Abstract

Lithium-ion sieve (LIS)-based adsorption technology offers a promising solution for seawater lithium extraction, as it overcomes the challenge posed by the high Na+/Li+ ratio. However, its broader application is hindered by the performance degradation and dissolution loss of LISs after granulation, as well as the low Li+ concentration in seawater. Herein, we propose an Albizia julibrissin-inspired adsorption-responsive photothermal ion pump (APIP) for enhanced and reversible Li+ extraction from seawater. The APIP integrates an interpenetrating network hydrogel with confined hydrogen manganese oxide (HMO) via an innovative in-situ crosslinking and ion-exchange strategy, ensuring the uniform distribution of HMO. The specific adsorption-responsive swelling behaviour of APIP exposes more adsorption sites, resulting in a high Li+ extraction capacity of 34 mg g-1 HMO, even surpassing HMO powders. Moreover, the low free water characteristics and the selective chelation of the polymer chain on Mn2+ effectively mitigate Mn dissolution. Under solar irradiation, the Li+ extraction kinetics of the APIP increased by a remarkable 2.9-fold owing to the evaporative convection and photothermal effects. Collectively, APIP overcomes the application key limitations of powdered LISs, and opens new avenues for seawater utilization and the advancement of the Sustainable Development Goals.

Similar content being viewed by others

Introduction

The growing demand for lithium resources across various industries poses significant challenges to the global lithium supply1,2,3. The battery industry, in particular, has experienced a sharp increase in lithium demand owing to the rapid expansion of renewable energy technologies4,5. For instance, in 2019, the battery industry accounted for over 60% of global lithium demand (Supplementary Fig. 1)5. As energy storage technologies and electric vehicles continue to advance, global lithium demand is expected to rise even further6. In the electric vehicle sector alone, lithium demand is projected to reach 18 million tonnes by 2050 (Supplementary Fig. 2)7. However, the currently known economically viable lithium reserves in ores and brines currently amount to only 115 million tonnes8. This substantial gap between available reserves and rapidly growing demand highlights the urgent need to develop new methods for lithium extraction9,10.

Seawater holds an enormous lithium reserve, exceeding 230 billion tonnes, approximately 2000 times the amount found on land11,12,13. Extracting lithium from seawater represents an innovative and potentially transformative solution that could alleviate future supply concerns, with the potential to establish new industry standards14. While numerous innovative designs have been developed for lithium extraction from salt lakes15,16,17, extracting Li+ from seawater remains a significant challenge due to its extremely low concentration (<0.2 mg L−1) and the high Na+/Li+ ratio (~19,000)18,19,20. Current technologies struggle to overcome these obstacles21. Adsorption-based technologies utilising lithium-ion sieves (LISs), such as hydrogen manganese oxide (HMO) and hydrogen titanate (HTO), are widely employed to extract Li+ from seawater22,23,24. However, these processes are hindered by slow adsorption kinetics and the dissolution loss of LISs, resulting in low energy efficiency and poor cycle stability25. In addition, granulating LIS powders for practical applications often leads to a significant reduction in adsorption performance. Therefore, there is an urgent need to develop more efficient, stable, and environmentally friendly technologies to enable large-scale Li+ extraction from seawater.

Solar-driven interfacial evaporators (SIEs) have been widely employed in seawater desalination26,27,28, and recent efforts have focused on improving the evaporation performance of SIEs29,30,31. One effective strategy involves constructing hydrogel networks with low evaporation enthalpy, which can surpass the thermodynamic limits of traditional SIEs32,33. Beyond clean water production, well-engineered SIEs can accelerate ion transport by mimicking transpiration, opening new avenues for enhancing lithium extraction34,35. For example, a separated SIE using n-shaped H2TiO3-modified fabric demonstrated a high Li+ extraction capacity (20.09 mg g−1) and a stable evaporation rate of 1.51 kg m−2 h−1 under 1 sun36. Utilising the synergistic effect of gravity and solar evaporation process, a photothermal ion pump achieved a high Li+ extraction capacity of 4.87 mg m−2 h−1 during one month37. Existing SIEs, designed for Li+ extraction, are typically made from LIS-based fibres, films, or particles. Despite significant advances, the limited swelling ability of these substrates hinders the full exposure of adsorption active sites, preventing LIS powders from maintaining high Li+ adsorption performance38,39. Moreover, these SIEs do not address the dissolution loss of LISs. In contrast, hydrogels represent an ideal carrier for LISs owing to their adjustable swelling properties, strong elasticity, and three-dimensional porous structure40. Better yet, hydrogel-based SIEs are promising to achieve high trade-offs between evaporation and Li+ extraction performance owing to the low evaporation enthalpy. However, few hydrogel-based SIEs have been reported for seawater lithium extraction to date.

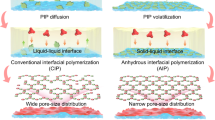

Albizia julibrissin is a common hyperaccumulator, meaning it can absorb specific ions from the soil into the plant cells through specialised ion pumps and the transpiration process, creating a pseudo-concentration gradient. As a result, the accumulation of specific metal ions increases as Albizia julibrissin matures, often surpassing the levels found in the soil, while the concentrations of other ions remain relatively constant. Additionally, the flowers of Albizia julibrissin exhibit notable light- and heat-responsive behaviour. They gradually bloom in the presence of light and close in the absence of light (Fig. 1a). The flower’s expansion under light enhances material exchange with the surroundings.

a The digital photos of Albizia julibrissin flower. b Schematic of APIP for enhanced Li+ extraction imitating ion pumps and transpiration process of Albizia julibrissin. c, Schematic of APIP for enhanced and stable Li+ extraction imitating the light- and heat-responsive behaviour of Albizia julibrissin flower.

Inspired by this, we introduce an adsorption-responsive bionic photothermal ion pump (APIP) designed for reversible and enhanced lithium extraction under solar irradiation (Fig. 1b). First, the APIP integrates an interpenetrating network hydrogel with confined HMO through an innovative in-situ crosslinking and ion-exchange strategy. This approach ensures an even distribution of HMOs throughout the APIP. Second, the APIP mimics transpiration to accelerate Li+ enrichment via an evaporation-induced flowing process (Fig. 1b-I). Meanwhile, Li+, functioning as the specific ion for the APIP, is spontaneously extracted, much like the ion extraction mechanism in Albizia julibrissin (Fig. 1b-II). More advanced, the APIP imitates the light- and heat-responsive behaviour of Albizia julibrissin flower by exhibiting adsorption-responsive swelling. During the Li+ extraction process, the APIP gradually expands, thereby exposing more adsorption sites (Fig. 1c-I), resulting in a high Li+ extraction capacity, even surpassing that of HMO powders. After the Li+ extraction is completed, the APIP can be regenerated by acid washing. The carefully designed APIP contains less free water, which helps to inhibit the dissolution of Mn2+. Additionally, the molecular chains within the APIP chelate Mn2+, further preventing its dissolution. As a result, the APIP exhibits lower Mn2+ solubility loss than HMO powders (Fig. 1c-II). Under the above combined effect, APIP successfully broke the limitations of LIS powder applications. In conclusion, this pioneering bionic design enabled enhanced, stable, and cyclic Li+-extraction performance. The subsequent sections elaborate on the structure and properties of the APIP.

Results and discussion

Preparation and characterisation

Interpenetrating network hydrogel (PPH) with confined HMO (HMO@PPH) was prepared using an innovative in-situ crosslinking and ion exchange method (Supplementary Fig. 3). This approach enabled an even distribution of HMO nanoparticles throughout the APIP. Specifically, lithium manganese oxide (LMO) was introduced into both a polyvinyl alcohol (PVA) rigid network and a polyacrylamide flexible network during the crosslinking process, resulting in the formation of PPH with confined LMO nanoparticles (LMO@PPH). After Li+/H+ ion exchange in a 0.5 M HCl solution, the LMO@PPH was easily converted into the HMO@PPH, which served as the main component of the APIP. X-ray diffraction (XRD) patterns confirmed the presence of LMO and HMO in LMO@PPH and HMO@PPH samples (Supplementary Fig. 4), respectively. Additionally, energy-dispersive X-ray spectroscopy (EDX) mapping images showed that the LMO and HMO nanoparticles were uniformly confined within the hybrid hydrogel (Supplementary Figs. 5 and 6).

As expected, the HMO@PPH expanded in simulated seawater, leading to a significant increase in internal pore size (Fig. 2a). The measured water contact angle of HMO@PPH (40.8°) indicated favourable hydrophilic properties, suggesting efficient water transfer performance (Supplementary Fig. 7). The high optical absorption of HMO@PPH, exceeding 90% across the entire spectrum, underscores its efficiency in photothermal conversion (Fig. 2b). Additionally, HMO@PPH exhibited a lower evaporation enthalpy (1.46 MJ kg−1) than pure water (Supplementary Fig. 8), indicating a higher evaporation potential for the APIP based on HMO@PPH. Finally, both LMO@PPH and HMO@PPH exhibited high chemical stability (Supplementary Fig. 9).

a Digital photographs and SEM images of HMO@PPH in the simulated seawater in 0 h and 48 h. b Ultraviolet-visible-near-infrared spectra of HMO@PPH. c Digital and infrared photographs of APIP under different solar fluxes. d Mass change as a function of time for APIP under different solar fluxes. e Li+ extraction capacity (Qe) of APIP for different durations under 1 sun illumination or in the dark. f Enhancement factor (EF) corresponding to different solar fluxes and Li+ extraction time. g Li+ extraction capacity (Qe) of APIP in different samples of real seawater under 1 sun illumination. h Cyclic Li+ extraction capacity (Qe) under 1 sun illumination. Error bars represent the standard deviations from three-time measurements. i Water production rate (WPR) and Li+ extraction capacity (Qe) of APIP during one-day outdoor experiments.

Solar-driven Li+ extraction performance

APIPs based on HMO@PPH demonstrated a higher evaporation rate (approximately 2.22 kg m−2 h−1) than HMO and pure water (Supplementary Fig. 10). Increasing the solar flux from 0.5 to 1.5 suns further enhanced the evaporation performance of the APIP, with the steady-state temperature rising from 29.1 to 45.1 °C (Fig. 2c) and the evaporation rate increasing from 1.03 to 4.42 kg m−2 h−1 (Fig. 2d). Additional details on evaporation and desalination performance are presented in Supplementary Note 1. Raman measurements were employed to examine the water structure in HMO@PPH. Unlike pure water (Supplementary Fig. 11a), the water in HMO@PPH could be classified into free water (FW) and intermediate water (IW), with an IW-to-FW ratio of 0.4 (Supplementary Fig. 11b). Therefore, the higher evaporation rate of the APIP, which exceeded the thermodynamic evaporation limit (1.47 kg m−2 h−1 under 1 sun illumination), is attributable to the presence of IW in HMO@PPH32,33.

We also evaluated the Li+ extraction performance of the APIP in LiCl solution under 1 sun. Compared with dark conditions, solar irradiation improved both the kinetics and capacity of Li+ extraction by the APIP (Fig. 2e). Specifically, the Li+-extraction kinetics of the APIP increased 2.9 times within 2 h under 1 sun. X-ray photoelectron spectroscopy characterisation was conducted to confirm the Li+ adsorption process (Supplementary Fig. 12). To quantify the enhancement of the Li+ extraction process due to solar irradiation, we introduced an enhancement factor (EF), which was calculated using Eq. (1)41.

where Qe-solar (mg g−1) and Qe-dark (mg g−1) denote the Li+ extraction capacity of HMO@PPH under solar irradiation and in the dark, respectively. Under a radiation time of 2 h, increasing the solar flux from 0 to 1.5 suns increased the EF from 1 to 4.6 (Fig. 2f). Conversely, extending the irradiation time from 2 to 8 h resulted in a reduction of EF. The Li⁺ extraction capacity of APIP exhibited a rapid increase within the first 4 h under 1-sun illumination, followed by a gradual rise until reaching equilibrium (Fig. 2e). In contrast, under dark conditions, the Li⁺ extraction capacity continued to increase even after 4 h (Fig. 2e), resulting in a progressive decline in the enhancement factor (EF) of APIP over time. Nevertheless, it is essential to highlight that APIP maintained superior Li⁺ extraction performance under solar irradiation, coupled with faster extraction kinetics. The specific mechanism is discussed in the following subsection. To eliminate the influence of other metal ions, we also assessed the Li+ extraction performance of the APIP in simulated seawater (Supplementary Fig. 13). The APIP demonstrated a high Li+ extraction capacity of 4.136 mmol g−1 HMO, while showing weak extraction capacity for Na+ and K+. This high selectivity for Li+ highlights the significant potential of the APIP for extracting Li+ from seawater. After 60 h of continuous operation, the APIP effectively extracted Li+ across various seawater compositions. Notably, it achieved the highest Li+ extraction performance in the Bohai Sea, with approximately 32.6 mg g−1 HMO (Fig. 2g), likely owing to the higher Li+ content in that region. Subsequently, the APIP maintained a stable Li+ extraction capacity of approximately 34 mg g−1 HMO over seven cycles (Fig. 2h).

Finally, the outdoor performance of the APIP was evaluated at the City University of Hong Kong using a large-size HMO@PPH, with seawater sourced from Shenzhen Bay (Supplementary Fig. 14). The setup of the outdoor device based on the APIP is illustrated in Supplementary Fig. 15. Despite a gradual decrease in solar flux (Supplementary Fig. 16), which led to a reduction in the water production rate from 2.88 to 1.11 kg m−2, the APIP maintained an overall WPR of 6.6 kg m−2 (Fig. 2i). Moreover, it demonstrated a high Li+ extraction performance of 6.7 mg g−1 HMO (Fig. 2i).

Mechanism for enhancement of Li+ extraction

The enhanced Li+ extraction performance of the APIP is primarily due to the following factors.

-

(1)

Uniform distribution of HMOs across the APIP: To ensure the even distribution of HMOs, HMO@PPH was prepared using the in-situ crosslinking method described earlier (Supplementary Fig. 1). We also dispersed HMO directly in PPH to obtain HMO-doped PPH (HMO/PPH). The potent oxidative ability of HMO accelerated the polymerisation of the PPH, resulting in stratification phenomenon in the HMO/PPH containing 10 wt% HMO (Supplementary Fig. 17). In contrast, LMO exhibited a uniform distribution in the LMO@PPH, both before and after swelling, regardless of the amount of LMO loaded (Supplementary Figs. 18–21). This uniform distribution of LMO in LMO@PPH achieved the uniform HMO loading in HMO@PPH through a simple ion-exchange process, which was not achievable in HMO/PPH. Consequently, the APIP based on HMO@PPH demonstrated a higher Li+ extraction capacity (9.4 mg g−1 hydrogel) compared to that based on HMO/PPH (1.9 mg g−1 hydrogel) under the same HMO content, owing to the superior Li+ extraction performance of the evenly dispersed HMO in the former APIP (Fig. 3a).

Fig. 3: Mechanism for enhancement of Li+ extraction. a The Li+ extraction capacity (Qe) comparison in the dark. The initial conditions: 298 K, pH = 10, the concentrations of Li+ solution is 25 ppm. b Differential charge and binding energy between LMO (or HMO) and PPH. c The schematic diagram of lithium adsorption enhanced by swelling process (left), and simulated Li+ distribution in the channels of HMO@PPH with different swelling properties (Right). d The Li+ extraction capacity (Qe) of HMO@PPH based on hydrogel weight. e The Li+ extraction capacity (Qe) of HMO@PPH based on HMO weight. The horizontal dotted line is the Li+ adsorption capacity of HMO powders. f The Li+ distribution in APIP under the different conditions: (I) in the dark and (II) under 1 sun illumination, as simulated in COMSOL software. g TEF at different locations in APIP obtained by COMSOL software. h Theoretical Li+ adsorption concentration of APIP under different solar fluxes obtained by COMSOL software. The dotted line refers to the Li+ saturated adsorption concentration by APIP.

-

(2)

Adsorption-responsive swelling behaviour: Density functional theory (DFT) calculations were conducted to examine the interaction between LMO (or HMO) and the PPH (Fig. 3b). The binding energy between LMO and PPH molecules was less negative than that between HMO and PPH molecules. Thus, compared with HMO/PPH and HMO@PPH, LMO@PPH exhibited weaker intermolecular forces and enhanced swelling properties. This finding aligns with experimental results: when immersed in water, the diameter of LMO@PPH increased significantly over time, whereas that of HMO/PPH and HMO@PPH remained largely unchanged (Supplementary Fig. 22). Meanwhile, increasing the LMO content from 10 to 40 wt% improved the swelling performance of LMO@PPH (Supplementary Fig. 23 and Supplementary Fig. 24), owing to the weaker interactions between LMO and the PPH. Fourier-transform infra-red spectra (Supplementary Fig. 25) supported this observation, indicating that the higher LMO content weakened hydrogen bonding. This reduction in hydrogen bonding facilitated the penetration of water molecules into the hydrogel network, leading to significantly enhanced swelling. However, increasing the LMO content to 50 wt% led to worsened swelling behaviour (Supplementary Fig. 23 and Supplementary Fig. 24) and some agglomeration (Supplementary Fig. 26). This decline in swelling performance can be attributed to supersaturation and the resulting weakening of hydrogen bonds (Supplementary Fig. 25). Thus, LMO@PPH with a 40 wt% LMO loading was selected to prepare HMO@PPH.

During the Li+ extraction process, HMO@PPH gradually transformed into LMO@PPH, and the variable swelling characteristics of LMO@PPH caused it to expand (Supplementary Fig. 27 and Fig. 3c). Consequently, more HMO to participate in Li+ adsorption (Fig. 3c). To verify this mechanism, we conducted a COMSOL simulation in which the porous structure of HMO@PPH was modelled as a two-dimensional channel (details are provided in Supplementary Note 2). The Li+ concentration in the channels in a swollen state decreased more rapidly than in those in a non-swollen state, indicating the superior adsorption effect in the former state (Fig. 3c). Compared with other lithium-extraction materials such as membranes, particles, and fibers, the APIP, with its excellent swelling characteristics, shows superior Li+ extraction performance as it provides more exposed adsorption sites. As the loading amount of LMO increased, the Li+ extraction capacity based on the hydrogel weight increased linearly (Fig. 3d). When used in real seawater on a large scale, HMO powder adsorbent cannot reach its full potential due to agglomeration. In comparison, APIP performed obvious adsorption corresponding swelling behaviour, which retains and even surpasses the HMO powders on Li+ extraction capacity (Fig. 3e). After Li+ extraction, LMO@PPH was regenerated into HMO@PPH by treatment with a solution of HCl, and the volume of LMO@PPH gradually decreased (Supplementary Fig. 27). Nevertheless, the porous structure of the regenerated HMO@PPH remained unchanged from its original state (Supplementary Fig. 27). Through this adsorption-regeneration process, APIP demonstrated cyclic Li+-extraction performance.

-

(3)

Low solubility loss of HMO: The Mn dissolution primarily stemmed from the disproportionation reaction of Mn3+, as described in Eq. (2)42:

$$2{\rm{M}}{{\rm{n}}}^{3+}\to {\rm{M}}{{\rm{n}}}^{4+}+{\rm{M}}{{\rm{n}}}^{2+}$$(2)Compared to HMO powder, the carefully designed HMO@PPH offers two significant benefits. First, unlike traditional membrane materials or particles, HMO@PPH contains less free water (Supplementary Fig. 11) that can reduce the dissolution of Mn2+43. Second, DFT calculations were employed to examine the interaction between Mn2+ with PPH. The negative binding energy of Mn2+ with PPH (−0.72 eV) implied that the molecular chains within HMO@PPH can chelate Mn2+, further preventing HMO’s dissolution. XPS results also revealed a significant increase in the Mn4+/Mn3+ ratio in HMO@PPH compared to bare HMO after acid treatment (Supplementary Fig. 28). This observation strongly indicates that the PPH effectively inhibits the disproportionation reaction, promoting the oxidation of Mn3+ to Mn4+ rather than its reduction to Mn2+44. Although some Mn2+ may temporarily detach from the lattice, the PPH chains effectively recapture and stabilise these ions, preventing their permanent leaching into the acidic medium. As a result, HMO@PPH exhibits a lower Mn dissolution than powder materials (Supplementary Fig. 29a). Meanwhile, the lithium extraction performance of HMO@PPH remained basically unchanged (Fig. 2h) while that of HMO decreased by 37% after 7 cycles (Supplementary Fig. 29b). In brief, APIP demonstrates an effective inhibition of Mn dissolution by capitalising on the low free water characteristics and the selective chelation of the polymer chain. To the best of our knowledge, few prior studies have employed this mechanism to address Mn dissolution in HMO. Note that although the negative binding energy between Li+ and PPH (−0.23 eV) indicates PPH can chelate partial Li+, the Li+ extraction capacity of pure PPH hydrogel is only 0.1 mg g−1, just 1% of that of HMO@PPH (9.4 mg g⁻¹, Fig. 3a), suggesting its limited extraction effectiveness. Therefore, the high Li+ extraction capacity of APIP is primarily attributed to the promotional effect of adsorption-responsive swelling performance, as well as the homogeneous dispersion of HMO in APIP.

-

(4)

Enhancement of the solar-driven evaporation process38: The evaporation process plays a key role in enhancing the Li+ extraction process. First, the evaporation process creates a localised region rich in Li+. Owing to the absence of an effective salt-transfer design, the evaporation interface of the APIP formed a high-concentration field of Li+ under illumination. This increased Li+ concentration improved the APIP’s adsorption capacity (Supplementary Fig. 30). Additionally, the evaporation process generated strong convection effects, significantly increasing the interaction between the APIP and Li+ in seawater, thus enhancing Li+ adsorption. These behaviours were further validated through COMSOL simulations. As illustrated in Fig. 3f, the APIP exhibited enhanced Li+ enrichment under 1 sun illumination. The simulated Li+ concentration of APIP at the same site under 1 sun illumination and dark conditions was captured from Fig. 3f, denoted as Cs and Cd, respectively. The theoretical enhanced factor (TEF) was then calculated using Eq. (3).

$$T{EF}=\frac{{C}_{s}}{{C}_{d}}$$(3)Proximity to the evaporation interface corresponded to a higher TEF (Fig. 3g). The TEF reached approximately 7 at the evaporation interface, compared with only 1.2 at the bottom. Overall, the APIP showed an average TEF of ~3.2. Additionally, we simulated the Li+ adsorption capacity of the APIP under different solar fluxes by COMSOL software (Fig. 3h). As the solar flux increased, the Li+ adsorption capacity of APIP significantly improved for the same adsorption duration. The Li+ adsorption capacity reached saturation (dotted line in Fig. 3h) at about 2 h and 8 h under 1 sun and 1.5 sun illumination, respectively. Therefore, although the Li+ concentration in the APIP continued to increase, the increase was mainly due to the evaporation enrichment of ions rather than actual Li+ extraction. Note that the photothermal process can promote the enrichment of various ions, but only Li+ can enter the HMO owing to the ion radius exclusion limit, hydration free energy effect, and thermodynamic ion exchange preference45,46,47,48. Additionally, solar irradiation generated a local thermal field that further enhanced the Li+ extraction performance (Supplementary Fig. 31). In summary, the synergistic effects of photothermal-induced concentration fields, flowing fields, and localised thermal fields collectively contribute to APIP’s superior Li+ extraction performance.

Discussion

Based on the outdoor performance of the APIP and the global solar flux distribution, we estimated the daily water production rate (DWPR) and annual Li+ extraction capacity (Qe) of the APIP in different regions (Fig. 4a). Generally, the APIP’s performance depends on latitude, with higher latitudes corresponding to lower solar flux and thus leading to weaker output. For example, the APIP achieved its highest DWPR and annual Li+ extraction capacity (approximately 8.7 kg m−2 and 2.2 g g−1 HMO, respectively) in Perth (Australia). In contrast, the APIP exhibited its lowest DWPR and annual Li+ extraction capacity (approximately 6.3 kg m−2 and 1.6 g g−1 HMO, respectively) in Tianjin (China). Notably, the APIP exhibited a high Li+ extraction efficiency of over 70% but a low magnesium-ion (Mg2+) extraction efficiency of ~2.4% in high-salinity brine with varying Mg/Li ratios (Supplementary Fig. 32). Additionally, its Li+ extraction capability improved when the pH exceeded 10 (Supplementary Fig. 33). These results suggest that the APIP is also suitable in salt-lake environments except for seawater. We estimated the annual Li+ extraction capacity of the APIP in the typical salt lakes, observing high values of 2.19 and 1.82 g g−1 HMO in Namtso and the Great Salt Lake, respectively. Overall, the APIP demonstrates significant potential for Li+ extraction across diverse regions.

a Predicted daily water production rate (DWPR) and Li+ extraction capacity (Qe) of APIP around the world. b Comparison of different technologies for Li+ extraction from salt lake/seawater: molar ratio of Na+ and Li+ in the feed solution (M(Na+/Li+)) and energy consumption (EC). Note that the corresponding data can be found in Supplementary Table 1. c Pathway for seawater resource utilization based on interfacial evaporation technology.

In addition to the APIP, various Li+ extraction technologies have been extensively reported. The most common technologies include the electrochemical method (Ele-Li), the membrane method (Mem-Li), and the adsorption method (Ads-Li). When deciding between these methods, their applicability, extraction capacity, kinetics, cost, and energy consumption must be considered. Among these methods, Ads-Li stands out as the most promising in terms of applicability and energy consumption. However, the low extraction kinetics, as well as significantly reduced performance and dissolution loss of LISs after granulation, limit the broad use. The well-designed APIP can effectively solve the aforementioned challenges. Note that many advanced Li+-extraction designs consider the effect of the Mg2+-to-Li+ ratio but ignore that of the Na+-to-Li+ ratio on Li+-extraction performance. In seawater, the Na+-to-Li+ molar ratio is as high as 20,000:1, and many reported Li+-extraction technologies often fail in seawater although they are effective in salt lakes18. In contrast, the APIP demonstrated excellent Li+ extraction performance even in environments with high Na/Li ratios and low Li+ concentrations (Fig. 4b). Furthermore, the APIP exhibited approximately zero energy consumption during the Li+ extraction process (Fig. 4b)16. In terms of extraction performance and energy consumption, APIP for seawater lithium extraction is ahead of numerous reported advanced designs (Supplementary Table 1). Therefore, the APIP holds promise for achieving high-efficiency and sustainable Li+ extraction from seawater.

In conclusion, interfacial solar evaporation constitutes a promising approach for harnessing seawater resources. The APIP can be directly utilised in seawater to produce clean water and extract lithium (Route I, Fig. 4c). Additionally, it can process concentrated seawater from traditional desalination plants, facilitating tiered recovery of both clean water and lithium ions (Route II, Fig. 4c). However, neither the APIP nor existing seawater desalination technologies are effective for managing fully saturated concentrated seawater. This challenge can be addressed by employing a solar crystallisation pool based on interfacial evaporation technology, which can produce crude salts such as NaCl and KCl (Route III, Fig. 4c). To further recover valuable resources such as magnesium salts and uranium ions, the APIP can be integrated with uranium extraction or other technologies (Route IV, Fig. 4c)41. The specific process route should be carefully chosen based on factors such as cost and energy consumption. In summary, the application prospects of the APIP demonstrate significant potential to address current water and energy shortages and contribute to achieving Sustainable Development Goals.

Methods

Preparation of HMO and LMO

LMO was first prepared through the heat-treatment of a mixture of MnCO3 and Li2CO3 in a Li/Mn mole ratio of 1.33:1.67 at 500 °C for 4 h in air48,49. Subsequently, Li+/H+ ion exchange was conducted in 0.5 M HCl solution for 24 h to HMO. The resulting HMO was then thoroughly washed with deionized water until the pH of the supernatant approached 7.0. Finally, the HMO was dried at 60 °C.

Preparation of LMO@PPH, HMO@PPH, and HMO/PPH

A specific amount of LMO was added to 1.5 g of a 5% PVA solution, followed by the addition of 0.5 g of acrylamide and 0.0030 g of methylene-bis-acrylamide (MBA). After stirring for 30 min, 5 μL of N, N, N’, N’-tetramethylethylenediamine (TEMED) and 1.5 mg of ammonium persulfate (APS) were dissolved into the solution. The mixture was then incubated at 50 °C for 5 h. After thorough cleaning with deionized water, LMO@PPH was obtained. Subsequently, after Li+/H+ ion exchange in 0.5 M HCl for 24 h, the HMO@PPH hydrogel was produced. The fabrication method for HMO/PPH was the same as that of LMO@PPH, except that HMO was used instead of LMO during the in-situ polymerisation process.

Solar-driven Li+ extraction experiments

A specific amount of LiCl was dissolved in deionized water to prepare a Li+ solution (0–100 ppm). The pH of the solution was adjusted using sodium hydroxide and hydrochloric acid. Solar-driven Li+ extraction experiments were conducted in this Li+ solution under 1 sun illumination unless otherwise specified. After the extraction experiments, 2 mL of the solution was sampled from the bottom. The Li+ concentrations in the solution were measured via inductively coupled plasma mass spectrometry (ICP-MS). And the extraction capacity was calculated using Eq. (S2). The cyclic Li+ extraction experiment was conducted in real seawater. Following the adsorption process, HMO@PPH was regenerated using a 0.5 M HCl solution.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The data that supports the findings of the study are included in the main text and supplementary information files. Source data are provided with this paper.

References

Xiang, W. et al. Solar-powered selective mineral extraction via interfacial photothermal evaporation for sustainable lithium supply. Carb. Neutrality. 4, 17 (2025).

Nair S. K., Rocke B. N., Sutton S. Lithium, magnesium, and copper: contemporary applications of organometallic chemistry in the pharmaceutical industry. In: (eds Blakemore D.C., Doyle P.M., Fobian Y.M., Blakemore D., Fobian Y., and Doyle P.) Synthetic Methods in Drug Discovery Vol. 2, 1–74 (The Royal Society of Chemistry, 2016).

Yong, M. et al. Sustainable lithium extraction and magnesium hydroxide co-production from salt-lake brines. Nat. Sustain. 7, 1662–1671 (2024).

Ma, R. et al. Pathway decisions for reuse and recycling of retired lithium-ion batteries considering economic and environmental functions. Nat. Commun. 15, 7641 (2024).

Greim, P., Solomon, A. A. & Breyer, C. Assessment of lithium criticality in the global energy transition and addressing policy gaps in transportation. Nat. Commun. 11, 4570 (2020).

Degen, F., Winter, M., Bendig, D. & Tübke, J. Energy consumption of current and future production of lithium-ion and post lithium-ion battery cells. Nat. Energy 8, 1284–1295 (2023).

Yang, J. et al. Lithium metal recovery from sea water by a flexible and scalable membrane with lithium-ion exclusive channels. Angew. Chem. Int. Ed. 63, e202411957 (2024).

USG Survey. Mineral commodity summaries 2025. Mineral Commodity Summaries (USGS Publications, 2025).

Darling, S. B. The brine of the times. Science 385, 1421–1422 (2024).

Zhang, G. et al. Spontaneous lithium extraction and enrichment from brine with net energy output driven by counter-ion gradients. Nat. Water 2, 1091–1101 (2024).

Yang, S., Zhang, F., Ding, H., He, P. & Zhou, H. Lithium metal extraction from seawater. Joule 2, 1648–1651 (2018).

Mao, K. et al. Functionalizing solar-driven steam generation towards water and energy sustainability. Nat. Water 3, 144–156 (2025).

He, X., Kaur, S. & Kostecki, R. Mining lithium from seawater. Joule 4, 1357–1358 (2020).

Chen, X. et al. Spatially separated crystallization for selective lithium extraction from saline water. Nat. Water 1, 808–817 (2023).

Xu, R. et al. Continuous lithium extraction from brine by efficient redox-couple electrodialysis. Matter 7, 3876–3890 (2024).

Song, Y. et al. Solar transpiration–powered lithium extraction and storage. Science 385, 1444–1449 (2024).

Li, Z. et al. Lithium extraction from brine through a decoupled and membrane-free electrochemical cell design. Science 385, 1438–1444 (2024).

Zhang, S. et al. Solar-driven membrane separation for direct lithium extraction from artificial salt-lake brine. Nat. Commun. 15, 238 (2024).

Liu, C. et al. Lithium extraction from seawater through pulsed electrochemical intercalation. Joule 4, 1459–1469 (2020).

Li, Z. et al. Continuous electrical pumping membrane process for seawater lithium mining. Energy Environ. Sci. 14, 3152–3159 (2021).

Yang, S., Wang, Y., Pan, H., He, P. & Zhou, H. Lithium extraction from low-quality brines. Nature 636, 309–321 (2024).

Roobavannan, S. et al. Seawater lithium mining by zeolitic imidazolate framework encapsulated manganese oxide ion sieve nanomaterial. Chem. Eng. J. 474, 145957 (2023).

Sun, J. et al. Preparation of high hydrophilic H2TiO3 ion sieve for lithium recovery from liquid lithium resources. Chem. Eng. J. 453, 139485 (2023).

Li, X. et al. Membrane-based technologies for lithium recovery from water lithium resources: a review. J. Membr. Sci. 591, 117317 (2019).

Tan, G., Wan, S., Chen, J.-J., Yu, H.-Q. & Yu, Y. Reduced lattice constant in Al-doped LiMn2O4 nanoparticles for boosted electrochemical lithium extraction. Adv. Mater. 36, 2310657 (2024).

Yu, Z. et al. Micro-nano water film enabled high-performance interfacial solar evaporation. Nano-Micro Lett. 15, 214 (2023).

Guo, S. & Tan, S. C. Unlocking solar-driven synergistic clean water harvesting and sustainable fuel production. Joule 8, 291–294 (2024).

Lin, F. et al. Isolating the salt and oil discharging area enables the continuous and effective purification of saline oily wastewater. Environ. Sci. Technol. 59, 13754–13764 (2025).

Wang, Y. et al. Quasi-waffle solar distiller for durable desalination of seawater. Sci. Adv. 10, eadk1113 (2024).

Guo, S. et al. Leaf-based energy harvesting and storage utilizing hygroscopic iron hydrogel for continuous power generation. Nat. Commun. 16, 5267 (2025).

Zheng, S. et al. Upscaling 3D engineered trees for off-grid desalination. Environ. Sci. Technol. 56, 1289–1299 (2022).

Yang, B. et al. Flatband λ-Ti3O5 towards extraordinary solar steam generation. Nature 622, 499–506 (2023).

Yu, Z. et al. High-flux flowing interfacial water evaporation under multiple heating sources enabled by a biohybrid hydrogel. Nano Energy 98, 107287 (2022).

Chen X. et al. Solar-driven lithium extraction by a floating felt. Adv. Funct. Mater. 34, 2316178 (2024).

Xia, Q. et al. Solar-enhanced lithium extraction with self-sustaining water recycling from salt-lake brines. Proc. Natl Acad. Sci. USA 121, e2400159121 (2024).

Chen K. et al. Simultaneous fresh water collection and Li+ selective adsorption enabled by a salt-resistant separated solar evaporator. Adv. Funct. Mater. 34, 2402221 (2024).

Li, H.-N. et al. Design of photothermal “ion pumps” for achieving energy-efficient, augmented, and durable lithium extraction from seawater. ACS Nano 18, 2434–2445 (2024).

Yu, Z. et al. Microplastic detection and remediation through efficient interfacial solar evaporation for immaculate water production. Nat. Commun. 15, 6081 (2024).

Choe, J. H. et al. Boc protection for diamine-appended MOF adsorbents to enhance CO2 recyclability under realistic humid conditions. J. Am. Chem. Soc. 146, 646–659 (2024).

Ravi, S. K. et al. A mechanoresponsive phase-changing electrolyte enables fabrication of high-output solid-state photobioelectrochemical devices from pigment-protein multilayers. Adv. Mater. 30, 1704073 (2018).

Xu, S. et al. Ion pump-inspired biomimetic interfacial evaporation platform for simultaneous seawater desalination, uranium extraction, and electricity generation. Nano Energy 131, 110232 (2024).

Zhang, Y. et al. Operando characterization and regulation of metal dissolution and redeposition dynamics near battery electrode surface. Nat. Nanotechnol. 18, 790–797 (2023).

Dong, H. et al. Insights on flexible zinc-ion batteries from lab research to commercialization. Adv. Mater. 33, 2007548 (2021).

Li, X., Xu, Z., Qian, Y. & Hou, Z. In-situ regulated competitive proton intercalation and deposition/dissolution reaction of MnO2 for high-performance flexible zinc-manganese batteries. Energy Storage Mater. 53, 72–78 (2022).

Chen, Q., Chen, Z., Li, H. & Ni, B.-J. Advanced lithium ion-sieves for sustainable lithium recovery from brines. Sustain. Horiz. 9, 100093 (2024).

Qi, S. et al. Cross-linked HMO/PVA nanofiber mats for efficient lithium extraction from salt-lake. Sep Purif. Technol. 323, 124382 (2023).

Zhu, G., Wang, P., Qi, P. & Gao, C. Adsorption and desorption properties of Li+ on PVC-H1. 6Mn1. 6O4 lithium ion-sieve membrane. Chem. Eng. J. 235, 340–348 (2014).

Tang, L. et al. Highly efficient, stable, and recyclable hydrogen manganese oxide/cellulose film for the extraction of lithium from seawater. ACS Appl. Mater. Interfaces 12, 9775–9781 (2020).

Yan, W. et al. Facile solid-phase method for preparing a highly active and stable PtZn-based oxygen reduction/hydrogen evolution bifunctional electrocatalyst: effect of bi-facet lattice strain on catalytic activity. ACS Appl. Energy Mater. 5, 13791–13801 (2022).

Acknowledgements

M.W. acknowledged the support from the National Natural Science Foundation of China (No. 22378289), Central Government Guides Local Funds for Science and Technology Development (YDZJSX2022 A021) and the Special Fund for Science and Technology Innovation Teams of Shanxi Province (202304051001026). S.C.T. acknowledged the financial support from the Singapore Ministry of Education - Academic Research Fund Tier 1 (A-8002144-00-00). J.L. acknowledged the support from the Hong Kong Research Grants Council-Strategic Topics Grant STG2/P-705/24-R, Hong Kong JLFS-RGC-Joint Laboratory Funding Scheme (Grant No. JLFS/E-102/24), Guangdong Province Science and Technology Plan Project 2023B1212120008, and the Hong Kong Innovation and Technology Commission via the Hong Kong Branch of National Precious Metals Material Engineering Research Center. J.L. thanked for the IMR-CityU Joint Laboratory of Nanomaterials & Nanomechanics and Guangdong-Hong Kong Joint Laboratory of Modern Surface Engineering Technology. Professional English language editing support provided by AsiaEdit (asiaedit.com).

Author information

Authors and Affiliations

Contributions

J.L., S.C.T., and M.W. conceived and designed the project. Z.Y., X.C., and C.L. conducted the experiments. S.G., F.D., L.L., and Y.L. contributed to the theoretical analysis. Z.Y. and Z.M. organised the data and wrote the manuscript. Y.Z., W.L., and Y.L. polished the manuscript and conducted theoretical calculations. All authors discussed the results and approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Ji Liu, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yu, Z., Mao, Z., Guo, S. et al. Adsorption-responsive bionic photothermal ion pump for reversible seawater lithium extraction. Nat Commun 16, 8825 (2025). https://doi.org/10.1038/s41467-025-63890-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-63890-5