Abstract

Propylene oxide (PO) is a key industrial chemical, often produced by epoxidizing propylene with H2O2 over titanium silicalite-1. However, current H2O2 production via the anthraquinone process relies on fossil-derived hydrogen, leading to substantial CO2 emissions. Sustainable PO synthesis requires green H2O2 production. Here, we present a fully unassisted, solar- and bias-free system that generates H2O2. This platform enables modular, eco-friendly on-site PO synthesis by coupling formaldehyde oxidation with two-electron O2 reduction under alkaline conditions. Efficient propylene epoxidation under these conditions is achieved using titanium silicalite-1 modified by introducing dinuclear titanium sites with Ti–O–Ti bonds, as revealed by density functional theory and instrumental analyses. The unassisted H2O2 production system is integrated with the modified titanium silicalite-1 to realize continuous PO production (1657 μmolPO cm−2 over 24 h), without electric or solar energy input. This unassisted PO production method can thus be energy-independent, offering a sustainable alternative to conventional processes.

Similar content being viewed by others

Introduction

Propylene oxide (PO) is widely utilized in the production of valuable chemicals such as polyurethanes, polyesters, and propylene glycol (PG)1,2,3. The global annual production of PO is estimated at 11.2 million tons and is expected to rise because of the increasing demand for this chemical4. However, the current industrial methods of PO production5,6 rely on toxic reagents and generate substantial amounts of byproducts that need to be removed using additional purification steps7. The synthesis of PO via titanium silicalite-1 (TS-1)-catalyzed epoxidation of propylene with H2O2 offers the advantages of a low environmental impact and high selectivity ( > 95%)8,9,10, although its reliance on H2O2, which is typically generated through the large-scale anthraquinone process, results in the use of expensive H2 and production of substantial amounts of organic waste and CO211,12,13. Previously, we reported an integrated photo-electro-heterogeneous catalytic system combining photoelectrochemical H2O2 production and propylene epoxidation14. However, this system requires solar energy (which limits PO production to daytime hours) and a substantial amount of land because of the low efficiency of light-driven H2O2 production15,16,17, which limits practical applications.

Herein, we developed an unassisted H2O2 production system requiring no solar or electrical energy by combining the two-electron O2 reduction reaction (2e– ORR) with the formaldehyde oxidation reaction (FOR). This system also generates H2 in situ, which is particularly notable given that H2 serves as a promising energy carrier and an essential reactant in the anthraquinone process currently used for commercial H2O2 production11,12,13. However, the above system is active in alkaline solutions and is therefore incompatible with the current propylene epoxidation process based on conventional TS-1, which is only active in neutral solutions8,9,10.

To overcome the inhibitory effects of alkali metal ions and alkaline conditions on the propylene epoxidation, we modified TS-1 by treating it with tetrapropylammonium bromide (TPABr) and ethanolamine. This modification resulted in the formation of dinuclear titanium sites featuring Ti–O–Ti bonds. The presence of these sites was verified using X-ray absorption spectroscopy (XAS), ultraviolet-visible (UV-Vis) spectroscopy, and Raman spectroscopy confirmed the presence of these dinuclear Ti sites. The results of density functional theory (DFT) calculations supported these findings, demonstrating that dinuclear Ti sites were active for propylene epoxidation and synergistically interacted with alkali metal ions to inhibit the hydrolysis of PO to PG. The modified TS-1 exhibited a high epoxidation activity even under alkaline conditions (pH 11), thus holding promise for efficient propylene epoxidation in challenging environments. By integrating the unassisted H2O2 production system with the modified TS-1–promoted propylene epoxidation system, we successfully demonstrated unassisted PO production with in situ H2 generation without the need for solar or electrical energy and achieved a PO productivity (1657 μmolPO cm−2 over 24 h) more than eight times that previously reported for a photoelectrochemical system relying on solar energy14, and our system simultaneously produced H2 in situ (3344 μmol cm−2 over 24 h). Technoeconomic analysis in this work indicates that our process features production costs (H2O2: $1.209 kg–1; PO: $2.168 kg–1) comparable with those of conventional PO production processes while featuring markedly lower utility and capital investment demands and therefore enables more sustainable decentralized PO production.

Results

Unassisted H2O2 production system with in situ H2 generation

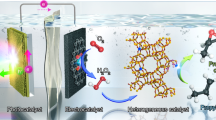

The thermodynamic potential for the production of H2O2 via the 2e– ORR is 0.69 V versus the reversible hydrogen electrode (VRHE)18. Coupling this reaction with an oxidation reaction having a thermodynamic potential more negative than 0.69 VRHE is crucial for achieving unassisted H2O2 production without any solar or electric energy input. Conventional coupling with the oxygen evolution reaction, which features a high potential of 1.23 VRHE and considerable activation energy, necessitates the input of solar or electric energy for H2O2 production19,20. In contrast, we have coupled the 2e– ORR with the FOR, which has a highly negative thermodynamic potential of –0.22 VRHE21, enabling unassisted H2O2 production (Fig. 1a). Furthermore, the FOR generates H2 in situ, along with formic acid. To demonstrate unassisted H2O2 production, we employed graphitic ordered mesoporous carbon (GOMC) and copper nanowire (CuNW)-based electrocatalysts for the 2e– ORR and FOR, respectively (Fig. 1a).

a Schematic of the unassisted H2O2 production system showing a transmission electron microscopy image of the O2 reduction catalyst (graphitic ordered mesoporous carbon, GOMC) and scanning electron microscopy image of the formaldehyde oxidation catalyst (copper nanowires on copper foam, CuNW/CF). b O2 reduction activity of GOMC and c Faradaic efficiency (FE) of H2O2 formation over GOMC determined at 0.45 VRHE in the presence and absence of the gas-diffusion electrode in 0.1 M sodium phosphate buffer (NaPi) solutions with various pH. d Linear sweep voltammetry (LSV) profiles showing the oxidation of formaldehyde over CuNW/CF in alkaline and neutral solutions. e FEs of H2 and formic acid formation over CuNW/CF determined at 0.1–0.4 VRHE in 0.1 M NaPi at pH 11 containing 50 mM formaldehyde. f Superposition of the LSV curves and g time-dependent H2 and H2O2 productions at the anode obtained for the combined CuNW/CF (formaldehyde oxidation, FLD is formaldehyde)–GOMC with GDE (H2O2 production) system at 0 V vs. the counter electrode in 0.1 M NaPi, containing 50 mM formaldehyde at the anode. Inset: magnification of productions for 3–5 h in 0.1 M NaPi at pH 6. The error bars indicate the standard deviation based on three independent measurements. Source data are provided as a Source data file.

GOMC was prepared by mixing Al-SBA-15 mesoporous silica22 with an aromatic mesophase pitch, heating the mixture, and removing the silica template by treatment with HF and HCl23,24. This electrocatalyst featured a high density of active edge sites (Fig. 1a), which are recognized as the active centers for the 2e– ORR in alkaline solutions24. The edge-rich structure was confirmed using X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), and Raman spectroscopy analyses (Supplementary Fig. 1). N2 adsorption–desorption isotherm analysis revealed that GOMC had a high specific surface area (334 m2 g–1) and well-defined mesoporous (2–10 nm) structure, which provided abundant accessible sites and facilitated mass transport25,26 (Supplementary Fig. 2). The presence of an ordered mesoporous framework was confirmed by small-angle X-ray scattering (SAXS) analysis, with the distinct q*(100), √3q*(110), and 2q*(200) reflections indicating a hexagonally arranged mesostructure (P6mm symmetry)27,28 (Supplementary Fig. 3). Building upon this well-defined mesostructure, we evaluated the 2e– ORR performance of GOMC in a sodium phosphate buffer (Fig. 1b). The catalyst exhibited markedly enhanced activity in an alkaline environment (0.1 M NaPi, pH 11), with performance exceeding that observed under a nearly neutral condition (0.1 M NaPi, pH 6), which is typically optimal for conventional TS-1–catalyzed propylene epoxidation, although the efficiency is inherently limited by the low solubility of O2 in aqueous media.

To address the problem of low O2 solubility in aqueous solutions, we distinctively incorporated a gas-diffusion electrode (GDE)29 into the GOMC system and thus increased the current density at 0.45 VRHE more than 15.8-fold in an alkaline buffer (0.1 M NaPi, pH 11) (Fig. 1b and Supplementary Fig. 4). The onset potential of GOMC (0.65 VRHE) was very close to the thermodynamic potential of the 2e– ORR (0.69 VRHE), even after GDE incorporation. The faradaic efficiency (FE) of H2O2 production during a 5 h reaction at 0.45 VRHE under alkaline conditions (pH 11) was close to 87%, exceeding that at pH 6 by 20% (Fig. 1c).

For the selective FOR, we used copper catalysts, which are widely used for partial aldehyde oxidation30. To maximize the number of active sites available for the FOR, we deposited copper nanowires onto the surface of copper foam (CF) through a straightforward chemical reaction and electroreduction (Fig. 1a and Supplementary Fig. 5)31. The current density for the FOR in the alkaline solution (pH 11) markedly exceeded that in the nearly neutral solution (pH 6), as in the case of the 2e– ORR (Fig. 1d). Furthermore, the FEs of H2 and formic acid production approached 100% at pH 11 (Fig. 1e). To evaluate the durability of the CuNW/CF catalyst during the FOR, we conducted postreaction characterizations after 5 h of operation (Supplementary Figs. 6 and 7), confirming that the catalyst maintained its morphological, crystallographic, and electronic structural integrity under the employed conditions.

Finally, we combined the 2e– ORR GOMC system with the FOR CuNW system to achieve unassisted H2O2 production with the intersection of the current density curves for the 2e– ORR and FOR indicating the operational conditions for H2O2 production (Fig. 1f). This intersection represents the point at which the anode and cathode operate at the same energy level without an external bias, which enables spontaneous electron flow between the two half-reactions. At pH 11, the predicted operating current was 4.45 mA cm–2 at ~0.45 VRHE (equivalent to 0 V vs. the counter electrode), exceeding that at pH 6 (0.16 mA cm–2, Fig. 1f and Supplementary Fig. 8) more than 27.8-fold. The yields of H2O2, H2, and formic acid after 5 h (265, 306, and 617 μmol cm–2, respectively) markedly exceeded those achieved under neutral conditions, in which case barely detectable production was observed under the neutral conditions (Fig. 1g and Supplementary Figs. 9 and 11). To elucidate the mechanistic origin of this enhanced H2O2 production, we employed electrochemical in situ Raman spectroscopy to probe the reaction intermediates on the GOMC catalyst (Supplementary Fig. 12). Notably, a weak but gradually increasing Raman peak appeared at ~850 cm–1 as the potential was decreased below 0.6 V vs. RHE. Based on Raman mechanistic studies, we attribute this emerging signal to the *OOH intermediate32. This observation provides direct spectroscopic evidence for the formation of *OOH under alkaline reaction conditions and highlights its mechanistic role as a key intermediate in the 2e– ORR pathway. These findings underscore the importance of an alkaline environment for the efficient in situ production of H2O2.

The integration of the H2O2 production system with the propylene epoxidation process is crucial for achieving unassisted PO production. However, the conventional TS-1 zeolite, commonly used for propylene epoxidation, is neither active nor stable in the alkaline environments8,9,10 required for efficient H2O2 production. Therefore, developing a TS-1 zeolite catalyst that is both active and stable in basic solutions is critical for achieving high-performance unassisted PO production.

Propylene epoxidation over unmodified and modified TS-1

To clarify the effect of alkali metal ions under various pH conditions, which are critical for electrochemical H2O2 production, on propylene epoxidation over TS-1 catalysts, we compared the PO production rates of TS-1 containing only mononuclear Ti sites (TS-1(100)) in deionized (DI) water, 0.1 M NaPi at pH 6, and 0.1 M NaPi at pH 11 (Fig. 2a). These rates decreased in the order of DI water (498 μmolPO h−1 gcat−1) > 0.1 M NaPi at pH 6 (220 μmolPO h−1 gcat−1) > 0.1 M NaPi at pH 11 (16 μmolPO h−1 gcat−1), which demonstrated the inhibitory effect of alkali metal ions and alkaline conditions on propylene epoxidation. Based on the results of Gordon et al.33, we prepared a TS-1 catalyst containing mono- and dinuclear Ti sites (TS-1(33)) to investigate the activity of the dinuclear Ti sites for propylene epoxidation (Fig. 2a). It is important to note that groundbreaking work of Gordon et al. focused on neutral conditions and not the effect of existing alkali metal conditions where TS-1 is typically considered inactive33. Compared with TS-1(100), TS-1(33) exhibited a lower PO production rate in DI water (355 μmolPO h–1 gcat–1). However, the PO production rate of TS-1(33) in 0.1 M NaPi solution at pH 6 was marginally lower (318 μmolPO h−1 gcat−1) than that in DI water and substantially exceeded that of TS-1(100) under the same conditions. In 0.1 M NaPi at pH 11, TS-1(33) exhibited a PO production rate (103 μmolPO h−1 gcat−1) six times that of TS-1(100). Thus, compared with TS-1(100), TS-1(33) achieved an improved PO production rate under alkaline conditions and in the presence of alkali metal ions, which is potentially because of the presence of dinuclear Ti sites in TS-1(33).

a PO production rates of nonmodified TS-1(100) and TS-1(33) catalysts. b PO production rates of modified TS-1(100)-m and TS-1(33)-m catalysts. c UV-Vis diffuse reflectance spectra of silicalite-1, TS-1, and modified TS-1. d Ti K-edge XANES of TiO2 (anatase), TiO2 (rutile), TS-1, and modified TS-1. e Fourier transform magnitude of the Ti K-edge EXAFS signal for TS-1(33)-m. f Wavelet transform of the Ti K-edge EXAFS data of TS-1(33)-m obtained using Morlet’s method with η = 5 and σ = 144,45. Reaction conditions for (a, b): 0.1 M NaPi (pH 11), 45 mg catalyst, gas flow O2:C3H6 = 40:1 (41 sccm total), room temperature, H2O2 supply rate is 24.1 μmol h–1; PO production rates averaged over 4–6 h. Source data are provided as a Source data file.

To overcome the inhibitory effect of alkali metal ions and alkaline conditions on propylene epoxidation, we modified TS-1(33) by treatment with TPABr and ethanolamine under hydrothermal conditions, adapting an earlier regeneration method developed for TS-1 deactivated during cyclohexanone ammoxidation under high pH34 (see “Methods” for details). Compared with TS-1(33), the modified TS-1(33) (TS-1(33)-m) exhibited a lower PO production rate in DI water (89 μmolPO h−1 gcat−1), in line with the common understanding that the monomeric Ti sites in TS-1 are responsible for propylene epoxidation (Fig. 2b)5,7,9,10. However, in 0.1 M NaPi at pH 6, the PO production rate of TS-1(33)-m (387 μmolPO h−1 gcat−1) exceeded that of TS-1(33) (Fig. 2b). Even in 0.1 M NaPi at pH 11, TS-1(33)-m showed PO production rate (260 μmolPO h−1 gcat−1) two times that of TS-1(33) and 16 times that of TS-1(100) (Fig. 2b). These results demonstrated the high activity of TS-1(33)-m for propylene epoxidation under alkaline conditions. To rationalize the low activity of TS-1(33)-m in DI water and its high activity in the presence of alkali metal ions, we analyzed the liquid phase obtained after the reaction by gas chromatography (GC), revealing that a substantial amount of PG formed after 6 h of the reaction in water (Supplementary Table 1). The above findings suggest that PO hydrolysis was inhibited in the presence of alkali metals and demonstrated that (i) TS-1(33)-m was active for propylene epoxidation under alkaline conditions and (ii) alkali metal ions exhibited synergistic rather than inhibitory effects, contrary to what is generally understood for TS-135,36. To understand the active site structure and reaction mechanism of TS-1(33)-m, we analyzed it through instrumental methods and DFT simulations.

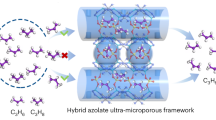

Characterization of unmodified and modified TS-1

XRD and scanning transmission electron microscopy-energy-dispersive X-ray spectroscopy analyses showed that TS-1(33) and TS-1(33)-m preserved the crystal structure of TS-1 and featured well-distributed Ti species (Supplementary Figs. 13–15). N2 physisorption and Barrett–Joyner–Halenda (BJH) pore size distribution analyses reveal that TS-1(33)-m exhibited hierarchical porosity with ~4.0 nm mesopores and the intrinsic micropores of TS-1 (Supplementary Table 2 and Supplementary Fig. 16). Despite the presence of hierarchical mesopores, the significantly improved catalytic activity of modified TS-1 under alkaline conditions was primarily attributed to dinuclear Ti–O–Ti sites rather than enhanced mass transport through mesopores, as demonstrated by the pronounced activity difference between the modified and unmodified catalysts in neutral (DI water) and alkaline media (Fig. 2a, b). The diffuse reflectance UV-Vis spectra of freshly prepared and modified TS-1(100) and TS-1(33) showed an absorption band at 220 nm, attributed to isolated tetrahedral Ti species in the zeolite framework (Fig. 2c)37,38,39. The additional band at 260–280 nm observed for TS-1(33)-m was ascribed to oligomeric TiOx species and indicated the presence of Ti-O-Ti bonds in dinuclear Ti sites, as reported by Gordon et al.33. Although the extraction of detailed structural information from the extended X-ray absorption fine structure (EXAFS) spectra results of TS-1(100)-m (Si/Ti = 100) proved challenging because of the low Ti contents and poor data quality (Supplementary Fig. 17), UV-Vis spectroscopy revealed a similar 260–280 nm band (Fig. 2c), confirming the presence of Ti–O–Ti species within TS-1(100)-m. These structural differences between TS-1(100) and TS-1(100)-m probably contributed to PO productivity of TS-1(100)-m in 0.1 M NaPi buffer at pH 11 exceeding that of TS-1(100) under the same conditions nine-fold. The simulated UV spectrum of a model dinuclear Ti cluster obtained using the CIS/6-31 G exchange functional featured peaks at 250.6, 264.7, and 280.9 nm (Supplementary Fig. 18)40,41. The molecular cluster of this model featured pentacoordinate Ti and an OH group providing a bridging oxygen, while a proton was attached to the adjacent oxygen and accounted for charge neutrality. As the introduction of dinuclear Ti sites into the zeolite framework can substantially influence its UV-Vis spectrum, we simulated the UV–Vis spectrum of an optimized zeolite model featuring dinuclear Ti species with Ti occupying stable T-sites (Supplementary Fig. 19)42,43. This spectrum featured a weak peak in the 220–280 nm range, in line with our experimental data (Fig. 2c), supporting the existence of dinuclear Ti sites. Raman spectroscopy analysis confirmed the changes in Ti species in TS-1 upon modification (Supplementary Fig. 20). The additional Raman bands at 144, 514, and 638 cm–1 in the spectrum of TS-1(33)-m were attributed to Ti–O–Ti species related to the TiOx oligomers formed during the modification (Supplementary Fig. 20 and Supplementary Table 3)33. Together, UV–Vis and Raman spectroscopic analyses indicated that TS-1(33)-m contained dinuclear Ti species with Ti–O–Ti bonds. The change in Ti coordination upon the modification of TS-1(33) was confirmed by X-ray absorption near-edge structure analysis (Fig. 2d), which revealed a minor reduction in the intensity of the 1s–3d transition corresponding to a tetrahedral symmetry (4970 eV)44,45,46 This decrease was attributed to the transformation of the Ti coordination geometry, influenced by the presence of bridging oxygen, from tetragonal to pentagonal. To gain insights into the structural details of the TiOx species, we recorded the Ti K-edge EXAFS spectra of TS-1(33) and TS-1(33)-m (Fig. 2e and Supplementary Fig. 21). A fourth-shell fitting was performed on the zeolite before and after modification while keeping the coordination number constant in accordance with the model structure. The EXAFS spectrum of TS-1(33) featured two separate peaks at 1.8 and 2.8 Å, in agreement with the Ti–O–Ti structure (Supplementary Fig. 21 and Supplementary Table 4), while that of TS-1(33)-m exhibited a more intense Ti−O peak at 2.5 Å (Fig. 2e and Supplementary Table 5), thus indicating a modification in the Ti−O−Ti coordination structure. Further structural analysis using k3-weighted wavelet-transformed extended X-ray absorption fine structure (WT-EXAFS) spectroscopy (Fig. 2f) showed that the local maxima from the Ti−O and Ti−O−Ti contributions of the Ti K-edge had overlapping values in k-space47,48. This finding suggests that the second shell in the Ti K-edge EXAFS spectra indeed arises from the same single scattering. The good overlap of the WT-EXAFS spectra reconstructed and projected to k-space with the experimental EXAFS spectra indicates that the WT-EXAFS data provided a good structural representation of dimeric Ti sites in the zeolite framework. DFT simulations were conducted to gain further structural insights and corroborate the existence of dinuclear Ti sites in TS-1(33)-m. The designed zeolite model contained dinuclear Ti sites, including three distinct Ti–O pairs and a Ti–O–Ti pair (Supplementary Figs. 22 and 23). A bridging OH group could form even for a single Ti site, although the scattering intensity at 3 Å (corresponding to the Ti–O–Si pair) was relatively weak. The modification of the zeolite-containing dinuclear Ti sites substantially altered the radial distribution function, leading to the formation of a bridging oxygen between framework-bound Ti atoms (Fig. 2e). The distances determined for the Ti–O and Ti–O–Ti pairs reasonably agreed with the structure generated by DFT simulations (Supplementary Table 5). These findings strongly suggest that the modification of the Ti-incorporated zeolite resulted in the formation of bridging oxygens between pairs of Ti atoms but do not fully explain the behavior of dinuclear Ti sites in the presence of alkali metal ions. To address this problem, we conducted additional DFT simulations in the presence and absence of Na+ ions.

DFT calculations performed for propylene epoxidation under alkaline conditions

The structure of dinuclear Ti sites in TS-1(33)-m was characterized using DFT simulations, employing the nudged elastic band (NEB) method with a 0.1 eV Å–1 force convergence threshold to estimate the minimum energy path, followed by the climbing-image nudged elastic band (CI-NEB) method with a stricter 0.05 eV Å–1 to refine transition states (TSs) (“Methods”)49. The DFT model incorporated propylene or PO and H2O2, with and without Na+ ions, in a zeolite cage containing dinuclear Ti sites (Fig. 3, Supplementary Table 6, Supplementary Fig. 24, and Supplementary Data 1). However, modeling the exact material under catalytic conditions is challenging due to limitations in capturing the full complexity of the zeolite environment, including dynamic interactions and solvent effects, which may affect the reliability of the results.

a, b Catalytic active site containing dinuclear Ti simulated using the NEB module. c Transition state for the stepwise conversion of propylene to PO in the zeolite cavity obtained using a threshold of 0.1 eV Å–1 through the climbing-image nudged elastic band (CI-NEB) simulation. A more detailed image is provided in Supplementary Fig. 24. (Black spheres: C; pink spheres: H; brown sphere: Na; red spheres: O; blue spheres: Si; turquoise sphere: Ti). Source data are provided as a Source data file.

To explore the influence of alkali metal ions, the proton in the bridging OH group was replaced with Na+. Initial configurations of propylene and PO within the zeolite cavity were optimized, but the idealized nature of the DFT model may not fully reflect the heterogeneous catalytic environment. TS structures were approximated using NEB (“Methods”) and refined with CI-NEB, and activation energies were calculated under various conditions (Fig. 3c, Supplementary Table 7, Supplementary Fig. 25, Supplementary Data 1, and Supplementary Movie 1). For zeolites with mononuclear Ti sites, no activation barrier was observed for converting propylene to PO without Na+ ions (Supplementary Table 6), but the presence of Na+ ions appeared to increase the activation energy to 0.4 eV, suggesting a possible reduction in epoxidation rate. However, these findings may be sensitive to the model’s assumptions, such as the simplified representation of Na+ ions interactions. For zeolites with dinuclear Ti sites, the calculated activation energies (0.0916 eV without Na+ and 0.0405 eV with Na+) were relatively low, suggesting efficient epoxidation, but these values may not fully account for real-world catalytic conditions, such as temperature or pH variations. The influence of Na+ ions was consistent with the proposed chemical environment, but the model’s simplifications could limit its predictive power. To elucidate the role of the bridging oxygen between the Ti atoms in the TS, we examined the Ti coordination shell by tracking changes in bond lengths (Fig. 3c, Supplementary Table 7, and Supplementary Movie 1). The coordination shell around Ti remained unaltered, although the μ-O–O• and O•–C bond lengths substantially changed as active oxygen and propylene merged to form PO. No change in the μ–O–Na bond length was observed, which suggested that the conversion of propylene to PO occurred readily even in the presence of Na+ ions. In the final (product) state, PO appeared to interact with the bridging OH via hydrogen bonding. The DFT results suggest that alkali metal ions might reduce PO hydrolysis under alkaline conditions while potentially enhancing PO selectivity in dinuclear Ti sites compared to traditional TS-1 catalysts. Simulations under alkaline conditions indicated that dinuclear Ti sites could facilitate propylene conversion to PO, even with Na+ ions present, while the effect of solvent dynamics or surface defects may be missed. Based on these simulations, a TS-1(33)-m-based electro-heterogeneous catalytic system was proposed for improved PO production, still the limitations of DFT in fully replicating experimental conditions are present.

Unassisted PO production over TS-1(33)-m using bias-free H2O2 produced under alkaline conditions

To achieve high-performance unassisted PO production under alkaline conditions, we combined the TS-1(33)-m-catalyzed propylene epoxidation system with the bias-free H2O2 production system (Fig. 4a, Supplementary Note 1, and Supplementary Fig. 26). To effectively operate our electro-heterogeneous catalytic system, we considered not only the propylene epoxidation performance of TS-1(33)-m but also the 2e– ORR activity of the GOMC electrocatalyst for H2O2 production and CuNW/CF activity for the FOR. After systematically evaluating various alkaline electrolyte systems (sodium phosphate, borate, and sulfite), we selected sodium borate as the optimal electrolyte because of its nonprecipitating nature above 0.3 M (Fig. 4b and Supplementary Fig. 27) and superior PO production rate (266 μmolPO h–1 gcat–1 vs. 260 and 130 μmolPO h–1 gcat–1 for phosphate and sulfite, respectively; Supplementary Fig. 28). Sodium borate concentration studies (0.1–0.6 M) revealed a critical balance (Supplementary Figs. 29–31): 0.1 M maximized PO production (266 μmolPO h–1 gcat–1) but suppressed H2O2 production (43 μmol h–1 cm–2), while 0.6 M accelerated H2O2 production rate (183 μmol h–1 cm–2) but decelerated PO production rate (93 μmolPO h–1 gcat–1) by ~35% because Na⁺ promoted the disruption of the TS-1 active sites, in agreement with the titanium site blocking mechanisms of Na+ reported for sodium-modified TS-150. Under the optimal condition of 0.3 M condition balanced both processes, sufficient H2O2 (108 μmol h–1 cm–2) and PO (170 μmolPO h–1 gcat–1) productivities were achieved without substantially compromising the FOR activity at an elevated pH (Supplementary Figs. 29 and 32). Considering the above results, H2O2 production for our system could be advantageously operated under higher electrolyte concentrations due to increased ionic conductivity. This finding underscores the necessity of modifying the TS-1 catalysts for use in elevated Na⁺ concentrations for this system to be realized and function optimally. Finally, the TS-1(33)-m–based unassisted electro-heterogeneous catalytic system was integrated with the anodic FOR system under alkaline conditions to enable bias-free PO production (Fig. 4a). In this setup, H2O2 was continuously generated without any additional electric or solar energy input (Fig. 4c and Supplementary Fig. 33) at a rate of 140 μmol h−1 cm–2, 35 times higher than the previously reported value of 4 μmol h−1 cm–2 and close to that required for practical PO production (Supplementary Fig. 34)14. However, introducing TS-1(33)-m into this alkali-metal-containing high-pH buffer system in the presence of formaldehyde still presented a considerable challenge. Formaldehyde readily crossed the membrane and reacted with the peroxide generated by the 2e– cathodic ORR to induce the undesirable generation of formic acid at the cathode (Supplementary Fig. 35). This interaction critically poisoned TS-1(33)-m, substantially reducing system stability (Supplementary Fig. 36)51,52. To overcome this formaldehyde crossover, Na-A zeolite was used as a filter within the reactor (Fig. 4a, d and Supplementary Fig. 37), effectively capturing formaldehyde (Fig. 4d), preventing its migration to the cathode and subsequent formation of formic acid, and thereby protecting TS-1(33)-m from poisoning (Fig. 4e and Supplementary Figs. 38–41). Consequently, continuous and stable PO production was observed, reaching 238 μmolPO cm−2 over 5 h and 1657 μmolPO cm−2 over 24 h (Fig. 4f and Supplementary Figs. 34, 42, and 43). This result represents an eight-fold increase in PO production compared that reported previously14 (205 μmolPO cm–2 over 24 h, Supplementary Figs. 34a and 44) and underscores the potential of improved H2O2 production over TS-1(33)-m for efficient and stable PO production under alkaline conditions. Furthermore, H2 (3344 μmol cm–2, 162 μmol h–1 cm–2) and formic acid (6558 μmol cm–2, 334 μmol h–1 cm–2) were produced in situ with nearly 100% FEs via the FOR (Fig. 4f, g and Supplementary Figs. 34b and 45). Techno-economic analysis (Supplementary Note 2 and Supplementary Tables 8–13) revealed that the integrated unassisted PO production system requires 150,000 ton year–1 of formaldehyde to produce 200,000 ton year–1 of PO at $2.168 kg–1 which is lower than PO produced by conventional hydrogen peroxide to propylene oxide (HPPO) process ($2.36 kg–1) (Supplementary Figs. 46 and 47)4,53. Given that the South Korean supply of methanol used to produce formaldehyde is 1.88 million tons year–1, this demand can be easily met, accounting for only 8% of the national methanol consumption54. Similarly, the global supply of methanol (110 million tons year–1) used to produce formaldehyde readily covers the demand of our process, with <1.0% of this supply required55.

a Schematic of the unassisted catalytic system for propylene epoxidation. b PO production rate over TS-1(33) and TS-1(33)-m in 0.1 M NaPi, 0.1 M sodium borate, and 0.3 M sodium borate (all at pH 11). c H2O2 production in the unassisted catalytic system with GDE technology in 0.3 M sodium borate (pH 11). d Schematic of the Na-A zeolite filter. e Effect of the Na-A zeolite filter. (FLD is formaldehyde; reaction conditions: 0.3 M sodium borate buffer (pH 11), 60 mg of TS-1(33)-m, gas flow O2:C3H6 = 15:10 (25 sccm total), room temperature, continuous H2O2 supply rate of 24.1 μmol h–1). f PO and H2 productions for 5 h (Inset: extended data up to 24 h) and g selectivity of PO formation in the unassisted electro-heterogeneous catalytic system in 0.3 M sodium borate (pH 11) determined based on PO and propylene glycol yields (chemically) and the FE of H2 formation (electrochemically). The error bars indicate the standard deviation based on three independent measurements. Source data are provided as a Source data file.

Discussion

Unassisted PO production in an alkaline solution on modified TS-1 containing dinuclear Ti sites was achieved bias-free H2O2 generated without any electrical or solar energy input. Furthermore, H2 was produced in situ during the unassisted PO production. TS-1 was treated with a mixed solution of TPABr and ethanolamine to increase PO production rate to 260 μmolPO h−1 gcat−1 at pH 11. The results of DFT simulations suggested that the dinuclear Ti sites could catalyze propylene epoxidation in the presence of alkali metal ions and synergistically interacted with them to prevent the undesired hydrolysis of PO to PG. Hence, we configured a suitable system exploiting the enhanced activity of TS-1 under alkaline conditions. The modified TS-1 was integrated with an unassisted H2O2 production system combining the 2e– ORR and FOR. This integrated unassisted PO production system achieved a PO production rate (1657 μmolPO cm−2 over 24 h operation under 0.3 M sodium borate with pH 11) eight times higher than that previously reported for a photo-electro-heterogeneous catalytic system14 while producing valuable H2 (3344 μmol cm–2) in situ, thus holding promise for the green and efficient synthesis of various other petrochemicals.

Techno-economic analysis further underscores that the decentralized configuration achieves production costs (H2O2: $1.209 kg–1; PO: $2.168 kg–1) comparable to those of the conventional route (H2O2: $1 kg–1; PO: $2.36 kg–1), while lowering utility consumption and capital expenditures. Our system demonstrates a favorable combination of high productivity, long-term stability, and full energy independence relative to other recently reported strategies (Supplementary Table 14). The H2O2-generating platform features a modular architecture that is electrochemically compatible with a variety of small-molecule electron donors, such as formaldehyde, glycerol, and furfural (Supplementary Fig. 48). This versatility allows flexible tuning of anodic oxidation without compromising cathodic peroxide generation, further enhancing the adaptability of the system. Here, by integrating H2O2 generation, in situ H2 evolution, and PO synthesis into a single streamlined platform, our unassisted and decentralized platform not only achieves efficient performance but also significantly reduces energy demands and system complexity, suggesting its potential for sustainable PO manufacturing.

Methods

TS-1 synthesis

TS-1(100) was prepared following conventional hydrothermal method56. Tween 20 (2 g, Sigma-Aldrich) was added to DI water (21 mL), and the resulting solution was stirred and supplemented dropwise with aqueous tetrapropylammonium hydroxide (30.3 g, 1 M in water, Alfa Aesar), followed by tetraethyl orthosilicate (36 g, ≥99.0%, Sigma-Aldrich). After 1 h of stirring, a solution of titanium (IV) butoxide (0.61 g, 97%, Sigma-Aldrich) in isopropyl alcohol (9.12 g, ≥99.5%, Daejung Chemicals and Metals) was added dropwise. This synthesis gel had a molar ratio of 1 SiO2:0.01 TiO2:0.17 TPAOH:14.5 H2O:0.009 Tween 20:0.88 isopropyl alcohol. After 1 h of agitation, the mixture was transferred to a Teflon-lined stainless-steel autoclave and heated at 150 °C for 26 h. The resulting precipitate was isolated by centrifugation, washed multiple times with water, dried overnight at 110 °C, and calcined in a muffle furnace at 550 °C for 15 h to obtain TS-1(100). TS-1(33) was synthesized similarly but with a molar ratio of 1 SiO2:0.33 TiO2:0.17 TPAOH:14.5 H2O:0.009 Tween 20:0.88 isopropyl alcohol. The Si/Ti molar ratio of the TS-1 zeolites is denoted in parentheses following the material name, e.g., TS-1(X) corresponds to a Si/Ti molar ratio of X.

TS-1 modification34

Calcined TS-1 (2 g) was modified according to the following procedure: TS-1 was mixed with TPABr (0.78 g, 98%, crystals, Sigma-Aldrich) and ethanolamine (1 g, ≥98%, Sigma-Aldrich) in deionized water (13.2 mL). After stirring at room temperature for 2 h, the mixture was hydrothermally treated at 175 °C for 72 h in a Teflon-lined stainless-steel autoclave. After filtering, washing, and drying, the solid product was calcined at 350 °C for 1 h and 550 °C for 6 h to afford TS-1(100)-m and TS-1(33)-m, respectively.

Synthesis of GOMC

SBA-15 mesoporous silica was prepared through a process involving the dissolution of Pluronic P123 (Mn ≈ 5800, Sigma-Aldrich) in a water–HCl (Sigma-Aldrich) mixture followed by the addition of tetraethyl orthosilicate (98%, Sigma-Aldrich), aging, hydrothermal treatment, washing with ethanol, and calcination22. The silica walls of the SBA-15 were aluminated using a solution of AlCl3 (98%, Sigma-Aldrich) in ethanol, followed by drying and calcination to afford Al-SBA-15. GOMC was prepared by using Al-SBA-15 as the template and an aromatic mesophase pitch as the precursor, as reported elsewhere23. Al-SBA-15, mesophase pitch, and anhydrous ethanol were added to an agate mortar and mixed, and the resulting black slurry was dried at 60 °C. The dried grey powder was heated to 300 °C and maintained at that temperature for 4 h, and subsequently the temperature was increased to 900 °C and maintained at that temperature for 2 h under a flow of N2. The resulting GOMC/Al-SBA-15 composite was mixed with an ethanol solution of HF (Sigma-Aldrich) + HCl (Sigma-Aldrich) and stirred to remove the Al-SBA-15 template, and the solid was separated by centrifugation. The etching process was repeated once more, and the product was filtered, washed with ethanol and DI water, and dried at 60 °C to afford GOMC.

Fabrication of CuNW/CF30

Commercial copper foam (CF) (1 cm × 1 cm, 99.96%, MTI, Korea) was surface-cleaned via sequential sonication in isopropanol and 1 M HCl (30 min each, Samchun Chemical), oven-dried at 60 °C for 1 h, and immersed into an aqueous solution containing 2.67 M NaOH (98% pellets, Alfa Aesar) and 0.13 M (NH4)2S2O8 (98%, Sigma-Aldrich) for 2 h at 40 °C to induce the growth of Cu(OH)2 wires on the surface. Subsequently, the CF was rinsed and annealed in a flow of Ar at 200 °C for 2 h, convert Cu(OH)2 into Cu2O. Finally, Cu2O was converted into metallic copper via 10 min electrochemical reduction at a current density of –100 mA cm–2 in 1 M KOH (Samchun Chemical) using a three-electrode configuration.

Catalyst characterization

XRD patterns were recorded using a high-resolution X-ray diffractometer (SmartLab, Rigaku), operating at 200 kV and 45 mA with Cu Kα radiation (λ = 1.54 Å). Data acquisition was conducted in step mode over a 2θ range of 5–75° at a scan rate of 0.05° s−1. SAXS measurements were conducted at the PLS-II 6D UNIST-PAL beamline of Pohang Accelerator Laboratory (PAL) in Korea. The incident X-ray energy was 11.564 keV (λ = 1.07216 Å). SAXS patterns were collected using a 2D CCD detector (MX225-HS, Rayonix, USA) with a sample-to-detector distance of 3048.36 mm. The distance and scattering vector (q) were calibrated using a standard mesoporous silica. The Raman spectra of GOMC catalyst was carried out on a confocal microscope Raman system inVia Qontor (Renishaw). The excitation wavelength was 633 nm, and a ×50 microscope objective with a numerical aperture of 0.55 was used in all Raman measurements. It was performed in a spectroelectrochemical cell with an SP-50e potentiostat. UV-Vis diffuse reflectance spectra were measured using a Cary 5000 instrument (Agilent Technologies). SEM was performed on a SU8220 instrument (Hitachi High-Technologies) at 10 kV (Supplementary Fig. 49). TEM images were captured using a JEM-2100F microscope (JEOL) at an acceleration voltage of 200 kV (Supplementary Fig. 50). HRTEM images of the foam shape, samples were prepared using a Helios 450HP FIB system (FEI). N2 sorption isotherms were recorded on a Belsorp-Max II system (MicrotracBEL), following sample pre-treatment under vacuum at 110 °C for 4 h. Fourier-transform infrared spectra were collected using a Nicolet iS10 spectrometer equipped with a mercury cadmium telluride detector (Supplementary Fig. 51). Samples were pre-treated in a He flow at 400 °C for 3 h and cooled to room temperature under He for 30 min. Spectra were recorded using an average of 64 scans and a resolution of 4 cm−1 every 50 s. Raman spectra of TS-1 samples were obtained using an alpha300R micro-imaging Raman spectrometer (WITec, grating density = 1800 grooves mm–1) with a 532-nm Nd/yttrium-aluminum-garnet excitation laser and an electrically cooled charge-coupled-device detector. Ti K-edge X-ray absorption spectra (17,038 eV) were collected at the PLS-II 6D UNIST-PAL beamline at the Pohang Accelerator Laboratory (PAL) in transmission mode using a double-crystal Si(111) monochromator.

The Demeter program package, along with Athena and Artemis software, was used for EXAFS analysis57. After data processing in Athena, the background was subtracted using Rbkg = 1 Å to extract the EXAFS signal. The Kaiser–Bessel window function (1 Å−1 after k2-weighting) was applied to the extracted EXAFS data in k-space for Fourier transformation. Feff6L was utilized to generate the phase shifts and amplitude functions for the reference. The number of independent data points (Nidp) for curve fitting was determined to be greater than the number of variables (Nvar) following the Nyquist theorem, ensuring sufficient degrees of freedom. The scattering path in the model structure obtained from DFT simulations, was calculated using Feff. The amplitude reduction factor (S02) for Ti was set to 0.80 based on the fitted EXAFS spectrum of Ti foil. The statistical quality of the curve fitting was evaluated using the R-factor and χ2 function provided by the refinement tools.

Electrolyte preparation

For all buffers, solutes were dissolved in DI water and the pH was adjusted to the specified value with 1 M NaOH (Daejung Chemical Co., Ltd.). The final volume was set to 1 L. All reagents were used as received. To prepare 0.1 M sodium phosphate at pH 6, 13.80 g of NaH2PO4·H2O (97%, Duksan Co., Ltd.) and 15.60 g of NaH2PO4·2H2O (98-102%, Duksan Co., Ltd.) were dissolved to yield 0.1 M total phosphate concentration, then adjust the pH to 6. For 0.1 M sodium phosphate, pH 11, take the 0.1 M phosphate buffer at pH 6.0 and add 1 M NaOH dropwise until pH 11 is reached. For sodium borate, pH 11, dissolve H3BO3 (≥99.5%, powder, Sigma-Aldrich) in DI water and adjust to pH 11 using 1 M NaOH to obtain buffers of 0.1 M (6.18 g H3BO3), 0.3 M (18.55 g H3BO3), 0.6 M (37.1 g H3BO3). All solutions were stored in sealed glass bottles at room temperature and used within 2–3 months.

Propylene epoxidation test and product analysis by GC

The catalyst (45 mg) was suspended in a test solution (9 mL) within a 10-mL single cell (45 mm × 45 mm × 25 mm). O2 ( ≥ 98%, Techno Industrial Gas) and propylene gases (≥98%, Techno Industrial Gas) were continuously bubbled into the solution for 20 min prior to the start of the reaction to stabilize the gas flow. The reaction continued until completion, with the outlet gases periodically analyzed using a gas chromatograph (GC) (GC 7820 A, Agilent Technologies) equipped with an HP-FFAP column (30 m × 530 μm × 1 μm) and a flame-ionization detector. The leftover liquid samples were filtered through a 0.45-μm hydrophilic syringe filter (13HP045AN, Advantec MFS) and the filtrate was injected into a GC equipped with an HP-5 column (30 m × 320 μm × 0.25 μm) for component identification.

Residual H2O2 was quantified using the DPD method after the 6-h propylene epoxidation test. The H2O2 conversion rate (\({X}_{{{{\rm{H}}}}_{2}{{{\rm{O}}}}_{2}}\), %) was calculated as

where \({n}_{{{{\rm{H}}}}_{2}{{{\rm{O}}}}_{2}}\) and \({n}_{{{{\rm{H}}}}_{2}{{{\rm{O}}}}_{2}}^{r}\) are the amounts of injected and remaining H2O2, respectively.

PO selectivity (SPO, %) was calculated as

where nPO and nPG are the amounts of the produced PO and PG, respectively.

Product analysis and quantification

Product detection and quantification were performed using phase-specific analytical techniques:

PO, present in the gas phase, was quantified using gas chromatography with a flame ionization detector (GC-FID, Agilent 7890B) equipped with an HP-FFAP column. For the quantification of PO, we employed external calibration (200–3000 μM, R2 = 0.997) with direct collection of samples from the reactor outlet to prevent hydrolysis (Supplementary Fig. 52). H2O2 was quantified using the N,N-diethyl-p-phenylenediamine (DPD) method58. DPD (0.05 g, ≥98.0%, MilliporeSigma) was dissolved in 0.1 N H2SO4 (5 mL, Samchun Chemical), and horseradish peroxidase (5 mg, MilliporeSigma) was separately dissolved in DI water (5 mL). Both solutions were stored at 5 °C. Then, 0.1 M NaPi buffer (pH 6, 2.7 mL) was mixed with the DPD solution (0.05 mL), peroxidase solution (0.05 mL), and the sample (0.2 mL). The absorbance of the resulting mixture was measured at 551 nm using a Shimadzu UV-2600 spectrophotometer. An external standard curve with a coefficient of determination of R2 > 0.99 was used to quantify H2O2. Formaldehyde (37 wt%, Fisher Scientific) was quantified using a colorimetric method relying on acetylacetone59. Ammonium acetate (15.4 g, Sigma-Aldrich) was dissolved in water (50 mL), and the solution was supplemented with acetylacetone (0.2 mL, Sigma-Aldrich) and acetic acid (0.3 mL, Samchun Chemical) upon stirring and diluted with water (49.5 mL). The resulting acetylacetone reagent was stored in a refrigerator for no more than one day. For quantitative analysis, a 20.0 μL sample was acidified with 20.0 μL of 1 M HCl (Samchun Chemical) and then diluted with deionized water to a total volume of 2.0 mL. Next, 2.0 mL of the acidified sample was mixed with 2.0 mL of the acetylacetone reagent and heated to 60 °C for 10 min. The absorbance of the resulting mixture was measured at 414 nm using a UV-Vis spectrophotometer. Formaldehyde concentration was determined based on a calibration curve generated using standard formaldehyde solutions. For liquid product analysis, aliquots of the reaction mixture were analyzed by high-performance liquid chromatography (1260 Infinite, Agilent) with UV–vis detection at 220 nm. Samples were adjusted to pH 7 using 0.5 M H2SO4 (HPLC grade, Sigma-Aldrich) and then diluted with DI water to bring their concentrations within the range of the calibration curve. A Hi-Plex H column (7.7 mm × 300 mm, 8 μm) was used under the following conditions: analysis time = 20 min, flow rate = 0.6 mL min−1, and column temperature = 60 °C. H2SO4 (5 mM, HPLC grade, Sigma-Aldrich) was used as the mobile phase. The reaction products were quantified using a linear external standard curve (R2 > 0.99) for each compound. For gas product analysis, Ar gas (99.99%, Techno Industrial Gas) was continuously bubbled into the anolyte, and the outlet gas lines were directly connected to a gas chromatograph (6500 GC system, YL Instrument) equipped with a molecular sieve 13X column (Supelco) and thermal conductivity detector. The detection information is clearly summarized in the Supplementary Table 15 and Supplementary Fig. 53.

Yield and efficiency calculations

Yield and efficiency calculations are as follows.

where nPO is moles of PO produced quantified by GC, \({{n}_{{{{\rm{C}}}}_{3}{{{\rm{H}}}}_{6}}}^{{{\rm{i}}}{{\rm{n}}}}\), \({{n}_{{{{\rm{C}}}}_{3}{{{\rm{H}}}}_{6}}}^{{{\rm{o}}}{{\rm{u}}}{{\rm{t}}}}\) is inlet and outlet propylene molar flow rates, respectively. SPO was determined as mentioned above.

where F is Faradaic efficiency (96,485 C mol–1), \({n}_{{{{\rm{H}}}}_{2}{{{\rm{O}}}}_{2}}\) is moles of generated H2O2 quantified by photometric method, Qtotal is the total charge passed (C).

Combined PO production system test and product analysis by GC

The reactor setup comprised three integrated chambers (Supplementary Fig. 54). The cathodic part contained 9 mL of 0.3 M sodium borate buffer (pH 11) with 60 mg of TS-1(33)-m catalyst suspended in the solution. A gas diffusion electrode (GDE) was integrated into a gas-chamber assembly, with O2 (15 sccm) fed through the GDE’s O2 needle and propylene (10 sccm) continuously bubbled into the solution. The mixture was stirred at 600 rpm to ensure homogeneous catalyst dispersion.

In the anodic part, a total of 10 mL of 50 mM formaldehyde solution was continuously injected at 6 mL h–1 using a syringe pump (KDS-100). Formaldehyde was circulated between chambers at 6 mL h–1 via a peristaltic pump (Masterflex L/S), while O2 gas convection through the GDE drove catholyte flow without mechanical stirring.

The reaction was conducted at 25 °C for 24 h under steady-state conditions.

DFT calculations

DFT calculations were performed using the Quantum ESPRESSO package, incorporating periodic plane-wave and ultrasoft pseudopotentials within the generalized gradient approximation proposed by Perdew, Burke, and Ernzerhof43,60. Electron-ion interactions were modeled using norm-conserving ultrasoft pseudopotentials, accounting for scalar relativistic effects. A plane-wave energy cutoff of 52 Ry and a charge density cutoff of 575 Ry were employed. Brillouin zone sampling was limited to the Γ-point. All atoms within the unit cell were allowed to relax, with the convergence criterion for the forces on each atom set to 0.02 eV Å–1. The Grimme-D3 method61 was used to address dispersion forces at the DFT level by applying posterior dispersion corrections to each energy calculation during the iterative energy minimization process for structure optimization and TS searches. The initial structures were optimized for both reactant and product states and then perturbed positionally and orientationally before being reoptimized to confirm that they represented global energy minima. The CI-NEB method was then applied to identify reaction coordinates and TS structures62. In brief, the NEB method was used to locate the minimum-energy paths between two minima, with the convergence criterion of 0.1 eV Å−1. The TSs along the NEB path were identified using the CI-NEB method, with a stricter convergence criterion of <0.05 eV Å–1. All calculations were performed using the NEB module of the Quantum ESPRESSO (Version 7.0) software. Additionally, the UV-Vis spectrum of the optimized Ti dimer in zeolites was simulated using the Quantum ESPRESSO package.

Electrochemical measurements and product quantification

All electrochemical measurements were performed using an electrochemical workstation (IviumStat). To obtain electrochemical activity of GOMC, a three-electrode setup was utilized with Pt wire counter electrode, Hg/HgO reference electrode (RE-61AP, ALS Co., Ltd). For analysis, the Pt counter electrode was replaced with a nickel foam electrode. For the working electrode, GOMC (5 mg), anhydrous ethanol (540 µL, Samchun Chemical), DI water (540 µL), and a Nafion solution (25 µL, Sigma-Aldrich) were homogeneously mixed using sonication, and the resulting ink was deposited onto hydrophobic carbon paper (1 × 1 cm, Sigracet 39BB, FuelCellstore) for the GDE system and hydrophilic carbon paper (1 × 1 cm, HCP020N, Wizmac) for the non-GDE system at a GOMC loading of 3 mg cm–2. All electrochemical reactions were performed in a lab-made H-type cell with the catholyte and anolyte (10 mL of 0.3 M sodium borate) separated by a Nafion 117 membrane. For the FOR, CuNW/CF was used as the working electrode (1 × 1 cm), Pt wire as counter electrode and Hg/HgO as reference electrode. Electrolyte contained 50 mM formaldehyde.

Potentials versus Hg/HgO were converted to those versus the RHE as

The conversion was validated by measuring the open-circuit potential of a clean Pt electrode in H₂-saturated 1 M KOH, which yielded ~0 V vs. RHE.

Linear sweep voltammograms were recorded at a scan rate of 1.5 mV s–1. Chronoamperometry tests were conducted under the same conditions, and I–V measurements were performed using the Ivium electrochemical workstation. For bias-free operation, a two-electrode system was utilized, with GOMC on carbon paper as the working electrode (hydrophobic carbon paper for GDE and hydrophilic carbon paper for non-GDE) and CuNW/CF as the counter electrode. The chronoamperometry tests of the overall system were carried out at 0 V. All measured potentials are reported without iR compensation.

In situ Raman measurements were performed using a Renishaw inVia Qontor confocal microscope system equipped with a custom-designed spectroelectrochemical cell (Supplementary Fig. 55). Raman spectra were acquired with a 633 nm excitation laser and a 50× objective lens (NA = 0.55). The electrochemical environment was controlled using a BioLogic SP-50e potentiostat.

The FE of hydrogen or formic acid formation was calculated as

where n is the number of transferred electrons (one for formic acid and two for H2). The error bars represent the standard deviation from three independent measurements. The exact standard deviation values are provided in the Source data. Where error bars are not shown, the data were obtained from a single measurement

Na-A zeolite preparation

Commercial molecular sieve 5 A (2 g, Sigma-Aldrich) was stirred in 200 mL of 1 M NaCl (Samchun Chemical) solution. The mixture was continuously stirred at 80 °C for 3 h. After ion exchange, the sample was thoroughly washed with DI water to remove residual NaCl, filtered, oven dried at 100 °C overnight, and calcined in a muffle furnace at 300 °C for 6 h to afford the Na-A zeolite.

Data availability

All data supporting the findings of this study are available within the article, its Supplementary Information, or from the Figshare repository63 (https://doi.org/10.6084/m9.figshare.29616110.v3). This includes the Source data underlying all main and Supplementary Figures (in Excel format) and Supplementary Data 1 (a .zip archive containing .xyz files from DFT calculations). The dataset is freely accessible for non-commercial academic use.

References

Zuwei, X., Ning, Z., Yu, S. & Kunlan, L. Reaction-controlled phase-transfer catalysis for propylene epoxidation to propylene oxide. Science 292, 1139–1141 (2001).

Torres Galvis, H. M. & de Jong, K. P. Catalysts for production of lower olefins from synthesis gas: a review. ACS Catal. 3, 2130–2149 (2013).

Kube, P. et al. Green synthesis of propylene oxide directly from propane. Nat. Commun. 13, 7504 (2022).

ECHEMI.com. Propylene oxide: from a gap of 467,000 tons to self-sufficiency is just around the corner. https://www.echemi.com/cms/257860.html (2021).

Nijhuis, T. A., Makkee, M., Moulijn, J. A. & Weckhuysen, B. M. The production of propene oxide: catalytic processes and recent developments. Ind. Eng. Chem. Res. 45, 3447–3459 (2006).

Teržan, J., Huš, M., Likozar, B. & Djinović, P. Propylene epoxidation using molecular oxygen over copper- and silver-based catalysts: a review. ACS Catal. 10, 13415–13436 (2020).

Ghanta, M., Fahey, D. R., Busch, D. H. & Subramaniam, B. Comparative economic and environmental assessments of H2O2-based and tertiary butyl hydroperoxide-based propylene oxide technologies. ACS Sustain. Chem. Eng. 1, 268–277 (2013).

Clerici, M. G. TS-1 and propylene oxide, 20 years later. In DGMK/SCI Conference Oxidation and Functionalization: Classical and Alternative Routes and Sources 165–176 (DGMK, 2005).

Lin, M., Xia, C., Zhu, B., Li, H. & Shu, X. Green and efficient epoxidation of propylene with hydrogen peroxide (HPPO process) catalyzed by hollow TS-1 zeolite: a 1.0kt/a pilot-scale study. Chem. Eng. J. 295, 370–375 (2016).

Russo, V., Tesser, R., Santacesaria, E. & Di Serio, M. Chemical and technical aspects of propene oxide production via hydrogen peroxide (HPPO process). Ind. Eng. Chem. Res. 52, 1168–1178 (2013).

Campos-Martin, J. M., Blanco-Brieva, G. & Fierro, J. L. G. Hydrogen peroxide synthesis: an outlook beyond the anthraquinone process. Angew. Chem. Int. Ed. 45, 6962–6984 (2006).

Yi, Y., Wang, L., Li, G. & Guo, H. A review on research progress in the direct synthesis of hydrogen peroxide from hydrogen and oxygen: noble-metal catalytic method, fuel-cell method and plasma method. Catal. Sci. Technol. 6, 1593–1610 (2016).

Yang, S. et al. Toward the decentralized electrochemical production of H2O2: a focus on the catalysis. ACS Catal. 8, 4064–4081 (2018).

Ko, M. et al. Direct propylene epoxidation with oxygen using a photo-electro-heterogeneous catalytic system. Nat. Catal. 5, 37–44 (2022).

Wang, Q. & Domen, K. Particulate photocatalysts for light-driven water splitting: mechanisms, challenges, and design strategies. Chem. Rev. 120, 919–985 (2020).

Rau, U. et al. Guide for the perplexed to the Schockley-Queisser model for solar cells. Nat. Photonics 13, 501–505 (2019).

Domen, K. et al. Photocatalytic solar hydrogen production from water on a 100 m2 scale. Nature 598, 304–307 (2021).

Gao, J. & Liu, B. Progress of electrochemical hydrogen peroxide synthesis over single atom catalysts. ACS Mater. Lett. 8, 1008–1024 (2020).

Wang, J. et al. Non-precious-metal catalysts for alkaline water electrolysis: operando characterizations, theoretical calculations, and recent advances. Chem. Soc. Rev. 49, 9154–9196 (2020).

Zhang, L., Wang, Z. & Qiu, J. Energy-saving hydrogen production by seawater electrolysis coupling sulfion degradation. Adv. Mater. 34, 2109321 (2022).

Li, G. et al. Dual hydrogen production from electrocatalytic water reduction coupled with formaldehyde oxidation via a copper-silver electrocatalyst. Nat. Commun. 14, 525 (2023).

Zhao, D. et al. Triblock copolymer syntheses of mesoporous silica with periodic 50 to 300 angstrom pores. Science 279, 548–552 (1998).

Lim, J. S. et al. Designing highly active nanoporous carbon H2O2 production electrocatalysts through active site identification. Chem 7, 3114–3130 (2021).

An, J. et al. Electrosynthesis of H2O2 through a two-electron oxygen reduction reaction by carbon based catalysts: from mechanism, catalyst design to electrode fabrication. Environ. Sci. Ecotechnol. 11, 100170 (2022).

Ahmad, Z. U. et al. Neodymium embedded ordered mesoporous carbon (OMC) for enhanced adsorption of sunset yellow: characterizations, adsorption study and adsorption mechanism. Chem. Eng. J. 359, 814–826 (2019).

Shi, L. ei et al. Remarkably enhanced photocatalytic activity of ordered mesoporous carbon/gC3N4 composite photocatalysts under visible light. Dalton Trans. 43, 7236–7244 (2014).

Xia, Y. et al. Sulfur diffusion within nitrogen-doped ordered mesoporous carbons determined by in situ X-ray scattering. Langmuir 34, 8767–8776 (2018).

Wang, J. et al. Kilogram-scale synthesis of ordered mesoporous carbons and their electrochemical performance. Carbon 49, 4580–4588 (2011).

Wakerley, D. et al. Gas diffusion electrodes, reactor designs and key metrics of low-temperature CO2 electrolysers. Nat. Energy 7, 130–143 (2022).

Wang, T. et al. Combined anodic and cathodic hydrogen production from aldehyde oxidation and hydrogen evolution reaction. Nat. Catal. 5, 66–73 (2022).

Wang, T. et al. Transforming electrocatalytic biomass upgrading and hydrogen production from electricity input to electricity output. Angew. Chem. Int. Ed. 61, e202115636 (2022).

Wang, Y.-H. et al. In situ spectroscopic insight into the origin of the enhanced performance of bimetallic nanocatalysts towards the oxygen reduction reaction (ORR). Angew. Chem. Int. Ed. 58, 16062–16066 (2019).

Gordon, C. P. et al. Efficient epoxidation over dinuclear sites in titanium silicalite-1. Nature 586, 708–713 (2020).

Zhang, M. et al. Improved Ti species distribution and hierarchical pores in TS-1: towards regeneration of TS-1 deactivated due to alkali corrosion. N. J. Chem. 44, 6394–6401 (2020).

Wang, G. et al. Liquid-phase epoxidation of propylene with H2O2 over TS-1 zeolite: impurity formation and inhibition study. Ind. Eng. Chem. Res. 60, 12109–12122 (2021).

Khouw, C. B. & Davis, M. E. Catalytic activity of titanium silicates synthesized in the presence of alkali-metal and alkaline-earth ions. J. Catal. 151, 77–86 (1995).

Su, J. et al. Amorphous Ti species in titanium silicalite-1: structural features, chemical properties, and inactivation with sulfosalt. J. Catal. 288, 1–7 (2012).

Li, C. et al. UV resonance Raman spectroscopic identification of titanium atoms in the framework of TS-1 zeolite. Angew. Chem. Int. Ed. 38, 2220–2222 (1999).

Fan, W. et al. Synthesis, crystallization mechanism, and catalytic properties of titanium-rich TS-1 free of extraframework titanium species. J. Am. Chem. Soc. 130, 10150–10164 (2008).

Gordon, M. S. & Schmidt, M. W. in Theory and Applications of Computational Chemistry (eds Dykstra, C. E., Frenking, G., Kim, K. S. & Scuseria, G. E.) 1167–1189 (Elsevier, 2005).

Schmidt, M. W. et al. General atomic and molecular electronic structure system. J. Comput. Chem. 14, 1347–1363 (1993).

Giannozzi, P. et al. Advanced capabilities for materials modelling with Quantum ESPRESSO. J. Phys. Condens. matter 29, 465901 (2017).

Giannozzi, P. et al. QUANTUM ESPRESSO: a modular and open-source software project for quantum simulations of materials. J. Phys. Condens. Matter 21, 395502 (2009).

Guda, A. A. et al. Understanding X-ray absorption spectra by means of descriptors and machine learning algorithms. npj Comput. Mater. 7, 203 (2021).

Signorile, M. et al. Effect of Ti speciation on catalytic performance of TS-1 in the hydrogen peroxide to propylene oxide reaction. J. Phys. Chem. C 122.16, 9021–9034 (2018).

Rzepka, P. et al. Quantitative localisation of titanium in the framework of titanium silicalite-1 using anomalous X-ray powder diffraction. Nat. Commun. 15, 7757 (2024).

Munoz, M., Argoul, P. & Farges, F. Continuous Cauchy wavelet transform analyses of EXAFS spectra: a qualitative approach. Am. Mineral. 88, 694–700 (2003).

Funke, H., Scheinost, A. & Chukalina, M. Wavelet analysis of extended x-ray absorption fine structure data. Phys. Rev. B 71, 094110 (2005).

Henkelman, G., Uberuaga, B. P. & Jónsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000).

Miao, C. et al. Effect of sodium ions on catalytic performance of TS-1 in gas-phase epoxidation of propylene with hydrogen peroxide vapor. Catal. Lett. 150, 281–290 (2020).

Bellat, J.-P. et al. Capture of formaldehyde by adsorption on nanoporous materials. J. Hazard. Mater. 300, 711–717 (2015).

Bellat, J.-P. et al. Selective adsorption of formaldehyde and water vapors in NaY and NaX zeolites. Microporous Mesoporous Mater. 288, 109563 (2019).

Halden, R. U. et al. Carcinogenic formaldehyde in U.S. residential buildings: mass inventories, human health impacts, and associated healthcare costs. Sci. Total Environ. 944, 173640 (2024).

ChemAnalyst. South Korea methanol market size, share & forecast 2034. https://www.chemanalyst.com/industry-report/south-korea-methanol-market-179 (2023).

Statista. Global methanol production 2022. https://www.statista.com/statistics/1323406/methanol-production-worldwide/ (2024).

Khomane, R. B., Kulkarni, B. D., Paraskar, A. & Sainkar, S. R. Synthesis, characterization and catalytic performance of titanium silicalite-1 prepared in micellar media. Mater. Chem. Phys. 76, 99–103 (2002).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Bader, H., Sturzenegger, V. & Hoigné, J. Photometric method for the determination of low concentrations of hydrogen peroxide by the peroxidase catalyzed oxidation of N,N-diethyl-p phenylenediamine (DPD). Water Res. 22, 1109–1115 (1988).

Nash, T. The colorimetric estimation of formaldehyde by means of the Hantzsch reaction. Biochem. J. 55, 416–421 (1953).

Giannozzi, P. et al. Quantum ESPRESSO toward the exascale. J. Chem. Phys. 152, 154105 (2020).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Ruttinger, A. W., Sharma, D. & Clancy, P. Protocol for directing nudged elastic band calculations to the minimum energy pathway: nurturing errant calculations back to convergence. J. Chem. Theory Comput. 18, 2993–3005 (2022).

Kim, K. et al. Source data and computational structures for “Self-driven propylene epoxidation on modified titanium silicalite-1 by in situ generated hydrogen peroxide”. https://doi.org/10.6084/m9.figshare.29616110.v3 (2025).

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT): NRF-2022H1D3A3A01081140 (K.H.K., H.K., and J.H.K.), RS-2024-00343146 (K.H.K., H.K., and J.H.K.), RS-2025-02316153 (K.H.K., H.K., S.W.H., J.-W.J., and J.H.K.), RS-2025-25450520 (K.H.K., H.K., S.W.H., J.-W.J., and J.H.K.). This work is also supported by the Institute for Basic Science (IBS-R019-D1). The authors acknowledge Prof. Sang Hoon Joo and Dr. June Sung Lim for the preparation of GOMC samples. The authors thank UCRF (UNIST Central Research Facilities) for supporting the use of the equipment. Experiments at the 6D UNIST-PAL beamline were partially supported by MEST, POSTECH, and UNIST-UCRF.

Author information

Authors and Affiliations

Contributions

J.H.K., J.-W.J., and S.J.C. proposed and directed the project. K.H.K., S.W.H., and T.K. conceived and designed the experiments. K.H.K., H.K. synthesized and characterized the TS-1 catalyst. S.W.H., T.K., and M.K. measured their selectivity for H2O2 production. K.H.K., S.W.H., and T.K. measured the performance of PO conversion. W.J. and K.S. contributed to the initial experimental setup. S.W.H., T.K., and K.H.K. measured and analyzed the PO production performance of the electro-heterogeneous catalytic system. S.J.C. analyzed XAS measurements. M.S.K., S.S.Y., and T.H.O. contributed to the investigation and writing of the techno-economic analysis of the system. M.-J.K. performed in situ Raman spectroscopy to identify key reaction intermediates and elucidate the electrochemical mechanism. K.H.K., S.W.H., T.K., S.J.C., J.-W.J., and J.H.K. co-wrote the manuscript. All authors read and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Xinqing Chen and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kim, K.H., Hwang, S.W., Kim, T. et al. Self-driven propylene epoxidation on modified titanium silicalite-1 by in situ generated hydrogen peroxide. Nat Commun 16, 8636 (2025). https://doi.org/10.1038/s41467-025-63828-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-63828-x