Abstract

Despite enormous efforts, copper corrosion remains a key inducement causing huge economic losses in electrical, construction, and military industries, and deteriorates the performance of semiconductor devices. Here we show that a set of ligands functionalized with both catechol and aromatic amine groups achieves environmentally-adaptive copper passivation and fully preserves the intrinsic electrical and thermal conductivities of copper and its alloys. The oxidation of ligands in corrosive environments causes the structure-adaptation of the passivation layer, further enhancing the corrosion resistance to harsh environments including alkali and salt solutions, thermal treatment, and UV-light- and oxygen-enriched conditions. Simply adsorbing these ligands on the surface of copper, brass, copper powder, copper-based flexible printed circuits, and copper inks for flexible electronics results in strong liquid and air anticorrosion performances. Our copper passivation technique only requires a room temperature soaking procedure, providing a high industrialization possibility for copper protection, particularly in semiconductor electronics and flexible electronics.

Similar content being viewed by others

Introduction

Copper is one of the most important materials for modern industry and electronic information technology because of its cost-effectiveness (compared to noble metals), easy processibility, mechanical robustness, and high electrical and thermal conductivities1,2,3. However, the durability and environmental adaptability of copper are severely constrained by its ready oxidation nature, which not only causes huge economic losses but also limits its application in high-tech fields4,5. Particularly in semiconductor electronics, the oxidation of copper dramatically deteriorates the electrical and thermal conductivities, thus causing device malfunction or even serious accidents6. Moreover, toward the flexible (or even stretchable) electronics, although copper-based conductive inks and pastes have a cost advantage, they exhibit no competitiveness compared to the ones enabled by silver or liquid metals because of the stability issues7,8. The past few decades have witnessed advancements in copper anticorrosion9,10. However, simultaneously passivating the surface of copper and ensuring its intrinsic physical properties remains a daunting challenge6.

Classical copper anticorrosion strategies include coating11, molecular inhibition12,13, and molecular passivation14,15. The coating strategy usually requires constructing a thick protective layer to resist environmental corrosion, sacrificing the inherent electrical and thermal conductivities of copper16. The molecular inhibition strategy achieves a protective effect on copper by dissolving inhibitors in corrosive mediums, which is generally adopted in industrial copper anticorrosion17. In comparison, the molecular passivation strategy directly attaches anticorrosion molecules on the copper surface, exhibiting enhanced environmental adaptability and reduced impact on the intrinsic physical properties of copper15. Therefore, molecular passivation has been considered to be the most promising copper anti-oxidation strategy in semiconductor electronics and flexible electronics8. However, the industry application of molecular passivation technique remains challenging, not only due to the limited anti-oxidation capability, but also the complicated passivation procedures such as hydrothermal treatment15, chemical grafting18, and electrodeposition14. The development of facile, robust, durable, and highly adaptable copper anti-oxidation strategies is of great significance for the high-density integration semiconductor industry, flexible electronics, and optoelectronics.

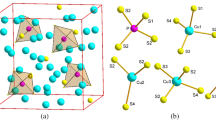

In this work, we develop a ligand oxidation structure-adaptive (LOSA) method to achieve self-strengthening, long-term, and non-destructive copper anticorrosion. LOSA-treated copper and its alloys show unexpectedly high anti-oxidation capability in both liquid and air environments, while fully exhibiting their intrinsic electrical and thermal conductivities. Unlike the reported molecular passivation mechanisms including inert molecular layer formation14, ligand-copper complexing19, and crystallographic reconstruction15, our LOSA method adopts a structure-adaptive mechanism, thus exhibiting self-reinforceable copper protection in more corrosive media. A key principle for the LOSA method relates to designing a set of molecules comprising both catechol and aromatic amine groups. Due to the high binding affinity of catechol groups (or its oxidized form: quinones) towards copper, copper ions, and copper oxides20,21,22, these ligands can be attached to the surface of copper and its alloys through a facile soaking procedure, which facilitates industrial application. The as-formed nanolayer undergoes structure-adaptivity in oxidative media due to the further ligand oxidation (Fig. 1a). Catechol groups change into quinones, which show specifically enhanced binding affinity to copper species and facilitate the formation of coordinatively crosslinked networks, while triphenylamine groups transform into radical cations which can form intermolecular cation-π interactions with the quinone rings23,24. Through this structure-adaptive behavior, a compact and highly-stable nanolayer can be formed on the surface of copper and its alloys. Our LOSA method is highly effective in passivating copper, brass, and copper powder. For example, in alkaline solutions (0.1 M NaOH), LOSA-treated copper can easily withstand 30 days while retaining high electrical (5.46 × 107 S m−1) and thermal conductivities (332.17 W m−1K−1 at 100 °C) approximating to its intrinsic values. With the self-reinforceable copper protection capability, pre-oxidation of LOSA-passivated copper in alkaline solutions shows dramatically increased anti-oxidation in NaCl solutions and air at elevated temperatures (up to 130 °C). Our LOSA method can directly protect copper-based flexible printed circuits (FPC) and copper inks, providing an industrializable technique for copper anti-oxidation in semiconductor electronics and flexible electronics.

Results and Discussions

Anti-oxidation performances of the LOSA method

The exploration of our LOSA method starts with a three-armed catechol- and triphenylamine-bearing molecule named TAC (Fig. 1b, Supplementary Fig. 38 and Supplementary Note 7). Simply immersing cleaned bare copper foils (thickness: about 50 μm) in a methanol solution of TAC (0.1 mM) for 12 h affords passivated samples. This sample was denoted as Cu-TAC0.1–12, in which “0.1” represents the TAC concentration and “12” represents the soaking duration. Digital, optical microscopy, and scanning electron microscopy (SEM) images show that the attachment of TAC molecules has no observable microstructure and metallic luster impacts on the copper surface (Fig. 2a and Supplementary Fig. 1a). Raman spectra verify this result (Fig. 2e and Supplementary Fig. 1c), as Cu-TAC0.1–12 displays no evident Raman signals at a wavenumber range of 200–1000 cm−1, which is consistent with pristine copper. The X-ray diffraction (XRD) pattern of Cu-TAC0.1–12 shows diffractive peaks at 2θ = 43.30, 50.43, and 74.13°, respectively, corresponding to the crystal planes of (111), (200), and (220) of copper, which agree well with those of pristine copper in both peak position and intensity (Supplementary Figs. 1d and 2a). We used the focused ion beam (FIB) milling technique to prepare samples for high-resolution transmission electron microscopy (HR-TEM) observation. A thin amorphous layer (thickness: 6.9 ± 0.2 nm) appears on the surface of Cu-TAC0.1–12 (Fig. 2i). High-angle annular dark field scanning transmission electron microscopy (HAADF-STEM) image and energy-dispersive X-ray spectroscopy (EDX) mappings (Supplementary Fig. 2b) suggest that this nanolayer is rich in carbon, nitrogen, and oxygen elements, providing the indication that this amorphous layer is derived from TAC. No heterogeneous crystal structure was generated between the copper crystal phase and the amorphous layer, as indicated by the HR-TEM image and the electron diffraction pattern (Fig. 2j). This result, combined with the XRD pattern, further verifies that TAC has a negligible impact on the crystal structure of copper. We adopted EDX spectrum and element contents (Supplementary Fig. 2c) to estimate the ligand density of the passivation nanolayer. The analysis reveals that the ligand density of Cu-TAC0.1–12 is approximately 4.5 molecules/nm2, which is slightly larger than the theoretical calculation result of 2.8 molecules/nm2 (Detailed experimental analysis and theoretical calculation are described in the section of Methods.).

Digital, optical microscopy, and SEM images of Cu-TAC0.1–12 a before and after exposure to 0.1 M NaOH for b 1, c 7, and d 30 days. e Raman spectrum evolution of Cu-TAC0.1–12 when treating with 0.1 M NaOH. f Electrical and g Thermal conductivities of Cu-TAC0.1–12 before and after exposure to 0.1 M NaOH. h Electrical conductivity evolution of brass-TAC0.1–24 during 0.1 M NaOH treatment. The error bars in f, g and h reflect the standard deviations from three individual experiments. Cross-sectional HR-TEM images of Cu-TAC0.1–12 (i, j) before and (k, l) after 1 day of 0.1 M NaOH treatment, inserts are the electron diffraction patterns.

In 0.1 M NaOH at room temperature, unprotected copper rapidly loses its metallic luster within 8 h (Supplementary Fig. 1b). Raman spectra and XRD patterns (Supplementary Fig. 1c, d) reveal that CuO, Cu(OH)2, and Cu2O species are formed, which is typical for the corrosion of copper in alkaline environments25. The surface of corroded copper exhibits numerous short-range ordered lattice structures of copper oxide (Supplementary Fig. 1e–h)3,26. Under the same corrosive conditions, Cu-TAC0.1–12 maintains metallic luster even after 30 days, while optical microscopy and SEM images demonstrate that Cu-TAC0.1–12 undergoes no obvious microstructure evolution (Fig. 2b–d). Raman spectra and XRD patterns display no signals of copper oxides (Fig. 2e, Supplementary Fig. 2a, and Supplementary Note 1). HR-TEM images and EDX mappings (Fig. 2k, l, and Supplementary Fig. 2d) reveal that the amorphous layer on the surface of Cu-TAC0.1–12 shows no morphology change after corrosion, and its thickness is 5.7 ± 0.1 nm. No change in lattice and electron diffraction of copper can be observed, featuring the high protective effect of the amorphous layer. Note that bare copper has an electrical conductivity of 5.72 × 107 S m−1, this value was dramatically reduced to 0.03 S m−1 after 8 h of corrosion (Supplementary Fig. 1i). By contrary, Cu-TAC0.1–12 delivers electrical conductivities of 5.75 × 107, 5.68 × 107, and 5.46 × 107 S m−1, respectively, after 1, 7, and 30 days of corrosion, respectively (Fig. 2f), almost equal to that of bare copper. At temperatures ranging from 25 to 100 °C, pure copper after 8 h of corrosion shows 69.03–69.91% reductions in thermal conductivity compared to pristine copper (Supplementary Fig. 1j). In comparison, Cu-TAC0.1–12 after 30 days of corrosion exhibits thermal conductivity of 332.17 W m−1K−1 at 100 °C, close to the values of pristine Cu-TAC0.1–12 and copper (Fig. 2g). These results suggest that Cu-TAC0.1–12 has a high anti-oxidation capability in corrosive liquid while maintaining the high electrical and thermal conductivity of copper.

To evaluate the bonding strength of TAC toward copper, we performed tape test experiments and tracked the surface micromorphology and anti-corrosion property evolutions of Cu-TAC0.1–12. Optical and SEM images (Supplementary Fig. 3a–g) illustrate that 10 cycles of the tape attachment/detachment have no observable effect on the microstructure of the TAC nanolayer. XRD patterns show that after 10 cycles of tape test, Cu-TAC0.1–12 can withstand the corrosion of 0.1 M NaOH for 30 days at room temperature. These results feature the high bonding strength and adhesion stability of the TAC nanolayer on the surface of copper. Our copper passivation method is even adaptable to slightly oxidized uncleaned copper. For example, we soaked an uncleaned copper foil in a methanol solution of TAC (0.1 mM) for 12 h and fabricated Cuuncleaned-TAC0.1–12, which shows almost the same Raman spectrum with that of Cu-TAC0.1–12. This means that TAC can also be attached to the surface of uncleaned copper. Probably, the high coordinative capability of TAC can consume Cu+ and Cu2+ derived from the oxidized species. Raman spectra, XRD spectra, optical images, and SEM images indicate that Cuuncleaned-TAC0.1–12 can withstand the corrosion of 0.1 M NaOH at room temperature for at least 30 days (Supplementary Fig. 4).

The TAC nanolayer has a relatively low resistance to an oxidizing acidic media. For example, Cu-TAC0.1–12 can only persist in an aqueous solution of H2O2 (10 wt%) for 3 days without evident surface oxidation and loss of the TAC nanolayer (Supplementary Fig. 5a–c). In this corrosive condition, increasing the treating duration to 7 days results in an obvious oxidation of copper and a destruction of the TAC nanolayer (Supplementary Fig. 5d–h). Probably, the protonation of triphenylamine groups and the cleavage of imine groups cause the desorption and degradation of the TAC nanolayer under an oxidizing acidic condition. The TAC nanolayer is not sensitive to neutral oxidative conditions, as 1 day of treatment in ozone-enriched water results in no observable composition and surface structure evolutions (Supplementary Fig. 5i).

Taking brass (H65) as an example, we demonstrate that TAC can also passivate copper alloys. Bare brass was evidently corroded within 3 h in 0.1 M NaOH at room temperature, as indicated by the optical microscopy and SEM images, Raman spectra, and XRD patterns (Supplementary Fig. 6 and Supplementary Note 2). No obvious micro- and macro-structure change was observed on the surface of TAC-modified brass (denoted as brass-TAC0.1–24) before and after 1–30 days of corrosion in the same corrosive conditions (Supplementary Fig. 7a–d). Moreover, characteristic peaks of copper oxides were not detected in the Raman spectra and XRD patterns of 0.1 M NaOH-treated brass-TAC0.1–24 samples (Supplementary Fig. 7e, f). Note that brass corroded for 12 h only has an electrical conductivity of 0.05 S m−1 (original value: 1.49 × 107 S m−1), brass-TAC0.1–24 corroded for 1, 7, and 30 days shows electrical conductivities of 8.91 × 106, 8.63 × 106, and 8.44 × 106 S m−1, respectively (Fig. 2h).

Formation mechanism of the passivation nanolayer

Then we are interested in clarifying the underlying mechanism for the high-efficiency protective effect of TAC to copper and its alloys. Therefore, we adopted a series of control molecules (Supplementary Fig. 8a) to modify copper, which contains one or two aforementioned functional groups. All these modified copper samples were evidently corroded after soaking in 0.1 M NaOH for 3 h at room temperature, as indicated by the SEM images (Supplementary Fig. 8). These results reveal that a synergistic effect may exist in between catechol and triphenylamine groups, thus resulting in prominent anticorrosion capability towards copper.

To gain insights into the synergy between catechol and triphenylamine groups in TAC, spectroscopy analyses including Fourier transform infrared spectroscopy (FTIR), Raman, and X-ray photoelectron spectroscopy (XPS) were conducted. The FTIR spectra of TAC and Cu-TAC0.1–12 before and after corrosion in 0.1 M NaOH are displayed in Fig. 3a and Supplementary Fig. 9a. For TAC, peaks at 3400, 1445, and 1316 cm−1 correspond to the stretching vibration (νO-H), deformation vibration (δO-H), and in-plane vibration (βO-H) of the phenolic hydroxyl group, respectively. The C-H out-of-plane binding vibration (γC-H) from 1,4-disubstituted benzene rings of the triphenylamine group appears at 821 cm−1, 27,28. For Cu-TAC0.1–12, absorption peaks of the catechol group (δO-H and βO-H) and o-quinone (the stretching vibration of C = O group νC=O: 1644 cm−1) co-exist, while the νO-H band almost completely disappears. The γC-H peak shifts to 825 cm−1 due to the oxidation of the triphenylamine group. For Cu-TAC0.1–12 exposed to 0.1 M NaOH for 24 h, peaks of δO-H and βO-H are significantly weakened. Additionally, the γC-H peak shifts to a higher wavenumber (829 cm−1). These results imply that both catechol and triphenylamine groups of TAC can be partially oxidized on the surface of copper. Under an alkaline condition, these two groups are almost completely oxidized.

a FTIR, b Raman, and c variable-temperature Raman spectra of Cu-TAC0.1–12. d UV/vis spectra of the reaction mixture of TPA + Cu2+, Catechol + Cu2+, and TPA + Catechol + Cu2+ in CH3CN. e O 1 s and f N 1 s XPS spectra of TAC, and Cu-TAC0.1–12 before and after soaking in 0.1 M NaOH for 24 h. g Cu 2p3/2 XPS fine spectra, a board satellite peak is caused by Cu2+; h Auger Cu LMM spectra of bare copper and Cu-TAC0.1–12 before and after corrosion in 0.1 M NaOH for 24 h. i Tafel plots of bare Cu and Cu-TAC0.1–12 in 0.1 M NaOH.

The results from Raman spectra (Fig. 3b) verify this oxidation phenomenon. Under the excitation wavelength of 532 nm, the peaks at 1139 and 1442 cm−1 in the Raman spectrum of Cu-TAC0.1–12 are attributed to ring vibration signals of o-quinone coordinatively attached on the Cu surface29,30. Simultaneously, the C-N stretching vibration signal of triphenylamine radical cations (C-N+) appears at 1398 cm−1, 31. When increasing the Raman excitation wavelength to 785 nm, more detailed information for the o-quinone-copper coordination can be detected at 504, 528, and 631 cm−1, 32,33. After the alkaline treatment of Cu-TAC0.1–12, the ring vibration signals of o-quinone coordinated with Cu shift towards lower wavenumbers (1134 and 1439 cm−1)34. Additionally, the peak of triphenylamine radical cations shifts to 1392 cm−1, and exhibits significantly increased intensity. Probably, the cation-π interaction between radical cations and o-quinone rings leads to a shift of these signals toward lower wavenumbers. Variable-temperature Raman spectroscopy characterization also indicates the presence of cation-π interactions in the passivation nanolayer. As displayed in Fig. 3c, a broad peak located at a wavenumber range of 1579–1604 cm−1 is assigned to the C-C stretching of the benzene ring of triphenylamine35. This peak moves to low wavenumbers with the temperature increasing from 20 °C to 80 °C. This is a typical phenomenon for the reduced cation-π interactions due to the improved molecular thermal motion36. The Raman shoulder peaks at wavenumbers ranging from 1350 to 1365 cm−1 can be assigned to the vibration of o-quinone at a coordinative state37. The weakened intensity of these signals during temperature rising provides a piece of evidence for the coordination interactions between copper species (Cu0, Cu+, and Cu2+) and TAC, because the Raman signal of copper-ligand coordination is highly sensitive to temperature38.

In addition, we conducted a control experiment by directly reacting triphenylamine and catechol with Cu2+. This streamlined reaction system helps to understand the oxidation of triphenylamine and catechol groups by Cu2+ ions, as well as the interaction between triphenylamine radical cations and o-quinone groups. The UV/vis spectrum evolution of this reaction system was recorded. Note that catechol in acetonitrile (CH3CN) shows a dominant absorption at 275 nm, the Fenton reaction between catechol and Cu2+ affords o-quinone, resulting in a maximum absorption at 310 nm39 (Supplementary Fig. 9b). Cu2+ can oxidize triphenylamine groups into radical cations, which are highly unstable in CH3CN, resulting in a minor shoulder peak at 355 nm in the UV/vis spectrum (Supplementary Fig. 9c). In the reaction system containing triphenylamine, catechol and Cu2+, the cation-π interaction between triphenylamine radical cations and o-quinone groups evidently stabilizes the radical cations, as evidenced by the detection of a peak envelope at 500 ∼ 700 nm40,41 (Fig. 3d). These results verify that Cu2+ can oxidize catechol and triphenylamine groups, causing the cation-π interaction between triphenylamine radical cations and o-quinone groups.

We further confirmed the oxidation of TAC through XPS spectra (Fig. 3e–g). The O 1 s spectrum of TAC displays a symmetric peak at 533.7 eV (catechol C-O-H)42. In comparison, the curve-fitted O 1 s spectrum of Cu-TAC0.1–12 indicates the co-exitance of the catechol C-O-H bond (533.7 eV) and the o-quinone C = O bond (532.0 eV)43. After corrosion in 0.1 M NaOH, the O 1 s signal of Cu-TAC0.1–12 is exclusively associated with the o-quinone C = O bond. Moreover, the deconvoluted N 1 s spectrum of Cu-TAC0.1–12 (Fig. 3f) also shows the signal of triphenylamine radical cations with a binding energy of 400.13 eV44,45. Thus, TAC molecules can be oxidized in strong corrosive environments, resulting in enhanced cation-π interaction between quinones and triphenylamine radical cations. Cu 2p3/2 XPS spectra of naked copper exhibits a dominate signal of Cu0 at 932.60 eV, accompanied with no satellite peak (Fig. 3g). Cu-TAC0.1–12 and 0.1 M NaOH-treated Cu-TAC0.1–12 show very similar 2p3/2 XPS spectra, comprising signals of Cu0 (from the copper substrate) and Cu+ (932.60 eV), Cu-O = C (933.90 eV), and Cu2+ (935.05 eV), as well as a board satellite peak caused by Cu2+. For the Auger Cu LMM spectra (Fig. 3h), naked copper shows an evident peak Cu0, while Cu-TAC0.1–12 and 0.1 M NaOH-treated Cu-TAC0.1–12 show dominated signals of Cu+ and Cu2+ from TAC nanolayer14. Moreover, treating Cu-TAC0.1–12 with 0.1 M NaOH almost has no impact on the Auger Cu LMM spectrum.

To analyze the elemental composition of the ligand nanolayer more accurately, we conducted angle-resolved XPS (ARXPS) characterization. This was achieved by setting the take-off angle between the direction of the analyzer and Cu-TAC0.1–12 sample to 45°. With this signal acquiring mode, we can only collect the elemental signals of the passivation nanolayer while avoiding those of the copper substrate (Supplementary Fig. 9d). Both the O 1 s and N 1 s ARXPS spectra of Cu-TAC0.1–12 are consistent with those of the XPS spectra, implying the reliability of the ARXPS spectra (Supplementary Fig. 9e and f). The Cu 2p3/2 ARXPS spectrum (Supplementary Fig. 9g) of the passivation nanolayer can be curve-fitted into binding energies of 932.6 and 934.5 eV, corresponding to Cu+ and Cu2+ ions with an atom content of about 1.42 at%. Auger Cu LMM spectra of Cu-TAC0.1–12 delivers a dominant signal of Cu+ at 916.4 eV14 (Supplementary Fig. 9h). The combined results of ARXPS and Auger Cu LMM spectra indicate that the passivation nanolayer comprises a considerable amount of Cu+ and Cu2+ ions.

The above spectroscopy analyses indicate that the formation mechanism of the passivation nanolayer is related to the driving forces of copper-ligand coordination and cation-π interaction. During the treatment of copper foils in TAC solutions, the ligand layer is attached to the copper crystal through the coordinative interaction between catechol (or o-quinone) groups and Cu0 atoms. Then, Cu+ and Cu2+ ions interact with the ligand and act as crosslinking sites for the growth of the passivation nanolayer. Simultaneously, some of the triphenylamine and catechol groups are oxidized by Cu2+ to form radical cations and o-quinones, facilitating the formation of intermolecular cation-π interactions. The ligand-copper coordinative interactions promote the formation of the nanolayer, while the cation-π interactions strengthen the intermolecular interaction among ligands.

The Tafel plots of bare copper and Cu-TAC0.1–12 in 0.1 M NaOH are given in Fig. 3i. By fitting the cathodic and anodic branches of the Tafel curves, the corrosion potential (Ecorr) of bare copper was determined to be −0.219 V, indicating a relatively high susceptibility to corrosion. The corrosion current density (icorr) is about 26.03 μA cm−2, signifying a high corrosion rate. By contrast, the corrosion potential of Cu-TAC0.1–12 exhibits a substantial negative shift (Ecorr = −0.294 V), accompanied by a marked reduction in icorr (1.98 μA cm−2). The corrosion inhibition efficiency is approximately 92%. Therefore, the TAC nanolayer provides effective cathodic protection for the copper foil. We also tracked the corrosion behavior of a scratched Cu-TAC0.1–12. As illustrated by the SEM images (Supplementary Fig. 10), slight oxidative corrosion was confined locally to the breached areas after 1 day of immersing in 0.1 M NaOH, demonstrating the superiority of our copper passivation method over techniques employing pinhole-free cathodic coatings41,46.

Structure-adaptability mechanism of the passivation nanolayer

Theoretical calculations based on the van der Waals radius of atoms summarized by Hu et al.47 show that pristine TAC has a molecular size of 23.11 Å × 22.40 Å × 4.96 Å, while oxidized TAC exhibits a molecular size of 23.18 Å × 22.25 Å × 4.80 Å (Supplementary Fig. 11a, b). Therefore, the passivation nanolayer on the surface of Cu-TAC0.1–12 should be a multilayer structure. To gain a better understanding of the relationship between the ligand anchoring geometry and the passivation effect, we regulated the ligand concentration and soaking time during the passivation process. By reducing the TAC concentration to 0.01 mM and soaking time to 0.1 h, we prepared Cu-TAC0.01–0.1 with limited TAC molecules absorbed on the copper surface. In comparison, we also fabricated Cu-TAC0.1–0.5 with a passivation nanolayer thickness of 2.4 ± 0.1 nm (Fig. 4a and Supplementary Fig. 12a–d). According to the theoretical molecular size of TAC, both Cu-TAC0.01–0.1 and Cu-TAC0.1–0.5 may have a monolayer structure. However, O 1 s and N 1 s XPS spectra (Supplementary Fig. 11c, d and Supplementary Note 3) indicate that TAC molecules in Cu-TAC0.01–0.1 prefer a flat-lying adsorption geometry, while those in Cu-TAC0.1–0.5 prefer upright or tilted adsorption geometries (Supplementary Fig. 12i–l). Corrosion tests show that Cu-TAC0.01–0.1 undergoes obvious oxidation after 10 min of exposure in 0.1 M NaOH, manifesting its low passivation capability (Supplementary Fig. 11e–h). In the same corrosive condition, Cu-TAC0.1–0.5 can persist for 40 min, implying that the upright or tilted absorption of ligand is beneficial anti-corrosion (Fig. 4e and Supplementary Fig. 12e–h). We also prepared Cu-TAC0.1–2, Cu-TAC0.1–8.0, and Cu-TAC0.1–24 with TAC nanolayer thicknesses of 3.8 ± 0.2, 5.1 ± 0.3, and 26.1 ± 0.5 nm, respectively (Fig. 4b–d and Supplementary Figs. 13–15). Microstructure characterizations indicate the anti-corrosion properties of Cu-TAC0.1–2 are weak (Fig. 4f). Cu-TAC0.1–8 and Cu-TAC0.1–24 show anti-corrosion properties as high as Cu-TAC0.1–12 (Fig. 4g, h). This means that a sufficiently thick TAC nanolayer ensures the passivation effect.

Cross-sectional HR-TEM images of a Cu-TAC0.1–0.5, b Cu-TAC0.1–2, c Cu-TAC0.1–8, and d Cu-TAC0.1–24; and e Cu-TAC0.01–0.5, f Cu-TAC0.1–2, g Cu-TAC0.1–8, and h Cu-TAC0.1–24 after 0.1 M NaOH treatment. i Water contact angles on the surfaces of bare Cu, and Cu-TAC0.1–12 before and after exposure in 0.1 M NaOH. The error bars in i reflect the standard deviations from three individual experiments. j Frontier molecular orbital diagrams of the initial and oxidized states of TAC. k Electrostatic potential distributions of TAC and oxidized TAC. l Adsorption configuration of isolated oxidized TAC on Cu(110).

The oxidation of TAC on the surface of copper endows the passivation nanolayer with structure-adaptability. An intuitive phenomenon is the improved surface hydrophobicity of Cu-TAC0.1–12 and brass-TAC0.1–24 (Fig. 4i and Supplementary Fig. 7g). For example, the contact angles of water on the surface of bare copper, newly prepared Cu-TAC0.1–12, and 0.1 M NaOH-treated Cu-TAC0.1–12 are 78°, 94.6°, and 106.7°. Calculations based on the Owens-Wendt-Rabel-Kaelble (OWRK) method48 show that the surface free energies of fresh and corroded Cu-TAC0.1–12 samples are 39.52 and 29.74 mJ m−1, respectively. This means that the amorphous nanolayer undergoes structure-adaptability to reduce the surface free energy and improve its barrier capability to corrosive species49. Moreover, our LOSA method is not dependent on the crystal plane of copper. By anchoring TAC on the surface of single crystal coppers with exposed (100), (110), and (111) crystal planes, we fabricated Cu100-TAC, Cu110-TAC, and Cu111-TAC, respectively. All samples can resist 14 days of corrosion in 0.1 M NaOH without sacrificing the metallic luster and the appearance of corrosive products like CuO and Cu(OH)2 species (Supplementary Fig. 16).

To further understand the structure-adaptability of TAC on the copper surface, density functional theory (DFT) calculations were performed. Spectroscopy analyses have indicated that the catechol and triphenylamine moieties of TAC on the surface of copper are oxidized into o-quinone and triphenylamine radical cation moieties, respectively, as illustrated in Fig. 1b. Therefore, our calculations were carried out with the pristine and oxidized TAC molecules. As shown in Fig. 4j and Supplementary Fig. 17, TAC has the highest occupied molecular orbital (HOMO) and lowest unoccupied molecular orbital (LUMO) levels of −5.02 and −1.89 eV, respectively, and a molecular frontier orbital energy gap (Eg) of 3.13 eV. After oxidation, TAC undergoes a change from a closed-shell singlet state to an open-shell doublet state. Due to the presence of α- and β-spin orbitals at different energy levels, it is difficult to determine the lowest energy for the electron transitions. Compared to pristine TAC, oxidized TAC has a smaller Eg (2.13 eV for β-spin orbital) and increased delocalization of electron cloud on o-quinone groups. This means that oxidized TAC is more prone to forming bonds with metal atoms and displaying enhanced reactivity. Furthermore, the electrostatic potential (ESP) distribution of pristine and oxidized TAC was calculated (Fig. 4k). For TAC, the negative ESP values are on most of the molecular surface, and the positive ESP values are observed on the local of catechol groups. For oxidized TAC, the large ESP difference between the negative o-quinone groups and the positive triphenylamine radical cations improves intermolecular cation-π interaction41,50, which is beneficial for improving the corrosion resistance. Also, transforming catechol groups into o-quinone groups can further enhance the interaction between TAC and copper. As shown in Fig. 4l, the Cu(110) surface was chosen to calculate the adsorption energy (ΔEads) of the singlet oxidized TAC. We found that the oxidized TAC tends to adsorb on the bridge site of the copper surface vertically (ΔEads = −5.01 eV).

Benefiting from the structure-adaptability, we show that Cu-TAC0.1–12 can reinforce its anticorrosion capability when pre-treated with alkaline corrosive liquids. For example, fresh Cu-TAC0.1–12 has a low stability in 0.1 M NaCl as it can be evidently corroded within 24 h at room temperature (Supplementary Fig. 18). Specifically, Raman signals of Cu2O and Cu(OH)2 can be detected in the corroded microdomains (Supplementary Note 4). However, after pre-treating with a NaOH solution for 1 h, Cu-TAC0.1–12 can withstand the corrosion of NaCl solution for 14 days without detectable microscopic corrosion traces and maintain high electrical conductivity (Supplementary Fig. 19). Tape test experiments indicate that pre-treatment of Cu-TAC0.1–12 with a 0.1 M NaOH has no obvious impact on the surface microstructure and anticorrosion performances (Supplementary Fig. 3). A similar high anticorrosion capability was achieved when soaking Cu-TAC0.1–12 in a mixed solution of NaCl (0.1 M) and NaOH (0.1 M) (Supplementary Fig. 20). After pre-treatment in an alkaline environment, Cu-TAC0.1–12 exhibits stronger antioxidant properties in the air atmosphere. Under a heating treatment at 130 °C for 20 h, bare copper has been completely oxidized, and fresh Cu-TAC0.1–12 shows some localized corrosion spots. Following 1 h of treatment in 0.1 M NaOH, Cu-TAC0.1–12 remains predominantly unaltered with no indications of oxidation detected (Supplementary Fig. 21). We also improved the corrosiveness of environments by oxygen filling or thermal treating the NaOH corrosive liquids to evaluate the resistance of Cu-TAC0.1–12. In the oxygen-enriched NaOH solution (0.1 M), Cu-TAC0.1–12 can easily maintain its microstructure integrity (Supplementary Fig. 22).

After soaking Cu-TAC0.1–12 foils in NaOH solutions at elevated temperatures (40 °C, 60 °C, 80 °C, and 100 °C) for 24 h, no evident decay in physical properties can be observed (Supplementary Fig. 23a–h). Even after 4 days of corrosion in NaOH solution at 100 °C, Cu-TAC0.1–12 keeps well its metallic luster and shows no evident signals of corrosion products (Supplementary Fig. 23i, j). Further increasing the corrosion time to 8 days in 0.1 M NaOH at 100 °C causes the failure of Cu-TAC0.1–12. As evidenced by the Raman spectra (Supplementary Fig. 24a), signals of oxidized copper become apparent. Simultaneously, enhanced Cu2+ signals appear in both the Cu 2p3/2 and Auger Cu LMM spectra (Supplementary Fig. 24d, e, and Supplementary Note 5). The Raman signals of different functional groups of TAC, including coordinated o-quinone groups (1139 and 1439 cm−1) and positive aromatic amine radical cations (1392 cm−1), exhibit very similar intensity decays. Moreover, the N 1 s and O 1 s XPS signals remain largely consistent with those of the pristine Cu-TAC0.1–12 (Supplementary Fig. 24b, c). Probably, the failure of the TAC nanolayer may be caused by desorption. The Tafel plots of Cu-TAC0.1–12 after 8 days of soaking treatment in 0.1 M NaOH at 100 °C undergo evident changes (Supplementary Fig. 24f), delivering Ecorr and icorr values of −0.270 V and 3.86 μA cm−2, respectively. Compared with the pristine Cu-TAC0.1–12, the antioxidation performance of the passivation nanolayer on the copper surface decreases markedly. Nevertheless, the inhibition efficiency remains approximately 85%. The TAC nanolayer also has a high protective effect toward copper under dynamic corrosive conditions. For example, soaking Cu-TAC0.1–12 in a flowing NaOH aqueous solution (0.1 M, flowing speed: 0.1 mL/s) for 30 days causes no observable surface corrosion and oxidation (Supplementary Fig. 25). We further immersed Cu-TAC0.1–12 in 0.1 M NaOH and cyclically switched the temperature between 20 °C and 100 °C. After 10 cycles (duration: 70 h) of test, digital images, microphotographs, SEM images, XRD patterns, and Raman spectra (Supplementary Fig. 26) verify the high stability of Cu-TAC0.1–12.

According to the mechanism of our LOSA method, various molecules bearing with both catechol and aromatic amine groups can be designed. As a proof of concept, we synthesized three more ligands named NPC-Ca, TPA-Ca, and TNC (Fig. 5a, Supplementary Figs. 41–50, and Supplementary Note 7), and copper foils treated with these molecules are denoted as Cu-NPC-Ca1–36, Cu-TPA-Ca0.1–48, and Cu-TNC0.01–36, respectively (Supplementary Figs. 27–32). After 1 day of corrosion in 0.1 M NaOH, the electrical conductivities of Cu-NPC-Ca1–36, Cu-TPA-Ca0.1–48, and Cu-TNC0.01–36 only decrease by 5.00%, 2.80%, and 2.99% (Supplementary Figs. 27e, 29e, and 31e), respectively, while their corresponding thermal conductivities are only reduced by 1.4%, 2.26%, and 5.42% at 100 °C, respectively (Supplementary Figs. 27f, 29f, and 31f). All protected copper foils can resist the corrosion of 0.1 M NaOH for 30 days without observable microstructural changes (Supplementary Figs. 28, 30, and 32). All corroded samples show increased hydrophobicity (Fig. 5b) and decreased surface free energy (Supplementary Fig. 33), confirming the versatility of the structure-adaptative mechanism. To further demonstrate the stable chemical adsorption of these ligands on copper substrates, DFT calculations were conducted (Supplementary Fig. 34). After oxidization, the energy levels of NPC-Ca, TPA-Ca, and TNC undergo a transition from closed-shell singlet states to open-shell doublet states. The decrease in HOMO/LUMO energy levels and the narrowing of energy gaps facilitate their secure anchoring onto the copper surface (Fig. 5c). The large ESP difference between the negative o-quinone groups and the positive aromatic amine radical cations promotes the formation of intermolecular cation-π interaction (Fig. 5d). Oxidized NPC-Ca, TPA-Ca, and TNC can adsorb on Cu(110) with the bridge sites (Fig. 5e–g). Due to the above advantages, our LOSA method may provide a robust platform for copper protection towards various practical applications.

a Chemical structures of NPC-Ca, TPA-Ca, and TNC. b Water contact angles of bare Cu and modified Cu (including Cu-NPC-Ca1–36, Cu-TPA-Ca0.1–48, and Cu-TNC0.01–36) before and after immersion in 0.1 M NaOH. The error bars in b reflect the standard deviations from three individual experiments. c Frontier molecular orbital diagrams and d electrostatic potential distributions of the initial and oxidized states of NPC-Ca, TPA-Ca, and TNC. Adsorption configurations of isolated e oxidized NPC-Ca, f oxidized TPA-Ca, and g oxidized TNC on Cu(110).

Anti-oxidation applications in electronics

Finally, we demonstrate the possibility of applying our LOSA method in semiconductor electronics and flexible electronics, in which copper materials with different crystal structures, sizes, and morphologies are used as conductors. Due to the huge demand for FPC in the electronic industry, we directly used commercially available FPC films to test the feasibility of our LOSA method. As shown in Fig. 6a, the metallic luster of bare copper circuits on the surface of FPC films fades evidently after soaking in 0.1 M NaOH for 1 day. SEM images (Fig. 6b) and Raman spectra (Supplementary Fig. 35a) reveal the generation of corrosion products including CuO and Cu(OH)2. After corrosion, the electrical conductivity of FPC films decreases from 5.54 × 107 to 0.05 S m−1. Modifying FPC films with TAC has no evident impacts on their appearance and electrical conductivity. In the same liquid corrosive environment, FPC-TAC0.1–15 films keep well their metallic luster (Fig. 6a), exhibit no detectable microstructure and composition changes, and only undergo a 9.75 % reduction of electrical conductivity after corrosion for 7 days (Supplementary Fig. 35b).

a Photographs and b SEM images of FPC and FPC-TAC0.1–15 before and after corrosion, b1 and b2 are the SEM images of bare FPC before and after corrosion in 0.1 M NaOH for 1 day, respectively. b3 and b4 are SEM images of FPC-TAC0.1–15 before and after exposure in 0.1 M NaOH for 7 days, respectively. c Optical microphotographs and d electrical conductivities of Cu-p and Cu-p-TAC0.1–18 before and after corrosion in 0.1 M NaOH for 24 h. The error bars in d reflect the standard deviations from three individual experiments. e Digital images of Cu-p-PVA and Cu-p-TAC0.1–18-PVA inks. Photographs of f Cu-p-TAC0.1–18-PVA and g Cu-p-PVA circuits after subjecting to a harsh environment with a humidity of 98% and a UV index of 11 at 50 °C. h Photographs of Cu-p-TAC0.1–18-PVA circuits after being stored at room temperature for 60 days.

Copper powder (Cu-p) is a key component of copper-based conductive inks and pastes for flexible electronics due to their high electrical conductivity and inexpensiveness51. However, their practical applications are seriously limited because of the easy oxidation of copper nano- or micro-particles. By using a set of Cu-p with a size range of 10–20 μm, we demonstrate that our LOSA method can dramatically improve the anti-oxidation of copper inks. Pristine Cu-p has an electrical conductivity of 7.42 × 105 S m−1, which is decreased to 0.02 S m−1 after corroding in 0.1 M NaOH for 1 day (Fig. 6c and d). With the protection of TAC, the as-formed Cu-p-TAC0.1–18 delivers an electrical conductivity of 4.54 × 105 S m−1. Under the same corrosion conditions, the electrical conductivity of Cu-p-TAC0.1–18 is only reduced by 20.78% (Fig. 6d and Supplementary Fig. 36). Motivated by these results, we dispersed Cu-p and Cu-p-TAC0.1–18 in aqueous solutions of polyvinyl alcohol (PVA) to fabricate conductive inks (denoted as Cu-p-PVA and Cu-p-TAC0.1–18-PVA), and printed flexible circuits on PVA films with a thickness of 80 μm (Supplementary Fig. 37a). The Cu-p-TAC0.1–18-PVA ink has better fluidity and uniformity compared to Cu-p-PVA ink (Fig. 6e). The Cu-p-TAC0.1–18-PVA circuits not only have a brighter metallic luster than the Cu-p circuits, but also exhibit a high electrical conductivity (2.85 × 104 S m−1), far exceeding that of the Cu-p circuits (184.4 S m−1) (Supplementary Fig. 37b). SEM images indicate that Cu-p-PVA ink is easily oxidized during ink fabrication, while Cu-p-TAC0.1–18-PVA keeps well its original microstructure (Supplementary Fig. 37c, d). Even after 24 h of corrosion in air environment at 50 °C with a humidity of 98% and a UV index of 11, Cu-p-TAC0.1–18-PVA circuits retain metallic luster as pristine Cu-p-TAC0.1–18-PVA circuits, while Cu-p-PVA circuits are mostly oxidized (Fig. 6f, g, and Supplementary Fig. 37e, f). Moreover, the Cu-p-TAC0.1–18-PVA circuits show good flexibility and can light up light-emitting diodes (LEDs) (Supplementary Fig. 37g, h). After being stored at room temperature (humidity: 40%) for 60 days, the Cu-p-TAC0.1–18-PVA circuits still maintain good electrical conductivity to power LEDs (Fig. 6h). Our copper anti-oxidation strategy provides a promising route to reduce the energy and resource consumed in the field of integrated circuits (including both semiconductor electronics and flexible electronics) caused by copper oxidation.

In summary, we have developed a robust copper passivation strategy to preserve the intrinsic electrical and thermal conductivities of copper and its alloys in harsh corrosive environments. With the structure-adaptivity, our strategy can strengthen its passivating effect during the aggravation of corrosive conditions. Bulk copper, brass, copper powder, and copper-based flexible circuits protected with the as-designed catechol- and aromatic amine-bearing molecules show highly anti-oxidation capabilities in both liquid- and air-corrosive environments. Our passivation strategy outperforms previously reported molecular passivation methods from the perspectives of resistance time in harsh corrosive environments, intrinsic performance maintenance, and adaptability to different corrosive environments (Supplementary Table 1). By combining the advantages of simple procedure, broad adaptability, molecular structure versatility, and non-destructivity, this facile copper protection technique may find industry applications in copper and its alloy anticorrosion.

Methods

Characterization

Raman spectra were obtained on the HR Evolution confocal Raman microscopy (Horiba France SAS) instrument. The excitation wavelengths were 532, 633 and 785 nm, provided by the Nd-YAG and the He-Ne laser sources, respectively. An objective with 50 times magnification was used to focus the laser onto the samples. Unless otherwise specified, the excitation wavelength for Raman spectra in this work is assumed to be 532 nm. The FIB technique (SOLARIS, TESCAN) with a gallium ion source was used to prepare the cross-sectional TEM specimens of Cu foils. HR-TEM, HAADF-STEM, EDX mappings, and EDX spectra measurements were conducted on an FEI Talos F200 instrument with an acceleration voltage of 200 kV. SEM images were taken with SU-70 (Japan Hitachi Nake High-tech Enterprise) at an accelerating voltage of 5 kV. The crystalline structure of the samples was characterized by XRD on Bruker AXS D8-A25 using Cu Kα radiation (λ = 0.15141 nm). XPS and X-ray-induced Auger electron spectroscopy (AES) were performed on Escalab Xi+ (Thermo Fisher Scientific Inc.) using Al Kα radiation (1486.68 eV, 500 μm diameter of irradiated area). Avantage software program was used to fit all XPS spectra. All binding energies were calibrated by referencing the C 1 s peak at 284.8 eV. Deconvolution of high-resolution XPS peaks was carried out by mixed Gaussian-Lorentzian functions after a smart-type background subtraction. FTIR characterization of the samples was performed by scanning from 4000 to 650 cm−1 on a Nicolet iS10 FTIR spectrometer (Thermo Scientific Inc.) in the attenuated total reflection mode. 1H nuclear magnetic resonance (1H-NMR) spectra were characterized on an AVANCE NEO 500 MHz Digital Fourier transform nuclear magnetic resonance (FT-NMR) Spectrometer at room temperature. 13C NMR spectra were collected using the same instrument at 126 MHz. The high-resolution mass spectrometry (HRMS) was recorded on an ultra-high performance liquid chromatography-quadrupole time-of-flight mass spectrometer (Agilent 1290–6545XT). Ozone (O3) was prepared by the multipurpose portable ozone generator (Nanjing Zhongzixing Technology Co., Ltd), and used immediately upon production. The UV/vis spectra were measured on a UV/vis spectrophotometer (Shimadzu UV-2550). The concentration of all reactants is fixed at 0.02 mM. Tafel plots of the Cu samples were acquired on a CHI 760E electrochemical workstation in a standard three-electrode cell at 25 °C. A large platinum plate (2 cm2) was used as the counter electrode, while the Ag/AgCl electrode was used as the reference electrode. The working electrode is bare copper foil or Cu-TAC0.1–12.

Passivation of copper and brass

Bare copper and brass were immersed in 0.1 M hydrochloric acid for 1 min to remove the oxide layer, followed by rinsing in ultrapure water several times. After dried with nitrogen flow, bare copper and brass with clean surfaces were obtained. Tacking Cu-TAC0.1–12 foils as an example, the passivation procedure is described as follows. Cleaned copper foils were immersed in a methanol solution of TAC (0.1 mM) for 12 h to facilitate surface assembly of TAC molecules. Afterward, the modified Cu foils were subjected to ultrasonic cleaning in methanol to eliminate any excess TAC from the copper surface, and dried with nitrogen flux to obtain the Cu-TAC0.1–12 foils. By changing the concentration of TAC methanol solution and the soaking time of copper foils, Cu-TAC samples with different thicknesses of passivation layers can be obtained. The structure of catechol (CA), triphenylamine (TPA), Im-Ca, TBC, and TAM are shown in Supplementary Fig. 8a. Upon immersing cleaned copper foils in methanol solution (0.1 mM) of the aforementioned molecules for 18 h, the modified copper foils were obtained and designated as Cu-CA0.1–18, Cu-TPA0.1–18, Cu-Im-Ca0.1–18, Cu-TBC0.1–18, and Cu-TAM0.1–18, respectively. To prepare brass-TAC0.1–24, the immersion time was extended to 24 h. Flexible printed circuits (FPC) passivated after soaking in the TAC methanol solution (0.1 mM) for 15 h, are labeled as FPC-TAC0.1–15. Using the same procedure, other passivated copper foils were prepared. Cu-NPC-Ca1–36 foils were fabricated by soaking Cu foils in a methanol solution of NPC-Ca (1 mM) for 36 h. Cu-TPA-Ca0.1–48 foils were obtained by treating Cu foils with a methanol solution of TPA-Ca (0.1 mM) for 48 h; Cu-TNC0.01–36 foils were prepared through passivating Cu foils in a solution of TNC (solvent: methanol and DCM with a volume ratio of 1: 99, concentration: 0.01 mM) for 36 h.

Preparation of Cu-p-TAC0.1–18

Cu-p (50 g) was added into a methanol solution of TAC (0.1 mM) and stirred for 18 h. After centrifugation, the obtained solid was washed with methanol and dried under vacuum to obtain Cu-p-TAC0.1–18.

Preparation of oxygen-enriched NaOH solution

An aqueous solution of NaOH solution (0.1 M) enriched with oxygen was obtained by saturating ultra-pure water with high-purity oxygen.

Synthesis of copper inks

Copper inks were prepared by introducing Cu-p or Cu-p-TAC0.1–18 in the polymer matrix of PVA. For example, to prepare the Cu-p-PVA ink, 0.48 g of PVA was dissolved in 3.5 mL of deionized water at 90 °C. To this solution, 8 g of Cu-p was added, followed by stirring at 90 °C for 30 min. The Cu-p-TAC0.1–18-PVA ink was prepared using the same method.

Printing of copper circuits

A flexible electronic printer (Scientific 3, Shanghai Zhongbin Technology Co. Ltd.) was adopted to print the Cu-p-PVA and Cu-p-TAC0.1–18-PVA inks on PVA films (thickness: 80 μm) into flexible circuits using a 250 μm nozzle. The printing speed was 3 mm s−1 and the printing pressure was 30 kPa. The temperature of the printing substrate was fixed at 90 °C for 5 min to ensure the smoothness of printed lines. Printing paths and operation processes were designed and controlled using BitsAssembler software. All the copper circuits were treated with the thermocompression sintering. Typically, the hot press mold (BS-6170-B-50T) was initially coated with a layer of Teflon film to prevent adhesion between the circuits and the mold. After 10 min of thermocompression (170 °C, 300 Bar) with vacuum control via a Programmable Logic Controller (PLC), the sintering of the copper circuits was achieved.

Measurements and theoretical calculations

Measurement of the electrical conductivity

The electrical conductivities of bare copper foils were measured on a 4-point probes resistivity measurement system (RTS-9, 4Probes Tech. Ltd.). This measurement method was also applied to other modified copper foils and alkali-treated copper foils. The Cu powder was initially filled into the mold, followed by pressing and forming using a press machine (SSP-10A Shimadzu (Shanghai) Global Laboratory Consumables Co., Ltd.). Subsequently, the electrical conductivity of the resulting sheet material was measured to determine the electrical conductivity of Cu powder.

Determination of the thermal diffusivity of Cu foil

The thermal diffusivities (α; in m2 s−1) of the copper and its alloys before and after passivation were measured on a LFA Nanoflash 447 Light flash system (NETZSCH Scientific Instruments Trading Ltd.) using an in-plane mode. The thermal conductivity (κ) was calculated according to the Eq. (1):

where ρ is the density of copper (ρ = 8.96 g cm−3), and Cp represents the specific heat capacity of copper (0.39 × 103 J kg−1 K−1).

Water contact angle measurement and calculation of surface free energy

The contact angles of water on the copper and its alloys before and after passivation were measured using an optical contact angle measuring and contour analysis system equipped with a dispensing needle (OCA20, Data Physics Instruments GmbH). A water droplet (2 μL) was generated using the automatic dispenser of the goniometer. All tests were carried out in air at room temperature. The axisymmetric drop-shape analysis profile method was used to estimate the contact angle of the water droplet.

The WORK (Owens-Wendt-Rabel-Kaelble) method is widely used for calculating the surface free energy of solids from the liquid contact angles. According to Yong’s equation, there is a relationship (Eq. (2)) among the contact angle θ, the surface tension of the liquid σl, the interfacial tension between the liquid and the solid σsl, and the surface free energy of solid σs:

Based on the Fowkes method, the interfacial tension σsl was calculated based on the two surface tensions σs and σl. These interactions are interpreted as the geometric mean of a disperse part σD and a polar part σP of the surface tension or surface free energy (Eq. (3)):

In our study, water and ethylene glycol (EtGly) were employed to determine the surface free energy of the copper and its alloys before and after passivation. The liquid surface tensions (mN m−1) were: σl, water = 72.75, σl, waterD = 22.10, σl, waterP = 50.65, σl, EtGly = 48.0, σl, EtGlyD = 29.0, σl, EtGly P = 19.0.

Ligand density calculation

The mass percent (mass%) of copper (mCu) and carbon (mC), as determined via EDS, were employed to calculate the weight of copper atoms (wCu) in the substrate and carbon atoms (wC) in the passivation nanolayer. The thickness of the copper slice for the TEM test is approximately 40 nm, and both sides are coated with TAC (C39H30N4O6). Taking Cu(110) crystal plane as an example, the weight of copper atoms contained in the copper slice in the test area is described as Eq. (4):

where VCu is the volume of copper in the test area; ρCu(110) is the atom density of Cu(110); MCu is the molar mass of copper (63.55 g/mol); NA is Avogadro’s constant.

The weight of ligands in the passivation nanolayer of the test area is described as Eq. (5):

where nC is the number of carbon atoms in a ligand molecular; ρligand is the number of ligands per unit area (nm2) on the surface of copper slice (ligand density); MC is the molar mass of carbon (12.01 g/mol); S is the surface where ligands can be attached.

The relationship between the mass percent and weights of copper in the substrate and carbon in the passivation nanolayer accords Eq. (6):

To sum up, the density of the ligands on the copper surface can be calculated.

Taking Fig. 1k as an example, the corresponding element contents of Cu-TAC0.1–12 are shown in supplementary Fig. 3c. The mass percent of Cu (mCu) in the substrate and C (mC) in the passivation nanolayer are 79.41 and 10.61 mass%, respectively. The top view of the copper slice in the test area is a rectangle approximately 50 nm × 27.5 nm, and the top side is a rectangle of 40 nm × 50 nm, resulting in an S value of 4750 nm2. The volume of the copper slice in the test area is 40 nm × 27.5 nm × 50 nm, and the final calculated ligand density of Cu-TAC0.1–12 is about 4.5 molecules/nm2. According to the van der Waals radius of atoms summarized by Hu et al.47, the calculated results of molecular dimensions of TAC and oxidized TAC are presented in Supplementary Fig. 11a, b. Due to the presence of cation-π interactions between ligands, they can be assumed to be closely packed on the surface of the copper foil. For Cu-TAC0.1–12 with a ligand nanolayer thickness of about 6.9 nm, the theoretical ligand density is about 2.8 molecules/nm2. The measured value is slightly higher than the theoretical value, likely attributable to the cation-π interactions shortening the distance between ligands.

Bonding test for the passivation nanolayer on the surface of copper foil

A 3 M tape was firmly applied to the surface of Cu-TAC0.1–12 or 0.1 M NaOH treated Cu-TAC0.1–12, uniformly rubbed with an applicator to ensure proper contact, and allowed to dwell for 120 s. Then, the tape was rapidly peeled off at a 180° angle in a continuous motion. This process was repeated 10 times. The bonding stability of the passivation nanolayer was evaluated by examining the optical microscopy, and SEM images of samples after 3 M tape removal. In order to further verify the integrity of the passivation layer on copper foil, the tested samples were immersed in 0.1 M NaOH for anticorrosion evaluation.

Measurement of Tafel plots

Tafel plots of the samples were measured on a CHI 760E electrochemical workstation in a standard three-electrode cell at 25 °C. The electrolyte was not deoxygenated and was opened to the air during each measurement process. Bare copper foil or Cu-TAC0.1–12 acted as the working electrode, with a geometric area of 2 cm². A large platinum plate (2 cm2) was used as the counter electrode, while the Ag/AgCl electrode was used as the reference electrode. In this study, all potential values were referred to the reference electrode. The inhibition efficiency (Ei) values were calculated by using the following Eq. (7)19:

where \({i}_{{corr}}^{0}\) and \({i}_{{corr}}\) represent the corrosion current densities of the bare copper and Cu-TAC0.1–12 in 0.1 M NaOH solution, respectively.

Anticorrosion performances in dynamic corrosive conditions

The stability of the TAC nanolayer in dynamic corrosive environments was determined through the following two processes. First, Cu-TAC0.1–12 was soaked in a flowing 0.1 M NaOH with a flowing speed of 0.1 mL/s. Second, Cu-TAC0.1–12 was immersed in 0.1 M NaOH and the treating temperatures are cyclically switched between 20 and 100 °C for 10 cycles (duration: 70 h). The stability of the passivation layer was determined through characterizations of digital images, microphotographs, and SEM images.

Density functional theory calculations

Based on the Gaussian 16 program package52, the M06-2X functional53 and def2-SVP basis set54,55 were adopted for all calculations. The DFT-D3 dispersion correction56 was applied to correct the weak interaction, thus improving the calculation accuracy. The solvation model based on density (SMD) implicit solvation model57 was used to account for the solvation effect. Orbital energy level analysis and electrostatic potential surfaces (SPC) analysis were performed on the GaussView 6 program.

We used Materials Studio software to calculate the adsorption energy based on the first-principles. The cut-off energy (Rc) was set to 400 eV and the energy was minimized until its variation in the following steps became lower than 10−4 eV/atom. Spin-polarization calculations were carried out according to Dmol3 modules at the Generalized gradient approximation (GGA) and Perdew-Burke-Ernzerh (PBE) level58,59,60,61,62. The convergence criteria were that the maximum atomic displacement is 0.005 Å, and the corresponding total energy converged to 1 × 10−5 Ha. The self-consistent field method (SCF) convergence criterion was 1 × 10−5. To isolate the influence of van der Waals forces between layers, a vacuum layer with a thickness of 15 Å was placed above the copper crystal surface and adsorbed molecules. The adsorbed molecules were added while keeping all copper atoms in the bottom layer fixed and allowing the remaining atoms to be in a free state. The adsorbed molecules optimized using density functional theory were then incorporated into the system and further optimized to achieve the minimum energy. For the calculations, a four-layer 9 × 9 × 4 supercell was built to model the Cu(110) crystal surface, which accommodated the adsorption molecule. The k-point sampling was performed following the Monkhorst-Pack procedure with a 4 × 4 × 1 mesh.

The adsorption energy (ΔEads) of the molecule on the Cu(110) crystal surface was defined as the Eq. (8):

where, ΔE(substrate + molecule) is the total energy of the Cu(110) crystal surface with adsorbed molecule, E(substrate) is the energy of the Cu(110) crystal without adsorbed molecule, and ΔE(molecule) is the energy of adsorbed molecule. From the adsorption energy definition, a positive value indicates that the adsorbed molecule requires energy for adsorption on the surface, while a negative value indicates good adsorption.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The data generated in this study are provided in the Supplementary Information and Source Data files. Source data are provided with this paper. Any additional data supporting the findings are available from the corresponding author upon request. Source data are provided with this paper.

References

Rueda, A., Sedlmeir, F., Kumari, M., Leuchs, G. & Schwefel, H. G. L. Resonant electro-optic frequency comb. Nature 568, 378–381 (2019).

Kim, S. J. et al. Flat-surface-assisted and self-regulated oxidation resistance of Cu(111). Nature 603, 434–438 (2022).

Chung, K. et al. Non-oxidized bare copper nanoparticles with surface excess electrons in air. Nat. Nanotechnol. 17, 285–291 (2022).

Zaki, A. Principles of Corrosion Engineering and Corrosion Control. (Butterworth-Heinemann, 2006).

Peters, D. W. Corrosion and Passivation of Copper in Handbook of Cleaning in Semiconductor Manufacturing 395-428 (Wiley, 2010).

She, X., Peng, J., Qiang, Y., Zhou, Y. & Zhang, S. Recent advances in protective technologies against copper corrosion. J. Mater. Sci. Technol. 201, 75–94 (2024).

Lee, W. et al. Universal assembly of liquid metal particles in polymers enables elastic printed circuit board. Science 378, 637–641 (2022).

Zeng, X. et al. Copper inks for printed electronics: a review. Nanoscale 14, 16003–16032 (2022).

Wu, S. et al. Structural design and fabrication of multifunctional nanocarbon materials for extreme environmental applications. Adv. Mater. 34, 2201046 (2022).

Zhao, M. et al. Enhanced copper anticorrosion from Janus-doped bilayer graphene. Nat. Commun. 14, 7447 (2023).

Singh Raman, R. K. et al. Graphene coatings for corrosion resistance of nickel and copper in acidic, alkaline and neutral environments. J. Mater. Sci. Technol. 142, 124–133 (2023).

Li, W. et al. The effect of structural properties of benzo derivative on the inhibition performance for copper corrosion in alkaline medium: Experimental and theoretical investigations. Colloids Surf. A 649, 129531 (2022).

Finšgar, M. Electrochemical, 3D topography, XPS, and ToF-SIMS analyses of 4-methyl-2-phenylimidazole as a corrosion inhibitor for brass. Corros. Sci. 169, 108632 (2020).

Berg, I., Amit, E., Hale, L., Toste, F. D. & Gross, E. N-heterocyclic carbene based nanolayer for copper film oxidation mitigation. Angew. Chem. Int. Ed. 61, e202201093 (2022).

Peng, J. et al. Surface coordination layer passivates oxidation of copper. Nature 586, 390–394 (2020).

Cao, H., Fang, M., Jia, W., Liu, X. & Xu, Q. Remarkable improvement of corrosion resistance of silane composite coating with Ti3C2Tx MXene on copper. Compos. Part B 228, 109427 (2022).

Shinato, K. W., Zewde, A. A. & Jin, Y. Corrosion protection of copper and copper alloys in different corrosive medium using environmentally friendly corrosion inhibitors. Corros. Rev. 38, 101–109 (2020).

Li, L.-Y. et al. Advances in functionalized polymer coatings on biodegradable magnesium alloys-A review. Acta Biomater. 79, 23–36 (2018).

Chen, M.-A., Lu, X.-B., Guo, Z.-H. & Huang, R. Influence of hydrolysis time on the structure and corrosion protective performance of (3-mercaptopropyl)triethoxysilane film on copper. Corros. Sci. 53, 2793–2802 (2011).

Patil, N., Jérôme, C. & Detrembleur, C. Recent advances in the synthesis of catechol-derived (bio)polymers for applications in energy storage and environment. Prog. Polym. Sci. 82, 34–91 (2018).

Wu, J. et al. Low-cost mussel inspired poly(catechol/polyamine) coating with superior anti-corrosion capability on copper. J. Colloid Interface Sci. 463, 214–221 (2016).

Grindy, S. C. et al. Control of hierarchical polymer mechanics with bioinspired metal-coordination dynamics. Nat. Mater. 14, 1210–1216 (2015).

Gebbie, M. A. et al. Tuning underwater adhesion with cation-π interactions. Nat. Chem. 9, 473–479 (2017).

Mahadevi, A. S. & Sastry, G. N. Cation-π interaction: its role and relevance in chemistry, biology, and material science. Chem. Rev. 113, 2100–2138 (2012).

Frost, R. L. Raman spectroscopy of selected copper minerals of significance in corrosion. Spectrochim. Acta Part A 59, 1195–1204 (2003).

Kim, S. J. et al. Color of copper/copper oxide. Adv. Mater. 33, 2007345 (2021).

Su, C., Ye, Y., Xu, L. & Zhang, C. Synthesis and charge-discharge properties of a ferrocene-containing polytriphenylamine derivative as the cathode of a lithium ion battery. J. Mater. Chem. 22, 22658–22662 (2012).

Zhao, C. et al. In situ electropolymerization enables ultrafast long cycle life and high-voltage organic cathodes for lithium batteries. Angew. Chem. Int. Ed. 59, 11992–11998 (2020).

Filippidi, E. et al. Toughening elastomers using mussel-inspired iron-catechol complexes. Science 358, 502–505 (2017).

Holten-Andersen, N. et al. pH-induced metal-ligand cross-links inspired by mussel yield self-healing polymer networks with near-covalent elastic moduli. Proc. Natl Acad. Sci. USA 108, 2651–2655 (2011).

Kvarnström, C. et al. Raman and FTIR spectroscopic characterization of electrochemically synthesized poly(triphenylamine), PTPA. J. Solid State Electrochem. 6, 505–512 (2002).

Harrington, M. J., Masic, A., Holten-Andersen, N., Waite, J. H. & Fratzl, P. Iron-clad fibers: a metal-based biological strategy for hard flexible coatings. Science 328, 216–220 (2010).

Kim, S. et al. In situ mechanical reinforcement of polymer hydrogels via metal-coordinated crosslink mineralization. Nat. Commun. 12, 667 (2021).

Schmitt, C. N. Z. et al. Mechanical homeostasis of a DOPA-enriched biological coating from mussels in response to metal variation. J. R. Soc. Interface 12, 20150466 (2015).

Littleford, R. E., Tackley, D. R., Cherryman, J. C., Dent, G. & Smith, W. E. A Raman and DFT study of substituted triphenylamines for use as charge transfer materials in light emitting polymers. J. Mol. Struct. 692, 81–90 (2004).

Wu, J., Wang, H., Xu, S. & Xu, W. Comparison of shearing force and hydrostatic pressure on molecular structures of triphenylamine by fluorescence and raman spectroscopies. J. Phys. Chem. A 119, 1303–1308 (2015).

Yu, J. et al. Adhesion of mussel foot protein-3 to TiO2 surfaces: the effect of pH. Biomacromolecules 14, 1072–1077 (2013).

Evans, R. C., Douglas, P. & Winscom, C. J. Coordination complexes exhibiting room-temperature phosphorescence: evaluation of their suitability as triplet emitters in organic light emitting diodes. Coord. Chem. Rev. 250, 2093–2126 (2006).

Goia, S. et al. Ultrafast spectroelectrochemistry of the catechol/o-quinone redox couple in aqueous buffer solution. ChemPhotoChem 8, e202300325 (2024).

Sumalekshmy, S. & Gopidas, K. R. Reaction of aromatic amines with Cu(ClO4)2 in acetonitrile as a facile route to amine radical cation generation. Chem. Phys. Lett. 413, 294–299 (2005).

Zheng, X. et al. Coulombic-enhanced hetero radical pairing interactions. Nat. Commun. 9, 1961 (2018).

Yuan, C. et al. Predictable particle engineering: programming the energy level, carrier generation, and conductivity of core-shell particles. J. Am. Chem. Soc. 140, 7629–7636 (2018).

Qiang, T., Chen, L., Zhang, Q. & Liu, X. A sustainable and cleaner speedy tanning system based on condensed tannins catalyzed by laccase. J. Clean. Prod. 197, 1117–1123 (2018).

Mu, Y., Mu, P., Wu, X. & Wan, X. The two facets of the synergic effect of amine cation and catechol on the adhesion of catechol in underwater conditions. Appl. Surf. Sci. 530, 146973 (2020).

Zhang, T. et al. Ion-modulated radical doping of spiro-OMeTAD for more efficient and stable perovskite solar cells. Science 377, 495–501 (2022).

Cui, C., Lim, A. T. O. & Huang, J. A cautionary note on graphene anti-corrosion coatings. Nat. Nanotechnol. 12, 834–835 (2017).

Sheng-Zhi, H., Zhao-Xiong, X. & Zhao-Hui, Z. 70 Years of crystallographic van der Waals Radii. Acta Phys. Chim. Sin. 26, 17955–11800 (2010).

Albert, J. N. L., Baney, M. J., Stafford, C. M., Kelly, J. Y. & Epps, T. H. Generation of monolayer gradients in surface energy and surface chemistry for block copolymer thin film studies. ACS Nano 3, 3977–3986 (2009).

Fan, H. et al. Inhibition of brass corrosion in sodium chloride solutions by self-assembled silane films. Corros. Sci. 53, 4273–4281 (2011).

Neel, A. J., Hilton, M. J., Sigman, M. S. & Toste, F. D. Exploiting non-covalent π interactions for catalyst design. Nature 543, 637–646 (2017).

Wang, L. et al. Antioxidant high-conductivity copper pastes based on core-shell copper nanoparticles for flexible printed electronics. Adv. Funct. Mater. 33, 2215127 (2023).

Gaussian 16 (Wallingford, CT, 2016).

Zhao, Y. & Truhlar, D. G. The M06 suite of density functionals for main group thermochemistry, thermochemical kinetics, noncovalent interactions, excited states, and transition elements: two new functionals and systematic testing of four M06-class functionals and 12 other functionals. Theor. Chem. Acc. 120, 215–241 (2008).

Weigend, F. & Ahlrichs, R. Balanced basis sets of split valence, triple zeta valence and quadruple zeta valence quality for H to Rn: design and assessment of accuracy. Phys. Chem. Chem. Phys. 7, 3297–3305 (2005).

Weigend, F. Accurate Coulomb-fitting basis sets for H to Rn. Phys. Chem. Chem. Phys. 8, 1057–1065 (2006).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Marenich, A. V., Cramer, C. J. & Truhlar, D. G. Universal solvation model based on solute electron density and on a continuum model of the solvent defined by the bulk dielectric constant and atomic surface tensions. J. Phys. Chem. B 113, 6378–6396 (2009).

Kresse, G. & Hafner, J. Ab initiomolecular dynamics for liquid metals. Phys. Rev. B 47, 558–561 (1993).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Grimme, S. Semiempirical GGA-type density functional constructed with a long-range dispersion correction. J. Comput. Chem. 27, 1787–1799 (2006).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (52033008, L.D.; U24A20200, C.Y.; U22A20149, L.D.; and 52173045, C.Y.). The authors thank Guorong Chen and Weiang Luo (College of Materials, Xiamen University) for material property characterizations. The authors thank Dr. Lin Zhang (College of Chemistry and Chemical Engineering, Xiamen University) for his support in the theoretical calculations.

Author information

Authors and Affiliations

Contributions

C.Y. and L.H. conceived the idea and initiated the study. C.Y. and L.D. supervised and designed the project. L.H. and J.H. prepared the samples and investigated their anticorrosion. W.Z. contributed to the printing of flexible circuits. X.S. contributed to the HR-TEM characterization. L.H., X.L., H.L., and B.Z. performed the spectroscopic analysis of samples. J.L. and Y.X. analyzed the data. C.Y., L.H., and L.D. wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Zhichang Wang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

He, L., Huang, J., Zheng, W. et al. A ligand oxidation structure-adaptive strategy for copper passivation. Nat Commun 16, 7615 (2025). https://doi.org/10.1038/s41467-025-62603-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-62603-2