Abstract

Transformable micro/nanostructures endow optical and mechanical metamaterials with customization and tunability. However, employing existing transformation mechanisms to achieve large mechanical deformations remains challenging due to the restricted displacement in the nanometric scale. Here, we present a transformation strategy using nanoscale kirigami structures with ultrahigh deformability enabled by synthetic designs. Theoretically and experimentally reconfigurable large-range and bi-directional out-of-plane deformations are achieved on combined Archimedean spirals with well-designed length, both of which obtain ultrahigh deformability in aspect ratio. Benefited from the ultrahigh deformability, high-performance optical modulation and high-resolution dynamic information display are experimentally achieved, which are well controlled by the spiral angles of synthetic nano-kirigami arrays with a pitch size of only 2.2 μm. Our strategy enables large deformation of nano-kirigami with exceptional tuning accuracy in a large range, which greatly improves the electromechanical reconfigurability for high-precision miniaturized devices and enables potential applications in information encryption, micro-/nano-opto-electro-mechanical systems (MOEMS/NOEMS), and photonics/phononics.

Similar content being viewed by others

Introduction

Transformable micro/nanostructures have garnered significant attention across the fields of optical and mechanical metamaterials with tunability and programmability. Versatile geometric deformation, reconfiguration and assembly have enabled diverse applications, such as bionics1,2,3, stretchable batteries4,5,6, energy harvesting7,8,9, flexible electronics10,11,12, four-dimensional printing13,14,15, robotic materials16,17,18, three-dimensional (3D) micro/nanorobots19,20,21,22, and stimulus-responsive actuators23,24,25. One critical characteristic determining the performances of these emerging fields is the capacity of achieving large controllable structural deformation. For example, in optical micro-electro-mechanical systems (MEMS), the reconfiguration capability and modulation depth are highly dependent on the reversible displacement range of the transformable components within limited space26,27,28. Therefore, improving structural deformability is of great significance for developing transformable micro/nanoscale devices with high performance, large dynamic range and multiple functionalities.

In this regard, kirigami, an ancient art of cutting and folding to obtain diverse morphological transformations, has aroused great interests due to its superb shape change capability from two-dimensional (2D) to 3D states. Macroscale kirigami has been employed in the areas of healthcares29, metasurfaces30,31,32, and stretchable devices5,33,34, etc. Moreover, empowered by advanced micro/nanofabrication technologies, nano-kirigami, which is actuated by mechanical35, thermal36, electric37, and magnetic38 fields, has shown exceptional capability for deformable 3D micro/nanostructures with exotic geometries. Appealing characteristics and applications, such as tunable optical vortices39, dynamic metasurfaces36,37,38,40,41, reconfigurable optical chirality37,40 and chiral sign reversal42,43, have been explored based on the 3D deformation capability of nano-kirigami. However, the deformability of existing nano-kirigami structures typically reached only ~25%35,37,40, as evaluated by the aspect ratio between the out-of-plane deformation height and structural span width. This limited deformability constrains the design freedom and performance of functional structures within the very confined space of few cubic micrometers. Meanwhile, the bi-directional deformations, which are highly desirable in nano-kirigami applications, are also an important goal.

Here, we propose and experimentally demonstrate a synthetic nano-kirigami structure to realize largely out-of-plane and bi-directional deformations with ultrahigh deformability by elaborately designing nano-kirigami structures combined with Archimedean spirals of desired length, which are actuated by harnessing residual stress and capillary force during fabrication, respectively. Electromechanical reconfigurations and high-performance electrical-optical modulations are achieved based on the ultrahigh deformability of synthetic nano-kirigami structures. As a result, the proof-of-concept demonstration of electrically tunable and high-resolution optical information display is further achieved with a pitch size of only 2.2 μm. Our approach greatly enriches the design diversity and complexity of functionalities for the field of highly compact reconfigurable metastructures. It holds a great promise for the applications of multichannel information encryptions, high-performance reconfigurable metamaterials, tunable topological photonics/phononics, novel MOEMS/NOEMS, etc.

Results

Concept of synthetic nano-kirigami

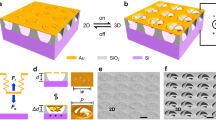

The deformation ability of mechanical structures is significantly influenced by their geometrical designs, besides the intrinsic material properties. The design determines overall structural stiffness, affecting how the structure deforms under external forces. Mechanical stiffness, which measures resistance to deformation, is the ratio of applied force to resulting deformation. The concept of synthesis refers to the compounding of multiple simple elements into one complex object to greatly increase the degree of freedom of morphology transformation for constructing structures, which brings a new avenue for the design of micro/nanostructures. Figure 1a shows a synthetic nano-kirigami structure with a core (red region), four arms (green region), and an outer base (blue region), in which the blank regions are defined by four Archimedean spirals with the width of 70 nm and angle of 270° on a gold film with the thickness of 60 nm (see details in Methods and Supplementary Fig. 1). To evaluate the deformation capability of the design, the structural deformation evolving from flat to out-of-plane states is simulated by applying the prestress (see simulation details in the Methods, Supplementary Fig. 2 and Note 1). As plotted in Fig. 1b, the synthetic nano-kirigami structure has a large vertical displacement of ~0.8 μm under applied stress of 4.6 GPa. Consequently, an ultrahigh deformability of ~0.5 (here the deformability is defined by the aspect ratio between deformation height and structural span width) can be obtained from this 3D deformed nano-kirigami structure, as shown in Fig. 1c. This synthetic design has the simple structural morphology and excellent mechanical property, which demonstrates the universality and representativeness in structural optimization. Based on this concept, here we demonstrate the electromechanically reconfigurable high-resolution optical information display employing the synthetically designed nano-kirigami, as shown in Fig. 1d. The electromechanical reconfiguration is enabled by the electrostatic forces when a voltage is applied between the top gold nanostructures and the bottom silicon substrate. That is, when a proper voltage is applied to the electromechanically reconfigurable sample with the structural pattern of “BIT”, dynamic information encryption is presented due to the local deformation induced changes in reflection intensity. Next, we will primarily focus on the simulation, experiment, and application exploration of the synthetic nano-kirigami with ultrahigh deformability.

a–c Synthetic design strategy (a) with simulated mechanical deformation (b) and deformability curve (c). The synthetic structure consists of a red core, four green arms, and a blue outer base. During simulations, the prestress is applied. The out-of-plane displacement and corresponding deformability (defined as the aspect ratio between deformation displacement and structural span width) show that the synthetic design processes the ultrahigh deformability. d Schematic of electromechanically reconfigurable information display by synthetic nano-kirigami structures. Here, by applying the voltage, the programmed pattern “BIT” can be obviously displayed.

Conceptual design

To enable maximum deformation, we employ a new bi-directional deformation design, which means both upward and downward deformations can be achieved depending on the different external stimuli. To quantify the large deformation and ultrahigh deformability of synthetic nano-kirigami structures, two deformation mechanisms are employed in mechanical simulations. Figure 2a shows the upward deformation of the cantilever by using a bilayer prestress model32, in which the residual stress of a gold layer possesses different distributions under global ion beam irradiation. As a result, the top and bottom layers are contracted and stretched, respectively, which make the cantilever deform upward due to the stress difference existed in the bilayer. In contrast, the downward deformation (Fig. 2b) can be simply obtained when a pressure (blue arrows) is vertically loaded on the top surface of the cantilever36. As the simulated out-of-plane upward and downward deformation results shown in Fig. 2c, d, the displacement amplitudes increase almost linearly with the increase of applied prestress and pressure (see more details in Methods and Supplementary Fig. 2 and Note 1). The colour images in the insets clearly show the continuous and gradual deformations of the structures from the flat state to the maximum-displacement stereo state (Supplementary Movie 1). In addition, the deformabilities (ξ) versus the applied prestress and pressure are calculated in the left insets of Fig. 2c, d. It can be seen that the maximum total deformability (including the sum of the upward and downward cases) reaches nearly 100%, which reveals an ultrahigh level than the previous works of nano-kirigami, providing a novel strategy for improving the deformation capacity and achieving high-performance functional structures at the micro/nanoscale.

a Schematic of the upward deformation with a bilayer prestress model32, in which the residual stress distribution in the cantilever is different (causing the top and bottom of the cantilever to be contracted and stretched, respectively), the cantilever will deform upward due to the stress difference existed in the bilayer areas when one side is fixed (as marked by the red region). b Schematic of downward deformation of the cantilever under a vertically downward pressure36. c, d Simulated out-of-plane upward and downward deformation displacements of the synthetic nano-kirigami (with a spiral angle of 360°) under prestress and pressure, respectively. Left insets: The corresponding calculated deformability (\(\xi\)) versus the applied prestress and pressure. Here \(\xi=D/d\), where D and d represent the deformation displacement and structural span width, respectively. Simulated stress (e, Von Mises stress) and strain (f) distributions of the dynamically deformed synthetic nano-kirigami structure (with a spiral angle of 270°).

To reveal the mechanism of the largely deformed synthetic nano-kirigami, we analyze the stress and strain distributions in the nano-kirigami structure. Figure 2e presents the simulated stress distribution (Von Mises stress) of the dynamically deformed synthetic nano-kirigami structure with the spiral of 270° under the applied prestress of 3 GPa (here 3 GPa is the value of an intermediate prestress used in simulations, which could induce sufficient deformation while the structural stability is preserved). In the meantime, the corresponding strain distribution of the structure is also displayed under the same simulation conditions (Fig. 2f). It can be seen that the synthetic nano-kirigami structures with flat, intermediate, and stereo states experience continuous stress and strain changes (Supplementary Movie 2). First, with the increase of deformation height, the stress of kirigami regions with the core and arms first increases from the initial 3 GPa to a maximum value of 5.64 GPa, and finally decreases to 0 at the largest height, which is in a stable state. In addition, the corresponding strain increases from the initial 0 to a maximum value of 13.7%, which uniformly distributes in the regions of the buckling kirigami structures. Here, the helical design consisting of the four Archimedes spirals results in a stable and symmetric buckling deformation. Therefore, it can be concluded that the large and uniform strain distribution in the deformed structure is a vital condition for achieving ultrahigh deformability in the proposed synthetic nano-kirigami structures under external mechanical stimuli. More mechanical simulations of synthetic nano-kirigami can be found in Supplementary Figs. 3 and 4.

Experimental realizations

To verify the synthetic nano-kirigami concept with bi-directional deformation and ultrahigh deformability, we experimentally fabricated the synthetic nano-kirigami structures following the flow chart illustrated in Fig. 3a. First, ion beam milling is used to etch the four-spiral pattern on an Au-SiO2 sample with a gold layer thickness of 60 nm. Then the bottom SiO2 beneath etched structural area is removed by wet etching. Finally, the structure of the upward deformation is fabricated by employing ion beam irradiation32 (see details in the Methods). It’s worth noting that different from the use of prestress in simulations, the realistic stresses in experiments are actually instant due to the swift collision between the high-energy ion beam and the gold film, which causes both the knocking out of gold atoms and implantation of gallium ions. Figure 3b–d shows the side-view scanning electron microscopy (SEM) images of the fabricated upward nano-kirigami structures under different irradiation dosages with spiral angles of θ = 180°, 270°, and 360°, respectively. It can be seen that the arm width of the fabricated spirals is less than 100 nm. Such a small feature size, together with the sub-100-nm film thickness, prompts the use of “nano-kirigami” in this work. In these cases, the diameters of the structural areas are 1.3 μm, 1.6 μm, and 2.0 μm, respectively. It is found that the structures transform gradually from the flat state to the stereo state by applying four-step focused ion beam (FIB) irradiations (see Supplementary Movie 3). Particularly, capillary force is introduced by the dry process of wet etching36, which leads to a downward deformation of the fabricated structure. Here, the case of the downward deformation of the structure with a spiral angle of 360° is also obtained under the capillary force, as shown in Fig. 3e, f and Supplementary Movie 3. Since it is challenging to monitor and quantify the fluid changes in real time at microscopic scale, we merely consider the resultant deformation height of the structure at each stage to study the overall influences of the continuously changing capillary forces. In this manner, the equivalent prestresses obtained in simulations are used for relative comparison of the overall effects of capillary forces under different structural designs. It can be seen that these fabricated structures are highly consistent with the simulated results in Fig. 2 in terms of 3D morphologies, indicating the highly precise fabrication of synthetic nano-kirigami.

a Flow chart for fabricating synthetic nano-kirigami by using ion beam irradiation (upward deformation). b-d Side-view SEM images of the fabricated upward nano-kirigami structures with spiral angles of θ = 180°, 270°, and 360°, respectively. e Schematic of fabricating the downward synthetic nano-kirigami structure with a spiral angle of 360° by using wet etching. f Side- and top-view SEM images of the fabricated downward nano-kirigami structure under the capillary force introduced by wet etching. g, h Measured deformation displacement and corresponding deformability extracted from the results in (b-d), respectively. i Cyclic AFM tests of the elastic deformation of the nano-kirigami structures. The structure with θ = 270° retains its original morphologies and mechanical properties after cyclic press/release of 1000 times at a frequency of 1 Hz and under a vertical displacement of over 100 nm. Insets, enlarged views of the tests at the beginning and ending stages.

To quantitatively evaluate these fabrication results, the measured deformation displacement and calculated deformability with error analyzes under different dosages are depicted in Fig. 3g, h, respectively. Instead of linking the deformation with the actual stresses, here the experimental irradiation dosage is employed as a more straightforward parameter to accurately realize the structures with desired degrees of deformation, other than measuring the deformation height and stresses at each time. Nevertheless, the relationship between the actual stress and the irradiation dosage can be established by correlating the applied stresses in simulations and irradiation dosages in experiments when both cases reach the same deformation height (see Supplementary Fig. 5). It can be seen that as the dosage of FIB irradiation increases, both the displacement and deformability continuously increase and the maximum total deformability also reaches to nearly 100%, which agrees well with the simulations. In fact, further structural deformation can be achieved by further increasing the dosages of ion irradiation. However, as high-dose ion beams continue to irradiate the sample, the gold film and arms will become thinner and thinner, resulting in reduced stability or even destroy of the structural morphology and related optical properties. Therefore, a relatively safe dosage of 40 pC/μm2 is chosen as the upper limit of global FIB radiation.

To experimentally quantify the structural stiffness, mechanical press tests were conducted by using an in-situ atomic force microscope (AFM) probe (Supplementary Fig. 6a). It was found that the structural stiffness decreases with the increase of spiral angles, which is in a good agreement with the simulations, as shown in Supplementary Fig. 6b. In order to evaluate the structural switching times and durability, a cyclic AFM test with press and release of 1000 times was conducted at a frequency of 1 Hz and under a displacement of over 100 nm. As shown in the Fig. 3i, it was found that the structure maintained its original elastic deformation state without any damage after 1000 s of test. The measured variation in displacement was within 3.6% for 1000 times, showing good durability and consistency. Therefore, the experimental results provide a reliable verification for the synthetic nano-kirigami with an ultrahigh deformability, and also establish a foundation for further applying the synthetic nano-kirigami and constructing highly deformed micro/nanostructures with high performances. For example, these structures with ultrahigh deformability could be potentially applied to novel optoelectronic micro-/nano-devices whose optical properties change significantly when their shapes are deformed, providing a useful scheme for applications such as optical displays, light manipulations, and mechanical sensing.

Electromechanical reconfigurations

To investigate the functionality and application of synthetic nano-kirigami, we perform the electromechanical measurements using the synthetic nano-kirigami structures with different spiral angles. As shown in Fig. 4a, a 2D structural array can be transformed into the 3D downward state by applying the attractive electrostatic force induced by the applied direct current (DC) voltage. Referring to the general case of an electromechanical capacitor with conductive plates, the initial electrostatic force can be expressed as26:

where V is the applied voltage, C is the capacity and \(C=\frac{\varepsilon A}{d}\), A is the effective area of the plates, d and \(\varepsilon\) are the initial thickness and permittivity of the material between the plates, respectively.

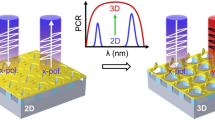

a Schematic of a suspended 2D array (voltage off) and its downward deformed 3D state by electrostatic forces (voltage on). b Top-view SEM images of the fabricated flat structures with different spiral angles and same period of 2.2 μm. c, d Comparison of electromechanical modulation contrast (defined as |\(\Delta {{{\rm{R}}}}/{{{\rm{R}}}}\) | ) of the reflected signals in normal direction in the structures of θ = 240° and 270°. \(\Delta {{{\rm{R}}}}\) represents the reflection difference between the structural arrays with and without the applied DC voltages. e Modulation contrast versus spiral angle at the applied voltages of 15 V and 36 V, respectively. f Required voltage versus spiral angle at the modulation contrasts of 8% and 35%, respectively. More testing results are shown in Supplementary Fig. 10.

For sample preparations, the local suspended structures are obtained by etching the bottom SiO2 with the thickness of 300 nm (see details in the Methods and Supplementary Fig. 7). As we know, the spiral angle greatly affects the structural stiffness. Hence, to find the optimal structure with excellent properties, a series of spiral configurations are designed and fabricated with the period of 2.2 μm and the Archimedes spirals (see the spiral define in Supplementary Fig. 1) of θ = 180°, 210°, 240°, 270°, 300°, and 330°, as shown in the SEM images of single structure in Fig. 4b and structural arrays in Supplementary Fig. 8. Under the same structural parameters, the larger horizontal span of the structural area will lead to the smaller overall structural stiffness. In other words, the structure becomes “softer”. Actually, the structural arm length and duty cycle keep a linear relationship with the spiral angle (Supplementary Fig. 9a), indicating that the increase of spiral angle will result in the decrease of structural stiffness, as shown in Supplementary Fig. 6b. Such a trend is confirmed by the simulation results and electrostatic forces calculated from the Eq. 1 in Supplementary Fig. 9b, c, where the increase of spiral angle results in the decreased actuation voltage under the same vertical displacement of ~250 nm.

The dependence of structural stiffness on the spiral angle can be used to control the optical modulation performances of electromechanically reconfigurable nano-kirigami structures. In experiment, the modulation contrast of the reflected signal strongly depends on the deformability of structural arrays, due to the more obvious structural transformation within the region of per unit area will produce the stronger light-structure interactions. As shown in Fig. 4c, d, the structural array with θ = 240° has a low modulation contrast of less than 10%, while a high modulation contrast of ~37% under the low voltage of 36 V and broadband wavelength of 400 to 1000 nm is achieved in the array with θ = 270°, indicating that a subtle structure distinction can lead to a significant difference of the modulation contrast (see results of other spirals in Supplementary Fig. 10). It should be mentioned that to analyze the effects merely induced by different spiral angles, symmetric designs are employed in this study, while the unsymmetric designs that offer additional controllability and functionality provide potential optimization directions of future studies (Supplementary Fig. 11). To quantify the modulation performances, the modulation contrast and applied voltage versus the six spiral angles at certain circumstances are plotted in Fig. 4e, f, respectively. Specifically, as the increase of spiral angle, the modulation contrast increases while the required voltage decreases, which are consistent with the simulations. The underlying mechanism is that the performance of the structures depends mainly on the overall structural stiffness, which determines the deformation ability of the structures. Under identical etching conditions and fabrication process, the structures with a large in-plane structural span, narrow structural arms, and a thin film contribute to a larger structural deformation under the same external force, resulting in a reduced structural stiffness (i.e., the structure becomes softer). This enhanced deformability facilitates reconfigurable shape changes within a small pixel area, enabling optical modulations with high performance such as low operating voltage, high contrast, and broadband functionality. It should be mentioned that here the period of each reconfigurable unit is only 2.2 μm, providing a vital reference for miniaturizing conventional spatial optical modulation devices and systems, such as miniaturized spectrometers, digital micromirror devices (DMD), optical phased arrays (OPA), light detection and ranging (LiDAR), etc.

Applications on high-resolution optical information encryption

The ultrahigh deformability is highly desirable for high-resolution information display in the electromechanical systems. This is because on the premise of the same display contrast, the ultrahigh deformability is beneficial to reduce the minimum pixel size, which results in a large number of pixels per unit area that are preferred by high-resolution displays (see discussions in Supplementary Note 2). In this regard, the spiral-dependent deformability of synthetic nano-kirigami provides a novel strategy for the electrically controllable and high-resolution information encryption based on the difference of reflection contrast between structural flat state and deformed state. On the basis of previous electromechanical characterization, here two kinds of spiral structures with θ = 240° and 270° (inset of Fig. 5a), with large difference in modulation contrast (Fig. 4c, d), are employed to construct the programmable and customizable patterns with the period of 2.2 μm and the structural width of only 1.6 μm. Based on this method, the patterns with Morse codes (“-…”, “..”, “-”, decoded as “BIT”) and capital letters “BIT” are fabricated, as the SEM images shown in Fig. 5a, c. Specifically, the areas enclosed by the black dotted lines employing the spiral structures with θ = 270° to pattern the corresponding shapes, while the structures with θ = 240° are arranged in the rest of the area. In such cases, the experimental images of dynamically reversible encryption (voltage off) and decryption (with voltage of 36 V) can be captured, as displayed in Fig. 5b, d (see details in the Methods). Besides, the large-area and complex pattern programmed by the Chinese characters “北理工” with the meaning of Beijing Institute of Technology is fabricated by the processes of electron beam lithography (EBL) and wet etching, as the fabrication illustration and SEM image shown in the Methods and Supplementary Fig. 12. Here, the size of each reconfigurable unit is 1.8 μm with a period of 2.5 μm, which brings the smaller structural stiffness and actuated voltage. The experimental images of dynamically reversible encryption (voltage off) and decryption (with a low voltage of 15 V) are displayed in Fig. 5e. The three patterns are clearly displayed and perfectly vanished by switching the deformed states of the spiral structures (Supplementary Movies 4 to 6). It should be mentioned that one structural unit in Fig. 5d does not undergo switchable deformation, mainly due to the FIB resolution of a few tens of nanometer or unwanted environmental static electricity, which led to about 5% ineffectiveness of electrically controlled deformation in Fig. 5e. A higher yield of kirigami units can be obtained by employing high-precision EBL with resolution of better than 10 nm. With such a proof-of-concept demonstration, the display of smaller pixel and larger area for complex images can be envisioned by employing EBL, which may open a new way to the high-resolution display with flexibly tunable functionalities.

a, c Top-view SEM images of structural patterns encoded with Morse codes (decoded as “BIT”) and capital letters “BIT”. The spiral patterns are enclosed by the black dotted lines with the structures of θ = 270° while other structures have θ = 240° (as illustrated in the inset of a). b, d Captured images of dynamically reversible encryption (voltage off) and decryption (with voltage of 36 V). The patterned information is obviously displayed and perfectly vanished by utilizing the different reconfiguration responses of two kinds of spirals. e Captured images of dynamic encryption (voltage off) and decryption (with voltage of 15 V) of the large-area and complex pattern programmed by Chinese characters “北理工”. Images taken from Supplementary Movies 4 to 6. Scale bars: a–d 5 μm; e 25 μm.

Application exploration on freely encoded information displays

In practical applications of information encoding and displays, it is highly desirable to address independent manipulations of individual pixel and achieve real-time and freely programmable optical information displays. To demonstrate the potential application of nano-kirigami design in this aspect, a pixelated electromechanical configuration is proposed based on the multi-line addressing (MLA) strategy44,45,46. As shown in Fig. 6a, the configuration consists of three parts: the bottom layer with parallel gold ribbons (with 4.1 μm in width and 25 nm in thickness) as the electrodes in the columns noted by 1, 2, 3,…, j; the intermediate insulating SiO2 layer with thickness of 500 nm; the top layer with parallel gold ribbons (with 4.65 μm in width and 60 nm in thickness) as the electrodes in the rows noted by 1, 2, 3,…, i, on which the nano-kirigami spirals are fabricated in the crossing regions. The top and bottom electrodes can be extended and connected to electric board through wire bonding, as illustrated in Fig. 6b. With such a scheme, the nano-kirigami spirals at pixel with coordinates (i, j) can be deformed by applying a certain voltage between the electrodes in the top i-th row and the bottom j-th column, which enables the addressing of arbitrary pixel in the array. Furthermore, by applying specific voltages to the top and bottom electrodes at programmed locations, multiple spiral structures can be deformed at well-designed pixels, accomplishing the real-time optical displays on demand.

a, b Schematics of the multi-line addressing (MLA) method and the wire-bonded device configuration. In the MLA strategy, the pixels with numbers (i, j), enclosed by the dashed circle, can be actuated by applying certain voltage between the electrodes in the top i-th row and the bottom j-th column, which enables the reconfigurable and programmable pattern displays. c Camera image and d microscopic image of a sample substrate with connecting electrodes of 100 rows and 100 columns. e Microscopic image of the nano-kirigami array fabricated on the corner of the sample substrate with electrodes. f, g Microscopic images of the free reconfiguration of individual pixel and multiple pixels. h, i Encoded displays with the Morse codes of “NANO” and “BIT”, respectively. See details in Supplementary Movie 7. j In-situ scattering images of the programmed characters “LIGHT” displayed in the same area with a stroke width of one pixel under a dark-field microscope (see Methods). k, l In-situ scattering images of the programmed characters “THE” with a stroke width of two pixels and the numbers “123” with a stroke width of four pixels. All the spiral structures in the pixels of Fig. 6 have the same θ = 270°. Scale bars: c 5 mm; d 200 μm; e–j 10 μm; k, l 20 μm. The applied voltages are between 39 and 47 V.

To realize such a proposal, a multi-step fabrication process is developed to prepare the substrates with crossed electrodes (see Methods and Supplementary Fig. 13). As shown in Fig. 6c, d, a substrate with ribbon-like electrodes of 100 rows and 100 columns is successfully fabricated with overlay alignment assisted UV lithography (Supplementary Fig. 13). Based on such a substrate, the spiral nano-kirigami patterns are fabricated in the crossing regions, where both bottom and top electrodes exist. The sample for individual pixel addressing is shown in Fig. 6e, where both pitch width and length are 4.8 μm (limited by the fabrication resolution of the available stepper lithography machine). With such a design and employing a programmable circuit module (see Methods and Supplementary Fig. 14), the independent reconfigurations of individual pixel are successfully achieved under the voltage of 40 V, as clearly shown in Fig. 6f. Based on such ability, the micro-displays of multiple pixels and the Morse codes of “NANO” and “BIT” are readily realized in Fig. 6g, h, i, respectively. Moreover, in order to achieve more complex pattern displays, the structural arrays are fabricated in larger area (Supplementary Fig. 13). To display the image actuated by the MLA method, a dark-field microscope and the visual persistence effect are employed to capture the images during a long-time exposure, during which the relevant pixels are swiftly deformed in programmed orders. With such a strategy, the downward deformation of the structures can help to “light up” the pixel units at the programmed positions. Figure 6j shows the experimentally captured images of five characters “LIGHT” in the same area consisting of individually reconfigurable pixel under the exposure time of 1.4 s. Moreover, the stroke width can be increased by combining more pixels in each character, as the examples with “THE” and “123” shown in Fig. 6k, l. In such a way, the real-time information encryption and freely programmable optical displays with nano-kirigami structures are successfully demonstrated, providing a potential platform for high-resolution reconfigurable information micro-displays. It should be mentioned that here the MLA strategy merely serves an easy-to-implement method to demonstrate the programmable capability of the nano-kirigami patterns, while the image contrast is preliminarily limited by the unoptimized electrical actuation and unrefined display strategy. For future improvement, more advanced electrical controls with the assistance of Complementary Metal Oxide Semiconductor (CMOS) or Field-Programmable Gate Arrays (FPGAs) might be a good candidate for the generation of arbitrary patterns with enhanced performances.

Discussion

In summary, we have designed and demonstrated synthetic nano-kirigami structures with ultrahigh deformability in aspect ratio. Bi-directional out-of-plane deformations with large-range displacement were observed in both mechanical simulation and experimental verification. Optical modulations with high contrast, low voltage, and broadband wavelengths were achieved based on electromechanical reconfigurations of synthetic nano-kirigami structures, which could provide a feasible solution for developing new types of optical-modulation-based devices and systems. As a proof-of-concept demonstration, high-resolution optical information encryption was realized by utilizing the differential deformability between two synthetic spiral nanostructures. Beyond the dynamically optical information display under a fixed pattern, freely electromechanical reconfiguration of individual and multiple pixels was further demonstrated, with reconfigurable and real-time information displays achieved in designed area.

Comparing with previous works on nano-kirigami, this study achieves large structural deformations and corresponding high-resolution information displays by employing a new synthetic design with Archimedean spirals. Specifically, the design curves used in previous works were unable to produce high degree of structural deformations due to their limited arm length within a limited area35,37,40, which consequently limited the change of structural stiffness at the same scale. Here, we designed a synthetic nano-kirigami configuration with ultrahigh deformability benefited from the Archimedean spirals with a highly desirable curvature and a long arm span within a limited area (Supplementary Fig. 9a). The ultrahigh deformability results in considerable contrast in reflection within a small pixel size. As a result, high-contrast information displays with a high resolution of 2.2 μm in pixel size are achieved. While in all previous related works, the deformation induced modulation can only be observed in optical spectra from the overall array without the capability of addressing to individual pixel35,37,40. As such, this work provides new methodologies for the generation and reconfiguration of high-performance micro-display devices and systems.

It should be mentioned that the proposed nano-kirigami designs can be generally applied on other material platform to generate interesting functionalities. For example, all the nano-kirigami structures in this work have only one stable state once the stress, pressure or electrostatic force is fixed unidirectionally. When the forces are variable or the top gold nano-patterns are replaced with other materials such as silicon, complex deformation with bistable states can occur due to the competition between mechanical restoring forces and external stimulus forces (results not shown). Therefore, this study not only brings forward a meaningful step for electromechanically reconfigurable synthetic nano-kirigami to practical information displays, but also opens a new avenue for the study of multichannel information encryptions, reconfigurable optical/mechanical metamaterials, tunable photonics/phononics, novel MOEMS/NOEMS, etc. For example, with the advanced functionality of freely programmed information display in Fig. 6, the reconfigurable nano-kirigami structures can be applied as an image generator for light projection, as illustrated in Supplementary Fig. 15.

Methods

Numerical simulations

Prestress based deformation

The nano-kirigami structures with out-of-plane upward deformation were simulated via the solid mechanics module of finite element software COMSOL Multiphysics. The user-defined subroutines were inserted for applying a bilayer prestress32 model to induce global deformation of nano-kirigami structures. The Young’s modulus, density and Poisson’s ratio of gold are set as 30 GPa, 19281.71 kg/m3, and 0.4422, respectively. The values of the prestress in simulations were selected based on the realistic experimental deformation height. For example, the reason for choosing the stress value of 4.6 GPa in Fig. 1b is that there exists a maximum deformation height (~0.8 μm) in experiments due to the realistic structural and material conditions. Correspondingly in simulations, the stress that induced the same deformation height was found to be at 4.6 GPa. Therefore, the maximum value of 4.6 GPa was selected in simulations of Fig. 1b.

Pressure based deformation

Out-of-plane downward deformations of nano-kirigami structures were performed by using the solid mechanics module of the same software. Here, structural boundaries were fixed and the downward pressure was loaded on the top surface of the nano-kirigami structures36.

Electromechanical deformation

Downward electromechanical deformations were performed by using solid mechanics and electrostatics modules in the same software. The simulation model consists of three layers of Au, SiO2 and Si, respectively, with thickness 60 nm, 300 nm, and infinite). The upper gold film was set to initial voltage of 0 V while the bottom silicon substrate was set with desired voltages34.

More details about the simulations can be found in Supplementary Fig. 2 and Note 1.

Fabrication strategies

Upward deformed samples by ion beam irradiation

Commercial SiO2 substrate (Lijingkeji Co., Ltd., 500 μm thick, P-doped) was deposited with 5-nm-thick chromium and 60-nm-thick gold. Next, Archimedes spirals were milled (with high doses, >600 pC/μm2) on the sample using a dual-beam FIB/SEM system (FEI Helios G4 UC). Then, the etched sample was dipped into diluted hydrofluoric acid (40%, HF:H2O = 1:4) to etch the SiO2 in the beneath of spirals and suspended flat structures were formed. Finally, FIB irradiations with relative low doses (10 to 40 pC/μm2) were employed to irradiate the etched regions. Here, the acceleration voltage and current beam of Ga+ were set to 30 kV and 24 pA, respectively. Consequently, four arms and the core of nano-kirigami structures were lifted up and transformed into stereo structures.

Downward deformation samples by capillary force

The above milled Au-SiO2 sample (before wet etching) was dipped into diluted hydrofluoric acid to remove beneath SiO2, due to the large capillary force generated during the sample drying after etching, the flat structures can be downward dragged and transformed into the downward stereo state.

Samples for electromechanical tests

Commercial SiO2/Si substrate (Lijingkeji Co., Ltd., 500 μm thick, P-doped) was deposited with 5-nm-thick chromium and 60-nm-thick gold. First, structural arrays were fabricated using a dual-beam FIB/SEM system (FEI Helios G4 UC) with 12×12 units arranged in a period of 2.2 µm (Supplementary Fig. 8). Then, the sample was dipped into diluted hydrofluoric acid (40%, HF:H2O = 1:4) to remove the SiO2 material beneath the etched patterns. Here, the thickness of SiO2 was chosen at 300 nm by balancing the availability of the test sample and proper the range of downward deformation. Besides, for the fabrication of large-area and complex pattern, the above pristine Au/SiO2/Si sample was spin-coated with a thin layer of electron resist (polymethyl methacrylate, PMMA, AR-P-672.05). Then, designed patterns were formed on the electron resist layer by using an EBL system (Raith Co., Ltd., eLine SEM). Next, an ion beam etching (IBE) system (AdvancedMEMS IBE-150) was used to etch the exposed gold material to obtain 2D synthetic nano-kirigami structures and a reactive ion etching (RIE) system (NANO-MASTER NRE-4000) was employed to remove the unexposed electron resist. Finally, suspended large-area nano-kirigami patterns were fabricated on the electrically tuned sample. The schematic process can be found in Supplementary Fig. 12a.

Sample preparations for freely encoded information displays

The preparation process mainly includes three parts (see Supplementary Fig. 13). (i) Fabrication of the bottom electrodes. The process started with a commercially available SiO2 substrate (JGS2, Sibranch Microelectronics Co., Ltd.), on which a 5-nm-thick chromium film and a 25-nm-thick gold film were deposited by utilizing magnetron sputtering (KJLC LAB18). Next, the substrate was spin-coated with a thin layer of positive photoresist (S1805), on which periodical ribbons were patterned by stepper lithography with a mask aligner (Nikon NSR 1755i7B). Subsequently, an IBE system (AdvancedMEMS IBE-150) was used to etch the gold film to produce ribbon-like bottom electrodes and a RIE system (SENTECH SI 591) was used to remove the unexposed photoresist. After the fabrication of the bottom electrodes, a plasma enhanced chemical vapor deposition (PECVD) system (SENTECH SI 500) was employed to deposit 550-nm-thick SiO2 layer onto the electrodes, followed by using a chemical mechanical polishing (CMP) system (Universal-200 D) to achieve a flat intermediate sacrificial layer. (ii) Fabrication of the top electrodes. After depositing a 5-nm-thick chromium layer followed by a 60-nm-thick gold layer using magnetron sputtering (KJLC LAB18), the top electrodes were patterned by repeating the stepper lithography process. Next, the same IBE and RIE systems were employed for the metal etching and resist removal, forming the final top electrodes. (iii) Fabrication of the reconfigurable nano-kirigami structures. To facilitate the subsequent wire bonding tests, the center of the sample was protected by positive photoresist (AZ5214) and the sample was immersed in diluted hydrofluoric acid (40%, HF:H2O = 1:9) for pre-wetting etching. Then, the sample was spin-coated at 6000 rpm with a thin layer of electron resist (PMMA, AR-P-672.05) and then baked at 180 °C for 60 s. An EBL system (Raith Co., Ltd., eline SEM) was used to expose the designed 2D mask patterns on the electron resist layer. Here, the acceleration voltage and current of electron beam were set to 20 kV and 0.25 pA, respectively. Next, the IBE system was used to etch the gold film and create spiral nano-kirigami arrays and the RIE system was used to remove the unexposed electron resist. Subsequently, the sample was dipped into diluted hydrofluoric acid (40%, HF:H2O = 1:9) to remove the SiO2 material beneath the etched nano-kirigami patterns. After the wet etching process, suspended gold membranes with synthetic spiral nanostructure array was formed on top of the etched region. Finally, wires were bonded onto the electrodes of the sample, which was then ready for functionality tests.

Optical characterizations

The optical measurements were conducted by using a home-build spectroscopy system (Supplementary Fig. 7). For the tests of reflected signal, white light from a tungsten halogen source (HL-2000, Ocean Optics) was focused onto the structural area of the fabricated sample by an objective lens (×10, NA 0.25, Olympus). The reflected signal was collected by the same objective lens and delivered to a spectrometer (Idea Optics, PG2000 PRO, 400 to 1000 nm). In electromechanical deformations, the DC voltage was applied via a source meter (Keithley 2450). For the experiment of optical information encryption, the above spectrometer was replaced with a CCD monitor (Shanghai Puqian Optical Instrument Co., Ltd., with ×50 objective imaging lens). The dynamic image information was captured during encryption and decryption by switching off and on the voltages. The dynamic modulations are provided in Supplementary Movies 4 to 6. The switching time of the images in Fig. 5b was found to be ~5.1 ms by employing a high-speed camera (Flare 4M180MCL, IO Industry Co., Ltd.) with a speed of 590 frames/s under manual voltage control. The actual switching time is expected to be shorter and more precise time-resolved measurements will be explored in future work. Besides, for the tests of freely encoded displays, in addition to utilizing the basic electrical and optical test platforms described above, a new electrically programmable module was introduced (see Supplementary Fig. 14). By employing the multi-line addressing strategy, the individual pixel can be freely addressed. For example, by applying a certain voltage between the electrodes in the top i-th row and the bottom j-th column, the pixel unit with the number (i, j) can be deformed. In such a way, the deformation of any pixel unit is addressable (Fig. 6f–i). Moreover, the displayed complex images (Fig. 6j–m) were captured by employing a long-time exposure method, in which relevant pixels were actuated in programmed orders and the images can be freely changed based on the visual persistence effect. Details about the dynamic modulations are provided in Supplementary Movie 7.

Mechanical characterizations

An AFM system (Bruker Dimension XR FastScan) was used to evaluate the mechanical properties of the structures. Specifically, the AFM tip (RTESPA-300), with an elastic coefficient of 23.6 N/m and a deflection sensitivity of 71.18 nm/V after calibration, was kept on a fixed spot of the surface of the suspended structure. During the testing process, the probe was landed at a constant speed until the force applied to the structure reached a preset value, at which the deformation height was recorded. In such a way, the structural stiffness can be precisely obtained based on the deformation height of the structure under various preset forces according to the Hooke’s Law. Furthermore, the structural durability was tested by pressing and releasing the same structure under a constant force at a rate of 1 Hz for the cycles of 1000 s, which corresponded to switching by 1000 times.

Data availability

All the data supporting the findings of this study are available within the article, its Supplementary Information files, or from the corresponding authors upon request. Source data is availably within the Source Data file. Source data are provided with this paper.

Code availability

Related code for the purpose to reproduce the results of this paper is available upon request.

References

Wang, W. et al. Cilia metasurfaces for electronically programmable microfluidic manipulation. Nature 605, 681–686 (2022).

Han, D.-D. et al. Carnivorous plants inspired shape-morphing slippery surfaces. Opto-Electron. Adv. 6, 210163–210163 (2023).

Yu, Z. et al. Bio-inspired copper kirigami motifs leading to a 2D-3D switchable structure for programmable fog harvesting and water retention. Adv. Funct. Mater. 33, 2210730 (2023).

Qian, J. et al. Toward stretchable batteries: 3D-printed deformable electrodes and separator enabled by nanocellulose. Mater. Today 54, 18–26 (2022).

Kim, K. B. et al. Extremely versatile deformability beyond materiality: a new material platform through simple cutting for rugged batteries. Adv. Eng. Mater. 21, 1900206 (2019).

Praveen, S., Kim, T., Jung, S. P. & Lee, C. W. 3D-printed silicone substrates as highly deformable electrodes for stretchable Li-ion batteries. Small 19, 2205817 (2022).

Evke, E. E. et al. Kirigami-based compliant mechanism for multiaxis optical tracking and energy-harvesting applications. Adv. Eng. Mater. 23, 2001079 (2021).

Li, Y. et al. Printed kirigami organic photovoltaics for efficient solar tracking. Adv. Funct. Mater. 32, 2204004 (2022).

Lee, K. et al. Origami solar-tracking concentrator array for planar photovoltaics. ACS Photonics 3, 2134–2140 (2016).

Jiang, S. et al. Flexible metamaterial electronics. Adv. Mater. 34, 2200070 (2022).

Yan, Z. et al. Hierarchical serpentine-helix combination for 3D stretchable electronics. Adv. Mater. 35, 2210238 (2023).

Kim, J. H., Lee, S. E. & Kim, B. H. Applications of flexible and stretchable three-dimensional structures for soft electronics. Soft Sci. 3, 16 (2023).

Wang, J. et al. A 4D-printing inverse design strategy for micromachines with customized shape-morphing. Small 19, 2302656 (2023).

Raviv, D. et al. Active printed materials for complex self-evolving deformations. Sci. Rep. 4, 7422 (2014).

Ge, Q., Qi, H. J. & Dunn, M. L. Active materials by four-dimension printing. Appl. Phys. Lett. 103, 131901 (2013).

Wang, Y., Li, L., Hofmann, D., Andrade, J. E. & Daraio, C. Structured fabrics with tunable mechanical properties. Nature 596, 238–243 (2021).

Shklyaev, O. E. & Balazs, A. C. Interlinking spatial dimensions and kinetic processes in dissipative materials to create synthetic systems with lifelike functionality. Nat. Nanotech. 19, 146–159 (2024).

Li, M., Pal, A., Byun, J., Gardi, G. & Sitti, M. Magnetic putty as a reconfigurable, recyclable, and accessible soft robotic material. Adv. Mater. 35, 2304825 (2023).

Ze, Q. et al. Spinning-enabled wireless amphibious origami millirobot. Nat. Commun. 13, 3118 (2022).

Han, M. et al. Submillimeter-scale multimaterial terrestrial robots. Sci. Robot. 7, eabn0602 (2022).

Duhr, P. et al. Kirigami makes a soft magnetic sheet crawl. Adv. Sci. 10, 2301895 (2023).

Zheng, Z. et al. Ionic shape-morphing microrobotic end-effectors for environmentally adaptive targeting, releasing, and sampling. Nat. Commun. 12, 411 (2021).

Li, D. et al. Recent advances in electrically driven soft actuators across dimensional scales from 2D to 3D. Adv. Intell. Syst. 2300070 (2023).

Xu, W. et al. Photo-actuators via epitaxial growth of microcrystal arrays in polymer membranes. Nat. Mater. 22, 1152–1159 (2023).

Sun, J., Liao, W. & Yang, Z. Additive manufacturing of liquid crystal elastomer actuators based on knitting technology. Adv. Mater. 35, 2302706 (2023).

Midolo, L., Schliesser, A. & Fiore, A. Nano-opto-electro-mechanical systems. Nat. Nanotechnol. 13, 11–18 (2018).

Kim, D. U. et al. Programmable photonic arrays based on microelectromechanical elements with femtowatt-level standby power consumption. Nat. Photonics 17, 1089–1096 (2023).

Shin, D. et al. Spiderweb nanomechanical resonators via Bayesian optimization: inspired by nature and guided by machine learning. Adv. Mater. 34, 2106248 (2022).

Brooks, A. K., Chakravarty, S., Ali, M. & Yadavalli, V. K. Kirigami-inspired biodesign for applications in healthcare. Adv. Mater. 34, 2109550 (2022).

Xu, H. X. et al. Adaptable invisibility management using kirigami-inspired transformable metamaterials. Research 2021, 9806789 (2021).

Zheng, Y. L. et al. Kirigami reconfigurable gradient metasurface. Adv. Funct. Mater. 32, 2107699 (2022).

Han, D. et al. Kirigami-inspired planar deformable metamaterials for multiple dynamic electromagnetic manipulations. Laser Photonics Rev. 17, 2300374 (2023).

Zheng, W. et al. Kirigami-inspired highly stretchable nanoscale devices using multidimensional deformation of monolayer MoS2. Chem. Mater. 30, 6063–6070 (2018).

Bao, Y. et al. Customized kirigami electrodes for flexible and deformable lithium-ion batteries. ACS Appl. Mater. Interfaces 12, 780–788 (2019).

Liu, Z. G. et al. Nano-kirigami with giant optical chirality. Sci. Adv. 4, eaat4436 (2018).

Zhao, Y. H. et al. Thermally actuated micro-/nanoscale deformations for optical reconfigurations. J. Opt. 24, 054007 (2022).

Chen, S. S. et al. Electromechanically reconfigurable optical nano-kirigami. Nat. Commun. 12, 1299 (2021).

Chen, Y. et al. A magnetic actuation scheme for nano-kirigami metasurfaces with reconfigurable circular dichroism. J. Appl. Phys. 131, 233102 (2022).

Hong, X., Liang, Q., Liu, X., Ji, C.-Y. & Li, J. Manipulation of fractal nano-kirigami by capillary and electrostatic forces. Adv. Opt. Mater. 11, 2202150 (2023).

Liu, Z. G. et al. Fano-enhanced circular dichroism in deformable stereo metasurfaces. Adv. Mater. 32, 1907077 (2020).

Chen, S. S. et al. Reconfigurable nano-kirigami metasurfaces by pneumatic pressure. Photonics Res. 8, 1177–1182 (2020).

Li, X. et al. Phase enabled circular dichroism reversal in twisted bi-chiral propeller metamolecule arrays. Adv. Opt. Mater. 9, 2101191 (2021).

Ji, C. Y. et al. Artificial propeller chirality and counterintuitive reversal of circular dichroism in twisted meta-molecules. Nano Lett. 21, 6828–6834 (2021).

Guo, T. et al. Durable and programmable ultrafast nanophotonic matrix of spectral pixels. Nat. Nanotechnol. 19, 1635–1643 (2024).

Chen, B. et al. Electrically addressable integrated intelligent terahertz metasurface. Sci. Adv. 8, eadd1296 (2022).

Park, J. et al. All-solid-state spatial light modulator with independent phase and amplitude control for three-dimensional LiDAR applications. Nat. Nanotechnol. 16, 69–76 (2021).

Acknowledgements

We thank the Jiaweinano (Beijing) Technology Co., Ltd. for technical support of the light projection, and Dr. Xichuan Zhao and Prof. Feng Li from School of Physics, Beijing Institute of Technology for technical support and fruitful discussions on high-speed photography. The authors gratefully acknowledge the support from the National Key Research and Development Program of China (Grant No. 2024YFB2809204), the National Natural Science Foundation of China (Grant Nos. 52488301, T2325005, 62375016, 12102315), the Beijing Natural Science Foundation (Grant No. 2242018), the Sanya Yazhou Bay Science and Technology City (Grant No. SCKJ-JYRC-2023-54), the Australian Research Council through the Discovery Project scheme (Grant Nos. DP250100980, FT220100559, and FT210100806), the Linkage Project scheme (Grant No. LP210100467), the Industrial Transformation Research Hubs scheme (Grant No. IH240100009), the Centre of Excellence Program (Grant No. CE230100006), the Analysis and Testing Center at Beijing Institute of Technology, and the Micro/nano Fabrication Laboratory of Synergetic Extreme Condition User Facility (SECUF).

Author information

Authors and Affiliations

Contributions

J.L., X.R.H., and F.M. conceived the idea. X.R.H., J.L. designed the structures. X.R.H., H.S., Y.Z., C.L., Q.L., and W.D. performed the fabrications. X.R.H., F.M., H.S., Y.C., and Q.J. performed the simulations. X.R.H., M.N., H.S., and X.Z. performed the tests. J.L., B.J., X.D.H., and H.L. supervised the project. X.R.H., H.S., and F.M. wrote the manuscript. J.L., B.J., X.D.H., H.L., Y.W. revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Georg Fantner, Kazuko Fuchi and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hong, X., Sun, H., Meng, F. et al. Synthetic nano-kirigami with high deformability for reconfigurable information displays. Nat Commun 16, 7843 (2025). https://doi.org/10.1038/s41467-025-63169-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-63169-9