Abstract

The demand for high-performance permanent magnets continues to grow across a wide range of advanced technologies. However, conventional powder metallurgy routes for rare-earth magnets such as Sm–Co are limited by the intrinsic brittleness of the powders, reducing manufacturability and yield. Here, we report a single-step, solid-state processing method—friction consolidation (FC)—that enables simultaneous deformation, heating, and chemical transformation of brittle Sm–Co powders. Using commercial SmCo₅ powders containing Sm₂Co₇, FC induces a thermo-mechano-chemical pathway in which Sm₂Co₇ undergoes oxidation to form nanoscale SmCo(5–x) (where x < 1) and Sm₂O₃ phases. The heat generated from redox reactions and adiabatic shear deformation aids densification without requiring external thermal input. The extent of phase transformation is controlled by local strain and temperature during processing, with higher deformation levels leading to enhanced Sm₂Co₇ decomposition and improved saturation magnetization. This study demonstrates that FC offers a scalable, low-temperature route to consolidate brittle magnetic powders while refining their phase composition and microstructure. By tuning the starting powder chemistry and processing atmosphere, the approach reduces unwanted secondary phases and tailors the final magnetic response—offering a new pathway to fabricate high-performance Sm–Co magnets through a compact, energy-efficient process.

Similar content being viewed by others

Introduction

Sm-Co alloys have an exceptionally high Curie temperature, strong anisotropy field, relatively high saturation magnetization, and outstanding temperature stability1. Due to these excellent magnetic properties, Sm-Co alloys are considered a promising candidate for permanent magnets2. The demand for Sm-Co magnets has steadily grown in clean energy technology, driven by the rising production of advanced motor and drive systems, wind turbine generators, hybrid electric vehicles, micro-electro-mechanical systems (MEMS) and more. These magnets are typically manufactured using the powder metallurgy (PM) process3 and are often followed by heat treatment to achieve sufficient magnetic properties. However, P/M route results in oxidization, low density and high energy input during the process. In MEMS applications, traditional sintering is unsuitable, making SmCo-based film deposition ideal4,5,6,7,8. Additionally, using magnetic field-assisted magnetron sputtering and rapid thermal treatment can offer greater flexibility in buffer layer selection and SmCo layer thickness control9,10. Here we apply a shear-assisted Friction Consolidation (for brevity abbreviated as FC) process which is a single-step, energy-efficient method to consolidate and modify complex alloys like SmCo5, creating unique microstructures for advanced applications.

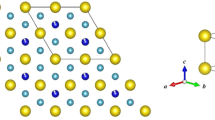

In general, Sm-Co alloys can form multiple intermetallic phases with a range of magnetic responses. Optimization of phase fractions and their distribution, therefore, could immensely influence the permanent magnetic properties. The heat treatment of SmCo5 alloy is generally carried out at temperature range of 850 °C−900 °C and generally forms Co-rich Sm2Co17 phase11,12,13. During low-temperature hot deformation of SmCo5 magnets, Sm-rich, Sm2Co7 (faulted Sm2Co7 and Sm5Co19) phase could form. While the magnetic properties of SmCo5 have been extensively studied, the Sm2Co7 phase has not yet received similar in-depth investigation. A general observation is that the presence of Sm2Co7 phase tends to decrease the coercivity of the magnet14 as the magneto-crystalline anisotropy constant and saturation magnetization of Sm2Co7 phase are comparatively lower than those of SmCo5 phase.

Generally, the coercivity of SmCo5 magnets lies within a range from ~15 to 25 kOe. However, coercivity of as low as 3.5 kOe in P/M manufactured (wet milling followed by spark plasma sintering) SmCo5 magnets has also been reported15. The low coercivity in this case was attributed to the larger and inhomogeneous grain structure. Besides grain size and homogeneity, the magnetic properties of the SmCo5 alloys are greatly influenced by crystallographic texture16,17 and density18. The magnetic properties of Sm-Co alloys could be significantly enhanced by hydrogenation, disproportionation, desorption, and recombination (HDDR) process19,21,21. Nanocrystalline SmCo5 magnets with enhanced magnetic properties were achieved by combining the HDDR and ball milling processes, i.e., milling in a hydrogen atmosphere at elevated temperatures20. Despite the adequate magnetic properties, the manufacturing yield of the Sm-Co magnets is often restricted by their inherent brittleness. Recently, an attempt was made to increase the strength of the SmCo5 magnet by adding cryo-milled Sm2O322. The mechanical strength of SmCo5 magnet was enhanced significantly by this method which further decreased the failure rate and loss during manufacturing. While several unique approaches have been reported to make the manufacturing of the SmCo5 magnets more efficient, economic (cost and efficiency) feasibility must also be considered.

We infer that shear-assisted, adiabatic consolidation analogous to Friction Stir Processing (FSP) can be an effective technique for single-step consolidation of complex alloy and intermetallic powders such as SmCo5. Our FC approach aims to integrate multiple stimuli, such as mechanical stress, chemical reactivity, and thermal activation to create a simple one-step process capable of serving multiple purposes i.e., consolidation, densification, and microstructural modification (Fig. 1a)23,25,26,26. FC has gained attraction in the recent past because of its autogenous nature i.e., no external heat source is required to consolidate the materials. Leveraging the hot working process of FC, novel alloys and composites with reasonable properties were developed successfully, which are challenging to achieve through convention metal processing routes27,28,29,30. Previous literature showed that the density and microstructure of the shear-assisted consolidated material can be a function of the process parameters24. The FC process can also be applied to a variety of metal powders but no effort has been reported on brittle magnetic particles. Our approach reveals the possibility of processing a variety of materials where new transformation pathways can be explored while reducing the overall energy input and developing a range of non-equilibrium or persistently metastable microstructural states for advanced engineering applications.

a Schematic of FC process and setup, demonstrating change from initial segregated SmCo5 and Sm2Co7 (mix of faulted Sm2Co7 and Sm5Co19) powder particles into a consolidated sample. Backscattered electron (BSE) images depict different phases that are present in both steps. b Schematic illustrating the microstructural and energetic interfacial profile evolution of Sm2Co7 and SmCo5 during FC processing. c From the orientation maps collected using EBSD technique, the Image quality (IQ) map and Kernal Average Misorientation (KAM) map of consolidated FC sample display high concentration of strain energy in the grain (or particle) boundaries indicating the particle fragmentation during FC. d Hypothetical energy landscape profile of the SmCo phases under FC processing, experiencing divergence due to thermal and mechanical stimuli, producing a chemical reaction and formation of metastable SmCo(5-x).

In this work, Friction Consolidation (FC) was employed as a single-step densification method to consolidate Sm-Co-based magnet powders containing SmCo₅ and Sm₂Co₇ phases (Fig. 1a and Figure S1). The Sm-rich Sm₂Co₇ particles exhibit a faulted structure comprising both Sm₂Co₇ and Sm₅Co₁₉. For simplicity, we refer to this Sm-rich, SmCo₃.₅-type stoichiometric structure—appearing as bright gray in the SEM micrographs—as Sm₂Co₇ in this manuscript. A multi-length-scale characterization approach was used to investigate the phase transformations occurring during consolidation. The interface between Sm₂Co₇ and SmCo₅ acts as a reactive front where chemical transformation is triggered by mechanical stimuli and further driven by frictional and adiabatic heating. (Fig. 1b). Air triggers oxidation on the interface, with Sm2Co7, with lower formation energy (−0.065 eV) compared to SmCo5 (−0.045 eV), is more susceptible to react, resulting in new phase (Fig. 1b). Besides the phase transformation, particle fragmentation during the process also contributed to forming the ultrafine (UF) or nanocrystalline (NC) grains. Figure 1c shows the experimental results from the orientation mapping (conducted in SEM) where the Kernel Average Misorientation (KAM) map highlights stress-affected boundaries. During FC, the Sm-Co powder particles experienced intense shear stress. However, their plastic deformation was restricted by the limited slip systems of the alloy31. Consequently, the strain energy was concentrated around the periphery of the particles as evidenced by the KAM map (Fig. 1c). This led to the fragmentation of the coarse particles, leaving UF and NC grains at the periphery and resulting in a heterogeneous microstructure. The stress distribution varies with grain fragmentation and areas where phase transformation-induced new grain formation led to a heterogeneous grain structure. We hypothesize that the consolidation process of these powder particles initiates a divergence in energy due to mechanical stirring and thermo-chemical stimuli (from adiabatic heating and phase transformation), resulting in an additional metastable SmCo(5-x) (x < 1) species (Fig. 1d). Further, microstructure-magnetic property correlation indicates an enhancement in the saturation magnetization.

Results and discussion

Spatial variation in density, microstructure, and texture during consolidation

A comprehensive microstructural analysis of various zones in the FCed magnet is presented in Fig. 2. In Fig. 2b–d, a series of BSE images (left ones) of different locations (Fig. 2a) depicts the transition from loose particles (density of ~4.64 g/cm³) to a fully consolidated region at the top (density of 8.56 g/cm³) of the sample, demonstrating the successful consolidation achieved through FC. Cui et al.22 demonstrated that cryo-milling SmCo₅ powder before sintering enhanced its density from 8.1 to 8.5 g/cm³ through the P/M route. FC serves as a superior alternative for fabricating denser materials compared to the conventional powder metallurgy (PM) route3,32. The increased density in our process may also result from reduced oxidation compared to sintering. Increased density could also be due to limited oxidation in our process compared to sintering process. In comparison to the conventional PM route, the effectiveness of FC in achieving denser compacts is further demonstrated by FEM-based modeling, as depicted in Figure S2. The model suggests that a slight rotation (10°) to the tool, alongside a specific axial force (in the present study, the axial force was 4536 kg or 10k pounds), can significantly reduce porosity defects, a feature that is absent in the conventional PM route.

a Macroscopic view of the consolidated material with three regions, i.e., fully consolidated top region, partially consolidated middle region, and loosely compacted bottom region. The corresponding BSE image, band contrast and grain size distribution plot (form left to right) for (b) fully consolidated top region and (c) partially consolidated middle region. d BSE image of the loosely compacted bottom region. (e) (0001) pole figure of the top (left) and middle (right) region.

Careful observation of the BSE images of the fully and partially consolidated regions (Fig. 2b, c, respectively) reveals three distinct contrasts, indicating the presence of three different phases. A magnified view of these three phases is provided in Figure S3b. Combined BSE and energy dispersive spectroscopy (EDS) analysis of the fully consolidated region (Figure S3) unveiled the brightest and darkest contrasts as the Sm oxide (>40 at. % O) and SmCo5 (Sm:Co >4.5) phases, respectively. The intermediate grey contrast was identified as the Sm2Co7 phase (Sm:Co ~3.5). Additionally, EDS analysis (Figure S3f) confirmed the presence of newly formed SmCo(5-x) (x < 1) phases around the Sm2Co7 phase. However, due to the minimal difference in atomic number of SmCo₅ phase and SmCo(5-x) metaphases, distinguishing them based on BSE contrast is challenging. The formation of the oxide and SmCo(5-x) phases can be attributed to atmospheric effects during the consolidation process. Since FC was conducted in an open atmosphere, it is reasonable to assume the presence of trapped oxygen and limited moisture content around the Sm-Co particles. Under the combined influence of high temperature (980 °C) and pressure during FC, the trapped atmosphere served as a source of oxygen (and possibly hydrogen), initiating a reaction at the outer layer of Sm-Co powder particles. The Sm-rich phase (Sm2Co7) has a higher affinity for oxidation, leading to phase transformation at the Sm2Co7 particle boundaries after interacting with oxygen. A previous report suggests that in the presence of oxygen, the Sm-rich phase (Sm2Co7) can undergo oxidation at high temperatures (~1100 °C) to form SmCo5 and Sm2O3 phases, following the reaction:

A similar reaction was expected in the present case, however, instead of SmCo5 phase being formed, the formation of SmCo(5-x) (where x˂1) phase was observed. This discrepancy is likely due to the limited supply of oxygen during the FC process. As, the consolidation process was conducted in an argon atmosphere, the availability of oxygen (which was trapped among the particles) was minimal. A lower O/Sm2Co7 ratio could lead to the formation of SmCo(5-x) phase, as exemplified by the reaction:

Redox-driven phase transformation and chemical partitioning

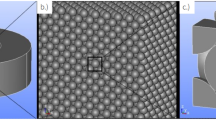

The nucleation of the newly formed, ultrafine SmCo(5-x) (SmCo4.7) grains and Sm oxide phases around the Sm2Co7 phase were observed in the magnified BSE image of the fully consolidated region which is shown in Fig. 3a. The formation of fine SmCo(5-x) grains around the coarse Sm2Co7 grains could result in a bimodal grain size distribution within the consolidated material. To examine the grain size distribution in both fully and partially consolidated regions, electron backscattered diffraction (EBSD) analysis was conducted, and the results are shown in Fig. 2b, c, respectively. In Fig. 2b, c, the band contrast images are shown in the middle and their corresponding grain size distribution charts were shown on the right. The EBSD analysis clearly confirms the bimodal grain size distribution in both regions, with an average grain size of approximately 5 µm. In addition to the phase transformation and new phase nucleation, particle fragmentation also plays a critical role in achieving such bimodal grain size distribution. During the initial stage of FC, both SmCo5 and Sm2Co7 powder particles were subjected to intense shear stress. The limited slip systems of the brittle powder particles restrict their plastic deformation, causing strain energy to concentrate around their periphery, as shown by the KAM map (Fig. 1c). Consequently, the brittle SmCo5 and Sm2Co7 particles fragmented into ultrafine grains at their edges. This particle fragmentation and grain formation are highlighted in Figure S4. The interface between the ultrafine grains and the coarse grains in Figure S4 displays either sharp or serrated morphologies. Sharp interfaces are indicative of particle fragmentation, while serrated interfaces suggest the nucleation of new grains.

a Magnified BSE image showing the nucleation of SmCo(5-x) (shown by red arrows) and Sm2O3 phases (shown by black arrows) around the Sm2Co7 grain in the consolidated sample, note that the APT analysis was performed at the interior of SmCo5 phase and at the boundary of Sm2Co7 phase which are highlighted by yellow and blue colors. b HAADF image of the consolidated sample and corresponding EDS maps of Co, Sm and O elements. c APT analysis showing uniform chemical distribution in the grain interior of SmCo5 phase and (d) the presence of three distinct phases at the boundary of Sm2Co7 phase. e, f Chemical distribution of different elements along the cylinder indicated in (d).

For crystallographic texture analysis on both the fully and partially consolidated region, orientation data obtained from EBSD scans was processed and arranged as {0001} pole figures (PFs) which are shown in Fig. 2e. The dominant deformation mode in FC is expected to resemble simple shear texture, characterized by the crystallographic plane and direction aligning with the shear plane and shear direction, respectively. The working principle of FC is analogous to high-pressure torsion (HPT) deformation processes. In HPT, it is well-established that deformation predominantly occurs through simple shear, with the shear plane normal aligned to the loading direction and shear direction is tangentially to the rotation axis. Accordingly, the PFs of the FCed materials are presented in the RD and TD planes, where RD represents the loading direction and TD corresponds to the tangential direction relative to the rotation axis. It is important to note that while the sintered magnets are often characterized with strong c-axis texture where the basal poles 〈0001〉 were aligned parallel to the normal direction (ND), the FCed magnets showed nearly random texture. In conventional powder metallurgy route, an external magnetic field is applied before and/or during the pressing to align the c-axis. During FC process, it is challenging to form c-axis alignment due to low symmetry and few slip systems in SmCo5 magnets. Such random texture of the FCed material could adversely affect its magnetic properties, which are further discussed in the manuscript.

Further, the transmission electron microscopy (TEM) and atom probe tomography (APT) analyses were carried out in that region to comprehend the chemical and phase distribution, and the results are shown in Fig. 3. Figure 3b shows the high-angle annular dark-field (HAADF) image and the corresponding EDS maps for Sm, Co, and O. The selected area electron diffraction (SAED) patterns for SmCo5, Sm2Co7, and Sm2O3 phases are shown in Figure S5. A detailed description of Fig. 3a, b is provided in the supplementary file (Figures S6 and S7). The TEM-EDS maps confirm the previous observation regarding the presence of oxide phase near Sm2Co7 phase. Although the presence of a thin oxide layer on the surface of the SmCo5 particles is often reported1, such a considerable fraction of the oxide phase in the present study is unlikely to be derived solely from those surface oxides, thus indicating oxide formation during the consolidation process.

For APT analysis, samples were extracted from two different locations on the fully consolidated region; (i) at the center of the SmCo5 grain and (ii) along the interface of Sm2Co7 phase which is highlighted by blue and yellow color in Fig. 3a, respectively. The APT reconstruction from the grain interior is shown in Fig. 3c and the corresponding quantitative chemical distribution is presented in Table 1. Table 1 shows that in addition to Sm and Co, a trace amount of Fe and Cu were also present in the SmCo5 phase. The presence of Fe and Cu was not expected and indicates the commercial purity initial powders. The APT reconstruction along the interface is shown in Fig. 3d. The chemical distribution along the cylinders in Fig. 3d is shown in Fig. 3e, f. The quantitative chemical distribution along each cylinder is also provided in Table 1. Table 1 shows that in addition to Sm and Co, a trace amount of Fe and Cu were also present in the SmCo5 phase. Fe can be strategically added to form Sm(Co,Fe)₅ alloys to enhance specific magnetic properties33, while Cu is often introduced to regulate grain boundaries and improve consolidation. However, in this study, Fe and Cu were not intentionally added to the initial feedstock powder, and their presence indicates the commercial purity initial powders. Given the relatively low concentrations of Fe and Cu, their effect on the overall phase evolution or magnetic properties in the present case is considered negligible. The chemical distribution suggests the formation of three distinct regions at the interface, i.e., Sm2O3, a Sm-rich interface, and a SmCo4.3 phase, labeled in Fig. 3d. it is evident that the oxide phase contains over 7.8 at.% H, ~1.9 at.% Fe and a Sm:O ratio of 1:1.3 (instead of the expected 1:1.5), highlighting the transitional/metastable nature of the oxide phase at the interface. TEM results (Figure S5) concluded that crystallographically, the oxide can be consistently indexed as Sm2O3. Additionally, the interfacial enrichment layer (~53 nm thick) contained over 71.4 at. % Sm and less than 19 at. % Co (~Sm3.9Co). It is unclear whether this is solely a compositional enrichment or a new structure phase at the interface. Such enrichment was not observed during the TEM examination; hence, it could also be heterogeneously located. The Sm:Co ratio in the interfacial formed SmCo5 phase is 1:4.3 which is lower than expected 1:5. This is consistent with our earlier hypothesis that transformation occurs under limited oxygen presence during processing. It is crucial to consider that at elevated temperatures and in the presence of oxygen, Sm₂Co₇ or SmCo₅ phases can decompose into a soft magnetic Co(Fe) phase, accompanied by the formation of (CoO/Co₃O₄) or Sm₂O₃ phases34. The presence of such soft magnetic phases could adversely impact the magnetic properties. However, no evidence of these phases (Co(Fe) and CoO/Co₃O₄) was found during the multi-length scale characterization (SEM, TEM, and APT) in the present investigation. This suggests that the far-from-equilibrium conditions achieved in FC do not favor their formation.

Based on the contrast obtained from Fig. 2b, a quantitative phase (SmCo5, Sm2Co7, and Sm2O3) analysis of different regions (fully consolidated, partially consolidated and loosely compacted region) of the consolidated material was performed and the result is shown in Fig. 4a. Due to difficulties in distinguishing SmCo5 from SmCo(5-x) phase in the BSE images, in this analysis, the percentage of SmCo5 represents the combined occurrence of both initial SmCo5 and newly formed SmCo(5-x) phases. The quantitative analysis revealed an increase in the percentage of the Sm2Co7 phase from the fully consolidated region to the loosely compacted region, from ~10% to ~26%, while the occurrence of the SmCo5 phase showed a decreasing trend, from ~81% to ~74%. Additionally, there was a noticeable decrease in the occurrence of the oxide phase, from ~8.5% to ~0%, from the fully consolidated region to the loosely compacted region. This variation in the occurrence percentage of different phases of the compacted material could be attributed to the location-dependent variation in the effective strain and temperature during FC. Previously, Li et al.35 showed that during friction stir consolidation, the effective strain and temperature are highest at the contact surface that is adjacent to the rotating tool and gradually decrease toward more remote regions. Distribution of stress and heat during FC processing results in a significant difference in microstructure between the top (fully consolidated region) and bottom (loosely compacted) regions. The fully consolidated region experiences direct transfer of heat and stress from the tool, resulting in an elevated temperature and pressure that allows total compaction and high reaction rates. As a result, a higher fraction of SmCo(5-x) and Sm oxide was formed at the top (fully consolidated region) compared to the bottom region which is shown in Fig. 4a. Figure 4a represents the average phase fraction obtained from image thresholding analysis of multiple high-resolution BSE-SEM images per location, more details on these measurement can be seen in supplementary information S9.

a Quantitative analysis of different phases at top (fully consolidated), middle (partially consolidated) and bottom (loosely compacted region) of the consolidated material, (b) magnetization (M) vs magnetic Field (H) curves from top and middle regions, (c) second quadrant of the M-H curve of regions going from fully consolidated section of the material to less consolidated, (d) magnetic force microscope (MFM) image of the top region, (e) magnified view of the marked region in (d) which highlights the domain wall and presence of non-magnetic Sm2O3 phase and (f) Quantified phase shift degree based on the line indicated on (e). Values were measured based on the grey values and contrast of grains based on the MFM image. The different bands used in (f) (1-7) are just to highlight the change in magnetic moment from one domain to other.

Furthermore, thermogravimetric analysis and differential scanning calorimetry (TGA-DSC) was done on fully and partially consolidated regions (Figure S8a). The result shows a significant mass increase at >220 °C coupled with a broad exothermic reaction which suggests that oxidation reaction proceeds beyond ~650 °C, which is considerably lower than the maximum temperature reached in this our process i.e., ~980 °C. Between fully and partially consolidated regions (Figure S8b), the later achieved a higher mass gain under the same condition, hence, it can be inferred that the heat released during the reaction aided the consolidation process, and thus the fully consolidated region is more resistant to oxygen diffusion. EDS results (Figure S8d–g) also show the occurrence of preferential oxidation of Sm2Co7 phase. The partially consolidated region where the inherent Sm2Co7 fraction was higher showed a higher weight gain, while the fully consolidated region had a lower weight gain due to oxidation.

Magnetic property variation across consolidation depths

Magnetic properties of the fully and partially consolidated regions of the consolidated material are shown in Fig. 4b, c. The magnetic properties of the FCed magnets in comparison to sintered magnets prepared by P/M route is listed in Table 2. It was found that the coercivity, remanence, saturation magnetization, and maximum energy product (BHmax) of samples showed a strong dependency on the process. The explicit definition of these different magnetic properties is provided in supplementary information. As seen in Fig. 4c, the trends in coercivity going from the fully consolidated region to less consolidated (Top 1 and 2 to Bottom 1 and 2) are rather complicated. It is evident that the partially consolidated region exhibited higher coercivity than the others. Such variation in the coercivity values could be attributed to the variation in the fraction of porosity and Sm₂Co₇/Sm₂O₃ phases along different regions. It was observed that the decomposition of the Sm₂Co₇ phase into SmCo₅ (with slightly lower Co then stoichiometric composition) and Sm₂O₃ is an exothermic process, with its extent increasing progressively from the loosely compacted to the fully consolidated region. This decomposition influences the local coercivity in two opposing ways. On one hand, a greater degree of decomposition leads to a higher fraction of Sm₂O₃ (a paramagnetic phase) which tends to reduce the coercivity. On the other hand, the presence of more Sm₂O₃ indicates improved consolidation and less residual Sm₂Co₇, which can locally enhance coercivity. In the present case, the higher coercivity in the partially consolidated region can be attributed to its relatively lower fraction of the Sm₂O₃ phase. The remanence shows a more straightforward increase from the partially to fully consolidated region. Broadly, the partially consolidated region showed remanence and BHmax of 3.90 kG and 3.45 MGOe, which increased up to 5.26 kG and 5.50 MGOe for the fully consolidated region, respectively. Similarly, the fully consolidated region showed sufficiently higher saturation magnetization as compared to partially consolidated region. The location-dependent variation in the fraction of the Sm2Co7 phase in the FCed samples further affected the saturation magnetization. Previous literature suggests that the occurrence percentage of the SmCo5 and Sm2Co7 phases could significantly affect the magnetic properties of Sm-Co magnets. The magnetocrystalline anisotropy constant (>17 MJ/m3 for SmCo5 and less than 5 MJ/m3 for Sm2Co7) and saturation magnetization of Sm2Co7 phase can be comparatively lower than those of SmCo5 phase36,37. Previously, Campos et al.38 suggested an empirical relationship among the phase fraction, porosity content and degree of alignment of SmCo5 magnet with their remanence and saturation polarization.

where, Jr and Js represent the magnet remanence and saturation polarization of the SmCo₅ phase, respectively, P denotes the packing factor, defined as the ratio of the magnet’s density to the theoretical density of SmCo₅, N is a parameter associated with microstructural constituents, excluding pores, that do not contribute to remanence, and cos θ represents the grain alignment factor.

Further, the saturation polarization of Sm-Co magnets (\({J}_{{{\rm{s}}}}^{{magnet}}\)) with varying phases can be calculated using the rule of mixtures, as shown in Eq. 2.

Where: \({J}_{{{\rm{s}}}}^{1:5}\) and \({J}_{{{\rm{s}}}}^{2:7}\) are the saturation polarization of SmCo5 (1.12 T) and Sm2Co7 phase (0.79 T), respectively and, \({f}_{1:5}\) and \({f}_{2:7}\) are the volume fractions of the SmCo5 and Sm2Co7 phase in the Sm-Co magnet, respectively.

By considering the presence pores and other phases, the volume fraction SmCo5 could be expressed as

where fpores = (1 − (density of the magnet/8.6), foxides = (0.0726·density of the magnet·% O)/7.4 with density for Sm2O3 = 7.4 g cm−3. In the present case, the contribution of carbide can be excluded from Eq. 3, as it was not observed in the microstructural analysis.

Equation 3 suggests that the saturation polarization of Sm-Co magnet increases when the volume fraction of the SmCo5 phase increases. As a result, the sample (from fully consolidated region) or the location (top portion) with a more of the SmCo5 phase showed higher saturation magnetization. By combining Eqs. 1, 2 and 3, the remanence of the Sm-Co magnet (\({J}_{s}^{{magnet}}\)) could be expressed as

Equation 4 suggests that the remanence of the Sm-Co magnets could be improved by reducing porosity, decreasing the volume fraction of the Sm₂Co₇ and Sm2O3 phases, and maximizing the degree of alignment of the grains. In the present case, the higher remanence and saturation magnetization observed in the fully consolidated region as compared to the partially consolidated one is consistent with this formalism. Equation 4 also indicates that achieving textured magnets via FC could further enhance their remanence.

The coercivity of FCed magnets is lower than that of sintered magnets, primarily due to the presence of non-spherical coarse grains (Fig. 2b, c) and high density of misorientation boundaries (Fig. 1c)39,40. Tang et al.39 previously reported that in SmCo5 magnets, maintaining grain size within the stable single-domain range of 740–870 nm enhances coercivity. In the present study, while some grains in both the fully and partially compacted regions are smaller than 1 µm, the majority exceed this size, with many reaching up to 8 µm. These non-spherical coarse grains are likely to contribute to the reduced coercivity of the FCed magnets. By optimizing FC parameters such as pressure, rotational speed, and dwell time, a more uniform refined microstructure in Sm-Co magnets could be achieved. Increasing dwell time during FC will lead to a longer exposure of the material to elevated temperature and strain, which facilitates the decomposition of Sm₂Co₇ into SmCo(5–x) and oxide phases. Furthermore, a longer dwell time enables a larger volume of material to undergo consolidation due to the extended duration of plastic deformation and thermal input. However, we also acknowledge that excessive dwell times can result in undesirable grain growth and increased oxidation, both of which may negatively impact the overall magnetic performance. This underscores the need for optimization of processing time to strike a balance between promoting beneficial phase transitions and minimizing microstructural degradation. While our current work focused on demonstrating the feasibility of the process, future studies will explore time-dependent effects in greater detail to optimize magnetic properties.

In conventional PM processing, dislocations can form in Sm-Co magnets during ball milling41, and an increased dislocation density is known to impact negativdely the coercivity by pinning domain walls42. The work of Fidler et al.43 demonstrated that prismatic dislocations in SmCo5 can act as pinning sites for magnetic domain walls, providing early evidence of this effect. To mitigate the negative impact of dislocations in the conventional PM process, a post-processing heat treatment is commonly applied. Beyond grain size and microstructural strain, the coercivity of Sm-Co alloys can also be significantly reduced by dissolved H44,45.

Magnetic force microscopy (MFM) was performed to understand the magnetic characteristics of the different phases in the fully consolidated region and record their magnetic interaction. The maps generated using MFM are displayed in Fig. 4d, e, which depict a similarity to the phase distribution observed in the SEM analysis. Comparing the SEM images and the MFM maps, it appears that the larger grains in the microstructure (SmCo5) contain sub-boundaries that can be representative of the domain walls. The distance between domain walls ~3 µm in the fully consolidated region. It is important to differentiate between the domain wall width and the interdomain wall distance. In high magnetocrystalline anisotropy SmCo magnets, the former is generally on the nanometer scale, while later can be significantly larger, often extending to the micrometer range46,47,48,49. Our measured value of ~3 µm is consistent with previous experimental findings for Sm-Co magnets produced via the conventional PM route.

The brightest regions on the map match well with the location of Sm2O3 particles, suggesting non-magnetic interaction with the MFM tip. Image analysis of the MFM map shows clear distinction between regions based on their phase shift angles. Conversion of gray values and contrast analysis shows clear boundaries between different species in the region as indicated by the sharp peaks and domains, whether it is an inflection or deflection (Fig. 4f).

Nanocrystalline grains act as single magnetic domains, maximizing coercivity, whereas grains above the single-domain size become multi-domain, facilitating domain-wall motion and reducing coercivity. In Sm–Co alloys, grain coarsening above 900 °C has been shown to degrade magnetic performance. Remarkably, even after exposure to ~980 °C in our fully consolidated (FCed) samples, both fully and partially consolidated regions retain an ultrafine, nanocrystalline microstructure—evidence of exceptional thermal stability. We attribute this stability to finely dispersed oxide particles formed during consolidation. These oxides exert a Zener-pinning effect, inhibiting grain growth, and simultaneously reinforce the matrix: Cui et al. demonstrated that adding 0–3 wt % Sm₂O₃ to Sm₂(CoFeCuZr)₁₇ magnets halved the grain size (45 µm → 22 µm) and boosted flexural strength by ~62% without sacrificing magnetic properties22.

Mechanical property mapping of fully consolidated Sm–Co phases via nanoindentation and vickers testing

Uniform hardness and ensures dimensional stability of SmCo₅ magnets under mechanical and thermal loads. The crack path on indentation (if not intergranular) also highlights completion of particle-fusion in the consolidate. In this study, fully consolidated (FCed) samples were characterized by load-dependent nanoindentation and Vickers hardness tests (Fig. 5a–e). Nanoindentation measurements—performed with indents spaced 10 µm apart in a 30×30 grid—revealed a heterogeneous hardness distribution reflecting the SmCo₅, Sm₂Co₇, and Sm₂O₃ phases. At low loads (50 mN), the hardness averaged 13.8 ± 1.2 GPa, then decreased to a plateau of 9.5 ± 0.5 GPa above 200 mN, consistent with the indentation-size effect arising from surface roughness and elastic recovery. In contrast, Vickers tests—with indents separated by 200 µm—yielded a constant hardness of 9.2 ± 0.1 GPa across loads from 100 to 500 g, confirming the bulk mechanical response. To prevent strain-hardening artifacts, indent spacing was maintained at ≥ 50 µm (Fig. 5b). Brittle intragranular cracks observed at 200 mN (Fig. 5c) suggest strong interparticle bonding yet intrinsic phase brittleness. Hardness and Young’s modulus maps at 200 mN (Fig. 5d, e) showed an average modulus of 132.5 ± 2.0 GPa, with local maxima of 10.5 GPa hardness and 136.5 GPa modulus co-located in Sm₂Co₇-rich regions. While individual-phase properties could not be isolated at this load, these elevated values underscore the higher stiffness of Sm₂Co₇ and its contribution to the composite’s mechanical performance.

a Hardness-load plot of the fully consolidated sample obtained by nanoindentation and Vickers hardness test, b BSE image showing the sufficient gaps between each consecutive indent to avoid the strain hardening effect near the indents, (c) cracks near the indents at 200 mN load, (d) hardness and (e) Young’s modulus mapping of fully consolidated region obtained by nanoindentation hardness test performed at 200 mN load. Note that in Fig. 5a, an average of 5 individual datapoints at each load was considered to ensure statistical reliability. The error bars represent the range between the maximum and minimum hardness values at each load, while the solid squares denote the corresponding average hardness values.

In this study Friction consolidation (FC) was successfully employed as a single-step densification technique for consolidating Sm-Co based magnet powder particles containing SmCo5 and Sm2Co7 phases. Comprehensive multi-length scale characterization techniques were used to understand the phase transformations during the consolidation process. Based on the analysis, the following conclusions can be drawn:

-

1.

The boundaries of Sm2Co7 phase were identified as a critical site for chemical reactions, driven by the mechanical stimuli of high-speed stirring and enhanced by frictional and adiabatic heating. Atmospheric oxygen-induced oxidation at the interface, favoring phase transformation in Sm2Co7 due to its lower formation energy, leading to the formation of new phases around Sm2Co7.

-

2.

The consolidation process results in a dense, heterogeneous grain structure, with the formation of an additional metastable SmCo(5-x) (x < 1) and Sm oxide phases.

-

3.

The study also highlighted the excellent thermal stability of the FCed samples, attributed to the presence of fine oxide particles exerting a Zener pinning effect, restricting grain growth at high temperatures. This thermal stability, along with the observed improvements in magnetic properties, demonstrates the potential of FC as an effective technique for producing high-performance Sm-Co magnets.

-

4.

The quantitative phase analysis showed a location-dependent variation in the phase fractions, influenced by the effective strain and temperature during FC.

-

5.

The magnetic properties of the compacted magnets demonstrated a strong dependency on the location. In the top layer near the rotating tool, the formation of the new SmCo(5-x) phase by replacing the less magnetic Sm2Co7 phase enhanced the magnetic properties of the consolidated product, specifically the saturation magnetization. Moving from the top to bottom of the compacted magnet, a gradual increment in the occurrence percentage of the Sm2Co7 phase was observed which further caused a reduction in the saturation magnetization.

The current approach could be more efficient than conventional powder metallurgy routes for achieving consolidated bulk magnets with higher density and reduced porosity. The phase transformation process during this process was exothermic, potentially aiding the compaction process. Future optimization of the process parameters, including rotation speed, forge force, environmental control, and dwell time could further enhance the properties and performance of compacted material.

Methods

Materials and sample preparation

Sm-Co jet milled powder particles (an irregular shape with an average size of ~ 6.5 ± 10 µm) containing Sm2Co7 and SmCo5 phases procured from American Elements (Los Angeles, CA) were used as a starting material. The BSE image of the powder particles (Fig. 1a) shows bright and dark contrasts corresponding to Sm2Co7 and SmCo5 phases, respectively. These powder particles were subjected to Friction consolidation (FC) with the setup depicted in Figure S1. The TEM analysis along with the magnetic properties of the feedstock powders are provided in Figure S1c, f, respectively. To assess the magnetic properties of the loose particles, they were embedded in polymer resin to prevent movement caused by the magnetic field during testing. The working principle of the FC process is described by Komarasamy et al.27. The FC was carried out at a constant tool rotational speed, pressure, and dwell time of 300 RPM, 4536 Kg (10 klbs) and 120 s, respectively in an argon atmosphere. The maximum temperature reached during the consolidation process was measured using a K-type thermocouple. The consolidated sample was sectioned in the ND-TD plane and was polished using standard metallography techniques for microstructural characterization and subjected to backscattered electron (BSE), energy dispersive spectroscopy (EDS), and electron backscatter diffraction (EBSD) analyses using in a Hitachi SU3900 field emission-scanning electron microscope (FE-SEM). The strain distribution in the consolidated samples was analyzed via kernel average misorientation (KAM) map obtained from the EBSD scan. The KAM represents the measurement of the average misorientation around a given measurement point in relation to a defined set of nearest neighbor points. In this method, the local misorientation is evaluated for the central point of a specific grain considering all points along the perimeter of the kernel. Generally, deformed grains exhibit higher KAM values due to an increased dislocation density50. Based on the understanding of local lattice distortions, localized deformation, and high dislocation density, the KAM maps could suggest stored strain energy in the grain.

Transmission Electron Microscopy: Bright-field transmission electron microscopy (BFTEM) and high-angle annular dark field (HAADF) observation were performed on consolidated sample using a FEI Titan 80–300 operated at 300 kV. The chemical distribution at the grain interior and boundary were examined using APT. A CAMECA LEAP 4000X HR APT was used in pulsed voltage mode at a 200 kHz pulse frequency with 20% pulse fraction, a specimen temperature of 50–60 K, and a detection rate that was maintained at 0.005 atoms/pulse. Samples for TEM and APT analyses were prepared using Thermo Fisher Scientific Quanta 200 FIB-SEM equipment. For magnetic property evaluation, Quantum Design MPMS 3 superconducting quantum interference device vibrating sample magnetometer (SQUID-VSM) was used for magnetic measurements. Magnetic moment (M) was measured at room temperature with respect to the applied magnetic field (H) up to 70 kOe to construct the M-H loop. To determine the magnetic energy product, the true density of the solid sample was measured at room temperature using a Quantachrome Micro-Ultrapyc 1200e Automatic Gas Pycnometer employing Grade 5 nitrogen.

To image the magnetic domain structures, a Dimension ICON magnetic force microscope (MFM) equipped with a probe having magnetic CoCr coated cantilever with resonance frequency of 70 kHz and a spring constant of 2–3 N/m was used. Initially, a topography scan was performed in tapping mode, followed by measuring the magnetic contrast at a predetermined tip lift. In the resulting images, regions of bright and dark contrast correspond to the magnetic field perpendicular to the film plane and parallel to the magnetization of the tip, respectively.

Scale of the phase shift degree from the MFM images were converted from the scale bar by using imageJ software. Image conversion was performed to measure the gray values within the image, from which contrast from different regions can be measured.

Thermogravimetric analysis (TGA)/Differential Scanning Calorimetry (DSC) experiment: thermal analysis for SmCo5 sample taken from different regions (fully and partially consolidated regions) was performed using a Mettler Toledo TGA/DSC 3 + . Sample (~20 mg) was placed in an open 70 μl alumina crucible under 20 ml grade 6 argon (99.99% purity) purge gas. Thermal measurement was measured up to 1100 °C with 10 °C/min ramp rate. All data was analyzed using the Mettler Toledo Star-e software.

Hardness measurements: To measure the hardness of the consolidated material, Vickers and nanoindentation hardness testing was employed. The Vickers hardness testing was carried out in a Mitutoyo Vickers hardness tester at a load of 1962–9810 mN and dwell time of 10 s. The nanomechanical testing was performed using the Hysitron (Bruker) PI89 pico indenter, equipped with a cubic boron nitride Berkovich indenter tip. Nanoindentation mapping was conducted with a single cycle load-controlled indentation protocol, where a load of 25–250 mN load was applied at 5 μm intervals between a total of 100 indents. This process involved a 5 s linear load to the maximum force, a 2 s hold, and a subsequent 5 s linear unload. Nanoindentation hardness (H) and reduced Young’s modulus (Er) were determined using the Oliver–Pharr analytical method.

Inclusion & ethics statement

This study was conducted in accordance with ethical research practices and principles of diversity, equity, and inclusion. The research team values collaboration across diverse backgrounds and perspectives, fostering an inclusive environment for scientific discovery. We affirm that this research adheres to the highest standards of scientific integrity, including proper attribution of data sources, avoidance of conflicts of interest, and transparency in reporting. The authors acknowledge the contributions of all collaborators and respect the principles of fairness and equal opportunity in scientific research and authorship.

Data availability

All data were available in the main text or the supplementary materials. The raw data has been uploaded alongside the manuscript. Source data are provided with this paper.

References

Korn, N., Vaimann, T., Kallaste, A. & Belahcen, A. Comparative study of slow-speed slotless synchronous generator using SmCo and NdFeB permanent magnets. 2014 Electric power quality and supply reliability conference 247–250 (2014).

Zhou, X., Huang, A., & Cui, B. & Sutherland, J. W. Techno-economic assessment of a novel SmCo permanent magnet manufacturing method. Procedia CIRP 98, 127–132 (2021).

Carriker, R. C. & Ludewig, G. H. Production of SmCo5 magnets using single phase sintering aid. AIP Conf. Proc. 5, 1077 (1972).

Hong, Y. et al. Microstructure, phase compositions, and coercivity evolution in micron-thick SmCo-based permanent magnetic films. J. Alloy. Compd. 1010, 177023 (2025).

Qiu, Z. et al. Atomic diffusion and microstructure of SmCo5 multilayers with high coercivity. J. Alloy. Compd. 733, 45–52 (2018).

Zheng, X. R. et al. Magnetic properties and microstructures of multi-component Sm–Co-based films prepared by high-throughput experiments. Rare Met. 44, 1284–1293 (2025).

Gong, Y. et al. Strategy of preparing SmCo based films with high coercivity and remanence ratio achieved by temperature and chemical optimization. J. Rare Earths 42, 1289–1297 (2024).

Hong, Y. et al. Influencing mechanisms of atomic diffusion and compositional distribution on the magnetic anisotropy of Cr/SmCo/(Cu)/Cr thin films. Acta Mater. 164, 627–635 (2019).

Wei, L. et al. Effects of temperature gradients on magnetic anisotropy of SmCo based films. J. Alloy. Compd. 898, 162900 (2022).

Li, H. et al. Microstructure and magnetic anisotropy of SmCo-based films prepared via external magnetic field assisted magnetron sputtering. Adv. Eng. Mater. 25, 2101456 (2023).

Broeder, F. J. A. D. & Zijlstra, H. Relation between coercive force and microstructure of sintered SmCo5 permanent magnets. J. Appl. Phys. 47, 2688–2695 (1976).

Campos, M. F. D. et al. Chemical composition and coercivity of SmCo5 magnets. J. Appl. Phys. 84, 368–373 (1998).

Zhuge, Y. et al. Morphology and magnetic properties of Sm2Co7/α-Fe nanocomposite magnets produced by high energy ball milling and spark plasma sintering. J. Rare Earth. 39, 312–316 (2021).

Akhtar, S., Khan, M., Khan, A. N. & Jaffery, S. H. I. Effect of microstructure on the coercivity of SmCo5 intermetallic compound. Mater. Trans. 61, 2195–2200 (2020).

Fang, L., Zhang, T., Wang, H., Jiang, C. & Liu, J. inghua Effect of ball milling process on coercivity of nanocrystalline SmCo5 magnets. J. Magn. Magn. Mater. 446, 200–205 (2018).

Chen, J. S., Zhang, L. N., Hu, J. F. & Ding, J. Highly textured SmCo5 (001) thin film with high coercivity. J. Appl. Phys. 104, 093905 (2008).

Cui, B. Z., Li, W. F. & Hadjipanayis, G. C. Formation of SmCo5 single-crystal submicron flakes and textured polycrystalline nanoflakes. Acta Mater. 59, 563–571 (2011).

Rong, C. et al. High temperature magnetic properties of SmCo5/α-Fe(Co) bulk nanocomposite magnets. Appl. Phys. Lett. 101, 152401 (2012).

Handstein, A., Kubis, M., Gutfleisch, O., Gebel, B. & Müller, K.-H. HDDR of Sm–Co alloys using high hydrogen pressures. J. Magn. Magn. Mater. 192, 73–76 (1999).

Gutfleisch, O., Kubis, M., Handstein, A., Müller, K.-H. & Schultz, L. Hydrogenation disproportionation desorption recombination in Sm–Co alloys by means of reactive milling. Appl. Phys. Lett. 73, 3001–3003 (1998).

Bulyk, I. I. et al. Enhanced coercivity in SmCo5 magnet subjected to hydrogen treatment. J. Alloy. Compd. 866, 158272 (2021).

Cui, B. et al. Overcoming mechanical fragility in Sm-Co permanent magnet materials. Acta Mater. 196, 528–538 (2020).

Catalini, D., Kaoumi, D., Reynolds, A. P. & Grant, G. J. Friction consolidation of MA956 powder. J. Nucl. Mater. 442, 112–118 (2013).

Buffa, G., Baffari, D., Ingarao, G. & Fratini, L. Uncovering technological and environmental potentials of aluminum alloy scraps recycling through friction stir consolidation. Int. J. Precis. Eng. Manuf. -Green. Technol. 7, 955–964 (2020).

Baffari, D., Buffa, G., Ingarao, G., Masnata, A. & Fratini, L. Aluminium sheet metal scrap recycling through friction consolidation. Procedia Manuf. 29, 560–566 (2019).

Jiang, X., Whalen, S. A., Darsell, J. T., Mathaudhu, S. N. & Overman, N. R. Friction consolidation of gas-atomized Fe-Si powders for soft magnetic applications. Mater. Charact. 123, 166–172 (2017).

Komarasamy, M. et al. Microstructural evolution in Cu–Nb processed via friction consolidation. J. Mater. Sci. 56, 12864–12880 (2021).

Wang, X. et al. Manufacturing ODS steels from GARS Powders by friction consolidation and extrusion. JOM 76, 2899–2913 (2024).

Wang, T. et al. Upcycled high-strength aluminum alloys from scrap through solid-phase alloying. Nat. Commun. 15, 10664 (2024).

Li, X. et al. Exceptional strength and wear resistance in an AA7075/TiB2 composite fabricated via friction consolidation. Mater. Des. 242, 113006 (2024).

Li, W., Li, A. & Wang, H. Anisotropic fracture behavior of sintered rare-earth permanent magne. IEEE Trans. Magn. 41, 2339–2342 (2005).

Buschow, K. H. J., Naastepad, P. A. & Westendorf, F. F. Preparation of SmCo5 permanent magnet. J. Appl. Phys. 40, 4029–4032 (1969).

Ito, M., Majima, K., Umemoto, T., Katsuyama, S. & Nagai, H. Magnetic properties and microstructure of SmCo5+α-Fe nanocomposite magnets prepared by mechanical alloying. J. Alloy. Compd. 329, 272–277 (2001).

Wang, X. et al. High temperature oxidation and its induced coercivity loss of a 2:17 type SmCo-based magnet. J. Appl. Phys. 117, 093902 (2015).

Li, X., Baffari, D. & Reynolds, A. Friction stir consolidation of aluminum machining chips. Int. J. Adv. Manuf. Technol. 94, 2031–2042 (2018).

Das, B. et al. Anisotropy and orbital moment in Sm-Co permanent magnets. Phys. Rev. B 100, 024419 (2019).

Sankar, S. G., Rao, V. U. S., Segal, E. & Wallace, W. E. Magnetocrystalline anisotropy of Sm and its interpretation on a crystal-field model. Phys. Rev. B 11, 435 (1975).

Campos, M. F. D. et al. A model relating remanence and microstructure of SmCo5 magnets. J. Alloy. Compd. 267, 257–264 (1998).

Tang, H., Mamakhel, M. A. H. & Christensen, M. Enhancing the coercivity of SmCo5 magnet through particle size control. J. Mater. Chem. C. 8, 2109–2116 (2020).

Staab, F. et al. Hard magnetic SmCo5-Cu nanocomposites produced by severe plastic deformation. Acta Mater. 246, 118709 (2023).

Chowdary, K. M., Giri, A. K., Pellerin, K., Majetich, S. A. & Scott, J. H. J. Annealing effects on the coercivity of SmCo5 nanoparticles. J. Appl. Phys. 85, 8 (1999).

Taylor, R. A., Jakubovics, J. P., Astié, B. & Degauque, J. Direct observation of the interaction between magnetic domain walls and dislocations in iron. J. Magn. Magn. Mater. 31-34, 970–972 (1983).

Fidler, J., Kirchmayer, H. & Skalicky, P. Pinning of magnetic domain walls at dislocations and precipitates in Co5Sm crystals. Philos. Mag. B 43, 765–780 (1981).

Zijlstra, H. & Westendorp, F. F. Influence of hydrogen on the magnetic properties of SmCo5. Solid State Commun. 7, 857–859 (1969).

Eldosouky, A. & Škulj, I. Hydrogen reaction with SmCo compounds: literature review. J. Sustain. Metall. 4, 516–527 (2018).

Morrison, G. R., Gong, H., Chapman, J. N. & Hrnciar, V. The measurement of narrow domain-wall widths in SmCo5 using differential phase contrast electron microscopy. J. Appl. Phys. 64, 1338–1342 (1988).

Szmaja, W. Studies of the domain structure of anisotropic sintered SmCo5 permanent magnets. J. Magn. Magn. Mater. 311, 469–480 (2007).

Szmaja, W., Grobelny, J. & Cichomski, M. Domain structure of sintered SmCo5 magnets studied by magneticforce microscopy. Appl. Phys. Lett. 85, 2878–2880 (2004).

Wang, J., Yang, C., Liu, Y., Li, Y. & Xiong, Y. Using nanoindentation to characterize the mechanical and creep properties of shale: load and loading strain rate effects. ACS Omega 7, 14317–14331 (2022).

Chen, J., Ren, J. K. & Liu, Z. Y. Deformation microstructures as well as strengthening and toughening mechanisms of low-density high Mn steels for cryogenic applications. J. Mater. Res. Technol. 13, 947–961 (2021).

Yang, C. et al. Single Domain SmCo5@Co Exchange-coupled magnets prepared from core/shell Sm[Co(CN)6].4H2O@GO particles: A novel chemical approach. Sci. Rep. 3, 3542 (2013).

Coey, J. M. D. Magnetism and Magnetic Materials. Cambridge University Press, (2010).

Acknowledgements

A part of this research was supported by ONR under grant N00014-23-1-2758 (B.G.) and by the U.S. National Science Foundation under Award No. 2243104 (M.T.) at NC State University. The authors thank the support provided by Pacific Northwest National Laboratory. Pacific Northwest National Laboratory is operated by Battelle for the U.S. Department of Energy (DOE) under contract DE-AC05-76RL01830. This work made possible by funding from the U.S. DOE, Vehicle Technology Office, through the Powertrain Materials Core Program. We thank DOE Program Manager Jerry Gibbs, and Core Program Manager Allen Haynes for their continuous support. We gratefully acknowledge Bruker for their support for the Magnetic force microscope analysis. Part of this work was conducted at the Analytical Instrumentation Facility (AIF) at North Carolina State University, supported by the State of North Carolina and the National Science Foundation (award number ECCS-2025064). The AIF is part of the North Carolina Research Triangle Nanotechnology Network (RTNN), a site within the National Nanotechnology Coordinated Infrastructure (NNCI).

Author information

Authors and Affiliations

Contributions

Conceptualization, Project Administration, Funding Acquisition: B.G., ME.; Methodology: A Mal, F.I., C.S., A.Y., M.P., J.D., T.W., J.H., J. B.T., M.L., L.K. and G.G.; Formal analysis: A.Mal., A.Mar., B.G., M.T. and M.E., Data curation: A.Mar, A.Mal., B.G. and M.E., Writing—original draft: A.Mal., B.G.; Writing—review and editing: B.G. J.T., and M.E.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Xiao Li, Zhaoguo Qiu, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Malakar, A., Martin, A., Ishrak, F. et al. In-situ thermo-mechano-chemical transformation and consolidation of Sm-Co powders via a single-step route for bulk magnet fabrication. Nat Commun 16, 7524 (2025). https://doi.org/10.1038/s41467-025-62804-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-62804-9