Abstract

The Haber-Bosch process is used for industrial ammonia production worldwide, and it accounts for ~2% of the global energy consumption and 1.3% anthropogenic carbon footprint. Ammonia synthesis under ambient conditions with minimum carbon emission is highly desired, but it is still in the initial stage. Herein, we report a cobalt-based catalyst for ammonia continuous synthesis under ambient conditions via mechanochemistry. To describe mechanochemistry of ammonia synthesis, density functional theory (DFT) calculation was carried out and a transient confinement was discovered. 5 dual side models with Fe, Co, Ni, Cu, Ag have been set up and the Co dual side model exhibits the highest transient confinement effect with the maximum energy barrier reducing from 1.3 eV to 0.62 eV. The experiment confirmed cobalt powders in mechanochemical synthesis of ammonia showed the highest catalytic activity. By using the Co catalyst, up to 13.7 μmol·gcat−1·h−1 ammonia has been achieved under ambient conditions, and the cobalt-based catalyst can maintain its activity more than 350 h without deactivation. This represents the longest lifespan for ammonia synthesis among all the various methods reported under room temperature and atmospheric pressure to the best of our knowledge, which is also 10 times longer than the recent reported FeCs catalysts via mechanocatalysis under ambient conditions. This study suggests that continuous mechano-synthesis of ammonia under ambient condition is valuable.

Similar content being viewed by others

Introduction

Ammonia synthesis has long been an important reaction owing to its crucial role in the production of fertilizers, pharmaceuticals, and fibers. Currently, the Haber-Bosch process is primarily used for the industrial production of ammonia and is considered as one of the most influential technological achievements of the 20th century1,2,3. However, ammonia production via this process generates approximately 1.3% of the anthropogenic CO2 emissions annually, and accounts for ∼2% of the worldwide annual energy consumption, as the industrial Haber-Bosch process needs to achieve a desired ammonia concentration (approximately 15 vol.%) at >400 °C and >100 atm3,4. Considering environmental degradation due to carbon emissions and implementation of increasingly stringent emission legislations, a sustainable or green revolution is necessary for NH3 synthesis study5,6.

In recent years, several approaches for ammonia synthesis under ambient conditions, including photocatalytic and electrocatalytic methods, have been continuously reported7,8,9,10,11,12,13. Since employed H2O is a clean H2 source and moderate working conditions presents a low energy consumption, these two methods have attracted considerable attention, and attempts are being made to scale up some of the electrocatalytic processes toward industrial applications7,12. Besides, ammonia synthesis via mechanocatalysis has emerged as an energy-efficient alternative to the energy-intensive Haber-Bosch process14. Coupling with renewable power and green hydrogen, it enables decentralized production of ammonia in remote areas with much less carbon footprint15.

In 2020, Sievers et al. pioneered mechanocatalysis approach using TiN catalysts, and proposed a Mars–van Krevelen mechanism in which cyclic activation-relaxation phases created transient microenvironments to achieve dynamic N2 dissociation through localized heating and lattice strain effects, effectively bypassing steady-state thermodynamic limits16. Later, Baek’s group demonstrated high defect densities generated in situ on Fe catalysts via mechanical collisions boosted nitrogen dissociation, while energy transfer during dynamic relaxation accelerated NHx intermediate desorption17,18. Concurrently, Schüth’s team revealed the mechanical collisions could crush Fe powders continuously and create more active sites on FeCs catalysts, while elemental Cs consumed trace oxygen impurities on Fe and promoted ammonia formation under near-ambient conditions19,20.

Theoretical mechanism of mechanocatalysis is still under development. Previously, Baek’s group put forward an instructive theoretical understanding of the mechanism by density functional theory (DFT) calculations, where they proposed a dynamic relaxation model to explain the violent impact inducing arrangement of the lattice parameters and atom positions of Fe on ammonia synthesis17. It is intriguing that N2 could be activated and dissociated on metallic Fe powders via Fe ball milling under RT, nevertheless, the boosting pattern of mechanical energy on N2 activation and NHx hydrogenation have not been examined at all. Therefore, it is urgent to unveil the rationale behind ammonia synthesis during this dynamic mechanical process to guide improvements in catalytic efficiency. This includes optimizing reaction conditions and designing new catalysts. Moreover, the study of how the process not only transfers mechanical energy but also generates local high temperatures, high pressures, and stresses at the contact surfaces between milling balls and powder catalysts remains inadequately explored.

In this work, we discovered a transient confinement effect in the ball milling process, which significantly influences ammonia synthesis. This was analyzed through a theoretical model focusing on dual metallic surface sites. Among five economically viable transition metals tested, cobalt emerged as the optimal catalyst, characterized by a nitrogen activation energy of 0.62 eV and a hydrogenation energy of approximately 0.98 eV. Our experimental results further confirmed that metallic Co powder surpassed other metals in continuous ammonia synthesis via mechanocatalysis at 25 °C and 1 bar. The optimal reaction conditions for the Co catalyst were also screened, and the NH3 synthesis rate reached 13.7 μmol·gcat−1·h−1 over 350 h under continuous gas flow without deactivation. In addition, the structural variations of Co catalyst during the N2 pre-milling and hydrogenation stages were systematically elucidated, and the corresponding N2/H2 activation and hydrogenation behaviors were proposed to determine the reaction mechanism of ammonia synthesis using theoretical calculations. Finally, to establish a green route for NH3 production, we utilized solar panels as individual energy sources to supply the complete energy required for H2 production from H2O electrolysis, N2 separation from air, and subsequent ammonia synthesis in a vibration reactor. This benchmark experiment provided a sustainable ammonia synthesis route without carbon emissions via mechanocatalysis and electrocatalysis.

Results

Transient confinement addressed by density functional theory (DFT)

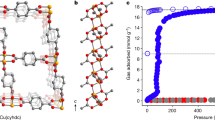

Combining the procedure of ammonia synthesis via mechanocatalysis in literatures, the reaction system usually involves the interaction between milling medium (e.g., metallic balls) and powder catalysts (e.g., metal powders) in presence of high-energy impacts21. As shown in Fig. 1a, we choose the vibration reactor to introduce the mechanical energy onto the powder catalyst. In detail, the up-and-down working mode of vessel could induce the physical collision among metal balls, and it is easy to know that two approaching Fe balls would build a confined environment during transient collisional moment. The adjacent metallic powders sandwiched in this spatial environment supply abundant metal-metal (M-M) dual sides. During the frequent and transient collision process, it is meaningful to examine the N2 activation on this M-M dual side, and this transient confinement could be mimicked through theoretical method. Furthermore, the theoretical understanding of mechanocatalysis by relating this macroscopic phenomenon to the microscopic level gives us the principle to design and screen an optimal candidate of metallic powder to activate N2 and hydrogenate NHx into NH3.

a The mechanism diagram of ammonia synthesis via mechanocatalysis. b The linear relation between N adsorption energy and N2 dissociation energy barrier (the dots and lines in red represent dual side, and the black ones represent isolated side). c Energy barrier diagram for the dissociation pathway of the ammonia synthesis reaction based on DFT calculations, where * represented the adsorption site, and TSn denoted the transition state. Simulated models of Fe and Co surfaces with and without mechanical ball milling. The blue and red lines correspond to sFe(110) and sCo(001), which are isolated side, used to simulate the reaction process without mechanical ball milling. The cyan and orange lines represent dFe(110) and dCo(001), which are dual side used to simulate the reaction process with the mechanical ball milling.

Theoretical investigation indicates that the activity of transition metal-based catalysts for ammonia synthesis is constrained by scaling relationship, a trade-off relation between the ability to nitrogen dissociation and further hydrogenation capability of atomic nitrogen adsorbed on the surface22,23,24. The N2 dissociation barrier directly links to the energy of the final state of the elementary step, i.e., the adsorption energy of atomic N through a linear scaling relation. Catalysts, such as Ag, Cu, Ni, and Co, which bind weakly to nitrogen atoms, possess faster hydrogenation kinetics but cannot activate N2 at a sufficient rate due to high barriers. In contrast, catalysts like Fe and Mo, which bind strongly to nitrogen atoms, present lower barriers for N2 dissociation but suffer from nitrogen poisoning due to slow NHx hydrogenation kinetics. The same relationship existed for the most stable metal surface we calculated in this work. Governed by the Sabatier principle, the reaction rate of ammonia synthesis as a function of N adsorption energy follows a volcano-shaped relationship. Therefore, an ideal catalyst for ammonia synthesis should have a nitrogen atom adsorption energy of approximately −0.62 eV25.

Based on aforementioned mechanical catalysis approach for ammonia synthesis under mild conditions17,18,19,20, it was confirmed that ammonia only appeared under ball milling conditions using metallic balls as milling medium, but not under static, mild reaction conditions. We constructed a dual side model (Fig. S1) to describe the state of the collision on a microscopic scale. Different with previous understanding on N2 activation on a single metal surface, we hypothesized that the active sites should be two metal surfaces approaching each other under mechanical reaction conditions. As Fig. 1a shown, the adjacent metal surface between two milling balls supplies a transient reaction environment, and the corresponding mechanical energy originates from the physical collision of balls. Accordingly, we build a theoretical model of a mechanocatalysis mechanism grounded in realistic conditions. N2 dissociates between two approaching metal surfaces. This state enables simultaneous interaction of both terminal nitrogen atoms with adjacent metal surfaces, which effectively weakens the N ≡ N triple bond and facilitates molecular dissociation at the interfacial region (Fig. S1). Through the transient confinement mechanism, both occupied and unoccupied d-states participate in bidirectional electron transfer. Specifically, they accept electron density from the bonding orbitals of nitrogen while simultaneously donating electrons to its antibonding π* orbitals. The electron transfer process is significantly enhanced by the participation of both metal surfaces, each playing an active role. This transient confinement leads to a more efficient electron transfer than would occur if only a single isolated surface were involved (Fig. S2). By simulating the collision process through continuously reducing the distance between two surfaces from 10 Å to 3 Å (Fig. S3 and Table S1), we determined that the dual side model with an interlayer distance of 4.5 Å, which forms a transient confinement for reactions was the optimal configuration for simulating the reaction. This was because if the distance was shorter, the two colliding surfaces would merge, and if it was longer, the dual side model did not achieve the most stable structure.

We selected five cost-effective metals for theoretical analysis. As illustrated in Fig. 1b, the nitrogen dissociation capability of the isolated side model is less effective compared to the dual side model. This suggests that mechanocatalysis significantly enhances the performance of most metals in ammonia synthesis. It is noteworthy that the predicted nitrogen atom adsorption energies for Fe and Co are approximately −0.62 eV. This suggests that Fe or Co among these catalysts may effectively balance the challenges associated with both N2 dissociation and nitrogen atom hydrogenation steps. Thus, we conducted full pathway calculations (Fig. 1c) for Fe and Co, which have nitrogen atom adsorption energies closest to −0.62 eV, and found that dual side Co(001) (dCo(001)) has advantages over Fe catalysts in both nitrogen dissociation and hydrogenation processes. Without mechanical action, the rate-determining step for the Fe catalyst is hydrogenation with an energy barrier of 1.37 eV, while for Co, the rate-determining step is N2 dissociation with an energy barrier of 1.30 eV. When mechanical ball milling is introduced, Co exhibits superior performance, with its N-N dissociation barrier reduced to 0.62 eV and rate-determining step hydrogenation barrier reduced to 0.98 eV, lower than that of Fe under mechanical ball milling (N-N dissociation barrier is 0.70 eV and rate-determining step barrier is 1.28 eV). All structures are shown in Table S2. Based on these theoretical predictions, we infer that the Co catalyst will exhibit excellent ammonia synthesis performance under mechanical ball milling conditions.

Based on the existing mechanistic studies of ammonia synthesis on metal surfaces, the possibility of an associative hydrogenation mechanism cannot be ruled out in addition to the conventional dissociative nitrogen activation pathway26,27,28,29,30,31,32,33. To address this, the present study systematically evaluates the feasibility of the associative pathway using the dual side model. As shown in Fig. S4, the rate-determining step of the association mechanism is the hydrogenation of N2, with an energy barrier of 1.15 eV. In contrast, the rate-determining step of the dissociation pathway demonstrates a lower energy barrier of 0.98 eV. This suggests that the dissociation mechanism is more favorable for the reaction.

Procedure for continuous ammonia synthesis via mechanocatalysis

Continuous ammonia synthesis by mechanocatalysis was conducted in a home-made vibration reactor (Fig. S5 and Figs. S5–S8 supplied the home-made and customized facility used in this work) at 25 °C and 1 bar using Co powders as the catalyst and Fe balls as the milling medium. If N2 and H2 were directly introduced into the vibration reactor under ambient conditions continuously, no NH3 was detected in the effluent (Fig. S9). After many attempts of N2/H2 activation pattern, a two-stage optimized reaction procedure was developed: (1) The N2 pre-milling stage. If Co catalyst was mechanically milled under pure N2, the subsequent introduction of H2 + N2 produced NH3, demonstrating that N2 activation into active nitrogen species on Co surface (denoted as Co(N*)) was essential during the milling process. Considering the co-existence of various Co oxidation states during the pre-ball milling stage, theoretical calculation results also demonstrate the importance of Co3+ species for this reaction (Figs. 1c and S4). According to the calculation results, the Co1+/Co2+ species predominantly engage in the association pathway or undergo further oxidation to form Co3+. However, Co3+ species tend to follow dissociation pathway, which presents a lower reaction energy barrier compared with the association pathway as aforementioned and favors subsequent ammonia synthesis. Besides, we also studied the magnetic moments of Co in the different oxidation states and its relation with the N2 activation (Table S3). When Co exists in its metallic state, it is in the 0 oxidation state. Upon adsorption of a partially activated N2 molecule, Co converts to the +1–+2 oxidation states. When Co adsorbs fully dissociated N atoms, it adopts a + 3 oxidation state. When Co is in the metallic state, it’s magnetic moment is 1.77 μB. At this point, there are many unpaired electrons in the d orbitals, resulting in a high magnetic moment. After nitrogen adsorption on the surface, the magnetic moment decreases from 1.77 μB to 1.515 μB, with a reduction in the number of unpaired electrons in the d orbitals. At this stage, Co corresponds to the 1–2 valence state, and the N2 bond length is 1.27 Å, indicating that N2 is activated, and N ≡ N bond is weakened. After fully pre-ball milling, N2 is highly activated and dissociated into N atom. Co adsorbed with N atoms is in the Co3+ state with the magnetic moment further decreasing to 1.022 μB. (2) The continuous hydrogenation stage. After N2 pre-milling, N2 and H2 could be introduced into the reaction system simultaneously and continuous ammonia synthesis was achieved. Accordingly, we inferred that N2 could be activated and hydrogenated over Co catalyst through only mechanical energy without external heating or pressurization. In the following sections, we would provide detailed explanations to analyze N2 dissociation and hydrogenation behaviors on Co catalyst.

Performance of the Co catalyst

To optimize the ammonia yield, the relationship between nitrogen dissociation and the vibration frequency of the reactor was examined. Our experiments showed that the activated Co(N*) (quantified by desorbed N2 content after N2 pre-milling with a subsequent Ar purge) followed a volcanic profile as a function of the vibration frequency, with an optimal vibration frequency of 1000 rpm (Fig. S10). Besides, the activated Co(N*) was positively correlated with the N2 pre-milling time (Fig. S11). In addition, the activated N2 content followed a volcanic profile as a function of Co particle diameter, with an optimal diameter of 1 μm (Fig. S12).

To eliminate the possibility of ammonia contamination, we conducted a control experiment, using argon gas (Ar) instead of N2. Under identical mechanical conditions, no ammonia was detected (less than 1 ppm).

The performance of ammonia synthesis over 20 g of Co catalyst according to the aforementioned procedure was shown in Fig. S13. Under ambient conditions with 3 h N2 pre-milling, after the introduction of 10 mL/min of the reactant (H2:N2 = 3:1), NH3 appeared after 2 h and its generation rate reached a maximum of 0.66 μmol·gcat−1·h−1. Subsequently, the NH3 signal gradually diminished and eventually disappeared after 12 h of continuous operation.

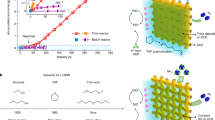

Next, in order to extend the lifespan of Co catalysts, some approaches were employed and proved to be effective. (1) Vary the H2/N2 ratios in the feed gas. If the H2/N2 ratio was changed from 3:1 to 1:9, the lifespan of Co catalysts prolonged from 12 h to 20 h (Fig. S14). But the NH3 yield per gram Co catalysts declined by 33%. (2) Increase the space velocity. When the space velocity increased from 0.03 L·gcat−1·h−1 to 0.6 L·gcat−1·h−1, as shown in Fig. 2, it was found that Co lifespan extended from 12 h to 350 h without deactivation. Meanwhile, the NH3 yield of per gram Co catalysts under high space velocity became 917.40 times higher than that under low space velocity. This is an attempt of continuous ammonia synthesis via mechanocatalysis in absence of alkali metal conditions, and represents the longest lifetime for ammonia synthesis among all the various methods under real ambient conditions to the best of our knowledge, which is 10 times longer than the recent reported FeCs catalysts via mechanocatalysis under ambient conditions19. Furthermore, when the space velocity was improved to 2.4 L·gcat−1·h−1, the NH3 production rate could achieve 13.7 μmol·gcat−1·h−1 (Fig. S15), which was comparable with FeCs catalysts via mechanocatalysis approach (Table S4).

As shown in Fig. S16, the generation of gaseous water was also recorded during hydrogenation stage, which was induced by the inevitable existence of surface oxygen impurities on Co powders. Those surface oxygen impurities mainly originate from production and transport process. For the deactivated Co catalysts in Fig. S13, a subsequent temperature programmed desorption in Ar carrier were conducted from RT to 250 °C and maintained for 2 h. Prior to the temperature ramping, the reaction system was purged by Ar over 2 h to eliminate the residual or physically adsorbed H2 and water. It was seen that obvious water desorption peaks were recorded, which was considered as the main reason for catalysts deactivation (Fig. S17). Meanwhile, DFT calculations also reveal a stronger adsorption propensity of water compared to ammonia on the Co surface (Fig. S18), and this thermodynamic preference of generated water could gradually accumulate on catalysts surfaces and ultimately lead to catalysts deactivation. Besides, the poisoning effect of water on Ni/LaN, Co/LaN, and Co/La-Al-N catalysts during ammonia synthesis was also found by Hideo Hosono’s group34.

In addition, the increment of space velocity suppressed water generation and solved the catalysts deactivation. In Fig. S16, the integrated water content under 0.03 L·gcat−1·h−1 (0.0105 gH2O·gcat−1) was much higher than that under 0.6 L·gcat−1·h−1 (0.0018 gH2O·gcat−1). Besides, theoretical calculation results present that increase of space velocity weakens water adsorption energy from −0.22 eV to −0.143 eV (Supplementary Note and Fig. S19), which demonstrates that water accumulation on catalysts surface is inhibited, thereby preventing the Co catalysts deactivation during hydrogenation stage. However, further in-depth studies are still needed to thoroughly explore the related mechanisms.

Systematic experimental validation was also performed on other candidate metals identified through computational screening. Compared with other metals (Fe, Ni, Cu, Ag), the experimental results presented that Co catalyst possessed the best catalytic performance under the same conditions, which consistent with theoretical prediction (Fig. S20).

Catalyst structure characterization

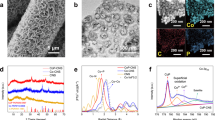

The characterization spectra after N2 and H2 activation and conversion over Co powders were shown in Fig. 3. For nitrogen fixation on Co after N2 pre-milling, the fresh and N2 pre-milled Co powder was collected and characterized by an X-ray diffraction (XRD) analysis (Fig. S21). The characteristic peaks at 41.7°, 44.8°, and 47.5° were assigned to the (100), (001), and (101) crystal planes of Co (Co-050727), respectively. After 2 h of N2 pre-milling, the crystal structure of the Co powder started to change. The peak intensity of the (001) crystal face weakened compared with that of the (100) and (101) crystal planes, and its full width at half maximum widened gradually. These variations indicated that the (001) crystal face was active and necessary for N2 fixation. As shown in Fig. 3a, after 24 h of N2 pre-milling, the grain size decreased from 11.2 nm (fresh Co) to 5.3 nm (Co(N*)) (according to the Debye-Scherrer formula, as shown in the Supplementary Notes). Figure 3b gave the evolution of the XRD peaks during in situ hydrogenation. Since the mechanical collision conditions could not be mimicked for the XRD cell, thermal energy was provided as a substitute for mechanical energy to catalyze Co(N*) hydrogenation. We confirmed that a mere increase in temperature elevation in the presence of an inert gas cannot induce any clear variation in the intensity of diffraction peaks (Fig. S22). At 400 °C and under atmospheric pressure, in the presence of H2 the peak intensity of Co(N*), especially the intensity of the (001) crystal face continued to rise. The fact that the peak of the (001) face recovered the highest peak intensity among the (100), (001) and (101) faces again verified that the N* species from Co(N*) was consumed during hydrogenation and that the (001) crystal face possessed the most active capacity for N2 fixation from comparison.

a X-ray diffraction (XRD) patterns of fresh Co and Co(N*) after N2 pre-milling. b Evolution of Co(N*) XRD patterns during hydrogenation; the reaction conditions were as follows: 20 mL/min H2; 10 °C/min rate heating to 400 °C and then holding at 400 °C for 70 min. c, d X-ray photoelectron spectroscopy (XPS) patterns of fresh Co, Co(N*) after N2 pre-milling, used Co after reaction: c N 1s and d Co 2p. e Radial distribution function (RDF) of the Co foil, CoO, CoxN, fresh Co, Co(N*) after N2 pre-milling, and used Co. The RDFs were derived from extended x-ray-absorption fine structure (EXAFS) data. f Isotope exchange experimental results. Fresh Co (15 g) was pre-milled for 24 h in 14N2, and then 15N2 and D2 were introduced to record the reaction products. Reaction conditions were as follows: 25 °C, 1 bar, 1000 rpm, and 600 g Fe balls as the milling medium. Prior to the test, the Co catalyst was pretreated in 10% H2/Ar at 250 °C for 2 h.

The morphological evolution of Co catalyst was systematically characterized through scanning electron microscopy (SEM) and atomic force microscopy (AFM). As revealed in SEM images (Figs. S23a and S24a, b), fresh Co particles exhibited planar surfaces with significant agglomeration tendencies. In contrast, both Co(N*) and used Co catalysts displayed distinctively irregular surface morphologies accompanied by enhanced specific surface areas (Fig. S24c, d). This morphological transformation suggested the generation of structural defects, particularly step-edge configurations, during mechanical milling process. Subsequent AFM characterization corroborated these observations, with topographic profiles demonstrating abundant step structures on used Co catalyst (Fig. S25b), in stark contrast to the atomically flat terraces observed on fresh Co catalyst (Fig. S25a). These collective findings provide direct evidence that mechanical milling effectively induces particle fragmentation and surface roughening.

High-resolution transmission electron microscopy (HRTEM) analysis revealed distinct structural evolution among various Co catalysts. Fresh Co catalysts displayed well-defined lattice fringes with a characteristic interplanar spacing of 0.202 nm (Fig. S26), corresponding to the (001) crystallographic plane of metallic cobalt. Mechanical ball milling induced substantial structural modifications in Co(N*) after N2 pre-milling process, as evidenced by the emergence of structural defects and residual short-range ordered domains amidst long-range disordered configurations (Fig. S27). This structural amorphization was further amplified in used Co catalyst (Fig. S28), where HRTEM images unveiled a characteristic nanocomposite architecture comprising amorphous domains interspersed with crystalline regions with lattice parameters of Co (d001 = 0.202 nm, Fig. S28), CoN (d111 = 0.248 nm, Fig. S28) and other phases. Combining the same structural amorphization trend obtained from characterization results, it was deduced that the generated amorphous Co structures possess higher activity on nitrogen activation than crystalline Co structures35,36,37.

The X-ray photoelectron spectroscopy (XPS) patterns of N 1s and Co 2p also supported the formation of Co(N*) after the N2 pre-milling of Co powder. In Fig. 3c, appearance of the Co-N signal at 399.8 eV over the N2 pre-milled sample proved the formation of N* species via mechanical milling; meanwhile, the disappearance of the Co-N signal over the used Co sample proved that the N* species was consumed after hydrogenation. For Co 2p signal in Fig. 3d, two peaks corresponding to binding energies of 778.2 and 793.3 eV were attributed to the Co3+ species. Two peaks at the binding energies of 781 and 797 eV were attributed to the Co2+ species. Co2+ and Co3+ presented in the fresh Co samples were induced by inevitable surface oxygen impurities originated from their production and transport. After N2 pre-milling, the Co3+/Co2+ proportion on the Co(N*) sample increased as the Co-N structure formed; the Co0 signal appeared in the spectrum of used Co sample after hydrogenation, indicating that the oxidative Coδ+ species was gradually reduced by H2. The decline of Co3+/(Co2+ + Co0) proportion on the used Co sample also demonstrated N* conversion in presence of H2.

X-ray absorption spectroscopy (XAS) spectra revealed the precise coordination environments of Co atoms during two stage reaction. A comparison of the X-ray absorption near-edge structure results (Fig. S29) illustrated that the absorption edges of fresh Co, CoxN, Co(N*) and used Co were located between that of Co foil and CoO, revealing that their valence states laid between Co0 and Co2+. The used Co, fresh Co, Co(N*) changed to high energy successively, reflecting the sequential increase in the oxidation state of Co. This phenomenon was induced by the oxidation of Co0 into Co2+/3+ states of Co(N*) during the N2 pre-milling process as theoretical calculation results aforementioned and complete H2 reduction of used Co after hydrogenation reaction. In Fig. 3e, the Fourier transform extended X-ray absorption fine structure (FT-EXAFS) of the Co-O on the fresh Co sample and Co-N on Co(N*) confirmed their existence. More importantly, the detected Co-N structure on Co(N*) and its elimination from the used Co sample indicated that the N* species was consumed during hydrogenation stage, consistent with the results of above-mentioned characterizations. For the used Co sample, only the Co-Co bond was detected, indicating the reduction of Coδ+ to Co0 on the used Co catalyst.

Isotopic experiments were also designed to analyze the N2 activation and hydrogenation behaviors. As shown in Fig. S30, at 25 °C and 1 bar, the N2 isotope exchange reaction (1/2 14N2 + 1/2 15N2 → 14N15N) revealed an m/z = 29 signal and confirmed that ball milling could overcome the high triple bond energy of N2 under ambient conditions.

Next, Fig. 3f presented the N2 activation and hydrogenation behaviors during hydrogenation stage. To minimize the impact of surface oxygen impurities on fresh Co samples, we intentionally reduced the Co catalyst in H2 at 200 °C for 2 h prior to the test. After this, Co catalysts were pre-milled in a 14N2 atmosphere for 24 h to form Co(14N*), and then, 15N2 and D2 were introduced into the system to initiate the isotope reaction. As shown in Fig. 3f, the reaction behavior of 15N2 during the hydrogenation stage was examined. At the initial 10 min, the m/z = 29 signal rapidly increased, indicating the 15N2 could be dissociated and exchanged with Co(14N) on Co sites. Subsequently, the m/z = 29 signal decreased due to the consumption of 14N. With gradual activation of 15N2 on Co sites, the increase of m/z = 17, 19, 21 signals confirmed the generation of 15ND (17), 15ND2 (19), and 15ND3 (21) from 15N* hydrogenation. The profile of m/z = 20 was assigned to 14ND3 and 15ND2H through a reaction between residual 14N* or 15N* and newly introduced D, which finally decreased for consumption of 14N and H. The presence of H was induced by H2 reduction treatment, which could not be completely eliminated by subsequent N2 purge. In short, the profiles proved that N2 dissociation also occurred during hydrogenation stages except the N2 pre-milling stage.

Benchmark test for green route of ammonia synthesis

Finally, we built a green reaction system employing solar panel to supply all the energy consumption from reactants production to NH3 production. Since H2 was produced from water electrolysis and pure N2 was separated from air directly (Fig. 4), the whole process for ammonia synthesis via vibration reactor would not produce any CO2 emission. In detail, four solar panels were utilized to convert solar energy into electricity, and excessive energy could be stored in a battery. The power of four solar panels and energy consumption facilities, including the H2 generator, N2 generator, and vibration reactor, were summarized in the note in Fig. S7. It was seen that the power generated from four solar panels could meet the demand of mechanical reaction system throughout the day (more details about energy consumption was summarized in Table S5), and the consecutive ammonia synthesis experiment in Fig. 2 were actually powered by solar energy system. The energy consumed per ton of ammonia was 26.9 × 1011 J via mechanocatalysis method. This value was lower than that consumed in the Haber-Bosch method in the laboratory and other method (Table S6).

In summary, we have studied the impact of transient confinement on N2 activation and NHx hydrogenation through a theoretical dual sides model of mechanical collision for ammonia synthesis via mechanocatalysis. As predicted, the Co-based catalyst is an excellent choice for ammonia synthesis under ambient conditions via mechanochemistry. Under mechanical conditions, the ammonia synthesis rate achieved >13.7 μmol·gcat−1·h−1 by Co catalyst at 25 °C and 1 bar. The ammonia synthesis from N2 + H2 conversion process consumed 26.9 × 1011 J of energy per ton of ammonia production, which was considerably competitive in comparison with the Haber-Bosch process at the laboratory scale (Table S6). Further, this work designed a sustainable ammonia synthesis route without carbon emissions via mechanocatalysis and electro-catalysis approach, and the catalyst characterization and rationale exploration give the guidance for future mechanical study.

Methods

Materials and chemicals

All chemicals and gaseous reactants were purchased and used without pretreatment except specific clarification. The employed metallic catalysts and reference samples included Co (zkyn, 99.95%, 100 nm, 1 μm, 10 μm, 100 μm), Ni (zkyn, 99.95%, 1 μm), Fe (zkyn, 99.95%, 1 μm), Cu (zkyn, 99.95%, 1 μm), Ag (zkyn, 99.95%, 1 μm), CoxN (3 A Chem, 99.99% with N percentage of 0.13 wt%), Fe balls (Ruiheng, 8 mm, 10 mm, 12 mm). Gaseous reactants included N2 (weierda, 99.999%), Ar (weierda, 99.999%), mixed gas (weierda, N2: H2 = 1:3 or 9:1), 15N2 (weierda, 99%), D2 (weierda, 99%).

Sample characterization

XRD patterns were recorded on a PANalytical Model Xpert3 instrument equipped with a Cu Kα radiation source (λ = 0.15406 nm) operating at 40 kV and 10 mA. X-ray photoelectron spectroscopy (XPS) was performed using a Thermo Fisher ESCALAB 250Xi spectrometer with a monochromatized Al Kα X-ray source (1486.6 eV) and an applied power of 150 W. The C 1s (binding energy 284.8 eV) was used as a reference. SEM images were recorded with a Quanta 250 FEG instrument. The X-ray absorption spectra (XAS) of Co K-edge were collected at the beamline of TPS44A1 in National Synchrotron Radiation Research Center, Taiwan, China. The XAS data were analyzed via Athena software. AFM (SPI 3800N SPA400) was applied to estimate the surface morphology of metallic powder. High-resolution atomic images were measured using a transmission electron microscope (JEM-2100F, JEOL). HRTEM with an energy resolution of 0.3–2 eV, using the Gatan imaging filter (GIF 200) attached to the transmission (TEM) TECNAI G2 F20 operated at 200 k eV, were used to analyze the bulk structure of various Co catalysts.

Catalytic activity tests

The ammonia synthesis reaction was performed in a home-made vibrational reactor at 25 °C, 1 bar. The outlet products were analyzed by a gas chromatograph (Trace GC 1600, Thermo Fisher Scientific) with two thermal conductivity detector for N2, H2, and NH3 identification. The GC spectra of standard ammonia gaseous and an experimental outcome were presented in Fig. S31 to demonstrate the quantitative analysis process of ammonia. Meanwhile, the NH3 in outlets were also adsorbed by a 0.3 M hydrochloric acid solution to calculate NH3 yield through the measurement of NH4+ concentration by ion chromatography (IC) with conductivity detection (Thermo Fisher Scientific ICS-6000 system). More details about the facilities (including mechanical reaction system, green gas supply system, and in situ XRD) and experimental procedures (including continuous ammonia synthesis, nitrogen pre-milling condition screening, and isotope exchange experiments) were presented in the Supplementary information.

Computational details

The DFT calculations were performed using first-principles within the Vienna Ab initio Simulation Package38,39. The electron-ion interactions were treated using the Projector Augmented-Wave40,41 method, and the Generalized Gradient Approximation with the Perdew–Burke–Ernzerhof42 functional was employed for exchange-correlation potentials43. To account for van der Waals interactions, the Grimme’s44 DFT-D3 method was introduced. A cutoff energy of 500 eV was set to ensure accuracy. Spin-polarized calculations were performed to examine magnetic effects. For surface calculations, the convergence criterion for electronic self-consistent calculations was set to 1 × 10−5 eV, and the Hellmann–Feynman forces on free atoms during ionic relaxation were optimized to less than 2 × 10−2 eV/Å. The Brillouin zone was sampled using the Monkhorst–Pack method, ensuring k × a > 3045. During the simulation, the bottom two atomic layers were fixed, while the remaining atoms were fully relaxed. Transition states were searched using the Climbing Image Nudged Elastic Band method and the dimer method and confirmed by frequency analysis to ensure only one imaginary frequency for the transition state46,47.

Differing from isolated surface model, the z-axis of the 1st–2nd and 7th–8th layers, corresponding to the topmost and bottommost metal layers of atoms was fixed during the optimization of the initial N2 adsorption configuration in the dual side model, satisfying the degrees of freedom for position, shape, and volume to capture the deformation and displacement state of the surfaces upon collision. After determining the adsorption configuration of N2, this configuration was used as the initial state for subsequent transient-state reaction simulations. In these calculations, the cell shape, cell volume, and the topmost and bottommost two layers were fixed.

Data availability

Source data are provided with this paper. The data that support the findings of this study are available from the corresponding author [T.Y. and W.Q.D.] upon request. Source data are provided with this paper.

References

Chen, J. G. et al. Beyond fossil fuel–driven nitrogen transformations. Science 360, eaar6611 (2018).

Smil, V. Detonator of the population explosion. Nature 400, 415–415 (1999).

Duinen, G. V. How a century of ammonia synthesis changed the world. Nat. Geosci. 1, 636–639 (2008).

Kandemir, T., Schuster, M. E., Senyshyn, A., Behrens, M. & Schlögl, R. The Haber–Bosch process revisited: on the real structure and stability of “ammonia iron” under working conditions. Angew. Chem. Int. Ed. 52, 12723–12726 (2013).

Editorials. Green ammonia synthesis. Nat. Synth. 2, 581–582 (2023).

Ye, D. & Tsang, S. C. E. Prospects and challenges of green ammonia synthesis. Nat. Synth. 2, 612–623 (2023).

Fu, X. et al. Continuous-flow electrosynthesis of ammonia by nitrogen reduction and hydrogen oxidation. Science 379, 707–712 (2023).

Guan, Y. et al. Light-driven chemical looping for ammonia synthesis. Nat. Chem. 16, 373–379 (2024).

Andersen, S. Z. et al. A rigorous electrochemical ammonia synthesis protocol with quantitative isotope measurements. Nature 570, 504–508 (2019).

Johansen, C. M., Boyd, E. A. & Peters, J. C. Catalytic transfer hydrogenation of N2 to NH3 via a photoredox catalysis strategy. Sci. Adv. 8, eade3510 (2022).

Du, H.-L. et al. Electroreduction of nitrogen with almost 100% current-to-ammonia efficiency. Nature 609, 722–727 (2022).

Li, S. et al. Long-term continuous ammonia electrosynthesis. Nature 629, 92–97 (2024).

Garrido-Barros, P., Derosa, J., Chalkley, M. J. & Peters, J. C. Tandem electrocatalytic N2 fixation via proton-coupled electron transfer. Nature 609, 71–76 (2022).

Lee, J. S., Han, G. & Baek, J. Mechanochemical ammonia synthesis: old is new again. ChemSusChem 16, e202300459 (2023).

Castillejos, E. & García‐Bordejé, E. Innovative approaches to sustainable ammonia synthesis under mild conditions. ChemCatChem 16, e202301603 (2024).

Tricker, A. W. et al. Mechanocatalytic ammonia synthesis over TiN in transient microenvironments. ACS Energy Lett. 5, 3362–3367 (2020).

Han, G.-F. et al. Mechanochemistry for ammonia synthesis under mild conditions. Nat. Nanotechnol. 16, 325–330 (2021).

Kim, J.-H. et al. Achieving volatile potassium promoted ammonia synthesis via mechanochemistry. Nat. Commun. 14, 2319 (2023).

Reichle, S., Felderhoff, M. & Schüth, F. Mechanocatalytic room‐temperature synthesis of ammonia from its elements down to atmospheric pressure. Angew. Chem. Int. Ed. 60, 26385–26389 (2021).

Reichle, S. et al. Mechanocatalytic synthesis of ammonia: state of the catalyst during reaction and deactivation pathway. Angew. Chem. Int. Ed. 63, e202317038 (2024).

Baláž, P. Mechanochemistry in Nanoscience and Minerals Engineering (Springer Berlin Heidelberg, Berlin, Heidelberg, 2008).

Vojvodic, A. & Nørskov, J. K. New design paradigm for heterogeneous catalysts. Natl. Sci. Rev. 2, 140–143 (2015).

Wang, P. et al. Breaking scaling relations to achieve low-temperature ammonia synthesis through LiH-mediated nitrogen transfer and hydrogenation. Nat. Chem. 9, 64–70 (2017).

Medford, A. J. et al. From the Sabatier principle to a predictive theory of transition-metal heterogeneous catalysis. J. Catal. 328, 36–42 (2015).

Mao, C. et al. Hydrogen spillover to oxygen vacancy of TiO2–xHy/Fe: Breaking the scaling relationship of ammonia synthesis. J. Am. Chem. Soc. 142, 17403–17412 (2020).

Liu, J. C. et al. Heterogeneous Fe3 single-cluster catalyst for ammonia synthesis via an associative mechanism. Nat.Commun. 9, 1610 (2018).

Higham, M. D., Zeinalipour-Yazdi, C. D., Hargreaves, J. S. J. & Catlow, C. R. A. Mechanism of ammonia synthesis on Fe3Mo3N. Faraday Discuss. 243, 77–96 (2023).

Ye, T. N. et al. Dissociative and associative concerted mechanism for ammonia synthesis over Co-based catalyst. J. Am. Chem. Soc. 143, 12857–12866 (2021).

Zeinalipour-Yazdi, C. D., Hargreaves, J. S. J. & Catlow, C. R. A. Low-T mechanisms of ammonia synthesis on Co3Mo3N. J. Phys. Chem. C 122, 6078–6082 (2018).

Zhang, K. et al. Spin-mediated promotion of Co catalysts for ammonia synthesis. Science 383, 1357–1363 (2024).

Li, Z. et al. Multiple reaction pathway on alkaline earth imide supported catalysts for efficient ammonia synthesis. Nat. Commun. 14, 6373 (2023).

Sfeir, A. et al. Unlocking the potential of MXene in catalysis: decorated Mo2CTx catalyst for ammonia synthesis under mild conditions. J. Am. Chem. Soc. 146, 20033–20044 (2024).

Cao, A. et al. The Co/NbN interphase as an effective ammonia synthesis catalyst. Chem 11, 102618 (2025).

Lu, Y. et al. Approach to chemically durable nickel and cobalt lanthanum‐nitride‐based catalysts for ammonia synthesis. Angew. Chem. Int. Ed. 134, e202211759 (2022).

Zhang, C. et al. Enabling unconventional “alternating-distal” N2 reduction pathway for efficient ammonia electrosynthesis. Angew. Chem. Int. Ed. 64, e202502957 (2025).

Wang, Y. et al. Ammonia electrosynthesis from nitrate using a stable amorphous/crystalline dual-phase Cu catalyst. Nat. Commun. 16, 897 (2025).

Chen, C. et al. Oxidation of metallic Cu by supercritical CO2 and control synthesis of amorphous nano-metal catalysts for CO2 electroreduction. Nat. Commun. 14, 1092 (2023).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Liu, Q. et al. Direct catalytic hydrogenation of CO2 to formate over a Schiff-base-mediated gold nanocatalyst. Nat. Commun. 8, 1407 (2017).

Chen, X., Ge, F., Chen, T. & Lai, N. The effect of GGA functionals on the oxygen reduction reaction catalyzed by Pt(111) and FeN4 doped graphene. J. Mol. Model. 25, 180–185 (2019).

Grimme, S., Ehrlich, S. & Goerigk, L. Effect of the damping function in dispersion corrected density functional theory. J. Comput. Chem. 32, 1456–1465 (2011).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000).

Henkelman, G. & Jónsson, H. A dimer method for finding saddle points on high dimensional potential surfaces using only first derivatives. J. Chem. Phys. 111, 14 (1999).

Acknowledgements

This work was supported by the National Key Research and Development Program of China (No. 2022YFA1503104 to W.D.), Taishan Scholars Project (No.tspd20230601 to W.D.), State Key Laboratory of Catalysis funds of Dalian Institute of Chemical Physics (No. N-22-16 to T.Y.), and the Shandong University Future Program for Young Scholars (No. 62460082064083 to T.Y.), the project from Zhilian Guoneng (Tianjin) Technology Co., Ltd. (1190025042 to T.Y.), the Strategic Priority Research Program of the Chinese Academy of Sciences (XDB0450101 to Z.L.). The authors are grateful for the technical support for Nano-X from Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences (SINANO). The authors thank Xiaoju Li and Haiyan Sui from Shandong University Core Facilities for Life and Environmental Sciences for their help with the TEM. We also appreciate the Mass Spectrum measurements assisted by Fanping Zhu from Analytical Testing Center, School of Environmental Science and Engineering, Shandong University.

Author information

Authors and Affiliations

Contributions

W.D. supervised the project and conceived the idea. K. L., C. W., and X. F. designed and carried out the catalysis experiments. T.Y. discussed the catalysis experiments and wrote the manuscript. M.X. performed the DFT studies. Z. L., L. Y., and J. S. discussed the DFT results. All authors discussed the results and assisted during manuscript preparation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Jong-Beom Baek and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lv, K., Xu, M., Yang, L. et al. Cobalt-based catalyst for ammonia synthesis under ambient conditions via transient confinement. Nat Commun 16, 7887 (2025). https://doi.org/10.1038/s41467-025-63145-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-63145-3