Abstract

Simultaneous oxidation of soot and CH4 emitted from natural gas-diesel dual fuel engine is a new challenge. Herein, a robust catalyst of binary Ru-Pd components supported on three-dimensional ordered macro-mesoporous cerium-zirconium oxide (RuPd/3DOMM-CZO) is elaborately constructed. Ordered macro-mesopore structure in novel hierarchical porous cerium-zirconium oxide can respectively enhance mass transfer of soot and gaseous reactants, and binary Ru-Pd active components can improve activation for NO and CH4. RuPd/3DOMM-CZO catalyst exhibits excellent catalytic performance and stability during simultaneous soot and CH4 oxidation. Based on the results of characterizations and theoretical calculations, Ru site in binary Ru-Pd components is responsible for catalyzing NO oxidation to NO2, which is key step of NOx-assisted soot oxidation mechanism, while Pd site can activate the C-H bond of CH4 for boosting oxidation to CO2; the catalytic cooperation between Ru and Pd atoms can promote the rate-determining step to realize simultaneous oxidation of soot and CH4.

Similar content being viewed by others

Introduction

The natural gas-diesel (dual-fuel) engine with high energy efficiency is an innovative power source for motor vehicles and vessels, but it results in a new challenge to engine exhaust purification1. Under the operating conditions of natural gas and diesel fuel, methane (CH4) and particulate matter (soot), as the important atmospheric pollutants, are simultaneously present in engine exhaust2. The catalytic after-treatment technology is an indispensable part for engine exhaust purification3. Nowadays, some high-efficient catalysts for single soot or CH4 oxidation have been reported4,5,6,7. However, there is a research gap on simultaneous oxidation of soot and CH4 emitted from dual-fuel engine. Thus, it is urgent and challenging to design and construct the efficient catalysts for boosting purification of engine exhaust.

The catalytic simultaneous oxidation of soot and CH4 is a typical heterogeneous deep oxidation reaction, which involves a solid catalyst, a solid reactant (soot) and multiple gaseous reactants (O2, CH4, and NO)8. It is well known that the catalytic performance in heterogeneous oxidation reaction is strongly dominated by two factors: diffusion/mass transfer efficiency of reactants and adsorption/activation properties for reactants9,10,11,12. It has been found that the mass transfer efficiency of reactants is dependent on the porous nanostructure of the catalyst13. The three-dimensional ordered macroporous (3DOM) structure of the catalysts can permit soot particles into the inner space of catalyst with the flow of exhaust gases for improving soot-catalyst contact efficiency9. And, the further constructed two-dimensional ordered mesopores on the macroporous wall can reduce the resistance of diffusion/mass transfer of gas molecule, which can facilitate the oxidation of gaseous reactants and the migration of the products (CO2 and NO2)14. The NO2 intermediate species, as a powerful oxidant, can boost soot oxidation by the NO2-assisted catalytic pathway9,15. Thus, the design of hierarchical porous material with macroporous and mesoporous structure is a practical approach to enhance diffusion/mass transfer efficiency of reactants during simultaneous oxidation of soot and CH4.

The adsorption/activation properties of catalysts for reactants are critically related to the stable presence of isolated active sites, which enables simultaneous adsorption/activation of NO and CH4. Ruthenium (Ru)-based catalysts have been recognized as a promising catalyst for soot oxidation owing to excellent NO adsorption/activation properties15. However, the study on the C-H bond activation by Ru site during CH4 oxidation is lacking, and the thermal stability of Ru at high temperature is still an obstacle to its practical application16. Thus, the development of high-efficient and stabilized Ru-based catalysts for soot and CH4 oxidation is of innovative significance. The micro-modification of Ru active sites can be achieved by adding another platinum group metal for forming a binary Ru-M catalyst17,18. Presently, palladium (Pd) is one of the most active elements in realizing catalytic oxidation of CH419,20. It is a potential strategy to design new binary Ru-Pd catalysts, which can endow Ru-Pd synergistic site for simultaneous activation ability of C-H and N-O bonds, and the thermal stability of Ru component can be also improved by Ru-Pd metal bond.

Herein, we have elaborately fabricated the multifunctional catalysts of binary Ru-Pd active components supported on the surface of Ce0.3Zr0.7O2 with three-dimensional ordered macro-mesoporous structure (RuPd/3DOMM-CZO) via the gas bubbling-assisted membrane reduction (GBMR) method21. The hierarchical porous structure can improve the contact efficiency between catalysts and reactants (soot, NO, CH4, and O2), and binary Ru-Pd active components have super activation capacity for gaseous reactants. RuPd/3DOMM-CZO catalyst shows excellent catalytic activity and stability for simultaneous oxidation of soot and CH4. Based on the results of the characterizations and density functional theory (DFT) calculations, it is revealed that the catalytic cooperation between Ru and Pd atoms can promote the oxidation of NO to NO2, and boost the activation of first C-H bond in CH4 to realize simultaneous oxidation of soot and CH4. This study provides a reliable solution for the design of multifunctional catalysts and new insights into the simultaneous oxidation of multiple pollutions emitted from engine exhaust.

Results

Morphology and phase structure of hierarchical porous catalysts

The binary Ru-Pd active components were supported on the inner wall of 3DOMM-CZO support (Fig. S1) by the GBMR method, denoted as RuPd/3DOMM-CZO. The synthesis scheme of RuPd/3DOMM-CZO catalyst is illustrated in Fig. S2. Fig. 1a is the scanning electron microscopy (SEM) image of RuPd/3DOMM-CZO catalyst. It is observed that, after the introduction of binary Ru-Pd active components, the macroporous structure of catalyst is intact, which is derived from the long-range replication of polymethyl methacrylate (PMMA) microspheres templates (Fig. S3), indicating the well-qualified mechanical stability of 3DOMM-CZO support.

SEM (a), ADF-STEM images of 3D macroporous skeleton (b) and 2D hexagonal (P6mm) mesoporous structure (c), high-resolution ADF-STEM (d, f) and high-resolution BF-STEM (e) images of the catalyst. The inset in (a) is PMMA template of 3DOMM catalyst. The inset in (c) is a model of mesopores on the macroporous walls. The inset in (d) is the standard atomic structure of Ce-Zr oxide on (111) orientation. e, f shows the interface between RuPd NP and 3DOMM-CZO support.

To visualize the existence of hierarchical porous structure with macropore and mesopore, the annular dark-field scanning transmission electron microscopy (ADF-STEM) images of RuPd/3DOMM-CZO catalyst are shown in Fig. 1b, c. As shown in Fig. 1b, the catalyst presents the three-dimensional ordered macroporous skeleton with diameter of 250 nm, which is large enough to permit soot particles (10-30 nm particle sizes) into the interior of the catalyst22. As shown in Figs. 1c and S4, the ordered mesoporous structure is distributed in the form of 2D hexagonal (P6mm) on the macroporous walls, which is derived from the Pluronic F127 templates. The N2 adsorption-desorption isotherms of the catalysts (Fig. S5a) have obvious H4 (P/P0 = 0.4–0.7) and H3 (P/P0 = 0.8–1.0) hysteresis loops, suggesting the formation of ordered mesoporous and macroporous structure, respectively.

In high-resolution ADF-STEM image of RuPd/3DOMM-CZO catalyst (Fig. 1d), the interplanar d-spacing of Ce-Zr solid solution is 0.31 nm corresponding to the exposed (111) facet, and the distinct step sites can be observed at the edges of the Ce-Zr oxide. The strain distribution maps of RuPd/3DOMM-CZO catalyst from geometrical phase analysis (GPA) are depicted in Fig. S6. Based on the GPA analysis, the main zone of the catalyst (shown mainly in red) shows a strain value of almost 0%, suggesting that the strain effect is not a major factor influencing the RuPd cooperation23. As shown in Fig. S7, RuPd NPs were supported on 3DOMM-CZO with a relatively concentrated particle size of ~7.41 nm. To further observe the microstructure of binary Ru-Pd components, Fig. 1e exhibits the high-resolution bright-field scanning transmission electron microscopy (BF-STEM) image of RuPd/3DOMM-CZO catalyst, the interplanar d-spacing are 0.19 and 0.31 nm, corresponding to the exposed (111) facet of RuPd alloy and (111) facet of Ce-Zr oxide, respectively24. Figure 1f shows the high-resolution ADF-STEM image of RuPd/3DOMM-CZO catalyst. One RuPd nanoparticle (NP), with interplanar d-spacing of 0.26 nm corresponding to (101) facet of oxygen-adsorbing RuPd NPs, is located on the surface of Ce-Zr support. It indicates that metal and oxide states of binary Ru-Pd components coexist on the surface of catalyst. The X-ray diffraction (XRD) patterns are shown in Fig. S8. After the introduction of supported Ru and Pd components, the diffraction peaks of (111), (200), and (311) crystal facets slightly shift to left, which may be due to the change in the redox state of the CZO bulk by the Ru/Pd on the surface. The EDX line-scanning analysis of the binary RuPd NP verifies the formation of atomic-level Ru-Pd homogeneous phase (Fig. S9). And the element distribution mapping of RuPd/3DOMM-CZO catalyst further indicates homogeneous dispersion of binary Ru-Pd components on the surface of Ce-Zr solid solution (Fig. S10).

Catalytic performances for simultaneous oxidation of soot and CH4

The catalytic performances of the catalysts for simultaneous oxidation of soot and CH4 were investigated by temperature-programmed oxidation (TPO), and the single Ru or Pd catalysts as references are also listed (Fig. 2a, b), and the complete temperature-conversion curves from the beginning to the end of the reaction are shown in Fig. S11. The catalytic activity for simultaneous oxidation of soot and CH4 is assessed by the T10, T50 and T90 values, defined as temperatures at 10%, 50%, and 90% conversion of soot and CH4, respectively (Table S2). Under the conditions of without catalyst, it is very difficult to achieve the simultaneous oxidation of soot and CH4, whose T50 values are respectively 592 and 692 °C. It is higher than the temperature of engine exhaust (<400 °C)25. Thus, it is important to design the catalyst for boosting simultaneous oxidation of soot and CH4 at the exhaust temperature. 3DOMM-CZO catalyst exhibits higher simultaneous oxidation activity of soot (T50 = 418 °C) and CH4 (T50 = 620 °C) in comparison with three-dimensional ordered macroporous Ce-Zr oxide (3DOM-CZO) and mesoporous Ce-Zr oxide (Meso-CZO) catalysts (Fig. S12), indicating that the hierarchical porous structure can enhance the catalytic performance for simultaneous oxidation of soot and CH4.

Temperature-conversion curves of catalytic soot (a) and CH4 (b) oxidation. CH4 conversion at fixed temperature in the presence/absence of NO (c). Temperature-conversion curves for simultaneous soot (d) and CH4 (e) oxidation in the presence/absence of NO. Stability of RuPd/3DOMM-CZO catalyst after five-cycle tests for simultaneous soot (f) and CH4 (g) oxidation.

After the introduction of Ru and/or Pd component, their catalytic activities are remarkly improved, which is attributed to enhance adsorption-activation capacities for gaseous reactants (Fig. 2a, b). The activity of RuPd/3DOMM-CZO catalyst during simultaneous oxidation of soot and CH4 is strongly dependent on the Ru/Pd ratio in binary RuPd active components (Fig. S13). Among the catalysts, RuPd/3DOMM-CZO catalyst (the Ru/Pd mass ratio is 1:1) exhibits the best catalytic performances and the binary-metal cooperation-dependence activity during the simultaneous oxidation of soot and CH4, i.e., its T50 values of soot and CH4 oxidation are 357 and 334 °C, respectively, which is 74 and 212 °C lower than those of single Pd catalyst for soot oxidation and single Ru catalyst for CH4 oxidation, respectively. And RuPd/3DOMM-CZO catalyst can achieve completely simultaneous oxidation of soot and CH4 below 410 °C, which is fulfilled by Ru/3DOMM-CZO catalyst at 650 °C (Fig. S14). In addition, the selectivity of soot and CH4 oxidation to CO2 product over RuPd/3DOMM-CZO catalyst is above 99% (Fig. S15), indicating that CO pollutant derived from engine exhaust can be immediately removed by the catalyst. To explore the reaction energy barrier on RuPd/3DOMM-CZO catalysts during soot and CH4 oxidation, the apparent activation energy (Ea) was evaluated under an approximate kinetic regime of the low-temperature range (Fig. S16). The RuPd/3DOMM-CZO catalyst exhibits the lowest apparent activation energy for soot (48.4 kJ mol−1) and CH4 (63.5 kJ mol−1) oxidation, which is far lower than those of 3DOMM-CZO and single Ru/Pd catalysts, indicating that binary Ru-Pd active components play a pivotal role in catalyzing soot and CH4 oxidation.

It is well known that nitrogen oxides (NOx) in engine exhaust is important to catalytic soot oxidation via the NOx-assisted oxidation mechanism26. However, it is still unclear to understand the role of NOx during simultaneous oxidation of soot and CH4. To investigate the effect of NO on simultaneous soot and CH4 oxidation, Fig. 2c shows the conversion curves of CH4 oxidation over the catalysts at a fixed temperature. In the presence of NO, the conversion rates of CH4 over Ru-based catalysts significantly decrease compared with that in the absence of NO, while its disturbance over Pd/3DOMM-CZO catalyst can be ignored. It suggests that NO can inhibit CH4 oxidation over Ru-based catalysts, but not over Pd/3DOMM-CZO catalyst during simultaneous oxidation of soot and CH4. As shown in Fig. 2d, introducting NO into the reaction atmosphere, the conversion curves of soot oxidation over the catalysts shift to the lower temperature during simultaneous oxidation of soot and CH4. And the T50 value of soot oxidation over three catalysts decreases more than 50 °C. It indicates that the presence of NO can promote the soot oxidation, and the catalytic activity of Ru-based catalysts for soot oxidation is more dependent on the role of NO compared with Pd-based catalysts. As shown in Fig. 2e, the conversion curves of CH4 oxidation over Ru-based catalysts in the presence of NO shift to the higher temperature during simultaneous oxidation of soot and CH4. But the T50 value of CH4 oxidation over RuPd/3DOMM-CZO catalyst reduces even less than Ru/3DOMM-CZO catalyst. It suggests that the binary RuPd active structure in RuPd/3DOMM-CZO catalyst can release the disinhibition of NO during CH4 oxidation. Thus, the reaction of CH4 oxidation over the catalysts is a competitive reaction to NO oxidation, which is key step of catalytic soot oxidation. And the cooperation between Ru and Pd atoms in binary RuPd active component is an effective strategy to boost simultaneous oxidation of soot and CH4.

The catalytic and structural stability of RuPd/3DOMM-CZO catalyst is important to practical application. The catalytic stability of RuPd/3DOMM-CZO catalyst was tested by consecutive TPO reactions and hydrothermal aging treatment. As shown in Fig. 2f, g, RuPd/3DOMM-CZO catalyst exhibits good catalytic stability for simultaneous soot and CH4 oxidation, and its T50 values varies within 3 °C during five cycle tests of TPO. As shown in Fig. S17, the simultaneous soot and CH4 oxidation activities of the RuPd/3DOMM-CZO catalyst after high temperature and high humidity environments remained stable compared to the fresh catalyst. Figure S18 shows the SEM and TEM images of RuPd/3DOMM-CZO catalyst after catalytic stability testing. The hierarchical porous structure of the catalysts keeps perfect, illustrating the excellent structural stability of hierarchical porous catalysts. The stable mechanical structure of Ce-based hierarchical porous catalysts can be attributed to the introduction of Zr into CeO2 to form a Zr-Ce solid solution. The excellent stability of the catalysts is potential to practical application.

Surface chemistry states and adsorption/activation capacity of catalysts

X-ray photoelectron spectroscopy (XPS) was conducted to investigate the surface chemistry states of the catalysts, and the resulsts are shown in Fig. S19 and Table S3. As shown in Fig. S19a, the deconvolved results of Ru 3p spectra contain two pairs of peaks at 461.6, 483.5 and 464.1, 485.8 eV belonging to the metallic (Ru0) and oxidized (Run+) states, respectively. And the proportion of metallic Ru species (59.7%) in RuPd/3DOMM-CZO catalyst decreases compared with Ru/3DOMM-CZO catalyst (67.5%). Only the Pd 3d5/2 component was analyzed to avoid effects arising from the overlap of Pd 3d spectrum and Ca 2p line (or possibly Mg KLL). In Fig. S19b, Pd 3d spectra are deconvoluted to three peaks, which are assigned to Pd0 (335.1 eV), Pd2+ (336.8 eV), Pd4+ (339.2 eV) species. The deconvolution results of Pd 3d show that the proportion of Pd0 species in RuPd/3DOMM-CZO catalyst increases to 60.5% compared with Pd/3DOMM-CZO catalyst (54.7%). In contrast to single Ru and Pd catalysts, the Run+/Ru0 ratio of RuPd/3DOMM-CZO catalyst increases, while its ratio of (Pd2++Pd4+)/Pd0 decreases. It indicates that the formation of binary RuPd alloy can change the electronic environment of Ru and Pd, resulting in atomic Ru-Pd cooperation. The deconvolved curves of Ce 3d spectra include 10 or 11 peaks (Fig. S19c), and the peaks located at 882.4, 888.4, 900.8, and 906.6 eV are assigned to Ce3+ species, and other peaks are assigned to Ce4+ species. The Ce spectrum of 3DOMM-CZO and Ru/3DOMM-CZO catalysts shows the additional peak at ~916 eV contrasting with the standard Ce spectrum. It is attributed to that the existence of structural defects leads to a valence state of Ce between +3 and +427. RuPd/3DOMM-CZO catalyst has the highest Ce3+ content (35.8%) in comparison to the single Ru and Pd catalysts. It suggests that the binary Ru-Pd components can induce the surface lattice transformation from Ce4+ into Ce3+ cations. Furthermore, the increasing Ce3+ content can induce the formation of oxygen vacancies on the catalyst surface, which is critical to the increasing of active oxygen species. As shown in Fig. S19d, the O 1s spectra are deconvoluted into three peaks corresponding to lattice oxygen (O2-) (~529.7 eV), surface peroxide (O22-) (~531.3 eV) and super-oxygen (O2-) (~532.7 eV). The O22- and O2- species are considered to active oxygen species for deep oxidation reaction. The (O2- + O22-)/O2- ratio in RuPd/3DOMM-CZO catalyst is the highest (0.45), suggesting that the binary Ru-Pd active components enhance the adsorption-activation of O2, which is responsible for boosting the simultaneous oxidation of soot and CH4.

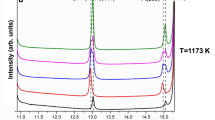

X-ray absorption fine structure (XAFS) spectra of Ce L3-edge was collected to further investigate the neighbor structure around Ce atoms of catalysts (Fig. 3a)28,29. The Ce L3-edge near-edge XAFS (NEXAFS) spectra of the catalysts can be well fitted by four peaks (A, B, C, and D) using arctangent function and Gaussian function. Peak (A) is attributed to O 2p-Ce 5d hybridization, and the formation of (B) peak is related to the Ce3+ species30,31. The (C) and (D) peaks correspond to the characteristic electron transitions of Ce4+ species32. The Ce3+ concentration in the catalysts can be calculated from the area of (B) peak (Table S4). The Ce3+ concentration of RuPd/3DOMM-CZO catalyst is the highest (23.5%), which is consistent with the results of Ce 3d. It confirms that the unsaturated coordination of Ce3+ species is generated on RuPd/3DOMM-CZO catalyst. The information on the hybridization between O 2p and Ce 2p states is obtained by probing the O 1s → Ce 2p transition using the O K-edge soft X-ray absorption spectra (sXAS) (Fig. 3b). In the ground state of Ce-Zr oxides, the O 2p valence band is filled completely, which hybridizes with the Ce 4f orbitals aggressively. Thus, it can be observed that the (α) peak is attributed to the transition from the O 1s to p-symmetry components of Ce 4f orbitals. As shown in Fig. 3b, the (α) peak of the RuPd/3DOMM-CZO catalyst is significantly smaller, implying the Ce 4f orbitals are partially filled with electrons forming the Ce3+ (4f 1) state, while reducing the Ce4+ (4f 0) state because of the formation of oxygen vacancies. Ru or Pd embedding in Ce-based supports can lead to electron migration from RuPd to the support and defect formation on CZO. The increase in Ce3+ content is mainly due to electron migration from RuPd components to 3DOMM-CZO, which leads to Ce4+ changing to Ce3+. It is consistent with the analysis results of Ce L3-edge NEXAFS spectra. Other four peaks labeled as β, γ, δ, and ε also arise in the O K-edge sXAS. The (β) and (γ) peaks are attributed to transition from O 1s → Ce 5d (eg) and O 1s → Ce 5d (t2g) levels in the conduction band, respectively. The (δ) and (ε) peaks are also obtained at the higher energy side because of the local hybridization of Ce 4f and O 2p state electronic levels.

The concentration of oxygen vacancies in the lattice of Ce-based oxides can be estimated by the area ratio between (β) and (γ) peaks (defined as Iβ/Iγ). As shown in Fig. 3c and Table S4, the fitting results of O K-edge over RuPd/3DOMM-CZO catalyst possess the largest Iβ/Iγ value, indicating that the binary Ru-Pd components can induce the generation of Ce3+ species and oxygen vacancies on Ce-Zr oxides significantly33. It results from the strong Ru/Pd-O-Ce electronic interaction, which is crucial for boosting the catalytic activity of deep oxidation. In Raman spectra (Fig. S20), the relative intensity of two peaks, associated with oxygen defect (D) and F2g symmetric stretching mode of the oxygen atoms (denoted as ID/IF2g), are used to assess the surface density of oxygen vacancies. The results obtained by Raman spectra are consistent with that of O K-edge sXAS (Table S4). The O2 molecule can be adsorbed directly onto the catalyst surface to form superoxide species (O2–) species34. In addition, oxygen vacancies contribute to the adsorption-activation of O2 to form active oxygen species, i.e., the O2 molecule can occupy the oxygen vacancy on Ce-based support forming peroxide (O22–) species, which can react with NO and CH435. In-situ Raman experiments were performed to dynamically examine the density of oxygen vacancies on the RuPd/3DOMM-CZO support during simultaneous NO and CH4 oxidation. As shown in Fig. S21, after the introduction of 5% vol O2 for 10 and 20 min, the ID/IF2g value was reduced to 1.06 and 0.85, respectively, relative to the conditions in the absence of O2 (ID/IF2g = 1.50). It indicates that the oxygen vacancies are gradually filled by O2 molecules in this process. And the peaks attributed to superoxide (O2-) at ~1043 cm−1 become stronger progressively with the introduction of O2, indicating that O2 is also adsorbed on the catalyst surface. But the peak of peroxide (O22–) species at ~847 cm−1 is not present in the in-situ Raman spectra clearly, which may be due to the O2 decomposition. Then, the gas feed was switched to a 0.1 % vol NO/0.1 % vol CH4 flow. After the introduction of NO/CH4 for 10 and 20 min, the ID/IF2g value was increased to 0.99 and 1.33, respectively. It implies that the O2 adsorbed on the oxygen vacancy is consumed by NO/CH4 oxidation resulting in elevated oxygen vacancy density.

The redox property is crucial for the catalytic activity during deep oxidation reaction, which can be evaluated by temperature-programmed reduction of H2 (H2-TPR), and the result is shown in Fig. 3d. For 3DOMM-CZO support, one peak at 580 °C is related to the reduction of Ce4+ to Ce3+ species (light yellow region). After the introduction of Ru, Pd and binary Ru-Pd components, the reduction peak of Ce4+ to Ce3+ species shifts to a relatively low temperature, indicating that the redox property of the catalysts can be improved by the strong metal-support interaction between Ce-Zr oxides and Ru/Pd components. For supported Ru, Pd and RuPd catalysts, one reduction peak at low-temperature region (purple region) can be observed, which is assigned to the reduction of noble metal oxides and the interfacial oxygen (Ru/Pd-O-Ce)36. The single Ru and Pd catalysts show two peaks at 157 and 161 °C, which is assigned to reduction of RuOx and PdOx species, respectively. RuPd/3DOMM-CZO catalyst exhibits the lowest reduction temperature (138 °C), indicating that the redox capacity of catalysts can be enhanced by Ru-Pd cooperation at atomic scale. The initial H2 consumption rate (Fig. S22) can reflect the low-temperature surface oxygen species activity of catalysts. The initial H2 consumption rate for the RuPd/3DOMM-CZO catalyst (0.369 mmol gcat−1 s−1) is seven-fold of bare 3DOMM-CZO catalyst (0.052 mmol gcat−1 s−1), resulting in low-temperature oxidation of soot and CH4.

During soot oxidation, active oxygen species on the surface of catalysts can react with NO species to form NO2 intermediate with strong oxidizing, which promotes soot oxidation to CO2. Thus, the oxidation efficiency of soot can be improved by oxidizing NO to NO2 via NO2-assisted mechanism. The temperature-programmed oxidation of NO (NO-TPO) was applied to evaluate the NO adsorption-activation capacity of catalysts. As shown in Fig. 3e, the single Ru catalyst exhibits a lower temperature of NO2 concentration peak and a much higher NO2 concentration compared with the single Pd catalyst, indicating that the Ru active component is primarily responsible for NO oxidation rather than Pd. And the NO2 concentration peak of RuPd/3DOMM-CZO catalyst has the lowest temperature (319 °C), its intensity is the highest. Thus, the binary Ru-Pd atoms cooperation can enhance adsorption-activation capacity for NO.

The temperature-programmed surface reaction of CH4 (CH4-TPSR) experiment was applied to further investigate the adsorption-activation capacities of CH4 and O2. As shown in the CH4-TPSR curve of Fig. 3f, the peak temperature of CH4 consumption over single Pd catalyst (331 °C) is lower than single Ru catalyst (351 °C), suggesting that the Pd component is critical for adsorption-activation of CH4 compared to Ru component. And RuPd/3DOMM-CZO catalyst shows the lowest peak temperature of CH4 consumption (306 °C). Thus, the atomic Ru-Pd cooperation in the catalysts can effectively enhance the consumption capacity for CH4 via surface oxygen species (green region). The O2 adsorption-activation capacity of the catalysts can be measured by H2O and CO2 signals, which originate from complete oxidation of CH4 in the presence of sufficient surface oxygen species. RuPd/3DOMM-CZO catalyst exhibits the strongest peak intensity of H2O and CO2, reflecting the strongest O2 adsorption-activation capacity. The great O2 adsorption-activation capacity of the catalyst is vital for boosting the deep oxidation reaction. The CO is the product of incomplete oxidation of CH4 depending bulk oxygen in the high-temperature region (pink region). It indicates that, after almost complete depletion of surface oxygen, the bulk oxygen of RuPd/3DOMM-CZO catalyst is potential to realize CH4 oxidation.

Intermediate Species and Reaction Pathways During Simultaneous Oxidation of Soot and CH4

To insight into intermediate species of binary Ru-Pd catalysts for simultaneous oxidation of NO and CH4, Fig. 4 shows the in-situ diffuse reflectance infrared Fourier transform spectra (in-situ DRIFTS) under conditions of reaction atmosphere. As shown in Fig. 4a, d, the peaks in the region of 3500–3800 cm−1 are ascribed to the desorption of water or hydroxyl groups37. The characteristic peaks of NO oxidation are assigned to bidentate nitrates (1586 cm−1), linear nitrites (1480 cm−1), free ionic nitrates (1378 cm−1), monodentate nitrates (1300 cm−1)38,39,40,41. With the temperature rising, the peak intensity of linear nitrites (1480 cm−1) and monodentate nitrates (1300 cm−1) become weaker gradually. Moreover, the rising temperature also results in the gradual appearance of characteristic peaks of bidentate nitrates (1586 cm−1) and free ionic nitrates (1378 cm−1), and the characteristic intensity of free ionic nitrates increases significantly. It suggests that the adsorbed NOx species gradually transform into labile NO3- intermediates, and subsequently decompose into NO2.

Temperature-dependent in-situ DRIFT spectra (a) and corresponding contour projection results (d) of NO oxidation. Temperature-dependent in-situ DRIFT spectra (b) and corresponding contour projection results (e) of CH4 oxidation. Temperature-dependent in-situ DRIFT spectra (c) and corresponding contour projection results (f) of simultaneous NO and CH4 oxidation.

As shown in Fig. 4b, e, the double peaks in the range of 2280–2400 cm−1 are attributed to the stretching vibration of adsorbed CO2, and its intensity increases with the rise of temperature42. The peaks at 1305 and 3013 cm−1 are assigned to the bending and strong characteristic antisymmetric stretching signals for free CH4 molecules, respectively37. With the temperature rising, the intensities of peak decreases, suggesting that CH4 is consumed to produce CO2. At below 350 °C, the peak at 1467 cm−1 can be attributed to the bending of methoxy species (*OCH3)43. And the peak at 1374 cm−1 can be ascribed to the formate species (HCOO*) with temperatures above 200 °C44. The first C-H bond of the CH4 molecule is broken to obtain the methyl group (−CH3), which combines with the oxygen atom on the surface of the catalyst to form the methoxy species. With the temperature rising, the methoxy species continue to dehydrogenate and react with oxygen species to formate species. And, the formate species will decompose into CO2, eventually37.

Figure 4c, f depict the process of simultaneous oxidation under conditions of NO (0.1vol %) and CH4 (0.1vol %), which is a similar evolution of in-situ DRIFTS to the NO oxidation, i.e., those peaks almost coincide the NO oxidation in the range of 1000 to 1600 cm−1. In Fig. 4c, the characteristic peaks of intermediates (formate and methoxy) during CH4 oxidation are masked by the intermediate peaks of NO oxidation. It demonstrates the competitive oxidation of CH4 and NO over RuPd/3DOMM-CZO catalyst, where CH4 oxidation is inhibited by NO. In the process of simultaneous oxidation, the free ionic nitrates exhibit the strongest peak, combined with NOx adsorption behaviors, thus, the free ionic nitrates are recognized as the key intermediates. And the gaseous reactants (NO and O2) can be absorbed on the binary Ru-Pd active site and converted to NO3- intermediates, which then decompose into NO2 for boosting soot oxidation.

To further illustrate the role of Ru and Pd active components and the advantages of binary Ru-Pd cooperation during the simultaneous oxidation reaction, the DFT calculations were carried out. We build the structures of Ru/CZO, Pd/CZO and RuPd/CZO catalysts for NO and CH4 oxidation, and the detailed model is shown in Fig. S23. The path and energy for catalyzing NO oxidation to NO2 can be divided into the following six stages (Figs. 5a and S24). Firstly, a gaseous NO molecule is adsorbed on the active site of catalysts via O-N-M (M = Ru or Pd) bonds forming surface NO* species. The NO adsorption energies (Eads(NO)) at Ru/CZO, Pd/CZO and RuPd/CZO catalysts are −2.65, −2.37, and −3.21 eV, respectively, indicating that the adsorption of single Ru site for NO is stronger than single Pd site, and the binary RuPd site exhibits the strongest adsorption capacity of NO. Secondly, a gaseous O2 is adsorbed at the interface between noble metal sites (Ru, Pd, and RuPd) and Ce-Zr support via O-Ce and O-M (M = Ru or Pd) bonds forming surface adsorbed O2*. The ensemble of binary RuPd clusters and Ce-Zr solid solutions is responsible for adsorption-activation of O2. The O2 adsorption energies (Eads(O2)) at Ru/CZO, Pd/CZO and RuPd/CZO catalysts are −1.90, −0.79, and −2.13 eV, respectively. Thirdly, the O-O bond of the adsorbed O2 molecule is dissociated to produce active atoms (O*), which combine with the adsorbed NO species forming surface intermediate NO2* species. The third step in the NO oxidation is generally regarded as the rate-determining step, and the energy barriers (Ea) of those processes are as follows: Ru/CZO (1.31 eV), Pd/CZO (1.62 eV) and RuPd/CZO (0.93 eV), indicating that the NO molecules are most prone to react at the binary RuPd site to form NO2. Fourthly, the NO2 species is desorbed from the catalyst surface. The NO2 desorption energy (Edes(NO2)) of RuPd/CZO (2.09 eV) is lower than that of Ru/CZO (2.36 eV) and Pd/CZO (2.21 eV), suggesting that NO2 is more easily desorbed from the binary RuPd site compared to the single Ru and Pd sites. Fifthly, the free NO molecules are adsorbed onto the Ru or Pd sites and continue to react with O* adsorbed on the catalyst to form ONO* species. Finally, NO2* species is desorbed from the catalyst surface, which fulfills the cyclic process of NO oxidation on the surface of catalysts. The calculated values of Ea and Edes(NO2) for NO2 species illustrate that the single Ru site is more efficient in NO oxidation compared to the single Pd site, and NO2 tend to be generated at binary RuPd site relative to the single Ru site. The generated NO2 can migrate to the soot surface with the gas flow through hierarchical porous structure, and oxidize soot to CO2 (NO + 1/2O2 → NO2 and NO2+soot→CO2).

Energy change diagram for catalytic NO oxidation to NO2 (a) and the first C-H bond dissociation of a CH4 molecule (b). Final energy of the first C-H bond dissociation in the presence/absence of O2 (c). The PDOS of Ru-4d orbital in Ru/CZO and RuPd/CZO (d). The PDOS of Pd-4d orbital in Pd/CZO and RuPd/CZO (e).

The first C-H dissociation of CH4 molecule over the Ru/CZO, Pd/CZO and RuPd/CZO catalysts (CH4 → CH3 + H), as a rate-determining step in CH4 oxidation, are used to study the CH4 reactivity on different active sites (Figs. 5b and S25)45,46. The energy barriers of the first C-H dissociation at single Ru, single Pd and binary RuPd sites are 1.91, 1.63, and 1.03 eV, respectively. The lower energy barriers of first C-H bond dissociation indicate that the reactivity of CH4 molecule at single Pd site is significantly superior than single Ru site, and the binary RuPd site exhibits superior reactivity of CH4 molecule compared to the single Pd site. The full energy diagram for CH4 oxidation to CO2 and H2O is present to study the effect of O2 on CH4 dehydrogenation (Fig. S26). Firstly, a gaseous O2 is adsorbed at the interface between noble metal sites (Ru, Pd, and RuPd) and Ce-Zr support via O-Ce and O-M (M = Ru or Pd) bonds forming surface adsorbed O2*. The O2 adsorption energies (Eads(O2)) at Ru/CZO, Pd/CZO and RuPd/CZO catalysts are −1.73, −1.26, and −1.89 eV respectively, indicating that the binary RuPd site exhibits the strongest adsorption capacity of O2 relative to single Ru and Pd sites. Then, the first C-H bond of the adsorbed CH4 molecule is broken forming the *O-H, active atoms (O*) and adsorbed *CH3 species in the presence of O2, and the formation of the *OH also leads to cleavage of the O2* molecule. As shown in Fig. 5c, the first C-H bond dissociation generates a more stable final state with lower energy in the presence of O2 (CH4 + O2 → CH3 + O + OH), which suggests that O2* can promote the first C-H bond dissociation. The energy barriers of the first C-H bond dissociation with O2-assisted regime at single Ru, single Pd and binary RuPd sites are 2.30, 1.81, and 1.24 eV, respectively, indicating that binary RuPd site exhibits superior reactivity of CH4 molecule compared to the single Ru and Pd sites. Subsequently, the adsorbed *CH3 species migrates to the interface and combines with O* to form methoxy (*OCH3) species for subsequent oxidation reactions, which require the lower absorption energy for RuPd/CZO (0.17 eV) relative to Ru/CZO (0.52 eV) and Pd/CZO (0.42 eV). It implies that *OCH3 species, as the key intermediate species, is most prone to be generated on RuPd/CZO. The second H atom separates from *OCH3 and combines with *OH forming adsorbed H2O*, which releases energy of 1.03, 1.27 and 1.25 eV on Ru/CZO, Pd/CZO, and RuPd/CZO, respectively. After H2O* is desorbed from Ce-based support, the Ce site can continue to adsorb O2 molecules. The O2 adsorption energies (Eads(O2)) at Ru/CZO, Pd/CZO and RuPd/CZO catalysts are −1.29, −1.24 and −1.31 eV, respectively. And then, the H atom and *OCH species, created by the third C-H bond dissociation, combine with the two O* to form *OH and formate (*COOH) species respectively, and the releases energy of those processes are as follows: Ru/CZO (0.11 eV), Pd/CZO (2.55 eV) and RuPd/CZO (1.85 eV). The C-H bond dissociation of *COOH species results in the formation of *CO2 and H atom, and the generated H atom combines with HO* to form H2O*. Finally, CO2* and H2O* species are desorbed from the catalyst surface, which fulfills the cyclic process of CH4 oxidation on the surface of catalysts.

To reveal the origin for catalytic cooperation between Ru and Pd atoms, the projected densities of state (PDOS) for Ru/CZO, Pd/CZO and RuPd/CZO concentrating on d orbitals of Ru and Pd were simulated (Fig. 5d, e). According to the d-band center theory, the d-band centers of Ru (−1.250 eV) and Pd (−1.511 eV) in RuPd/CZO shift toward the Fermi level relative to that of Ru in Ru/CZO (−1.590 eV) and Pd in Pd/CZO (−1.884 eV), indicating that the adsorption of gaseous reactant on RuPd/CZO is stronger than that on Ru/CZO and Pd/CZO47. And in Fig. S27, a significant overlap between the Ru−4d and Pd-4d orbitals of RuPd/CZO catalyst can be observed between −4 and 0 eV, implying that the formation of the Ru-Pd electronic interaction. The cooperation between Ru-Pd accelerates the rate-determining step of NO oxidation and CH4 activation, which leads to the excellent catalytic activity of RuPd/CZO catalyst for simultaneous soot and CH4 oxidation.

Based on the above results, we found that Ru site in the RuPd NPs is responsible for catalyzing NO oxidation to NO2, while Pd site can activate the C-H bond for boosting CH4 oxidation to CO2. The interface site is the key for adsorption-activation of O2. NO and CH4 oxidation reactions occur efficiently at the interfacial site. And the catalytic properties at Ru or Pd sites can be enhanced by incorporating each other to form binary Ru-Pd cooperativity sites, which can suppress the competitive oxidation reactions between NO and CH4. The conclusion of DFT calculations is consistent with the experimental results. The binary Ru-Pd site easily boosts NO oxidation and C-H bond activation, which is beneficial to further promote simultaneous oxidation of soot and CH4.

Discussion

In summary, we report a multifunctional RuPd/3DOMM-CZO catalyst for engine exhaust aftertreatment of natural gas-diesel dual-fuel engines. The ordered macropore and mesopore structure in novel hierarchical porous catalysts can respectively enhance the mass transfer diffusion of solid and gaseous reactants for boosting simultaneous soot and CH4 oxidation. And the binary Ru-Pd active components can improve activation efficiency for NO and CH4 molecules. RuPd/3DOMM-CZO catalyst exhibits excellent catalytic performance and stability during simultaneous oxidation of soot and CH4 compared with single Ru or Pd catalysts and single porous catalysts, i.e., its T50 values of soot and CH4 oxidation are respectively 357 °C and 334 °C, and its efficiency of simultaneous oxidation is 95% at 393 °C. Based on the results of characterizations and DFT calculations, Ru site in binary Ru-Pd active components is responsible for catalyzing NO oxidation to NO2, which is a key step of NOx-assisted soot oxidation mechanism, while Pd site can effectively activate the C–H bond for boosting CH4 oxidation to CO2. The catalytic cooperation between Ru and Pd atoms in binary Ru-Pd active components can adjust the competing oxidation reaction and promote the rate-determining step to realize simultaneous oxidation of soot and CH4. This study would provide a reliable solution for the design of multifunctional catalysts and new insights into the simultaneous oxidation of multiple substances.

Methods

Chemicals

Methyl methacrylate (C5H8O2, 99%), potassium persulfate (K2S2O9, 99%), Pluronic F127 (average Mn ~5800), ethanol (CH3CH2OH, 99.8%), cerium(III) nitrate hexahydrate (Ce(NO3)3·6H2O, 99%) and zirconyl(IV) chloride octahydrate (ZrOCl2·8H2O, 99%), ruthenium(III) chloride (Ru content 45-55%), palladium(II) nitrate solution (Pd 10 wt% in 10 wt% nitric acid), poly(N-vinyl-2-pyrrolidone) (PVP, 99%), and sodium borohydride (NaBH4, 99%) were purchased from Aladdin Ltd. (Shanghai, China)

Catalyst preparation

Preparation of polymethyl methacrylate microsphere template

The long-range replication Polymethyl methacrylate (PMMA) microspheres were synthesized by modified emulsifier-free emulsion polymerization method with deionized water as solvent. Methyl methacrylate (MMA) as monomer was purified by reduced pressure distillation, and potassium persulfate (KPS) as polymerizer was purified by recrystallization. Deionized water (240 mL) and MMA (120 mL) were poured into a 2000 mL four-necked flask. The mixture was heated to 80 oC by a hot water bath and stayed stable for 20 min. A Teflon stirring paddle attached to the flask was driven by an electric motor after nitrogen was bubbled to deaerate the air completely. In another beaker, 0.3 g KPS was added into the 40 mL deionized water to form a solution and kept in 80 °C by a water bath. After the temperature of flask stayed stable for a while, the KPS solution was added into the flask rapidly. Under the constant stirring rate (380 r min−1) and the protection of nitrogen, the mixture was kept at 80 °C for 90 min. Waiting for the polyreaction reaction finished, the reaction system was cooled to room temperature, and the homogeneous latex with nearly monodispersed PMMA microspheres were obtained by the filtration with filter paper (pore sizes, ~1 μm). The filtered latex was centrifuged at 3000 rpm (1006.2 g) for 600 min to form tightly packed PMMA microspheres. Removing the supernatant liquid, the solid block was dried at 50 °C for 36 h. Finally, long-range replication PMMA template was obtained.

Preparation of hierarchical porous Ce0.3Zr0.7O2 solid solution

The hierarchical porous Ce0.3Zr0.7O2 solid solution was fabricated by the evaporation-induced self-assembly with colloid crystal template (EISA-CCT) method. 1.0 g Pluronic F127 was dissolved in 10.0 mL ethanol under stirring in 40 °C water-bath and the settled solution was marked as solution A. 3 mmol cerium(III) nitrate hexahydrate and 7 mmol zirconyl(IV) chloride octahydrate were dissolved in 10.0 mL ethanol under stirring in 40 °C water-bath, and the settled solution was marked as solution B. Waiting for solution A and B dissolved completely for 2 h, solution B was dropped into solution A dropwise with gentle stirring. After 4 h of continuous thermostatic mixing, the mixture turned into a translucent sol state. Then the sol was mixed with 3.5 g PMMA microsphere template. After being impregnated completely and filtered, the solid-liquid mixture was put into vacuum oven at 50 °C to age for 8 h. The obtained light-yellow solid after the aging process was calcined in the air ambient at a ramp of 2 °C min−1 from room temperature to 500 °C and kept for 240 min, then cooled to room temperature. the desired three-dimensional ordered macro-mesoporous cerium-zirconium oxide was obtained, abbreviated as 3DOMM-CZO.

Preparation of 3DOMM-CZO supported binary Ru-Pd components catalyst

The 3DOMM-CZO supported binary Ru-Pd components catalyst was synthesized by the gas bubbling-assisted membrane reduction (GBMR) method. 0.5 g 3DOMM-CZO support was distributed in 200 mL of deionized water with stirring vigorously. The ruthenium(III) chloride and palladium(II) nitrate solutions were mixed thoroughly before being added to the Ce0.3Zr0.7O2 slurry and stirred for 1.5 h after mixing with the slurry. Theoretically, the supporting of Ru-Pd components were 2 wt%. The stabilizer poly (N-vinyl-2-pyrrolidone) (PVP) solution (20 mL, 1.275 mol L−1) was mixed into the hybrid solution and then stirred thoroughly for 0.5 h. At the same time, sodium borohydride (NaBH4) solution (40 mL, 0.5 g L−1) as the reducing agent was slowly injected into the membrane reactor at a rate of 0.6 mL min−1 via a constant-flow pump. After the NaBH4 solution was consumed completely, RuPd/3DOMM-CZO catalyst could be obtained just by centrifugation and calcination. The Ru/3DOMM-CZO and Pd/3DOMM-CZO catalysts can be prepared using a similar process.

Characterizations

Powder X-ray diffraction (XRD) patterns were obtained by a diffractometer (Bruker D8 advance) over the 2θ range from 5 to 90 ° with a 5 ° min−1 scanning rate using Cu-Kα radiation to obtain the phase structure of all as-prepared catalysts. Scanning electron microscopy (SEM), transmission electron microscope (TEM) images were obtained by Quanta 200 F and FEI Tecnai G2 F20 transmission electron microscope, respectively. ADF/ABF/SE-STEM images and ADF-STEM-EDX (line-scanning profile and mapping) were obtained by Hitachi HF5000, working at an accelerating voltage of 200 kV. The BET surface areas and pore size distribution of catalysts were determined by nitrogen adsorption/desorption in a Micromeritics TriStar-II 3020 instrument at −196°C by N2 adsorption. The surface element valence state was detected by X-ray photoelectron spectra (XPS, XPSPHI−1600 ESCA spectrometer), calibrated using a C 1s binding energy of 284.8 eV. Ce L3-edge X-ray absorption fine structure (XAFS) spectra were measured at the XRD station of beamline 4B9A of Beijing Synchrotron Radiation Facility (BSRF) in fluorescence mode. The X-ray absorption near-edge structure (XANES) spectra of soft X-ray for the O K-edge were collected from the XMCD-B beam lines at National Synchrotron Radiation Laboratory (NSRL), Hefei, China, with the total electron yield mode in a vacuum chamber (<5 × 10−8 Pa). Raman spectra of all catalysts were measured on an inVia Reflex-Renishaw spectrometer with an excitation wave-length of 532 nm. In-situ Raman experiments were conducted on the high-resolution Raman spectrometer system. For in-situ Raman measurements, the catalysts were deposited on an in-situ cell with a quartz window. The sample was pretreated in a N2 gas flow (50 mL min−1) at 300 °C for 30 min. Then the reaction atmosphere switched to 5 vol% O2 balanced with N2 (50 mL min−1) and the temperature is maintained at 300 °C for 20 min. Finally, the gas feed was switched to a 0.1 vol% NO and 0.1 vol% CH4 balanced with N2 (50 mL min−1) at 300 °C for 20 min. The spectra were recorded at 10-min intervals. The temperature programmed reduction of hydrogen (H2-TPR) was carried out on an Automatic Chemisorption Analyzer (BSD-C200, BSD Instrument). The catalysts were pretreated with N2 at 350 °C for 30 min before test. After cooling to room temperature, H2-TPR was conducted with flowed the gaseous contained H2 (7 vol%) balanced with N2 (30 mL min−1). And the temperature range of the H2-TPR is 50 to 900 °C with a ramp rate of 10 °C min-1. The temperature-programmed oxidation of NO (NO-TPO) was carried out on a fixed-bed tubular quartz reactor, and the products can be detected by online FT-IR. The catalysts were pretreated with N2 at 100 °C for 30 min before test. After cooling to room temperature, NO-TPO was conducted with flowed the gaseous contained O2 (5 vol%) and NO (0.1 vol%) balanced with N2 (50 mL min−1). And the temperature range of the NO-TPO reaction is 50 to 500 °C with a ramp rate of 2 °C min−1. The temperature-programmed surface reaction of methane (CH4-TPSR) was carried out on the MS (Hidden, DECRA) to obtain CH4, CO2, H2O, and CO signals. The catalysts were pretreated with Ar at 150 °C for 30 min before test. Then, catalysts were treated with O2 (5 vol%) balanced with Ar (50 mL min−1) at 400 °C for 30 min. After cooling to room temperature, the excess O2 was blown off with Ar. Finally, CH4-TPSR was conducted with flowed the gaseous contained CH4 (4 vol%) balanced with Ar (50 mL min−1). And the temperature range of the CH4-TPSR is 50 to 700 °C with a ramp rate of 10 °C min−1. In-situ diffuse reflectance infrared Fourier transforms spectra (in-situ DRIFTS) were carried on a Bruker FT-IR spectrometer (TENSOR II) equipped with a liquid nitrogen-cooling mercury-cadmium-telluride (MCT) detector. The catalyst was added into high-temperature IR cell with ZnSe window, and heated in N2 flow at 200 °C for 30 min to remove adsorbed H2O and other materials. After cooling down to 50 °C with N2 atmosphere, the background spectrum was recorded. Finally, the gas to be measured were fed into cell at a flow rate of 50 mL min−1. IR spectra of NO oxidation were recorded in a flow of 0.1 vol% NO/5 vol% O2/N2 balance (50 mL min−1) under heating from 50 to 400 °C; IR spectra of CH4 oxidation were recorded in a flow of 0.1 vol% CH4/5 vol% O2/N2 balance (50 mL min−1) under heating from 50 to 400 °C; IR spectra of simultaneous NO and CH4 oxidation were recorded in a flow of 0.1 vol%NO/0.1 vol% CH4/5 vol% O2/N2 balance (50 mL min−1) under heating from 50 to 400 °C.

Catalytic activity and kinetic tests

The simultaneous oxidation catalytic activity and selectivity are evaluated via temperature-programmed oxidation (TPO) reaction with Printex-U modeled soot particles (∼25 nm in diameter) and CH4 dilution gas. The TPO reaction ranges from 150 to 700 °C at a ramping rate of 2 °C min−1. Mixing catalyst (100 mg) and soot particles (5 mg) until loose contact can simulate realistic conditions for catalytic oxidation of soot. The gaseous reactants are flowed at a rate of 50 mL min−1 and consisted of O2 (5 vol%), NO (0.1 vol%) and CH4 (0.1 vol%) balanced with N2. The gaseous products after the oxidation reaction occurred are injected into an online gas chromatograph (GC 9890B, Shanghai) equipped with the FID detector via an autosampler for analysis at 5 min intervals. The signals of CO and CO2 can be detected on the online gas chromatograph at approximately 0.6 and 3.4 min, respectively. As the temperature increases, soot and CH4 can be oxidized, and thus we are able to obtain temperature-product concentration curves. As the temperature rises with reaction time, soot becomes oxidized fully, and CH4 can also be fully oxidized at high temperatures. The signal of the CO2 and CO product stops changing, indicating that the soot was fully oxidized and the signal of CO2 and CO was generated exclusively by oxidation of CH4. Catalytic activity is assessed through the T10, T50, and T90 values, defined as temperatures at 10%, 50%, and 90% conversion of CH4 and soot, respectively.

The SCO2 is selectivity of CO2 for simultaneous soot and CH4 oxidation, which can be calculated by the ratio of CO2 concentration to the sum of CO and CO2 concentration according to the Eq. (1):

Here, the [CO2]out and [CO]out represent the outlet CO2 and CO concentration, respectively.

The CH4 conversion (XCH4) is calculated from the changed CH4 concentration according to the Eq. (2):

The [CH4]in is the initial concentration of CH4 in the inlet gas (0.1 vol%). The [CH4]out is the concentration of unoxidized CH4 in the outlet gas, which is detected by online gas chromatograph directly.

The soot conversion (Xsoot) was evaluated from the changed concentration of CO2 + CO according to the Eq. (3):

The [CO2 + CO]soot is the concentration of CO2 + CO generated from soot oxidation at a certain temperature, which is calculated from the CO2, CO and CH4 concentrations directly detected by the online gas chromatograph. The [CO2 + CO]soot is equal to the concentration of CO2 + CO generated from simultaneous oxidation minus the concentration of oxidized CH4, i.e., [CO2 + CO]soot = [CO2]out + [CO]out-([CH4]in-[CH4]out). The [CO2 + CO]soot,total is the total concentration of CO2 + CO generated by complete soot oxidation, which is obtained by integrating [CO2 + CO]soot.

The apparent activation energy of soot oxidation was measured by the single heating rate method (Coats-Redfern integral method) according to the Eq. (4):

Where β is the heating rate (K min−1), α is the soot conversion rate (α < 15 %), T is the reaction temperature (K), k is the reaction rate constant, f(α) is the kinetic expression for the reaction model, f(α)=(1-α)n, where n is the number of reaction stages. A is the pre-finger factor (s−1), Ea is the apparent activation energy (kJ mol−1), R is the ideal gas constant. Previous studies have shown that the reaction of soot with NO2 is a one-stage reaction, i.e., n = 1. The Eq. (5) can be obtained:

In most cases, \(\frac{{\rm{2RT}}}{{\rm{E}}_{\rm{a}}}\) much smaller than 1, and \({\rm{In}}\left[\frac{{\rm{AR}}} {{{\upbeta }} {{\rm{E}}_{\rm{a}}}}\left(1-\frac{2{\rm{RT}}} {{\rm{E}}_{\rm{a}}}\right)\right]\) can be regarded as a constant. Then, the apparent activation energy is estimated by plotting \({\rm{In}}[-\frac{\mathrm{ln}(1-{\rm{\alpha }})}{{{\rm{T}}}^{2}}]\) vs 1/RT.

When the conversion of CH4 is <15 %, a dependence of the CH4 reaction rate (rCH4) on the products of CO2 and H2O could be ignored; therefore, the empirical kinetic expression of the reaction rate of CH4 oxidation can be described by Eq. (6):

where [CH4] is the CH4 concentration in the feed gas, XCH4 is the CH4 conversion, F represents the total flow rate (mL min−1) and mcatalyst is the catalyst mass (g). The apparent activation energy of CH4 oxidation is measured according to Eq. (7):

When the CH4 conversion is very low (<15%), both CH4 and O2 conversions are approximately constant, and the correlation between InrCH4 and 1/RT is close to linear:

Where Ea is the apparent activation energy (kJ mol−1), rCH4 is the reaction rate (mol g−1 s−1) and A is pre-finger factor (s−1). Then, the apparent activation energy is estimated by plotting InrCH4 vs 1/RT.

Density functional theory (DFT) calculations

DFT calculations were conducted using the VASP package code48. The exchange-correlation energy function was described using the Pardew–Burke–Ernzerhof (PBE) generalized gradient approximation (GGA)49. The kinetic cutoff energy is 400 eV for the plane-wave basis set, and the k point was set to the γ point in the Brillouin zone. Ce-Zr oxide models were obtained by substitution of Ce atoms for Zr atoms at eight vertices of the ZrO2 cubic cell50. All calculations for Ce atoms of Ce-Zr oxide models were performed by the DFT + U method. The value of Ueff was set to 4.5 eV for Ce 4f 51. Ce-Zr oxide supercells (2 × 2) were built, with (111) surfaces exposed. The bottom three atomic layers were fixed during all calculations. The thinness of the vacuum layer for all the models was set as 17 Å. Ce-Zr oxide slab had been established and the 10-atom active sites had been inserted into our slab models. The adsorption and desorption energy were calculated by the equations:

Where Eads is the adsorption energy, Edes is the desorption energy, EMS is the total energy of a surface slab with the adsorbate, and ES is the energy of pure substrate. EM represents the energy of an adsorbate molecule.

The climbing image-nudged elastic band (CI-NEB) code was used to identify the reaction coordinates from initial state (IS) to final state (FS)52, which located the transition state (TS). The activation energy (Ea) was determined with the following equation:

Where EIS and ETS represent the energy of IS and TS, respectively.

Data availability

The data that support the findings of this study are included in the published article (and its Supplementary Information). Source data are provided with this manuscript and is available from the corresponding author upon request. Source data are provided with this paper.

References

Karim, G. A. A review of combustion processes in the dual fuel engine—The gas diesel engine. Prog. Energy Combust. 6, 277–285 (1980).

Cesar de Lima Nogueira, S. et al. Prediction of the NOx and CO2 emissions from an experimental dual fuel engine using optimized random forest combined with feature engineering. Energy 280, 128066 (2023).

Janssens, T. V. W. & Vennestrøm, P. N. R. A molecular dance to cleaner air. Science 357, 866–867 (2017).

Mei, X. et al. Decreasing the catalytic ignition temperature of diesel soot using electrified conductive oxide catalysts. Nat. Catal. 4, 1002–1011 (2021).

Wang, W. et al. Mixed-phase oxide catalyst based on Mn-mullite (Sm, Gd) Mn2O5 for NO oxidation in diesel exhaust. Science 337, 832–835 (2012).

McCarty, J. G. Durable catalysts for cleaner air. Nature 403, 35–36 (2000).

Farrauto, R. J. Low-temperature oxidation of methane. Science 337, 659–660 (2012).

He, C. et al. Recent advances in the catalytic oxidation of volatile organic compounds: a review based on pollutant sorts and sources. Chem. Rev. 119, 4471–4568 (2019).

Wei, Y. et al. Highly active catalysts of gold nanoparticles supported on three-dimensionally ordered macroporous LaFeO3 for soot oxidation. Angew. Chem. Int. Ed. 50, 2326–2329 (2011).

Mortensen, M. & Laursen, S. Catalytic site seeing. Nat. Chem. 14, 483–485 (2022).

Guo, Y. et al. Photo-thermo semi-hydrogenation of acetylene on Pd1/TiO2 single-atom catalyst. Nat. Commun. 13, 2648 (2022).

Tang, Y. et al. Synergy of single-atom Ni1 and Ru1 sites on CeO2 for dry reforming of CH4. J. Am. Chem. Soc. 141, 7283–7293 (2019).

Zhang, P. et al. Boosting catalytic purification of soot particles over double Perovskite-type La2-xKxNiCoO6 catalysts with an ordered macroporous structure. Environ. Sci. Technol. 55, 11245–11254 (2021).

Xiong, J. et al. Synergetic effect of K sites and Pt nanoclusters in an ordered hierarchical porous Pt-KMnOx/Ce0.25Zr0.75O2 catalyst for boosting soot oxidation. ACS Catal. 10, 7123–7135 (2020).

Li, Y. et al. A single site ruthenium catalyst for robust soot oxidation without platinum or palladium. Nat. Commun. 14, 7149 (2023).

Zhao, M. & Xia, Y. Crystal-phase and surface-structure engineering of ruthenium nanocrystals. Nat. Rev. Mater. 5, 440–459 (2020).

Enache, D. I. et al. Solvent-free oxidation of primary alcohols to aldehydes using Au-Pd/TiO2 catalysts. Science 311, 362–365 (2006).

Mori, K., Sano, T., Kobayashi, H. & Yamashita, H. Surface engineering of a supported PdAg catalyst for hydrogenation of CO2 to formic acid: elucidating the active Pd atoms in alloy nanoparticles. J. Am. Chem. Soc. 140, 8902–8909 (2018).

Jiang, D. et al. Dynamic and reversible transformations of subnanometre-sized palladium on ceria for efficient methane removal. Nat. Catal. 6, 618–627 (2023).

Willis, J. J. et al. Systematic identification of promoters for methane oxidation catalysts using size- and composition-controlled Pd-based bimetallic nanocrystals. J. Am. Chem. Soc. 139, 11989–11997 (2017).

Wei, Y. et al. Fabrication of inverse opal TiO2-supported Au@CdS core–shell nanoparticles for efficient photocatalytic CO2 conversion. Appl. Catal. B 179, 422–432 (2015).

Wei, Y. et al. Preparation and characterization of Co0.2/Ce1-xZrxO2 catalysts and their catalytic activity for soot combustion. Chin. J. Catal. 31, 283–288 (2010).

Wang, C. et al. Structural regulation of Au-Pt bimetallic aerogels for catalyzing the glucose cascade reaction. Adv. Mater. 36, 2405200 (2024).

Tang, M. et al. RuPd alloy nanoparticles supported on N-doped carbon as an efficient and stable catalyst for benzoic acid hydrogenation. ACS Catal. 5, 3100–3107 (2015).

Jung, Y. & Bae, C. Immaturity of soot particles in exhaust gas for low temperature diesel combustion in a direct injection compression ignition engine. Fuel 161, 312–322 (2015).

Andana, T. et al. CuO nanoparticles supported by ceria for NOx-assisted soot oxidation: insight into catalytic activity and sintering. Appl. Catal. B 216, 41–58 (2017).

Guo, S.-N., Dong, Y.-J., Qiao, M., Wang, D. & Wang, J.-X. Variable valence Ce-based Cs2CeAgBr6 perovskite nanocrystals for highly selective photoconversion of CO2 to CH4. Small 21, 2408765 (2025).

Liu, Y., Sheng, W. & Wu, Z. Synchrotron radiation and its applications progress in inorganic materials. J. Inorg. Mater. 36, 901–918 (2021).

Cheng, W. et al. Recent advances in battery characterization using in situ XAFS, SAXS, XRD, and their combining techniques: from single scale to multiscale structure detection. Exploration 4, 20230056 (2024).

Zhao, S. et al. Spontaneous formation of asymmetric oxygen vacancies in transition-metal-doped CeO2 nanorods with improved activity for carbonyl sulfide hydrolysis. ACS Catal. 10, 11739–11750 (2020).

Barreau, M. et al. Ionic Nickel embedded in ceria with high specific CO2 methanation activity. Angew. Chem. Int. Ed. 62, e202302087 (2023).

Wilson, H. H. et al. Synthesis and characterization of a bridging cerium (IV) nitride complex. J. Am. Chem. Soc. 145, 781–786 (2023).

Xiong, J. et al. Highly reactive peroxide species promoted soot oxidation over an ordered macroporous Ce0.8Zr0.2O2 integrated catalyzed diesel particulate filter. Environ. Sci. Technol. 58, 8096–8108 (2024).

Feng, X. et al. Unraveling the principles of lattice disorder degree of Bi2B2O7 (B = Sn, Ti, Zr) compounds on activating gas phase O2 for soot combustion. ACS Catal. 11, 12112–12122 (2021).

Li, Y. et al. Enhancing catalytic removal of autoexhaust soot particles via the modulation of interfacial oxygen vacancies in Cu/CeO2 catalysts. Environ. Sci. Technol. 59, 2327–2338 (2025).

Chen, J., Liu, X. & Zhang, F. Composition regulation of bimetallic RuPd catalysts supported on porous alumina spheres for selective hydrogenation. Chem. Eng. J. 259, 43–52 (2015).

He, Y. et al. In situ identification of reaction intermediates and mechanistic understandings of methane oxidation over hematite: a combined experimental and theoretical study. J. Am. Chem. Soc. 142, 17119–17130 (2020).

Tamm, S., Vallim, N., Skoglundh, M. & Olsson, L. The influence of hydrogen on the stability of nitrates during H2-assisted SCR over Ag/Al2O3 catalysts—a DRIFT study. J. Catal. 307, 153–161 (2013).

Hu, H. et al. Mechanistic aspects of deNOx processing over TiO2 supported Co–Mn oxide catalysts: structure–activity relationships and in situ DRIFTs analysis. ACS Catal. 5, 6069–6077 (2015).

Wang, L., Cheng, X., Wang, Z., Ma, C. & Qin, Y. Investigation on Fe-Co binary metal oxides supported on activated semi-coke for NO reduction by CO. Appl. Catal. B 201, 636–651 (2017).

Yao, X. et al. A comparative study of different doped metal cations on the reduction, adsorption and activity of CuO/Ce0.67M0.33O2 (M=Zr4+, Sn4+, Ti4+) catalysts for NO+CO reaction. Appl. Catal. B 130-131, 293–304 (2013).

Zhang, S. et al. Catalysis on singly dispersed Rh atoms anchored on an inert support. ACS Catal. 8, 110–121 (2018).

Artsiusheuski, M. A., Verel, R., van Bokhoven, J. A. & Sushkevich, V. L. Methane transformation over copper-exchanged zeolites: from partial oxidation to C–C coupling and formation of hydrocarbons. ACS Catal. 11, 12543–12556 (2021).

Li, Q. et al. Metal–support interactions within a dual-site Pd/YMn2O5 catalyst during CH4 combustion. ACS Catal. 12, 4430–4439 (2022).

Chin, Y.-H., Buda, C., Neurock, M. & Iglesia, E. Consequences of metal–oxide interconversion for C–H bond activation during CH4 reactions on Pd catalysts. J. Am. Chem. Soc. 135, 15425–15442 (2013).

Tao, F. F. et al. Understanding complete oxidation of methane on spinel oxides at a molecular level. Nat. Commun. 6, 7798 (2015).

Tao, L. et al. Precise synthetic control of exclusive ligand effect boosts oxygen reduction catalysis. Nat. Commun. 14, 6893 (2023).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comp. Mater. Sci. 6, 15–50 (1996).

Yashima, M. Crystal structures of the tetragonal ceria-zirconia solid solutions CexZr1-xO2 through first principles calculations (0 ≤ x ≤ 1). J. Phys. Chem. C. 113, 12658–12662 (2009).

Tan, R. et al. Liberating C–H bond activation: achieving 56% quantum efficiency in photocatalytic cyclohexane dehydrogenation. J. Am. Chem. Soc. 146, 14149–14156 (2024).

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000).

Acknowledgements

This work was financially supported by National Key Research and Development Program of China (2022YFB3504100), National Natural Science Foundation of China (22208373, 22376217, 12305372), Key Laboratory of Jiangxi Province for Persistent Pollutants Prevention Control and Resource Reuse (2023SSY02061), and Financial Support by Open Research Fund of Key Laboratory of the Ministry of Education for Advanced Catalysis Materials and Zhejiang Key Laboratory for Reactive Chemistry on Solid Surfaces in Zhejiang Normal University (KLMEACM202303). We thank the 4B9A beamline (https://cstr.cn/31109.02.BSRF.4B9A) of Beijing Synchrotron Radiation Facility (BSRF) for providing technical support and assistance in XAFS data collection.

Author information

Authors and Affiliations

Contributions

L.X. and Y.W. conceived, synthesized the catalyst and completed most of the experiments and characterizations, and wrote the paper. T.Q., X.L., and Q.H. completed the electron microscopy test. Y.L., P.Z., and X.Y. helped with the catalytic performance and carried out theoretical calculations and analyses. Y.M., J.X., and Y.L. helped analyze the experiment data. H.G., J.Z., and Z.Z. modified the manuscript. All the authors discussed the results in the manuscript. All authors have approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Hyung Chul Ham, and Piotr Legutko for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xu, L., Qin, T., Li, Y. et al. Catalytic cooperation between Ru and Pd atoms on hierarchical porous Ce-based oxide for boosting engine exhaust purification. Nat Commun 16, 7796 (2025). https://doi.org/10.1038/s41467-025-63089-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-63089-8