Abstract

Acetone is a crucial chemical and solvent with extensive industrial applications, traditionally synthesized from propane through multi-step processes that demand high temperatures and pressures. Here, we report a selective one-step conversion of propane to acetone using a heterogeneous electro-Fenton process (h-EFP) under mild conditions. In this process, concentrated ·OH radicals are generated in an iron/carbon hybrid cathode via a two-electron oxygen reduction reaction followed by H2O2 conversion. Co-feeding propane and oxygen into such a cathode of an electrolyzer leads to the direct conversion of propane to acetone via isopropanol, with the acetone selectivity ranging from 50% to 80% depending on the current densities. Propane oxidation is unexpectedly accelerated at lower temperatures due to the enhanced ·OH generation. Optimal conditions are identified at 10 °C and 6.2 bar, near the propane liquefaction threshold. Furthermore, the automated separation of gaseous and liquid products at the cathode outlet enables straightforward purification of acetone to 96%. This work provides an alternative and sustainable approach to converting propane, offering a direct and efficient route for activating inert C–H bonds under mild conditions.

Similar content being viewed by others

Introduction

Acetone is a vital chemical and solvent with widespread applications across various industrial sectors, including the production of methyl methacrylate and paints1,2. The global acetone market is expected to reach approximately $20 billion by 20303. Currently, the primary methods for acetone synthesis are propane dehydrogenation and the cumene process (Fig. 1a)4. However, due to the chemical inertness of propane, its dehydrogenation to propylene requires high temperatures (500 °C)5,6, resulting in significant energy consumption and substantial carbon emissions. Moreover, the cumene process, which involves the reaction of propylene with benzene under high pressure (30 bar), necessitates a continuous supply of benzene and a complex industrial chain integration, making it less suitable for localized production7. As a result, traditional multi-step acetone synthesis methods are neither environmentally sustainable nor operationally efficient.

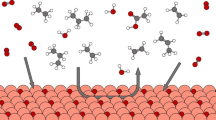

The direct oxidation of propane to acetone presents a more straightforward and potentially efficient pathway. However, achieving propane oxidation reactions (POR) under mild conditions, particularly below 100 °C, is challenging due to the high stability of the C-H bond, with a bond dissociation energy of approximately 100 kcal/mol8,9. Previous research has shown that reactive oxygen species, such as hydroxyl radicals (·OH, E0 = 2.7 V for ·OH/H2O) and singlet oxygen (1O2, E0 = 2.5 V for 1O2/O2⁻), can effectively activate C-H bonds10,11,12,13,14,15,16,17. More recent studies have investigated the use of chlorine radicals (·Cl, E0 = 2.4 V for ·Cl/Cl⁻) and hydrogen peroxide (H2O2, E0 = 1.8 V for H2O2/ H2O) to facilitate POR and produce acetone under ambient conditions18,19. These findings underscore the potential of leveraging strong oxidizing agents to overcome the inherent challenges of propane oxidation.

Electrochemical methods powered by renewable energy offer significant industrial potential20,21,22, with the electro-Fenton process (EFP) being particularly notable for its efficiency in generating highly reactive ·OH under mild conditions (Fig. 1b)23,24. The EFP operates through two key electroreduction reactions (O2/H2O2 and FeIII/FeII) followed by a subsequent chemical reaction (H2O2 + FeII → ·OH) (Supplementary Fig. 1). Traditionally, the EFP has been employed in wastewater treatment25,26, but recent studies have highlighted its potential for activating inert molecules such as CH4 and N227,28,29. Despite these advances, applying the conventional EFP to POR presents several challenges. Firstly, the low solubility of propane in aqueous electrolytes can significantly limit the reaction rate30. Secondly, homogeneous EFP systems that utilize FeIII-containing solutions often suffer from low H2O2 utilization and the formation of iron sludge31,32. More critically, the separation of POR products from the aqueous electrolyte poses a significant challenge33. Therefore, the successful implementation of POR via the EFP remains a formidable challenge.

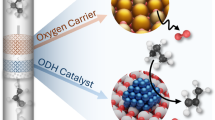

In this work, we present a significant advancement in the direct conversion of propane to acetone using a heterogeneous electro-Fenton process (h-EFP). By employing an electrode catalyst composed of an iron-based metal-organic framework (Fe-MOF) and activated carbon black, we achieve the efficient in situ generation of highly concentrated ·OH radicals, which effectively drive the POR (Fig. 1b). Furthermore, utilizing a membrane electrode assembly (MEA) configuration eliminates the need for aqueous electrolytes, thereby preventing product contamination. This setup also enables the liquefaction of propane within the electrode at low temperature and mild pressure, enhancing both the POR rate and the product selectivity. As a result, 96% pure acetone can be readily collected through a simple gas-washing process at the cathode outlet of the electrolyzer (Fig. 1b).

Results

Material basis of h-EFP

The Fe-MOF component of the cathode catalyst, MIL-100(Fe), was synthesized via a hydrothermal method, followed by heat treatment to enhance its catalytic activity34,35. X-ray powder diffraction patterns (Supplementary Fig. 2) of the synthesized material align with the simulated MIL-100(Fe) structure. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) analyses reveal that MIL-100(Fe) exhibits a micrometer-scale size with a uniform distribution of Fe, O, and C elements, as confirmed by energy-dispersive spectroscopy (EDS) element mapping (Fig. 2a). X-ray photoelectron spectroscopy (XPS) analysis (Fig. 2b) indicates the presence of both Fe(II) and Fe(III) valence states within the MIL-100(Fe) crystals36. Typical Fourier transform infrared spectrum and Raman spectrum of MIL-100(Fe) were also obtained (see detailed analysis in Supplementary Figs. 3a and 3b), consistent with those reported in the literature35,37. N2 sorption experiment was conducted to ascertain the porous nature of MIL-100(Fe) (Supplementary Figs. 3c and 3d). The Brunauer–Emmett–Teller specific surface area was determined to be 1120 m2g-1, and pore diameter distribution was below 2 nm. Given that the rate of ·OH generation depends on the efficiency of electron transfer from the Fe species38, we investigated the electron transfer properties of MIL-100(Fe) using cyclic voltammetry (CV) (Fig. 2c). The results demonstrate that the Fe species in MIL-100(Fe) exhibit relatively symmetric redox peaks with a narrower peak separation (0.44 V) compared to the aqueous 2.5 mM (for each) Fe3⁺/Fe2⁺ couple (1.07 V), indicating a faster electron transfer rate in MIL-100(Fe)39.

a TEM and SEM images of MIL-100(Fe). b Experimental and fitting results of the Fe 2p XPS spectrum for MIL-100(Fe). The baseline is subtracted. The inset is the illustration of MIL-100(Fe) structure. c Cyclic voltammetry curves of MIL-100(Fe) and 2.5 mM (for each) Fe3+/Fe2+ on glassy carbon electrode (GCE) in 0.05 M H2SO4 solution with 100 mV/s of potential scan rate without iR-correction. d TEM and SEM images of KB-a. e Experimental and fitting results of the C 1 s XPS spectrum for KB-a. The baseline is subtracted. The inset is the illustration of KB-a structure. f H2O2 faradaic efficiency, production rate and current density calculated from oxygen reduction tests conducted with KB-a coated GDE. The flow rate of O2 is 25 sccm. The error bars represent ±1 standard deviation calculated from triplicate independent experiments.

Another key component of the cathode catalyst was nitric acid-treated Ketjen black (KB-a). The acid treatment process has been reported to enhance the two-electron reduction of O2, thereby improving H2O2 production40. SEM and TEM images reveal that KB-a consists of stacked nanoparticles (Fig. 2d). EDS mapping shows a uniform distribution of oxygen (O) on the surface of KB-a (Fig. 2d). Deconvolution of the C 1 s spectrum (Fig. 2e) indicates the presence of functional groups such as -COO- and C-O, which are likely responsible for the catalytic activity in the two-electron reduction of O241,42. To evaluate H2O2 selectivity, we performed oxygen reduction tests using KB-a on a gas-diffusion electrode (GDE) in 0.05 M H2SO4 solution. The H2O2 selectivity (Fig. 2f) decreases gradually with a negative shift in potential, while the H2O2 production rate or current density initially increases before plateauing. At 0 V vs. RHE, the H2O2 yield reached up to 300 µmol cm–2 h–1.

Propane oxidation by h-EFP

To initiate the h-EFP, a GDE made of hydrophobic carbon paper was coated with the cathode catalyst. A series of control experiments were conducted in an H-cell (Fig. 3a) using various electrolyte solutions and cathode reactants. The first experiment aimed to confirm the generation of ·OH during oxygen reduction. For this, the radical trapping agent 5,5-dimethyl-1-pyrroline N-oxide (DMPO) was added to the electrolyte solution, and O2 gas was fed into the GDE. Electron paramagnetic resonance (EPR) was employed to detect the captured radical (DMPO-OH) post-experiment. As shown in Fig. 3b, no discernible signal was observed in the EPR spectra at 0.4 V vs. RHE. However, with a further negative shift in potential, a characteristic signal of the DMPO-OH adduct, with an intensity ratio of 1:2:2:1, appeared and gradually intensified, indicating potential-dependent generation of ·OH through the h-EFP43.

a Schematic illustration of the non-flow H-cell used for four experiments with different solutions and cathode reactants. The term “expt.” is an abbreviation for experiment. C3H8-o stands for different oxidation states of C3H8. b Electron paramagnetic resonance (EPR) spectra of the DMPO-containing electrolyte after the oxygen reduction test (expt. 1) at varying potential. c Production rate of POR through h-EFP under 25 sccm O2 and 25 sccm C3H8 at room pressure (expt. 2). The error bars represent ± 1 standard deviation calculated from triplicate independent experiments. d Production rate of POR with electrolyte containing 100 mM H2O2 under 25 sccm C3H8 (expt. 3). e Stepwise reaction analysis of POR at 0 V using different reactants (1 bar propane, 100 mM acetone and 100 mM i-PrOH) (expt. 4). The arc lengths in the diagram represent product selectivity. f The proposed mechanism of POR coupled with h-EFP. Red arrow: radical oxidation reaction; verdigris arrow: electrochemical reaction; gray arrow: ordinary chemical reaction.

The second experiment aimed to investigate the progress of the POR upon simultaneous feeding of 25 sccm O2 and 25 sccm C3H8 into the GDE at 30 °C and room pressure. By analyzing the products collected from the GDE outlet and the electrolyte, three major compounds—acetone, isopropanol (i-PrOH), and acetic acid (AcOH)—were identified using NMR (Supplementary Fig. 4; trace amounts of propionic acid and propanol were also detected). As the potential shifted negatively, the production rates exhibited a volcanic trend (Fig. 3c and Supplementary Fig. 5), mirroring the trend observed in H2O2 production (Supplementary Fig. 6). The highest production rate, 4.9 μmol cm-2 h-1, was observed at 0 V, with acetone accounting for 58% of the total product yield. The detail faradaic efficiencies were summarized in Supplementary Table 1. Post-test characterization (Supplementary Figs. 7) of the electrode by XRD, SEM, and Raman spectroscopy confirmed the structural stability of MIL-100(Fe) catalyst during the electrochemical process. Inductively coupled plasma optical emission spectrometry analysis (Supplementary Fig. 7 d) confirmed minimal Fe leaching into the electrolyte, with the majority of Fe remaining in the framework. To rigorously evaluate the role of leached iron species, we have conducted control experiments with 10 ppm Fe3+ or Fe2+ (simulating leaching levels) in the absence of MIL-100(Fe). The negligible POR activity (Supplementary Figs. 8a and 8b) confirms that leached Fe contributes minimally to the overall reactivity, validating the dominance of h-EFP in our system. As it has been reported that the oxidative capacity of ·OH is enhanced in acidic media44, we did find no propane oxidation products under neutral or alkaline conditions (Supplementary Figs. 8c and 8d). Similarly, in absence of MIL-100(Fe), no POR products were detected either, indicating the generation of ·OH through the h-EFP rather than ORR and H2O2 electroreduction (Supplementary Figs. 8e and 8f). POR rate was considerably reduced when only MIL-100(Fe) was present at the cathode without KB-a (Supplementary Figs. 8g and 8h), demonstrating that efficient H2O2 production matters.

Coupling mechanism of h-EFP and POR

In a normal Fenton process, Fe(II) regeneration relies on the reaction between Fe(III) and H2O2 (Eq. (1)), which suffers from a slow kinetic45. In contrast, the EFP enables rapid Fe(II) regeneration through the electrochemical reduction of Fe(III) (Eq. (2)), a key advantage that sustains efficient ·OH production (Eq. (3))45,46,47. To demonstrate the necessity of this cathodic process, we added 100 mM H2O2 to the electrolyte and compared POR performance under polarized conditions (enabling electrochemical Fe(II) regeneration, Eq.(2)) and open-circuit potential (OCP) (where Fe(II) regeneration depends solely on the sluggish H2O2-driven pathway, Eq.(1)). Based on the CV curve of MIL-100(Fe) (Fig. 2c), the reduction peak of Fe(III) to Fe(II) appears at 0.51 V, indicating that Fe(III) can be electrochemically reduced to Fe(II) at more negative potentials. As shown in Fig. 3d, the POR rates under polarization were significantly higher than at OCP. Notably, the POR rate at 0.2 V vs. RHE was more than 100 times greater than at OCP, indicating that the electrochemical regeneration of Fe(II) plays a critical role in enhancing both the EFP and the POR.

Although acetone was identified as the predominant product in the POR, it can be formed via the oxidation of i-PrOH rather than directly from propane, and it can also undergo further oxidation to AcOH. To achieve a more comprehensive understanding of the POR, we conducted stepwise reaction studies (expt. 4) where 100 mM i-PrOH or acetone was supplied to the h-EFP, respectively. When the electrode was held at 0 V, i-PrOH was primarily oxidized to acetone, with only a small amount of AcOH detected. Conversely, acetone was oxidized to AcOH and CO2 (Fig. 3e and Supplementary Fig. 9). These results indicate that the transformation between POR products is unidirectional, highlighting the importance of acetone’s escape from the cathode to prevent further oxidation to AcOH. Given acetone’s lowest vapor pressure among the three major POR products (Supplementary Fig. 10), this step is critical for achieving high acetone selectivity in the h-EFP.

Based on the above analyses, we propose a mechanism for the POR coupled with the h-EFP (Fig. 3f). Specifically, the highly reactive ·OH species generated from h-EFP facilitates sequential dehydrogenation and oxygenation, converting propane first to i-PrOH and subsequently to acetone. Any residual acetone within the electrode is further oxidized to form AcOH.

POR in electrolyzer

The H-cell requires the use of a liquid electrolyte (H2SO4 solution), which dilutes both the POR products and the in situ generated H2O2/·OH (Supplementary Fig. 11). This dilution increases the costs of product enrichment and limits the POR rate due to the reduced concentration of reactive oxygen species. To overcome these limitations, a polymer electrolyte membrane, typically Nafion, should be used in place of liquid electrolytes. In this work, we employed an electrolyzer with a MEA configuration (Fig. 4a), which demonstrated superior POR performance compared to the H-cell (Supplementary Fig. 12). The typical performance of the MEA electrolyzer is shown in Fig. 4b and Supplementary Fig. 13, and the detailed faradaic efficiencies were summarized in Supplementary Table 2. At an operating current density of 100 mA/cm2, the total POR rate reached 32 µmol cm-2 h-1, with acetone comprising over 50% of the products. Operating the electrolyzer at lower current densities further increased the acetone ratio to nearly 80%. This trend is consistent with the proposed reaction mechanism (Fig. 3f), where higher current densities generate more ·OH, enhancing the overall POR rate but also leading to increased oxidation of acetone to AcOH, as illustrated in Fig. 4b.

a Schematic illustration of the MEA electrolyzer for POR. b POR performance at various current densities. The partial pressure of propane and O2 were maintained at 1 bar each. c POR performance at 50 mA/cm2 with different propane pressure and cell temperature. The darkness of blue core represents the total production rate, and the brown circle indicates product ratio, with colors labeled in (b). The partial pressure of O2 was maintained at 1 bar under varying conditions. d Schematic illustration of the self-separation of gas and liquid products at cathode outlet. e Collecting efficiency, production rate and purity of gas products. The error bars represent ± 1 standard deviation calculated from triplicate independent experiments.

The MEA electrolyzer allows for greater flexibility in regulating operating temperature and gas pressure. We tested the MEA electrolyzer across a range of propane partial pressures (from 1 bar to nearly 7 bar), temperatures (10 °C to 70 °C) (Fig. 4c), and propane flow rates (Supplementary Table 4). The Faradaic efficiencies of electrolyzers are presented in Supplementary Fig. 14 and summarized in Supplementary Table 3. An increase in propane partial pressure from 1 bar to 5 bar resulted in an accelerated POR rate, while pressure-invariant selectivity indicated propane excess relative to radical concentration. In contrast, temperature had a significant impact on both the POR rate and product selectivity. Notably, Fig. 4c reveals that the POR rate increased at lower temperatures, indicating an unexpected negative apparent activation energy for the POR (Supplementary Fig. 15)48,49. To further explore this temperature effect, we conducted separate studies on the h-EFP and POR. Temperature-dependent h-EFP studies (Supplementary Fig. 16) showed that lower temperatures enhance the selectivity for the two-electron oxygen reduction reaction, increasing H2O2 production. Conversely, the POR via the thermal Fenton process accelerated with rising temperatures (Supplementary Fig. 17). These findings suggest that lower temperatures promote H2O2 formation, resulting in higher POR rates compared to elevated temperatures. This intriguing temperature effect underscores the unique advantages of the h-EFP in facilitating POR.

Additionally, we investigated the influence of O2 pressure on POR (Supplementary Fig. 18). From 0.2 bar to 1 bar, O2 pressure exhibits a marginal effect on POR, indicating that the h-EFP is well-adapted to variations in O2 pressure. Considering the explosion risk associated with the propane and O2 mixture, we opted to use air as a safer alternative (Supplementary Fig. 19). The use of air results in a slightly low POR rate compared to O2 but offers a similar acetone production rate.

Regarding the temperature effect on POR product selectivity, we observed an increase in i-PrOH selectivity with rising temperatures (Fig. 4c), while AcOH selectivity notably increased as the temperature decreased. This temperature-dependent selectivity can be attributed to two key factors. First, temperature influences the vapor pressure of the products (Supplementary Fig. 10a), with higher temperatures promoting the transport of i-PrOH out of the electrolyzer via the gas stream, thereby reducing its availability for oxidation to acetone. Second, temperature affects the efficiency of h-EFP, with lower temperatures leading to higher concentrations of ·OH, which in turn promotes the formation of AcOH as a deep oxidation product.

In practical applications, the separation and purification of products require additional human and financial resources, thereby increasing the overall capital investment50. In homogeneous catalysis systems, even with high product selectivity, separating the products from the catalyst and solvent presents significant challenges51. In contrast, the MEA-cell, as a solid-gas heterogeneous reaction system, avoids contamination of the catalyst and electrolyte solution52,53. Although acetone selectivity in POR products ranges from 50% to 80%, its high vapor pressure compared to i-PrOH and AcOH (Supplementary Fig. 10) facilitates easier separation and purification. At 30 °C, the vapor pressure of acetone is 12 times that of AcOH and 4 times that of i-PrOH (Supplementary Fig. 10b). Consequently, acetone predominantly exits the cathode in gaseous form, while AcOH tends to remain in liquid droplets within the electrode (Fig. 4d and Supplementary Fig. 20). By using a simple chiller unit to absorb acetone from the gas stream (Supplementary Fig. 21), we achieved acetone purities of up to 90%, with virtually no AcOH detected (Supplementary Fig. 22). To further enhance acetone purity, we reduced the operating temperature to 10 °C, resulting in acetone purity as high as 96% (Fig. 4e). Notably, due to the higher vapor pressure of acetone, its concentration in the gas phase is significantly higher than in the cathode outlet droplets, leading to a collection efficiency of over 90%.

Impact of propane liquefaction on POR

In electrochemical reactions, the low solubility of gaseous reactants in electrolytes often presents a significant limitation. Notably, propane can be readily liquefied at 10 °C under a pressure of 6.4 bar (Supplementary Fig. 23). While the concentration of gaseous propane in water is approximately 1.5 mM, the concentration of liquid propane exceeds 10 M54. Given that higher H2O2 selectivity is also achieved at 10 °C compared to higher temperatures, it is compelling to explore whether the combination of liquid propane and elevated H2O2 selectivity could lead to significant performance in POR.

At 10 °C, POR performances were evaluated under varying propane partial pressures (Fig. 5a). Interestingly, the POR rate exhibited a non-monotonic, volcano-shaped relationship with propane pressure. When the pressure exceeded the liquefaction threshold (greater than 6.4 bar), the POR rate declined. To better understand the impact of propane pressure on the reaction environment, we developed an optical viewing device (Fig. 5b). Microscopic images (Figs. 5c, d and e) revealed that increasing propane pressure gradually “wetted” the catalyst layer with liquid propane. The amber-colored MIL-100(Fe) became progressively obscured due to the accumulation of liquid propane. When pressures exceeded 6.4 bar, liquid propane fully inundated the GDE (Supplementary Fig. 24), potentially impeding O2 mass transfer and thereby hindering the oxygen reduction reaction. This led to a reduction in the POR rate in the liquefaction range. Notably, both propane liquefaction and the maximum POR rate occurred at 6.2 bar. The slight deviation of liquefaction pressure from the standard can be attributed to the Kelvin equation, owing to the presence of mesopores within the catalyst layer (Supplementary Fig. 25). At this optimal point, concentrated liquid propane and sufficient O2 availability facilitated the highest POR rate. In summary, liquid propane oxidation is a feasible process, provided that O2 supply is adequately maintained.

a POR performance under various propane pressure at 10 °C. The gray equation is Kelvin equation and p* is the saturated vapor pressure at 10 °C (Supplementary Fig. 25). The error bars represent ± 1 standard deviation calculated from triplicate independent experiments. b Schematic illustration of optical viewing device system for liquid propane observation. c−e Optical microscopic images of the catalyst layer at 10 °C under various propane pressure: (c) 6.0 bar, (d) 6.2 bar and (e) 6.4 bar. The scale bars represent 200 μm. The insets between images are schematic illustrations of the formation of liquid propane and consequent blockage of gas passages.

Discussion

We successfully achieved the direct oxidation of propane to acetone under mild conditions using a h-EFP. A comprehensive study of the coupling mechanism between h-EFP and POR revealed that in situ generated ·OH radicals sequentially dehydrogenate and oxygenate propane to acetone via i-PrOH, with the potential for over-oxidation to AcOH. Implementing the h-EFP coupled POR in MEA electrolyzers allowed operation across a broader range of temperatures and gas pressures. Notably, POR acceleration was observed at lower temperatures, attributable to the enhanced efficiency of H2O2 generation. The gas-phase products (acetone and i-PrOH) were efficiently separated from the liquid-phase AcOH, with acetone purification up to 96% achieved through a simple chiller unit. The optimal operational point for the MEA electrolyzer was identified at 10 °C and 6.2 bar pressure, coinciding with the propane liquefaction threshold. This highly selective approach to direct propane oxidation to acetone demonstrates potential applicability for converting other alkanes.

Methods

Chemicals

Iron powder (Shanghai Kefeng Industry & Commerce Co., Ltd, 98.0%), Trimesic acid (Shanghai Aladdin Biochemical Technology Co. Ltd, 98%), HNO3 (Sinopharm Chemical Reagent Co., Ltd, Guaranteed reagent), HF (Sinopharm Chemical Reagent Co., Ltd, Guaranteed reagent), Ketjen Black (Lion Corporation, EC-600JD), Ce(SO4)2 (Shanghai Aladdin Biochemical Technology Co., Ltd, 99.9% metals basis), 5,5-Dimethyl-1-pyrroline N-oxide (Shanghai Aladdin Biochemical Technology Co., Ltd, 97%), Nafion-117 (Dupont, 183 μm), Nafion NR211 (Dupont, 25.4 μm), Nafion D1020 solution (Dupont), carbon paper (Ballard, AvCarb GDS 3250), Propane (Wuhan Newradar Special Gas Co., Ltd, 99.9%), Oxygen (Wuhan Newradar Special Gas Co., Ltd, 99.999%). Ultrapure water (18.25 MΩ cm) was prepared by Advanced-II-16 (Tang’s Kangning Technology Development Co., Ltd.).

Characterization

The morphology images of MIL-100(Fe) and KB-a were acquired by a scanning electron microscope (Zeiss Merlin Compact). The TEM images of MIL-100(Fe) and KB-a were acquired by Field Emission Transmission Electron Microscope (JEM-F200). X-ray diffraction patterns were obtained on X-ray diffractometer (Rigaku Miniflex600) with Cu-Kα radiation in the range 5-30o. Optical microscopy images were shot on a Digital Microscope (VHX-1000E). EPR spectra were recorded on an EPR spectrometer (Bruker X-Band A200). Mass spectra were acquired by PM-DEMS (Shanghai Pro-tech Limited Company). The infrared spectrum was acquired by a Fourier transform infrared spectrometer (Thermo Fisher Nicolet 6700). The Raman spectrum was acquired by a XPLORA PLUS confocal microscope Raman system. The N2 adsorption-desorption isotherms of catalysts were acquired by a gas adsorption instrument (Autosorb iQ, Quantachrome) at 77 K. The concentration of leached Fe species in the post-reaction electrolyte was quantitatively analyzed using inductively coupled plasma optical emission spectrometry (Agilent 5110).

Catalyst preparation

MIL-100(Fe) is synthesized using the hydrothermal method55. Iron powder (355 mg), Trimesic acid (891 mg), HNO3 (263 μL), HF (566 μL), and ultrapure water (34 mL) were added to 50 mL of Teflon lined autoclave and reacted at 150 °C for 24 hours. The synthesized particles were washed alternately with boiling water and hot ethanol until the washing liquor was free of color-bearing impurities. The particles were then dried under vacuum at 80 °C overnight, followed by vacuum heat treatment at 200 °C for 6 hours. Ketjen Black (1 g) powder was added to of 60% HNO3 (250 mL) and heated in an oil bath at 80 °C for 12 hours. Afterward, the slurry was washed with ultrapure water until the washing liquor became neutral, and then dried under vacuum at 80 °C overnight.

Cyclic voltammetry measurement of MIL-100(Fe)

A MIL-100(Fe) ink was prepared by uniformly dispersing 10 mg MIL-100(Fe) in 1 mL ethanol containing 10 μL 10% Nafion solution via 15 minute ultrasonication. Subsequently, 20 μL of the homogeneous ink was drop-cast onto a 6 mm diameter glassy carbon electrode and dried. CV measurement was conducted in Ar-saturated 50 mM H2SO4 electrolyte at a scan rate of 100 mV/s. For comparison, control experiments were carried out using the bare glassy carbon electrode in 2.5 mM Fe3+/Fe2+ aqueous solution under identical conditions.

GDE preparation for POR and ORR

For POR, 20 mg of MIL-100(Fe), 20 mg of KB-a and 100 μL of 10 wt% Nafion solution were dispersed in 6 mL ethanol to form an ink. The resulting ink was sonicated for 30 minutes and then sprayed onto carbon paper, with a total catalyst loading of approximately 2 mg cm-². For ORR, 20 mg of KB-a and 50 μL of 10 wt% Nafion were dispersed in 6 mL ethanol to form an ink. The resulting ink was sonicated for 30 minutes and then sprayed onto carbon paper, with a total catalyst loading of approximately 1 mg cm-2.

H2O2 faradaic efficiency of ORR

The concentration of H2O2 in the cathode electrolyte was determined using the cerium quantitative method56.

Following constant potential electrolysis, 50 µL of the cathode electrolyte was and added to a 4 mL Ce(SO4)2 solution. The concentration of Ce4+ was analyzed using a UV-vis spectrophotometer (UV-6100PC double beam spectrophotometer). The formula for calculating the concentration of H2O2 was as follows:

where \(\left[{{{\rm{H}}}}_{2}{{{\rm{O}}}}_{2}\right]\) represents the concentration of H2O2, while \({[{{{\rm{Ce}}}}^{4+}]}_{{{\rm{before}}}}\) and \({[{{{\rm{Ce}}}}^{4+}]}_{{{\rm{after}}}}\) are the concentration of Ce4+ in the stock solution before and after mixing with the catholyte, respectively. The faradaic efficiency of H2O2 is calculated as follows:

where \(F\) is the Faraday constant (96485 C mol-1), Vcatholyte is the volume of catholyte, I and t are current and electrolysis time, respectively.

POR in H-cell

A homemade H-cell was used for the experiment. A titanium plate loaded with iridium oxide was used as anode, while the cathode was a GDE loaded with MIL-100(Fe) and KB-a. A homemade reversible hydrogen electrode, conducted by a capillary tube, served as the reference electrode. Both the cathode and anode electrolytes were 0.05 M H2SO4, which separated by Nafion 117 membrane without any treatment. A mixture of and O2 (25 sccm) and C3H8 (25 sccm) controlled by mass flow controllers (Beijing Sevenstar Electronics Co., Ltd) was passed through the cathode side, while the anode side was left open.

Stepwise analysis of POR

Stepwise analyses were conducted at 0 V vs. RHE in the H-cell containing 50 mM H2SO4 electrolyte supplemented with either 100 mM i-PrOH or acetone. The cathode was continuously purged with 25 sccm O2 during testing.

POR in electrolyzer

A homemade electrolyzer was used, where the anode was a titanium plate loaded with iridium oxide, and the cathode was a GDL loaded with MIL-100(Fe) and KB-a. The cathode and anode were clamped to a Nafion NR211 membrane. The Nafion NR211 was pretreated by sequential boiling in 5% H2O2 (80 °C, 1 h), 0.5 M H2SO4 (80 °C, 1 h), followed by ultrapure water rinsing. The cathode was fed with a mixture of O2 and C3H8, and the operating pressure was controlled using a backpressure valve and monitored by a pressure sensor. The anode side was filled with purified water and pressurized with Ar to equalize the cathode pressure.

Product analysis of POR

The oxygenated products of POR in liquid solution were detected and quantified using 1H nuclear magnetic resonance spectroscopy (Bruker AVANCE III HD 400 MHz). Typically, 450 μL liquid aliquot was mixed with 50 μL 2 mM DMSO as internal standard in D2O.

The oxidant for all oxidation reactions is attributed to ·OH.

Since each ·OH consumes one electron, the Faradaic efficiency of POR product is calculated as follows:

where \({n}_{{{\rm{i}}}}\) is the amount of product i, \({n}_{{{{\rm{e}}}}^{-}}\) is the required number of electron transfer (equivalent to the number of ·OH) for one product i molecule, \(F\) is the Faraday constant (96485 C mol-1), Ii is the partial current of product i, I is current and t is electrolysis time.

The total rate of POR is calculated as follows:

where \({v}_{{{\rm{total}}}}\) is the total rate and \({v}_{{{\rm{i}}}}\) is the production rate of liquid product i excluding undetectable HCOOH and CH3OH. The rate of POR herein was calculated not based on carbon balance.

Liquid product selectivity is calculated as follows:

Capture efficiency of acetone is calculated as follows:

where \({n}_{{{\rm{g}}}}\) and \({n}_{{{\rm{l}}}}\) is the number of moles for acetone in gaseous portion and drops, respectively.

Purity of acetone is calculated as follows:

where \({n}_{{{\rm{acetone}}}}\) and \({n}_{{{\rm{total}}}}\) is the number of moles for acetone and the number of moles for total products of collection through the gas-washing process, respectively.

Data availability

The authors declare that the data supporting the findings of this study are available within the article and its Supplementary Information files. Source data are provided as a Source Data file. Additional data are available from the corresponding author upon request. Source data are provided with this paper.

References

Darabi Mahboub, M. J., Dubois, J.-L., Cavani, F., Rostamizadeh, M. & Patience, G. S. Catalysis for the synthesis of methacrylic acid and methyl methacrylate. Chem. Soc. Rev. 47, 7703–7738 (2018).

Liew, F. E. et al. Carbon-negative production of acetone and isopropanol by gas fermentation at industrial pilot scale. Nat. Biotechnol. 40, 335–344 (2022).

RESEARCH AND MARKETS. Global Acetone Market—Forecast 2024–2030. https://www.grandviewresearch.com/industry-analysis/acetone-market (2024).

Zakoshansky, V. M. The cumene process for phenol-acetone production. Pet. Chem. 47, 273–284 (2007).

Almallahi, R., Wortman, J. & Linic, S. Overcoming limitations in propane dehydrogenation by codesigning catalyst-membrane systems. Science 383, 1325–1331 (2024).

Chen, S. et al. Defective TiOx overlayers catalyze propane dehydrogenation promoted by base metals. Science 385, 295–300 (2024).

Sun, J., Yamamoto, H. & Matsui, M. Horizontal integration management: an optimal switching model for parallel production system with multiple periods in smart supply chain environment. Int. J. Prod. Econ. 221, 107475 (2020).

Latimer, A. A. et al. Understanding trends in C–H bond activation in heterogeneous catalysis. Nat. Mater. 16, 225–229 (2017).

Oksdath-Mansilla, G. Stronger bonds bring bigger challenges. Science 369, 34–35 (2020).

Agarwal, N. et al. Aqueous Au-Pd colloids catalyze selective CH4 oxidation to CH3OH with O2 under mild conditions. Science 358, 223–227 (2017).

Fan, Y. et al. Insight into selectivity of photocatalytic methane oxidation to formaldehyde on tungsten trioxide. Nat. Commun. 15, 4679 (2024).

Nguyen, T. H., Park, E. D. & Yu, S. Plasmon-driven selective methane oxidation to formic acid at ambient conditions. ACS Energy Lett. 9, 538–546 (2024).

Meng, Q.-Y. et al. Identifying key intermediates generated in situ from Cu(II) salt–catalyzed C–H functionalization of aromatic amines under illumination. Sci. Adv. 3, e1700666 (2017).

Li, A. et al. Electrocatalytic Conversion of methane to ethanol via promoted ⋅OH generation in aqueous electrolyte. ACS Sustain. Chem. Eng. 12, 9558–9567 (2024).

Qiu, H. et al. Electrocatalytic methane conversion via in-situ generated superoxide radicals in an aprotic ionic liquid. J. Colloid Interface Sci. 684, 449–456 (2025).

Kim, J. et al. Electro-assisted methane oxidation to formic acid via in-situ cathodically generated H2O2 under ambient conditions. Nat. Commun. 14, 4704 (2023).

Vass, A., Mul, G., Katsoukis, G. & Altomare, M. Challenges in the selective electrochemical oxidation of methane: Too early to surrender. Curr. Opin. Electrochem. 47, 101558 (2024).

Rogolino, A. et al. Direct synthesis of acetone by aerobic propane oxidation promoted by photoactive iron(III) chloride under mild conditions. ACS Catal. 13, 8662–8669 (2023).

Yang, C. H. et al. Selective conversion of propane by electrothermal catalysis in proton exchange membrane fuel cell. ChemSusChem 16, e202300699 (2023).

Liu, C., Chen, F., Zhao, B.-H., Wu, Y. & Zhang, B. Electrochemical hydrogenation and oxidation of organic species involving water. Nat. Rev. Chem. 8, 277–293 (2024).

Huang, B., Sun, Z. & Sun, G. Recent progress in cathodic reduction-enabled organic electrosynthesis: trends, challenges, and opportunities. eScience 2, 243–277 (2022).

Shen, K. et al. Electrochemical oxidation of methane to methanol on electrodeposited transition metal oxides. J. Am. Chem. Soc. 145, 6927–6943 (2023).

Sirés, I. & Brillas, E. Upgrading and expanding the electro-Fenton and related processes. Curr. Opin. Electrochem. 27, 100686 (2021).

Sheng, H. et al. Linear paired electrochemical valorization of glycerol enabled by the electro-Fenton process using a stable NiSe2 cathode. Nat. Catal. 5, 716–725 (2022).

Jain, B., Singh, A. K., Kim, H., Lichtfouse, E. & Sharma, V. K. Treatment of organic pollutants by homogeneous and heterogeneous Fenton reaction processes. Environ. Chem. Lett. 16, 947–967 (2018).

Yang, C. et al. Electro-driven cycling Fenton catalysis through two-dimensional electroresponsive metal–organic frameworks for water purification. Nat. Water 2, 793–802 (2024).

Song, Y. et al. High-pressure electro-Fenton driving CH4 conversion by O2 at room temperature. J. Am. Chem. Soc. 146, 5834–5842 (2024).

Chen, S. et al. Direct electroconversion of air to nitric acid under mild conditions. Nat. Synth. 3, 76–84 (2024).

Dong, K. et al. H2O2-mediated electrosynthesis of nitrate from air. Nat. Synth. 3, 763–773 (2024).

Chan, S. I., Yu, S. S. F., Liu, C.-C. & Mou, C.-Y. Selective oxidation of light alkanes under mild conditions. Curr. Opin. Green. Sustain. Chem. 22, 39–46 (2020).

Lei, Y., Song, B., van der Weijden, R. D., Saakes, M. & Buisman, C. J. N. Electrochemical induced calcium phosphate precipitation: importance of local pH. Environ. Sci. Technol. 51, 11156–11164 (2017).

Wang, Z. et al. Recent advances and trends of heterogeneous electro-Fenton process for wastewater treatment-review. Chin. Chem. Lett. 33, 653–662 (2022).

Wei, Z. et al. Electrochemical synthesis in company with hydrogen production via renewable energy: opportunities and challenges. Chin. J. Catal. 58, 1–6 (2024).

Yoon, J. W. et al. Controlled reducibility of a metal–organic framework with coordinatively unsaturated sites for preferential gas sorption. Angew. Chem. Int. Ed. 49, 5949–5952 (2010).

Tofoni, A. et al. Full spectroscopic characterization of the molecular oxygen-based methane to methanol conversion over open fe(II) sites in a metal–organic framework. J. Am. Chem. Soc. 145, 21040–21052 (2023).

Yamashita, T. & Hayes, P. Analysis of XPS spectra of Fe2+ and Fe3+ ions in oxide materials. Appl. Surf. Sci. 254, 2441–2449 (2008).

Li, W. et al. Surface hydrophobic MIL-100(Fe) MOFs to boost methane oxidation with nearly total selectivity to C1 oxygenates under mild conditions. J. Catal. 429, 115243 (2024).

Deng, F. et al. Critical review on the mechanisms of Fe2+ regeneration in the electro-fenton process: fundamentals and boosting strategies. Chem. Rev. 123, 4635–4662 (2023).

Klingler, R. J. & Kochi, J. K. Heterogeneous rates of electron transfer. Application of cyclic voltammetric techniques to irreversible electrochemical processes. J. Am. Chem. Soc. 102, 4790–4798 (1980).

Lu, Z. et al. High-efficiency oxygen reduction to hydrogen peroxide catalysed by oxidized carbon materials. Nat. Catal. 1, 156–162 (2018).

Lu, X., Wang, D., Wu, K.-H., Guo, X. & Qi, W. Oxygen reduction to hydrogen peroxide on oxidized nanocarbon: Identification and quantification of active sites. J. Colloid Interface Sci. 573, 376–383 (2020).

Chen, S. et al. Chemical identification of catalytically active sites on oxygen-doped carbon nanosheet to decipher the high activity for electro-synthesis hydrogen peroxide. Angew. Chem. Int. Ed. 60, 16607–16614 (2021).

Zhang, Y., Dai, M. & Yuan, Z. Methods for the detection of reactive oxygen species. Anal. Methods 10, 4625–4638 (2018).

Buxton, G. V., Greenstock, C. L., Helman, W. P. & Ross, A. B. Critical review of rate constants for reactions of hydrated electrons, hydrogen atoms and hydroxyl radicals (⋅OH/⋅O−) in aqueous solution. J. Phys. Chem. Ref. Data 17, 513–886 (1988).

Sirés, I. et al. Catalytic behavior of the Fe3+/Fe2+ system in the electro-Fenton degradation of the antimicrobial chlorophene. Appl. Catal. B Environ. 72, 382–394 (2007).

Luo, Z. et al. High H2O2 selectivity and enhanced Fe2+ regeneration toward an effective electro-Fenton process based on a self-doped porous biochar cathode. Appl. Catal. B Environ. 315, 121523 (2022).

Ko, Y.-J. et al. Ionic-liquid-derived nitrogen-doped carbon electrocatalyst for peroxide generation and divalent iron regeneration: its application for removal of aqueous organic compounds. ACS Sustain. Chem. Eng. 6, 14857–14865 (2018).

Atkinson, R. Kinetics of the gas-phase reactions of OH radicals with alkanes and cycloalkanes. Atmos. Chem. Phys. 3, 2233–2307 (2003).

Xiao, F., Sun, X., Li, Z. & Li, X. Theoretical study of radical–molecule reactions with negative activation energies in combustion: hydroxyl radical addition to alkenes. ACS Omega 5, 12777–12788 (2020).

Chen, H. et al. Techno-economic analysis of acetone-butanol-ethanol distillation sequences feeding the biphasic condensate after in situ gas stripping separation. Sep. Purif. Technol. 219, 241–248 (2019).

Zaera, F. Designing sites in heterogeneous catalysis: are we reaching selectivities competitive with those of homogeneous catalysts?. Chem. Rev. 122, 8594–8757 (2022).

Zhu, P. & Wang, H. High-purity and high-concentration liquid fuels through CO2 electroreduction. Nat. Catal. 4, 943–951 (2021).

Zhu, P. et al. Direct and continuous generation of pure acetic acid solutions via electrocatalytic carbon monoxide reduction. Proc. Natl. Acad. Sci. USA 118, e2010868118 (2021).

Haynes, W. M. & Hiza, M. J. Measurements of the orthobaric liquid densities of methane, ethane, propane, isobutane, and normal butane. J. Chem. Thermodyn. 9, 179–187 (1977).

Tan, F. et al. Facile synthesis of size-controlled MIL-100(Fe) with excellent adsorption capacity for methylene blue. Chem. Eng. J. 281, 360–367 (2015).

Adler, Z. et al. Hydrogen peroxide electrosynthesis in a strong acidic environment using cationic surfactants. Precis. Chem. 2, 129–137 (2024).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (22472121, 22172115), the Science and Technology Innovation Talent Program of Hubei Province, China (2024DJA024), and the Start-Up Grant of Wuhan University (2025-1303-017).

Author information

Authors and Affiliations

Contributions

L. Z., L. X. and G. W. supervised the research project. X. H. conducted all experiments. M. L., W. J. and Z. Y. assisted in material preparation and characterizations. X. H., G. W., L. X. and L. Z. contributed in data analysis. X. H. and L. Z. wrote the article.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Marco Altomare, who co-reviewed with Akash Raman, and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hu, X., Li, M., Jiang, W. et al. One-step electrochemical conversion of propane to acetone of 96% purity. Nat Commun 16, 8068 (2025). https://doi.org/10.1038/s41467-025-63342-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-63342-0