Abstract

Solution-based soft matter self-assembly (SA) promises unique material structures and properties from approaches including additive manufacturing/three-dimensional (3D) printing. The 3D printing of periodically ordered porous functional inorganic materials through SA unfolding during printing remains a major challenge, however, due to the often vastly different ordering kinetics of separate processes at different length scales. Here, we report a “one-pot” direct ink writing process to produce hierarchically porous transition metal nitrides and precursor oxides from block copolymer (BCP) SA. Heat treatment protocols identified in various environments enable mesostructure retention in the final crystalline materials with periodic lattices on three distinct length scales. Moreover, embedded printing enables the first BCP directed mesoporous non-self-supporting helical oxides and nitrides. Resulting nitrides are superconducting, with record nanoconfinement-induced upper critical fields correlated with BCP molar mass and record surface areas for compound superconductors. Results suggest scalable porous functional inorganic material formation approaches for applications including catalysis, sensing, and microelectronics.

Similar content being viewed by others

Introduction

Ubiquitous self-assembly (SA) phenomena in Nature have inspired the development of artificial/synthetic systems with well-defined and highly organized structures resulting in specific desired properties1. Solution based SA is a powerful strategy to achieve often intricate nanostructures with potential scalability but with only limited control over their macroscopic form. Additive manufacturing/three-dimensional (3D) printing dramatically expands the accessible range of form factors and has been extensively used in the field of soft matter2. While new printing techniques continue to advance this field3,4,5,6, challenges remain in the 3D printing of functional crystalline porous inorganic nanomaterials where the SA processes unfold during printing. So far, hierarchical porous solids are typically printed from inks with preformed inorganic additives, e.g., in the form of nanocrystals leading to porous interstitials or powdered porous inorganic solids7,8. This may require separate time-consuming syntheses, e.g., of porous zeolites or metal-organic frameworks (MOFs). In contrast, in-situ SA-based inks as envisioned here would enable less time-consuming and more cost-effective “one-pot” type 3D printing approaches.

Such materials may combine atomic lattices, SA-based mesoscale lattices, and 3D printing-induced macroscopic lattices. This requires exquisite structure control over three separate length scales to achieve the desired properties, which explains why reports on such studies remain scarce. Block copolymer (BCP) SA-derived mesostructures, a hallmark of soft condensed matter science, have recently gained attention in 3D printing due to their exquisite structure control over mesoscale lattices and lattice parameters typically across 50–500 Å9,10. To the best of our knowledge, however, 3D printed BCP SA-based hierarchically ordered mesoporous transition metal compounds have not been reported. In fact, despite first reports on 3D printed BCP SA-directed mesostructured amorphous silica11,12, a large part of the periodic table of elements remains unexplored. Transition metals and their compounds (e.g., oxides and nitrides) are attractive candidates, as they are relevant for a large number of applications, including catalysis, energy storage and conversion, and microelectronics. Compared to silica, however, their 3D printing is complicated by the rapid kinetics of the associated sol-gel synthesis processes13.

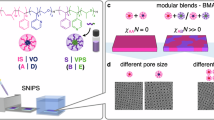

Here, we report 3D printed transition metal compounds accessible through sol-gel chemistry13,14 under the structure direction of Pluronic-family BCPs (Fig. 1). Appropriate “one-pot” ink formulation and printing conditions in direct ink writing (DIW) create free-standing, hybrid woodpile lattices. Subsequent thermal processing in various environments leads to the formation of hierarchically ordered and porous crystalline oxides and nitrides with self-assembled periodic mesostructures. In these materials, atomic, mesoscale, and macroscale lattices are controlled via oxide or nitride crystallization, different BCP-directed hexagonal structures, and cubic versus cylindrical 3D printed woodpile structures, respectively. Moreover, we show the first 3D printed SA-directed mesoporous helical structures of oxides and nitrides, a non-self-supporting configuration particularly challenging to print, adding to the variety of achievable form factors. Resulting porous nitrides with various form factors are superconducting and show, to the best of our knowledge, the highest nanoconfinement-induced enhancements to date for the upper critical field of the superconductors (SCs) as well as record high surface areas. The enhancement is controllable by BCP molar mass, thereby mapping a SC property onto a macromolecular characteristic. Results pave the way to classes of “one-pot” type 3D printed and SA-directed mesoporous transition metal compounds with enhanced properties. Applications for these materials range from catalysis across microelectronics and energy storage and conversion all the way to superconducting magnets, offering substantial academic as well as technological promise.

a The ink is composed of Pluronics-family block copolymers (BCPs) mixed with transition metal sols hydrolyzed from metal alkoxides in acidic ethanol solutions. The syringe pump-type print head extrudes the ink into a dish containing either hexane for periodic cubic woodpile structures or gel-like 25% Pluronic F127 by mass in water for periodic helical structures. After drying and annealing, b 3D printed Pluronics-sol hybrid woodpiles with self-assembled periodic hexagonal mesostructures and helices are calcined in air to yield c mesoporous transition metal oxides. After further heat treatments in ammonia and carburizing gas (mixture of methane, hydrogen, and nitrogen) at higher temperatures up to 950 °C, oxides are converted to d mesoporous crystalline transition metal nitride helices and hexagonally ordered woodpiles with cubic rocksalt atomic lattices.

Results

3D printed BCP SA-directed porous transition metal compounds

We first selected amphiphilic Pluronics-family PEO-b-PPO-b-PEO ABA-type BCP F127 as the structure-directing agent for an inorganic niobia sol (Fig. 1). Directly writing the F127-niobia ink in air produced poor results, however, with solvent evaporation being too slow to lead to ink mechanical properties conducive to layer-by-layer depositions without collapse of the printed structures (Fig. 2b). Rheological results confirmed a liquid-like ink with low moduli inappropriate for 3D printing (Fig. 2a,c).

a Plot of storage and loss moduli as a function of stress as the strain was swept from 0.01–100 % at the frequency of 1 Hz in the oscillatory mode. b Plot of storage and loss moduli averaged over the plateau region in (a) as a function of immersion time. Error bars represent the standard deviation of 3 trials. Inset: Photo of a woodpile with a poor structure after printing directly in air without being immersed in hexane. c Plot of storage and loss moduli as a function of frequency at 1% strain. d Plot of viscosity as a function of shear rate in the flow mode. The same color scheme regarding immersion time in (a) applies to (b–d). The same line style for storage and loss moduli is used in (a, c).

Inorganic additives could in principle take on the role of rheological modifiers in such extrusion-based printing5,15. Targeting a particular morphology, e.g., hexagonally packed cylinders, does not, however, leave much compositional leeway. This is because the amount of inorganic sol relative to a given BCP typically dictates the self-assembled morphology in the final BCP-additive hybrids16. To overcome this limitation, we improved ink printability by adopting a coagulation bath in which, upon extrusion, the polymer and/or additive would precipitate and gain the required mechanical strength for structure retention of printed parts17. Since the polyethylene oxide (PEO) blocks in the Pluronic BCPs and niobia sol are hydrophilic, we found a hydrophobic alkane bath, such as hexane suitable to induce precipitation while preventing outward diffusion of the ink. In rheological tests, the ink storage modulus increased by more than two orders of magnitude upon immersion in hexane (Fig. 2b). Furthermore, storage and loss moduli quickly switched relative magnitudes and the yield stress and the yield frequency both increased with immersion time (Fig. 2a–c), signaling the desired more elastic behavior. The characteristic shear-thinning behavior was also conducive to a 3D printable ink (Fig. 2d). A 7 × 7 × 7 mm3 periodic cubic woodpile could now be printed from such a DIW setup (Fig. 1 left side, Supplementary Fig. 1, and Supplementary Movie 1), showing conformity to designed print paths and stable overhanging structures (Fig. 3a–c). Aside from a periodic cubic woodpile, other form factors could be printed as exemplified by a cylindrical woodpile (Fig. 3l).

a–c Photos of as-printed periodic cubic woodpile of Pluronic F127-niobia sol hybrid. d, g Photos of resulting oxide (d) and nitride (g) woodpiles after heat treatment in the furnace under various gas environments. e, f, h, i Scanning electron microscopy (SEM) micrographs at different magnifications of periodic hexagonal mesostructures of oxide (e, f) and nitride (h, i). j, k Optical micrographs of oxide woodpile in (d). l Photos of as-printed cylindrical woodpile of Pluronic F127-niobia sol hybrid. Blue (a–c) and orange (l) colors are from methylene blue and Sudan I dyes dissolved in the ink, respectively. Pore sizes of the woodpile lattices shown in (a–c) and (l) vary between 240 and 1000 μm.

After thermal treatments at lower temperatures (40 °C to 60 °C) to remove residual solvents and further the condensation of the niobia sol, calcination in air at 450 °C decomposed the Pluronics BCP and resulted in white niobium oxide woodpiles with each dimension isotropically shrinking by about 30% relative to the hybrids (Fig. 3d, j, k). Thermogravimetric analysis showed the largest weight loss between 200 °C and 300 °C (Supplementary Fig. 2). Locally, as revealed by the lack of well-defined diffraction peaks in wide-angle X-ray scattering (WAXS, Fig. 4b), these 450 °C derived oxides remained atomically amorphous (like the hybrids). Scanning electron microscopy (SEM, Fig. 3e, f) suggested a hexagonally packed cylindrical pore structure on the mesoscale. This is corroborated by small-angle X-ray scattering (SAXS) results, showing Bragg reflections at relative q (scattering vector) positions of 1:\(\sqrt{3}\):2 in the reciprocal space (Fig. 4a), consistent with hexagonal lattices. The observed shift of the primary peak position from 0.043 Å-1 in the hybrid to 0.062 Å-1 in the oxide corresponds to a 30 % reduction in mesoscopic periodicity, which is in agreement with the macroscopic sample shrinkage (compare panels in Fig. 3a, d). A higher calcination temperature of 550 °C yielded crystalline Nb2O5 (Supplementary Fig. 3b) while maintaining the mesostructural control as evidenced by SAXS and SEM results (Supplementary Fig. 3a,c).

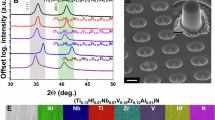

a Small-angle X-ray scattering (SAXS) and b wide-angle X-ray scattering (WAXS) profiles for 3D printed Pluronic F127-niobia sol hybrid and resulting oxide and nitride-type structures. Ticks in (a) denote relative scattering vector (q) positions (1:\(\sqrt{3}\):2) of Bragg reflections for hexagonal structures (symmetry group P6mm). Grey and black ticks in (b) represent relative intensities and q positions of peaks of rocksalt δ-NbN (PDF #01-089-5007) and NbC (PDF #03-065-8781), respectively. c Nitrogen adsorption (solid line) and desorption (dashed line) curves of mesoporous oxide and nitride. d Corresponding pore size distributions derived from the Barrett–Joyner–Halenda (BJH) model. V0 is the volume of adsorbed nitrogen gas at standard temperature and pressure p°. p/p°, gas pressure p divided by p°, is the relative pressure. V is the pore volume and W is the pore width. Color codes in (b–d) are the same as in (a).

The conversion of Pluronics BCP SA-directed oxide materials with periodic mesoscale lattices to crystalline nitrides has remained a major challenge18,19. The low molar mass of these BCPs and associated thin inorganic walls favor collapse of the porous mesostructure during nitride crystal formation due to crystal overgrowth. Careful systematic studies allowed us to overcome this problem by circumventing a thermodynamically more unfavorable crystal-to-crystal transformation employing the 450 °C treated amorphous niobia and identifying the following two-step chemical conversion approach (Supplementary Information): a first heating step under ammonia conducted at temperatures around 550 °C, i.e., substantially lower than suggested by earlier studies on large BCPs20,21 to prevent mesostructure collapse but high enough for nitride crystal precipitation; then, without cooling the material to room temperature in-between, a second heating step to a higher temperature (750 °C to 950 °C) performed in carburizing gas (CH4, H2, and N2 with molar ratios of 16:4:80) to improve nitride-type crystal quality but suppress grain growth. Relatively high flow rates of ammonia at 20 L h-1 and carburizing gas at 15 L h-1 (see Supplementary Information for details) minimized the formation of crystalline oxide while simultaneously driving conversions to the desired final nitride-type materials.

After treating the white amorphous oxides in ammonia at 550 °C and in carburizing gas at 750 °C, woodpile structures turned reflective black (Fig. 3g). WAXS results on such 3D printed materials were consistent with phase-pure rocksalt δ-NbN (and/or NbC, Fig. 4b). Both macroscopic (Fig. 3g) and SAXS analysis based nanoscopic (Fig. 4a) structures and dimensions barely changed from those of the oxides. SEM inspection corroborated SAXS results, showing hexagonal mesostructures were preserved (Fig. 3h,i). It is important to note that, as suggested by the SEM results, the hexagonal mesostructure is macroscopically isotropic, with domain sizes on the order of hundreds of nanometers to a micron. Furthermore, nitrogen sorption/desorption results on oxides and nitrides exhibited type IV(a) isotherms with a hysteresis loop intermediate between H1 and H2(b), with pore sizes for both materials narrowly distributed around 4 nm according to the Barrett–Joyner–Halenda (BJH) model (Fig. 4c, d). For comparison, we also used non-local density functional theory (NLDFT) to estimate pore sizes, which typically came out larger than suggested by SEM (Supplementary Fig. 4, Supplementary Table 1). Brunauer–Emmett–Teller (BET) based data analysis yielded specific surface areas around 126 m2 g-1 and 120 m2 g-1 for oxides and nitrides, respectively.

Similar sol-gel synthesis was applied to a Pluronic-titania sol system to check how well these approaches may be generalizable (Fig. 1). Non-optimized first results using a two-step heating protocol demonstrated mesoporous TiN and its oxides (crystalline or amorphous, Supplementary Figs. 5 and 6, Supplementary Table 2).

3D printing non-self-supporting mesoporous structures

Compared with woodpiles, where printed layers underneath act as a support for building an overhanging feature above, non-self-supporting structures such as helices are challenging to form via DIW22. Towards this goal and taking inspiration from embedded printing and other variants23,24,25, a gel-like support matrix consisting of 25% F127 by mass in water was utilized to stabilize helical form factors printed from a F127-niobia sol ink (Fig. 1, Supplementary Movie 2). Instead of selectively crosslinking the ink or the support matrix to enable separation of the two, however, the pH neutral environment of F127 in water induced rapid condensation of the niobia sol in the ink, which itself is strongly acidic to prevent premature aggregation of the sol nanoparticles. This inhibited substantial diffusion of the ink into the support matrix.

After cooling below the gel-to-fluid transition temperature ( ≈ 10 °C) for the F127 gel-like support, 3D printed periodic helices of various radii ranging from 2 to 4 mm and a pitch of 1.5 mm were removed and transferred to ethanol for rinsing (Fig. 5a). Helices in their hybrid state showed elastic behavior and could be reversibly compressed and released (Fig. 5b–d, Supplementary Movies 3 and 4). They could be scooped out of ethanol by tweezers for drying and subsequent heat treatments (Fig. 5e, f, Supplementary Movie 5). Freestanding inorganic oxide (Fig. 5g) and nitride-type (Fig. 5h) helices were obtained after calcination in air and the two-step heat treatments described earlier in ammonia and carburizing gas, respectively. While hybrids and oxides were amorphous, WAXS profiles of the black nitride-type helices showed peaks matching those of rocksalt δ-NbN (and/or NbC, Fig. 5i).

a A helix in ethanol after removal from the support matrix used for embedded printing. b–d Visualizing the elastic behavior of a hybrid helix by compressing (left pointing arrow) and releasing (right pointing arrow) in ethanol. e,f Picking a hybrid helix out with tweezers (refraction causes apparent misalignment). g Oxide helix after calcination in air to 450 °C (inset: view along helical axis). h Nitride helix after heat treatment to 950 °C in different environments. The helices in (a, g, h) and (b–f) were printed with radii of 2 and 3 mm, respectively. (i) WAXS profiles of hybrid, oxide, and nitride helices. Grey and black ticks represent relative intensities and corresponding q positions of peaks of NbN (PDF #01-089-5007) and NbC (PDF #03-065-8781), respectively. j Nitrogen adsorption (solid line) and desorption (dashed line) curves of mesoporous oxide (heat treated under air to 450 °C) and nitride-type (heat treated to 550 °C under ammonia and subsequently to 750 °C in carburizing gas) helices, and k corresponding pore size distributions derived from the BJH model. Same color scheme in (i) applies to (j, k).

Resulting 3D printing derived and Pluronics BCP SA directed oxide and nitride-type periodic helical materials were highly porous, reaching BET specific surface areas of 298 m2 g−1 and 129 m2 g−1, respectively (Fig. 5j), both surpassing the value for the similarly treated woodpile structures described earlier. Narrow pore size distributions were centered around 4 nm for oxide and nitride-type materials both characteristic of F127-directed mesostructures (Fig. 5k).

Superconducting properties of 3D printed porous inorganic materials

Hierarchically ordered and porous transition metal oxides and nitrides with form factors defined via 3D printing are functional inorganic materials interesting for a number of applications. To test for modulations in behavior as a result of the BCP SA directed mesostructure, we focused on the properties of the 3D printed niobium nitride-type materials. NbN is a type-II SC with a critical temperature (Tc) of around 17 K26. Indeed, superconductivity emerged in samples heat-treated to 750 °C in the second step (Supplementary Fig. 7). However, the low onset Tc as measured by vibrating sample magnetometry (VSM) around 7 K and material heterogeneities as suggested, e.g., by kinks in initial resistance curves, motivated our search for refined heating protocols.

To that end, we varied the first (under NH3) and second (under carburizing gas) heating step temperatures of our woodpile lattices from 500 °C to 600 °C and 750 °C to 950 °C, respectively. For these ranges, we did not observe structure collapse, presumably because once nitrides are formed via the first-step treatment under ammonia, the temperature in the second-step treatment remains far below the nitride melting point (Tm(NbN) > 2,500 °C), minimizing Ostwald ripening21. The onset Tc increased from around 7 K for samples treated first to 550 °C and then to 750 °C to 8–9 K and 15.2 K for samples treated to 850 °C and 950 °C in the second step, respectively, with concomitant monotonic increase in saturated magnetic moment normalized by sample mass (Fig. 6a). From the slope of field-dependent magnetic moment measurements (Supplementary Fig. 8), a magnetic flux exclusion of ≈ 20% was estimated for a woodpile sample treated to 950 °C as compared to a dense NbN SC with the same external dimensions (Supplementary Information). SEM micrographs of samples treated up to 950 °C retained hexagonally ordered mesostructures (Fig. 6a, inset), which was corroborated by SAXS data analyses. The periodic center-to-center distance between neighboring pores as calculated from SAXS results decreased from 11.7 nm, through 10.6 nm, to 10.3 nm for samples treated to 750 °C, 850 °C, and 950 °C, respectively (Supplementary Fig. 9a). With increasing temperature in the carburizing gas treatment from 750 °C to 950 °C, the single-phase cubic unit cell sizes increased from 4.352 to 4.400 Å (Supplementary Fig. 9b), while the coherently scattering domain sizes derived from Scherrer analyses of these data increased only slightly, from 4.0 nm to 4.7 nm, corroborating that substantial growth of crystalline domains was largely suppressed.

a Plot of magnetic moment normalized by mass (μ) of NbN-type samples treated to 550 °C in NH3 and higher temperatures in carburizing gas (inset: SEM micrograph of sample treated to 950 °C). b Plot of electrical resistance (R) of NbN-type sample treated to 500 °C in NH3 and then 950 °C in carburizing gas. c Plot of field-dependent R of sample in (a) treated to 950 °C (inset: variation of upper critical field (Bc2) with temperature (T) near Tc). d Plot of extrapolated Bc2 at T = 0 (Bc2(0), red) and corresponding Ginzburg–Landau coherence length (ξ(0), blue) as a function of room-temperature aging time (t, in days) in air for NbN-type sample treated to 575 °C in NH3 and then 950 °C in carburizing gas (error bars: extrapolation error, see Methods; inset: schematic of aging). e Plot of Bc2(0) for samples treated as in (c) as a function of Mn,PEO2/3, proportional to wall thickness, d (top axis). For a given Mn,PEO, lighter blue points represent results from separate samples, while the dark blue point represents the average (error bars: standard deviation). The green point represents a hexagonally ordered sample derived from a tailor-made PI-b-PS-b-PEO. The teal line indicates the Bc2(0) value for bulk NbN averaged from refs. 26,33,34. The dotted pink and red lines represent Bc2(0) values of NbN in confined geometries from ref. 36. and ref. 37, respectively. The inset shows a plot of Bc2(0) values (error bars: extrapolation error, see Methods) for F127-directed TiN samples (Supplementary Fig. 22) against the dotted green line, which indicates the Bc2(0) value reported for TiN under confinement from ref. 43.

A mesoporous 3D-printed helix treated at 950 °C was also shown by VSM measurements to be superconducting with an onset Tc over 12 K (Supplementary Fig. 10), the first non-self-supported 3D printed SCs27,28. With their mesostructure directed by BCP SA, the NbN-type materials described herein (both woodpiles and helices) constitute the highest surface area mesoporous compound SCs reported to date.

Elemental compositions have been shown to influence NbN-type SC’s behavior, including critical temperatures (and fields, vide infra)26,29. In our synthetic approach, oxygen was anticipated to be present in the final materials, since nitridation in ammonia followed oxide formation in the first calcination step and nitrides are known to form surface oxide layers under ambient conditions, particularly relevant for the present high surface area materials (vide infra). Furthermore, we expected carbon in the final compositions, as methane in the carburizing gas treatment is expected to form radicals during decomposition at high temperatures and be reduced to carbonaceous species. X-ray photoelectron spectroscopy (XPS) of 3D printed samples first treated to 550 °C under ammonia and then to 750 °C, 850 °C, or 950 °C under carburizing gas, as well as after etching attempts to remove carbonaceous species deposited on pore surfaces (Supplementary Information, Supplementary Table 3), suggested decreasing oxygen and increasing carbon content with increasing carburizing gas treatment temperature (Supplementary Figs. 11 and 12, and Supplementary Tables 3 and 4). We refer to these niobium oxycarbonitrides consistently as NbN-type materials throughout this text.

In contrast to typical metallic behavior, the resistance, R, of a 3D printed NbN-type material treated first to 500 °C and then to 950 °C increased upon cooling before reaching a Tc above 15 K (Fig. 6b). This behavior could be ascribed to scattering occurring at grain boundaries within polycrystalline metallic conductors30,31, consistent with the local granular structure revealed by high-resolution transmission electron microscopy (HRTEM) images of these materials (Supplementary Fig. 13). This observed granularity in the BCP SA directed hexagonal mesostructure also hinted at a possibly shortened Ginzburg–Landau coherence length, ξ. For type-II SCs the upper critical magnetic field, Bc2, defined as Bc2 = \(\frac{{\varPhi }_{0}}{2{{{\rm{\pi }}}}{\xi }^{2}}\), where Φ0 = \(\frac{h}{2e}\) is the magnetic flux quantum, h the Planck constant, and e the elementary charge, is inversely proportional to the square of ξ. Because of this high sensitivity to ξ, we investigated possible confinement-induced enhancements in the upper critical field of our DIW-derived and BCP-directed SCs. According to WHH theory32, the upper critical field at T = 0, Bc2(0), can be extrapolated from the rate of change of Bc2 versus T near Tc via Bc2(0) = \({{0.69T}_{c}\left.\frac{{{{{\rm{d}}}}B}_{c2}}{{{{\rm{d}}}}T}\right|}_{T={T}_{c}}\). Indeed, Tc values obtained from field-dependent resistance measurements of a 3D printed material first treated to 550 °C and then to 950 °C extrapolated to a Bc2(0) of 40 T (Fig. 6c). This is a substantial jump from bulk values26,33,34 found between 10 and 20 T as well as the Pauli paramagnetic limit35 of 1.84 T K-1 × Tc ≈ 23 T. Elevated critical fields have been observed in SCs with confined dimensions, such as ultrathin films, monolayer materials, or ultrafine powders36,37,38, but systematic studies of BCP SA based confinement effects on Bc2 in 3D printing derived mesostructured SCs remain unexplored.

To demonstrate that BCP SA-based wall thickness induced confinement effects in 3D printed NbN-type SCs contribute to observed Bc2(0) enhancements, we performed two control experiments. The first was to leave samples in the ambient air for extended periods of time allowing for surface oxide layer formation39. This should reduce nitride wall thickness of the porous BCP directed mesostructured SCs and therefore increase confinement effects. Aging in ambient air a NbN-type sample that had first been treated to 575 °C and then to 950 °C indeed increased the extrapolated Bc2(0) (Fig. 6d) to a value of 50.1 T at the longest aging time of about a month tested (top red graph of Fig. 6d, and Supplementary Fig. 14). The extrapolated Bc2(0) values obtained from aged samples also allowed estimates of the Ginzburg–Landau coherence length at T = 0, ξ(0) (bottom blue graph of Fig. 6d). Considering materials heterogeneities, lines connecting extrapolated data points for Bc2(0) and associated estimates for ξ(0) were obtained from fits with a Kohlrausch–Williams–Watts (KWW) stretched exponential function with exponent, β = 0.96. Asymptotically reaching a Bc2(0) value of 50.7 T obtained from this fit toward infinite time is consistent with self-limiting oxide surface layer formation. Estimated values for ξ(0) around 2.6 nm are well below the single-crystal NbN value of ξ0(0) > 6 nm40. As a result of the difference in pore sizes obtained from BJH and NLDFT models (Fig. 4d and Supplementary Fig. 4b, respectively), the thinnest parts of the walls in the hexagonal mesostructures were estimated from SEM micrographs of a non-aged sample (Fig. 6a, inset) to be around 4.6 nm, i.e., somewhat below the bulk ξ(0) value for NbN. These estimates are all consistent with stronger mesostructural confinement associated with smaller physical nitride dimensions after oxidation leading to the observed increases in Bc2(0). Diffuse electron scattering at wall surfaces will decrease the mean free path, ltr of electrons; in the dirty limit [ltr ≪ ξ0(T)], Ginzburg-Landau theory predicts ξ(T) = 0.855 [ξ0(T) ltr]1/2. Assuming ltr is comparable to the wall width (4.6 nm) we would expect ξ(0) no smaller than roughly 0.855 × (6 nm × 4.6 nm)1/2 = 4 ~ 5 nm, i.e., a value much greater than observed. We conclude that confinement introduces nontrivial effects on superconductivity in this system.

The second set of experiments to demonstrate BCP SA-based wall thickness-induced confinement effects was tuning mesostructure-associated wall thickness by varying BCP molar mass. To that end, in addition to F127 ( ≈ 12.6 kg mol-1), alternative Pluronics-family BCPs F108 ( ≈ 14.6 kg mol-1) and P123 ( ≈ 5.8 kg mol-1) with larger and smaller molar mass, respectively, than F127 were chosen for the preparation of 3D printed mesoporous NbN-type SCs (Supplementary Figs. 15 and 16). In order to deconvolute the contributions of thermal history and confinement effects on Bc2(0), in these experiments all 3D printed and Pluronics BCP directed samples underwent identical 2-step thermal treatments to 550 °C under ammonia and then to 950 °C under carburizing gas (Supplementary Figs. 17–19). As a reference, a separate sample was prepared from a tailor-made poly(isoprene-b-styrene-b-ethylene oxide) (PI-b-PS-b-PEO) triblock terpolymer of a much larger molar mass (88.3 kg mol-1), and then converted to the superconducting NbN-type materials (Supplementary Fig. 20) employing established protocols (i.e., without DIW)21. Extrapolated Bc2(0) values as a function of the number average molar mass of the hydrophilic PEO block of the BCP (the block that mixes with the inorganic sols) raised to the power of 2/3, Mn,PEO2/3, as a measure for its thickness, d (top axis)41, are summarized in Fig. 6e. For each of the Pluronics BCPs, at least 3 NbN-type samples (light blue) were tested and results averaged (points and associated error bars in dark blue). This plot reveals a clear trend: the shorter the structure directing BCP chains, the larger the critical field, Bc2(0). The smallest BCP P123 resulted in the largest Bc2(0) averaging near 50 T, while the largest customized BCP showed a Bc2(0) close to bulk values. From Fig. 6e, Bc2(0) starts to increase as the wall thickness falls below approximately twice the bulk value of the coherence length, ξ(0). This is similar to confinement effects in semiconductors which appear at length scales less than twice the bulk exciton Bohr radius42. Results of nitrogen sorption measurements on these samples also demonstrate, that pore size is controlled by BCP molar mass (Supplementary Fig. 19 and Supplementary Table 5).

Similar confinement effects were demonstrated for 3D printed TiN. While heat treating the oxide in ammonia produced superconducting TiN, direct nitridation of as-made hybrids in ammonia (i.e., without first forming the oxide) mitigated crystal coarsening and better retained the mesostructure directed by F127 compared with a two-step treatment via the oxide (Supplementary Fig. 21). Non-optimized single-step heat treatment combined with aging protocols resulted in confinement induced Bc2(0) enhancements up to values of 8.1 T from extrapolation (Supplementary Fig. 22). This is a multifold increase over values reported in the literature for TiN confined by varying film thickness, which are all under 1 T (Fig. 6e, inset)43. Results in Fig. 6d,e display, to the best of our knowledge, the highest nanoconfinement-induced Bc2(0) enhancement to date achieved for NbN-type and TiN SCs that are correlated with BCP molar mass, the first mapping of a tailorable SC property onto a macromolecular design parameter36,37,44,45. Such solution-based BCP SA controlled and confinement-induced SC properties should be translatable to numerous macroscopic form factors via 3D printing and subsequent thermal conversion processes.

Discussion

Mesoporous transition metal nitrides and precursor oxides with Pluronics BCP SA-directed mesostructures were fabricated by a “one-pot” type DIW approach and subsequent thermal treatments in various gas environments. Either a hydrophobic precipitation bath or a gel-like support matrix helped maintain the integrity of complex 3D printed structures, including non-self-supporting helices. The work combined (i) the freedom to choose various macroscopic periodic form factors by additive manufacturing, (ii) the periodic mesostructural control of BCP SA, and (iii) functional inorganic materials with periodic atomic lattices. Results suggest that solution-based “one-pot” type 3D printing approaches enable generation of hierarchically ordered porous transition metal compounds with a range of potential applications. For transition metal nitrides, achieved superconducting properties were substantially enhanced over bulk behavior via BCP SA-based nanoconfinement and could be mapped onto BCP molar mass, a macromolecular design parameter. As demonstrated materials were accessible from commercially available chemicals, polymers, and 3D printing equipment, results should enable a plethora of studies in various scientific communities. For example, the hitherto largely disconnected fields of additive manufacturing, mesoporous materials, and interfacial properties of correlated electron systems can be linked to facilitate bridging fundamental studies with application-oriented “proof-of-principle” device developments.

Methods

Ink preparation

0.40 g Pluronic F127 (Sigma-Aldrich) was mixed with 0.40 g anhydrous ethanol (C2H5OH, Sigma-Aldrich, ≥99.5 %), 0.185 mL 37% hydrochloric acid (EMD Millipore), and 0.285 mL glacial acetic acid (CH3COOH, Macron), and stirred until fully dissolved. Higher BCP concentrations led to nozzle clogging, while lower concentrations did not provide appropriate mechanical properties of the ink. For printing structures directed by other Pluronic BCPs, the F127 was replaced by the same amount of F108 (Alrich Chemistry) or P123 (BASF). For P123, F127, and F108, (x, y) subscripts in the formula PEOx–PPOy–PEOx are (20, 70), (100, 65), and (133, 50), respectively, i.e., the PEO block size hybridizing with niobia sol nanoparticles decreases in the sequence F108, F127, and P123, while the PPO block size responsible for the pore size in the mesoporous materials decreases in the reverse sequence. While stirring vigorously, 0.625 mL niobium(V) ethoxide (Nb(OC2H5)5, Alfa Aesar, 99.99 %, metal basis) was quickly injected into the F127 solution. For inks made with P123, up to 0.675 mL niobium ethoxide was added. The clear F127-niobia sol solution was left stirring for 3 days before being loaded into a 30 mL syringe (BD) with a tapered dispensing tip (Nordson, 27 gauge), or a blunt needle (CML Supply, 25 gauge, up to one and half inches long) for embedded printing. 50 μL of ethanol solutions of methylene blue (1 mg mL-1) or Sudan I (saturated) could be added to generate a colored ink.

For inks containing titania sol, the materials and procedures were the same except that the 0.625 mL niobium(V) ethoxide was substituted with 0.74 mL titanium(IV) tetraisopropoxide (Ti(OCH(CH3)2)4, 99.995 %, Thermo Scientific Chemicals).

Direct ink writing (DIW)

The ink containing syringe was mounted on an SDS30 print head connected to a Hyrel SR 3D printer (Supplementary Fig. 23). The movement of the print head and the platform was controlled by the built-in Repetrel software (version 4.2.494) with customized G-codes. DIW occurred in a glass petri dish (printing dish, 60 mm diameter, at least 15 mm depth) filled with hexane (Fisher chemical) and periodically replenished by a syringe pump (Supplementary Fig. 23) to keep printed parts submerged throughout the process. Each step of movement in the vertical direction was 30–40 μm.

For woodpile structures, the print head would move at a speed of 100–300 mm min-1 relative to the platform along the same path 8 times consecutively before switching directions to build enough thickness for each strut while allowing thin layers of ink to precipitate thoroughly in hexane. A slower speed of 100 mm min-1 was used for F127-titania sol inks, and the woodpile top during printing was kept just below the hexane surface so as to reliably produce high-quality printed structures. A typical cubic woodpile measured 7 × 7 × 7 mm3, with 1 mm between adjacent in-plane struts and a total of 240 layers. After printing was accomplished, hexane was poured out and a cover dish was put on the printing dish with the printed part still wet. In this configuration printed parts were aged in two steps before further heat treatments at higher temperatures to generate oxides and nitrides. In the first step, samples were brought to a slightly elevated temperature of 40 °C for one day. Samples were subsequently heat treated at 60 degrees in a second step for another day. After aging, residual solvents had evaporated and the BCP hybrid sol-gel materials consolidated.

For embedded printing, the printing dish was filled with a gel-like support matrix made from 25 % F127 by mass in water. On top of this gel-like matrix was deposited via pipette a ≈ 2 mm thick liquid layer of 21 % F127 by mass in water. This layer backfilled the crevices formed by the needle traversing through the support matrix during printing. In contrast to the multilayer approach used during printing of woodpile structures in hexane, there was no such multilayer approach taken for printing helices, i.e., there was no repetition along the same path during the embedded printing. The radii of the helices as set in the G-codes varied from 2 to 4 mm and the pitch was 1.5 mm (Supplementary Movie 2). The print head speed was 100 mm min-1 to 150 mm min-1. After the printing process concluded, like for the DIW into hexane, samples were aged in two steps. In the first step, a cover dish was sealed by parafilm with the printing dish containing the matrix and the printed part, which was then kept at room temperature for 1 day. In the second step, the sealed dishes with the printed samples were heated at 60 °C for another day to further consolidate printed hybrid materials. After these two aging steps and before further heat treatments of the printed parts, the support matrix and the fluid filler were separated from the printed parts by cooling below the gel-to-fluid transition temperature ( ≈ 10 °C) so that the printed parts could be picked out and rinsed with ethanol (EMD Millipore, 96%) (Supplementary Movie 5). Once residual ethanol had evaporated, parts were ready for further heat treatments at higher temperatures.

Heat treatments in different gas environments

The BCP-niobia hybrid printed parts were first heated at a ramp rate of 1 °C min-1 to 450 °C with a dwell time of 3 h in air in a tube furnace with an alumina tube of 1 inch diameter and ≈ 1 m length. To further improve structural integrity, a preceding heating step in nitrogen gas with the same ramp rate, dwell time, and dwell temperature could be used. Crystalline niobia samples were heated to 550 °C under the same ramp rate and dwell time. The amorphous niobium oxide parts were then heated in another tube furnace with a quartz tube of 1 inch diameter and ≈ 60 cm length under ammonia from room temperature ( ≈ 20 °C) to 50 °C to 600 °C in 100 min with a dwell time of 210 min, and subsequently followed by heating to the final highest temperature of 750 °C to 950 °C at a ramp rate of 20 °C min-1 with a dwell time of 90 min. Ammonia gas (NH3, Phoenix Electronics, electronic grade) flowed through the tube furnace at a flow rate of 20 L h-1 until it was switched (after being held for 180 min at the intermediate, e.g., 550 °C, temperature) to carburizing gas (methane, CH4, hydrogen, H2, and nitrogen, N2, mixed in a molar ratio of 16:4:80, Airgas) at a flow rate of 15 L h-1. The NbN-type samples were left to cool to room temperature while nitrogen gas flowed for 2 h to purge the tube. The nitrogen gas flow rate was lowered to 10 L h-1 at temperatures below 450 °C.

The BCP-titania hybrid printed parts were heated at a ramp rate of 1 °C min-1 to either 300 °C or to 400 °C with a dwell time of 3 h in air in the tube furnace with the alumina tube. 300 °C treated samples would result in amorphous titania while 400 °C treated samples would show the formation of crystalline anatase. The nitridation step took place all in ammonia using the same heating protocol as for niobia (500 °C in the first dwell, and 750–950 °C in the second dwell), using the amorphous oxide calcined in air at 300 °C. A final heating temperature of 900 °C and above was required for achieving superconductivity in TiN. Superconducting TiN in Fig. 6e, however, was derived by heating the hybrid materials in ammonia directly, reaching 500 °C in 25 min from room temperature to reduce the time spent at lower temperatures, thereby suppressing crystallization of the oxide. After holding at 500 °C for 3 h, the sample was further heated at a ramp rate of 20 °C min-1 to 900 °C or higher with a dwell time of 1 h before cooling to room temperature under ambient conditions. Ammonia flow rate was kept at 15 L min-1 throughout the process to drive the nitridation forward.

NbN-type samples prepared from custom-made BCPs

Procedures described in prior publications20,21 were followed to prepare superconducting NbN-type samples structure-directed by the custom-made BCP poly(isoprene-b-styrene-b-ethylene oxide) (referred to as ISO). The ISO terpolymer was synthesized via sequential anionic polymerization reported elsewhere46. Proton nuclear magnetic resonance (1H NMR) and gel permeation chromatography (GPC) were used to determine the total number-average molar mass (Mn) of 88.3 kg mol-1 and a polydispersity index (PDI, or using the updated term dispersity, Đ) of 1.14, with mass fractions of PI, PS, and PEO blocks being 13.4, 37.1, and 49.5 %, respectively. For BCP directed hybrid formation, 0.050 g of ISO was dissolved in 1.0 mL anhydrous tetrahydrofuran (THF, 99.9%, Sigma-Aldrich). In a separate vial to prepare the sol stock solution, 0.96 mL niobium(V) ethoxide was injected to a mixture of 0.56 mL 37 % HCl solution and 0.90 mL THF under vigorous stirring. After 5 min, another 4.5 mL THF was added followed by additional stirring of 2 min. Targeting the hexagonal morphology, 0.740 mL sol stock solution was added to the ISO solution, which was cast into a Teflon beaker after mixing thoroughly overnight and left to evaporate under a hemispherical glass dome at 50 °C. After evaporation-induced self-assembly the dried film was heated at 130 °C in a vacuum oven for 3 h before calcination in the tube furnace in the same way as the 3D printed samples. The reactive gas treatment took place at a higher temperature and for a longer duration to chemically convert the thicker walls of ISO-directed structures. Using the previous protocol, the oxide film was heated in ammonia for 9 h at 700 °C and in carburizing gas for 3 h at 1000 °C to prepare the final superconducting NbN-type material.

Characterization

Optical imaging. Optical images were captured by a Samsung Galaxy S8 phone, a Huawei P40 pro+ phone or an Andonstar microscope. Supplementary Fig. 24 was obtained using a Zeiss SteREO Discovery.V12 optical microscope equipped with an Olympus OM-D E-M5 camera.

Scanning electron microscopy (SEM). Pieces broken from printed parts (oxide or nitride) were imaged using a Zeiss Gemini500 scanning electron microscope with an in-lens EsB detector. The accelerating voltage was 2 kV and the working distance was around 4 mm. No conductive coating needed to be sputtered onto samples prior to imaging. SEM-based pore size and wall thickness estimates were obtained using the ImageJ software. Results were averaged over at least 10 measurements per estimate.

Transmission electron microscopy (TEM). Pulverized NbN-type samples from printed parts were suspended in absolute methanol and vortex mixed. 5 μL of the suspension was placed on a lacey carbon supported copper TEM grid (size 200 mesh) and left to evaporate. Samples were imaged in a Spectra 300 TEM (Thermo Fisher Scientific) with a cold field emission gun at 300 kV.

X-ray scattering. Small-angle and wide-angle X-ray scattering (SAXS and WAXS) were performed on pieces broken from printed parts at the Soft Matter Interfaces (SMI, 12-ID) beamline at the National Synchrotron Light Source II (NSLS-II) or the Functional Materials Beamline (FMB, ID3B) and BioSAXS Beamline at the Cornell High Energy Synchrotron Source (CHESS). At SMI, the X-ray energy was 16.1 keV. The SAXS detector was a Pilatus 1M pixel array detector at a distance of 5.00 m from the sample. The WAXS detector was a Pilatus 900KW pixel array detector. Two-dimensional (2D) scattering signals collected at various detector positions were stitched together to construct the WAXS scattering profiles over the entire q (scattering vector) range. At FMB, the X-ray energy was 9.79 keV. The SAXS detector was a Pilatus 300 K pixel array detector at a distance of 1.43 m from the sample. The WAXS detectors were two Pilatus 200 K pixel array detectors. At BioSAXS, the X-ray energy was 11.24 keV. The SAXS detector was an Eiger 4M detector at a distance of 1.78 m from the sample. All the 2D raw scattering data were processed and azimuthally integrated using custom-generated software packages at the respective beamlines. Crystal unit cell size and the coherently scattering domain size were obtained by performing whole pattern fitting (Rietveld refinement) against NbN (PDF #01-089-5007) using the JADE software (Supplementary Fig. 9b, Supplementary Tables 1 and 5).

Nitrogen sorption. Nitrogen sorption was conducted on a Micromeritics ASAP 2020 Accelerated Surface Area and Porosimetry System at 77 K. Printed and heat treated parts were degassed overnight at 120 °C prior to measurement. The surface area was obtained based on the Brunauer–Emmett–Teller (BET) theory. Pore size distributions were calculated using the non-local density functional theory (NLDFT) model or the Barrett–Joyner–Halenda (BJH) model provided by the associated instrument software. The NLDFT model assumed nitrogen in cylindrical pores with oxide surface. The adsorption curve was used for BJH model analysis with Faass correction. All nitrogen sorption data shown in this paper for NbN-type materials were obtained from samples heat-treated to 750 °C in carburizing gas.

Rheology. Rheological ink sample characterization was performed on a DHR3 rheometer by TA Instruments using a cone-and-plate geometry at 25 °C. The diameter for both cone and plate was 40 mm. The cone angle was 2°, and the truncation on the cone was 63 μm. A solvent trap enclosed the geometry during measurements to minimize effects from solvent evaporation. Apart from being directly measured, the ink was also separately coated on cone and plate parts and then immersed in hexane for various times (Supplementary Fig. 25) before cone and plate assembly for rheological measurements. Three sets of measurements were performed. First, the storage and loss moduli were measured as the strain was swept from 0.01 to 100% at a frequency of 1 Hz in the oscillatory mode. Second, the storage and loss moduli were measured as the frequency was swept from 0.1 Hz to 100 Hz at 1 % strain in the oscillatory mode. Lastly, the viscosity was measured as the shear rate was swept from 0.01 to 100 s-1 in the continuous flow mode.

X-ray photoelectron spectroscopy (XPS). Samples were first pulverized and then analyzed using a Thermo Scientific Nexsa G2 Spectrometer with an operating pressure of approximately 1×10-9 Torr. Monochromatic Al Kα X-rays (1486.6 eV) with photoelectrons were collected from a 400 μm diameter analysis spot at a 90° emission angle with source to analyzer angle of 54.7°. A hemispherical analyzer determined electron kinetic energy, using a pass energy of 200 eV for wide/survey scans, and 50 eV for high-resolution scans. A flood gun was used for charge neutralization of non-conductive samples. Etching was performed using an argon ion gun with an accelerating voltage of 500 V and an etch time of 120 s. The estimated etch depth was 10 nm. Data were analyzed using the CasaXPS software. Atomic percentages were quantified based on the survey scans using default regions of different elements in the software. Chemical bonding information was obtained from high-resolution scans by fitting the C 1s peak with carbide, C=O, C–C, and C–O components with the same relative sensitivity factor (RSF) and a mixed Gaussian/Lorentzian line shape (70/30).

Thermogravimetric analysis (TGA). Thermogravimetric analysis was performed on 3D printed F127-niobia hybrid by heating at a rate of 4 °C min-1 in air in a TA Instruments 5500 thermogravimetric analyzer.

Vibrating sample magnetometry (VSM). A Quantum Design Dynacool Physical Property Measurement System (PPMS) was used to collect VSM data. The sample mass was determined on a Cahn 28 automatic electrobalance. A printed sample piece was loaded into a pair of plastic holders that were then pressed into brass holders. Samples were cooled down to 1.8 K under zero external field (zero-field cooling, or ZFC) or 100 or 1000 Oe external field (field cooling, or FC). The sample’s magnetic moment was measured as the temperature was ramped to 20 K at a rate of 1 K min-1. For field dependent magnetization measurements, the external field was ramped to 50 kOe, then to -50 kOe, and back to 0 at a rate of 100 Oe s-1. Sample magnetic moments were measured with an averaging time of 1 s per measurement. For flux exclusion calculations, it was assumed that the mass of a 3D printed structure was proportional to the volume enclosed by the sample’s outer surface. For example, the woodpile nitride shown in Fig. 3g of the main text has a mass of ≈ 50 mg with an external dimension of (7 × 0.7 mm)3 = 117 mm3 (30 % shrinkage in each dimension with respect to the original printed hybrid woodpile cube). Therefore, a sample of mass m has a volume V = \(\frac{m}{50{{{\rm{mg}}}}}\times 117\) mm3 enclosed by its outer surface. At any externally applied field strength H, an ideal dense NbN superconductor with this volume would have a magnetic moment μ of -HV, by which the experimentally observed μ of the sample is divided to obtain the percentage of flux exclusion.

Electrical transport measurements. Field-dependent electrical resistance was measured using the resistivity option on a Quantum Design PPMS equipped with either a 9 T or 14 T magnet. A sample piece broken from a printed part was fixed using cryogenic varnish on a silicon substrate with a 100 nm wet thermal oxide finish. The substrate’s four corners were pre-patterned with four 40 nm gold contact pads with 20 nm chromium as the adhesion layer. 503 silver conductive paint (Electron Microscopy Sciences) was used to make four contacts between the sample and the gold contact pads (Supplementary Fig. 24). The silicon substrate carrying the sample was mounted and bonded through aluminum wires onto a Quantum Design resistivity puck using a West Bond 747630E wire bonder. After loading the puck into the PPMS, low-temperature resistance values were collected from 2.5 K up to 25 K at a direct current of 100 µA for each magnetic field from 0 up to 14 T at an increment of 2 T. For TiN samples, the magnetic field ranged from 0 to 2 T in increments of 0.2 T. A full temperature range up to 305 K of resistance was also measured as the sample warmed up to room temperature. Each data point was averaged from 5 or 25 measurements. Tc was determined as the midpoint of the resistance curve. The extrapolation error derived from the plots of Bc2 versus T is the standard error of the y-intercept, expressed as \(0.69\sqrt{\frac{{\sum }_{i=1}^{n}{x}_{i}^{2}{\sum }_{i=1}^{n}{\left({y}_{i}-\hat{{y}_{i}}\right)}^{2}}{n(n-2){\sum }_{i=1}^{n}{\left({x}_{i}-\bar{x}\right)}^{2}}}\), where ŷi is the corresponding value predicted by linear regression on n sets of data points (xi, yi) and \(\bar{x}\) is the mean of xi. Critical current measurements were performed using the AC transport option with a 60 Hz alternating current at temperatures ranging from 2 K to 15 K (Supplementary Fig. 26). Voltage was recorded as the current was swept from 0 until a jump was observed.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

All data generated or analyzed during this study are included in the Source Data file. Source data are provided with this paper.

Code availability

The G-code files for controlling the print head movement are available upon request from the corresponding author.

References

Whitesides, G. M. & Grzybowski, B. Self-assembly at all scales. Science 295, 2418–2421 (2002).

Truby, R. L. & Lewis, J. A. Printing soft matter in three dimensions. Nature 540, 371–378 (2016).

Tumbleston, J. R. et al. Continuous liquid interface production of 3D objects. Science 347, 1349–1352 (2015).

Kelly, B. E. et al. Volumetric additive manufacturing via tomographic reconstruction. Science 363, 1075–1079 (2019).

Skylar-Scott, M. A., Mueller, J., Visser, C. W. & Lewis, J. A. Voxelated soft matter via multimaterial multinozzle 3D printing. Nature 575, 330–335 (2019).

Walker, D. A., Hedrick, J. L. & Mirkin, C. A. Rapid, large-volume, thermally controlled 3D printing using a mobile liquid interface. Science 366, 360–364 (2019).

Song, M. et al. 3D microprinting of inorganic porous materials by chemical linking-induced solidification of nanocrystals. Nat. Commun. 14, 8460 (2023).

Gao, Y., Lalevée, J. & Simon-Masseron, A. An overview on 3D printing of structured porous materials and their applications. Adv. Mater. Technol. 8, 2300377 (2023).

Bobrin, V. A., Lee, K., Zhang, J., Corrigan, N. & Boyer, C. Nanostructure control in 3D printed materials. Adv. Mater. 34, 2107643 (2022).

Weidinger, B. et al. 3D printing hierarchically nano-ordered structures. Adv. Sci. 10, 2302756 (2023).

Li, L. et al. Hierarchical co-assembly enhanced direct ink writing. Angew. Chem. Int. Ed. 57, 5105–5109 (2018).

Shukrun et al. 3D printing of ordered mesoporous silica complex structures. Nano Lett. 20, 6598–6605 (2020).

Fan, J., Boettcher, S. W. & Stucky, G. D. Nanoparticle assembly of ordered multicomponent mesostructured metal oxides via a versatile sol−gel process. Chem. Mater. 18, 6391–6396 (2006).

Yang, P., Zhao, D., Margolese, D. I., Chmelka, B. F. & Stucky, G. D. Generalized syntheses of large-pore mesoporous metal oxides with semicrystalline frameworks. Nature 396, 152–155 (1998).

Kim, Y., Yuk, H., Zhao, R., Chester, S. A. & Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 558, 274–279 (2018).

Garcia, B. C. et al. Morphology diagram of a diblock copolymer—aluminosilicate nanoparticle system. Chem. Mater. 21, 5397–5405 (2009).

Gratson, G. M., Xu, M. & Lewis, J. A. Direct writing of three-dimensional webs. Nature 428, 386 (2004).

Beaucage, P. A., Susca, E. M., Gruner, S. M. & Wiesner, U. B. Discovering synthesis routes to hexagonally ordered mesoporous niobium nitrides using poloxamer/pluronics block copolymers. Chem. Mater. 29, 8973–8977 (2017).

Wei, J. et al. New insight into the synthesis of large-pore ordered mesoporous materials. J. Am. Chem. Soc. 139, 1706–1713 (2017).

Robbins, S. W. et al. Block copolymer self-assembly–directed synthesis of mesoporous gyroidal superconductors. Sci. Adv. 2, e1501119 (2016).

Beaucage, P. A., van Dover, R. B., DiSalvo, F. J., Gruner, S. M. & Wiesner, U. Superconducting quantum metamaterials from convergence of soft and hard condensed matter science. Adv. Mater. 33, 2006975 (2021).

Robertson, I. D. et al. Rapid energy-efficient manufacturing of polymers and composites via frontal polymerization. Nature 557, 223–227 (2018).

Wu, W., DeConinck, A. & Lewis, J. A. Omnidirectional printing of 3D microvascular networks. Adv. Mater. 23, H178–H183 (2011).

Bhattacharjee, T. et al. Writing in the granular gel medium. Sci. Adv. 1, e1500655 (2015).

Hinton, T. J. et al. Three-dimensional printing of complex biological structures by freeform reversible embedding of suspended hydrogels. Sci. Adv. 1, e1500758 (2015).

Williams, M. W., Ralls, K. M. & Pickus, M. R. Superconductivity of cubic niobium carbo-nitrides. J. Phys. Chem. Solids 28, 333–341 (1967).

Ahn, B. Y. et al. Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 323, 1590–1593 (2009).

Hu, J. & Yu, M.-F. Meniscus-confined three-dimensional electrodeposition for direct writing of wire bonds. Science 329, 313–316 (2010).

Pessall, N., Gold, R. E. & Johansen, H. A. A study of superconductivity in interstitial compounds. J. Phys. Chem. Solids 29, 19–38 (1968).

Reiss, G., Vancea, J. & Hoffmann, H. Grain-boundary resistance in polycrystalline metals. Phys. Rev. Lett. 56, 2100–2103 (1986).

Nigro, A., Nobile, G., Rubino, M. G. & Vaglio, R. Electrical resistivity of polycrystalline niobium nitride films. Phys. Rev. B 37, 3970–3972 (1988).

Werthamer, N. R., Helfand, E. & Hohenberg, P. C. Temperature and purity dependence of the superconducting critical field, Hc2. Iii. electron spin and spin-orbit effects. Phys. Rev. 147, 295–302 (1966).

Deis, D. W., Gavaler, J. R., Hulm, J. K. & Jones, C. K. High field properties of pure niobium nitride thin films. J. Appl. Phys. 40, 2153–2156 (1969).

Mathur, M. P., Deis, D. W. & Gavaler, J. R. Lower critical field measurements in NbN bulk and thin films. J. Appl. Phys. 43, 3158–3161 (1972).

Clogston, A. M. Upper limit for the critical field in hard superconductors. Phys. Rev. Lett. 9, 266–267 (1962).

Yan, R. et al. GaN/NbN epitaxial semiconductor/superconductor heterostructures. Nature 555, 183–189 (2018).

Troitskiy, V. N. et al. Synthesis and characteristics of ultra-fine superconducting powders in the Nb–N, Nb–N–C, Nb–Ti–N–C systems. J. Nanopart. Res. 5, 521–528 (2003).

Xi, X. et al. Ising pairing in superconducting NbSe2 atomic layers. Nat. Phys. 12, 139–143 (2016).

Frankenthal, R. P., Siconolfi, D. J., Sinclair, W. R. & Bacon, D. D. Thermal oxidation of niobium nitride films at temperatures from 20°–400 °C: I. The surface reaction. J. Electrochem. Soc. 130, 2056–2060 (1983).

Shoji, A., Kiryu, S. & Kohjiro, S. Superconducting properties and normal-state resistivity of single-crystal NbN films prepared by a reactive rf-magnetron sputtering method. Appl. Phys. Lett. 60, 1624–1626 (1992).

Ohta, T. & Kawasaki, K. Equilibrium morphology of block copolymer melts. Macromolecules 19, 2621–2632 (1986).

Bawendi, M. G., Steigerwald, M. L. & Brus, L. E. The quantum mechanics of larger semiconductor clusters (‘Quantum Dots’). Annu. Rev. Phys. Chem. 41, 477–496 (1990).

Saveskul, N. A. et al. Superconductivity behavior in epitaxial TiN films points to surface magnetic disorder. Phys. Rev. Appl. 12, 054001 (2019).

Baskaran, R., Thanikai Arasu, A. V., Amaladass, E. P. & Janawadkar, M. P. High upper critical field in disordered niobium nitride superconductor. J. Appl. Phys. 116, 163908 (2014).

Joshi, L. M. et al. Superconducting properties of NbN film, bridge and meanders. AIP Adv. 8, 055305 (2018).

Bailey, T. S., Pham, H. D. & Bates, F. S. Morphological behavior bridging the symmetric AB and ABC states in the poly(styrene-b-isoprene-b-ethylene oxide) triblock copolymer system. Macromolecules 34, 6994–7008 (2001).

Acknowledgements

We would like to thank Louisa Smieska for experimental assistance at CHESS, and Patryk Wasik for experimental assistance at NSLS-II. We would like to thank John Grazul for help in TEM characterizations and John Wright for help with TGA and XPS experiments. We would also like to thank Danni Tang for help with photography. This work was supported by the National Science Foundation (NSF) under grant DMR-2307013. We acknowledge the use of facilities and instrumentation supported by NSF through the Cornell University Materials Research Science and Engineering Center DMR-1719875. We also acknowledge the use of the SMI beamline of the National Synchrotron Light Source II (NSLS-II), a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Brookhaven National Laboratory under Contract No. DE-SC0012704, and the use of the FMB beamline of Cornell High Energy Synchrotron Source, sponsored by Air Force Research Laboratory (AFRL) under agreement numbers FA8650-19-2-5220 and FA8650-22-2-5200. Part of the SAXS experiments were performed at the Center for High-Energy X-ray Sciences (CHEXS), which is supported by the National Science Foundation (BIO, ENG and MPS Directorates) under award DMR-1829070, and the Macromolecular Diffraction at CHESS (MacCHESS) facility, which is supported by award 1-P30-GM124166-01A1 from the National Institute of General Medical Sciences, National Institutes of Health, and by New York State’s Empire State Development Corporation (NYSTAR).

Author information

Authors and Affiliations

Contributions

F.Y., R.P.T., and U.B.W. conceptualized and designed methodology. F.Y., R.P.T., T.A.T., S.S.S., G.F., W.R.T.T., P.A.B., W.L.M., Y.L., and J.G.W. carried out experimental investigations. F.Y. and U.B.W. visualized and interpreted experimental results. U.B.W. acquired funding and administered and supervised the project. F.Y. and U.B.W. wrote the original draft with input from J.T., S.M.G., and R.B.vD. All authors reviewed and edited the manuscript.

Corresponding author

Ethics declarations

Competing interests

U. B. W., F. Y. declare that a patent disclosure has been filed with Cornell’s Center for Technology Licensing (CTL). The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Muhammad Rahman and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yu, F., Thedford, R.P., Tartaglia, T.A. et al. Hierarchically ordered porous transition metal compounds from one-pot type 3D printing approaches. Nat Commun 16, 7704 (2025). https://doi.org/10.1038/s41467-025-62794-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-62794-8