Abstract

The use of redox active metal oxides to support noble metals is critical in the design of highly-active CO oxidation catalysts for gas emissions control. Unfortunately, supports promoting the activity, such as CeO2, tend also to promote acute catalyst deactivation by turning highly-active metallic Pt clusters into less-active PtOx species, under practical reaction conditions (high-temperature and/or the excess of O2). This leads to a problematic activity/stability tradeoff where Pt/CeO2 catalysts, highly-active, and Pt on non-reducible supports, highly stable, are bookends. Herein, we report a method to trap Pt at V-shaped pockets/stepped sites of CeO2 that break this undesired correlation by showing both high activity and stability in the CO oxidation reaction. XAS, CO-DRIFT, XPS, HAADF-STEM, and DFT are used to infer that the generation of low order metallic Pt clusters connected to two crystallographic planes of the support is key to inhibit (deactivating) re-oxidation paths of the metal, as a result of the high-energy required to form disordered/distorted PtOx ensembles at these positions. This new material allows, thus, to operate outside the commonly observed, limiting, activity/stability tradeoff.

Similar content being viewed by others

Introduction

In the last few years, the use of CeO2 as a support of catalytically active metals has received renewed interest, after the realization that unusual forms of the active species, including single metal atoms, small metal clusters and metal rafts, can be then stabilized under conditions that otherwise lead to metal aggregation1,2,3,4,5,6. Atomically dispersed metals have been shown to outperform typical supported nanoparticles in various industrially relevant reactions, turning into the focus of numerous studies in the last few years7. The Pt-on-CeO2 system is an illustrative example, and the CO oxidation reaction, in particular, has become a recurrent benchmark reaction to compare the activity of supported metal catalysts1,2,3,4,5,8,9.

Literature rationalizes the high CO oxidation activity of Pt/CeO2 following different arguments, among which two main should be highlighted: a) nuclearity effects, under the premise that atomically dispersed metal species, common on CeO2, could be the most active species1,10; and/or b) cooperativity effects, by which the metal and the support work in concert to most effectively catalyze this reaction8,11,12,13. Note that, by definition, the number of Pt atoms in direct contact with the support increases with decreasing particle size, being maximum when Pt is atomically dispersed.

The cooperation between noble metals and CeO2 was first reported in gold catalysts in the 2000s4,14, in supports made to incorporate a large number of defects to promote a Mars-van-Krevelen activation of O2, followed by reverse spillover of lattice oxygen to interfacial Au, where CO is activated. This mechanism, applicable to single atoms (SA) and metal nanoparticles (NPs)6, explains well a number of independent observations in the literature, including: a) why the activity of supported Pt catalysts generally correlates with the number of peripherical sites in particles of variable diameter6; b) why the activity of single Pt atoms increases as the energy needed to extract lattice oxygen from the support decreases15; and c) why single Pt atoms are rather active when supported on CeO21,13, but much less active than 2–3 nm NPs on supports that lack redox functionality, such as SiO2 or Al2O3. Altogether, these observations explain the recent discovery of small Pt NPs supported on nanocrystalline CeO2 as one of the most active CO oxidation catalysts16, together with Pt1/FeOx17. Unfortunately, literature also reveals that the high defectivity and redox reactivity of nanocrystalline CeO2 lead to acute deactivation of small Pt nanoparticles upon oxidative fragmentation in O2 or O2-rich CO mixtures, at moderate-to-high temperatures2,16. These conditions are relevant to various industrial applications, including the abatement of CO at the exhaust of combustion engines. Deactivation by the in-situ formation of single metal atoms is, indeed, a kind of deactivation mechanism observed with supports capable of trapping single metal atoms (i.e., Al-paired CHA, CeO2, and Al2O3 under certain conditions)16,18,19,20. However, while the redispersion issue occurs in pure O2 when the support is CHA, but not in O2-rich streams that carry small amounts of CO18,19, it takes place in both O2 and O2-containing CO streams when the support is CeO216. Thus, literature data strongly suggests that redox-active supports that most effectively promote catalysis at the metal/support interface, such as CeO2, tend to promote, at the same time, undesired redispersion of the metal into less active single atoms. This problem has been detoured in the literature by constraining the experimental scope to a) CO-rich O2/CO mixtures (the excess of CO inhibits oxidative fragmentation paths); b) low temperature processes (which also slow down the kinetics of the metal redispersion); and/or c) rather large Pt NPs, less prone to oxidative fragmentation, but with lower specific activities6,21. Thus, the design of highly active Pt samples (as active as state-of-the-art Pt/CeO2) that are moreover stable under practical reaction conditions remains a grand open challenge in catalysis.

Recently, we reported a highly active K-Pt@MFI catalyst able to sustain activity in O2-rich atmospheres, under conditions that prompt deactivation of state-of-the-art Pt/CeO2 catalysts22. This result was achieved by avoiding both oxidative fragmentation and uncontrolled reductive sintering of small Pt clusters in O2-rich CO atmospheres, using K-MFI zeolite as a unique non-reducible support22. Control of the cluster size (to avoid both single Pt atoms and large Pt aggregates), together with promotion of the metal clusters by K (to increase the metal electron density) was critical to attain high CO oxidation activity under steady reaction conditions (superior to that of Pt/CeO2 systems, which deactivate severely). However, the activity of K-Pt@MFI was low compared to that of fresh Pt/CeO2 catalysts, we infer, because the cooperation that takes place between Pt and the CeO2 at the metal/support interface is then overridden.

In this contribution, we report a new Pt/CeO2 catalyst whose activity is up to ~40 times greater than that of our previous K-Pt@MFI catalyst, under steady reaction conditions (i.e., after exposure to an O2-rich stream at a high temperature)22. The material comprises small Pt NPs located at V-sites of CeO2 grains (intersection between two CeO2 crystals) that have maximum interaction with the support and remain largely stable in the presence of O2 at high temperature. The result deviates from the general observation that highly active Pt nanoparticles on CeO2 rapidly deactivate in O2-rich streams16, allowing to operate outside a common, limiting, activity/stability tradeoff.

Results

Pt on conventional CeO2 supports (control experiments)

Consistent with previous literature, we observe that Pt on high surface area CeO2 (Pt/CeO2-HS), calcined in air at 450 °C, stabilizes quasi atomically dispersed PtOx species, as illustrated in Fig. 1a (see “Methods” Section for synthesis details, and Supplementary Table 1 and Supplementary Fig. 1 for more basis PXRD, BET, and STEM characterization). Spectroscopic evidence of these structures is provided, for example, by Diffuse Reflectance Infrared Fourier Transform (DRIFT) signatures of CO-adsorbed on Pt/CeO2-HS at room temperature (Supplementary Fig. 2a), which shows two main bands centered at 2114 and 2104 cm–1. Although the assignment of CO bands in atomically dispersed Pt species is still debated23, literature typically ascribes these two bands to small oxidized Pt clusters and cationic Pt single sites, respectively16, which is consistent with the rest of the characterization hereinafter16. The Pt L3-edge X-Ray Absorption Near Edge Spectroscopy (XANES) spectrum of this calcined sample (Fig. 1b) shows a white-line whose intensity is similar to that of bulk PtO2, and the corresponding Fourier Transform Extended X-Ray Absorption Fine Structure (FT-EXAFS) spectrum (Fig. 1c) is characterized by an intense Pt-O contribution that can be fitted to Pt-O with a coordination number of ~6 (Supplementary Fig. 3 and Supplementary Table 2), all indicating an average oxidation state of ~+4. A Pt-O coordination of 6 is typical of either bulk PtO2 (i.e., when the particle diameter is sufficiently large, as in particles measuring several nanometers) or single Pt atoms filling Ce vacancies near, or just below, the ceria surface2. The oxidized nature of Pt was confirmed by X-Ray Photoelectron Spectroscopy (XPS), which shows the absence of metallic Pt0 contributions (Fig. 1d). We note, however, a discrepancy in the valence of these Pt cationic species measured by XAS (4 + ) and XPS (2 + ) due to notable differences in the O2 partial pressures during the experiments (ambient vs ultra-high vacuum), as previously reported16,24. High-Angle Annular Dark-Field Scanning Transmission Electron Microscopy (HAADF-STEM) images corroborate the predominance of atomically dispersed Pt and Pt clusters smaller than 1 nm, and allow us to rule out the presence of large metal ensembles (Fig. 1e).

a Schematic illustration of the dynamic behavior of the Pt/CeO2-HS sample after various thermal treatments. Red, oxygen; yellow, cerium; gray, metallic Pt; blue, cationic Pt b, c Pt L3-edge XANES, and the corresponding magnitude of the k2-weighted FT-EXAFS spectra, respectively, after calcination in O2 at 450 °C, reduction in CO at 300 °C, and reaction with a 8:1 O2/CO mixture at 500 °C (sequential treatments); for comparison purposes, XAS spectra of PtO2 and a Pt foil are also provided d Pt 4 f XPS spectra of the same samples. e–g the corresponding HAADF-STEM images.

When tested in the CO oxidation reaction, the activity of the calcined Pt/CeO2-HS sample, expressed as mol converted per mol Pt per s, appeared to be similar to that reported by analogous catalysts in the literature25, under the same reaction conditions (Supplementary Table 3). Also consistent with previous reports, treatment of the Pt/CeO2-HS sample with CO at 300 °C, prior to the reaction step, caused a drastic boost of the catalytic activity, from 0.0003 s−1 to 0.099 s−1 at 80 °C (Supplementary Table 3)16. This activity raise, corresponding to a~160 °C drop in the temperature required to reach 50% CO conversion (T50, Fig. 2a, empty symbol), occurs concomitantly to the formation of metallic Pt clusters after the CO treatment (Fig. 1a), as evidenced by a) the DRIFT spectrum of CO-adsorbed at RT on the CO-treated sample, showing the appearance of new features at lower wavenumbers ( < 2080 cm−1) (Supplementary Fig. 2)23; b) the Pt L3-edge XANES spectrum, showing a drop in the white-line intensity relative to the calcined counterpart (see CO-treated in Fig. 1b); c) the Pt L3-edge EXAFS spectrum, showing a decrease in intensity of the Pt-O contribution (see CO-treated in Fig. 1c and Supplementary Table 3); d) XPS data, showing new Pt0 contributions (see CO-treated in Fig. 1d) and e) HAADF-STEM images, showing the formation of Pt nanoparticles (see Fig. 1f). We note, however, that metallic Pt is not the only species on the catalyst after the CO treatment, as all spectroscopic techniques denote the co-existence of oxidized Pt centers. Indeed, the absence of intense long-distant backscattering signals in the corresponding EXAFS R-space spectra suggests the occurrence of deconstructive attenuation phenomena that take place when various elements are present at similar bonding distances (in our case, likely, Pt-O-Ce, Pt-O-Pt and Pt-Pt). Unfortunately, given limitations of the EXAFS fitting process, it is not possible to quantify with statistical significance the extent of these contributions26.

a–c Light-off conversion vs temperature plots for Pt/CeO2-HS (a), 3.5%Pt/CeO2-HS (b) and Pt/CeO2-Derived (c) samples after aerobic calcination (full symbols), CO activation at 300 oC (empty symbols), and after two consecutive light-off cycles up to 500 oC (semi-full symbols) in the CO oxidation reaction. d Conversion vs time-on-stream plots for Pt/CeO2-Derived (blue), Pt/CeO2-LS (gray) and Pt/CeO2-HS (orange) in isothermal CO oxidation experiments at 120 °C. e, f In-situ CO-DRIFT spectra of CO-treated Pt/CeO2-HS (e) and Pt/CeO2-Derived (f) measured at 120 °C under O2-rich CO oxidation conditions; evolution from dark color to light color. Reaction conditions: 1.2% CO, 9.7% O2, 25 ml/min, normalized Pt content and WHSV = 5000 L/gPt·h.

When the CO-treated Pt/CeO2-HS sample was further reacted with O2 and CO at a moderate-to-high temperature, in an excess of O2, severe catalyst deactivation was observed, as previously reported16. The deactivation manifests both in back-to-back light-off curve experiments, as a shift towards higher temperatures of the whole conversion vs temperature curve (Fig. 2a, half full symbol), and also through isothermal reactions, which directly show the decay of conversion with the time-on-stream (Fig. 2d). At 120 °C and a O2/CO ratio of 8 in the feed, for example, the conversion drops from 93 to 18% in 18 h using this reference material18,19,20. Aging at temperatures in the range 300 to 500 °C causes the sample to deactivate in 2 h to activity levels close to those observed before the CO-treatment (Figs. 2a and S4a, respectively). X-Ray Absorption Spectroscopy (XAS), XPS, and STEM analyses confirm a reversible transformation of partially reduced nanoparticles into PtOx and atomically dispersed Pt species after their exposure to O2-rich O2/CO conditions at 500 oC (Fig. 1b–d, g), consistent with the occurrence of re-oxidation followed by oxidative fragmentation, as illustrated in Fig. 1a18,19,20.

In a previous communication, we tackled the acute deactivation of Pt/CeO2 catalysts by using all silica K-MFI zeolite as a non-reducible support, to yield small, metallic Pt clusters that remained stable under CO oxidation conditions, even if the O2/CO ratio was high27. However, we also noted that while the steady-state activity of this catalyst was high relative to that of typical calcined Pt/CeO2 samples, the initial activity of the reduced Pt/CeO2 catalysts was still notably superior (~100 times superior), thanks to the effective participation of the support in the reaction27.

In an attempt to overcome the activity/stability tradeoff observed with Pt/CeO2 and Pt/zeolite systems (i.e., reducible vs non-reducible supports), we started to investigate CeO2 supports with lower surface areas, based on the general consensus that single metal atoms bind more strongly to supports with high surface areas (i.e., high oxygen or Ce defectivity)2,25,28. Consistent with this hypothesis, Pt nanoparticles supported on a lower surface area CeO2 (Pt/CeO2-LS hereafter; Supplementary Table 1 and Supplementary Fig. 5), formed in CO at 300 °C, appeared to maintain CO oxidation activity better than the CO-treated high-surface CeO2 sample, under identical reaction conditions (Fig. 2d). Unfortunately, the deactivation rate of Pt/CeO2-LS was still significant at moderate temperatures (120 °C), causing the CO conversion to drop from 100 to 35% in 18 h (Fig. 2d), whereas the activity loss was complete at 500 °C (Supplementary Fig. 6).

Finally, we investigated the performance of Pt/CeO2 catalysts at high Pt loadings, based on the realization that ceria atom-trapping capacity is then typically exceeded29,30. Thus, we tested a catalyst prepared with a large excess of Pt (i.e. 3.5 wt%) on CeO2-HS and observed that its stability certainly improves, as the T50 of the catalyst treated in CO at 300 °C increases more moderately after being aged in CO and O2 at 300 and 500 °C, relative to the aged low Pt loading analog (half-filled symbols in Fig. 2a, b, and Supplementary Fig. 4a, c), and the TOF becomes 10-to-15-times higher (Supplementary Tables 4 and 5). However, the initial TOF of the CO-activated 3.5 wt% Pt sample is seriously compromised relative to that of the 0.5 wt% Pt/CeO2-HS analog under identical reaction conditions (i.e., 0.014 s−1 vs 0.099 s−1 at 80 °C).

These results evidence that the oxidative deactivation is a rather general problem of CeO2-supported Pt catalysts for the CO oxidation reaction, which made us seek alternative solutions.

Highly active, highly stable Pt/CeO2 catalysts

Recently, we reported a Pt-containing MOF sample that comprises single Pt atoms bonded to CeOx nodes, whose CO oxidation activity is higher compared to single Pt atoms on conventional CeO231. The applicability of this material is limited to mild reaction conditions (i.e., 60–80 °C), because the MOF structure starts to collapse at moderate temperatures when O2 is present31. At high temperatures in air (∼450 °C), the MOF organic linkers decompose, primarily, as CO2 and water, generating CeO2 crystals with a cubic fluorite structure (see PXRD patterns and HAADF-STEM images in Supplementary Fig. 7)32 that are decorated with Pt species. This material (Pt/CeO2-Derived, hereinafter) offers a surface area comparable to that of the Pt/CeO2-LS (∼40 m2/g, see Supplementary Table 1). However, the morphology is drastically different, as the Pt/CeO2-Derived material presents aggregates of relatively small CeO2 grains (FESEM, TEM and STEM images in Supplementary Fig. 7), whereas the Pt/CeO2-LS material consists of well-defined crystals between 10 and 40 nm (Supplementary Fig. 5). The calcined Pt/CeO2-Derived sample comprises a mixture of oxidized PtOx species (i.e., single atoms and small clusters) and metallic Pt NPs when calcined in air at 450 °C, attending to the following observations: a) the presence of a clear signal centered at 2072 cm−1, typical of metallic Pt, in the DRIFT spectrum of CO-adsorbed at RT, in addition to an intense band centered at 2093 cm−1, assigned to CO bonded to partially oxidized Pt sites (Supplementary Fig. 8)23,33; b) the intensity of the Pt L3-edge XANES white-line, still high compared to a Pt foil reference, but less intense than that of Pt/CeO2-HS, denoting, thus, less oxidized Pt species, on average (see Calcined in Fig. 3b); c) the average Pt-O coordination number determined from the FT-EXAFS data, which is also lower compared to that of the calcined Pt/CeO2-HS sample (4.8 vs 6) (Fig. 3c, Supplementary Fig. 3 and Supplementary Table 2) —the absence of clear long-distant backscattering signals in the corresponding EXAFS R-space spectra suggests the occurrence of deconstructive attenuation phenomena that can take place when various elements are present at similar bonding distances (in our case, likely, Pt-O-Ce, Pt-O-Pt and Pt-Pt); given limitations of the EXAFS fitting process, it is not possible to quantify with statistical significance the extent of these contributions— d) the presence of ~ 8 % Pt0, according to XPS (Fig. 3d); and e) the co-existence of single atoms, small clusters and 2–5 nm metal nanoparticles (the last two are most predominant) in the corresponding HAADF-STEM images (Fig. 3e and Supplementary Fig. 9). The d-spacing observed in some of these Pt nanoparticles is, moreover, ∼2.33 Å (Supplementary Fig. 10A), which directly evidences the presence of metallic Pt.

a Schematic illustration of the dynamic behavior of Pt/CeO2-Derived sample after various thermal treatments (red, oxygen; yellow, cerium; gray, metallic Pt; blue, cationic Pt) b, c Pt L3-edge XANES, and the corresponding magnitude of the k2-weighted FT-EXAFS spectra, respectively, after calcination in O2 at 450 °C, reduction in CO at 300 °C, and reaction with a 8:1 O2/CO mixture at 500 °C (sequential treatments); for comparison purposes, XAS spectra of PtO2 and a Pt foil are also provided d Pt 4 f XPS spectra of the same samples. e–g The corresponding HAADF-STEM images.

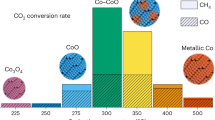

When tested in the CO-oxidation reaction, the calcined Pt/CeO2-Derived sample showed more active than the calcined Pt/CeO2-HS, Pt/CeO2-LS and 3.5%Pt/CeO2-HS counterparts (Fig. 2), corresponding to TOFs of 0.010 s−1, 0.0056 s−1, 0.0014 s−1 and 0.0009 s−1, respectively, at 150 °C (Supplementary Table 3). We attribute the superior activity of the Pt/CeO2-Derived sample to the presence of a non-negligible amount of metallic Pt resilient to (deactivating) oxidation after calcination. These metallic species are intriguing and were consequently subjected to further investigation.

To explore the potential stability advantage of the Pt/CeO2-Derived sample, we treated the sample in CO at 300 °C16, as previously done with the Pt/CeO2-HS and Pt/CeO2-LS catalysts, to promote the formation of new metallic Pt species. Evidences of the change in the Pt speciation after this treatment are summarized in Fig. 3 and Supplementary Table 2, and include: a) a decrease of the components at higher wavenumbers in the DRIFT spectrum of CO adsorbed at RT (i.e., > 2080 cm−1) (Supplementary Fig. 8), assigned to oxidized Pt species23; b) decreased white-line and Pt-O contributions in XANES and EXAFS spectra, respectively; c) increased Pt0 signals, from 8 to 67%, as inferred by XPS; and d) the appearance of more Pt nanoparticles with distinct 2.33 Å d-spacing in the HAADF-STEM images (Supplementary Fig. 10B). As expected, these changes in the Pt speciation induced a drastic increase in the CO oxidation activity ( ~ 128 times), corresponding to a change in TOF from ~0.003 s−1 with the calcined analog to ~0.385 s−1, at 120 °C (Supplementary Table 3, and Supplementary Fig. 11).

A critical difference between the Pt/CeO2-Derived sample and the rest of the Pt/CeO2 samples tested here, and those from the literature2,16,34,35,36, is that following the CO activation, the MOF-Derived material held most of its activity in O2-rich CO/O2 mixtures, even if the reaction temperature was high. For example, whereas complete oxidative deactivation was observed with the Pt/CeO2-HS and Pt/CeO2-LS samples at 300 °C and 500 °C in O2-rich reaction conditions (Figs. 2a, 4a and Supplementary Fig. 4), and early symptoms of deactivation were observed with these samples at temperatures as low as 120 °C (Fig. 2d), the new sample showed able to operate at 100 % conversion for more than 16 h at 120 °C, using the same WHSV. Accordingly, the T50 of the aged sample decreased significantly less at higher temperatures (Figs. 2c, 4c and Supplementary Fig. 4). Even after repeated exposure to O2-aged streams at 300 °C and 500 °C, the catalyst only deactivated partially, under conditions where conventional materials deactivate completely, resulting in activities that are ~157 times greater than those by the deactivated Pt/CeO2-HS (Supplementary Fig. 12 and Supplementary Table 3). Retention of activity over time, in excess of O2, occurred upon retention of multiple spectroscopic and microscopic features of the unreacted CO-treated sample, including relatively low white-line and Pt-O signals in the XANES and EXAFS spectra, respectively, an intense Pt0 signal in the XPS spectra, and the presence of abundant metallic Pt nanoparticles in the HAADF-STEM images (Fig. 3b–d, g). Although the sample still shows symptoms of reoxidation in O2 at 500 °C according to all these techniques, the fact that the activity of the aged material is 3 times higher than most active catalysts in the literature demonstrates that a significant portion of highly active species remain stable even under these harsh reaction conditions (Fig. 4).

a–c Activity, measured as the temperature required to attain 50% CO conversion (T50) under a constant WHSV (on a per Pt basis) for various representative Pt/CeO2 catalysts as a function of their activation/reaction history (the X axis denotes the gas and temperature of the treatments, run in sequence from left to right). a shows the results for Pt/CeO2-HS and Pt/CeO2-LS; (b) for 3.5%Pt/CeO2; and (c) for Pt/CeO2-Derived. d CO oxidation activity at 80 °C, as a TOF (mol of CO converted per mol of Pt and second, calculated at conversions lower than 20 %), of the Pt/CeO2-Derived sample compared to other reference materials, after catalysts had been subjected to O2-rich reaction conditions in the range 200–400 °C25,36,50,51,52 (bottom graph) or 400–500 °C1,2,53 (top graph); number of top of bars denote the reference number; e Direct comparison of the initial TOF vs the aged TOF for catalysts depicted in (d); f Representation of the initial TOF vs the catalyst stability (aged TOF/initial TOF x 100) for catalysts aged in an O2-rich stream at 300 °C. In (e) and (f), solid gray circles denote cationic single Pt atoms on CeO2; pink circle denotes Pt0 nanoparticles in zeolites, red circle denotes Pt0 nanoparticles on CeO2 at high Pt loadings; orange and green circles denote mostly Pt0 nanoparticles on CeO2 at low Pt loadings (high surface area and lower surface area CeO2, respectively); and blue circle denotes mostly Pt0 nanoparticles on V-pocketed CeO2 (this work). The color-shaded areas cluster the different materials as per the activity/stability relationship in (f): Pt/zeolite (metallic nanoparticles) and Pt1/CeO2 (single Pt atoms) show at the top left corner, corresponding to low activity/high stability (yellow shade); common reduced Pt/CeO2 catalysts (low Pt loadings) show high activity/low stability (blue area); reduced, high Pt loading Pt/CeO2 samples show low activity/low stability (red shade); and the CO-activated Pt/CeO2-Derived sample in this work shows high activity/high stability (green shade).

The different deactivation behavior of Pt on the Pt/CeO2-Derived sample is also reflected in time-resolved DRIFT experiments collected after exposing the CO-treated Pt/CeO2 samples to a O2/CO steam at 120 °C, that is, as the catalysis was taking place. As discussed above, the starting CO-treated materials in these experiments contain mixtures of oxidized and reduced Pt species. Accordingly, right after exposure to O2 and CO, at short TOS, the DRIFT spectra of both Pt/CeO2-HS and Pt/CeO2-Derived samples show signals at > 2090 cm−1, assigned to oxidized Pt, and a band centered at 2072 cm−1, assigned to metallic Pt (Fig. 2e). However, whereas the ~2111 and ~2103 cm−1 bands increase in the Pt/CeO2-HS sample as time progresses, with a concomitant decrease in the <2090 cm−1 contributions, as rapid deactivation occurs, the ratio between reduced and oxidized Pt species remains nearly constant in the Pt/CeO2-Derived material over the same period of time, as the activity decays very slowly (Fig. 2f). The overall intensity of CO signals increases during these experiments as the concentration of CO in the gas phase increases, due to decreasing CO conversion over time.

As a result of the high stability of metallic Pt species in this new Pt/CeO2-Derived sample, we achieve the highest TOFs ever reported for Pt/CeO2 catalysts under relevant reaction conditions. Figure 4c compares the TOF of various state-of-the-art Pt/CeO2 catalysts after exposure to O2 or O2-rich CO streams at moderate temperatures. Figure 4d represents the same data as the initial TOF vs the aged TOF, and Fig. 4e plots initial TOFs and the stability of various catalysts after treatment in a O2-rich stream at 300 °C (the stability is defined as the “aged TOF/initial TOF × 100”). In all cases, it can be concluded that the new catalyst breaks the general activity/stability tradeoff reported on common supported Pt catalysts, by which redox active supports that most effectively promote cooperative mechanisms at the metal/support interface also promote most rapidly undesired re-oxidation of the metal into less active sites (Fig. 4). It must be noted that some catalysts in the literature show extraordinary CO oxidation activity at low temperature. Unfortunately, these catalysts already show symptoms of fast deactivation under mild reaction conditions37.

Nature of the active site and mechanistic considerations

The results throughout this investigation support the idea that Pt catalysts that include a metallic component are, in general, more active than single Pt atoms for the CO oxidation reaction, as sustained by others11,13,16, and are also more active than fully oxidized Pt clusters11,15. For this reason, Pt/CeO2 materials typically see their activity boosted when exposed to reducing gases prior to the reaction step, and lose activity if later exposed to O2 (or O2-rich CO streams) at moderate-to-high temperatures, as the metal re-oxidizes.

A key differentiating characteristic of the Pt/CeO2-derived sample presented here is that a non-negligible fraction of the Pt appears reduced, in the form of small metallic nanoparticles, upon calcination in O2 at temperatures as high as 500 °C, prior to any reducing treatment. Moreover, and in contrast to most CeO2-based catalysts, the most abundant species are at this point PtOx nanoparticles, rather than single Pt atoms. Subsequent treatment of the catalyst with CO at 300 °C causes the formation of new Pt0 species, thus boosting the catalytic activity, which shows striking resilience to re-oxidation compared to other Pt/CeO2 alternatives and overcomes, thus, severe deactivating issues reported in the recent literature16.

Despite these observations, the correlation between the catalyst structure and the CO oxidation performance is rather complex, and the number of Pt0 sites on the surface of the Pt nanoparticles appears to be an insufficient activity descriptor13. This is evidenced, for example, by the relatively low activity of small metallic Pt nanoparticles on supports of a non-reducible nature, such as Al2O3 or SiO2, which are several orders of magnitude less active than best (reduced) Pt/CeO2 catalysts6,16. Accordingly, Cargnello et al. were able to correlate the CO oxidation activity of a series of Pt/CeO2 catalysts with the number of Pt atoms at the metal/support periphery (test were done under co-rich reaction conditions, to prevent deactivating oxidative phenomena), using Pt nanoparticles of precisely controlled sizes6, based on a reverse spillover mechanism of lattice oxygen from the support that denotes cooperativity13 between these two catalysts components, reminiscent of previous Au/CeO2 work4. In agreement with these postulates, Christopher’s group showed tunable catalytic activity of Pt as a function of the oxygen-vacancy formation energy at the metal/support boundary of various reducible supports38, in catalysts where the metal nuclearity was limited to 1 (i.e., single Pt atoms) to avoid the interference of particle size effects. Because the Mars-van-Krevelen O2 activation by CeO2 appears to be promoted by the presence of water, the CO oxidation activity of Pt/CeO2 is usually boosted under wet reaction conditions39, or when the reductive treatment to activate the catalyst is carried under H2 instead of CO, as the former introduces the possibility to incorporate surface hydroxyls onto the ceria surface37.

Moreover, some authors suggest that most active CO oxidation Pt/CeO2 catalysts include a PtOx interface between the support and the metallic part of the Pt nanoparticles, in partially reduced systems, that facilitates the catalysis37. We indeed identify both oxidized and metallic Pt species in highly active CO oxidation catalysts, but lack precise, statistically meaningful local information to determine whether those two types of sites are actually in close contact, or segregated, for example, as a function of the Pt particle size. In this regard, we must note that literature also reports highly active CO-oxidation Pt/CeO2 catalysts that appear to contain exclusively metallic Pt species (as measured by EXAFS, within the error of the technique)40.

On the other hand, although the CO oxidation activity of reduced Pt catalysts correlates with the number of metal/support boundary sites when the support is redox active6, it has been observed that the activity of Pt clusters also decays on non-reducible supports when the cluster size drops below ~1 nm27, which implies that the correlation between the cluster size (determining the extent of the metal/support interface) and the activity is not straightforward either. Indeed, the CO oxidation activity of Pt can be promoted via electron-transfer from the support to the metal, for example, using K-doped zeolites, which helps to bind the CO more weakly to facilitate O2 activation and, thus, the catalysis in these types of systems18.

Figure 5 summarizes most influential structural of supported Pt species for the CO oxidation reaction, and includes information on the magnitude of each effect based on experiments in our labs, unless stated otherwise, using thoroughly characterized samples.

a The activity of clusters below ~1 nm has been reported about 5-times lower than that of clusters slightly larger than 1 nm, using non-reducible supports27. b The use of electron-donating ligands (e.g. zeolites doped with K) to support electron-rich Pt clusters has been reported to boost the activity of Pt by a factor of ~327,54. c The activity of single Pt atoms is, typically, found at least ∼1800 times lower than that of Pt clusters16, consistent with the results presented in this investigation; although the nuclearity effect is believed more notorious on non-reducible supports that lack redox activity, the number of examples where single Pt atoms are successfully stabilized on this type of supports, in the presence of CO and O2 at moderate temperatures, is extremely limited. d PtOx nanoparticles are at least ∼100 times less active than catalysts containing Pt0 species, as demonstrated in the present investigation; PtOx particles, rather than single atoms, are more prominent species on redox active supports when the Pt/defect stoichiometry is greater than 1 (when the number of metal atoms exceeds the number of support sites with atom-trapping characteristics)55; Pt0 is, in contrast, the preferred form of the metal on non-reducible supports, even in samples treated in O2 at high temperatures, due to Ostwald-ripening sintering18. e The activity of Pt can be increased by up to a factor of ~120 by invoking supports with redox activity, in catalysis that happens at the metal/support interface (Mars-van-Krevelen activation of the O2 followed by reverse spillover to the Pt, where CO is reacted)4,6,13,38. f On reducible supports (i.e., redox active), the activity of Pt linearly correlates with the number of periphery metal/support sites, which increases with decreasing particle size6. Although some of these effects influence the behavior of Pt on both reducible and non-reducible supports, this figure illustrates where one particular effect is most noticeable. “<” is used to indicate moderately lower activity of the species drawn to the left of the symbol. “<<” is used to indicate significantly lower activity of the species drawn to the left of the symbol. See data reported in Supplementary Table 6. Black: metallic Pt, blue: ionic Pt, gray: non-reducible support, pink: NRS and RS, red: oxygen, yellow: cerium.

With regards to the catalyst stability, Fig. 4 shows that the deactivation is the highest when the activity is also the highest using literature Pt/CeO2 references. Since the deactivation is attributed to the formation of single Pt atoms or PtOx clusters, we simply infer that both processes, the CO oxidation reaction and the Pt re-oxidation, speed up in the presence of a highly active redox support. This activity/stability tradeoff is schematically captured in Fig. 6, where key elemental steps are outlined. Following Fig. 6 rationale, to overcome the inverse relationship between activity and stability, the ratio between r4 (the rate of reaction between CO and O* at the metal/support interface) to r2 and r3 (the rates at which a metallic Pt particle oxidizes into PtOx and single Pt cations, respectively) must be increased. We stress that non-reducible supports do not stabilize Pt cations or oxidized Pt clusters that are treated in O2 at moderate-to-high temperatures, with a few notable exceptions18,19, but form, instead, metallic Pt nanoparticles. Although the CO oxidation activity of this species has been recently enhanced by precise control of the cluster size and electronics27, without compromising the stability (Fig. 4e, far-right point of the Pt/zeolites and Pt1/CeO2 series), it still ranks low compared to the best Pt/CeO2 catalysts.

To understand why the Pt/CeO2-Derived sample attains both high CO oxidation activity and high stability in O2-rich CO streams, we analyzed the HAADF-STEM images of several catalysts in more detail and used Density Functional Theory to provide additional insights. HAADF-STEM images revealed that Pt nanoparticles in the CO-treated (i.e., highly active/highly stable) Pt/CeO2-derived sample are preferentially positioned at V-shaped pockets and stepped sites of the CeO2 crystals, offering, thus, increased periphery sites in contact with the support (Fig. 7a, b). The abundance of Pt at these crystallographic positions is high in the Pt/CeO2-Derived samples (Fig. 7a), but scarce in the rest of the materials (Fig. 7c and Supplementary Fig. 14). These V-pockets are already present in the calcined Pt/CeO2-Derived material, but the oxidized Pt clusters that exist at this point in the sample (see Fig. 3) are not located there (Supplementary Fig. 15). This result strongly suggests that the formation of oxidized Pt clusters at the V-pockets is somehow disfavored. We infer, thus, that the V-pockets result from the direct collapse of the parent Pt@MOF structure during the calcination process (Supplementary Fig. 7e), and that the CO-treatment is necessary to a) reduce the metal (Fig. 3), and b) mobilize it onto the V-sites. Moreover, the HAADF-STEM images show that the metallic clusters at the V-pockets are highly disordered, probably as a result of the strain caused by the interaction with two CeO2 surface at different angles. Some areas, however, show atomic resolution of Pt atoms separated by a projected HAADF-STEM distance of ~ 2.3 Å (Figs. 7a, b), typical of metallic [110] ensembles. As a reference, the closest projected distance for PtO2 would be 2.7 Å when projected along the [010] direction.

HAADF-STEM images of the spent CO-treated Pt/CeO2-Derived sample (i.e. after reaction), demonstrate that the Pt nanoparticles located within the V-shape structures remain trapped there after catalysis (Fig. 7b), whereas Pt nanoparticles on the other CeO2 supports re-disperse, to a large extent (Fig. 7d). After reaction, we find that Pt at the V-pockets in the Pt/CeO2-Derived sample continues to be highly disordered (Supplementary Fig. 16), showing certain areas where a projected Pt-Pt distances of, still, ~2.2 Å can be measured, demonstrating the resilience of metallic Pt species to re-oxidize when trapped at the V-sites.

On the other hand, if the MOF is calcined in the absence of Pt, a different CeO2 morphology, predominantly mesoporous, and with low abundancy of V-pockets, is obtained (Supplementary Figs. 17, 18 and Supplementary Table 1). When Pt is incorporated onto this type of CeO2, and the sample is subsequently reduced in CO at 300 °C, the resulting material deactivates fast under CO oxidation conditions at moderate temperatures (Supplementary Fig. 13), as we had observed with the Pt/CeO2-HS and Pt/CeO2-LS samples.

Putting the performance and characterization data together, we conclude that V and stepped sites of CeO2 derived from a Pt@MOF parent are key for the stabilization of highly active, highly stable Pt nanoparticles, and help to slow down a re-oxidation process that otherwise readily takes place on flat CeO2 surfaces, in the presence of O2 at moderate-to-high temperatures.

Collecting further experimental evidences to understand the exact mechanism by which Pt0 re-oxidation virtually stops at these V-pockets positions is challenging and, at this point, we decided to run a detailed DFT study to compute relevant properties of the Pt clusters as a function of the nature of the support. Taking into account that all Pt/CeO2 catalysts reported in the literature, regardless of differences in the surface area, density of surface defects (or the ratio between Pt atoms and number of surface defects), and other structural variables, as confirmed in this investigation, undergo acute deactivation once metallic Pt nanoparticles are exposed to O2 at moderate-to-high temperature, we limited our DFT work to only a couple of representative CeO2 terminations (CeO2(111) and CeO2(110) surfaces), and contrasted them to metallic Pt10 clusters modeled within the V-sites (Supplementary Fig. 19)41, which show a distinct deactivation-resistance.

The most stable isomer of Pt10 supported on CeO2(111) is a symmetric bilayer exposing {111} and {100} nanofacets (see Fig. 8a and Supplementary Fig. 19), while the multiple interactions of Pt10 with O atoms at both sides of the V-pocket in the CeO2-V model leads to a disordered Pt10 cluster more strongly bonded to the support (Eint values are −6.946 eV for CeO2(111) and −8.891 eV for CeO2-V, see Supplementary Table 7). The metal-support charge transfer in these two systems is similar, with the Pt10 cluster becoming positively charged by ~0.7 e, and two Ce4+ cations undergoing reduction to Ce3+ (see Supplementary Table 7). Pt10 supported on CeO2(110) represents an intermediate situation in terms of stability (Eint of −7.527 eV for the 3 L isomer), but the metal-support charge transfer is less, only one Ce4+ is reduced to Ce3+, and the net charge on the Pt10 cluster is <0.1 e (Supplementary Table 7).

a Optimized geometries of Pt10 clusters supported on CeO2(111), CeO2(110) and CeO2-V models. b, c optimized geometries of reactant (R), transition state (TS) and product (P) for O2 dissociation on (b) Pt10/CeO2(111) and (c) Pt10/CeO2-V models. The corresponding energy profiles are shown in (d), where solid circles correspond to O2 adsorbed on top of the cluster and open circles indicate a bridge mode of adsorption. e Calculated energy of interaction between Pt10/CeO2 and O2 to form partly oxidized Pt10Ox/CeO2 systems as a function of the number of O atoms x, and optimized geometries of partly oxidized Pt10O10/CeO2(111) and Pt10O10/CeO2-V systems. Ce, O and Pt atoms in the catalyst are depicted as gray, red and blue balls, and adsorbed O atoms are depicted as orange balls. The Ce4+ cations that are reduced to Ce3+ are highlighted in yellow.

Next, we studied the adsorption of molecular O2 at different positions on each Pt10/CeO2 model (see optimized geometries of all systems in Supplementary Fig. 20 and interaction energies and relevant charge transfer properties in Supplementary Table 8). Interestingly, the most stable mode of adsorption of O2 on each Pt10c/CeO2 model is different, as it is the strength of the interaction. The largest Eint value is obtained for O2 adsorbed at the metal-support interface on Pt10/CeO2(110) model (−1.892 eV), followed by O2 in a bridge mode on Pt10/CeO2(111) model (−1.786 eV). In contrast, the most stable mode of adsorption of O2 on Pt10/CeO2-V model is on top of the cluster, with the two O atoms bonded to the same low coordinated Pt atom (−1.745 eV) closely followed by O2 in a bridge mode (−1.716 eV). In all cases, a net transfer of electron density from the catalyst to O2 of ~−0.75e on average occurs, increasing the net positive charge on Pt10 to ~1.4e. However, no clear correlation exists between mode of adsorption, strength of interaction, and charge transfer between adsorbate and catalyst.

Then, we calculated the transition state for O2 dissociation and the product of the reaction for the most stable O2 adsorption complexes (those with Eint < −1.5 eV), with the only exception of O2 adsorbed at the metal-support interface in Pt10/CeO2(110) for which no TS structure was found. In the six successful cases, the O-O bond length increases from ~1.44 Å in adsorbed O2 to ~1.78 Å in the TS (see Fig. 8b, c, Supplementary Fig. 21 and Supplementary Table 9), and after dissociation the two O atoms remain adsorbed on Pt10 at distances >3.7 Å. The process is thermodynamically favored in all cases by 1–2 eV, and the positive charge on the Pt10 clusters increases up to values larger than 2e due to charge transfer to the adsorbed O atoms (see Table S9). Regarding the kinetics of the process, the calculated activation energies (Ea) are extremely low on top, side and bridge adsorption sites of Pt10/CeO2(111) (0.076, 0.085 and 0.128 eV, Table S10) and Pt10/CeO2(110) (0.071 eV). In contrast, the activation energy for dissociating O2 on top of Pt10/CeO2-V is as high as 1.0 eV, and the most favorable pathway starting from O2 on a bridge site still requires 0.281 eV (Supplementary Table 10 and Fig. 8d). The lowest activation energy on Pt10/CeO2-V is therefore four times higher than on Pt10/CeO2(111) and Pt10/CeO2(110). Moreover, the successive dissociation of multiple O2 molecules leading to partly oxidized Pt10Ox/CeO2(111) is energetically favored in comparison with the analogous process to form a hypothetical Pt10Ox/CeO2-V structure (Fig. 8e and Supplementary Table 11).

In summary, our DFT calculations suggest that metallic Pt clusters located at the V-pockets of the Pt/CeO2-derived sample may result in particularly strong metal support/interactions and highly disordered metal assembles that a) tend to dissociate O2 more slowly relative to clusters supported on flat CeO2 surfaces, and b) require more energy to become partially oxidized. These observations are consistent with the experimental observation that oxidic Pt migrates from flat CeO2 terminations to the V-pockets upon reduction in CO, where it remains stable even in the presence of O2 at high temperature. In this context, we postulate an inhibition of r2 in Fig. 6 to account for the observed stability enhancement relative to Pt clusters on common CeO2 supports, without overruling the cooperative reaction mechanism at the Pt/support interface that is needed to attain high catalytic activity (i.e., high r4 in Fig. 6).

Consistent with previous literature, we show that the CO oxidation activity by Pt strongly depends on the nuclearity and oxidation state of the metal, and the redox activity of the support. Although the cooperation between metallic Pt nanoparticles and CeO2 at the metal/support interface facilitates high activity, the migration of oxygen species from the support to the metal is a hard-to-avoid challenge when the temperature is high and O2 is used in excess, which causes severe catalyst deactivation upon re-oxidation of the supported metal. To shut down this deactivation mechanism, non-reducible supports can be used, but the resulting (stable) metallic Pt nanoparticles are only moderately active, since the support cannot participate in the catalysis (the metal/support synergistic effect is lost). In this contribution, we have developed a synthesis method to position metallic Pt clusters within V-pockets of a CeO2 surface. These particles, making contact with the support through two planes at different angles, appear to remain largely reduced in O2 at high temperatures and are, thus, both high active and highly stable under practical CO oxidation conditions. Evidence of the catalytic structures and correlations with their performance is provided by CO-DRIFT, XAS, XPS spectroscopies, as well as HAADF-STEM analyses, using a number of different benchmark catalysts and activation treatments to influence the nature of the active sites. This result breaks a common activity/stability trade-off in CO oxidation catalysis, by which most active catalysts also deactivate faster, and vice versa. The investigation gives novel and relevant fundamental information to rationalize the design of highly stable metallic clusters on reducible supports, to operate most effectively under harsh industrial conditions.

Methods

Synthesis of Pt/CeO2-derived

Synthesis of UiO-66(Ce)

This synthesis has been carried out following a previously reported recipe42. H2BDC (1,4-benzenedicarboxylic acid) (3.82 g, 23 mmol) and DMF (121 mL) were placed in a round-bottomed flask. Then, an aqueous solution of cerium ammonium nitrate (43 g, 0.53 M) was added to the mixture. The flask with the resulting solution was sealed and heated under magnetic stirring for 15 min at 100 °C. The as-obtained yellow precipitate was decanted by centrifugation from the mother solution and was washed 3 times with DMF and 3 times with acetone. Preparation of the supported Pt/UiO-66(Ce). The single-atom Pt catalyst deposited on UiO-66(Ce) was prepared by basic wet impregnation, using sodium bicarbonate as a basic component. Firstly, 20.0 mg of Pt(NH3)4(NO3)2 and 100 mg of NaHCO3 were dissolved in 20 mL of deionized water, resulting in a basic solution (pH~8.3). Then, 1.0 g of UiO-66(Ce) was added to the resultant mixture and stirred at room temperature for 14 h. The obtained solid, denoted as Pt/UiO-66(Ce), was filtered and washed with deionized water and acetone. Preparation of the final Pt/CeO2-derived. The as-synthesized Pt/UiO-66(Ce) was calcined at 450 °C (5 °C/min) for 4 h in flowing air to obtain the resulting derived-MOF material with 0.46 wt% Pt.

Activity measurements

In a typical experiment, 60 mg of the pelletized catalyst (pellets: ∼0.2–0.4 mm) was added with 0.3 g of silicon carbide (Fisher Chemical, pellets: ∼0.6 mm) and loaded in a conventional tubular plug-flow reactor (ID = 9 nm). For the typical light-off tests, the catalyst bed was heated from 50 °C to 500 °C flowing the reaction mixture at atmospheric pressure: 25 mL/min, containing 1.2% CO, 9.7% O2, balanced with N2 (O2-rich conditions), with a weight hourly space velocity (WHSV) of 5000 L/gPt·h. For comparison, CO oxidation has been tested under higher WHSV conditions: 100 mL/min, containing 1.2% CO, 9.7% O2, balanced with N2 (O2-rich conditions) with a weight hourly space velocity (WHSV) of 20 000 L/gPt·h. The downstream reaction effluents were analyzed continuously by gas chromatography (GC8890, Agilent). At each temperature point, the reaction was maintained for 30 min after observing that the CO conversion remained unaltered. The CO conversion was calculated as follows:

Characterization

The PXRD measurements were carried out using the Bragg–Brentano geometry with a PANalytical PW3050/60 X’Pert PRO MPD diffractometer with a Cu anode (Kα = 1.5418 Å) and an X’Celerator detector. The morphology of the samples was studied by field emission scanning electron microscopy (FESEM) using a ZEISS Ultra-55 microscope. The sample was placed on carbon tape stuck on aluminum stubs. Scanning transmission electron microscopy (STEM) was used to image the samples using high-angle annular dark-field (HAADF) conditions. The STEM images were acquired using a double aberration-corrected Themo Fisher Scientific Themis Z operated at an accelerating voltage of 300 kV. The samples were directly dispersed onto Lacey carbon TEM grids for STEM image acquisition. Isothermal N2 physisorption measurements at Liquid Nitrogen Temperature (LNT) were performed on a Micromeritics 3Flex. Prior to the measurement, the corresponding materials were degassed at 400 °C during 1 h. Specific surface areas using the Brunauer–Emmett–Teller model were extrapolated. ICP analyses were carried out in a Varian 715-ES ICP-Optical Emission spectrometer after MOF dissolution in H2SO4/H2O2 aqueous solution. DRIFT experiments were conducted with a Bruker Invenio spectrophotometer equipped with a commercial repocell (PIKE TECHNOLOGIES, DIFFUSIR™). Background spectrum was collected in a N2 flow (20 mL/min) at 120 °C. Spectra were recorded with 60 kHz, and each one was the result of an average of 32 scans (ca. 60 s/scan). Measurements were performed under similar reaction conditions, followed in the catalytic tests. The measurement protocol consisted in two main steps: activation and reaction. During activation, the catalyst was heated up to 450 °C (5 °C/min) under air flow (20 mL/min) and it was kept during 30 min. Then, the sample was flushed with N2, and it was cooled down to RT. A single spectrum in CO at RT (pulse of 24 mL/min, containing 8.3% CO and 91.7% N2) was collected after N2 purging. For the CO treatment at high temperature, the sample was activated with CO diluted in N2 (30 mL/min, 2.7% CO) at 300 °C during 30 min. Then, the sample was flushed with N2 and it was first cooled down to RT to collect a single spectrum in CO and then heated up to 120 °C, the temperature at which the reaction was performed at atmospheric pressure (16.7 mL/min, containing 1.2% CO and 9.7% O2). During reaction, spectra were collected (every 1 min) and reported in Kubelka-Munk units. Difference spectra were reported using the spectrum of the activated sample recorded initially in an air flow (20 mL/min) at 120 °C. X-Ray Absorption Fine Structure (XAFS) spectra were recorded at BM23 beamline of the European Synchrotron Radiation Facility (ESRF) during beamtime IH-CH-176043. A double mirror with Si coating was employed for harmonic rejections. Spectra were recorded in fluorescence mode on 13 mm2 pellets with a Si DRIFT Vortex detector. The spectra were collected in continuous mode in the energy range 11250–12350 eV with 0.025 eV/point energy step and 0.1 s/point. Every reported spectrum resulted from the average of 20 scans. The spectra were energy calibrated using Pt metal foil, while energy alignment was conducted using glitches on incoming beam. Spectra calibration, energy alignment, background subtraction and normalization were conducted using Athena software from Demeter package44. Reported FT-EXAFS spectra were extracted in the 3–12 Å−1 k-range. The reported FT-EXAFS fits were performed with Artemis software from Demeter Package44. All the spectra k-space, and FT-EXAFS imaginary component are reported in Supplementary Fig. 22 for clarity. X-Ray Photoelectron Spectra (XPS) were measured using a SPECS spectrometer equipped with a 150 MCD-9 detector and a non-monochromatic MgKα (1253.6 eV) X-ray source. Samples were transferred to the XPS sample holder after the various treatments in the fix-bed reactors, in a N2 atmosphere. The reactor inlet and outlet were isolated from the air through two-way valves, and it was transferred into a glove-bag that had been purged a minimum of 10 times with N2 through vacuum-nitrogen cycles. The sample was loaded onto the XPS holder inside the glove bag, sealed, and transferred to the XPS without air exposure. Spectra were recorded with 30 eV analyzer pass, an X-ray power of 50 W and under an operating pressure of 10−9 mbar. During data processing of the XPS spectra, binding energy (BE) values were referenced to C 1 s peak (284.8 eV). Spectra treatment has been performed using the CasaXPS software, and fitting parameters are summarized in the Supplementary Table 9.

Computational details

Periodic Density Functional Theory (DFT) calculations were performed using the Perdew-Burke-Ernzerhof (PBE) exchange-correlation functional within the generalized gradient approach (GGA)45 as implemented in the VASP code46. The valence density was expanded in a plane wave basis set with a kinetic energy cutoff of 420 eV, and the effect of the core electrons in the valence density was taken into account by means of the projected augmented wave (PAW) formalism. To account for self-interaction errors (SIE) in f-electrons, a Hubbard U-type term was added to the 4 f states with a value of U = 4.5 eV)47,48. Integration in the reciprocal space was carried out at the Γ-point of the Brillouin zone. Electronic energies were converged to 10−6 eV and geometries were optimized until forces on atoms were less than 0.01 eV/Å for minima and 0.03 eV/Å fro transition states. All calculations are spin-polarized. Atomic charges were calculated using the NBO approach49.

The CeO2(111) and CeO2(110) surfaces were modeled by means of supercell slabs containing 64 Ce and 128 O atoms, with lattice parameters a = b = 15.485 Å and c = 35.014 Å for CeO2(111), and a = 15.485 Å, b = 10.949 Å and c = 33.549 Å for CeO2(110). The CeO2-V model contains 76 Ce and 152 O atoms with lattice parameters a = 15.267 Å, b = 10.796 Å and c = 33.549 Å. During geometry optimizations, the two bottom layers in CeO2(111) and CeO2(110) models and the three bottom layers in CeO2-V model were kept frozen, and all other atoms in the system were allowed to relax without restrictions.

The interaction energies between Pt10 clusters of diverse morphology and the CeO2 surfaces were calculated as:

Where E(Pt10/CeO2) is the total energy of the supported cluster, E(CeO2) is the total energy of the clean CeO2 surface, and E(Pt10) is the total energy of the isolated Pt10 particle.

The interaction energies between the supported Pt10/CeO2 systems and O2 to form partly oxidized PtOx particles were calculated as:

Where E(Pt10Ox/CeO2) is the total energy of the partly oxidized supported PtOx cluster, E(Pt10/CeO2) is the total energy of the metallic supported cluster, and E(O2) is the total energy of the isolated O2 molecule. Activation energies for O2 dissociation were calculated as the difference in energy between the transition state and the related minimum corresponding to adsorbed O2.

Change history

06 October 2025

In this article the funding from 'Universitat Politècnica de València' was omitted. The original article has been corrected.

References

Nie, L. et al. Activation of Surface lattice oxygen in single-atom Pt/CeO2 for low-temperature CO oxidation. Science (1979) 358, 1419–1423 (2017).

Maurer, F. et al. Tracking the formation, fate and consequence for catalytic activity of pt single sites on CeO2. Nat. Catal. 3, 824–833 (2020).

Xie, S. et al. Pt atomic single-layer catalyst embedded in defect-enriched ceria for efficient CO oxidation. J. Am. Chem. Soc. 144, 21255–21266 (2022).

Carrettin, S., Concepción, P., Corma, A., López Nieto, J. M. & Puntes, V. F. Nanocrystalline CeO2 increases the activity of Au for CO oxidation by two orders of magnitude. Angew. Chem. Int. Ed. 43, 2538–2540 (2004).

Wang, H., et al. Surpassing the single-atom catalytic activity limit through paired Pt-O-Pt ensemble built from isolated Pt1 atoms. Nat. Commun. 10, 3808 (2019).

Cargnello, M. et al. Control of metal nanocrystal size reveals metal-support interface role for ceria catalysts. Science (1979) 341, 771–773 (2013).

Liu, L. & Corma, A. Metal catalysts for heterogeneous catalysis: from single atoms to nanoclusters and nanoparticles. Chem. Rev. 118, 4981–5079 (2018).

An, K. et al. Enhanced CO oxidation rates at the interface of mesoporous oxides and Pt nanoparticles. J. Am. Chem. Soc. 135, 16689–16696 (2013).

Liu, K., Wang, A. & Zhang, T. Recent advances in preferential oxidation of CO reaction over platinum group metal catalysts. ACS Catal. 2, 1165–1178 (2012).

Tan, W. et al. Fine-tuned local coordination environment of Pt single atoms on ceria controls catalytic reactivity. Nat. Commun. 13, 7070 (2022).

Ding, K. et al. Identification of active sites in CO oxidation and water-gas shift over supported Pt catalysts. Science (1979) 350, 189–192 (2015).

Gatla, S. et al. Room-temperature CO oxidation catalyst: low-temperature metal–support interaction between platinum nanoparticles and nanosized ceria. ACS Catal. 6, 6151–6155 (2016).

Serna, P. Cooperativity between atoms in supported “Single-Atom Catalysts” and metal clusters. Chem. Eng. J. 496, 153840 (2024).

Carrettin, S., Guzman, J. & Corma, A. Supported gold catalyzes the homocoupling of phenylboronic acid with high conversion and selectivity. Angew. Chem. Int. Ed. 44, 2242–2245 (2005).

DeRita, L. et al. Structural evolution of atomically dispersed Pt catalysts dictates reactivity. Nat. Mater. 18, 746–751 (2019).

Zhang, Z. et al. Memory-dictated dynamics of single-atom Pt on CeO2 for CO oxidation. Nat. Commun. 14, 2664 (2023).

Qiao, B. et al. Single-atom catalysis of CO oxidation using Pt1/FeOx. Nat. Chem. 3, 634–641 (2011).

Moliner, M. et al. Reversible transformation of pt nanoparticles into single atoms inside high-silica chabazite zeolite. J. Am. Chem. Soc. 138, 15743–15750 (2016).

Serna, P. et al. Single-site vs. cluster catalysis in high temperature oxidations. Angew. Chem. Int. Ed. 60, 15954–15962 (2021).

Goodman, E. D. et al. Catalyst deactivation via decomposition into single atoms and the role of metal loading. Nat. Catal. 2, 748–755 (2019).

Moliner, M., Gabay, J., Kliewer, C., Serna, P. & Corma, A. Trapping of metal atoms and metal clusters by chabazite under severe redox stress. ACS Catal. 8, 9520–9528 (2018).

Bohigues, B. et al. Highly stable subnanometric Pt clusters in all silica k-doped zeolites: implications for the CO oxidation reaction. ACS Catal. 15, 608–615 (2025).

Meunier, F. C. Relevance of IR spectroscopy of adsorbed CO for the characterization of heterogeneous catalysts containing isolated atoms. J. Phys. Chem. C. 125, 21810–21823 (2021).

Li, X. et al. Temperature and reaction environment influence the nature of platinum species supported on ceria. ACS Catal. 11, 13041–13049 (2021).

Li, X. et al. Functional CeOx nanoglues for robust atomically dispersed catalysts. Nature 611, 284–288 (2022).

Lytle, F. W., Sayers, D. E. & Stern, E. A. Report of the International Workshop on standards and criteria in x-ray absorption spectroscopy. Phys. B Condens Matter 158, 701–722 (1989).

Bohigues, B., et al. Highly Stable Subnanometric Pt Clusters in All Silica K-Doped Zeolites: Implications for the CO Oxidation Reaction. ACS Catalysis 15, 608–615 (2024).

Jones, J. et al. Thermally stable single-atom platinum-on-ceria catalysts via atom trapping. Science353, 150–154 (2016).

Resasco, J. et al. Uniformity is key in defining structure–function relationships for atomically dispersed metal catalysts: the case of Pt/CeO2. J. Am. Chem. Soc. 142, 169–184 (2020).

Kunwar, D. et al. Stabilizing high metal loadings of thermally stable platinum single atoms on an industrial catalyst support. ACS Catal. 9, 3978–3990 (2019).

Rojas-Buzo, S. et al. Synergic effect of isolated Ce3+ and Ptδ+ species in UiO-66(Ce) for Heterogeneous Catalysis. ACS Catal. 13, 9171–9180 (2023).

Rojas-Buzo, S. et al. CO2 to dimethylcarbonate synthesis: surface defects and oxygen vacancies engineering on MOF-derived CexZr1−xO2−y catalysts. Appl. Catal. B: Environ. Energy 346, 123723 (2024).

Groppo, E., Rojas-Buzo, S. & Bordiga, S. The role of in situ/operando IR spectroscopy in unraveling adsorbate-induced structural changes in heterogeneous catalysis. Chem. Rev. 123, 12135–12169 (2023).

Gänzler, A. M. et al. Tuning the structure of platinum particles on ceria in situ for enhancing the catalytic performance of exhaust gas catalysts. Angew. Chem. Int. Ed. 56, 13078–13082 (2017).

Liu, Z. et al. In-situ formed stable Pt nanoclusters on ceria-zirconia solid solutions induced by hydrothermal aging for efficient low-temperature CO oxidation. Chem. Eng. J. 498, 155427 (2024).

Jiang, D. et al. Tailoring the local environment of platinum in single-atom Pt1/CeO2 catalysts for robust low-temperature CO oxidation. Angew. Chem. Int. Ed. 60, 26054–26062 (2021).

Meunier, F. C. et al. Synergy between Metallic and oxidized pt sites unravelled during room temperature CO oxidation on Pt/Ceria. Angew. Chem. Int. Ed. 60, 3799–3805 (2021).

DeRita, L. et al. Catalyst architecture for stable single atom dispersion enables site-specific spectroscopic and reactivity measurements of CO adsorbed to Pt atoms, oxidized Pt clusters, and metallic Pt clusters on TiO 2. J. Am. Chem. Soc. 139, 14150–14165 (2017).

Wang, C. et al. Water-mediated mars–van krevelen mechanism for CO oxidation on ceria-supported single-atom Pt 1 catalyst. ACS Catal. 7, 887–891 (2017).

Kopelent, R. et al. Catalytically active and spectator Ce 3+ in ceria-supported metal catalysts. Angew. Chem. Int. Ed. 54, 8728–8731 (2015).

Yang, C., et al. Surface faceting and reconstruction of ceria nanoparticles. Angew. Chem. Int. Ed. 56, 375–379 (2017).

Lammert, M. et al. Cerium-based metal organic frameworks with UiO-66 architecture: synthesis, properties and redox catalytic activity. Chem. Commun. 51, 12578–12581 (2015).

Mathon, O. et al. The time-resolved and extreme conditions XAS (TEXAS) facility at the european synchrotron radiation facility: the general-purpose EXAFS bending-magnet beamline BM23. J. Synchrotron Radiat. 22, 1548–1554 (2015).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for x-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Dudarev, S. L., Botton, G. A., Savrasov, S. Y., Humphreys, C. J. & Sutton, A. P. Electron-energy-loss spectra and the structural stability of nickel oxide: an LSDA+U study. Phys. Rev. B 57, 1505–1509 (1998).

Lustemberg, P. G.; Yang, C.; Wang, Y.; Wöll, C.; Ganduglia-Pirovano, M. V. Vibrational frequencies of CO bound to all three low-index cerium oxide surfaces: a consistent theoretical description of vacancy-induced changes using density functional theory. J. Chem. Phys. https://doi.org/10.1063/5.0153745 (2023).

Reed, A. E., Weinstock, R. B. & Weinhold, F. Natural population analysis. J. Chem. Phys. 83, 735–746 (1985).

Fu, N. et al. Controllable conversion of platinum nanoparticles to single atoms in Pt/CeO2 by laser ablation for efficient CO oxidation. J. Am. Chem. Soc. 145, 9540–9547 (2023).

Guo, S., Zhao, Y., Wang, C., Jiang, H. & Cheng, G. J. A single-atomic noble metal enclosed defective MOF via cryogenic UV photoreduction for CO oxidation with ultrahigh efficiency and stability. ACS Appl Mater. Interfaces 12, 26068–26075 (2020).

Yang, X. et al. Large-pore mesoporous CeO2–ZrO2 solid solutions with in-pore confined Pt nanoparticles for enhanced CO oxidation. Small https://doi.org/10.1002/smll.201903058 (2019).

Pereira-Hernández, X. I. et al. Tuning Pt-CeO2 interactions by high-temperature vapor-phase synthesis for improved reducibility of lattice oxygen. Nat. Commun. 10, 1358 (2019).

Visser, T. et al. Promotion effects in the oxidation of CO over zeolite-supported Pt nanoparticles. J. Phys. Chem. B 109, 3822–3831 (2005).

Aitbekova, A., Wrasman, C. J., Riscoe, A. R., Kunz, L. Y. & Cargnello, M. Determining number of sites on ceria stabilizing single atoms via metal nanoparticle redispersion. Chin. J. Catal. 41, 998–1005 (2020).

Acknowledgments

This work has been supported by the Spanish Government through PID2021-122755OB-I00 funded by MCIN/AEI/10.13039/501100011033 and TED2021-130739B–I00 funded by MCIN/AEI/10.13039/501100011033/EU/PRTR and by the Generalitat Valenciana through the Prometeo Program (CIPROM/2023/34). The authors are also thankful for the Severo Ochoa financial support by the Spanish Ministry of Science and Innovation (CEX2021-001230-S/funding by MCIN/AEI/10.13039/501100011033). B.B. acknowledges the Spanish Government for a Severo Ochoa FPI scholarship (PRE2022-102555). The Electron Microscopy Service of the UPV is acknowledged for their help in sample characterization. The ESRF is kindly acknowledged for providing XAS beamtime at the BM23 beamline. We thank Red Española de Supercomputación RES for computational resources through QHS-2024-1-037 and QHS-2024-2-0015 projects, and V. Ganduglia-Pirovano for providing the CeO2-V model. Funding for open access charge: Universitat Politècnica de València.

Author information

Authors and Affiliations

Contributions

P.S. and S.R-B. supervised the project. B.B. synthesized the materials and noted interesting initial results. B.B., P.S. and M.M. designed and analysed the catalytic experiments. B.B. performed the activity tests. D.S. conducted and analysed the XAS experiments. T.W. and Y.X conducted and analysed the HAADF-STEM experiments. M.B. conducted and analysed the DFT calculations. S.R-B. conducted and analysed the DRIFT experiments. S.B. and A.C. provided useful feedback and revised the paper. P.S. drafted the article. All authors contributed to the discussions and to the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Frédéric Meunier and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bohigues, B., Rojas-Buzo, S., Salusso, D. et al. Overcoming activity/stability tradeoffs in CO oxidation catalysis by Pt/CeO2. Nat Commun 16, 7451 (2025). https://doi.org/10.1038/s41467-025-62726-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-62726-6