Abstract

Lignin refining still suffers from great challenges of selective depolymerization and cleavage of stubborn C‒C linkages. Here, a robust atomically dispersed Cu/Ni-SA@HNC catalyst is fabricated for super-selective hydrogenolysis of lignin and model compounds via an unusual “preferential Cα–Cβ bond cleavage in β-O-4 linkages” pathway, affording toluene in yield up to 75.7% from β-O-4 model compounds, and up to 33.7 ± 1.6 wt% (nine parallel experiments) from poplar lignin. The catalyst exhibits high stability, and the scale-up potential is demonstrated by the high space-time yield of toluene (33.7 g·gcat−1·h−1) in continuous flow reaction of β-O-4 model compound. The origin of the extraordinary selectivity towards Cα–Cβ bond cleavage rather than C‒O bond cleavage in β-O-4 model compounds is uncovered. This work conquers the major challenges in lignin valorization by using non-noble dual-metal single-atom catalyst, not only showcasing the application perspective of atomically dispersed catalysts in biopolymer refinery, but also providing a cost-efficient, petroleum independent solution to valuable commodity chemicals.

Similar content being viewed by others

Introduction

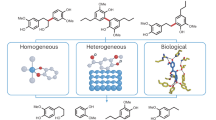

Lignin, one of the largest sources of natural aromatic biopolymers, is considered as the origin of renewable aromatic chemicals and materials1,2,3,4,5. In nature, lignin is bio-synthesized through oxidative polymerization of three monolignols (i.e., coniferyl alcohol (G unit), sinapyl alcohol (S unit), and p-coumaryl alcohol (H unit)) with a diverse array of interunit C‒O and C‒C linkages, accounting for around 70% and 30%, respectively, in the forms of β-O-4, α-O-4, 4-O-5, and β−1, etc6,7,8. Typically, C‒C bonds possess higher dissociation energy (226-494 kJ mol−1) than C‒O bonds (209-348 kJ mol−1)9,10,11,12,13,14. Thus, numerous strategies have achieved scission of C‒O bonds in lignin via acid/based catalysis, hydrogenolysis, photo/electro-catalysis, etc. to afford phenolic compounds, while leaving C‒C bonds intact, making more than half of the lignin oil a mixture of dimers and oligomers mainly consisting of C‒C linkages, which hampers its utilization15,16,17,18,19. To overcome the challenge of C‒C bonds cleavage, several elegant strategies have been documented by Sels2, Samec20, Han21, Klankermayer22, Hensen23, Wang12 and other groups24,25,26,27,28,29,30 via oxidative activation of C‒C bonds20, acid scissoring of the Csp2–Csp3 bonds under reductive conditions21,23,24, and hydrogen-transfer/retro-aldol mechanism22, to acquire phenolics, arenes, benzoquinones, and other chemicals. Nevertheless, considerable reported methods under reductive conditions rely on the construction of multifunctional sites such as metallic and acidic sites, and suffer from excessive use of noble metal catalysts, harsh reaction conditions, limited substrates of model compounds, and more critically, most of the depolymerized products are a mess of various types of mixtures without one special product stands out in the crowd. The development of robust catalyst for mild cleavage of the stubborn C‒C bonds of lignin to produce single bulk chemical is highly desirable for cost-effective biorefinery and green chemistry concepts.

Single atom catalyst (SAC) featuring minimum particle size and maximum atomic utilization. Since the progressed this concept in 201131,32,33, SAC has shown promise in different types of reactions34,35,36,37,38,39. Furthermore, based on the concept of SAC, geminal-atom catalysis was proposed to achieve satisfied results in complex catalytic processes40,41. Benefitting from the flexible active sites, easily modulated electronic structures, and the synergetic effects between two adjacent active sites, dual-metal single-atom catalysts (DSACs) offer more opportunities toward conquering the challenges faced by SAC42,43,44,45,46,47,48,49. In spite of the achievements in cascade synthesis from simple molecules to complex ones, the oriented depolymerization of macromolecules (e.g., lignin) over DSACs has not yet been reported till now.

β-O-4 linkage, containing both C‒O and C‒C bonds in structure, is the most abundant interunit linkage in lignin20,50. In this work, starting from typical β-O-4 model compounds of lignin, we present a novel “preferential Cα–Cβ bond cleavage in β-O-4 linkages” methodology to achieve efficient catalytic depolymerization of various lignin model compounds and even real lignin feedstock to afford high yield of toluene (Fig. 1). Inspired by the previous report that both Cu and Ni feature considerable reactivity in C–C bond cleavage reaction and hydrogenation reactions38,51,52,53,54,55,56,57,58, an atomically dispersed Cu/Ni dual sites decorated hierarchically porous carbon catalyst was fabricated (Cu/Ni-SA@HNC). Over Cu/Ni dual sites, selective cleavage of C–C bond in lignin β-O-4 model compound following by hydrogenation approves toluene as the major product; while the competitive C‒O bond cleavage is inhibited through extending the successive reaction pathway. DFT calculations verify this unusual reaction path and uncover the significantly enhanced capability of Cu/Ni-SA@HNC in H2 activation and substrate adsorption. Notably, the proposed strategy achieves mild, complete depolymerization of poplar (hardwood) lignin into aromatic oil, furnishing toluene in yield up to 33.7 ± 1.6 wt% (nine parallel experiments), and Cu/Ni-SA@HNC can be recycled not only in the conversion of model compounds, but also in lignin depolymerization.

Results

Synthesis and characterization of Cu/Ni-SA@HNC

First, atomically dispersed Cu/Ni dual sites were decorated on hierarchically porous nitrogen-doped carbon (Cu/Ni-SA@HNC) comprised of thin outer shells and porous inner networks. Overall, the synthesis approach (Fig. 2a) involves a chemical etching reaction and subsequent carbonization procedure. Specifically, uniform rhombic dodecahedrons of Cu/Ni-based zeolitic imidazolate framework (Cu/Ni-ZIF) with an average size of 210 nm were treated with tannic acid (TA) to obtain Cu/Ni-ZIF-TA, which was subsequently subject to high-temperature carbonization to yield Cu/Ni-SA@HNC (Supplementary Figs. 1, 2). Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) images of Cu/Ni-SA@HNC (Fig. 2b, c) show truncated rhombic dodecahedral morphology of particles with a uniform size of ca. 120 nm. High-angle annular dark-field scanning TEM (HAADF-STEM) image (Fig. 2d) further reveals that the carbon framework consists of mesoporous inner networks and thin outer shells. Typical type-IV isotherms with obvious hysteresis loops at high relative pressures and corresponding pore size distribution demonstrate the hierarchically porous feature (Supplementary Fig. 3a, b)59. The calculated specific surface area and total pore volume of Cu/Ni-SA@HNC are 516.3 m2 g−1 and 0.34 cm3 g−1 (Supplementary Table 1), respectively. Besides, hardly no metal aggregates are found, which can also be confirmed by the energy-dispersive X-ray (EDX) spectroscopy (Fig. 2f), showing the homogeneous distribution of C, N, Cu, and Ni over the Cu/Ni-SA@HNC particles.

a Schematic illustration of the preparation procedure for Cu/Ni-SA@HNC. b SEM, c TEM (inset: HAADF-STEM), d HAADF-STEM, e AC HAADF-STEM, and f element mapping images of Cu/Ni-SA@HNC. g Cu K-edge XANES spectra, h Fourier-transformed (FT) k3-weighted EXAFS spectra for the Cu K-edge, i Ni K-edge XANES spectra, j Fourier-transformed (FT) k3-weighted EXAFS spectra for the Ni K-edge.

X-ray diffraction (XRD) patterns (Supplementary Fig. 3c) exhibit two broad peaks of graphitic carbon at 26.2° and 44.1°. Raman spectrum (Supplementary Fig. 3d) with a high ID/IG value of 1.05 implies the defect-rich feature, which should be attributed to the N-doping and TA-etching treatments. High-resolution N 1 s X-ray photoelectron spectroscopy (XPS) spectrum (Supplementary Fig. 4) of Cu/Ni-SA@HNC suggests the existence of pyridinic N, metal-N, graphitic N, and oxidized N species. Moreover, spherical aberration-corrected HAADF-STEM was conducted to further identify the atomically dispersed Cu and Ni species, i.e., the bright spots in Fig. 2e. Inductively coupled plasma optical emission spectroscopy (ICP-OES) result indicates the loadings of Cu and Ni atoms are 1.76 and 1.38 wt%, respectively.

A more comprehensive understanding of the coordination environment of Cu and Ni species is obtained by X-ray absorption near-edge structure (XANES) and extended X-ray absorption fine structure (EXAFS) measurements (Fig. 2g–j, Supplementary Figs. 5–8, Supplementary Table 2). The absorption edge of Cu and Ni K-edge spectra (Fig. 2g–i) for Cu/Ni-SA@HNC is located between the corresponding metal foil and oxides, indicating the positively charged Cu and Ni species. The Fourier transform (FT) k3-weighted EXAFS spectra (Fig. 2h–j) of Cu/Ni-SA@HNC show dominant peaks at 1.49 and 1.42 Å, corresponding to the first coordination shell of Cu–N and Ni–N, respectively. There are no obvious Cu–Cu (2.16 Å), Ni–Ni (2.12 Å) or other high-shell peaks (e.g., Cu–Ni), demonstrating the atomically distributed nature of Cu and Ni species. The corresponding EXAFS fitting curves (Supplementary Figs. 5–7) of Cu/Ni-SA@HNC in the R and K space reveal that Cu and Ni atoms are coordinated to four N atoms. Furthermore, the Wavelet transform (WT) maximum at 1.42 and 1.45 Å−1 for Cu/Ni-SA@HNC (Supplementary Fig. 8) is assigned to Cu–N and Ni–N bonding, respectively. No intensity maximum for metal-metal bonding was detected, further confirming the atomic characteristic.

Importantly, this synthetic strategy can be applied to prepare atomically dispersed Cu or Ni materials, i.e., Cu-SA@HNC and Ni-SA@HNC (Supplementary Figs. 9–12). In addition, the counterparts of Cu/Ni-SA@NC (Supplementary Figs. 3, 4, and 13) and Cu/Ni-NP@HNC (Supplementary Figs. 3, 4 and 14) were also obtained by simply regulating the preparation procedure. Cu/Ni-SA@NC (confirmed by XANES and EXAFS measurements, Supplementary Fig. 15, Supplementary Table 3) exhibits similar chemical composition to Cu/Ni-SA@HNC but without hollow porous structure. Cu/Ni-NP@HNC (confirmed by XANES and EXAFS measurements, Supplementary Fig. 16, Supplementary Table 4) possesses similar hollow mesoporous structure to Cu/Ni-SA@HNC while loading with Cu/Ni nanoparticles (NP).

Catalytic hydrogenolysis of lignin typical dimer model compounds

Next, β-O-4 linked lignin model compounds, representing the most abundant moieties in lignin (approximately 50% depending on the types of lignin) were investigated as probe substrates in the hydrogenolysis reaction to evaluate the catalytic performance of the as-prepared Cu/Ni-SA@HNC (Fig. 3, Supplementary Figs. 17–19). Gratifyingly, β-O-4 model compounds containing different numbers and positions of methoxyl groups (1a, 2a, 3a, 4a) were depolymerized effectively with high selectivity towards C‒C bond cleavage, affording toluene and its derivate 4-methylanisole in yields of 71.8%-75.7% under relatively mild conditions. Moreover, the highly substituted β-O-4 model compounds 5a and 6a possessing γ-OH group also reacted well over Cu/Ni-SA@HNC, providing toluene and 3,4-dimethoxytoluene in yields of 60.6% and 61.3%, respectively. It is thus very interesting to find the scission of C‒C bonds, rather than C‒O bonds with lower bond dissociation energy, occurred in the transformation of all these β-O-4 model compounds.

Reaction conditions: substrates (0.5 mmol), catalyst (20 mg with a total amount of metals at ca. 0.01 mmol), 1,4-dioxane (4 mL), 180 °C, 12 h, H2 (0.5 MPa). [b] 200 °C, H2 (1 MPa). [c] 260 °C, n-hexane (4 mL), H2 (2 MPa). Taking 1a and 12 d as two examples, typical GC spectra and detailed calculation procedures are provided in Supplementary Figs. 18-19.

To further verify the capability of Cu/Ni-SA@HNC to cleave C‒C bonds, several lignin β-1 model compounds (7b ~ 10b) were also employed as substrates, the corresponding C‒C bond cleavage products toluene and its derivates were obtained in yields of 41.6–91.1%. Besides, it was also showed that typical lignin α-O-4 segment (11c) gave toluene in 85.1% yield, and resistant 4-O-5 analogous compound (12 d) containing only C‒O bond linkage can also be cleaved over Cu/Ni-SA@HNC, providing 64.2% conversion with satisfactory C‒O bonds cleavage performance. Taken together, the above results demonstrate that both the stubborn C‒C and C‒O bonds in lignin model dimers can be cleaved over Cu/Ni-SA@HNC under hydrogen atmosphere, and most of tested substrates produced toluene or its derivates as the major products.

Catalytic performance investigation for lignin β-O-4 model compounds hydrogenolysis

Then, a series of control experiments were conducted using the simplified model compound to further explore the hydrogenolysis mechanism of lignin β-O-4 model compound over Cu/Ni-SA@HNC, i.e., the hydrogenolysis of 2-phenoxy-1-phenylethanol (1a) into bulk chemicals (toluene). These reactions were conducted in a batch reactor at 180 °C and 0.5 MPa H2. In the absence of catalyst, a low conversion with trace of toluene product was obtained after 12 h of reaction (Fig. 4a). Cu/Ni-SA@HNC exhibits the best performance among all the tested catalysts, achieving 91.2% 2-phenoxy-1-phenylethanol (1a) conversion with 75.7% yield of toluene (for details, see Supplementary Fig. 18). In contrast, only 26.7% and 51.4% conversions with poor selectivity of toluene were observed over Cu-SA@HNC and Ni-SA@HNC, respectively. These results imply the excellent hydrogenolysis activity and high selectivity towards C‒C bond cleavage should be attributed to the synergistic effect between Cu and Ni moieties. The inferior performances of Cu/Ni-NP@HNC and Cu/Ni-SA@NC counterparts suggest the importance of the size of metal sites and porosity of carbonous support for the transformation of lignin β-O-4 model compounds. It should be noted that the yield of phenol is lower than that of toluene, which may be due to further dehydroxylation of phenol into benzene, unfortunately the peak of benzene in GC-FID picture was overlapped by dioxane solvent. In a verification experiment, we conducted the conversion of phenol in methanol solvent under otherwise identified conditions, and the results showed that 59.3% of phenol was converted into benzene. The conversion results of 12 d in Fig. 3 also suggested that phenol can undergo dehydroxylation reaction to generate benzene over Cu/Ni-SA@HNC.

a Catalytic hydrogenolysis of the 2-phenoxy-1-phenylethanol over different catalysts. Reaction conditions: 2-phenoxy-1-phenylethanol (0.5 mmol), catalyst (20 mg with a total amount of metals at ca. 0.01025 mmol), 1,4-dioxane (4 mL), 180 °C, 12 h, H2 (0.5 MPa). b Conversion and yield as a function of reaction time in hydrogenolysis of 2-phenoxy-1-phenylethanol over Cu/Ni-SA@HNC. Control reactions using benzyl alcohol (c), 1-phenylethanol (d), styrene oxide (e), or anisole (f) as the substrate. g Catalytic hydrogenolysis of the 2-phenoxy-1-phenylethanol over Cu/Ni-SA@HNC in a continuous flow reactor.

The effects of reaction conditions (e.g., temperature and H2 pressure) on the hydrogenolysis performances were investigated. At a H2 pressure of 0.5 MPa, when the temperature rises from 160 °C to 180 °C, the conversion of 2-phenoxy−1-phenylethanol (1a) increases from 44.4% to 91.2%, meanwhile the selectivity of toluene is enhanced from 56.6% to 85.6% (Supplementary Fig. 20). The results indicate that high temperature is favorable for C‒C bond cleavage. Increasing the H2 pressure not only improves the conversion and toluene selectivity, but also promotes the subsequent hydrogenation process (Supplementary Fig. 21). Ultimately, the catalytic system affords 79.0% yield of toluene at 180 °C and 1 MPa of H2.

The reaction time-course profile (Fig. 4b) shows that both the conversion of 2-phenoxy-1-phenylethanol (1a) and toluene yield increased fast and reached 81.4% and 64.0%, respectively, within the initial 8 h. Whereafter, the reaction smoothly proceeded and the substrate was completely consumed (>99%) at 20 h; during this period, the toluene yield was gently enhanced from 64.0% to 81.6%, which was much higher than the yields of other products. Thus, we speculate that the improved yield with time should be attributed to the faster reaction rate of C‒C cleavage than that of the competitive reactions (i.e., C‒O cleavage). Regarding the C‒O cleavage reaction, it was observed that styrene oxide gradually accumulated in the initial stage and reached its peak after 8 h, then gradually decreased until it was depleted after 20 h. At the same time, trace amounts of acetophenone and 1-phenylethanol were observed and then disappeared in the end; in response, ethylbenzene was detected after 12 h, and the yield gradually increased to 12.8% at 20 h.

Based on these experiments, two possible reaction pathways were proposed (Fig. 1). Pathway-I (i.e., C‒C bond cleavage) proceeds via hydrogenolysis of 2-phenoxy-1-phenylethanol (1a) to give benzyl alcohol and anisole, followed by hydrogenation to yield toluene and phenol, respectively. This C‒C bond cleavage pathway is different from the reported retro-aldol condensation pathway49, or by oxidative procedures and radical pathways20,60. For pathway II, styrene oxide and phenol are first obtained via C‒O bond cleavage. Then, styrene oxide undergoes a continuous hydrogenation process and is sequentially converted into acetophenone, 1-phenylethanol, and finally ethylbenzene. Another possible pathway involves direct hydrogenation of the ‒OH group of 2-phenoxy-1-phenylethanol (1a) to generate 2-phenylethyl phenyl ether according to literature24,61, while this pathway hardly occurred in the present catalytic system since no 2-phenylethyl phenyl ether was detected during the reaction process.

Subsequently, a series of control experiments using the intermediates detected in the reactions as substrates were performed to further identify the proposed reaction pathways (Fig. 4c–f). Under the same conditions, the conversion rate of benzyl alcohol to toluene is significantly higher than that of 1-phenylethanol hydrogenation to ethylbenzene (Fig. 4c, d). The time-course profile of the hydrogenation of styrene oxide indicates that within the initial 2 h, the conversion is only 3.0% with acetophenone as the sole product (Fig. 4e), implying that acetophenone is the primary product of styrene oxide hydrogenation. Then, 1-phenylethanol is detected in the system as the further hydrogenated product of acetophenone. After 6 h of reaction, only 2% yield of ethylbenzene is detected in the system. It is clearly seen that the hydrogenation rate of styrene oxide is also much slower than that of benzyl alcohol hydrogenation. Finally, we investigated the hydrogenation of anisole, i.e., the other product of the C‒C bond cleavage reaction of 2-phenoxy-1-phenylethanol (Fig. 4f), which exhibits a faster hydrogenation rate as compared to the conversion of benzyl alcohol.

Given the above experimental results, the essential reasons for the dominate C‒C bond cleavage in β-O-4 hydrogenolysis have also been confirmed. Over Cu/Ni-SA@HNC, the initial products of C‒C bond cleavage are benzyl alcohol and anisole, and the corresponding final products are toluene and phenol, respectively. In the path of C‒O bond cleavage, styrene oxide and phenol are the initial products. Notably, although both benzyl alcohol and anisole require only one-step hydrogenation to obtain the final products, the conversion rate of anisole is significantly faster than that of benzyl alcohol, indicating that anisole will be depleted faster in the system. However, for the C‒O bond cleavage pathway, only styrene oxide still needs to undergo subsequent hydrogenation (which is a relatively slow reaction process) and requires three steps to obtain the final product of ethylbenzene. As is well known, this is unfavorable in terms of reaction equilibrium. In addition, control experiments have also confirmed that the hydrogenation rate of styrene oxide is much slower than that of benzyl alcohol.

Finally, the hydrogenolysis reaction of 2-phenoxy-1-phenylethanol (1a) into toluene was further conducted in a continuous flow reactor (Fig. 4g). For stability examination, the reaction was carried out at a 75.5% conversion (average value) with 68.3% toluene yield (average value). After 100 h of reaction, the catalytic activity of Cu/Ni-SA@HNC remained almost unchanged, furnishing a space-time yield (STY) up to 33.7 g gcat−1 h−1, and the turnover number (TON) attained 2241.5. Furthermore, the recycling stability of Cu/Ni-SA@HNC was also investigated in batch reactions within 4 h (Supplementary Fig. 22). Characterization results of the used catalyst after 20 cycles (Supplementary Fig. 23) revealed its high stability, which was also demonstrated by hot filtration test (Supplementary Fig. 24).

Catalytic hydrogenolysis of poplar lignin

The excellent activity and stability of Cu/Ni-SA@HNC in the conversion of lignin model dimers provoked us to evaluate the catalytic performance of the catalyst in the conversion of the realistic lignin extracted from poplar wood sawdust by an in-situ generated NH3-reline system62 (for detailed extraction process, Supplementary Methods). This lignin feedstock exhibits native lignin substructure with high molecular weight and high β-O-4 content62, as demonstrated by the thioacidolysis results. After reaction, the used catalyst can be easily separated from the oily products through centrifugation, the obtained catalyst was in an almost same amount as the fresh one. Thermogravimetric analysis (TG) analysis of the used catalyst (Supplementary Fig. 25) showed a highly similar weight loss tendency to that of the fresh one. Besides, the used catalyst was also characterized by SEM, TEM, and AC HAADF-STEM, and results (Supplementary Fig. 26) implied its high stability. These results indicated the lignin had been completely converted to liquid and gas products. It should be noted that little gas products, including CO, CH4, CO2, C2H4, C3H8, C3H6, C5H12 were also identified by GC-TCD, as shown in Supplementary Fig. 27. Nine parallel experiments were conducted and the liquid mixture was identified by GC-FID (for details, see Supplementary Figs. 28–37). The results show that 51.6 ± 2.7 mg toluene (nine parallel experiments results) as the dominant monomer product, along with small amounts of ethylbenzene, phenol, 4-ethylguaiacol, 4-propylguaiacol, 1,2-diphenylethane and 4-propylbiphenyl were formed. To the best of our knowledge, in the limited literatures for the conversion of lignin into targeted compounds, the yield of single aromatic product is hard to surpass 20%2,20,21. It is thus very interesting that an extraordinary super selectivity of toluene in monomer products was obtained to give the yield up to 33.7 ± 1.6 wt% (nine parallel experiments results). Optical photos of the poplar lignin, fresh and recycled Cu/Ni-SA@HNC, obtained liquid phase and oily products were shown in Supplementary Fig. 38.

It should be noted that poplar lignin composes both syringyl (S) and guaiacyl (G) units in structure, however, almost no S monomer was identified in the reaction mixture, indicating that demethoxylation and/or other reactions should be occurred primarily on S units during the depolymerization process.

In order to look insight into the structural evolution during lignin depolymerization, the lignin and the oily product were measured by 2-dimensional heteronuclear single quantum coherence–nuclear magnetic resonance (2D HSQC-NMR) spectroscopy. As shown in Fig. 5a, the lignin feedstock has a high content of β-O-4 aryl ether linkages (up to 51.3/100 Ar for structure A), with 4.7/100 Ar of β-β linkages (structure B) and 1.0/100 Ar of β-5 linkages (structure C). After reaction, almost all the volatile arene products, i.e., toluene, ethylbenzene have been evaporated before analysis, and the remaining components are analyzed by HSQC NMR. It was found that almost all the signals representing A, B and C structures were disappeared (Fig. 5b), suggesting that the major β-O-4, β-β, β-5 linkages were effectively cleaved, showcasing the high efficiency of Cu/Ni-SA@HNC in the cleavage of both C‒O and stubborn C‒C bonds in lignin, so that high yield of liquid oil products was obtained.

As for the aromatic region of lignin (Fig. 5c), cross-signals related to S-type units were more intense than those associated with G-type units, and the ratio of S/G was around 1.31; in addition, noncanonical subunit p-hydroxybenzoate (PB) units were observed with the amount of 16.7/100 Ar. After reaction, the signals of G-type units were still very strong in lignin oil products, whereas the signal of S-type units was significantly reduced, as a result, the ratio of S/G was greatly decreased to 0.003 (Fig. 5d). These results agree with GC-FID analysis of the liquid products, further confirm that demethoxylation of S-type units should have occurred during the depolymerization process. These results evidently showed the high activity and stability of Cu/Ni-SA@HNC for the catalytic cleavage of C‒C and C‒O bonds not only in lignin dimer model compounds, but also in the real lignin feedstock.

Recent advances in catalytic lignin C‒C bond cleavage have expanded the toolkit for lignin valorization. A notable contribution by Palumbo et al. demonstrated a pioneering Mn/Zr-catalyzed autoxidation system for cleaving C‒C bonds within reductive catalytic fractionation-derived lignin oligomers63. This oxidative approach utilizes O2-driven pathways to generate aromatic carboxylic acids, which subsequently undergo biological upgrading to cis,cis-muconic acid. While this method excels in deconstructing pre-fractionated lignin substrates devoid of labile C–O linkages. Our work establishes a mechanistically distinct and complementary reductive paradigm. By employing a Cu/Ni dual-single-atom catalyst (Cu/Ni-SA@HNC) under H2 atmosphere, we achieve direct depolymerization of native poplar lignin (which contains coexisting C–O and C–C bonds) without preprocessing. The key mechanistic divergence lies in the ability of Cu/Ni sites to drive selective hydrogenolysis via an unusual “preferential Cα–Cβ bond cleavage in β-O-4 linkages” pathway, ultimately affording toluene as a dominant deoxygenated product, which is a sharp contrast to the oxygenated carboxylic acids produced via autoxidation. Critically, our strategy directly delivers a bulk petrochemical-ready product from poplar lignin, circumventing downstream biological conversion requirements. Furthermore, the process operates under non-corrosive conditions using non-noble heterogeneous catalysts, offering a scalable alternative to oxidative methods reliant on acidic media. Collectively, the Cu/Ni-SA@HNC enables a complementary route to lignin valorization, particularly valuable for direct lignin-to-chemicals applications targeting deoxygenated aromatics.

Mechanism investigation of hydrogenolysis reaction

The electronic properties, H2 adsorption-activation-disassociation patterns, and hydrogenolysis energy barriers over Cu/Ni-SA@HNC were also investigated by DFT calculations (Supplementary Fig. 39). The projected density-of-states (pDOS) plot of Cu/Ni-SA@HNC (Fig. 6a–c) demonstrates distinct contributions from the 3 d orbitals of Cu and Ni near the Fermi level. Notably, Cu exhibits a larger density of states compared to Ni in this critical energy region, suggesting its dominant role in electronic interactions. Spatial charge redistribution was visualized through differential charge density plots (Fig. 6d, Supplementary Fig. 40). These reveal asymmetric electron accumulation at Cu sites and electron depletion at Ni centers, creating complementary electronic environments. Comparative analysis between Cu/Ni-SA@HNC and its monometallic counterparts (Cu-SA@HNC and Ni-SA@HNC) confirms unique charge redistribution patterns in the bimetallic system, directly evidencing Cu–Ni electronic synergy. Moreover, quantitative charge partitioning (Supplementary Fig. 40) reveals that Cu and Ni single-atoms in Cu/Ni-SA@HNC carry reduced charges (0.786 |e| and 0.800 |e|, respectively) compared to their monometallic counterparts (0.818 |e| for Cu in Cu-SA@HNC and 0.810 |e| for Ni in Ni-SA@HNC). Conversely, the CuN4 and NiN4 moieties exhibit increased charges (−0.496 |e| and −0.337 |e| in Cu/Ni-SA@HNC vs. −0.590 |e| in Cu-SA@HNC and −0.662 |e| in Ni-SA@HNC), confirming bidirectional electron transfer between the metal centers and their coordination environments.

a–c Project density of states (pDOS). d Top view of the differential charge densities. Yellow and cyan isosurfaces with an isosurface level of 0.006 e/a03 and 0.006 e/a03 represent electron accumulation and depletion areas, respectively. e CI-NEB results of H2 disassociation. f Perspective view of the differential charge densities for H2 adsorption on Cu/Ni-SA@HNC; yellow and cyan isosurfaces with an isosurface level of 0.0003 e/a03 represent electron accumulation and depletion areas, respectively. Perspective view of the atomistic structures (R0-R4) of the initial, transition, and final states for the H2 molecular adsorption, activation, and disassociation over Cu/Ni-SA@HNC. The brown, bright silver, blue, purple, and pink balls represent C, N, Cu, Ni, and H atoms, respectively. g The free energy diagram for the hydrogenolysis of the 2-phenoxy-1-phenylethanol.

The most stable adsorption configuration of H2 on Cu/Ni-SA@HNC shows that H2 tends to be physically adsorbed by Cu atom with an exothermic adsorption energy of 0.07 eV. The projected density of states (pDOS) plots (Supplementary Fig. 41) reveals that the DOS of H2 is barely interacting with 3 d orbital of Cu/Ni, while a small amount of electron redistribution is observed in the differential charge densities (Supplementary Fig. 42), suggesting partial electrons accumulated between H2 and Cu center. Moreover, Bader charge analysis (Supplementary Fig. 42) unambiguously demonstrates the electronic evolution during adsorption, Cu and Ni atoms carry charges of 0.786 |e| and 0.800 |e| prior to H2 adsorption, which shift to 0.832 |e| and 0.796 |e| after H2 adsorption, respectively. The Bader charge of the adsorbed H2 molecule is –0.074 |e|, indicating slight electronic activation. The H2 splitting energy is calculated to be 0.43 eV, with the transition state analysis revealing an activation energy of 1.13 eV for the splitting process (Figs. 5f, 6e, Supplementary Fig. 43), which is substantially lower than those of the monometallic counterparts (1.87 eV for Cu-SA@HNC and 2.48 eV for Ni-SA@HNC). Given that the real poplar lignin depolymerization occurs under H2 atmosphere, these finding directly corroborate the critical role of hydrogen activation in enhancing reaction selectivity and efficiency.

Further investigations of β-O-4 adsorption configurations (Supplementary Fig. 44) and the corresponding adsorption and dissociation energies (Supplementary Tables 5, 6) demonstrate superior performance of the bimetallic system. Cu/Ni-SA@HNC exhibits the strongest adsorption energy (−536.5 eV), significantly lower than Cu-SA@HNC (−327.4 eV) and Ni-SA@HNC (−216.4 eV). Notably, 2-phenoxy-1-phenylethanol adsorbs on Cu/Ni-SA@HNC through dual anchoring, i.e., the ether oxygen (‒O‒) binds to the Cu atom while the hydroxyl (‒OH) interacts with a nitrogen site. In contrast, only single functional group (‒O‒ or ‒OH) interaction occurs in monometallic Cu-SA@HNC and Ni-SA@HNC. Moreover, Cu/Ni-SA@HNC achieves the lowest C‒C bond dissociation energy (239.2 eV) in β-O-4 cleavage, outperforming both Cu-SA@HNC (257.3 eV) and Ni-SA@HNC (258.2 eV).

Furthermore, we investigated the underlying thermodynamic and kinetic reasons for the preference of C–C cleavage over C–O cleavage on Cu/Ni-SA@HNC (Supplementary Fig. 45). Thermodynamic analysis revealed that cleavage of both the C–C and C–O bonds in the lignin β-O-4 model compound is endothermic, although C–O bond cleavage is thermodynamically more favorable (1.87 eV vs. 1.96 eV for C–C cleavage). However, transition state (TS) calculations showed a lower kinetic barrier for C–C bond cleavage (2.44 eV) as compared to C–O bond cleavage (2.81 eV). Each TS has only one imaginary frequency (beyond the three corresponding to translational modes). The vibrational mode associated with this imaginary frequency corresponds to C–C bond cleavage in TS-C–C (Supplementary Movie 1) and C–O bond cleavage in TS-C–O (Supplementary Movie 2), validating the reliability of the TS. Combining the thermodynamic and kinetic analyses, we believe that the cleavage processes are kinetically controlled, which result in the kinetic preference for C–C bond cleavage.

Next, the free energy diagram of the hydrogenolysis reaction of 2-phenoxy-1-phenylethanol (1a) was calculated (Fig. 6g, Supplementary Fig. 46). According to the results, 1a was easily transformed to toluene through C‒C bond cleavage via an exothermic pathway. The small energy change was attributed to the incorporation of spilt hydrogen molecules to form benzyl alcohol (H). Similar trend was also detected for the formation of ethylbenzene. But the endothermic generation of styrene oxide intermediate and the long pathway remarkably increased the difficulty. These results implied the high intrinsic reactivity of Cu/Ni-SA@HNC in C‒C cleavage to form toluene. DFT calculation was also carried out to get insights for the 1-phenylethanol hydrogenation or hydrogenolysis reaction (Supplementary Fig. 47), which indicated that the hydrogenation of 1-phenylethanol to ethylbenzene is thermodynamically easier to achieve than the hydrogenolysis of 1-phenylethanol to toluene.

Discussion

In conclusion, we have developed a novel methodology to achieve hydrogenolysis of both C‒O and C‒C bonds of lignin model compounds and real lignin over an elaborate Cu/Ni-SA@HNC catalyst in a “preferential Cα–Cβ bond cleavage in β-O-4 linkages” style. Complete depolymerization of poplar (hardwood) lignin gave toluene in yield up to 33.7 ± 1.6 wt% (nine parallel experiments) via the cleavage of major linkages of β-O-4, β-β and β-5. Control experiments and DFT calculations uncover the intermediates and reaction pathway from lignin β-O-4 segments to toluene. The Cu/Ni-SA@HNC catalyst exhibited high stability not only in model reactions, but also in the depolymerization of real lignin. This work conquers the major challenges in lignin depolymerization, i.e., selective scission of lignin complex structure and efficient cleavage of stubborn C‒C bonds, demonstrates the application prospective of DASCs in the selective valorization of biomass complex polymers, which might provide inspiration to the selective refining of other polymers, e.g., waste plastics, over atomically dispersed catalysts.

Methods

Chemicals

All chemicals were purchased from commercial sources and directly used without further purification. 2-Methylimidazole (2-MI, 98%, Aladdin), cetyltrimethylammonium bromide (CTAB, 99%, Aladdin), ammonium chloride (NH4Cl, 99.8%, Aladdin), zinc acetate dihydrate (Zn(OAc)2·2H2O, 99.99%, Aladdin), copper acetate monohydrate (Cu(OAc)2·H2O, 99%, Aladdin), nickel acetate tetrahydrate (Ni(OAc)2·4H2O, 99%, Aladdin), tannic acid (TA, 95%, J&K scientific), 2-phenoxy-1-phenylethanol (98.0%, Aladdin), benzyl phenyl ether (98.0%, Aladdin), 1,4-dioxane (99.0%, Aladdin).

Synthesis of Cu/Ni-ZIF, Cu-ZIF, Ni-ZIF

In a typical synthesis, 2-MI (13.6 mmol) and cetyltrimethylammonium bromide (CTAB, 0.8 mg) were dissolved in 5 mL deionized water. Then, 5 mL of aqueous solution containing Cu(OAc)2·H2O (0.075 mmol), Ni(OAc)2·4H2O (0.096 mmol), Zn(OAc)2·2H2O (1.36 mmol), and NH4Cl (20 mg) was added. After stirring for 1 min at room temperature, the mixed solution was aged for 150 min. The resulting Cu/Ni-ZIF was collected by centrifugation and washing with methanol for three times.

Cu-ZIF and Ni-ZIF were synthesized by using the same recipe without the addition of Ni(OAc)2·4H2O or Cu(OAc)2·H2O.

Synthesis of Cu/Ni-ZIF-TA

Typically, the as-synthesized Cu/Ni-ZIF (0.15 g) was dispersed into 130 mL of aqueous solution containing 0.65 g TA. The mixture was stirred for 10 min, followed by washing with ethanol and drying at 50 °C to obtain Cu/Ni-ZIF-TA.

Synthesis of Cu/Ni-SA@HNC, Cu-SA@HNC, Ni-SA@HNC

Typically, the as-synthesized Cu/Ni-ZIF-TA was placed in a tubular furnace and heated to 900 °C using a ramp rate of 5 °C min–1 and kept for 180 min under Ar atmosphere to obtain Cu/Ni-SA@HNC.

Cu-SA@HNC and Ni-SA@HNC were synthesized by the same recipe except for using Cu-ZIF-TA and Ni-ZIF-TA.

Synthesis of Cu/Ni-NP@HNC

In a typical synthesis, the dosage of Cu(OAc)2·H2O and Ni(OAc)2·4H2O for Cu/Ni-ZIF synthesis was expanded to 0.38 mmol and 0.48 mmol, respectively, followed by TA etching. After the similar pyrolysis procedure, Cu/Ni-NP@HNC was obtained.

Synthesis of Cu/Ni-SA@NC

Typically, the as-synthesized Cu/Ni-ZIF was directly placed in a tubular furnace and heated to 900 °C using a ramp rate of 5 °C min–1 and kept for 180 min under Ar atmosphere to obtain Cu/Ni-SA@NC.

Materials characterization

The size and morphology of materials were studied by SEM and TEM. SEM was carried out on a JEOL-6700 instrument. TEM, and high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) were recorded on an FEI Titan Cubed Themis G2 300 S/TEM with a probe corrector and a monochromator at 200 kV. Powder X-ray diffraction patterns of the samples were obtained on a Rigaku diffractometer (D/max-IIIA, 3 kW) with Cu Kα radiation (λ = 1.5406 Å) at a voltage of 40 kV and a current of 10 mA at room temperature. Raman spectra were recorded on a LabRAM ARAMIS Raman spectrometer (HORIBA Jobin Yvon). Brunauer-Emmett-Teller surface area and pore size measurements were performed on a Micromeritics ASAP 2020 M instrument at 77 K. Before the analysis, the samples were degassed at 150 °C for 12 h. XPS was collected on a Thermo Scientific K-Alpha system with the C 1 s peak (284.6 eV) as reference. The metal contents of the samples were determined by ICP-OES on an Optima 8300 instrument. The N elemental contents of the samples were measured on a Euro Vector EA3000 instrument. TG was performed on a NETZSCH STA449C instrument loaded with 5 mg sample using a heating rate of 5 °C/min under argon atmosphere.

The X-ray absorption spectra including XANES and EXAFS of the samples at Cu and Ni K-edge were collected at the Singapore Synchrotron Light Source center, where a pair of channel-cut Si (111) crystals was used in the monochromator. The acquired EXAFS data were extracted and processed according to the standard procedures using the ATHENA module implemented in the IFEFFIT software packages.

Calculation details

Spin-polarized density functional theory (DFT) calculations were performed with the Vienna ab initio simulation package, using projector augmented wave pseudopotential for the core electrons, a cutoff energy of 450 eV for the valence electrons, and the generalized gradient approximation in the form of Perdew‒Burke‒Ernzerhof for the exchange correlation potentials. All models were constructed based on a rectangle graphene supercell with lattice constants a and b as 21.30 and 14.76 Å, containing 120 carbon atoms. To avoid interactions between adjacent images the c axis of these models is set to be 15 Å. The atoms were relaxed fully until the energy convergence reached 0.00001 eV and the force acting on each atom was less than 0.02 eV/Å. The lattice constants of all models are relaxed, as well. Van der Waals interaction was considered at the DFT-D2 level as proposed by Grimme (IVDW = 12). The transition state was searched using the climbing image nudged elastic band (CI-NEB) algorithm.

All quantum chemical calculations, including geometry optimizations and frequency calculations, were performed at the B3LYP/6-31G* level for C, H, O, N and Lanl2dz for Cu and Ni with the D3 version of Grimme’s dispersion with Becke-Johnson damping in the quantum chemical package Gaussian 09. The adsorption energy (ΔE) was calculated as:

where the Etotal is the energy of the optimized system, i.e., β-O-4 adsorbed on the Cu/Ni-SA@HNC, Cu-SA@HNC, and Ni-SA@HNC models, respectively, E1 is the energy of Cu/Ni-SA@HNC, Cu-SA@HNC, and Ni-SA@HNC models; E2 is the energy of β-O-4.

The dissociation energy (ΔE) was calculated as:

where the Htotal is the enthalpy of β-O-4.

Hydrogenolysis of the lignin β-O-4 model compound in batch reactor

In a typical run, the reactant 2-phenoxy-1-phenylethanol (0.5 mmol), catalyst (2.05 mol%, i.e., 0.02 g with a total amount of metals at ca. 0.01025 mmol), and 1,4-dioxane (4 mL) were sealed in a high-pressure reactor (NSG25-P5-T3-SS1-SV, Anhui Kemi Machinery Technology Co., Ltd). The reactor was evacuated, refilled with 0.5 MPa H2, and heated at 180 °C for 12 h under magnetic stirring. After reaction, the reactor was cooled to room temperature. The catalyst was isolated by centrifugation and directly reused after washing and drying. The product was identified by a GC-MS spectrometer (Agilent, 7890B GC/5977A MS) equipped with a DB-35 MS UI capillary column (0.25 mm × 30 m), and quantified by a GC-FID spectrometer (Agilent 7890B GC, equipped with a flame ionization detector and DB-1701 capillary column (0.25 μm × 0.32 mm × 30 m)), for details, see Supplementary Methods in the Supplementary Information.

Hydrogenolysis of the lignin β-O-4 model compound in continuous flow reactor

Before reaction, Cu/Ni-SA@HNC (0.3 g) was pelletized, crushed, and sieved into particles in sizes of 20–30 mesh. The flowing phase formulated with 2-phenoxy-1-phenylethanol and 1,4-dioxane (0.05 g(2-phenoxy-1-phenylethanol)/mL(1,4-dioxane)) was injected into the reactor with a contacting time of 16 min at 200 °C. The flow rate of the flowing phase was set to 0.36 mL/min. The flow rate of H2 was set to be 40 mL min−1 (STP) while maintaining the reaction pressure at 4 MPa. The space time yield (STY) was calculated using the following equation:

The TON of the catalytic active sites calculated using the following equations:

Hydrogenolysis of the poplar lignin in batch reactor

In a typical run, the reactant poplar lignin (0.15 g), catalyst (15 wt%, i.e., 0.07 g with a total amount of metals at ca. 0.01025 mmol), and 1,4-dioxane (8 mL) were sealed in a high-pressure reactor (NSG25-P5-T3-SS1-SV, Anhui Kemi Machinery Technology Co., Ltd). The reactor was evacuated, refilled with 0.5 MPa H2, and heated at 280 °C for 12 h under magnetic stirring. After reaction, the reactor was cooled to room temperature. The product identification details were shown in Supplementary Methods in the Supplementary Information. Nine sets of parallel experimental data were provided for this reaction.

Data availability

The experimental data generated in this study are provided in the Supplementary Information file.

References

Shuai, L. et al. Formaldehyde stabilization facilitates lignin monomer production during biomass depolymerization. Science 354, 329–333 (2016).

Liao, Y. et al. A sustainable wood biorefinery for low-carbon footprint chemicals production. Science 367, 1385–1390 (2020).

Zhu, J., Wang, J. & Dong, G. Catalytic activation of unstrained C(aryl)-C(aryl) bonds in 2,2′-biphenols. Nat. Chem. 11, 45–51 (2019).

Li, C., Zhao, X., Wang, A., Huber, G. W. & Zhang, T. Catalytic transformation of lignin for the production of chemicals and fuels. Chem. Rev. 115, 11559–11624 (2015).

Ragauskas, A. J. et al. Lignin valorization: improving lignin processing in the biorefinery. Science 344, 1246843 (2014).

Wang, S., Shen, Q., Su, S., Lin, J. & Song, G. The temptation from homogeneous linear catechyl lignin. Trends Chem. 4, 10 (2022).

Karlen, S. D. et al. Monolignol ferulate conjugates are naturally incorporated into plant lignins. Sci. Adv. 2, e1600393 (2016).

Sergeev, A. G. & Hartwig, J. F. Selective, nickel-catalyzed hydrogenolysis of aryl ethers. Science 332, 439–443 (2011).

Xie, J. et al. Hydrogenolysis of lignin model compounds on Ni nanoparticles surrounding the oxygen vacancy of CeO2. ACS Catal. 13, 9577–9587 (2023).

Ding, Y. et al. Transition-metal-free synthesis of functionalized quinolines by direct conversion of β-O-4 model compounds. Angew. Chem. Int. Ed. 61, e202206284 (2022).

Guadix-Montero, S. & Sankar, M. Review on catalytic cleavage of C–C inter-unit linkages in lignin model compounds: towards lignin depolymerisation. Top. Catal. 61, 183–198 (2018).

Dong, L. et al. Breaking the limit of lignin monomer production via cleavage of interunit carbon‒carbon linkages. Chem 5, 1521–1536 (2019).

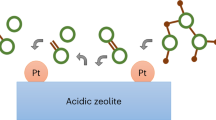

Meng, G. et al. Synergy of single atoms and lewis acid sites for efficient and selective lignin disassembly into monolignol derivatives. J. Am. Chem. Soc. 145, 12884–12893 (2023).

Li, H., Bunrit, A., Li, N. & Wang, F. Heteroatom-participated lignin cleavage to functionalized aromatics. Chem. Soc. Rev. 49, 3748–3763 (2020).

Bruijnincx, P. C. A. & Weckhuysen, B. M. Lignin up for break-down. Nat. Chem. 6, 1035–1036 (2014).

Rahimi, A., Azarpira, A., Kim, H., Ralph, J. & Stahl, S. S. Chemoselective metal-free aerobic alcohol oxidation in lignin. J. Am. Chem. Soc. 135, 6415–6418 (2013).

Nichols, J. M., Bishop, L. M., Bergman, R. G. & Ellman, J. A. Catalytic C‒O bond cleavage of 2-aryloxy-1-arylethanols and its application to the depolymerization of lignin-related polymers. J. Am. Chem. Soc. 132, 12554–12555 (2010).

Rahimi, A., Ulbrich, A., Coon, J. J. & Stahl, S. S. Formic-acid-induced depolymerization of oxidized lignin to aromatics. Nature 515, 249–252 (2014).

Zeng, H., Cao, D., Qiu, Z. & Li, C.-J. Palladium-catalyzed formal cross-coupling of diaryl ethers with amines: slicing the 4-O-5 linkage in lignin model. Angew. Chem. Int. Ed. 57, 3752–3757 (2018).

Subbotina, E. et al. Oxidative cleavage of C‒C bonds in lignin. Nat. Chem. 13, 1118–1125 (2021).

Meng, Q. et al. Sustainable production of benzene from lignin. Nat. Commun. 12, 4534 (2021).

Stein, T. et al. Ruthenium-catalyzed C–C bond cleavage in lignin model substrates. Angew. Chem. Int. Ed. 54, 5859–5863 (2015).

Luo, Z. et al. Carbon–carbon bond cleavage for a lignin refinery. Nat. Chem. Eng. 1, 61–72 (2024).

Yan, J. et al. Selective valorization of lignin to phenol by direct transformation of Csp2–Csp3 and C–O bonds. Sci. Adv. 6, eabd1951 (2020).

Sudarsanam, P., Peeters, E., Makshina, E. V., Parvulescu, V. I. & Sels, B. F. Advances in porous and nanoscale catalysts for viable biomass conversion. Chem. Soc. Rev. 48, 2366–2421 (2019).

Lan, W., de Bueren, J. B. & Luterbacher, J. S. Highly selective oxidation and depolymerization of α,γ-diol-protected lignin. Angew. Chem. Int. Ed. 58, 2649–2654 (2019).

Sun, Z., Fridrich, B., de Santi, A., Elangovan, S. & Barta, K. Bright side of lignin depolymerization: toward new platform chemicals. Chem. Rev. 118, 614–678 (2018).

Wang, S., Zhang, K., Li, H., Xiao, L. & Song, G. Selective hydrogenolysis of catechyl lignin into propenylcatechol over an atomically dispersed ruthenium catalyst. Nat. Commun. 12, 416 (2021).

Shen, X. et al. Selective catalytic transformation of lignin with guaiacol as the only liquid product. Chem. Sci. 11, 1347–1352 (2020).

Cai, Z. et al. Production of diethyl maleate via oxidative cleavage of lignin aromatic unit. Chem 5, 2365–2377 (2019).

Qiao, B. et al. Single-atom catalysis of CO oxidation using Pt1/FeOx. Nat. Chem. 3, 634–641 (2011).

Yang, X.-F. et al. Single-atom catalysts: a new frontier in heterogeneous catalysis. Acc. Chem. Res. 46, 1740–1748 (2013).

Wang, A., Li, J. & Zhang, T. Heterogeneous single-atom catalysis. Nat. Rev. Chem. 2, 65–81 (2018).

Tang, H.-T. et al. Single-atom manganese-catalyzed oxygen evolution drives the electrochemical oxidation of silane to silanol. Angew. Chem. Int. Ed. 63, e202315032 (2024).

Rao, Z. et al. Light-reinforced key intermediate for anticoking to boost highly durable methane dry reforming over single atom Ni active sites on CeO2. J. Am. Chem. Soc. 145, 24625–24635 (2023).

Chen, X. et al. Structure-dependence and metal-dependence on atomically dispersed Ir catalysts for efficient n-butane dehydrogenation. Nat. Commun. 14, 2588 (2023).

He, X. et al. Building up libraries and production line for single atom catalysts with precursor-atomization strategy. Nat. Commun. 13, 5721 (2022).

Gu, J. et al. Synergizing metal–support interactions and spatial confinement boosts dynamics of atomic nickel for hydrogenations. Nat. Nanotechnol. 16, 1141–1149 (2021).

Zhao, Y. et al. Simultaneous oxidative and reductive reactions in one system by atomic design. Nat. Catal. 4, 134–143 (2021).

Li, T. et al. Constructing single-atom Ni on N-doped carbon via chelation-anchored strategy for the hydrogenolysis of lignin. AIChE J. 69, e17877 (2023).

Hai, X. et al. Geminal-atom catalysis for cross-coupling. Nature 622, 754–760 (2023).

Jiao, L. et al. Non-bonding interaction of neighboring Fe and Ni single-atom pairs on MOF-derived N-doped carbon for enhanced CO2 electroreduction. J. Am. Chem. Soc. 143, 19417–19424 (2021).

Li, J. et al. Self-adaptive dual-metal-site pairs in metal-organic frameworks for selective CO2 photoreduction to CH4. Nat. Catal. 4, 719–729 (2021).

Li, R. et al. Polystyrene waste thermochemical hydrogenation to ethylbenzene by a N-bridged Co, Ni dual-atom catalyst. J. Am. Chem. Soc. 145, 16218–16227 (2023).

Ma, X. et al. Modulating coordination environment of single-atom catalysts and their proximity to photosensitive units for boosting MOF photocatalysis. J. Am. Chem. Soc. 143, 12220–12229 (2021).

Sun, J. et al. MOF-derived Ru1Zr1/Co dual-atomic-site catalyst with promoted performance for Fischer–Tropsch synthesis. J. Am. Chem. Soc. 145, 7113–7122 (2023).

Huang, F. et al. Low-temperature acetylene semi-hydrogenation over the Pd1–Cu1 dual-atom catalyst. J. Am. Chem. Soc. 144, 18485–18493 (2022).

Zhang, S. et al. Atomically dispersed bimetallic Fe–Co electrocatalysts for green production of ammonia. Nat. Sustain. 6, 169–179 (2023).

Zhao, X., Fang, R., Wang, F., Kong, X. & Li, Y. Atomic design of dual-metal hetero-single-atoms for high-efficiency synthesis of natural flavones. Nat. Commun. 13, 7873 (2022).

Zhang, B. et al. Transition-metal-free synthesis of pyrimidines from lignin β-O-4 segments via a one-pot multicomponent reaction. Nat. Commun. 13, 3365 (2022).

Fan, C., Lv, X.-Y., Xiao, L.-J., Xie, J.-H. & Zhou, Q.-L. Alkenyl exchange of allylamines via nickel(0)-catalyzed C–C bond cleavage. J. Am. Chem. Soc. 141, 2889–2893 (2019).

Qiu, X. et al. Cleaving arene rings for acyclic alkenylnitrile synthesis. Nature 597, 64–69 (2021).

Wang, H. et al. Quasi Pd1Ni single-atom surface alloy catalyst enables hydrogenation of nitriles to secondary amines. Nat. Commun. 10, 4998 (2019).

Yang, T. et al. Coordination tailoring of Cu single sites on C3N4 realizes selective CO2 hydrogenation at low temperature. Nat. Commun. 12, 6022 (2021).

Ye, T.-N. et al. Copper-based intermetallic electride catalyst for chemoselective hydrogenation reactions. J. Am. Chem. Soc. 139, 17089–17097 (2017).

Ma, J., Xing, F., Nakaya, Y., Shimizu, K. & Furukawa, S. Nickel-based high-entropy intermetallic as a highly active and selective catalyst for acetylene semihydrogenation. Angew. Chem. Int. Ed. 61, e202200889 (2022).

Shi, X. et al. Copper catalysts in semihydrogenation of acetylene: from single atoms to nanoparticles. ACS Catal. 10, 3495–3504 (2020).

Wang, P. et al. Highly efficient alloyed NiCu/Nb2O5 catalyst for the hydrodeoxygenation of biofuel precursors into liquid alkanes. Catal. Sci. Technol. 10, 4256–4263 (2020).

Zhao, R. et al. Puffing up energetic metal–organic frameworks to large carbon networks with hierarchical porosity and atomically dispersed metal sites. Angew. Chem. Int. Ed. 58, 1975–1979 (2019).

Hanson, S. K., Wu, R. & Silks, L. A. C–C or C–O bond cleavage in a phenolic lignin model compound: selectivity depends on vanadium catalyst. Angew. Chem. Int. Ed. 51, 3410–3413 (2012).

Zhou, M. et al. Catalytic hydrotreatment of β-O-4 ether in lignin: cleavage of the C–O bond and hydrodeoxygenation of lignin-derived phenols in one pot. ACS Sustain. Chem. Eng. 8, 14511–14523 (2020).

Lou, Y. et al. One-pot proto lignin extraction by targeted unlocking lignin–carbohydrate esters via nucleophilic addition–elimination strategy. Research 6, 0069 (2023).

Palumbo, C. T. et al. Catalytic carbon–carbon bond cleavage in lignin via manganese–zirconium-mediated autoxidation. Nat. Commun. 15, 862 (2024).

Acknowledgements

This work was supported by National Key R&D Program of China (2023YFA1507902, C.L.), the National Natural Science Foundation of China (21825802, Y.L.; 22138003, Y.L.; 22478135, R.F.; 22408109, X. Zhao), the China National Postdoctoral Program for Innovative Talents (BX20230131, X. Zhao), the China Postdoctoral Science Foundation (2023M741209, X. Zhao), the Natural Science Foundation of Guangdong Province (2023B1515040005, Y.L.), Guangdong Basic and Applied Basic Research Foundation (2025A1515011981, X. Zhao; 2023B1515020033, R.F.), Young Elite Scientists Sponsorship Program by CAST (2023QNRC001, R.F.), the Fundamental Research Funds for the Central Universities (2024ZYGXZR071, X. Zhao), the State Key Laboratory of Pulp and Paper Engineering (2024ZD09, R. Fang) and NSFC Center for Single-Atom Catalysis (22388102, T.Z.).

Author information

Authors and Affiliations

Contributions

T.Z., X.Z., C.L., R.F. and Y.L. developed the idea and designed experiments. X.Z. and R.F. performed the catalyst synthesis and most of the characterizations. X.Z. and Z.S. performed the electron microscopy characterization. J.W., Q.Q. and X.Z. performed most of the catalytic performance evaluation. Q.Q., C.L., F.Y., X. Zhou. and H.Y. performed the 2D-HSQC-NMR and discussed the results. Y.H. prepared poplar lignin. R.F., X.Z. and C.L. conducted and discussed the theoretical calculations. X.Z., C.L., Y.L. and R.F. co-wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Jinguang Hu, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, X., Li, C., Wen, J. et al. Catalytic refining lignin into toluene over atomically dispersed Cu/Ni dual sites. Nat Commun 16, 7967 (2025). https://doi.org/10.1038/s41467-025-63286-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-63286-5