore, by integrating the laser process with a conveyor system, continuous recycling of spent cathode materials can be easily achieved. This laser-based recycling strategy enhances leaching efficiency and reduces energy consumption and greenhouse gas (GHG) emissions. Thus, it offers significant financial and environmental benefits, presenting a promising alternative to conventional recycling methods.

Results

Limitations of metal extraction from spent cathodes

This study comprehensively analyzes the total quantification of battery metals present in spent nickel–cobalt–manganese ternary cathodes (S-NCM) utilizing aqua regia. The findings indicate significant concentrations of strategic metals, with measured concentrations as follows: Li at 49 g kg−1, Ni at 80 g kg−1, Co at 48 g kg−1, and Mn at 312 g kg−1. These metals constitute 48.9% of the total mass of S-NCM, as detailed in Fig. 1a and Supplementary Table 1. When S-NCM is subjected to leaching using a 0.1 M HCl solution, Li exhibits a leaching efficiency of 81%. In contrast, the leaching efficiencies for the other transition metals are notably lower, with Mn, Ni, and Co demonstrating efficiencies of 35%, 43%, and 40%, respectively, as depicted in Fig. 1b.

a Mass content of Li, Mn, Ni, and Co in S-NCM. b Leaching efficiency of Li, Mn, Ni, and Co from S-NCM using 0.1 M HCl. The error bars in (a, b) reflect the standard deviations from three individual experiments. c Gibbs free energy changes for different valence metal oxides and metal monomers in dilute HCl. Horizontal coordinates represent the metal valence states. d–f XPS spectra of Ni 2p, Co 2p, and Mn 2p in S-NCM. g TEM image of S-NCM. h SEM image of S-NCM. i C 1 s XPS spectrum of S-NCM.

The limited leaching efficiency of metals in S-NCM can be attributed to constrained thermodynamic conditions and slow leaching kinetics. Thermodynamic calculations concerning Gibbs free energy changes for various valence states of metal oxides and monomers in low-concentration hydrochloric acid, as demonstrated in Fig. 1c and Supplementary Table 2, indicate that metals in lower valence states exhibit greater solubility in low-concentration hydrochloric acid compared to those in higher valence states. This observation suggests that high valence states impede efficient leaching due to their less thermodynamically favorable dissolution. Furthermore, X-ray photoelectron spectroscopy (XPS) analysis corroborates the presence of high valence states for Ni, Co, Mn, and Li in S-NCM, revealing valences of +2, +3, +4/+3, and +1, respectively (Fig. 1d–f and Supplementary Fig. 1). The elevated valence states of these metals complicate the leaching process, thereby posing significant challenges for efficient metal extraction.

An impurity layer consisting of conductive agents, binders, and a compact solid electrolyte interphase (SEI) layer has been observed on the surface of S-NCM, which inhibits efficient metal leaching. Characterization via transmission electron microscopy (TEM) reveals a dense amorphous coating layer that corresponds to the compact SEI layer (Fig. 1g). Scanning electron microscopy (SEM) and TEM analyses indicate that the surface of the spherical S-NCM particles exhibits flocculent structures, confirming the presence of binders and conductive agents (Fig. 1h and Supplementary Fig. 2). Elemental analysis, in conjunction with Raman spectroscopy and XPS data, identifies the elements C, O, and F, thereby elucidating the composition of the impurity layer (Fig. 1i, Supplementary Fig. 3, and Supplementary Fig. 4). This impurity layer serves as a barrier that limits the interaction between S-NCM and the leaching solution, ultimately reducing the rate of the solid-liquid reaction and leading to diminished leaching kinetics.

Laser strategy improves metal leaching efficiency

We propose an instantaneous and controlled laser strategy for rapidly recycling spent cathodes to address the thermodynamic and kinetic challenges associated with the acid-leaching process and enhance metal recycling efficiency. This method allows for the recovery of materials from spent LIBs within seconds, negating the need for additional reducing agents. In this process, spent cathode sheets are securely affixed to a glass plate and receive thermal energy directly through laser irradiation (Fig. 2a). By manipulating the laser power and sweep speed via computer controls, we can accurately regulate the temperature and duration of irradiation.

a Schematic illustration of laser irradiation. XRD patterns of spent cathode materials under b different laser sweep speeds (0, 5, 10, 15, 20, 30%) at 35% laser power and under c different laser power (0, 20, 30, 35, 45, 55%) at 10% laser sweep speed. The boxes in (b, c) represent the diffraction peaks of S-NCM, while the shaded areas represent the diffraction peaks of MnO/NiO/CoO. Samples irradiated with a laser power of 35% at different sweep speeds are labeled V-x, while samples irradiated with a sweep speed of 10% at different laser powers are labeled L-x. d HR-TEM image of L-45. e SAED pattern of L-45. f FTIR and g Raman spectra of S-NCM, L-20, L-35, and L-45.

This laser technique facilitates the swift recycling of S-NCM materials, requiring just 2.7 h of irradiation under 45% laser power (27 W) and a sweep speed of 10% (125 mm s−1) across a 60 cm × 10 cm area. During laser irradiation, the active cathode materials detach from the Al foil, thus enabling the direct recycling of these materials without necessitating further pretreatment steps. When the sweep speed is maintained at 10% (125 mm s−1), the treated materials at laser power levels of 20% (12 W), 35% (21 W), and 45% (27 W) are designated as L-20, L-35, and L-45, respectively. However, employing lower sweep speeds (V-5) or significantly higher laser powers (L-55) may lead to excessive radiation temperatures, which impede the effective separation of active materials from the Al foil (Supplementary Fig. 5). Furthermore, since Al does not absorb the CO2 laser, the collected active materials exhibit minimal Al contamination, quantified at 0.08% for L-35 and 0.24% for L-45.

The effects of laser sweep speed and power on S-NCM were initially investigated, as illustrated in Fig. 2b, c. X-ray diffraction (XRD) analysis indicated significant phase transitions in the laser-treated samples; however, the diffraction peak corresponding to S-NCM remained detectable when the scanning speed was faster or the power was lower, as shown by the dotted enclosed line in Figs. 2b, c. Upon increasing the laser power to 35%, while maintaining the same scanning speed (designated as L-35), the diffraction peaks of S-NCM entirely vanished, leading to the formation of NiO, CoO, and MnO phases, as shown in Fig. 2c. A further increase in laser power to 45% did not result in any additional modifications to the XRD pattern. High-resolution transmission electron microscopy (HR-TEM) images provided further insight into the phase transitions caused by laser treatment. In the S-NCM sample, the observed lattice spacing of 0.20 nm aligns with the (104) plane of NCM, as depicted in Supplementary Fig. 6a. In contrast, the materials labeled L-35 and L-45 exhibited a lattice spacing of 0.24 nm, which corresponds to the (111) plane of MnO, NiO, and CoO, as shown in Fig. 2d and Supplementary Fig. 6b. Energy dispersive spectroscopy (EDS) elemental mapping revealed that elemental O is uniformly dispersed with Ni, Co, and Mn in the L-45 sample, as illustrated in Supplementary Fig. 7. Furthermore, the selected area electron diffraction (SAED) patterns attributed to MnO, NiO, and CoO demonstrated clear phase changes following laser treatment, as presented in Fig. 2e.

Fourier transform infrared spectroscopy (FTIR) analysis reveals distinct absorption peaks at 523 cm−1 and 618 cm−1 in the S-NCM sample, which are attributed to O-M-O bending vibrations and asymmetric stretching within the MnO6 octahedral groups33. The absence of the peak at 618 cm−1 in the L-20, L-35, and L-45 samples indicates a disruption in the M-O octahedral structure, thereby confirming significant structural modifications resulting from laser treatment (Fig. 2f). The prominent Raman peak at 625 cm−1 corresponds to the M-O stretching vibration in the MnO6 groups of the S-NCM sample, which is characteristic of the layered oxide structure (Fig. 2g)34. In the L-20 sample, a notable redshift of this peak is observed, attributed to the introduction of oxygen vacancies induced by laser-induced thermal shock34,35. As the laser power increases, the Raman spectra for the L-35 and L-45 samples exhibit vibrational signatures of Ni-O and Mn-O, indicating structural transformations within the material36,37,38.

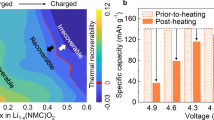

Following laser activation, the phase structure and surface impurities of S-NCM undergoes considerable damage, thereby enhancing the extraction of metals, as illustrated in Fig. 3a. The leaching efficiency of metals derived from laser-treated samples is assessed and compared to that of untreated S-NCM. For the sample L-35, over 99% of Li is successfully leached, even when utilizing a low concentration of HCl at 0.1 M. This represents a 22.2% improvement in leaching efficiency relative to S-NCM under identical conditions, as shown in Fig. 3c. The advantages of laser treatment are particularly notable for transition metals, with leaching efficiencies of 99% for Co, 85% for Ni, and 74% for Mn, reflecting increases of 147.5%, 97.7%, and 111.4% respectively, in comparison to S-NCM (Fig. 3c). As laser power escalates from 35% to 45%, the leaching efficiency of the metals continues to rise, despite no observable alterations in the physical phase. The leaching efficiencies for Co, Ni, and Mn reach 99%, 97%, and 84%, respectively, indicating increases of 147.5%, 125.6%, and 140.0% in relation to S-NCM (Fig. 3c). When the acid concentration is increased from 0.1 M to 0.5 M, 91% and 97% of the metals can be leached from samples L-35 and L-45, respectively (Fig. 3d). The leaching efficiencies for L-45 are 99%, 99%, 99%, and 90% for Li, Co, Ni, and Mn, respectively, which are also superior to those of L-35 under the same phase conditions (99%, 99%, 87%, and 79%, respectively) (Fig. 3d). A comparison of the metal leaching efficiencies derived from the laser strategy with previously reported methods is presented in Fig. 3b and Supplementary Table 3. This highlights the effectiveness of the laser high-temperature thermal shock strategy in enhancing metal leaching, thereby facilitating efficient extraction, even with low concentrations of HCl.

a Schematic illustration of the improvement of metal leaching efficiency by laser treatment. b Comparison of metal leaching efficiency in spent cathode materials with different leaching reagents. The (+) represents the addition of a reducing agent during the leaching process. The (−) represents no pre-treatment on the spent cathode materials. The bracketed references refer to the Supplementary References. Detailed parameters are shown in Supplementary Table 3. c Leaching efficiency of Li, Co, Ni, and Mn in S-NCM, L-35, and L-45 using 0.1 M HCl. d Leaching efficiency of Li, Co, Ni, and Mn in L-35 and L-45 using 0.5 M HCl. The error bars in (c, d) reflect the standard deviations from three individual experiments. e XPS spectra of Mn 2p, Co 2p, and Ni 2p in S-NCM, L-20, L-35, and L-45. f SEM image and g TEM image of L-45. h Nitrogen adsorption and desorption curves at standard temperature and pressure (STP) report S-NCM, L-20, L-35, and L-45 surface areas.

The enhancement in metal leaching efficiency can be ascribed to advancements in thermodynamics and kinetics. XPS results indicate changes in the valence states of transition metals, as depicted in Fig. 3e and Supplementary Fig. 8. The XPS Co 2p spectra demonstrate that the valence state of Co transitions from +3 to +2 in the samples subjected to laser treatment. Similarly, the valence state of Mn decreases from +4/+3 to +2. Notably, the concentrations of Co2+ and Mn2+ increase with elevated laser power. Li is released from the layered structure as the oxygen framework becomes compromised, leading to lithium carbonate (Li2CO3) formation during the laser treatment process (Fig. 2e and Supplementary Fig. 9).

Laser treatment has proven effective in eliminating the impurity layer from the surface of S-NCM, as evidenced by various characterization techniques. SEM imaging reveals that the laser treatment disaggregates the spherical particles of S-NCM into smaller, more dispersed forms and removes the flocculent aggregates that were previously observed on the surface (Fig. 3f and Supplementary Fig. 10). TEM images further validate the removal of the outer impurity layer from the particles as a result of laser irradiation (Fig. 3g and Supplementary Fig. 11). This conclusion is corroborated by XPS analysis of the O 1 s and C 1 s regions, as well as the full spectrum. The lack of peaks corresponding to C-F and C-O bonds, which are indicative of the impurity layer, in the laser-treated samples suggests that the laser treatment effectively eliminates surface contaminants (Fig. 4b, Supplementary Fig. 12, and Supplementary Fig. 13). Furthermore, Raman spectroscopy evidence indicates the absence of carbon peaks associated with the impurity layer in the treated S-NCM samples (L-20, L-35, and L-45), thereby confirming the successful removal of impurities (Fig. 2g). This removal enhances the purity of the recycled material, which in turn improves leaching kinetics by decreasing the diffusion barrier between the S-NCM and the leaching solution.

a EPR spectra, and b O 1 s XPS spectra of S-NCM, L-20, L-35, and L-45. c Mn K-edge X-ray absorption near-edge spectroscopy and the magnified Mn foil, MnO, Mn2O3, and L-45 region. Inset is the enlarged view of the boxed region, with the left-to-right arrow representing an increase in oxidation state of Mn. d EXAFS spectra, e EXAFS fitting curves in R-space, and f WT plots of L-45. g The Bader charge distribution of Mn in MnO and MnOv. Mn6, Mn11, Mn13, Mn14 and Mn15 are coordinated to vacant oxygen, while the other manganese atoms are not coordinated to vacant oxygen. h The differential charge density of MnO and MnOv, in which red and blue areas represent charge loss and charge accumulation, respectively. i The PDOS of O and H after adsorption in MnO and MnOv. The boxed areas represent the overlap of peaks.

Moreover, the laser treatment significantly increases the surface area of the spent cathode materials, a crucial factor for enhancing the efficiency of metal leaching. The specific surface area of sample L-20 increases from 3.38 m2 g−1 to 4.43 m2 g−1. As laser power is elevated, the specific surface areas of samples L-35 and L-45 further improve, reaching 5.17 m2 g−1 and 5.34 m2 g−1, respectively (Fig. 3h). Additionally, the analysis of pore size distribution indicates a rise in the number of nanopores following laser treatment, while the mean diameter of nanopores decreased from 7.4 nm to 4.9 nm due to the disaggregation of the secondary spherical particles of S-NCM into smaller and more dispersed individual particles as a result of the laser treatment (Supplementary Fig. 14). This enhancement in specific surface area and nanopore density fosters greater interaction between the spent cathode materials and the leaching solution, thereby facilitating increased exposure of the material for metal extraction. The improved contact with the leaching solution accelerates the dissolution of metals and optimizes overall leaching kinetics, resulting in higher metal recycling rates.

Subsequent investigations indicated that the laser’s instantaneous heating and cooling characteristics can disrupt the thermodynamically stable orientation of metal oxides, resulting in the formation of numerous oxygen vacancies. The electron paramagnetic resonance (EPR) spectra reveal a symmetric signal centered at g = 2.003, which indicates trapped electrons arising from these oxygen vacancies (Fig. 4a)39. This signal becomes more pronounced with increasing laser power, suggesting that elevated power levels generate a greater quantity of oxygen vacancies. Furthermore, XPS provides substantiation of the laser-induced activation of lattice oxygen. The XPS spectra for O 1 s (Fig. 4b) in untreated and laser-treated materials identify three primary chemical environments: lattice oxygen, vacant oxygen, and C = O from impurities40,41,42. An increase in laser power correlates with a rise in the content of vacant oxygen, while the content of lattice oxygen diminishes, implying that the thermal shock induced by the laser effectively releases lattice oxygen.

X-ray absorption spectroscopy (XAS), which includes both X-ray absorption near-edge structure (XANES) and extended X-ray absorption fine structure (EXAFS), was conducted to understand the local structure of the metals and their average electronic states in the bulk phase of L-4543. XANES is typically used to determine the oxidation states of elements in compounds. The analysis indicates that the near-edge position of L-45 closely aligns with that of the MnO reference, shifting towards lower energy, which signifies that the valence state of manganese is lower than +2 (Fig. 4c). EXAFS elucidates the coordination environment of the element. The intensities of the peaks depend on the coordination number and the Debye–Waller factor (σ2, which indicates the mean square disorder in the path lengths and structural disorder), while the positions of the peaks depend on the actual radius of the scattering shells around the atoms44. Compared to MnO, the significantly weakened peak intensity and shifted peak position of the L-45 material indicate a marked increase in structural disorder and a notable change in bond length after laser treatment (Fig. 4d). These structural changes are associated with the introduction of oxygen vacancies due to the laser treatment45. The introduction of oxygen vacancies is further corroborated by the decrease in the coordination number (CN) of Mn-O in L-45 (3) compared to MnO (6) (Fig. 4e, Supplementary Fig. 15, and Supplementary Table 4). In the wavelet transforms (WT) plots, a weakened signal of Mn-O in L-45 is observed, attributable to the lower CN46 (Fig. 4f and Supplementary Fig. 16).

Introducing oxygen vacancies modifies the electronic structure and surface characteristics, thereby enhancing the efficiency of metal-leaching processes. Density Functional Theory (DFT) calculations indicate that the presence of oxygen vacancies induces structural instability, as evidenced in Supplementary Fig. 17. This instability manifests itself through increased Mn-O bond lengths, which signify a reduction in bond strength (Supplementary Fig. 18). Furthermore, density of states (DOS) analysis demonstrates a notable decrease in the interaction between Mn d orbitals and O p orbitals following the introduction of oxygen vacancies (Supplementary Fig. 19). This reduction points to a diminished covalent interaction between Mn and O, a critical factor for effective leaching. Additionally, Bader charge analysis offers further elucidation, revealing that the charge of manganese atoms coordinated to vacant oxygen sites increases with the introduction of these vacancies, indicating a decrease in their valence states (Fig. 4g). Notably, even manganese that is not directly coordinated to the vacant oxygen sites exhibits an increase in Bader charges, further signifying a widespread reduction in valence states across the material. This phenomenon, in turn, enhances leaching thermodynamics.

To better understand how oxygen vacancies positively impact metal leaching efficiency, we examined the adsorption behavior of HCl molecules on both manganese oxide (MnO) and manganese oxide with vacancies (MnOv) systems. The introduction of oxygen vacancies results in an increase in the bond length of H-Cl from 2.05 Å to 2.72 Å (Supplementary Fig. 20). Concurrently, the adsorption energy demonstrates a significant increase from 1.075 eV to 2.084 eV (Fig. 4h). Further analysis utilizing differential charge density maps elucidates the influence of oxygen vacancies on charge transfer dynamics (Fig. 4h). In the scenario of MnO, there is limited charge interaction between the HCl molecules and MnO. However, introducing oxygen vacancies facilitates the redistribution of electrons, transferring 1.32 electrons from MnOv to HCl, which contributes to forming a charge accumulation region. This phenomenon enhances the dissolution of MnOv. The total density of states (TDOS) analysis indicates that the area near the Fermi level is predominantly influenced by the O and Mn orbitals (Supplementary Fig. 21). Following the introduction of oxygen vacancies, the coupling between the Mn d orbitals and the O p orbitals is substantially weakened (Supplementary Fig. 22). Moreover, several prominent new peaks corresponding to H s orbitals emerge, overlapping with the O p orbitals, suggesting the formation of strong covalent bonds (Fig. 4i). This observation further substantiates that oxygen vacancies augment the adsorption capacity of HCl.

The adaptability of the laser strategy is demonstrated here using spent LiFePO4. A similar reduction in valence and removal of the impurity layer is observed for LiFePO4 (Supplementary Figs. 23, 24), leading to significant improvements in leaching efficiencies. The leaching efficiency of Li and Fe in S-LFP was 42% and 99%, respectively, when utilizing a low concentration of HCl at 0.5 M, while the leaching efficiency of Li and Fe in Laser-LFP reached 95% and 99%, respectively (Supplementary Fig. 25).

The gaseous products observed during the laser activation process were collected using vacuum gas bags. These products were detected by gas chromatography-mass spectrometry (GC-MS), as shown in Supplementary Fig. 26 and Supplementary Table 5. The detected gaseous products included simple oxides such as carbon monoxide and carbon dioxide, oxygenated organics, hydrocarbons, fluorine-containing compounds (including 2-Butanone, 1,1,1-trifluoro- and n-Pentyl methylphosphonofluoridate), and silicon-containing compounds derived from the instrument’s internal background component. However, no HF was detected among the gaseous products. For treatment of the gaseous products, activated carbon can adsorb volatile organic compounds, specialized fluoride adsorbents combined with alkaline washing can treat fluorine-containing compounds, and condensation can recover high-boiling-point compounds, thus achieving the safe treatment of gases.

In addition, we conducted a comparison of the productivity of the laser strategy with other established methods for recycling LIBs, specifically industrial pyrometallurgy, hydrometallurgy, and laboratory-level flash Joule heating technology, as detailed in Supplementary Table 14. It is noteworthy that, due to the constraints of laboratory equipment, the production capacity of the laser strategy during the laboratory research phase is significantly lower than that of industrial pyrometallurgy and hydrometallurgy. Furthermore, the flash Joule heating strategy, recognized as an innovative recycling technology for spent LIBs, has demonstrated a marked increase in production capacity in laboratory settings through the implementation of a continuous system31,32,47. Consequently, the integration of the laser strategy with a continuous system has the potential to substantially enhance its production capacity. For the mass production of laser strategy, we proposed a continuous operation design combining the laser process and the conveyor belt (Supplementary Fig. 27). Spent cathode sheets are transported via the conveyor belt and continuously pass through the laser irradiation area. After laser irradiation, the cathode active materials are automatically separated from the Al foil. At the end of the conveyor belt, an adjustable scraper is equipped to collect the active materials and the Al foil, respectively. This design, in combination with industrially available continuous operation processes, offers great potential for laser strategy to recycle spent LIBs.

Economic and environmental assessment of laser strategy

Figure 5a summarizes technologies employed for recycling spent batteries, explicitly focusing on pyrometallurgical (Pyro), hydrometallurgical (Hydro), and laser strategy techniques. An in-depth environmental and economic assessment of these technologies has been conducted to ascertain the viability of implementing a laser-induced high-temperature thermal shock strategy for recycling spent LIBs. Conventional pyrometallurgical and hydrometallurgical approaches are characterized by their significant energy requirements and environmental pollution. These methods necessitate high-temperature smelting and aggressive acid or alkali leaching processes, which result in substantial energy consumption, prolonged processing durations, and noteworthy ecological challenges. In contrast, the laser-induced high-temperature thermal shock method presents a more efficient alternative. This technique simplifies operational procedures, effectively reducing the complexity and time required for the recycling process. Laser treatment facilitates the direct separation of spent cathode materials from the Al foil collector, eliminating the need for additional crushing and separation steps. This innovative strategy optimizes the recycling process and minimizes environmental impact, aligning with sustainability objectives in waste management and resource recovery.

a Schematic of Pyro, Hydro, and laser strategies for recycling spent LIBs. b The cost, c revenue, d profit, e energy use, f water consumption, and g GHG emissions of recycling 1 kg spent LIBs feedstock by pyro, hydro, and laser strategies. Specific data are shown in Supplementary Table 6–13. h Comprehensive comparison of the three battery recycling technologies.

The EverBatt model developed by Argonne National Laboratory is utilized for conducting life cycle assessment (LCA) and techno-economic analysis (TEA) of various recycling processes, including Pyro (Supplementary Fig. 28), Hydro (Supplementary Fig. 29), and laser strategies (Supplementary Fig. 30 and Supplementary Table 6). The data for pyrometallurgy and hydrometallurgy calculations was obtained from the EverBatt 2023 model48. The cost of equipment was considered in the economic and environmental analysis, and pricing information for laser equipment from several companies was collected to estimate the average price of the laser equipment at $23.4 (Supplementary Table 7). Material cost is a critical component in the cost analysis (Fig. 5b and Supplementary Table 8). The Hydro process incurs substantial costs of 3.99 $ per kg of feedstock, primarily due to the significant quantity of strong acids required to dissolve the battery components. Conversely, the laser strategy effectively converts high-valent metals in spent cathodes to low-valent states, facilitating a leaching process that does not necessitate strong acids or reducing agents. This approach results in a considerably lower total cost of merely 1.33$ per kg of feedstock. Furthermore, the revenue generated from the laser strategy is notably higher, reaching 5.45 $ per kg of feedstock, attributable to enhanced metal recovery efficiency (Fig. 5c, Supplementary Table 9, and Supplementary Table 10). Consequently, the laser technology achieves an impressive profit margin of 4.13$ per kg of feedstock, which is 4 times greater than that of Hydro (1.02$ per kg of feedstock) and 45 times greater than that of Pyro (0.09$ per kg of feedstock) (Fig. 5d).

In addition, the evaluation of recycling technologies necessitates consideration of environmental impact. The Pyro process, characterized by high-temperature smelting, and the Hydro process, which employs strong acids and alkalis, exhibit energy consumption rates of 40.91 MJ per kg of feedstock and 133.24 MJ per kg of feedstock, respectively (Fig. 5e and Supplementary Table 11). In stark contrast, the laser strategy demonstrates a significantly lower energy consumption of only 37.12 MJ per kg of feedstock and reduced water usage of 3.4 gallons per kg of feedstock (Fig. 5e, f and Supplementary Tables 11, 12). GHG emissions generated by the laser strategy are markedly reduced, mainly due to the elimination of high-temperature smelting and lower material consumption (Fig. 5g and Supplementary Table 13). Figure 5h presents a spider chart that illustrates the superiority of the laser strategy across various metrics, encompassing economic efficiency, minimal energy requirements, and reduced GHG emissions. Overall, the laser strategy exhibits significant financial and environmental advantages, establishing it as a highly effective and sustainable method for recycling spent LIBs.

Discussion

This study presents a recycling method for spent LIB cathodes using laser-induced high-temperature thermal shock. Directly irradiating cathode sheets, the active materials are rapidly separated from the Al foil in seconds, eliminating the need for pretreatment. The laser treatment disrupts the stable structure of the cathode materials, facilitating the reduction of high-valence metals and enhancing the thermodynamics of metal leaching. Additionally, the laser process increases the specific surface area of the materials, removes impurities, and accelerates leaching kinetics. Introducing oxygen vacancies further improves adsorption and charge transfer with HCl, resulting in a metal leaching efficiency of over 97% with 0.5 M HCl. Even at a lower concentration of 0.1 M HCl, Co, Ni, and Mn leaching efficiencies show notable improvements. This laser-based approach enhances leaching efficiency and reduces energy consumption and GHG emissions, offering significant economic benefits with a profit of $4.13 per kg of feedstock.

Methods

Chemicals and reagents

The spent battery company supplied the cathode sheets used in the experiment. First, the spent batteries were discharged by immersing them in a 1 M NaCl solution for 48 h. Then, after the batteries had been fully discharged, the spent cathode sheets were collected from the spent batteries by manual disassembly. The spent nickel–cobalt–manganese ternary cathodes are Li0.89Mn0.72Ni0.17Co0.11O2, with detailed metal element contents shown in Supplementary Table 1. Aqua regia was prepared by mixing nitric acid (HNO3, AR, Sinopharm Chemical Reagent Co.) and hydrochloric acid (HCl, AR, Sinopharm Chemical Reagent Co.) in a volume ratio of 1:3. To prepare 0.1 M and 0.5 M HCl, 0.83 mL and 4.15 mL of HCl were each dissolved in 100 mL of deionized water, respectively.

Laser-induced thermal reduction of S-NCM

A CO2 laser (Universal Laser, USA) was used to reduce S-NCM. The power and sweep speed of the laser were adjustable within the ranges of 0–60 W and 0–1250 mm s−1, respectively. These parameters and the laser-scanned area were carefully controlled through computer programming to ensure precision in the processing area and heating temperature. The S-NCM sheet was securely fixed onto a glass plate and subjected to laser scanning in an air atmosphere during the process. Various combinations of laser powers (20%, 30%, 35%, 45%, 55%) and sweep speeds (5%, 10%, 15%, 20%, 30%) were used. After the laser treatment, the active materials spontaneously detached from the Al foil. Following this, the spent cathode sheet containing a small amount of active materials is immersed in deionized water for 2 h, after which its surface is gently scraped to further obtain the cleaner Al foil.

Metal leaching

The samples’ metal content (Li, Mn, Ni, Co) was determined through a leaching process followed by atomic absorption spectroscopy (AAS) analysis. Aqua regia was employed as the leaching solution for total battery metal quantification. The leaching was conducted at 80 °C for 2 h with a solid-liquid ratio of 2 g L−1. After leaching, the solution was filtered using an MCE membrane (0.45 µm) and diluted to a final volume v1. The metal content in the diluted solution (c1) was then measured via AAS. For HCl leaching experiments, the samples were treated with different concentrations of HCl (0.1 M, 0.5 M) under identical leaching conditions. Afterward, the leachate was filtered, diluted to a volume v2, and analyzed for its metal content (c2) using AAS. The metal leaching efficiency of the samples was calculated using the following equation:

The enhancement in metal leaching efficiency of laser-treated samples compared to untreated ones under identical leaching conditions is calculated using the following equation:

Structural characterization

The samples’ Li, Ni, Co, and Mn contents were analyzed using atomic absorption spectroscopy (AAS, Contr AA700). The samples’ valence states and elemental compositions were characterized by XPS (Thermo ESCALAB 250XI), employing monochromatic Al Kα radiation. Data were analyzed using Thermo Scientific Avantage Data System software, where a smart background was applied before peak deconvolution and integration. The binding energies were calibrated using the C 1 s peak at 284.8 eV. The crystal structures and phases of the samples were identified through XRD (X’Pert PRO MPD) using Cu Kα radiation (λ = 1.5406 Å) over a 2θ range of 5–75°. Sample morphology and structure were examined using an SEM (Regulus 8100) equipped with energy-dispersive X-ray spectroscopy (EDS) and an HR-TEM (Talos F200X). Oxygen vacancies were detected using EPR (Bruker A300), while Raman spectra were obtained with a Renishaw RM2000, using a 532 nm excitation wavelength. Functional groups within the samples were identified using FTIR (Bruker VERTEX 70). The specific surface area and pore structure were measured using the Brunauer-Emmett-Teller (BET) method (Ipore 400). X-ray absorption spectroscopy (XAS) at the Mn K-edge was conducted with Si (111) crystal monochromators at beamline BL14W1 of the Shanghai Synchrotron Radiation Facility (SSRF) (Shanghai, China). The spectra were processed and analyzed using the software codes Athena and Artemis. The k2-weighted EXAFS spectra were obtained by subtracting the pre-edge and post-edge background from the overall absorption and then normalized with respect to the edge-jump step in first derivative line. Subsequently, the χ(k) data of the Mn K-edge were Fourier transformed to R space using hanning windows (dk = 1 Å−1) to separate EXAFS conditions from different coordination shells. For WT analysis, the χ(k) exported from Athena was imported into the Hama Fortran code. The parameters were listed as follow: R range is 0–6 Å, k range is 0–12 Å−1, k weight = 2, and Morlet function with κ = 5, σ = 2 was used as the mother wavelet to provide the overall distribution. The gaseous products during the laser activation process were detected by gas chromatography-mass spectrometry (Agilent 8890-5977B) equipped with an Agilent HP-5MS column (30 m × 250 μm × 0.25 μm) and using He carrier gas for headspace sampling.

Theoretical calculations

The DFT calculations presented in this work were conducted using the Vienna Ab initio Simulation Package (VASP) with projector augmented-wave (PAW) potentials. The exchange-correlation energy was treated using the generalized gradient approximation (GGA) with the Perdew-Burke-Ernzerhof (PBE) functional. To account for the on-site Coulomb repulsion effect in the Mn 3 d orbital, the DFT + U method was employed, with U-J values set to 3.90 eV for Mn49,50. All calculations were performed with spin polarization. The plane wave basis cutoff energy was set to 500 eV, and the self-consistent field convergence criterion was established at 10−5 eV. Atomic positions were optimized until the forces on all atoms were reduced to less than 0.02 eV/Å. Geometry optimization included Brillouin zone integrations using a Gamma-centered 3 × 3 × 2 k-point mesh. Structures with oxygen vacancies were modeled by removing one oxygen atom from the standard MnO structure. These modified structures were labeled MnO and MnOv, representing the original MnO and the oxygen vacancy structures, respectively (Supplementary Fig. 17). The adsorption energy (Ea) was calculated using Ea = EHCl+sub − EHCl − Esub, where EHCl+sub, EHCl, and Esub denote the energies of the adsorption system, isolated HCl, and the substrate, respectively.

Data availability

All the data generated in this study are provided in this paper and its Supplementary Materials. Cartesian coordinates of all the optimized structures are provided in Supplementary Data 1. Source data are provided with this paper.

References

Harper, G. et al. Recycling lithium-ion batteries from electric vehicles. Nature 575, 75–86 (2019).

Ma, J. et al. Subtractive transformation of cathode materials in spent Li-ion batteries to a low-cobalt 5 V-class cathode material. Nat. Commun. 15, 1046 (2024).

Lou, X. et al. Grave-to-cradle photothermal upcycling of waste polyesters over spent LiCoO2. Nat. Commun. 15, 2730 (2024).

Li, H. et al. A contact-electro-catalytic cathode recycling method for spent lithium-ion batteries. Nat. Energy 8, 1137–1144 (2023).

Cao, N. et al. Efficient reduction of spent cathode materials via in-situ thermal reduction by defect-rich petroleum coke. Sep. Purif. Technol. 334, 126029 (2024).

Yin, Y.-C. et al. Rapid, direct regeneration of spent LiCoO2 cathodes for Li-ion batteries. ACS Energy Lett. 8, 3005–3012 (2023).

Lv, X. W. et al. Selective recycling of spent lithium-ion batteries enables toward aqueous Zn-ion batteries cathode. Adv. Energy Mater. 14, 2402560 (2024).

Jia, X. et al. Coupling ferricyanide/ferrocyanide redox mediated recycling spent LiFePO4 with hydrogen production. Angew. Chem. Int. Ed. 63, e202318248 (2024).

Yang, T. et al. Sustainable regeneration of spent cathodes for lithium-ion and post-lithium-ion batteries. Nat. Sustain. 7, 776–785 (2024).

Yu, W. et al. Comprehensive recycling of lithium-ion batteries: fundamentals, pretreatment, and perspectives. Energy Storage Mater. 54, 172–220 (2023).

Su, Y. et al. High performance, pH-resistant membranes for efficient lithium recovery from spent batteries. Nat. Commun. 15, 10295 (2024).

Cao, L. et al. Tailoring nanoscale primary silicon in laser powder bed fusion for high-performance lithium-ion battery anodes. J. Mater. Sci. Technol. 211, 278–287 (2025).

Wang, Z. et al. A low-temperature solid-to-solid reaction for lithium-ion battery recycling and the utilization of defect-enriched Co3O4 from spent LiCoO2 batteries for efficient oxygen evolution reaction. Appl. Catal. B Environ. Energy 349, 123873 (2024).

Cao, N. et al. An innovative approach to recover anode from spent lithium-ion battery. J. Power Sources 483, 229163 (2021).

Wu, X. et al. Toward circular energy: exploring direct regeneration for lithium-ion battery sustainability. Adv. Mater. 36, 2403818 (2024).

Zhou, J. et al. Solvothermal strategy for direct regeneration of high-performance cathode materials from spent lithium-ion battery. Nano Energy 120, 109145 (2024).

Chen, Z. et al. Reaction-passivation mechanism driven materials separation for recycling of spent lithium-ion batteries. Nat. Commun. 14, 4648 (2023).

Ogihara, N. et al. Direct capacity regeneration for spent Li-ion batteries. Joule 8, 1364–1379 (2024).

Wang, J. et al. Sustainable upcycling of spent LiCoO2 to an ultra-stable battery cathode at high voltage. Nat. Sustain. 6, 797–805 (2023).

Fujita, T. et al. Reduction, reuse and recycle of spent Li-ion batteries for automobiles: a review. Int. J. Miner. Metall. Mater. 28, 179–192 (2021).

Chen, H. et al. Leaching of cathode materials from spent lithium-ion batteries by using a mixture of ascorbic acid and HNO3. Hydrometallurgy 205, 105746 (2021).

Ko, S. et al. Thermodynamically controlled chemical regeneration of spent battery cathodes using recyclable electron donors under ambient conditions. Energy Environ. Sci. 17, 4064–4077 (2024).

Zhou, F. et al. Recovery of valuable metals from spent lithium-ion batteries through biomass pyrolysis gas-induced reduction. J. Hazard. Mater. 459, 132150 (2023).

Lyu, Y. et al. Selective extraction of critical metals from spent Li-ion battery cathode: cation-anion coordination and anti-solvent crystallization. Adv. Mater. 36, 2312551 (2024).

Zhou, M. et al. The fischer-lactonization-driven mechanism for ultra-efficient recycling of spent lithium-ion batteries. Angew. Chem. Int. Ed. 64, e202414484 (2025).

Tan, J. et al. Achieving high solid–liquid ratio through competitive coordination towards efficient recovery of metals from spent batteries. Angew. Chem. Int. Ed. 64, e202422313 (2025).

Liu, T. et al. Short-time and high-performance recovery of critical metal elements from spent ternary lithium-ion batteries by selective synergic coordination effect. Adv. Funct. Mater. 35, 2417883 (2025).

Wang, J. et al. Green recycling of spent Li-ion battery cathodes via deep-eutectic solvents. Energy Environ. Sci. 17, 867–884 (2024).

Dodbiba, G. et al. Leaching of indium from obsolete liquid crystal displays: comparing grinding with electrical disintegration in context of LCA. Waste Manag. 32, 1937–1944 (2012).

Zhu, X.-H. et al. Recycling valuable metals from spent lithium-ion batteries using carbothermal shock method. Angew. Chem. Int. Ed. 62, e202300074 (2023).

Chen, W. et al. Flash recycling of graphite anodes. Adv. Mater. 35, 2207303 (2023).

Chen, W. et al. Battery metal recycling by flash Joule heating. Sci. Adv. 9, eadh5131 (2023).

Zhou, H. et al. Regeneration of LiNi0.5Co0.2Mn0.3O2 cathode material from spent lithium-ion batteries. Electrochim. Acta 291, 142–150 (2018).

Xiong, T. et al. Defect engineering of oxygen-deficient manganese oxide to achieve high-performing aqueous zinc ion battery. Adv. Energy Mater. 9, 1803815 (2019).

Wan, Y. et al. Laser thermal shock enabling ultrafast spin regulation of MnO2 for robust pseudocapacitive energy storage. Adv. Funct. Mater. 34, 2311157 (2024).

Marchesini, S. et al. Surface analysis of pristine and cycled NMC/graphite lithium-ion battery electrodes: addressing the measurement challenges. ACS Appl. Mater. Interfaces 14, 52779–52793 (2022).

Li, J. et al. Insight into the redox reaction heterogeneity within secondary particles of nickel-rich layered cathode materials. ACS Appl. Mater. Interfaces 13, 27074–27084 (2021).

Li, J. et al. In-situ probing the near-surface structural thermal stability of high-nickel layered cathode materials. Energy Storage Mater. 46, 90–99 (2022).

Peng, Z. et al. Sodium-intercalated manganese oxides for achieving ultra-stable and fast charge storage kinetics in wide-voltage aqueous supercapacitors. Adv. Funct. Mater. 32, 2206539 (2022).

Ye, J.-J. et al. Manipulating oxygen vacancies to spur ion kinetics in V2O5 structures for superior aqueous zinc-ion batteries. Adv. Funct. Mater. 33, 2305659 (2023).

Sayahpour, B. et al. Revisiting discharge mechanism of CFx as a high energy density cathode material for lithium primary battery. Adv. Energy Mater. 12, 2103196 (2021).

Jiang, Y. et al. Mechanochemistry-induced recycling of spent lithium-ion batteries for synergistic treatment of mixed cathode powders. Green. Chem. 24, 5987–5997 (2022).

Roy, A. et al. Synergistic catalytic sites in high-entropy metal hydroxide organic framework for oxygen evolution reaction. Adv. Mater. 36, 2408114 (2024).

Zhan, C. et al. Mn(II) deposition on anodes and its effects on capacity fade in spinel lithium manganate–carbon systems. Nat. Commun. 4, 2437 (2013).

Csernica, P. M. et al. Persistent and partially mobile oxygen vacancies in Li-rich layered oxides. Nat. Energy 6, 642–652 (2021).

Yuan, C. et al. Unveiling the bifunctional modulation evoked by bromine doping of CoP towards efficient hydrolytic hydrogen generation. Appl. Catal. B Environ. 343, 123562 (2024).

Deng, B. et al. Flash Joule heating for synthesis, upcycling and remediation. Nat. Rev. Clean. Technol. 1, 32–54 (2025).

Dai, Q. et al. EverBatt: a closed-loop battery recycling cost and environmental impacts model. www.anl.gov/amd/everbatt (2019).

Yang, H. et al. Simultaneously dual modification of Ni-rich layered oxide cathode for high-energy lithium-ion batteries. Adv. Funct. Mater. 29, 1808825 (2019).

Qu, X. et al. An integrated surface coating strategy to enhance the electrochemical performance of nickel-rich layered cathodes. Nano Energy 91, 106665 (2022).

Acknowledgements

This work is supported by the National Natural Science Foundation of China (No. 22138013, M.W. and 22378426, X.G.) and the Taishan Scholar Project (No. ts201712020, M.W.).

Author information

Authors and Affiliations

Contributions

N.C., X.G., and M.W. designed this project. N.C. and Y.Z. conducted the experiments, performed the DFT calculations, and analyzed the data with assistance from X.G. and M.W. X.G. and M.W. supervised the research and revised the manuscript. All authors discussed and contributed to the results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Bing Deng, Toyohisa Fujita, and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Cao, N., Zhang, Y., Gu, X. et al. Efficient recycling of spent Li-ion battery cathodes by laser-induced high-temperature thermal shock. Nat Commun 16, 7169 (2025). https://doi.org/10.1038/s41467-025-62434-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-62434-1