Abstract

Reactive transport in porous media is the key to heterogeneous catalysis, which is the central process in both natural and engineered systems. Elucidating nexus between porous architecture and reactive transport is of importance, but remains a challenge. Conventional text-based approach relies on quantitative structural features (QSFs; porosity, tortuosity, and connectivity), which fails to identify key reaction regions and predict local reaction rate for anisotropic architecture due to isotropic assumption. To address these issues, this study reports a data-driven deep learning computer vision (DLCV) method for visualizing nexus between porous architecture and reactive transport in heterogeneous catalysis. Here, we show that the 3D local reaction rate can be inferred from 2D lateral images of anisotropic porous catalysts using Conditional Generative Adversarial Network and feature representation transfer learning (cGAN-FRT). Efficiency and generalizability are validated by rapid and accurate prediction of reaction rate for heterogeneous electrocatalysis. Based on feature importance generated by cGAN-FRT, pore throat, curved flow channel, and their combined structures are identified to be the dominant factors that affect nonlinear variation of porous reactive transport, which can be interpreted by physical field synergy. This study realizes visualizing nexus between anisotropic porous architecture and local reactive transport powered by artificial intelligence.

Similar content being viewed by others

Introduction

Heterogeneous catalysis plays an important role in modern science and technology, such as chemical industries (e.g., production of base/fine chemicals, petrol, and pharmaceuticals)1,2,3,4, energy conversion (e.g., fuel cells and water splitting)5,6,7,8, and environmental protection (e.g., air pollution control and water purification)9,10,11,12. Heterogeneous catalysis occurs at the multi-phase interface, which couples complex dynamic interplay between catalytic reactions and mass transport, giving rise to what is termed reactive transport13,14. Porous materials are widely used for heterogeneous catalysis due to their unique capability to address the challenge of multi-scale reactive transport15,16. However, local reaction rate depends on pore geometry and flow patterns in a more subtle manner than on overall porosity, particularly in anisotropic structures17, which makes it a challenge to understand reactive transport, design catalytic architecture, and manipulate catalytic efficiency and selectivity18. To this end, it is highly desirable to create the structure-property relationship of porous catalysts by correlating catalytic effects to pore topologies.

The reactive transport of porous media has been investigated extensively by empirical and semi-empirical equations based on quantitative structural features (QSFs) like surface area, porosity, and tortuosity19,20. However, the structure-property relationship remains unclear due to anisotropic geometrical diversities, topological complexity as well as spatiotemporal nonlinearity21,22. This is where the emerging role of machine learning (ML) comes into play23,24. Given the advantages of ability to process complex networks of data relevant to reactive transport and anisotropic porous architectures19, ML algorithms can reveal patterns that are not apparent to QSFs. For example, Random Forest model was used to identify the relationship between effective reaction rate and QSFs (specific surface area and sphericity)25. However, QSFs-based ML method still unlikely to predict local reaction rate, handle structural anisotropy, and locate key reactive sites due to inherent limitations of QSFs in terms of (i) isotropic assumption26 and (ii) abstract nature of statistical information27. The importance of key reactive sites and local reactive rates lies in their role in manipulating catalytic activity, where site-specific kinetics can dictate overall efficiency and product selectivity28.

Compared with QSFs, morphological structural features (MSFs) are more advantageous by virtue of physical visualization, complete spatial information, and easy-to-handle acquisition from images29. By integrating MSFs with directional and reactive information, it is feasible to establish the structure-property relationship by using multi-model deep learning computer vision (DLCV) techniques30,31. Owing to predictability, reliability, and interpretability, Conditional Generative Adversarial Network (cGAN) excels in pixel-voxel reconstruction and interface prediction tasks, such as 3D object imaging, medical image segmentation, and fracture forecasting32. These outcomes inspire us to explore the feasibility of developing a mutil-model DLCV based on 3D reconstrcution-prediction steps to make visual nexus between 2D MSFs and 3D reactive transport. This would be helpful for not only predicting 3D local reaction rate from 2D lateral images, but also providing mechanistic insights into reactive transport of anisotropic porous networks in heterogeneous catalysis.

To this end, it is necessary to generalize DLCV models, as majority of models are available for finite structures and their variants generated by stretching and flipping in training-dataset21, but are unlikely to be generalized to infinite structural diversity of complex anisotropic porous catalysts. To address such issues, transfer learning (TL) offers a time-saving and cost-effective tool by exploiting the knowledge acquired from the source model to improve the learning process in transfer models33. With enhanced generalizability and adaptability, TL holds promise to address the challenge of geometric and topological diversity, by treating isotropic structures as the source work and making transfer to anisotropic structures.

The objective of this study is to visualize the nexus of reactive transport and anisotropic porous architectures by developing a DLCV-TL framework with reconstrcution-prediction strategy based on multi-modal cGAN and Feature Representation Transfer Learning (cGAN-FRT). First, we developed TL framework that divided reactive transport into source cases with isotropic structures and transfer cases with anisotropic structures. Second, we pre-trained the cGAN-FRT source model, followed by evaluation of its learning, prediction, and attention capabilities. Third, we tested the accuracy of cGAN-FRT framework in predicting reaction rate based on electrochemical conversion of K3[Fe(CN)6] on foam nickel. Last, the key MSFs to reactive transport were identified to reflect the reactive transport mechanisms within the context of physical field synergy (PFS). We will show that the cGAN-FRT framework developed herein allows (i) fast prediction of local and effective reaction rates in 3D pore network from 2D lateral images of anisotropic porous catalysts, (ii) improvement of generalizability limited by geometric diversity, and (iii) identification of the dominant reaction region and its underlying physical mechanisms for reactive transport in anisotropic porous catalysts.

Results

Design of cGAN-FRT framework

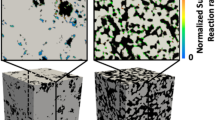

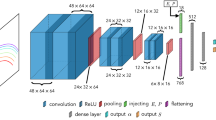

To predict 3D local reaction rate from 2D images, identify key reaction regions for reactive transport, and overcome geometric diversity limitations in structure-property relationship, we established the transferable cGAN-FRT framework with 3D reconstruction-prediction steps and two corresponding generative networks, i.e., Generator 1 and Generator 2 (Fig. 1 and Supplementary Fig. 1). In 3D reconstruction step (Generator 1), the lateral images and 3D reconstructed model for porous catalyst served as input and output, respectively. In prediction step (Generator 2), reactive information, inflow direction, and slices of reconstructed model were mapped to slices of normalized concentration field (cid). The normalized concentration could be converted into local reaction rate and normalized effective reaction rate (Rnorm) based on Eqs. 12–14 in “Materials and Methods”.

Input for model designed for (a) isotropic architectures and (b) anisotropic architectures. The directions 1, 2, and 5 represented x, y, and z direction in coordinate system, respectively. c Transfer learning strategy. Each model included two operating variables (Damköhler number, Da, and Péclet number, Pe) and four constant parameters [anisotropy factor gi, viscosity μ (Pa s), fluid density ρ (g cm−3) and diffusion coefficient D (cm2 s−1)]. Any change of the constant parameters required retraining the model through transfer learning. Workflow for (d) isotropic architectures and (e) anisotropic architectures. cid was the normalized concentration field. More detailed descriptions on cGAN-FRT framework were provided in “Materials and Methods”.

The reactive information was described by dimensionless Damköhler number (Da) and Péclet number (Pe), which represented the ratio of fluid-solid reaction rate to solute diffusion rate, and convective transport rate to diffusive rate, respectively34. The inflow and outflow face corresponded to the left and right sides of the porous catalyst, respectively. To train the generative networks, discriminative network was simultaneously trained for each generative model. Each pair of Generator and Discriminator constituted a cGAN module, as shown in Supplementary Fig. 1.

To enable rationality of transfer learning strategy, the reactive transport was categorized into isotropic cases with specific reaction modes (i.e., source task) and anisotropic cases with arbitrary modes (i.e., transfer task; Fig. 1c). So that the framework could extract fundamental structure-property relationship without interference of structural anisotropy, thereby enabling the fine-tuning of transfer models specific to various anisotropic structures based on small datasets. To achieve this goal, we regulated structural anisotropy using two-phase quartet structure generation set (QSGS) method to construct porous structures with desired porosity ε, core distribution probability cd, and growth probability in 26 directions gi (i = 1, 2, …, 26; Fig. 1a–c, “Method” and Supplementary Text 1). Theoretically, the TL strategy could potentially cover all the reactive transport scenarios.

For clarity, the workflow included base process and custom process. For base process (Fig. 1d), the source models were trained upon the source datasets to learn fundamental structural-property relationships for isotropic porous structures under extreme Da and Pe values. For the custom process (Fig. 1e), the gi values in 26 directions were first calculated from the images of porous structure using the method described by Chiang et al.35, so as to generate transfer dataset and corresponding transfer models for specific Da, Pe, and target porous structures (Materials and Methods). Finally, the attention map during prediction could highlight the key reaction regions inside porous catalyst, with the hydrodynamic mechanisms being derived from the synergy of physical fields. This framework would be applied for predicting and elucidating reactive transport in heterogeneous catalysis with various porous structures.

Pre-training performance for different algorithms

Pre-training is crucial to the overall performance of the DLCV framework. A comparative analysis was designed to assess pre-training performance for Generators 1 and 2, with respect to predictive precision, training loss, and attention ability (Fig. 2). As such, each Generator underwent a uniform training phase of 100 epochs upon source dataset. As shown in Fig. 2a–d, the learning curves for Generator 1 and Generator 2 exhibited similar patterns. Initially, their losses rapidly declined as the models adeptly captured simple features. As training progressed, the focus shifted to refine complex features, and ultimately stabilized at the plateau36. Generator 1 reached the lowest training loss of 0.12 at 20 epochs, and Generator 2 took longer (~40 iterations) to achieve the lowest training loss of 0.16.

a Framework and b Learning curves for Generator 1. c Framework and d Learning curves for Generator 2. e Statistical information and f Visual information for original and reconstructed 3D models. g Predicted results for normalized effective reaction rate (Rnorm) at different Damköhler number (Da) and Péclet number (Pe). h Predicted results and error for the normalized concentration field (cid). Normalized concentration field (cid) was calculated by cid=ci/c0, where ci and c0 (mol cm−3) represented the local and initial concentration, respectively. Then, the local reaction rate, effective reaction rate, and Rnorm could be calculated from Eqs. 12–14. i Heat map for Generator 2. Source data are provided as a Source Data file.

Precision of Generator 1 was evaluated by comparing statistical information in original and reconstructed 3D models. Results indicated that the reconstructed model closely matched the original in porosity, connectivity, tortuosity, and coordination number, with errors below 3% and high visual consistency (Fig. 2e, f). For Generator 2, the predicted and actual Rnorm were plotted with respect to Da and Pe values (Fig. 2g). The cGAN not only predicted Rnorm with 97.3% accuracy, but also effectively captured the dominant role of Pe in Rnorm variation under high Da value. Moreover, the prediction error of normalized concentration in structure slices were also plotted in Fig. 2h. Lighter regions indicate deviations, while black represents perfect matches. Remarkably, the deviations were less than 0.1 and were mainly observed near the dead zones.

Furthermore, we examined whether models trained on isotropic cases could be directly applied to anisotropic porous architectures. By adjusting gi values in 1–6 directions from 0.001 to 0.005, we generated 5 anisotropic porous structures (Supplementary Fig. 2). Unfortunately, source model failed to predict the Rnorm values with accuracy dropping to 21% (Supplementary Fig. 2). This necessitated the introduction of transfer learning strategy.

We then visualized the key features identified by DLCV models through attention task based on 0.3 porosity structure at cd = 0.00375, g1–26 = 0.001, Da = 1, and Pe = 100 (Fig. 2i). The attention score was obtained from the final layer that captured both structural features and their spatial relationships37. The areas of high attention were denoted by brighter colors, whereas the dimmer colors represented low-attention regions (Fig. 2i). On one hand, the DLCV model tended to focus on specific pore structures with clear boundaries. On the other hand, the cGAN effectively concentrated on the inflow side of the porous catalyst, demonstrating its capability to discern the fluid direction. Thus, cGAN had stable training efficiency, superior predicting performance, and ability to provide specific structural insights.

Transfer learning performance

To evaluate the transferability of cGAN-FRT, we next evaluated the transfer training performance and prediction precision after FRT strategy (Fig. 3). Specifically, all other layers were frozen except for the final layer to prevent the transfer model from overwriting previous features and parameters38. Then, the entire model was fine-tuned to boost performance. This model was trained over 100 epochs based on an anisotropic transfer dataset with 30 images-result pairs characterized by nonuniform gi, three Pe values (100, 1000, 10000) and one Da value (0.1) (Supplementary Fig. 3), which was not illustrated by the source model before.

a Learning curves for Generators 1 and 2. b Statistical information, and c Visual information for original and reconstructed 3D models. d Predicted results and error for the dimensionless concentration field (cid) using transfer model. e Predicted results for normalized effective reaction rate (Rnorm) using transfer model. f Heat map for transfer Generator 2. g Experimental setup for electrochemical conversion of K3[Fe(CN)6] on foam nickel. h Nickel foam electrode and representative images, along with the normalized concentration field (cid) at the fluid-solid interface at different Péclet number (Pe) and a fixed Damköhler number (Da) of 1.2. i Comparative analysis between tested and predicted Rnorm under different Pe and fluid directions. Source data are provided as a Source Data file.

Notably, both Generators 1 and 2 in transfer models held good training performance in terms of 68% reduction in loss over 40 epochs (Fig. 3a). The reconstructed structures from transfer model demonstrated 98% statistical consistency with the original 3D structures (Fig. 3b, c). Moreover, the transfer model achieved 97.5% accuracy in predicting Rnorm and <0.1 difference in normalized concentration distribution (Fig. 3d, e). Whereas training the model from scratch on the small-scale transfer dataset resulted in an overfitted model with accuracy as low as 22.1% (Supplementary Fig. 4). We next plotted the salient features identified by transfer model in Fig. 3f, where specific pore structures were also highlighted with clearly defined boundaries. This opened up opportunities to further explore the common mechanisms driving reaction rate variations in both isotropic and anisotropic porous architectures.

We next evaluated whether cGAN-FRT could be applied for Rnorm prediction in electrochemical conversion of K3[Fe(CN)6] on foam nickel (Fig. 3g–i) using the knowledge learned from pre-trained databases. This reaction served as a model heterogeneous catalysis system to understand reaction kinetics and optimize catalyst design in electrochemical catalysis for energy conversion and environmental remediation39. The selection of nickel electrode resulted from its high catalytic activity and selectivity for \({{\rm{Fe}}}{({{\rm{CN}}})}_{6}^{3-}\) reduction. The current density was fixed at 0.75 × 10−2 mA cm−2. Initial concentration c0 was 1.05 × 10−6 mol cm−3. Then, the transfer learning model could be built to capture reaction rate variations with three representative square images of foam-structured nickel (Fig. 3h, “Materials and Methods”). As shown in Fig. 3h, i, cGAN-FRT showcased a high performance in predicting the local concentration and Rnorm values with error not exceeding 6.8%. These results suggested the feasibility of obtaining high-performance structure-reaction rate relationships by cGAN-FRT source model and transfer model, without the need to develop new models from scratch.

Comparison of cGAN-FRT, QSFs, and numerical simulation

We assessed the predictive accuracy of cGAN-FRT and QSFs methods by evaluating their ability to capture the orientation sensitivity of Rnorm. The ML model reported by Liu et al.25 was used to represent QSFs-method due to high prediction accuracy and extensive training data.

Accuracy

We proposed two kinds of hypothetical structures (named HA and HB) with similar QSFs but different gi values, in which HA and HB had higher gi values along diagonal and principal axes directions, respectively (Supplementary Fig. 5). Compared with HA whose Rnorm was 0.57 and 0.42 for 0.3 and 0.7 porosity at Pe = 100, Rnorm for HB was reduced by half (0.33 and 0.24 for 0.3 and 0.7 porosity; Fig. 4a–d). Notably, the QSFs-method yielded similar results for HA (Rnorm = 0.52 and 0.38) and HB (Rnorm = 0.55 and 0.39), indicating its inability to capture Rnorm diversity across structures with similar QSFs but different structural anisotropy. In contrast, cGAN could predict the Rnorm with an accuracy up to 97.2%.

a–d Conditions with similar quantitative structural features (QSFs) but different anisotropy factor gi. a Normalized concentration (cid) distribution and b Normalized effective reaction rate (Rnorm) variations for axis anisotropic architecture; c cid distribution and d Rnorm variations for diagonal anisotropic architecture. e, f Conditions with the same QSFs and gi but different flow directions. e cid distribution and f Rnorm variations under x+ fluid for structure with diagonal textures on x-z plane. g cid distribution and h Rnorm variations under y+ fluid for structure with diagonal textures on x-z plane. HA and HB were hypothetical structures with similar QSFs but different gi values. HC was the hypothetical anisotropic structure with diagonal textures. Source data are provided as a Source Data file.

We also assessed the accuracy in capturing the orientation sensitivity of Rnorm for anisotropic structure (HC) with diagonal textures on x-z plane (Supplementary Fig. 5). We simulated the Rnorm values under x+ fluid and y+ fluid conditions defined in Fig. 1 at Da = 10 and Pe = 100, 1000, 10000. As shown in Fig. 4e–h, Rnorm varied significantly with fluid direction. When the fluid direction was changed from x+ to y+, Rnorm shifted from 0.72 and 0.65, to 0.56 and 0.41, for 0.3 and 0.7 porosity at Pe = 100. The QSFs-method failed to capture the orientation sensitivity of Rnorm (Fig. 4f) because most critical factors (e.g., specific surface area, pore orientation, and even coordination number) were scalars rather than vectors, in which only tortuosity and pore-throat ratio were adjusted according to fluid direction40. Notably, cGAN-FRT could achieve an accuracy of 96.9% (Fig. 4h). This suggested the robustness of cGAN-FRT in capturing orientation sensitivity of Rnorm for reactive transport within anisotropic porous structures.

Convenience

cGAN-FRT was more convenient than both numerical simulation and QSFs-method. First, unlike hard-to-obtain 3D physical models and QSFs information, it was much easier for cGAN-FRT to acquire binarized images by using standard camera and image processing software (e.g., ImageJ)41. Second, cGAN-FRT could generate valuable information within short time of 10 s by simple input command, whereas numerical simulation required longer than 6 h to produce results for single case. Third, cGAN-FRT workflow enabled rapid establishment of structure-property relationships for new anisotropic structures by only 80 iterations and 30 data pairs. This resulted in approximately 2000-fold reduction in CPU time compared with direct simulations. In summary, cGAN-FRT not only matched the prediction accuracy of numerical simulation, but also boosted convenience by reducing time, cost and operational complexity in practical applications.

Characterization of salient structural features

Our MSFs-based cGAN-FRT had unique utility in the case where source and transfer model could identify and visualize importance of specific pore structures to local reaction rate and Rnorm. This would not only boost our frameworks’ effectiveness, but also offer mechanistic insights into reactive transport in porous heterogeneous catalysis. To this end, we identified visual structural features underlying the model’s predictions for both isotropic and anisotropic cases.

The heat map shown in Fig. 5 was taken from the side view of porous structure with fluid from left to right side of images. It was interesting to find that the areas with high attention score were closely related to the structures of pore throats and curved channels (Fig. 5a–c). For example, for isotropic structure with 0.3 porosity and 0.0075 cd (Fig. 5a), cGAN-FRT focused on a curved channel and a pore throat with 0.5 throat-to-pore ratio (TPr). Similarly, for anisotropic structure with 0.3 porosity and 0.0075 cd (Fig. 5c), the pore throats with 0.4 TPr still had the highest attention score. Similar phenomena were also observed in the structures for other porosities (Supplementary Fig. 6).

a Heat maps for isotropic architectures with different porosities and throat-to-pore ratio (TPr). b Structural features for high-attention regions. c Heat maps for anisotropic architectures with different porosities and TPr. d Schematic diagram of local synergic angle and corresponding cloud diagram at different flow channels. Relationship between average synergic angle and Rnorm for different conditions: e Porosity (ε) = 0.1, f ε = 0.3. Relationship between attention score and Rnorm colored by average synergic angle: g isotropic and h anisotropic architectures. Source data are provided as a Source Data file.

It was also noticed that cGAN always focused on the inflow boundary (i.e., the left side of images), where attention areas displayed fractal-like structures (Fig. 5a and c) characterized by gradual decrease in pore size. This suggested that fractal structures might also be the important factor that exerted influence on reaction rate. This finding was consistent with Murray’s law in biomimetics42, where leaves and blood vessels relied on fractal patterns to enhance mass transfer and distribution. However, pore throats, curved channels, and fractal structures were unlikely to always receive high attention scores. When fluid direction was changed from x+ to y+ (Fig. 5 and Supplementary Fig. 7), the attention score for original fractal structures dropped from 0.72 to 0.22. This highlighted the orientation sensitivity in reaction rate and provided the most likely explanation to the reason why HA and HB with similar QSFs exhibited different Rnorm values.

The heatmaps above guided the prediction of the local reaction rate, rather than Rnorm. To ensure the validity of the results, we also developed a DLCV model based on 3DCNN to directly map six lateral images to Rnorm. Further details were provided in the “Materials and Methods” section and Supplementary Figs. 8–10. Our results showed that the 3DCNN, with 98% accuracy, also identified the inlet, pore throat, and curved channels as the key reaction zones, confirming the reliability of the cGAN-based heatmap structure.

Taken together, high-attention areas predominantly accounted for fractal structures consisting of pore throats and curved channels in both isotropic and anisotropic porous architectures. These discoveries inspired us to consider the common synergy of physical fields observed in these structures, which might have connections with reactive transport dynamics.

Physical field synergy revealed by salient structural feature

To verify the above hypothesis, we attempted to elucidate the physical fields within the salient pore throats and curved channels. According to Eq. 12, Rnorm was linked to two variables, i.e., reaction rate constant for fluid-solid interfacial reaction (kr, cm s−1) and local concentration (ci, mol cm−3). Since kr was constant, ci was the dominant variable that relied on mass transfer. To identify the dominant factors in local mass transfer, we integrated the governing equation (Eq. 8 in “Materials and Methods”) over the fluid-solid interface as

Nondimensionalization produced the correlation as

and further we had

In arbitrary geometries, the local synergic angle was written as

where Sh, Re, Sc was the local Sherwood number (Sh = kmx/D), local Reynolds number (Re = ρux/μ) and Schmidt number (Sc = μ/ρD). u (cm s−1) was the local velocity vector at any point on the surface. ∇C (mol cm−4) was the concentration gradient vector that varied spatially within the porous structure. θ (°) was the local synergic angle that measured the alignment of two vectors. Calculation of θ relied on dot product between ∇C and u vectors, in which θ was the scalar being independent on surface orientation, geometric configuration, and external reference frame. It was only the function of relative direction of the two vectors at any given point, making it applicable to the surface with arbitrary orientations.

Equations 2 and 3 suggested three pathways available for enhancing mass transfer, and they were (i) increasing Re value, (ii) using high-viscosity fluid, and (iii) increasing dimensionless integration (i.e., St, Sum of the mass sources within boundary layer) by increasing the value of cosθ, concentration gradient, and velocity43. Among them, minimizing θ allowed the maximization of cosθ and Shx value (Fig. 5d), giving rise to what is termed principle of PFS (θ is the synergic angle, St is synergic number)43,44. The PFS was adopted in the field of heat and mass transfer enhancement45,46. Evident is that smaller θ led to higher rate of reactant transport onto solid surface by water flow (Eqs. 3–4). To verify the effect of PFS on Rnorm, we performed the correlation analysis between Rnorm and average synergic angle θV calculated by volumetric averaging of local synergic angles as

where V (cm3) was the total porous volume, Vj (cm3) and θj (°) the volume and synergic angle of the jth pore unit, and n the total number of units at flow section.

Clearly is visible that, the smaller the synergic angle, the higher the rate at which reactants were carried by water flow onto the solid surface (Eqs. 4 and 5), leading to higher local concentration ci. Hence, we examined the local synergic angle distribution across various structural features (Fig. 5d). The results illustrated that the flat channels yielded larger θ values approaching 180°, whereas the curved channels exhibited much smaller θ values (70°–150°). The presence of pore throats even generated θ values being typically smaller than 60°. We next analyzed the correlation between global synergic angle (θV) and Rnorm. As shown in Fig. 5e, f, with increased θV from 70° to 100°for porosity of 0.1, the Rnorm values were decreased from 0.5 to 0.2 by nearly 60%. This inverse relationship was also observed for other porosities (Supplementary Fig. 11).

Based on these findings, we examined the connection between θV and attention score for both isotropic and anisotropic structures. Figure 5g, h showed that porous structures with high θV tended to have relatively low attention scores. As θV was decreased from 100° to 30°, attention score was increased from 0.2 to 0.8. This suggested a strong linkage between PFS and Rnorm variability. We next elucidated the hydrodynamic mechanisms behind PFS. The flow pattern analysis for these features indicated the close correlation between PFS and diversion of streamlines (Supplementary Fig. 12). For flat channels, the streamlines were almost parallel to channel, leading to less effective reactant-pore surface interaction. For curved channels, however, collision between streamlines and channel walls enhanced their mass transfer. For pore throats, the streamlines not only collided with pore surfaces inside throat channels, but also diverted towards pore surfaces at throat exits. This would greatly decrease the synergic angle and enhance local mass transfer according to PFS principle. The fractal structured pores comprised multi-scale curved channels and pore throats, which further enhanced their ability to initiate inertial flow. These flow patterns promoted synergy between concentration gradient and velocity field, which might provide the most likely explanation for the role played by these structural features in diversifying the Rnorm.

Discussion

In this study, we provide a proof-of-concept demonstration of data-driven DLCV method for visualizing the nexus between anisotropic pore network and reactive transport in porous heterogeneous catalysis. This can be achieved by combining a two-steps cGAN with feature representation transfer learning (cGAN-FRT) to reconstruct 3D pore network and predict local reaction rates from MSFs, directional and reaction features from pixel-scale images, Péclet number, and Damköhler number. Owing to limitation of training data, the methods developed herein were applicable for the characteristic length within porous media in the range of 10−5 to 10−3.

Compared with QSFs, the MSFs-based cGAN-FRT framework is more effective for predicting and elucidating the reactive transport within the anisotropic porous structures. First, unlike QSFs-method (e.g., surface area, porosity, and tortuosity) that is limited by isotropic assumption of statistical input information, the multi-model DLCV allows the prediction of local reaction rate in 3D anisotropic structure that is previously unachievable by traditional measurement and ML methods. This overcomes the inability to measure local reaction rates, which provides a convenient and precise tool for fine-tuning catalytic activity. Second, MSFs makes it feasible to create a transferable link between reaction rate and morphological features of anisotropic porous structures using simple photography and cGAN-FRT workflow. This not only addresses the generalizability associated with geometric diversity, but also overcomes the non-transferability of QSFs across different porous materials that may share similar QSFs values yet exhibit different structural anisotropy. We show that the structure-property relationship learned from dimensionless isotropic datasets can be transferred to arbitrarily anisotropic porous structures. In this manner, more accurate prediction for reaction rate can be accomplished for porous structure with diversity of anisotropies, Pe and Da values with an error below 7%. Third, the cGAN-FRT can provide mechanistic insights into how structural heterogeneity affects reaction rate by highlighting the key MSFs associated with PFS. It is worth noting that this task can never be done by fragmented QSFs-based methods. Last, cGAN-FRT can well address the trade-off between convenience and accuracy, by reducing dozens of operational steps (e.g., Gas Adsorption Spectroscopy, Brunauer–Emmett–Teller, and 3D Computed Tomography)40,41 for QSFs extraction and saving three orders of magnitude in CPU time compared with numerical simulations.

This study may have a broader implication that extends to reactive transport processes in other relevant fields. For example, combining cGAN-FRT with annealing algorithms47 enables inverse design of porous catalysts to optimize charge and mass transport in fuel cells, tune selectivity in CO2 electroreduction, and enhance heterogeneous catalytic degradation of pollutants48. Within above contexts, the fractal pore-throat structures widely observed in blood vessels and lungs are known for their high reactive transport efficiency44,46, which also inspires the development of porous materials toward separation and recovery of value-added elements in wastewater and seawater49. However, the current workflow relies on two-phase QSGS datasets, which only captured solid–pore growth at a single scale, but is incapable of reproducing the multiscale, self-organizing evolution of geological porous media, especially in the wormholing regimes50. To develop these applications, the multi-phase QSGS method (e.g., Fast-QSGS)51 should be used during dataset construction to capture multiscale pores with self-similar characteristics and complex diagenetic processes. On the other hand, applying 3DCNN-FRT algorithms to multi-molecular heterogeneous catalysis and intermolecular interaction remains a challenge because the databases are pre-trained based on the assumptions of continuum mechanics (Eqs. 6–10) and bimolecular dataset. Future effort will be needed to mitigate these limitations by training cGAN-FRT that is more suitable for multi-scale, multi-component, and multi-process reactive transport across both natural and engineered systems.

Methods

Input data for Generator 2

To simplify the setup, we focused on cube-shaped porous architecture with unidirectional flow perpendicular to its surfaces. The six faces of the cube were defined as upstream, top, bottom, two sides, and downstream based on the flow direction. This setup resulted in six possible fluid directions: x+ (direction 1), x− (direction 3), y+ (direction 2), y− (direction 4), z+ (direction 5), and z− (direction 6) (Fig. 1a, b). This represented a fundamental unit of the reactive transport process in heterogeneous catalysis, mineral dissolution, and environmental transport.

Input data for Generator 2 included Damköhler number (Da), Péclet number (Pe) and structure slices. To simplify the setup, we focused on cube-shaped porous architectures with unidirectional flow perpendicular to the surface. The cube porous structures were generated by two-phase QSGS method52, in which there were three major input parameters, i.e., porosity ε, core distribution probability cd, and growth probability in 26 directions gi (i = 1, 2, …, 26). The cd was used to control the averaged pore size, and the gi was used to control the anisotropy of the pore shape. Supplementary Fig. 13 and Table 1 showed the 26 growth directions of the pores. Supplementary Fig. 14 provided an example of the generated porous architecture model, where the pores (white phase) were stochastically distributed within the continuous solid phase (black phase). Structural anisotropy was obtained by changing gi in 26 directions (Fig. 1a, b), which corresponded to the vectors from the cube center to each edge midpoint, vertex, and face center. The directions 1, 2, and 5 represented x, y, and z direction in coordinate system, respectively. Notably, the characteristic lengths of these porous media ranged from 10−5 to 10−3, serving as a limitation on the available image information.

For source dataset with isotropic porous structures, the porosities ε were set to be 30%, 50%, 70%, and 90%. The pore sizes were controlled by taking different core distribution probability cd, including 0.0125(1-ε), 0.025(1-ε), 0.05(1-ε), and 0.1(1-ε). Structural isotropy was achieved by setting growth probability in 26 directions gi to 0.001. Each parametric combination was explored, generating 10 iterations per cluster. Each structure had six inlet directions, five Da values (i.e., 0.01, 0.1, 1, 10, 100) and three Pe values being typical of heterogeneous catalysis (i.e., 100, 1000, 10000), and this resulted in the construction of 14400 scenarios (4 × 4 × 10 × 6 × 5 × 3).

For transfer dataset with anisotropic structures, the porosities ε and core distribution probability cd were consistent with those in the source dataset. Each parametric combination was generated only once. The 0.0125(1-ε) and 0.1(1-ε) cases were designated for fluid flow in the x+ direction (Fig. 1), while 0.025(1-ε) and 0.05(1-ε) cases were assigned to the y+ and z+ directions, respectively. The gi values in 26 directions were calculated from the images of porous structure using the method described by Chiang et al.35. Each structure had one inlet direction with 1–5 Da values and 1–3 Pe values, which generated 30-240 scenarios (4 × 4 × 1 × 1 × [1 to 5] × [1 to 3]).

Output data generation by fluid dynamic-concentration coupled modeling

The output of Generator 2 was concentration field slices calculated using 3D fluid dynamics-concentration coupling models based on three assumptions, i.e., (i) the solid phase was stationary and non-deformed, and the porosity was constant, (ii) the fluid phase satisfied no-slip condition on the fluid-solid interface, and (iii) the porous media were saturated43. The fluid flow was described by using momentum conservation equation (Eq. 6) and continuity equation (Eq. 7), and the concentration was simulated by using mass conservation equation (Eq. 8).

where ρ (g cm−3) was the fluid density, u (cm s−1) the vector of flow velocity, t (s) the time, p (Pa)) the pressure, I the unit vector, μ (Pa s) the kinematic viscosity, c (mol cm−3) the concentration of reactant, and D (cm2 s−1) the diffusion coefficient of reactant.

For fluid-solid reactions in the porous architectures, we considered a bimolecular heterogeneous reaction expressed by a generalized equation as53

where A was chemical species in aqueous solutions, B the reactant in solid phase and C the product existed either in aqueous phase (dissolution) or solid phase (adsorption). This equation had been reported to be adequate for representing the chemical reactions in a wide range of heterogeneous systems and applications53. We implemented the bimolecular heterogeneous reaction by applying irreversible first-order reaction kinetics (intrinsic reaction rate constant at fluid-solid interface) as the boundary condition at fluid-solid interfaces according to

where n denoted the unit normal vector at the solid wall pointing to the fluid region, kr (cm s−1) the reactive rate constant for fluid-solid interfacial reaction and α the order of reaction kinetics. In this study, we only considered the first-order chemical reaction (α = 1.0). Then the internal concentration boundary could be rewritten as

where Da denoted the Damköhler number calculated by Da = kr/(D/L). L (cm) was the characteristic length calculated by π/sA, and sA (cm−1) was the specific surface area14. In this study, sA values of geometric model and actual porous media were calculated by three lateral images of porous structure based on the geometric Coefficient54.

The modeling was performed by using Comsol Multiphysics 5.5 Software55. Inlet flow velocity was obtained from the Péclet number (Pe) by u = Pe × D/L. All the coefficients obtained from the software were listed in Supplementary Table S2. The inflow, outflow, periodic, reactive, and zero-flux boundaries and initial conditions were given in Supplementary Text S2.

The output of cGAN-FRT was the dimensionless normalized concentration (cid), obtained by normalizing the steady-state local concentration with respect to the initial concentration (c0, mol cm−3). The local reaction rate (Rlocal, mol cm−2 s−1) and effective reaction rate (Rr, mol cm−2 s−1) were then calculated as follows

where N was the total number of pixels at fluid-solid interface, cid the steady-state normalized concentration of the i-th pixels at fluid-solid interface.

We next defined the normalized Rr as

where Rnorm was the dimensionless normalized effective reaction rate that quantified the discrepancy between Rr and the well-mixed reaction rate for c = c0.

Model architecture for cGAN-FRT

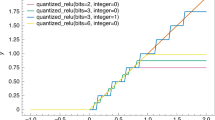

Generator 1 was trained based on SliceGAN32, which took a latent vector z, reshaped it to 64 × 4 × 4 × 4, and processed it through five 3D transposed convolution layers (kernel size k = 4, stride s = 2, and padding p varying between 2 and 3) to iteratively upsample the feature maps. The final output was a 3 × 64 × 64 × 64 volume, followed by a softmax activation. For discrimination 1, a 2D network (memory size ~11 MB) received 3-channel 64 × 64 inputs and processed them through five 2D convolution layers (kernel size k = 4, stride s = 2, and padding p varying between 1 and 0). The discriminator’s output was a 1 × 1 × 1 scalar, representing the real/fake classification.

Generator 2 was designed with a 3D U‑Net architecture. The model accepted a 1 × D × H × W grayscale input volume (i.e., 1 × 64 × 64 × 64) together with two scalar inputs (Da and Pe). These scalars were first embedded by a two‑layer fully connected network into a 64‑dimensional feature vector. The embedded feature map was then broadcast across the depth, height, and width dimensions and concatenated with the grayscale volume, yielding a 65‑channel tensor. This tensor passed through five 3‑D down‑sampling blocks (kernel k = 4, stride s = 2, padding p = 1; the first block omitted BatchNorm). The encoder outputs were fed into five 3D up‑sampling blocks (kernel k = 4, stride s = 2, padding p = 1), with skip connections from the corresponding encoder layers restoring spatial detail. Last, a 3D transposed‑convolution layer followed by a Tanh activation produced a 3 × D × H × W RGB volume whose voxel intensities lay within [−1, 1].

Discriminator 2 was built to distinguish between real and fake 3D images by incorporating the embedded Pe and Da features. It received a grayscale volume, scalar Da and Pe values, and a color volume as inputs. The scalar inputs were first processed by an encoder to produce a 64‑dimensional feature vector, which was then reshaped and broadcast to match the spatial dimensions of the input volumes. These broadcast features were concatenated with the grayscale and color volumes along the channel dimension, forming a 68‑channel tensor. The combined input was then passed through a sequence of three 3D convolutional layers (kernel k = 4, stride s = 2, padding p = 1), each being followed by a LeakyReLU activation. Batch normalisation was applied to the second and third layers. A final 3D convolution (kernel k = 4, stride s = 1, padding p = 1) produced a PatchGAN grid of logits, with each element evaluating the authenticity of its local 4 × 4 × 4 patch. Binary‑cross‑entropy with logits was used as the adversarial loss, enabling the network to progressively extract discriminative volumetric features being sensitive to the conditioning parameters.

In Generator 1, the input was three lateral images from the QSGS porous model, and the output was a reconstructed 3D model. The discriminator evaluated quality by comparing slices of the reconstructed model from different angles with the input images32. In Generator 2, the Da and Pe numbers served as reactive information, and structural information was collected from slices of the reconstructed model in Generator 1, spaced one pixel apart. The output was slices of normalized concentration (cid) field. All slices for both input and output were cut along the flow direction.

Model architecture for 3DCNN

For 3DCNN model, the six images were stacked in the order of upstream, top, bottom, two sides, and downstream into a 3D tensor with dimensions (6, 64, 64), where 6 was the channel number. These six channels represented the six faces of the cube, and their order was critical for the model’s learning and predicting. Then, the 3D tensor was fed into the model, which consisted of three 3D convolutional layers, three 3D max-pooling layers, and two fully connected layers. The first convolutional layer took in the six input channels and outputted 16 channels, followed by 3D max-pooling. The second and third convolutional layers outputted 32 and 64 channels, respectively, with each followed by pooling. After these layers, the tensor was flattened and mapped into a 64-dimensional space via a fully connected layer. Additionally, an embedding layer was used to map the Da and Pe values into the same 64-dimensional space, which was then combined with the image sequence information to better capture the features. Finally, the convolutional features, image sequence information, and Da-Pe embedding were passed through a final fully connected layer to produce the one target output.

The key hyperparameters of the 3D CNN model included as follows. The convolutional layers had a kernel size of 3 × 3 × 3 with 16, 32, and 64 channels; the pooling layers used a 3 × 3 × 3 kernel with a stride of 2; and the Da value was embedded into a 64-dimensional space. The learning rate was set to 0.001, and the model was trained for 100 epochs.

Data structure analysis for source dataset

To ensure rationality in transferring knowledge, the transfer learning strategy was established based on data structure analysis that illuminated data variation. The violin plot in Supplementary Fig. 15 shows the dependency of data distribution on pore structure features. For example, Rnorm distribution for porosity of 0.5 retained its dumbbell shape even when Da was increased from 0.01 to 100. As Rnorm distribution was shifted to violin shape as porosity was increased to 0.9. Considering that the feature representation transfer learning (FRT) was aimed to discover a shared feature space in which the data distributions across domains were close to each other, it was suitable to transfer the salient features focused by source models to a new transfer model to enhance learning of the new datasets with small sample size38.

Electrocatalytic setup and operation

To verify the applicability of our frameworks in real heterogeneous catalysis, we compared the predicted Rnorm values with experimentally measured values based on the electrocatalytic conversion of K4Fe(CN)6 on porous foam nickel electrodes. K4Fe(CN)6 was widely used for electrochemical analysis due to electron transfer-controlled reaction mechanism, which facilitated the direct manipulation of the rate constant (kr) with respect to current intensity10. Porosity, specific surface area, and characteristic length of nickel cathodes were 0.9, 26.7 cm−1, and 0.1177 cm, respectively.

The flow-through electrochemical cell was made of the carbon felt anode (1.5 cm × 1.5 cm × 1.5 cm) and foam nickel cathode (1.5 cm × 1.5 cm × 1.5 cm) with the electrode spacing of 1 cm. The mass loading of nickel was 2.1 g. To enable uniformity of inlet flow, the inlet cover was set by a 15° slope with an ostium (projected area of 5 × 10−2 cm2) located at the center (Supplementary Fig. 16). All the electrodes were connected to the external circuit by using alligator clips. The electrochemical measurements of nickel electrode (working electrode) were performed with a DC power station (750D, Chenhua Co. Ltd., China) at room temperature (24 °C). Prior to each group of experiments, the reactor was rinsed with deionized water (DI-water) for three times.

For measurement of Rnorm, the flow-through test was performed at 1.05 × 10−6 mol cm−3 K4Fe(CN)6 (99%) in 1 × 10−6 mol cm−3 KCl (98%) under superficial velocity of 2 × 10−2, 4 × 10−2, and 6 × 10−2 cm s−1 by adjusting the flow rate using peristaltic pump (BT300-1F; Longer Pump; China). The current density was fixed at 0.75 × 10−2 mA cm−2. Potential of 0.34 V was applied, and Tafel plot was given in Supplementary Fig. 17. No iR compensation was performed in this study. The kr (cm s−1) could be calculated by the Faraday law as13

where i (mA cm−2) was the current density, m (1.0) the number of electron transfer, c0 (mol cm−3) the initial concentration and F (9.65 × 104 C mol−1) the Faraday constant. Thus, the kr was 0.74 × 10−4 cm s−1. Then, the Da values could be computed as Da = kr/(D/L) = 1.2. With Da values, the boundary conditions for simulation were derived to calculate the reaction rates and consequently establish a dataset for TL. The outlet concentration (ce, mol cm−3) was recorded at intervals of five minutes over 30 min duration, and the effective reaction rate (Rr, mol cm−2 s−1) was derived from the curve-fitting of the concentration-time correlation (Supplementary Fig. 18) according to

where L (cm) was the characteristic length. Rnorm could be obtained by substituting Rr into Eq. 14.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The data supporting the findings of this study are available within the paper and source data files. Source data are provided within the paper. Due to size constraints, the full training dataset (>200 G) is available from the authors upon reasonable request. Data access requests will be addressed within 2 weeks. Source data are provided with this paper.

Code availability

All source code generated and used in this study are available on https://doi.org/10.5281/zenodo.1618586356.

References

Fechete, I., Wang, Y. & Védrine, J. C. The past, present and future of heterogeneous catalysis. Catal. Today 189, 2–27 (2012).

Schauermann, S., Nilius, N., Shaikhutdinov, S. & Freund, H.-J. Nanoparticles for heterogeneous catalysis: new mechanistic insights. Acc. Chem. Res. 46, 1673–1681 (2013).

Vásquez-Céspedes, S., Betori, R. C., Cismesia, M. A., Kirsch, J. K. & Yang, Q. Heterogeneous catalysis for cross-coupling reactions: an underutilized powerful and sustainable tool in the fine chemical industry?. Org. Process Res. Dev. 25, 740–753 (2021).

Cui, X., Li, W., Ryabchuk, P., Junge, K. & Beller, M. Bridging homogeneous and heterogeneous catalysis by heterogeneous single-metal-site catalysts. Nat. Catal. 1, 385–397 (2018).

Hauer, B. Embracing nature’s catalysts: a viewpoint on the future of biocatalysis. ACS Catal. 10, 8418–8427 (2020).

Lin, L. et al. Heterogeneous catalysis in water. JACS Au 1, 1834–1848 (2021).

Gao, P., Zhang, L., Li, S., Zhou, Z. & Sun, Y. Novel Heterogeneous Catalysts for CO2 Hydrogenation to Liquid Fuels. ACS Cent. Sci. 6, 1657–1670 (2020).

Wang, S. Application of solid ash based catalysts in heterogeneous catalysis. Environ. Sci. Technol. 42, 7055–7063 (2008).

Climent, M. J., Corma, A., Iborra, S. & Sabater, M. J. Heterogeneous catalysis for tandem reactions. ACS Catal. 4, 870–891 (2014).

Boudart, M. Turnover rates in heterogeneous catalysis. Chem. Rev. 95, 661–666 (1995).

Zhang, Z., Zandkarimi, B. & Alexandrova, A. N. Ensembles of metastable states govern heterogeneous catalysis on dynamic interfaces. Acc. Chem. Res. 53, 447–458 (2020).

Xu, H. et al. Gaseous heterogeneous catalytic reactions over Mn-based oxides for environmental applications: a critical review. Environ. Sci. Technol. 51, 8879–8892 (2017).

Chen, Y., Miller, C. J. & Waite, T. D. Heterogeneous fenton chemistry revisited: mechanistic insights from ferrihydrite-mediated oxidation of formate and oxalate. Environ. Sci. Technol. 55, 14414–14425 (2021).

Lin, Y., Yang, C., Wan, Z. & Qiu, T. Lattice Boltzmann simulation of intraparticle diffusivity in porous pellets with macro-mesopore structure. Int. J. Heat. Mass Transf. 138, 1014–1028 (2019).

Wu, C.-D. & Zhao, M. Incorporation of molecular catalysts in metal–organic frameworks for highly efficient heterogeneous catalysis. Adv. Mater. 29, 1605446 (2017).

Zhang, S. et al. Mechanism of heterogeneous fenton reaction kinetics enhancement under nanoscale spatial confinement. Environ. Sci. Technol. 54, 10868–10875 (2020).

Bruix, A., Margraf, J. T., Andersen, M. & Reuter, K. First-principles-based multiscale modelling of heterogeneous catalysis. Nat. Catal. 2, 659–670 (2019).

Liu, X. et al. Molecular transport in zeolite catalysts: depicting an integrated picture from macroscopic to microscopic scales. Chem. Soc. Rev. 51, 8174–8200 (2022).

Raoof, A., Nick, H. M., Hassanizadeh, S. M. & Spiers, C. J. PoreFlow: a complex pore-network model for simulation of reactive transport in variably saturated porous media. Comput. Geosci. 61, 160–174 (2013).

Varloteaux, C., Vu, M. T., Békri, S. & Adler, P. M. Reactive transport in porous media: pore-network model approach compared to pore-scale model. Phys. Rev. E 87, 023010 (2013).

Rabbani, A., Babaei, M., Shams, R., Wang, Y. D. & Chung, T. DeePore: a deep learning workflow for rapid and comprehensive characterization of porous materials. Adv. Water Resour. 146, 103787 (2020).

Nakano, K., Ohbuchi, A., Mito, S. & Xue, Z. Chemical interaction of well composite samples with supercritical CO2 along the cement - sandstone interface. Energy Procedia 63, 5754–5761 (2014).

Wang, H. et al. Scientific discovery in the age of artificial intelligence. Nature 620, 47–60 (2023).

Bratko, I. Machine learning in artificial intelligence. Artif. Intell. Eng. 8, 159–164 (1993).

Liu, M., Kwon, B. & Kang, P. K. Machine learning to predict effective reaction rates in 3D porous media from pore structural features. Sci. Rep. 12, 5486 (2022).

Stewart, M. L., Ward, A. L. & Rector, D. R. A study of pore geometry effects on anisotropy in hydraulic permeability using the lattice-Boltzmann method. Adv. Water Resour. 29, 1328–1340 (2006).

Koponen, A., Kataja, M. & Timonen, J. Permeability and effective porosity of porous media. Phys. Rev. E 56, 3319–3325 (1997).

Whiting, G. T., Nikolopoulos, N., Nikolopoulos, I., Chowdhury, A. D. & Weckhuysen, B. M. Visualizing pore architecture and molecular transport boundaries in catalyst bodies with fluorescent nanoprobes. Nat. Chem. 11, 23–31 (2019).

Kaestner, A., Lehmann, E. & Stampanoni, M. Imaging and image processing in porous media research. Adv. Water Resour. 31, 1174–1187 (2008).

Voulodimos, A., Doulamis, N., Doulamis, A. & Protopapadakis, E. Deep learning for computer vision: a brief review. Comput. Intell. Neurosci. 2018, 7068349 (2018).

Wang, Y. D., Blunt, M. J., Armstrong, R. T. & Mostaghimi, P. Deep learning in pore scale imaging and modeling. Earth-Sci. Rev. 215, 103555 (2021).

Kench, S. & Cooper, S. J. Generating three-dimensional structures from a two-dimensional slice with generative adversarial network-based dimensionality expansion. Nat. Mach. Intell. 3, 299–305 (2021).

Jha, D. et al. Enhancing materials property prediction by leveraging computational and experimental data using deep transfer learning. Nat. Commun. 10, 5316 (2019).

Menke, H. P., Bijeljic, B., Andrew, M. G. & Blunt, M. J. Dynamic three-dimensional pore-scale imaging of reaction in a carbonate at reservoir conditions. Environ. Sci. Technol. 49, 4407–4414 (2015).

Chiang, M., Wang, X., Landis, F., Dunkers, J. & Snyder, C. Quantifying the directional parameter of structural anisotropy in porous media. Tissue Eng. 12, 1597–1606 (2006).

Röding, M., Ma, Z. & Torquato, S. Predicting permeability via statistical learning on higher-order microstructural information. Sci. Rep. 10, 15239 (2020).

Hassanin, M., Anwar, S., Radwan, I., Khan, F. S. & Mian, A. Visual attention methods in deep learning: an in-depth survey. Inf. Fusion 108, 102417 (2024).

Lashkaripour, A. et al. Machine learning enables design automation of microfluidic flow-focusing droplet generation. Nat. Commun. 12, 25 (2021).

Beck, V. A. et al. Inertially enhanced mass transport using 3D-printed porous flow-through electrodes with periodic lattice structures. Proc. Natl. Acad. Sci. 118, e2025562118 (2021).

Katz, A. J. & Thompson, A. H. Quantitative prediction of permeability in porous rock. Phys. Rev. B 34, 8179–8181 (1986).

Gómez-de-Mariscal, E. et al. DeepImageJ: a user-friendly environment to run deep learning models in ImageJ. Nat. Methods 18, 1192–1195 (2021).

Zheng, X. et al. Bio-inspired Murray materials for mass transfer and activity. Nat. Commun. 8, 14921 (2017).

Yu, Y., Pei, S., Zhang, J., Ren, N. & You, S. Bio-inspired porous composite electrode for enhanced mass transfer and electrochemical water purification by modifying local flow pattern. Adv. Funct. Mater. 33, 2214725 (2023).

Guo, Z. Y., Li, D. Y. & Wang, B. X. A novel concept for convective heat transfer enhancement. Int. J. Heat. Mass Transf. 41, 2221–2225 (1998).

Cheng, J., Qian, Z. & Wang, Q. Analysis of heat transfer and flow resistance of twisted oval tube in low Reynolds number flow. Int. J. Heat. Mass Transf. 109, 761–777 (2017).

Guo, J. & Huai, X. Numerical investigation of helically coiled tube from the viewpoint of field synergy principle. Appl. Therm. Eng. 98, 137–143 (2016).

Zhang, J. & Medlin, J. W. Catalyst design using an inverse strategy: from mechanistic studies on inverted model catalysts to applications of oxide-coated metal nanoparticles. Surf. Sci. Rep. 73, 117–152 (2018).

De, S., Zhang, J., Luque, R. & Yan, N. Ni-based bimetallic heterogeneous catalysts for energy and environmental applications. Energy Environ. Sci. 9, 3314–3347 (2016).

Yang, L. et al. Bioinspired hierarchical porous membrane for efficient uranium extraction from seawater. Nat. Sustain. 5, 71–80 (2022).

Golfier, F. et al. On the ability of a Darcy-scale model to capture wormhole formation during the dissolution of a porous medium. J. Fluid Mech. 457, 213–254 (2002).

Yang, G., Liu, T., Lu, X. & Wang, M. Fast-QSGS: a GPU accelerated program for structure generation of granular disordered media. Comput. Phys. Commun. 302, 109241 (2024).

Guan, D., Wu, J. H. & Jing, L. A statistical method for predicting sound absorbing property of porous metal materials by using quartet structure generation set. J. Alloy. Compd. 626, 29–34 (2015).

Ryan, E. M., Tartakovsky, A. M. & Amon, C. Pore-scale modeling of competitive adsorption in porous media. J. Contam. Hydrol. 120-121, 56–78 (2011).

Rabbani, A., Jamshidi, S. & Salehi, S. Determination of specific surface of rock grains by 2D imaging. J. Geol. Res. 2014, 945387 (2014).

COMSOL Multiphysics v5.5. COMSOL Multiphysics Reference Manual (accessed November 2019) https://doc.comsol.com/5.5/doc/com.comsol.help.comsol/COMSOL_ReferenceManual.pdf.

Yuan, Y. Visualizing Nexus of Porous Architecture and Reactive Transport in Heterogeneous Catalysis by Deep Learning Computer Vision and Transfer Learning. code for Visualizing Nexus of Porous Architecture and Reactive Transport in Heterogeneous Catalysis by Deep Learning Computer Vision and Transfer Learning. https://doi.org/10.5281/zenodo.16185863 (2025).

Acknowledgements

Project supported by the National Natural Science Foundation of China (Grant No. 52325003, 52200190, U21A20161), the Fundamental Research Funds for the Central Universities (Grant No. HIT.OCEF2022019), and State Key Laboratory of Urban Water Resource and Environment (Harbin Institute of Technology, No. 2023DX03).

Author information

Authors and Affiliations

Contributions

Y.Y.: conceptualization, methods, software, formal analysis, investigation, writing–original draft, writing–review & editing, funding acquisition. B.W.: methods, software, formal analysis, investigation, data curation, writing–original draft, writing–review & editing, visualization. R.W.: investigation, validation, writing–original draft, writing–review & editing. N.R.: methods, data curation, validation, supervision, writing–review & editing. S.Y.: conceptualization, original draft, writing, focusing the investigation, methods, writing–review & editing, supervision, resources, funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yu, Y., Wu, B., Wei, R. et al. Visualizing nexus of porous architecture and reactive transport in heterogeneous catalysis by deep learning computer vision and transfer learning. Nat Commun 16, 8107 (2025). https://doi.org/10.1038/s41467-025-63481-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-63481-4